Page 1

Self Priming Sprinkler Pump

OWNER'S MANUAL

Be sure to have available proper and adequate wiring

material to complete the installation correctly.

READ AND FOLLOW SAFETY INSTRUCTIONS

This is the safety alert symbol. When you see

this symbol on your pump or in this manual, look

for one of the following signal words and be alert to the

potential for personal injury:

BEFORE YOU START

BEFORE INSTALLING PUMP, BE SURE TO READ

THIS OWNER’S MANUAL CAREFULLY.

REFER TO PRODUCT DATA PLATE(S) FOR

ADDITIONAL OPERATING INSTRUCTIONS AND

SPECIFICATIONS.

CAUTION

• Keep work area clean, well-lit and uncluttered.

• Keep safety labels clean and in good condition.

• Replace missing or damaged safety labels.

• Wear safety glasses while installing or performing

maintenance on pump.

• Adhere to the guidelines of the National Electric Code

(NEC) or Canadian Electric Code (CEC), and any other

state and local codes for ALL electrical installations.

Check with the appropriate agencies or contact a

licensed electrician.

DANGER

serious personal injury, death or major property damage

if ignored.

WARNING

serious personal injury, death or major property damage

if ignored.

CAUTION

cause minor personal injury or major property damage if

ignored.

NOTICE indicates special instructions, which are

important but not related to hazards.

Carefully read and follow all safety instructions in

this manual and on pump.

WARNING

HAZARDOUS PRESSURE: Do not run

pump against closed discharge. Release all system

pressure before working on any component.

warns about hazards that will cause

warns about hazards that can cause

warns about hazards that will or can

WARNING

WARNING

Most water system problems result from improper

installation. It is suggested that you read this

manual carefully before installing your pump. The

“TROUBLESHOOTING SECTION” will assist you in

locating and eliminating the cause of any trouble you

may encounter after installation. Check and make

available all the tools you will need to install your pump.

Required tools may include wrenches, pipe sealant, pipe

fi ttings and nipples, screwdriver, etc.

CAUTION

Do not run pump dry. Fill pump with

water before starting or pump will be damaged.

The motor on this pump is guaranteed by the

manufacturer and in event of failure it must be returned

to an authorized service station for repairs. Motor

warranty is void if repairs aren’t made by an authorized

repair station.

Page 2

Page 3

ELECTRICAL SAFETY

CAUTION

OFF before connecting any electrical wires.

WARNING

To discharge motor capacitor, hold insulated handle

screwdriver BY THE HANDLE and short capacitor

terminals together. Do not touch metal screwdriver blade

or capacitor terminals or electrical shock could occur. If

in doubt, consult a qualifi ed electrician.

WARNING

Hazardous voltage.

Can shock, burn, or

cause death.

Ground pump before

connecting to power

supply. Disconnect

power before working

on pump, motor

or tank.

Make sure all ELECTRICAL POWER IS

Capacitor voltage may be hazardous.

Wire motor for correct

voltage. See “Electrical

Installation” section of this

manual and motor nameplate.

Ground motor

before connecting to

power supply.

Meet National Electrical

Code (NEC) or Canadian

Electrical Code(CEC) and

local codes for all wiring.

Follow all pump wiring

instructions provided in

this manual.

INTRODUCTION

You have purchased one of the most user friendly

pumps available. The Turf Boss pumps are made with

high quality materials which are designed to provide

you with years of reliable service. Lawn sprinklers are

designed to maximize output fl ow, while still maintaining

the ability to draw water from a source up to 25 feet

below the pump. All mechanical parts, motor, impeller,

electrical controls, etc., are above ground within easy

reach. If service is ever necessary, simple hand tools will

do the job. This lawn sprinkler pump installs easily and

quickly without the need for special tools or pump rigs.

You can install it yourself provided you follow closely the

instructions contained in this manual.

INSPECT YOUR SHIPMENT

All Turf Boss lawn sprinkler pumps are carefully tested,

inspected, and packaged to insure their arrival in perfect

condition. When the pump is received, examine it closely

to make sure there is no damage or broken parts that

may have occurred in shipping. If damage is evident,

report this immediately to your shipping carrier and

dealer. This shipping carrier assumes full responsibility

for the shipment’s safe arrival. Any claim for damage to

the shipment, either visible or concealed, must be made

through the shipping carrier fi rst.

CAUTION

DO NOT touch an operating motor. The

surface of the motor may be HOT. Allow the motor to

cool for thirty (30) minutes before handling.

GENERAL SAFETY

• Do not allow pump or any system component to

freeze. To do so will void the warranty.

• This pump has been evaluated for pumping

water only. Pumping liquids other than water may

void warranty.

• Periodically inspect pump and system components.

1

Page 4

PRE-INSTALLATION CHECK

P

• Pump must not be more than 25 feet above the

surface of the water.

• Use as few elbows and fi ttings as possible to

reduce friction and maximize fl ow.

• Be sure pipe, fi ttings, and foot valve are clean

and free of debris.

• There should be no air pockets or leaks in the

suction pipe.

• Tefl on tape should be used to seal threaded pipe

connections.

INSTALLATION TIPS

• Wrap all threaded male pipe

ends and fi ttings with tefl on tape.

This will ensure a good seal around

all pipe connections.

• PVC Pipe Connections: Use

PVC pipe primer on all glue joints

before applying PVC cement.

After applying PVC cement to both

surfaces to be glued, connect pipe

and fi tting, turn pipe one-quarter

turn and hold for 30 seconds. This

will ensure a positive cementing of

all joints.

INSTALLATION

LOCATION OF PUMP

Decide on an area for the pump installation that

is suitable based on the enclosure rating of the

electric pump motor. All Turf Boss pumps are

UL778 approved and will be marked “ACCEPTABLE

FOR OUTDOOR or INDOOR USE.”

• INDOOR PUMP INSTALLATION OPTION:

Choose a clean, well-ventilated, weatherproof location

that affords protection from freezing, fl ooding, and

excessive heat. In addition, it should provide access

for servicing and allow convenient draining of the

pump and service pipes. A prepared foundation is not

essential, provided the surface is hard and level. It

can be located in the basement or utility room of your

house, at the well or between the point of use and

the well.

• OUTDOOR PUMP INSTALLATION OPTION:

When installing outside of the house, the pump should

be protected by a pump house with auxiliary heat to

prevent possible freezing.

Choose a clean location best suited for the water

system. A prepared foundation is not essential,

provided the surface is hard and level. It should provide

access for servicing and allow convenient draining of

the pump and service pipes. When installing outside

of the house, the pump and piping system must be

drained completely of water to prevent possible freezing

when weather dictates.

Decide how to seal the well from surface contamination

as required by local authorities. The most common

device for this purpose is the SANITARY WELL SEAL.

If the pipes from the well have to be kept below the

frost line, either bury the wellhead or use a PITLESS

ADAPTER that leaves the wellhead exposed for

servicing while providing sealed openings in the well

casing below the frost line.

Following are three well and water source

applications for the Turf Boss sprinkler pump.

Wells may differ slightly but the application is

essentially the same.

Single Shallow Well (Figure 1)

The single shallow well is typically a drilled well with

a 4" or 6" steel or plastic casing running vertically

into the ground. The surface of the water should not

exceed 25 feet in depth.

Connect the foot valve to the

fi rst length of suction pipe and

lower into well. Add pipe sections

as needed, securing them using

one of the sealing methods

previously mentioned. The foot

valve should be AT LEAST fi ve

feet below the surface of the water

to allow for water draw down.

Seal the top of the 4" or 6" well

casing with a well seal to prevent

debris from falling into the well.

Figure 1

1-1/2" PVC

ELBOW

1-1/2" MINIMUM

PVC ADAPTER

1-1/2" MINIMUM

FOOT VALVE

WELL

SEAL

Figure 3

1-1/2" MINIMU

RIDGED PVC

2

Page 5

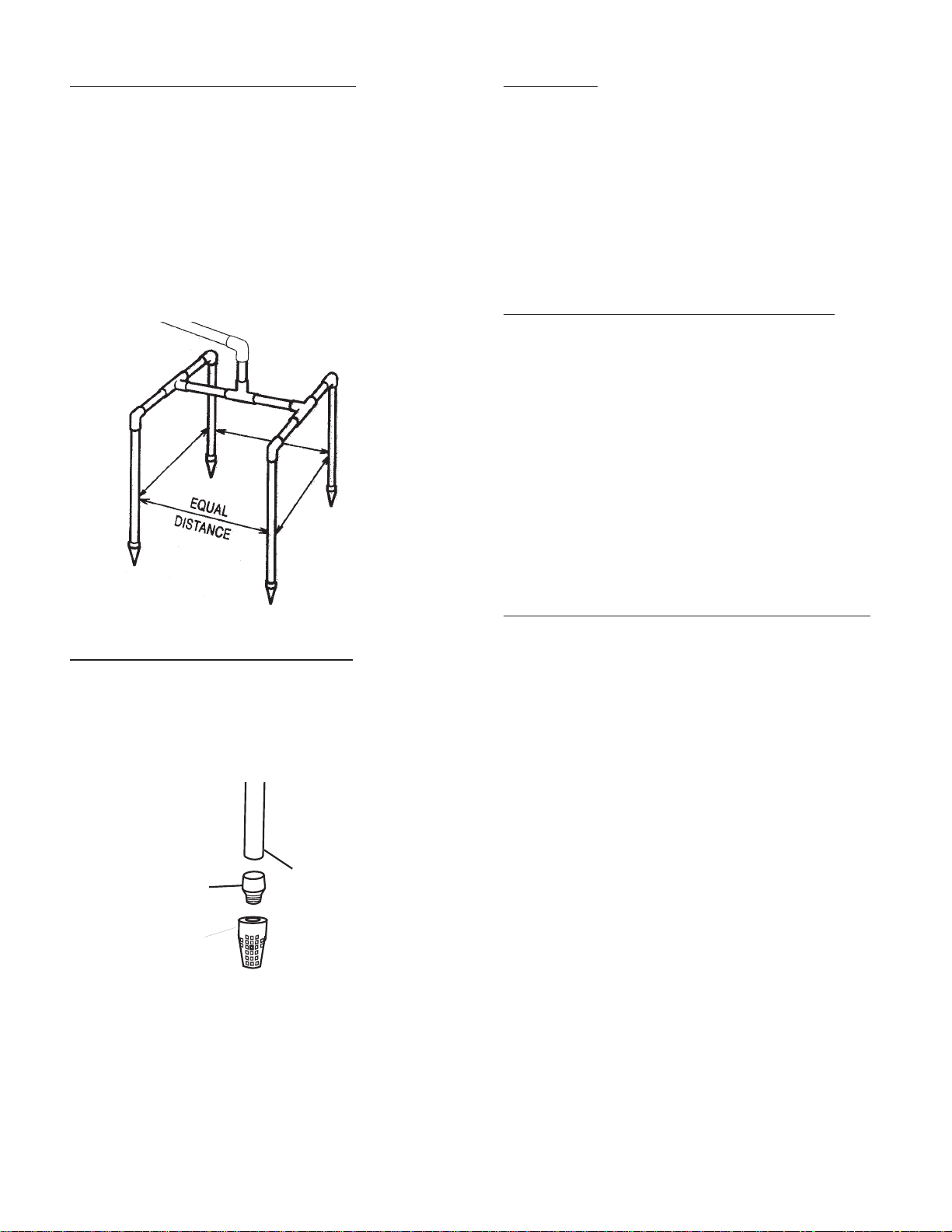

Multi-shallow Well Points (Figure 2)

The multi-point shallow well confi guration consists of

two or more wells as a water supply. The wells should

be at least fi ve feet apart. The wells may be spaced

as a straight line (two or more wells), a triangle (three

wells), or a square (four wells).

Install a check valve or a fi ne screen well point

on each well to ensure the pump maintains prime.

The fl ow arrow on a check valve must point toward

the pump.

PLUMBING

Bolt the pump to a level, solid foundation, if possible.

Position the pump with the suction port facing the

water source pipe(s). Avoid 90º angles whenever

possible and minimize turns when connecting pump

to your water source. Install the pump as close to the

water source as possible. This will help reduce friction

and maximize water pressure.

