Page 1

4” and 6”

SUBMERSIBLE PUMPS

OWNER'S MANUAL

All 4” models willl include either a built-in or external

mounted check valve with the discharge head. 6”

models do not include a check valve, and will need to be

purchased separately. Example: Franklin Control Box for

Franklin motors. Make certain that your available voltage

corresponds to that of your motor.

READ AND FOLLOW SAFETY INSTRUCTIONS

This is the safety alert symbol. When you see

this symbol on your pump or in this manual, look

for one of the following signal words and be alert to the

potential for personal injury:

BEFORE INSTALLING PUMP, BE SURE TO READ

THIS OWNER’S MANUAL CAREFULLY.

CAUTION

or pump will be damaged. The motor on this pump

is guaranteed by the manufacturer and in event of

failure it must be returned to an authorized service

station for repairs. Motor warranty is void if repairs

aren’t made by an authorized repair station.

Fill pump with water before starting

INSPECT THE SHIPMENT

Examine the pump when it is received to be sure there

has been no damage in shipping. Should any be evident,

report it immediately to the dealer from whom the pump

was purchased. Please check the pump package to see

that it includes pump, motor, and motor leads (if your

pump purchase includes a motor).

DANGER

serious personal injury, death or major property damage

if ignored.

WARNING

serious personal injury, death or major property damage

if ignored.

CAUTION

cause minor personal injury or major property damage if

ignored.

The label NOTICE indicates special instructions, which

are important but not related to hazards.

WARNING

Hazardous voltage.

Can shock, burn, or

cause death.

Ground pump before

connecting to power

supply. Disconnect

power before working

on pump, motor

or tank.

Meet National Electrical Code, Canadian Electrical

Code, and local codes for all wiring.

Follow wiring instructions in this manual when

connecting motor to power lines.

warns about hazards that will cause

warns about hazards that can cause

warns about hazards that will or can

Carefully read and follow all

safety instructions in this

manual and on pump.

Keep safety labels in good

condition.

Replace missing or damaged

safety labels.

Wire motor for correct

voltage. See “Electrical”

section of this manual and

motor nameplate.

Ground motor before

connecting to power supply.

Page 2

ATTENTION!

IMPORTANT INFORMATION FOR

INSTALLERS OF THIS EQUIPMENT!

THIS EQUIPMENT IS INTENDED FOR

INSTALLATION BY TECHNICALLY QUALIFIED

PERSONNEL. FAILURE TO INSTALL IT IN

COMPLIANCE WITH NATIONAL AND LOCAL

ELECTRICAL CODES, AND WITH FRANKLIN

ELECTRIC RECOMMENDATIONS, MAY RESULT

IN ELECTRICAL SHOCK OR FIRE HAZARD,

UNSATISFACTORY PERFORMANCE, AND

EQUIPMENT FAILURE. FRANKLIN INSTALLATION

INFORMATION IS AVAILABLE FROM PUMP

MANUFACTURERS AND DISTRIBUTORS, AND

DIRECTLY FROM FRANKLIN ELECTRIC. CALL

FRANKLIN TOLL FREE 800-348-2420 FOR

INFORMATION. RETAIN THIS INFORMATION

SHEET WITH THE EQUIPMENT FOR

FUTURE REFERENCE.