Figure 2

Lake Or Pond Installation (Figure 3)

Using a surface water source such as a lake or pond is

similar to using a single shallow well. The suction pipe

is placed in the water source and leads back to the

pump. This application may require a long horizontal

distance between water source and pump.

Figure 3

HORIZONTAL OFFSET SUCTION PIPING

When the pump is offset from the well, the horizontal

offset suction piping may have to be increased in

diameter to reduce friction loss. The friction loss in a

system increases:

1.) As the fl ow rate increases

2.) As the piping size decreases

Consult included Turf Boss performance tables

(Appendix III) and friction loss tables (Appendix IV)

to determine the amount of head lost for a given

application. Pipes from the well to the pump should

slope upward (about 1” of rise for every 30” of run).

DISCHARGE PIPE SIZES FOR INSTALLATION

When the pump is located at a distance from points of

water use, it is necessary to increase the discharge pipe

size in order to reduce friction loss. The friction loss in a

system increases:

1.) As the fl ow rate increases

2.) As the piping size decreases

Consult included Turf Boss performance tables

(Appendix III) and friction loss tables (Appendix IV)

to determine the amount of head lost for a given

application.

1-1/2" MINIMUM

PVC ADAPTER

1-1/2" MINIMUM

RIDGED PVC PIPE

1-1/2" MINIMUM

FOOT VALVE

The suction pipe size should increase by one

size to minimize pressure loss caused by friction from

pipe distance.

Place a foot valve at the end of the suction pipe to

protect the pump from debris.

3

Page 6

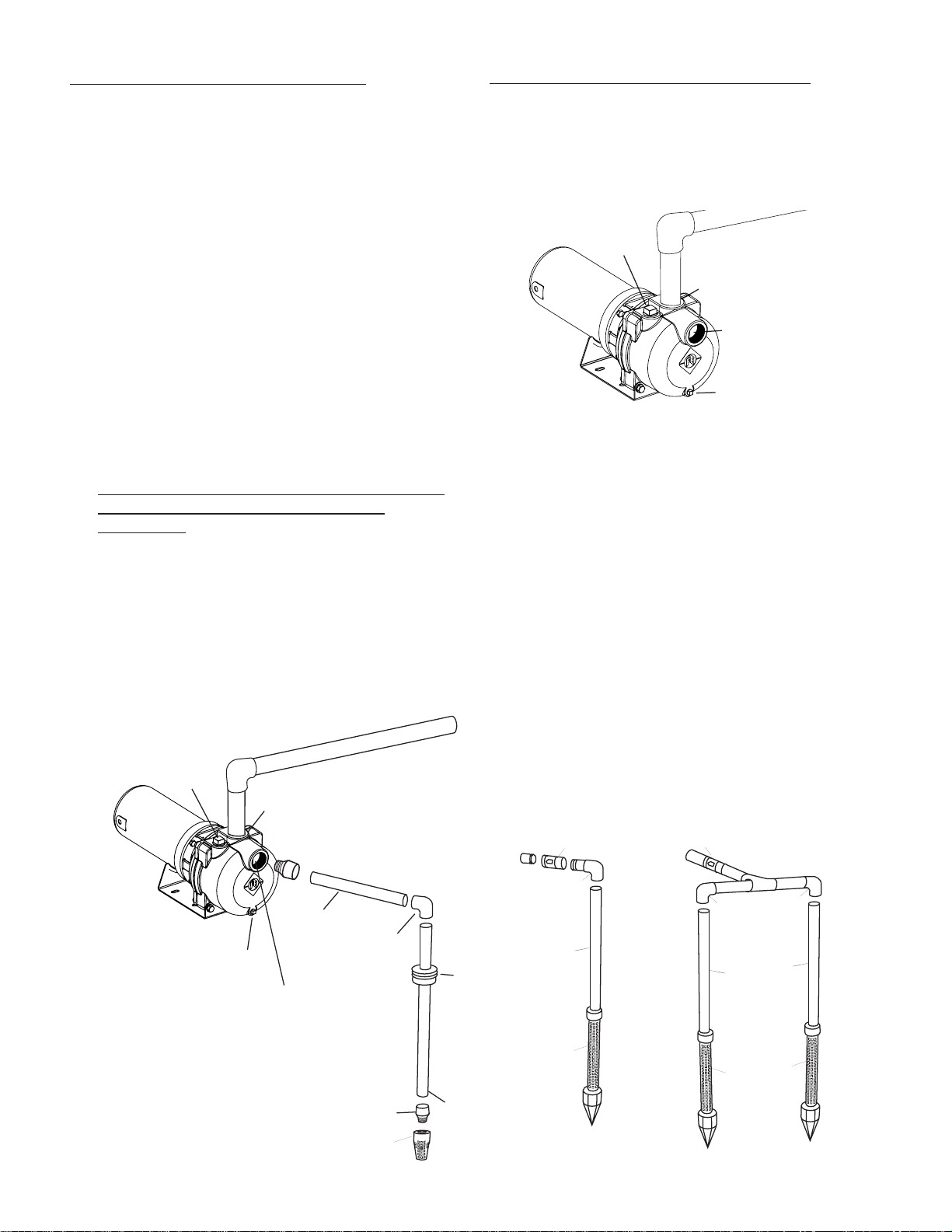

A. Suction Port Connection (Figure 4)

B. Discharge Port Connections (Figure 5)

Step 1:

Attach the foot valve or well point to pipe assembly

and lower pipe and foot valve until it is at least fi ve

feet below the water level. If you are using a well,

temporarily clamp the pipe to the well casing to

prevent the pipe from sliding into the well. If well is

in a 4" or 6" casing, use a well seal at the surface.

Never use a suction pipe size smaller than the size

of the suction port on the pump.

Step 2:

Connect the necessary elbows, fi ttings, check

valves, and pipe from the water to the pump suction

port on front of pump. When using PVC, pre-

assemble pipe and fi ttings to the pump BEFORE

applying PVC cement to ensure proper cuts and

inventory. Use tefl on tape on all male threads,

wrapping clockwise (when facing pipe) 1 to 2 layers

thick. Tighten all threaded pipe fi ttings until snug.

DO NOT OVER TIGHTEN PIPE AND FITTINGS!!

Tighten joints hand tight plus 1/2 turn with

pipe wrench.

Step 1:

Thread male adapter or pipe nipple into discharge port

on top of pump. (Use tefl on tape on thread)

Figure 5

PRIMING PORT

1-1/2" DISCHARGE PORT

1-1/2" SUCTION PORT

DRAIN PLUG

Step 2:

Connect pipe between the sprinkler manifold and

the pump discharge. Discharge pipe size should

increase with long pipe runs. Discharge pipe size

may equal discharge port size for distances up to

100'. Increase discharge pipe size by one size for

distances of 100' to 300'. For 300' to 600', increase

pipe size by two sizes. This will reduce pressure

loss caused by friction.

Figure 4

4

PRIMING PORT

DRAIN PLUG

TO SPRINKLE

1-1/2” DISCHARGE PORT

1-1/2” RIDGED

PVC PIPE

1-1/2” PVC

ELBOW

1-1/2” SUCTION PORT

1-1/2” PVC

ADAPTER

1-1/2” FOOT

VALVE

R SYSTEM

WELL

SEAL

1-1/2 RIDGED

PVC PIPE

Step 3:

Tighten all threaded pipe connections with pipe wrench

until snug. Do not over tighten.

WELL POINT

INSTALLATION

CHECK

VALVE

1-1/2” PVC

ELBOW

1-1/2”

GALVANIZED

PIPE

WELL POINT

MULTIPLE WELL

POINT INSTALLATION

CHECK

VALVE

TO

PUMP

1-1/2” PVC

ELBOW

1-1/2”

GALVANIZED

PIPE

WELL POINT

Page 7

INSTALLATION RECORDS

To keep an accurate record of your installation, be

sure to fi ll out the data below:

Date of Installation:

Model No.

Depth of Well (ft):

Depth to Water (ft):

Inside diameter of Well:

Suction Pipe Size:

Suction pipe length (ft):

Discharge pipe length (ft):

Motor:

HP:

Volts:

Wire gauge size:

DUAL VOLTAGE ADJUSTMENT

NOTE:

the dual voltage connector on the motor and reconnect

it in the position required to match the available

electrical system. The motor can be set for 115 volts

or 230 volts, except for 2 hp modles which are 230

volts only. The voltage setting of the motor can be

determined by looking at the alignment of the arrow

on the plug and the arrow on the motor terminal board

(located under the motor’s end cover). Any questions

as to which voltage setting is required for proper motor

and pump operation in your system should be directed

to an electrical professional. The factory preset is

230 volts.

To change the motor voltage(Figure 6) unplug

Figure 6

ELECTRICAL INSTALLATION

WARNING

WARNING

voltage can shock, burn or

cause death.

CAUTION

not sure of proper electrical

connections, consult a licensed

electrician.

CAUTION

can result in permanent damage

to the motor. All electrical wiring

should meet the local electrical

code.

Hazardous

If you are

Improper wiring

NOTICE

READ AND FOLLOW ALL INSTRUCTIONS!

• Pump connection must comply with National

Electric Code (NEC) or Canadian Electric Code

(CEC), and all applicable local codes.

• All dual voltage units come factory preset for

230 volts. (Figure 3)

• Disconnect power at electrical panel before

making any electrical connections.

• Supply voltage must be +/- 10% of motor

nameplate voltage. Low or high voltage can

damage the motor and will void the warranty.

• If possible, connect pump to dedicated branch

circuit with no other appliances on it.

• Do not operate pump unless pump is grounded

230V

115V 230V

115V

230V

115V

Wiring Installation

NOTICE: Check motor terminal cover or nameplate

for wiring instructions. The essential pump motor facts

are as follows:

1.) 3450 RPM

2.) Single Phase

3.) Dual Voltage, 115/230 on 1 and 1-1/2 HP; 230 V

only on 2 HP motors.

4.) 1/2, 3/4, 1, and 1-1/2 Horsepower motors are

wired for 230 volts as a factory standard.

Step 1:

Remove motor access cover at back of motor.

Step 2:

Feed the grounding wire (green or bare copper)

through the electrical conduit port in the side of the

motor. First connect the ground wire then connect

the power supply wires. Attach the grounding wire

to the motor ground screw (green). Secure wires to

prevent electrical shorts.

5

Page 8

Step 3:

G

WA

G

G

Connect the incoming power supply wires to the

motor terminal.

Step 4:

Replace priming port plug and tighten with wrench,

using tefl on tape on pipe threads.

Step 4:

Replace and secure motor cover.

NOTE: Single phase motors rotate counterclockwise

only (when facing suction port) and cannot

be reversed.

MOTOR

NOTICE: A motor operating under normal

conditions maintains its rated performance,

assuming a clean, dry motor with proper ventilation.

A dirty motor, or one “protected” by a burlap or

plastic bag, will overheat.

PRIMING AND START UP

WARNING

RNIN

water before starting pump. Operating pump dry may

cause damage to pump and will void warranty.

WARNING

WARNIN

discharge. This may cause hazardous pressure and

risk of explosion.

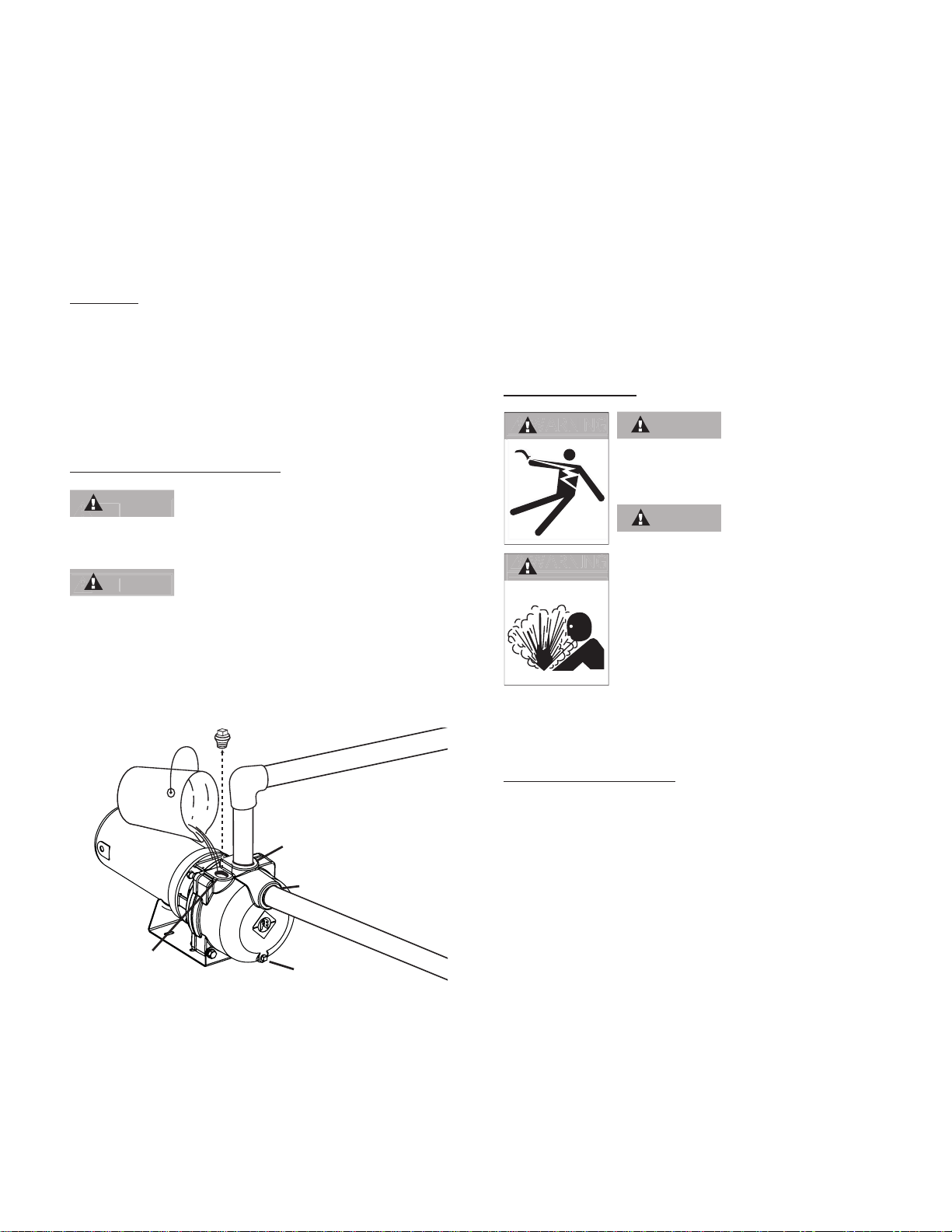

Step 1 (Figure 7):

Remove priming port plug from pump.

Figure 7

NEVER run pump dry. Fill pump with

NEVER run pump against a closed

Step 5:

Start the pump. A properly primed pump should

discharge water without air at a consistent

pressure. If the pump does not produce water after

fi ve minutes, stop the pump, release all pressure,

remove priming port plug, add more water, replace

plug, and try again. (Make sure that a foot valve

is properly installed on the suction pipe. See

"Suction port connection". Figure 4)

MAINTENANCE

WARNING

WARNING

WARNING

Failure to disconnect

electrical power before attempting

maintenance can cause shock, burns,

or death.

WARNING

Before disconnecting

pump, be sure fuse box leads are

disconnected or power is turned off.

After reassembling the pump, refer to

priming instructions before running.

HAZARDOUS PRESSURE!

-Do not run pump against

closed discharge.

-Release all pressure on system

before working on any component.

1-1/2" DISCHARGE PORT

1-1/2" SUCTION PORT

PRIMING PORT

DRAIN PLUG

Step 2:

Open discharge valves and any hoses on

discharge side of pump.

Step 3:

Fill pump with water through the priming port on

top of pump. Allow trapped air to escape for a few

minutes, then add more water until full.

6

A. Draining (Figure 8)

The pump should be drained if it is in danger of

freezing, if it will be out of service for an extended

period of time, or if it requires service.

To drain pump, disconnect power source,

remove priming port plug from pump case, remove

drain plug (below suction port), and drain system.

Replace drain plug.

Page 9

Priming Port

NOTICE: While this will drain the pump, it will

not necessarily drain all other parts of the piping

system. If there are any concerns with the proper

procedure or necessity of draining the suction

plumbing, contact your contractor.

Figure 8

Drain Plug

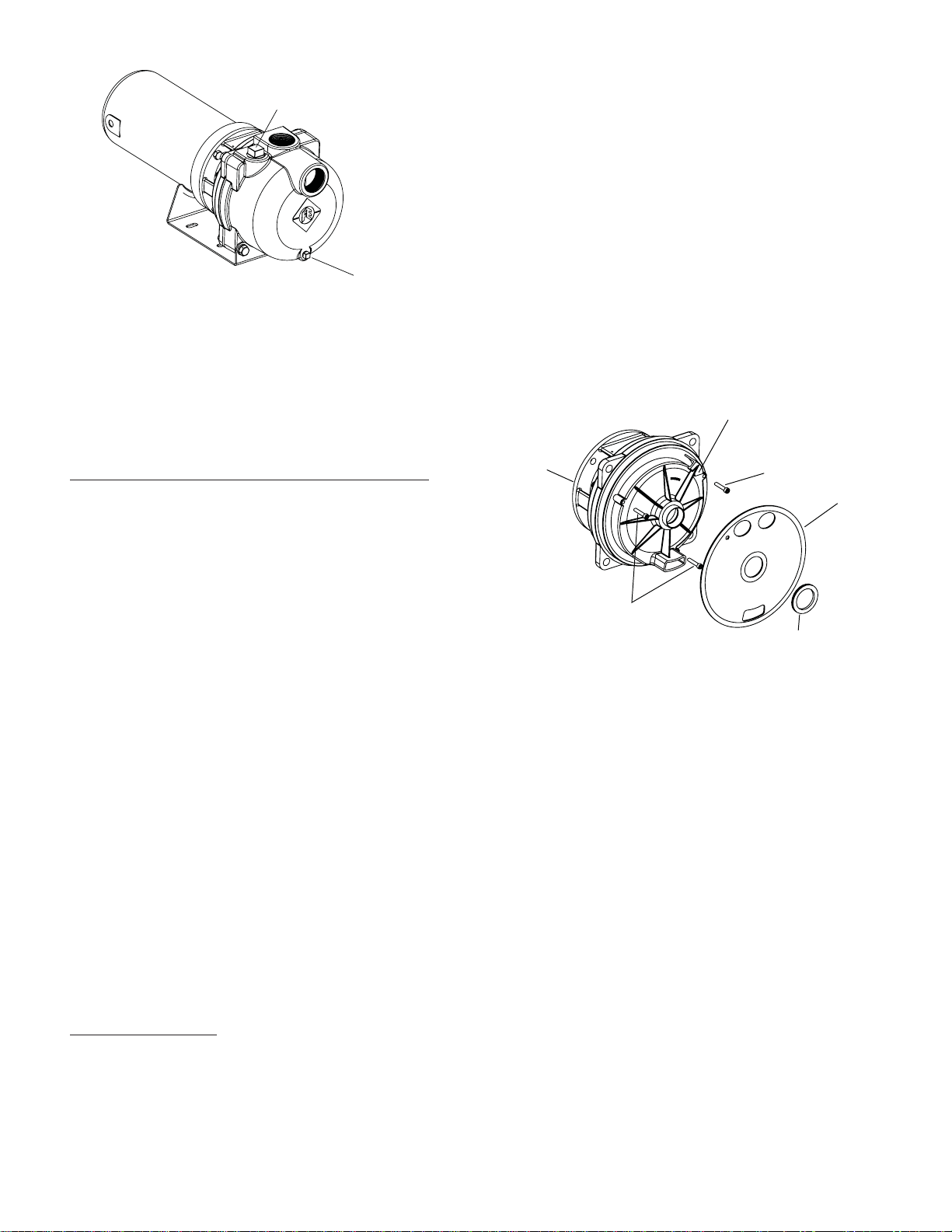

B. Pump Disassembly (Appendix I & Figure 9)

In order to access the internal components of the

pump, review the exploded diagram of the pump

assembly as shown on the repair parts page(Appendix

I). Drain the pump as described above and then

remove the four bolts that hold the pump case to the

motor bracket. This will allow the motor and hydraulic

sub-assembly to be removed from the case without

disturbing the plumbing. Locate and inspect the

diaphragm and grommet which are internal water

seals. Make sure they are in good condition and are

working properly. To remove the diffuser, loosen

the 3 bolts that attach it to the motor bracket. This

will expose the impeller and eye-seal. Remove the

eye-seal and then, in order to remove the impeller,

securely hold the motor shaft with a pair of vice grips

to prevent any unwanted rotation. Turn the impeller

counter-clockwise (when facing impeller) to remove

and this will reveal the mechanical shaft seal. This

seal can then be removed from the motor shaft for

inspection. The motor bracket can be removed from

the motor by removing the 4 bolts on the backside

of the motor bracket. To remove the ceramic shaft

seal, press gently from the backside on the ceramic

and it will fall out easily. Inspect, clean or replace

parts as needed.

to insure a proper fi t. Place the shaft seal on the motor

shaft and then install the impeller and eye-seal. The

diffuser is positioned by three bolts that can only be

installed when the diffuser is oriented properly (Figure

9). Position the diaphragm on the diffuser suction eye.

(as shown in Figure 9). The grommet will slide over

the diffuser eye on top of the diaphragm. Lift the motor

assembly up into the pump case and attach it using

the 4 bolts. When seating the pump case against the

motor bracket, the diaphragm should be captivated

between them around the entire perimeter. This allows

the diaphragm to serve as a water seal between the

two cast iron parts. If the diaphragm is not positioned

correctly the unit will leak once the case is fi lled with

water. Tighten all bolts to 185 in-lbs in a diagonal

pattern to insure proper seating of all components.

Figure 9

Diffuser

Motor

Bracket

Diffuser Bolt

Diaphragm

Diffuser Bolt

Grommet

C. Pump Assembly

Reassemble unit by fi rst pressing the ceramic seal into

the seal plate. Use rubbing alcohol as a lubricant. Do

not use an oil, vaseline or grease as this will damage

the sealing surfaces of the shaft seal during operation.

Next, install the motor bracket onto the motor using

the four bolts. Tighten the bolts in a diagonal pattern

7

Page 10

PARTS FOR TURF BOSS

SELF-PRIMING SPRINKLER PUMP

APPENDIX I

11 I

5D

5D

10H

5D

5D

9F,G

7E,G

8E,G

6E,G

5D

5D

12J

4C,G

3C,G

1A

5D

2B

5D

1A

Figure

Number

1

2

3

4

5

6

7

8

9

10

11

12

* Items with like identifi ers are sold/packaged together

** Fastener kits (5D) is a complete set of the hardware used to assemble the Turf Boss. As a convenience all other

repair kits contain the fasteners needed for the reassembly of its components.

Plug Kits A 305390901

Pump Case B 305491901

Grommet

Diaphragm

Fastener Kit* D 305393901

Diffuser

Wear Ring

Impeller

Mechanical Seal

Motor Bracket H 305397901

Motor I 305398901 305398902 305398903

Base Assembly J 305399901

Description

Kit Grouping

Identifi er*

C 305392901

G 305396901 305396902 305396903

C 305392901

G 305396901 305396902 305396903

E 305394901 305394902 305394903

G 305396901 305396902 305396903

E 305394901 305394902 305394903

G 305396901 305396902 305396903

E 305394901 305394902 305394903

G 305396901 305396902 305396903

F 305395901

G 305396901 305396902 305396903

Repair Part Order Codes by Model Number

TB1CI TB15CI TB2CI

8

Page 11

APPENDIX II - TROUBLESHOOTING

A. Pump does not deliver water or pressure

Cause: The pump is not full of water.

Remedy: Stop the pump, fi ll it with water, check all

pipe connections to make sure there are no air leaks

and try again.

B. Low pressure

Cause: The motor is not up to speed.

Remedy: Check for proper voltage and tight wiring

connections.

Cause: The impeller is partially plugged.

Remedy: Check impeller for rocks or debris. Refer

to disassembly instruction for getting to impeller.

Cause: Air is leaking into suction line.

Remedy: Check suction line connections.