WARNING

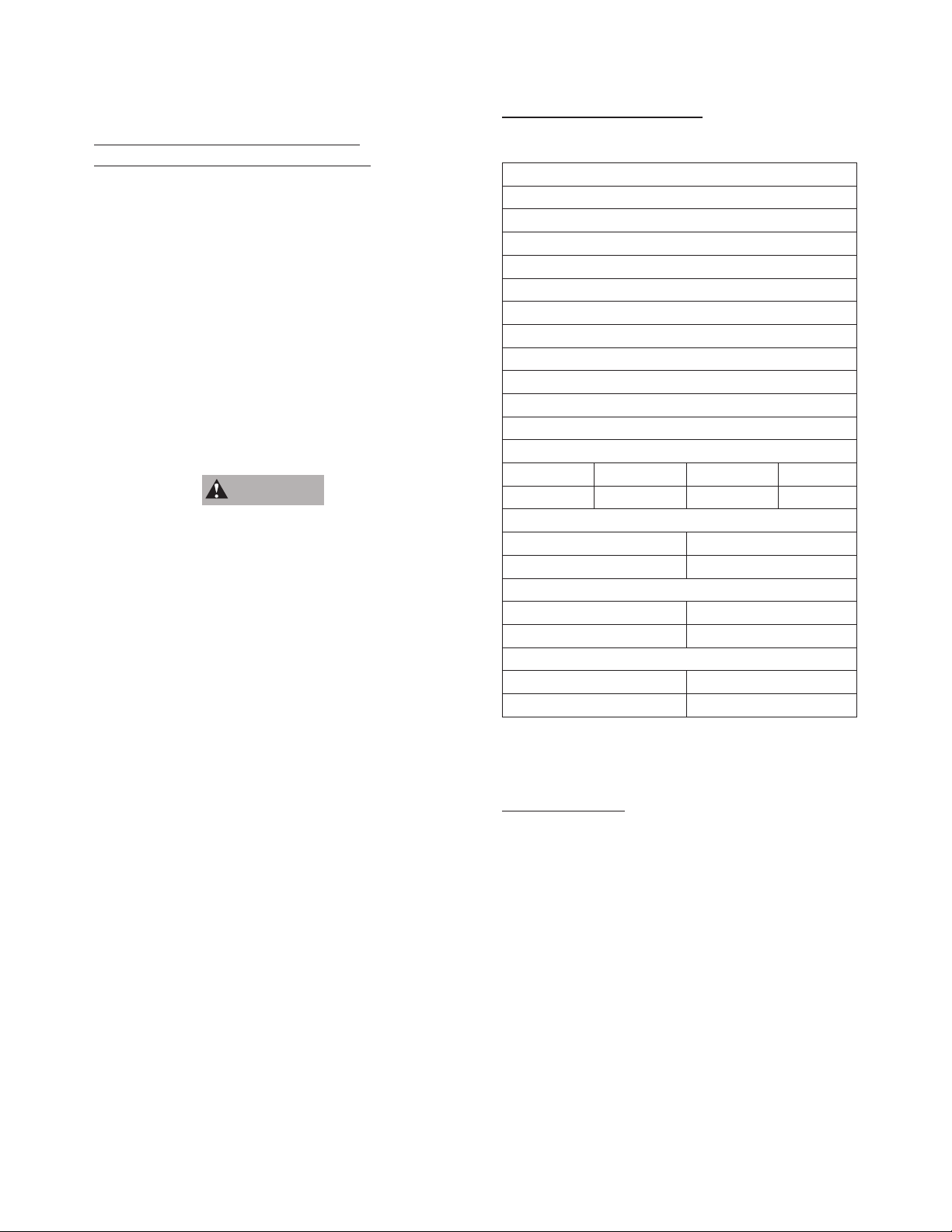

INSTALLATION RECORDS

It is good idea to keep an accurate record of your

installation. Be sure to record the data below:

Purchased From:

Date of Installation:

Pump Model No.*

Pump Date Code*

Well Inside Dia.(in/mm):

Depth of Well(ft/m):

Depth of Water(ft/m):

Pump Setting(ft/m):

Drop Pipe Size:

Wire Size(pump to control box):

Wire Size(control box to power source):

Horizontal Offset(between well & house):

Make of Motor*

Amps HP Volts Ph

SERIOUS OR FATAL ELECTRICAL SHOCK MAY

RESULT FROM FAILURE TO CONNECT THE

MOTOR, CONTROL ENCLOSURES, METAL

PLUMBING, AND ALL OTHER METAL NEAR THE

MOTOR OR CABLE, TO THE POWER SUPPLY

GROUND TERMINAL USING WIRE NO SMALLER

THAN MOTOR CABLE WIRES. TO REDUCE

RISK OF ELECTRICAL SHOCK, DISCONNECT

POWER BEFORE WORKING ON OR AROUND

THE WATER SYSTEM. DO NOT USE MOTOR IN

SWIMMING AREAS.

Make of Control Box

HP Volts

Power Supply

Volts HZ

Pressure Switch (PSI)

Cut-in Cut-out

* This Information is on your pump or motor tag. It will

help us identify your pump in case of later inquiries.

TEST RUNNING

If test running pump before installation:

1. Insure that the power supply corresponds with that

shown on the nameplate of the motor and control

box. (if required).

2. Install pump and components appropriate for the

test as shown in Fig. 1.

3. Make sure power supply is turned off and circuit

breaker or disconnect switch is open. Make

electrical connections appropriate to your motor as

shown in Fig. 2, 3 or 4.

4. THREE PHASE UNIT - A three phase motor

requires a magnetic starter equipped with quick-trip,

ambient compensated heaters of correct size for the

horsepower of the motor.

Page 3

To insure correct rotation of three phase units, brace

pump shell securely and apply power momentarily

by snapping line switch quickly on and off. If rotation

is correct, reaction of the shell will be clockwise

when viewed from pump discharge (that is, pump

shaft will rotate counter clockwise). Interchange any

two leads at magnetic starter to reverse rotation.

5. Run pump and motor unit for a few seconds to

ensure that it is in working order.