C. Low capacity

Cause: Your water level is deeper than 25 feet.

Remedy: Pump can’t pump below 25 feet. Call your

Franklin Pump Systems dealer.

Cause: You are using too long a pipe from the

water to the pump.

Remedy: You should use a larger diameter pipe.

Cause: You have a plugged impeller.

Remedy: Check impeller. Refer to disassembly

instructions above.

Cause: The pipe from the pump to the water is

partially plugged.

Remedy: Check pipe.

E. Motor will not start

Cause: Open switches, blown fuses or loose

connections.

Remedy: Check switches, fuses, and connections.

Cause: Improper connections to motor.

Remedy: Make sure connections are tight.

F. Air logging (excessive air in pipe)

Cause: Air leaks in pipe

Remedy: Check connections.

Cause: Water drops below the end of the pipe.

Remedy: Pump is out-producing well. Tighten down

control valve gradually until pump starts operating

properly.

G. Gravelly noises inside pump (cavitation)

Cause: Pump running over capacity

(NPSHR exceeds NPSHA)

Remedy: Call your Franklin Pump Systems dealer.

Cause: Suction pipe is too small or length of pipe is

too long.

Remedy: Use a larger diameter pipe.

Cause: End of suction pipe is in mud or sand.

Remedy: Raise end of suction pipe or clean

out well.

D. Motor overheats

Cause: Improper voltage or wiring connections.

Remedy: Check to see if your voltage is the same

as indicated on the motor name on dataplate. Be

sure all wiring connections are tight.

Cause: Improper ventilation for the motor.

Remedy: Check to see if motor is clean and

properly vented.

9

Page 12

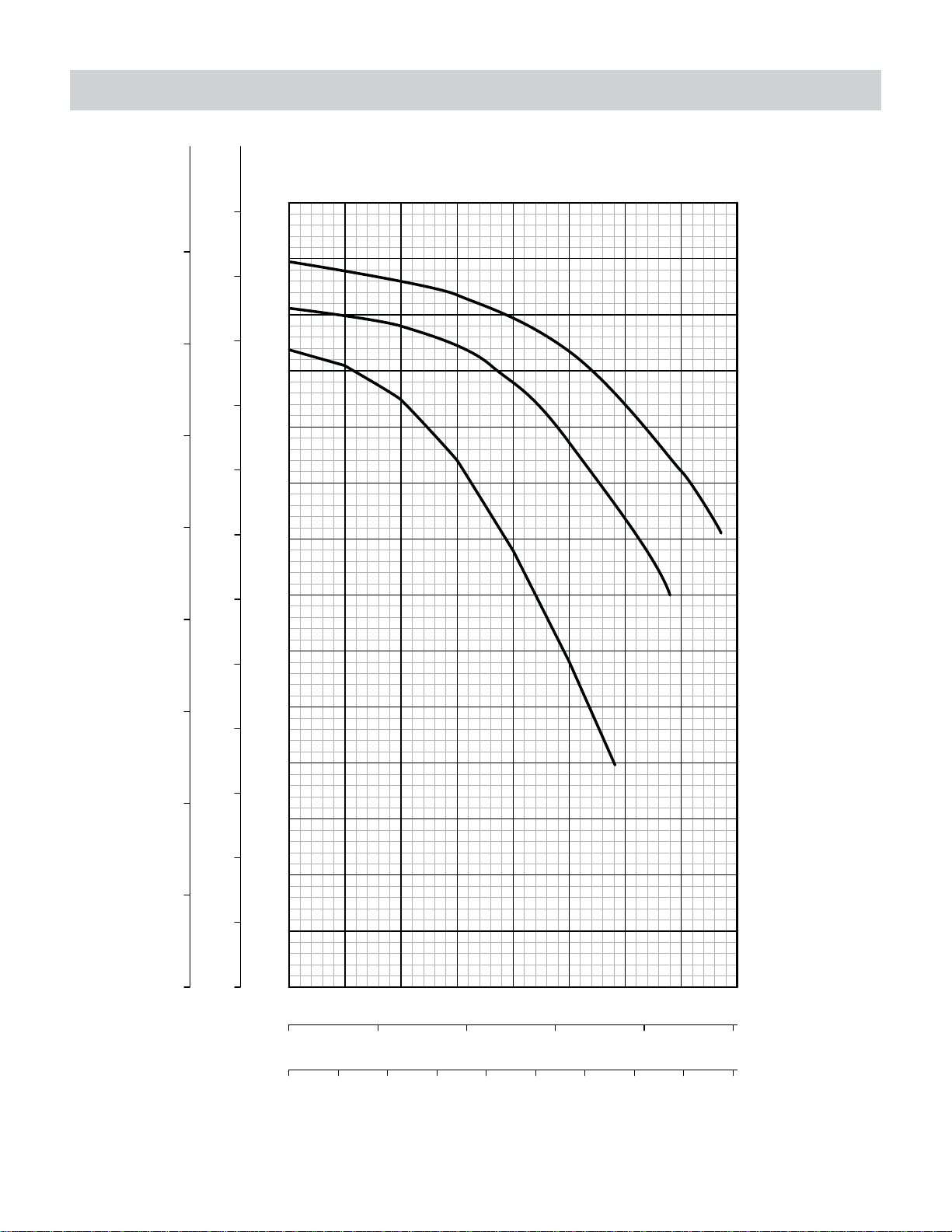

APPENDIX III - PERFORMANCE CURVE

METERS

40

35

30

25

20

60

55

50

45

40

35

30

PSI

140

130

120

110

100

FEET

2 HP

1.5 HP

1 HP

90

80

70

15

10

25

20

15

10

5

60

50

40

30

20

5

10

000

0 1020304050607080

0

0

12345

2 4 6 8 10 12 14 16 18

GPM

LPS

3

M PH

10

Page 13

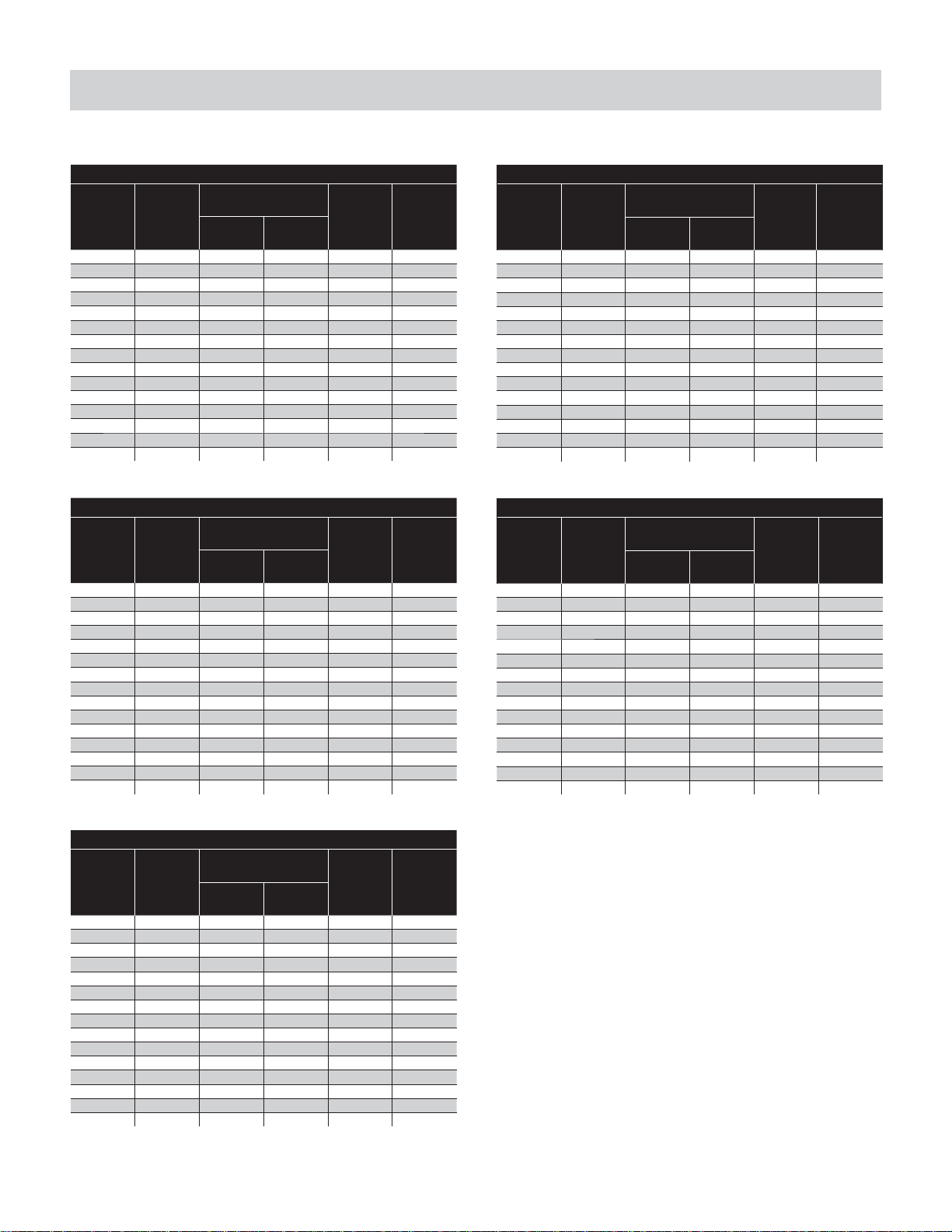

APPENDIX IV - FRICTION LOSS TABLES

1”

Schedule 40 pipe 1.049 in. i.d. / Type L Copper tube 1.025 in. i.d.

Friction Loss

GPM

2.0 0.74 0.60 0.32 .078 0.41

3.0 1.11 1.26 0.68 1.17 0.87

4.0 1.49 2.14 1.15 1.56 1.48

5.0 1.86 3.24 1.75 1.95 2.23

6.0 2.23 4.54 2.45 2.34 3.13

8.0 2.97 7.73 4.16 3.11 5.35

10 3.71 11.7 6.31 3.89 8.08

12 4.46 16.4 8.85 4.67 11.3

14 5.20 21.8 11.8 5.45 15.0

16 5.94 27.9 15.1 6.22 19.2

18 6.68 34.7 18.7 7.00 23.9

20 7.43 42.1 22.8 7.78 29.0

25 9.29 63.6 34.6 9.74 43.9

30 11.1 89.2 48.1 11.7 61.4

40 14.9 152 82.0 15.5 105

Velocity

Ft/S

Ft Hd./100’ of pipe

Steel

C=100

PVC

C=140

Velocity

Ft/S

1.5”

Schedule 40 pipe 1.610 in. i.d. / Type L Copper tube 1.505 in. i.d.

Friction Loss

GPM

6.0 0.95 0.57 0.31 1.08 0.49

8.0 1.26 0.96 0.52 1.44 0.82

10 1.58 1.45 0.79 1.80 1.24

12 1.89 2.04 1.10 2.16 1.73

15 2.36 2.95 1.59 2.70 2.62

20 3.15 5.24 2.83 3.60 4.46

25 3.94 7.90 4.26 4.51 6.74

30 4.73 11.1 6.00 5.41 9.44

40 6.30 18.9 10.2 7.21 16.1

50 7.88 28.5 15.4 9.01 24.3

60 9.46 40.0 21.6 10.8 34.1

70 11.0 53.2 28.7 12.6 45.5

80 12.6 68.1 36.8 14.4 58.1

90 14.2 84.7 45.7 16.2 72.1

100 15.8 103 56.6 18.0 87.7

Velocity

Ft/S

Ft Hd./100’ of pipe

Steel

C=100

PVC

C=140

Velocity

Ft/S

Ft Hd./

100’ Pipe

Fric. Loss

C=130

Ft Hd./

100’ Pipe

Fric. Loss

C=130

1¼”

Schedule 40 pipe 1.380 in. i.d. / Type L Copper tube 1.265 in. i.d.

Friction Loss

GPM

4.0 0.86 0.56 0.30 1.02 0.52

6.0 1.29 1.20 0.65 1.53 1.12

8.0 1.72 2.04 1.10 2.04 1.92

10 2.15 3.08 1.67 2.55 2.90

12 2.57 4.31 2.33 3.06 4.04

14 2.00 5.73 3.10 3.57 5.35

16 3.43 7.34 3.96 4.08 6.85

18 3.86 9.13 4.93 4.59 8.52

20 4.29 11.1 6.00 5.10 10.4

25 5.36 16.8 9.06 6.38 15.7

30 6.43 23.5 12.7 7.65 22.1

40 8.58 40.0 21.6 10.2 37.6

50 10.7 60.4 32.6 12.8 56.7

60 12.9 84.7 45.6 15.3 79.5

80 17.2 144 77.9 20.4 136

Velocity

Ft/S

Ft Hd./100’ of pipe

Steel

C=100

PVC

C=140

Velocity

Ft /S

2”

Schedule 40 pipe 2.067 in. i.d. / Type L Copper tube 1.985 in. i.d.

Friction Loss

GPM

10 0.96 0.43 0.23 1.07 0.35

15 1.44 0.92 0.50 1.60 .075

20 1.91 1.55 0.84 2.13 1.24

25 2.39 2.35 1.27 2.66 1.87

30 2.87 3.29 1.78 3.19 2.62

40 3.82 5.60 3.03 4.26 4.48

50 4.78 8.46 4.57 5.32 6.76

60 5.74 11.9 6.44 6.39 9.47

70 6.69 15.8 8.53 7.45 12.6

80 7.65 20.2 10.9 8.52 16.2

90 8.61 25.1 13.6 9.58 20.0

100 9.56 30.5 16.5 10.7 24.4

120 11.5 42.7 23.1 12.8 34.1

150 14.3 64.7 35.0 16.0 51.6

200 19.1 110 59.4 21.3 87.8

Velocity

Ft/S

Ft Hd./100’ of pipe

Steel

C=100

PVC

C=140

Velocity

Ft/S

Ft Hd./

100’ Pipe

Fric. Loss

C=130

Ft Hd./

100’ Pipe

Fric. Loss

C=130

2.5”

Schedule 40 pipe 2.469 in. i.d. / Type L Copper tube 2.465 in. i.d.

Friction Loss

GPM

20 1.21 0.66 0.35 1.34 0.40

30 2.01 1.39 0.75 2.02 0.85

40 2.68 2.36 1.27 2.69 1.46

50 3.35 3.56 1.92 3.36 2.20

60 4.02 4.99 2.69 4.03 3.08

70 4.69 6.64 3.58 4.70 4.11

80 5.36 8.50 4.59 5.37 5.25

90 6.03 10.6 5.72 6.04 6.52

100 6.70 12.8 6.90 6.71 7.94

110 7.37 15.3 8.22 7.38 9.44

130 8.71 20.9 11.3 8.73 12.9

150 10.0 27.3 14.7 10.1 16.8

200 13.4 46.3 25.0 13.4 28.6

250 16.8 81.7 44.1 16.8 43.4

300 20.1 98.1 52.9 20.1 61.1

Note: Chart shows friction loss per 100’ of pipe. To convert to friction loss per foot, move decimal point 2 places to the left.

Velocity

Ft/S

Ft Hd./100’ of pipe

Steel

C=100

PVC

C=140

Velocity

Ft /S

Ft Hd./

100’ Pipe

Fric. Loss

C=130

11

Page 14

U.S. LIMITED WARRANTY*

Franklin Electric Co., Inc.

Franklin Electric Co., Inc. warrants its new products to be free of defects in material and workmanship for a period

of 1 year from date of installation or 2 years from date of manufacture, whichever comes fi rst, WHEN installed in clean,

potable water applications. Warranty does not cover applications pumping saltwater or other corrosive liquids. Consult

and adhere to local codes for all applications. Franklin Electric Co., Inc. also provides additional warranty coverage on

specifi c products as specifi ed herein.

Franklin Electric’s warranty obligation with regard to equipment not of its own manufacture is limited to the warranty

actually extended to Franklin Electric by its suppliers.

This warranty extends only to the original retail purchaser and only during the time in which the original retail

purchaser occupies the site where the product was originally installed.

Requests for service under this warranty shall be made by contacting the installing Franklin Electric dealer (point

of purchase) as soon as possible after the discovery of any alleged defect. Franklin Electric will subsequently take

corrective action as promptly as reasonably possible.

Franklin Electric at its discretion may replace or repair any product that fails under this warranty after inspection by

an authorized company representative or after Franklin Electric has received the product at our factory. Replacement

or repair cannot be made until after the product is inspected. All charges or expenses for freight to and from the factory,

removal and reinstallation of the product, or installation of a replacement product are the responsibility of the purchaser.

THIS WARRANTY SUPERSEDES ANY WARRANTY NOT DATED OR BEARING AN EARLIER DATE. ANY

IMPLIED WARRANTIES WHICH THE PURCHASER MAY HAVE, INCLUDING MERCHANT ABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE APPLICABLE WARRANTY PERIOD.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not

apply to you. IN NO EVENT SHALL FRANKLIN ELECTRIC BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES. Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above may not apply to you.

This warranty does not apply to any product which has been subjected to negligence, alteration, accident, abuse,

misuse, improper installation, vandalism, civil disturbances, or acts of God. The only warranties authorized by Franklin

Electric are those set forth herein. Franklin Electric does not authorize other persons to extend any warranties with

respect to its products, nor will Franklin Electric assume liability for any unauthorized warranties made in connection

with the sale of its products.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH

MAY VARY FROM STATE TO STATE.

* Contact Franklin Electric Co., Inc. Export Division for International Warranty.

106258101 Rev. 0 3/08

400 E. Spring Street

Bluffton, IN 46714

Tel: 260-824-2900

Fax: 260-824-2909

www.franklin-electric.com

Page 15

Bomba para regadores autocebante

MANUAL DEL PROPIETARIO

Cerciórese de tener a disposición material adequado y

apropiado para el cableado para concluir la instalación

correctamente.

LEA Y SIGA LAS INSTRUCCIONES DE

SEGURIDAD

Éste es un símbolo de alerta de seguridad.

Cuando usted vea este símbolo en su bomba o en

este manual, busque una de las palabras siguientes y

esté alerta en cuanto a posibles lesiones:

ANTES DE COMENZAR

ANTES DE INSTALAR LA BOMBA, CERCIÓRESE

DE LEER CUIDADOSAMENTE EL MANUAL DEL

PROPIETARIO.

CONSULTAR INSTRUCCIONES DE OPERACIÓN Y

ESPECIFICACIONES EN LA(S) PLACA(S) DE DATOS

DEL PRODUCTO.

CUIDADO

• Mantenga el área de trabajo limpia, bien iluminada y

desobstruida.

• Mantenga las etiquetas de seguridad limpias y en

buenas condiciones.

• Substituya las etiquetas de seguridad perdidas o

averiadas.

• Use lentes de seguridad mientras instale o realice la

manutención de la bomba.

• Siga las orientaciones del NEC (Código Eléctrico

Nacional) o CEC (Código Eléctrico Canadiense y

cualquier otros códigos de estados o locales en

TODAS las instalaciones eléctricas. Verifi que estas

informaciones en los organismos apropiados o contacte

con un electricista habilitado.

La mayoría de los problemas en los sistemas de agua

provienen de una instalación inadecuada. Se sugiere

que lea este manual cuidadosamente antes de instalar la

bomba. La “SECCIÓN DE SOLUCIÓN DE PROBLEMAS”

lo ayudará a ubicar y eliminar la causa de los problemas

que pueda encontrar después de la instalación. Verifi que

y deje a mano todas las herramientas que precisará para

instalar la bomba. Las herramientas necesarias pueden

incluir pinzas, selladores de tuberías, accesorios y niples,

destornillador, etc.

PELIGRO

lesiones, muerte o daños materiales importantes cuando

se ignoren.

AVISO

graves lesiones, muerte o daños materiales importantes

cuando se ignoren.

CUIDADO

pueden causar lesiones menos importantes o daños

materiales cuando se ignoren.

AVISO indica instrucciones especiales, que son

importantes pero que no están relacionadas a peligros.

Lea cuidadosamente y siga todas las instrucciones

de seguridad en este manual y en la bomba.

AVISO

funcionar la bomba contra una salida cerrada. Libere

todos los sistemas de presión antes de trabajar en

cualquier componente.

CUIDADO

Llene la bomba con agua antes de comenzar o la

bomba puede averiarse.

El motor de esta bomba tiene garantía del fabricante y,

en caso de falla, debe devolverse a un puesto de servicio

autorizado para reparación. Motor warranty is void if

repairs aren’t made by an authorized repair station.

avisa sobre peligros que causarángraves

avisa sobre peligros que pueden causar

avisa sobre peligros que causarán o

AVISO

PRESIÓN PELIGROSA: No haga

No haga funcionar la bomba en seco.

AV I S O

Page 16

Page 17

SEGURIDAD ELÉCTRICA

CUIDADO

ELÉCTRICAS ESTÉN APAGADAS antes de conectar

cualquier cable eléctrico.

AVISO

peligroso. Para descargar el condensador del motor,

sujete un destornillador con mango aislado POR EL

MANGO y los terminales cortos del condensador

juntos. No toque la parte metálica del destornillador o

los terminales de condensador porque pueden causar

una descarga eléctrica. En caso de duda, consulte un

electricista cualifi cado.

!6)3/

_6OLTAJEPELIGROSA

0UEDECAUSARDESCARGA

ELÏCTRICAQUEMADURASO

CAUSARLAMUERTE

#ONECTELABOMBAATIERRA

ANTESDECONECTARLOALA

TOMADEFUERZA

$ESCONECTARLAENERGÓA

ANTESDETRABAJARENLA

BOMBAENELMOTOROEN

ELTANQUE

Cerciórese que todas las FUENTES

El voltaje del condensador puede ser

Instale el cable del

motor con el voltaje

correcto. Consulte la sección

“Instalación eléctrica” en

este manual y en la placa del

motor.

Conecte el motor a

tierra antesde conectarlo

a la toma de fuerza.

Cumpla el Código

Eléctrico Nacional

(NEC) o el Código Canadiense

(CEC) y los códigos locales

para el cableado.

Siga todas las

instrucciones de

cableado de la bomba que

constan en este manual.

INTRODUCCIÓN

Usted ha comprado una de las bombas de manejo

más amigable que existen. Las bombas TurfBoss se

fabrican con materiales de alta calidad diseñados para

ofrecerle años de servicio confi able. Los regadores de

jardín se proyectan para maximizar el fl ujo de salida,

manteniendo la capacidad de extraer agua de una

fuente hasta 25 pies abajo de la bomba. Todas las

partes mecánicas, motor, turbina, mandos eléctricos,

etc. quedan arriba del suelo y son de fácil alcance.

Si es necesario realizar algún servicio, herramientas

manuales simples son sufi cientes para el trabajo.

Esta bomba para regador de jardín se instala fácil y

rápidamente sin necesidad de herramientas especiales

o plataforma para la bomba. Usted mismo puede

instalarla siempre que siga cuidadosamente las

instrucciones de este manual.

INSPECCIÓN DEL EMBALAJE

Todas las bombas para regadores de jardín se

prueban, inspeccionan y embalan cuidadosamente para

asegurar su arribo en perfectas condiciones. Cuando

se recibe la bomba, examinarla cuidadosamente para

asegurarse que no hay averías o piezas quebradas

que puedan haber ocurrido durante el envío. Si existen

daños evidentes, relátelos inmediatamente a su

despachante y distribuidor. Ese despachante asume

total responsabilidad por la entrega segura del envío.

Cualquier reclamación por daños durante el embarque,

sean visibles o presumidos, se debe hacer primero al

despachante.

CUIDADO

NO toque el motor en funcionamiento.

La superfi cie del motor puede estar CALIENTE.

Deje enfriar el motor durante treinta (30) minutos antes

de manejarlo.

SEGURIDAD GENERAL

• No deje que la bomba ni otro componente del sistema

se congelen. Esto cancelará la garantía.

• Esta bomba se ha evaluado solamente para el

bombeo de agua. El bombeo de líquidos, excepto

agua, pueden invalidar la garantía.

• Periódicamente, inspeccione la bomba y los

componentes del sistema.

15

Page 18

VERIFICACIÓN ANTES DE LA INSTALACIÓN

• La bomba no debe de estar a más de 25 pies sobre

la superfi cie del agua.