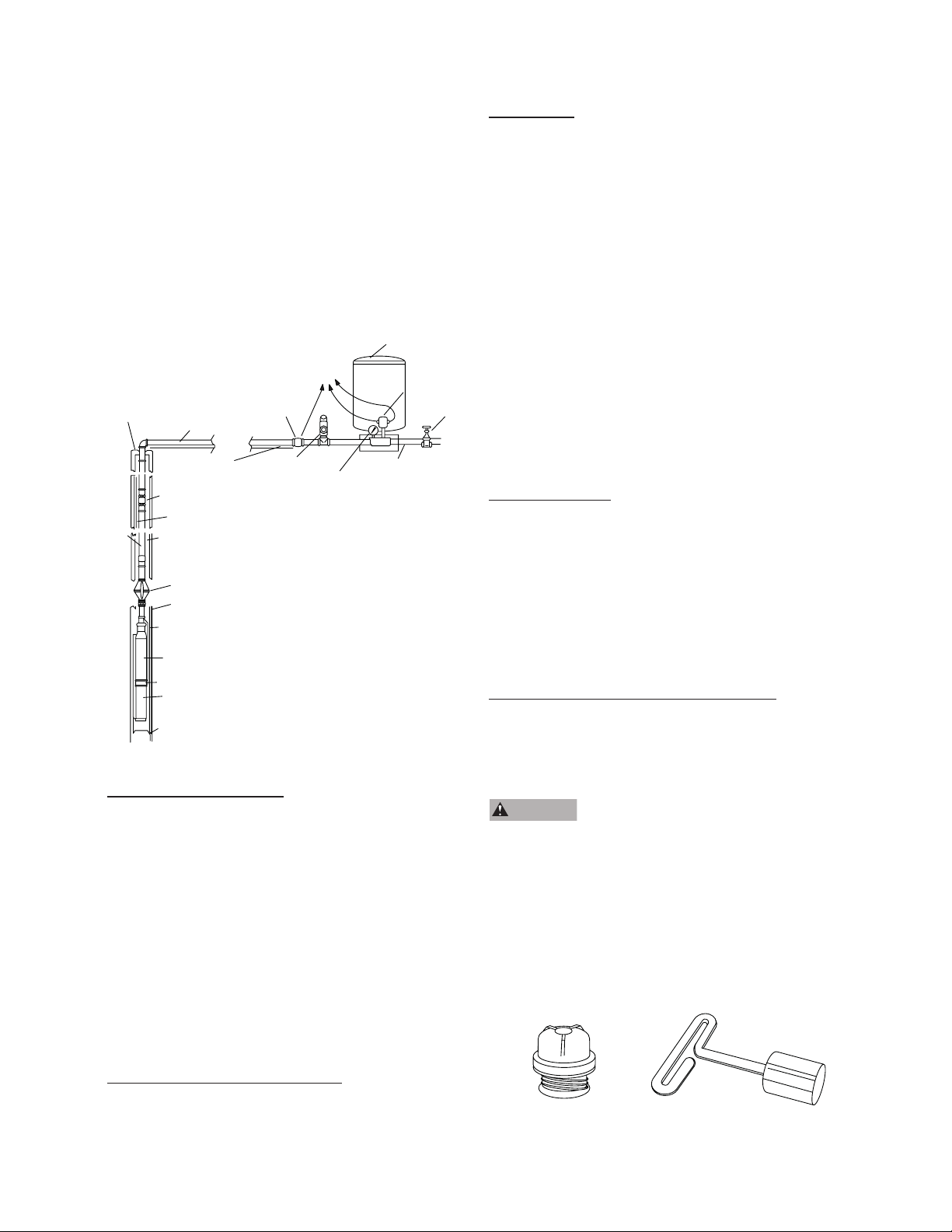

FIGURE 1 - Installation Diagram

Pressure Tank

Sanitary Well Seal

or Pitless Adapter

Drop Pipe

Discharge Pipe

Submersible Cable

Spring-Loaded

Check Valve

(Recommended every 100’/30m)

Safety Cable

Cable

(secured to drop

pipe with tape or

clamps every 10’/3m)

Torque Arrestor

Well Casing

Spring-Loaded

Check Valve

at Pump Discharge

Submersible

Pump Unit

Suction Screen

Motor

Well Screen or

Casing Perforations

See Wiring Diagrams

Spring-Loaded

Check Valve

Pressure Relief Valve

Note: Keep pump at least 5’ from

bottom of well and above well screen

or casing perforations.

Pressure Gauge

Pressure Switch

Service Pipe

SUITABILITY OF WELL

Install the pump only in a well that has been properly

developed. Water from an undeveloped well often

contains an excessive amount of sand, dirt, and

abrasives which can damage the pump. Check that

the well is large enough to allow the pump to be set

at the required depth. Don’t set the pump below the

casing perforations or well screen unless you make

arrangements to ensure an adequate fl ow of water

over the motor for cooling purposes. Determine the

correct pump setting from the driller’s record by taking

into account the static water level and the drawdown

at the proposed pumping rate. Keep the pump at least

fi ve feet from the bottom of a drilled well.