• Use el mínimo posible de codos y conexiones para

reducir la fricción y maximizar el fl ujo.

• Cerciórese que los caños, conexiones y la válvula

de pedestal estén limpios y libres de residuos.

• No debe haber burbujas o pérdidas en el caño de

succión.

• Se debe usar cinta tefl ón para sellar las conexiones

roscadas de la tubería.

• OPCIÓN DE INSTALACIÓN DE BOMBA EXTERNA:

Cuando se instale fuera de la casa, la bomba se debe

proteger con un alojamiento con calor auxiliar para

evitar posible congelamiento.

Elija un lugar limpio que mejor se adapte al sistema de

agua. No es esencial que haya una base preparada,

siempre que la superfi cie sea dura y nivelada. Debe

permitir fácil acceso para manutención y el drenaje

conveniente de la bomba y manutención de las

tuberías. Cuando se instale fuera de la casa, la

bomba y el sistema de tubería debe ser drenado

completamente para evitar posible congelamiento

cuando el clima lo cause.

INSTALACIÓN- CONSEJOS

• Envuelva todas las puntas de

tubos machos y conexiones

con cinta de tefl ón. Esto

asegurará un buen sellado

alrededor de las conexiones

de la tubería.

• Conexiones de tubos de PVC:

Usar primer para tubos de PVC

en todas las uniones pegadas

antes de aplicar cemento para

PVC. Después de aplicar el

cemento para PVC en ambas

superfi cies que se van a

pegar, conectar el tubo y las

conexiones, girar el tubo un

cuarto de vuelta y mantenerlo

durante 30 segundos. Esto

asegurará que todas las juntas

queden bien pegadas.

INSTALACIÓN

UBICACIÓN DE LA BOMBA

Elija un área para instalar la bomba que sea

adecuada con base en la capacidad de la caja

del motor eléctrico de la bomba. Todas las

bombas Turf Boss son aprobadas por la UL778

y se marcarán como “ACEPTABLE PARA USO

EXTERNO o INTERNO”.

• OPCIÓN DE INSTALACIÓN DE BOMBA INTERNA:

Elija un lugar limpio, bien ventilado y resguardado

de intemperies que permita proteger la bomba de

congelamiento, inundaciones o calor excesivo. Además,

debe permitir fácil acceso para manutención y el drenaje

conveniente de la bomba y manutención de las tuberías.

No es esencial que haya una base preparada, siempre

que la superfi cie sea dura y nivelada. Se puede ubicar

en el sótano o en un cuarto de servicio de su casa, en

un pozo o entre el punto de uso y el pozo.

Decida la forma de sellar el pozo para evitar

contaminaciones conforme exigido por las autoridades

locales. El dispositivo más común para esta fi nalidad

es el SELLADO SANITARIO DE POZO. Si la tubería

desde el pozo tiene que mantenerse abajo de la línea

de congelamiento, entierre el cabezal del pozo o use

un ADAPTADOR SIN CAMBIO que deja el cabezal del

pozo expuesto para manutención y, al mismo tiempo,

deja las aberturas selladas en el alojamiento del pozo

abajo de la línea de congelamiento.

A continuación hay tres aplicaciones para pozo

y fuente de agua para la bomba para regadores

Turf Boss. Los pozos pueden ser ligeramente

diferentes pero la aplicación es esencialmente la

misma.

Pozo simple llano (Figura 1)

El pozo simple llano normalmente es un pozo con

caja de acero o plástico de 4 ó 6 pulgadas perforado

verticalmente en el suelo.

La superfi cie del agua no debe estar a más de 25 pies

de profundidad.

Conectar la válvula de

pedestal al primer trecho del

tubo de succión y bajarla

dentro del pozo. Agregar los

trechos de tubos necesarios,

sujetándolos con ayuda de

uno de los métodos de sellado

mencionados anteriormente. La

válvula de pedestal debe estar

POR LO MENOS a cinco pies

abajo de la superfi cie del agua

para permitir la extracción del

agua.

Sellar la parte superior de la caja del pozo de 4

ó 6 pulgadas con una junta para evitar que caigan

residuos dentro del pozo.

Figura 1

CODO DE

PVC 1-1/2”

ADAPTADOR DE

PVC 1-1/2” (MÍNIMO)

VÁLVULA DE PEDESTAL

1-1/2” (MÍNIMO)

JUNTA

DE POZO

TUBO DE PVC

CORRUGADO

DE 1-1/2”

(MÍNIMO)

16

Page 19

Puntos de Múltiples Pozos llanos (Figura 2)

La confi guración pozo llano de múltiples puntos

consiste en dos o tres pozos como fuente de agua.

Los pozos deben estar por lo menos a cinco pies de

distancia entre sí. Los pozos tienen que estar en línea

recta (dos o más pozos), en triángulo (tres pozos), o

en cuadrado (cuatro pozos).

Instalar una válvula de verifi cación o un fi ltro fi no

en cada pozo para asegurar que la bomba mantenga

la fuerza. La fl echa de fl ujo en la válvula debe apuntar

hacia la bomba.

TUBERÍAS

Atornillar la bomba a una base nivelada y sólida, si

es posible. Ubicar la bomba con el bocal de succión

de frente para el(los) caño(s) de la fuente de agua.

Evitar ángulos de 90° siempre que posible y minimizar

las curvas al conectar la bomba a su fuente de agua.

Instalar la bomba lo más cerca posible de la fuente de

agua. Esto ayuda a reducir la fricción y maximizar la

presión del agua.

Figura 2

DISTANCIA

IGUAL

Instalación en lago o laguna (Figura 3)

El uso de una superfi cie de agua como la de un lago

o laguna es semejante al de un pozo llano único.

El tubo de succión se instala en la fuete de agua y

vuelve a la bomba. Esta aplicación puede exigir una

gran distancia horizontal entre la fuente de agua y la

bomba.

Figura 3

TUBERÍA DE SUCCIÓN DE DESVÍO

HORIZONTAL

Cuando la bomba está desviada del pozo, es posible

que se tenga que aumentar el diámetro de la tubería de

succión de desvío horizontal para reducir la pérdida por

fricción. La pérdida de succión en el sistema aumenta:

1.) A medida que el fl ujo aumenta

2.) A medida que el tamaño de la tubería se reduce

Consulte las tablas de desempeño (Apéndice III) y

las tablas de pérdida por fricción (Apéndice IV) para

determinar la cantidad de pérdida en el cabezal para

una determinada aplicación. Los tubos desde el pozo

hasta la bomba deben de tener una inclinación hacia

arriba (cerca de 1" de elevación cada 30" de longitud).

TAMAÑO DE LOS TUBOS DE SALIDA PARA

LA INSTALACIÓN

Cuando la bomba está ubicada a cierta distancia de los

puntos de uso del agua, hay que aumentar el tamaño

de los tubos de salida para reducir la pérdida por

fricción. La pérdida de succión en el sistema aumenta:

1.) A medida que el fl ujo aumenta

2.) A medida que el tamaño de la tubería se reduce

TUBO DE PVC

CORRUGADO

ADAPTADOR DE

PVC 1-1/2” (MÍNIMO)

VÁLVULA DE PEDESTAL

1-1/2” (MÍNIMO)

El tamaño del tubo de succión debe aumentar una

vez para minimizar la pérdida de presión causada por

la fricción de la distancia del tubo.

Instalar una válvula de pedestal en la punta del

tubo de succión para proteger la bomba de residuos.

DE 1-1/2”

(MÍNIMO)

Consulte las tablas de desempeño (Apéndice III) y

las tablas de pérdida por fricción (Apéndice IV) para

determinar la cantidad de pérdida en el cabezal para

una determinada aplicación.

17

Page 20

A. Conexión del Bocal de Succión (Figura 4)

B. Conexiones del Bocal de Salida (Figura 5)

Etapa 1:

Conectar la válvula de pedestal o el punto del pozo

a la tubería y bajar el tubo y la válvula de pedestal

hasta que queden por lo menos a cinco pies abajo

del nivel del agua. Si está usando un pozo, sujete el

tubo a la caja del pozo temporariamente para evitar

que el tubo caiga dentro del pozo. Si el pozo está

en una caja de 4 ó 6 pulgadas, usar una junta en la

superfi cie. Nunca usar un tubo de succión más chico

que el tamaño del bocal de succión de la bomba.

Etapa 2:

Conectar los codos, adaptadores, válvulas de

verifi cación y tubos necesarios desde el agua hasta el

bocal de succión de la bomba en la parte delantera.

Cuando se use PVC, monte previamente el tubo

y los accesorios en la bomba ANTES de aplicar el

cemento de PVC para asegurar que los cortes estén

bien hechos y que estén todas las partes necesarias.

Usar cinta de tefl ón en todas las roscas macho,

envolviéndolas con una o dos vueltas de izquierda

a derecha (mirando hacia el tubo). Apretar todas las

conexiones roscadas hasta el fi nal. ¡¡NO APRETAR

DEMASIADO LOS TUBOS Y CONEXIONES!! Apretar

las juntas manualmente y después apretar media

vuelta más con una llave de caños.

Etapa 1:

Enroscar el adaptador macho o el niple del tubo al bocal

de salida de la parte superior de la bomba. (Usar cinta

de tefl ón en la rosca)

Figura 5

BOCAL DE

CEBADO

BOCAL DE SALIDA DE 1-1/2"

BOCAL DE SUCCIÓN DE 1-1/2"

TAPÓN DE DRENAJE

Etapa 2:

Conectar el tubo entre el tuabo principal del regador

y la salida de la bomba. El tamaño del tubo de salida

aumenta con la longitud del tubo. El tamaño del tubo

de salida puede ser igual al tamaño del bocal de

salida para distancias hasta 100 pies. Aumentar el

tamaño del tubo de salida una vez para distancias de

100 a 300 pies. Para distancias de 300 a 600 pies,

aumentar el tamaño del tubo dos veces.

Eso reducirá la pérdida de presión por fricción.

Figura 4

BOCAL DE

CEBADO

TAPÓN DE

DRENAJE

AL SISTEMA DEL REGADOR

BOCAL DE

SALIDA DE 1-1/2"

TUBO DE PVC

CORRUGADO

1-1/2”

BOCAL DE

SUCCIÓN DE 1-1/2"

ADAPTADOR DE PVC 1-1/2”

CODO DE

PVC 1-1/2”

Etapa 3:

JUNTA

DE POZO

TUBO DE PVC

CORRUGADO

1-1/2”

Apretar todas las conexiones con rosca de los tubos

con una llave de caños hasta el fi nal. No apretar

demasiado.

INSTALACIÓN DEL

PUNTO DEL POZO

VÁLVULA DE

VERIFICACIÓN

CODO DE

PVC 1-1/2”

TUBO

GALVANIZADO

1-1/2”

PUNTO DEL

POZO

INSTALACIÓN DE POZO

DE PUNTOS MÚLTIPLES

VÁLVULA DE

VERIFICACIÓN

A LA

BOMBA

GALVANIZADO

PUNTO DEL

CODO DE

PVC 1-1/2”

TUBO

1-1/2”

POZO

18

VÁLVULA DE PEDESTAL DE 1-1/2”

Page 21

REGISTROS DE LA INSTALACIÓN

Para mantener un registro adecuado de su instalación,

cerciorarse de llenar los datos siguientes:

Fecha de la instalación:

Nº de modelo

Profundidad del Pozo (pies):

Profundidad del Agua (pies):

Diámetro interno del Pozo:

Tamaño del tubo de succión:

Longitud del tubo de succión (pies):

Longitud del tubo de salida (pies):

Motor:

H.P.:

Voltaje:

Tamaño del diámetro del cable:

AJUSTE DE BIVOLTAJE

NOTA:

desconectar el conector bivolt del motor y reconectarlo

en la posición necesaria para el sistema eléctrico

disponible. El motor se puede colocar en 115 o 230

voltios, excepto los modelos de 2 H.P. que funcionan

solamente con 230 voltios. El voltaje del motor se

puede determinar observando el alineamiento de la

fl echa del enchufe y la fl echa del cuadro del terminal

del motor (ubicado abajo de la tapa de la extremidad

del motor). Todas las preguntas relativas a la

determinación del voltaje necesario para la operación

correcta del motor y de la bomba en su sistema se

deben hacer a un electricista profesional. La fábrica lo

predetermina a 230 voltios.

Para cambiar el voltaje del motor (Figura 6)

Figura 6

INSTALACIÓN ELÉCTRICA

AVISO

AVISO

peligroso puede causar

descarga eléctrica, quemaduras

o causar la muerte.

CUIDADO

seguridad de las conexiones

eléctricas apropiadas, consulte

un electricista acreditado.

CUIDADO

incorrecto puede causarle daños

permanentes al motor. Todas

las conexiones eléctricas deben

cumplir las normas locales.

El voltaje

Si no tiene

El cableado

AVISO

¡LEA Y SIGA TODAS LAS INSTRUCCIONES!

• La conexión de la bomba debe cumplir las

normas del Código Eléctrico Nacional (NEC) o

del Código Eléctrico Canadiense (CEC), y todos

los códigos locales.

• Todas las unidades bivoltaje vienen preparadas

de fábrica para trabajar a 230 voltios. (Figura 3)

• Desconectar la energía en el tablero eléctrico antes

de hacer conexiones eléctricas.

• El voltaje debe ser +/- 10% del voltaje nominal del

motor. Un voltaje muy bajo o alto puede perjudicar el

motor e invalidar la garantía.

• Si fuese posible, conectar la bomba a un circuito

exclusivo sin otras aplicaciones.

• No operar la bomba a menos que esté conectada a

tierra

115 V. 230 V.

230 V.

115 V.

.

230 V

115 V.

Instalación del cableado

AVISO: Verifi car las instrucciones de cableado en

tapa del terminal del motor o en la placa.

Las características esenciales del motor de la bomba

son las siguientes:

1.) 3.450 R.P.M.

2.) Monofásico

3.) Bivolt, 115/230 V. en los motores de 1 y 1 1/2

H.P.; 230 V. Solamente en los motores de 2 H.P.

4.) Los motores de 1/2, 3/4, 1, y 1-1/2 caballos de

fuerza vienen cableados para 230 voltios como

norma de fábrica.

Etapa 1:

Sacar la tapa de acceso al motor en la parte de

atrás.

Etapa 2:

Pasar el cable de tierra (verde o de cobre sin

revestimiento) por la salida de la canaleta eléctrica

en la lateral del motor. Primero conectar el cable de

tierra, después conectar los cables de fuerza. Sujetar

el cable de tierra al tornillo de tierra del motor (verde).

Sujetar los cables para evitar descargas eléctricas.

19

Page 22

Etapa 3:

Conectar los cables de entrada de fuerza al terminal

del motor.

Etapa 4:

Recolocar y sujetar la tapa del motor.

NOTA: Los motores monofásicos giran solamente

de la derecha hacia la izquierda (de frente para el

bocal de succión) y no se pueden invertir.

MOTOR

AVISO: Un motor que funciona en condiciones

normales mantiene su desempeño nominal,

considerando que sea un motor limpio, seco y con

ventilación adecuada. Un motor sucio o que no esté

“protegido” con una bolsa de estopa o de plástico,

se recalentará.

Etapa 4:

Recolocar el tapón del bocal de cebado con una

llave, usando cinta de tefl ón en las roscas de los

tubos.

Etapa 5:

Hacer funcionar la bomba. Una bomba bien

cebada debe descargar agua sin aire a una

presión constante. Si la bomba no produce

agua después de cinco minutos, pararla,

soltar la presión, sacar el tapón del bocal de

cebado, agregar más agua, recolocar el tapón

y recomenzar. (Cerciorarse que la válvula de

pedestal está bien instalada en el tubo de succión.

Ver “Conexión del bocal de succión” Figura 4)

MANUTENCIÓN

CEBADO Y PARTIDA

AVISO

seco. Llene la bomba con agua antes de arrancar. La

operación de la bomba en seco puede causarle daños

e invalidará la garantía.

AVISO

salida cerrada. Esto puede causar presión peligrosa y

riesgo de explosión.

Etapa 1 (Figura 7):

Sacar el tapón de la salida del cebado de la

bomba.

Figura 7

BOCAL DE

CEBADO

Etapa 2:

Abrir las válvulas de salida y todas las mangueras

del lado de salida de la bomba.

NUNCA haga funcionar la bomba en

NUNCA opere la bomba contra una

BOCAL DE SALIDA DE 1-1/2"

BOCAL DE SUCCIÓN DE 1-1/2"

TAPÓN DE DRENAJE

AVISO

AVISO

AVISO

la energía eléctrica antes de hacer

la manutención, pueden ocurrir

descargas eléctricas, quemaduras o

la muerte.

AVISO

bomba, cerciorarse que los contactos de

la caja de fusibles estén desconectados

o que esté desenchufada. Después de

montar la bomba nuevamente, verifi car

las instrucciones de cebado antes de

ponerla a funcionar.

Si no de desconecta

Antes de desconectar la

¡PRESIÓN PELIGROSA!

- No haga funcionar la bomba

contra una salida cerrada.

- Deje salir toda la presión del sistema

antes de trabajar en cualquier

componente.

A. Drenaje (Figura 8)

La bomba debe drenarse si corre el riesgo de

congelarse, si estuvo fuera de servicio durante un

largo período de tiempo o si requiere manutención.

Para drenar la bomba, desconectar la fuente de

energía, sacar el tapón del bocal de cebado de la caja

de la bomba, sacar el tapón de drenaje (abajo del

bocal de succión) y drenar el sistema. Recolocar el

tapón de drenaje.

Etapa 3:

Llenar la bomba con agua por el bocal de cebado

en la parte superior de la bomba. Dejar salir el aire

por algunos minutos, después agregar más agua

hasta llenarla.

20

Page 23

3ALIDADECEBADO

AVISO: Aunque este proceso drene la bomba, no

necesariamente drenará las demás partes de la

tubería. Si existe alguna preocupación sobre el

procedimiento adecuado o necesidad de drenar

la tubería de succión, entre en contacto con su

contratista.

Figura 8

4APNDEDRENAJE

B. Desmontaje de la Bomba

(Apéndice I y Figura 9)

Para tener acceso a los componentes internos de la

bomba, revisar el diagrama explotado de la bomba

que se muestra en la página de piezas de reparación

(Apéndice I). Drenar la bomba como se describe

anteriormente y después sacar los cuatro tornillos

que sujetan la caja de la bomba al soporte del

motor. Esto permitirá sacar el motor y el subconjunto

hidráulico de la caja sin perjudicar la tubería. Ubicar

e inspeccionar el diafragma y el anillo aislante que

son sellos internos. Cerciorarse que estén en buenas

condiciones y funcionando correctamente. Para

sacar el difusor, afl ojar los 3 tornillos que lo sujetan

al soporte del motor. Esto dejará la turbina y la junta

a la vista. Sacar la junta y, después, para sacar la

turbina, sujetar bien el eje del motor con un par de

morsas para evitar que gire de forma imprevista. Girar

la turbina hacia la izquierda (mirando hacia la turbina)

para sacarla; esto dejará a la vista la junta mecánica

del eje. Esta junta se puede sacar del eje del motor

para inspeccionarla. El soporte del motor se puede

sacar, destornillando los 4 tornillos de la parte trasera

del soporte del motor. Para sacar la junta cerámica

del eje, apretar suavemente por la parte de atrás de la

cerámica y, entonces, caerá fácilmente. Inspeccionar,

limpiar o cambiar las partes necesarias.

las superfi cies de sellado de la junta del eje durante

la operación. A continuación, instalar el soporte

del motor en el motor usando los cuatro tornillos.

Apretar los tornillos en diagonal para garantizar el

ajuste correcto. Instalar la junta del eje y después

instalar la turbina y la junta. El difusor se posiciona

con tres tornillos y después solamente se puede

instalar cuando esté en el sentido correcto (Figura 9).

Posicionar el diafragma en el orifi cio de succión del

difusor. (como muestra la Figura 9). El anillo aislante

deslizará sobre el orifi cio del difusor en la parte de

arriba del diafragma. Levantar el conjunto del motor y

colocarlo dentro de la caja de la bomba, ajustándolo

con los 4 tornillos. Al asentar la caja de la bomba

contra el soporte del motor, el diafragma debe quedar

encajado entre ellos alrededor de todo el perímetro.

Esto permite que el diafragma sirva de junta entre

las dos partes de hierro fundido. Si el diafragma no

está ubicado correctamente la unidad tendrá pérdidas

cuando se llene la caja con agua. Apretar todos

los tornillos con un torque de 185 pulgadas/libra en

diagonal para asegurar el asentamiento adecuado de

todos los componentes.

Figura 9

Difusor

Tornillo

Soporte del

motor

del difusor

Diafragma

Tornillo del

difusor

Anillo aislante

C. Montaje de la Bomba

Montar nuevamente la unidad apretando

primeramente la junta cerámica en la placa de la

junta. Usar alcohol de fricción como lubricante. No

use aceite, vaselina o grasa, porque esto perjudicará

21

Page 24

PIEZAS PARA LA TURF BOSS

BOMBA AUTOCEBANTE PARA REGADORES

APÉNDICE I

11I

5D

5D

10H

5D

5D

9F,G

7E,G

8E,G

6E,G

5D

5D

12J

4C,G

3C,G

1Amp.

5D

2B

5D

1A

Figura

Número

1

2

3

4

5

6

7

8

9

10

11

12

* Los ítems con mismo identifi cador se venden/embalan juntos

** Los kits de fi jación (5D) son un juego completo de herrajes usados para montar la Turf Boss. Para mayor conveniencia todos los demás kits de reparación contienen

las fi jaciones necesarias para remontar sus componentes.

Descripción

Kits de tapones A 305390901

Caja de la bomba B 305491901

Anillo aislante

Diafragma

Kit de fi jación* D 305393901

Difusor

Anillo de desgaste

Turbina

Sello mecánico

Soporte del motor H 305397901

Motor I 305398901 305398902 305398903

Conjunto de la base J 305399901

Identifi cador de

Agrupamientode

Kit*

C 305392901

G 305396901 305396902 305396903

C 305392901

G 305396901 305396902 305396903

E 305394901 305394902 305394903

G 305396901 305396902 305396903

E 305394901 305394902 305394903

G 305396901 305396902 305396903

E 305394901 305394902 305394903

G 305396901 305396902 305396903

F 305395901

G 305396901 305396902 305396903

Códigos de Pedido de Repuestos por Número de Modelo

TB1CI TB15CI TB2CI

22

Page 25

APÉNDICE II - SOLUCIÓN DE PROBLEMAS

A. La bomba no expele agua o presión

Causa: La bomba no está llena de agua.

Solución: Parar la bomba, llenarla de agua, verifi car

las conexiones de la tubería para asegurarse que no

haya pérdidas de aire e intentar nuevamente.

B. Baja presión

Causa: El motor no está a la velocidad adecuada.

Solución: Verifi car el voltaje y apretar las

conexiones de los cables.

Causa: La turbina está parcialmente obstruida.

Solución:Verifi car si no hay piedras o residuos en la

turbina. Consultar las instrucciones de desmontaje

para tener acceso a la turbina.

Causa: Sale aire por el tubo de succión.

Solución: Verifi car las conexiones de la línea de

succión.

C. Poca capacidad

Causa: El nivel del agua está a más de 25 pies.

Solución:La bomba no puede bombear a más de

25 pies. Consulte un distribuidor de Franklin Pump

Systems.

Causa: Está usando un tubo muy largo desde el

agua hasta la bomba.

Solución: Debe usar un tubo de diámetro mayor.

Causa: La turbina está obstruida.

Solución:Verifi car la turbina. Consultar las

instrucciones de desmontaje anteriores.

Causa: El tubo desde la bomba al agua está

parcialmente obstruido.

Solución: Verifi car el tubo.

E. El motor no arranca

Causa: Interruptores abiertos, fusibles quemados o

conexiones fl ojas.

Solución: Verifi car los interruptores, fusibles y

conexiones.

Causa: Conexiones hasta el motor impropias.

Solución: Cerciorarse que las conexiones estén

apretadas.

F. Registro de aire (exceso de aire en el tubo)

Causa: Pérdidas de aire por el tubo

Solución: Verifi car conexiones.

Causa: Gotas de agua abajo de la punta del tubo.

Solución:La bomba está tirando demasiado.

Apretar la válvula de control hacia abajo

gradualmente hasta que la bomba comience a

funcionar adecuadamente.

G. Ruidos de piedras dentro de la bomba

(cavitación)

Causa:La bomba está funcionando por arriba de su

capacidad (NPSHR superior a NPSHA)

Solución: Consulte un distribuidor de Franklin

Pump Systems.

Causa: El tubo de succión es muy chico o muy

largo.

Solución: Use un tubo de diámetro mayor.

Causa: La punta del tubo de succión está en el

barro o en la arena.

Solución: Levantar la punta del tubo de succión o

limpiar el pozo.

D. Recalentamiento del motor

Causa: Voltaje o conexiones impropias.

Solución:Verifi car si el voltaje es el mismo indicado

en el motor o en la placa de datos. Cerciórese

de que todas las conexiones de cable están bien

ajustadas.

Causa: Ventilación del motor inadecuada.

Solución: Verifi car si el motor está limpio y bien

ventilado.

23

Page 26

APÉNDICE III - CURVA DE DESEMPEÑO

METROS

40

35

30

25

20

60

55

50

45

40

35

30

PSI

140

130

120

110

100

90

80

70

PIES

2 HP

1.5 HP

1 HP

15

10

25

20

15

10

5

60

50

40

30

20

5

10

000

0 1020304050607080

0

0

12345

2 4 6 8 10 12 14 16 18

GPM

l./seg.

3

M PH

24

Page 27

APÉNDICE IV - TABLAS DE PÉRDIDA DE FRICCIÓN

1”

Programar 40 tubos 1.049 pulgadas de diámetro interno/tubo de

cobre de 1.025 pulgadas de diámetro interno tipo L

Pérdida de fricción

GPM

Pies/

segundo

2.0 0.74 0.60 0.32 .078 0.41

3.0 1.11 1.26 0.68 1.17 0.87

4.0 1.49 2.14 1.15 1.56 1.48

5.0 1.86 3.24 1.75 1.95 2.23

6.0 2.23 4.54 2.45 2.34 3.13

8.0 2.97 7.73 4.16 3.11 5.35

10 3.71 11.7 6.31 3.89 8.08

12 4.46 16.4 8.85 4.67 11.3

14 5.20 21.8 11.8 5.45 15.0

16 5.94 27.9 15.1 6.22 19.2

18 6.68 34.7 18.7 7.00 23.9

20 7.43 42.1 22.8 7.78 29.0

25 9.29 63.6 34.6 9.74 43.9

30 11.1 89.2 48.1 11.7 61.4

40 14.9 152 82.0 15.5 105

Velocidad

Ft. Hd./100' de tubo

Acero

C= 100

PVC C= 140

Velocidad

Pies/

segundo

1.5”

Programar 40 tubos 1.610 pulgadas de diámetro interno/tubo de

cobre de 1.505 pulgadas de diámetro interno tipo L

GPM

Pies/

segundo

6.0 0.95 0.57 0.31 1.08 0.49

8.0 1.26 0.96 0.52 1.44 0.82

10 1.58 1.45 0.79 1.80 1.24

12 1.89 2.04 1.10 2.16 1.73

15 2.36 2.95 1.59 2.70 2.62

20 3.15 5.24 2.83 3.60 4.46

25 3.94 7.90 4.26 4.51 6.74

30 4.73 11.1 6.00 5.41 9.44

40 6.30 18.9 10.2 7.21 16.1

50 7.88 28.5 15.4 9.01 24.3

60 9.46 40.0 21.6 10.8 34.1

70 11.0 53.2 28.7 12.6 45.5

80 12.6 68.1 36.8 14.4 58.1

90 14.2 84.7 45.7 16.2 72.1

100 15.8 103 56.6 18.0 87.7

Velocidad

Pérdida de fricción

Ft. Hd./100' de tubo Velocidad

Acero

C= 100

PVC C= 140

Pies/

segundo

Ft Hd./

Pérdida

por fricción

100’ tubo

C = 130

Ft Hd./

Pérdida

por fricción

100’ tubo

C = 130

1¼”

Programar 40 tubos 1.380 pulgadas de diámetro interno/tubo de

cobre de 1.265 pulgadas de diámetro interno tipo L

Pérdida de fricción

GPM

Pies/

segundo

4.0 0.86 0.56 0.30 1.02 0.52

6.0 1.29 1.20 0.65 1.53 1.12

8.0 1.72 2.04 1.10 2.04 1.92

10 2.15 3.08 1.67 2.55 2.90

12 2.57 4.31 2.33 3.06 4.04

14 2.00 5.73 3.10 3.57 5.35

16 3.43 7.34 3.96 4.08 6.85

18 3.86 9.13 4.93 4.59 8.52

20 4.29 11.1 6.00 5.10 10.4

25 5.36 16.8 9.06 6.38 15.7

30 6.43 23.5 12.7 7.65 22.1

40 8.58 40.0 21.6 10.2 37.6

50 10.7 60.4 32.6 12.8 56.7

60 12.9 84.7 45.6 15.3 79.5

80 17.2 144 77.9 20.4 136

Velocidad

Ft. Hd./100' de tubo Velocidad

Acero

C= 100

PVC C= 140

Pies/

segundo

2”

Programar 40 tubos 2.067 pulgadas de diámetro interno/tubo de

cobre de 1.985 pulgadas de diámetro interno tipo L

GPM

Pies/

segundo

10 0.96 0.43 0.23 1.07 0.35

15 1.44 0.92 0.50 1.60 .075

20 1.91 1.55 0.84 2.13 1.24

25 2.39 2.35 1.27 2.66 1.87

30 2.87 3.29 1.78 3.19 2.62

40 3.82 5.60 3.03 4.26 4.48

50 4.78 8.46 4.57 5.32 6.76

60 5.74 11.9 6.44 6.39 9.47

70 6.69 15.8 8.53 7.45 12.6

80 7.65 20.2 10.9 8.52 16.2

90 8.61 25.1 13.6 9.58 20.0

100 9.56 30.5 16.5 10.7 24.4

120 11.5 42.7 23.1 12.8 34.1

150 14.3 64.7 35.0 16.0 51.6

200 19.1 110 59.4 21.3 87.8

Velocidad

Pérdida de fricción

Ft. Hd./100' de tubo Velocidad

Acero

C= 100

PVC C= 140

Pies/

segundo

2.5”

Programar 40 tubos 2.469 pulgadas de diámetro interno/tubo de

cobre de 2.465 pulgadas de diámetro interno tipo L

GPM

Pies/

segundo

20 1.21 0.66 0.35 1.34 0.40

30 2.01 1.39 0.75 2.02 0.85

40 2.68 2.36 1.27 2.69 1.46

50 3.35 3.56 1.92 3.36 2.20

60 4.02 4.99 2.69 4.03 3.08

70 4.69 6.64 3.58 4.70 4.11

80 5.36 8.50 4.59 5.37 5.25

90 6.03 10.6 5.72 6.04 6.52

100 6.70 12.8 6.90 6.71 7.94

110 7.37 15.3 8.22 7.38 9.44

130 8.71 20.9 11.3 8.73 12.9

150 10.0 27.3 14.7 10.1 16.8

200 13.4 46.3 25.0 13.4 28.6

250 16.8 81.7 44.1 16.8 43.4

300 20.1 98.1 52.9 20.1 61.1

Velocidad

Ft. Hd./100' de tubo Velocidad

Acero

C= 100

PVC C= 140

Pies/

segundo

Nota: El gráfi co muestra la pérdida por fricción para cada 100' de tubo. Para convertir para pérdida por fricción por pie, mover la coma

2 casillas hacia la izquierda.

Pérdida de fricción

Ft Hd./

Pérdida

por fricción

100’ tubo

C = 130

Ft Hd./

Pérdida por

fricción

100’ tubo

C = 130

Ft Hd./

Pérdida

por fricción

100’ tubo

C = 130

25

Page 28

GARANTÍA LIMITADA EN ESTADOS UNIDOS*

Franklin Electric Co., Inc.

Franklin Electric Co., Inc. garantiza sus productos nuevos contra defectos de material o mano de obra durante

un período de 1 año a partir de la fecha de instalación o de 2 años a partir de la fecha de fabricación, lo que ocurra

primero, SIEMPRE que se instalen en aplicaciones de agua potable limpia. La garantía no cubre aplicaciones para el

bombeo de agua salada u otros líquidos corrosivos. Consultar y cumplir las normas locales en todas las aplicaciones.

Franklin Electric Co., Inc también ofrece cobertura adicional a los productos aquí especifi cados.

La obligatoriedad de garantía de Franklin Electric en relación al equipo que no sea de su fabricación se limita a la

garantía de sus proveedores a Franklin Electric.

Esta garantía se limita apenas al comprador minorista original y solamente durante el tiempo de uso del comprador

original en el primer lugar de instalación.

Los pedidos de servicios bajo garantía se deben hacer al instalador de Franklin Electric (punto de compra) lo más

rápido posible una vez detectado el defecto alegado. Franklin Electric adoptará la acción correctiva lo más rápido

posible.

Franklin Electric, a su criterio, puede cambiar o reparar el producto que presente falla en garantía después de

inspeccionado por un representante autorizado o una vez recibido por Franklin Electric en su fábrica. El cambio

o reparación no se hará antes de que el producto sea inspeccionado. Todos los costos o gastos de fl ete para y

desde la fábrica, de retirada e reinstalación del producto o de instalación de un producto que se haya cambiado son

responsabilidad del comprador.

ESTA GARANTÍA SUBSTITUYE CUALQUIER OTRA GARANTÍA SIN FECHA O QUE TENGA FECHA

ANTERIOR. CUALQUIER GARANTÍA IMPLÍCITA QUE EL COMPRADOR PUEDA TENER, INCLUSIVE DE

CAPACIDAD O ADECUACIÓN PARA UNA FINALIDAD ESPECÍFICA, NO SE EXTENDERÁ MÁS ALLÁ DEL

PERÍODO DE GARANTÍA APLICABLE. Algunos estados no permiten limitaciones de la duración de garantías

implícitas, por eso, la limitación anterior puede no aplicarse en este caso. BAJO NINGUNA HIPÓTESIS

FRANKLIN ELECTRIC SE RESPONSABILIZARÁ POR DAÑOS ACCIDENTALES O CONSECUENTES. Algunos

estados no permiten la exclusión o limitación por daños accidentales o consecuentes, por eso, la limitación

anterior puede no aplicarse en este caso.

Esta garantía no se aplica a cualquier producto que haya sufrido descuido, alteración, accidente, abuso, uso

indebido, instalación impropia, vandalismo, disturbios civiles o actos de Dios. Las únicas garantías autorizadas por

Franklin Electric son las que se establecen aquí. Franklin Electric no autoriza otras personas a dar cualquier garantía

en relación a sus productos, ni asume responsabilidad por garantías no autorizadas relativas a la venta de sus

productos.

ESTA GARANTÍA LE OTORGA DERECHOS LEGALES ESPECÍFICOS Y USTED TAMBIÉN PUEDE TENER

OTROS DERECHOS QUE PUEDEN VARIAR DE ESTADO A ESTADO.

*Contacte la División de Exportación de Franklin Electric Co., Inc. para informarse sobre Garantía Internacional.

106258101 Rev. 0 3/08

400 E. Spring Street

Bluffton, IN 46714

Tel.: 260-824-2900

Fax: 260-824-2909

www.franklin-electric.com

Page 29

AVANT DE COMMENCER

AVANT DE PROCÉDER À L’INSTALLATION DE LA

POMPE, VEUILLEZ LIRE ATTENTIVEMENT CE GUIDE

D’UTILISATION

CONSULTEZ LES PLAQUES SIGNALÉTIQUES

POUR DES CONSIGNES D’UTILISATION ET DES

SPÉCIFICATIONS ADDITIONNELLES.

ATTENTION

• L’aire de travail doit être propre, bien illuminée et

dégagée.

• Gardez les étiquettes de sécurité propres et en bon état.

• Remplacez toute étiquette de sécurité manquante ou

endommagée.

• Portez des lunettes de protection pendant les travaux