Gate Valve

DROP PIPE

Galvanized pipe is recommended for suspending

submersible pumps into the well. Plastic pipe may

be used only when observing the plastic pipe

manufacturer’s recommendations of depth and pressure.

Give special consideration to:

1. A safety cable to prevent loss of pump if pipe should

break.

2. Torque arrestor just above pump to prevent chafi ng

the cable when pump and pipe twist during the starting

and stopping cycle. (See Figure 1)

Schedule 40 galvanized pipe is suitable for settings to

600 feet(180m). For deeper settings, use schedule 40

pipe for the bottom 600 feet(180m), and schedule 80 for

the remainder.

Take great care to keep pipes clean and free from

pebbles, scale and thread chips. Make sound, air-tight

connections at all fi ttings. Pipe sealant is recommended.

CHECK VALVES

Many pumps have a built-in or externally supplied check

valve. For a pump without one, install a check valve

immediately above the pump. Install an additional check

valve above the ground. If the pump is more than 100

feet (30m) below the wellhead, install another check

valve in the drop pipe 100 feet (30m) above it. For pump

settings deeper than 200 feet (60m), install additional

check valves at intervals of 100 feet (30m).

REMOVABLE POPPET CHECK VALVE

4” submersible pumps with a 1-1/4” discharge are

supplied with a spring-loaded REMOVABLE poppet style

check valve assembly. The check valve can be removed

from the pump discharge when the pump is installed in

applications where drain back is desired.

WARNING

can cause the pump to rotate backwards. If pump/

motor starts during this time; damage to the pump

can occur.

The check valve can be removed with the use of the

T-Handle Poppet Wrench(part no. 23498207). Ordered

separately. Or, with standard needle nose pliers. The

poppet assembly is left hand threaded and is removed

by turning CLOCKWISE.

If reinstalling a Popppet Check Valve assembly, the

assembly should be tightened to 15 inch-pounds.

Fluid draining back through the pump

SPLICING THE POWER CABLE

Follow the instructions enclosed in the cable splicing

kit you purchase.

Poppet Assembly

T-Handle Poppet Wrench

1

Page 4

INSTALLATION OF PUMP, DROP PIPE, AND

ASSOCIATED EQUIPMENT

Fig. 1 illustrates a typical well installation showing in

ground components. Adhere to the following items when

installing the pump and drop pipe:

1. Fasten the submersible cable to the drop pipe with

clamps or appropriate tape every 10 ft. (3m) to

prevent tangling and damage to the cable. The cable

must remain slack when using plastic drop pipe to

allow for stretching of pipe when installed in the well.

2. Take care not to scrape or pinch the submersible

cable against the well casing.

3. Use an ohmmeter or megger to make insulation and

continuity checks on the cable once the pump is

installed. This locates any fault in the cable.

4. Make sure a check valve is installed immediately

above the pump. Install additional check valves at

100’ (30m) intervals.

5. Install a torque arrestor just above the pump to

prevent chafi ng the cable when pump anad pipe twist

during starting and stopping.

6. Attach a safety cable to pump to prevent loss of pump

if pipe should break.

7. Place a sanitary well seal or pitless adapter with

an approved cover plate over top of well per

manufacturers recommendations.

8. Keep pump at least 5’ (1.5m) from bottom of well and

above well screen or casing perforations.

ELECTRICAL INFORMATION

1. Employ a licensed electrician to perform the wiring.

All wiring must be done in accordance with applicable

national and local electrical codes.

2. Check that the power supply corresponds with the

electrical rating of the submersible motor and the

control box(if required). Make sure that the control box

electrical rating matches the motor electrical rating.

3. Every installation requires a fused disconnect switch

or circuit breaker.

4. Every installation must be grounded. There must be

a reliable ground connection between the pump and

the distribution panel. The motor lead incorporates a

green grounding conductor.

5. Lightning arrestors are recommended for every

installation. All stainless steel, single phase motors

thru 5HP have built-in lightning arrestors. Any 6”

motor or 4”, 3-phase motor requires a separate

lightning arrestor installed as close to the wellhead

as possible. Install the arrestor in accordance with

manufacturers recommendations. A lightning arrestor

provides protection against induced voltage surges on

secondary power lines; it is not effective against direct

hits.

6. Mount the control box in an area protected from rain,

snow, direct sunlight or other high temperatures as

this may cause tripping of the overload protector.

Also protect the control box from extreme cold (below

o

25

F/-32oC) as this may have adverse effects on

starting capacitor.

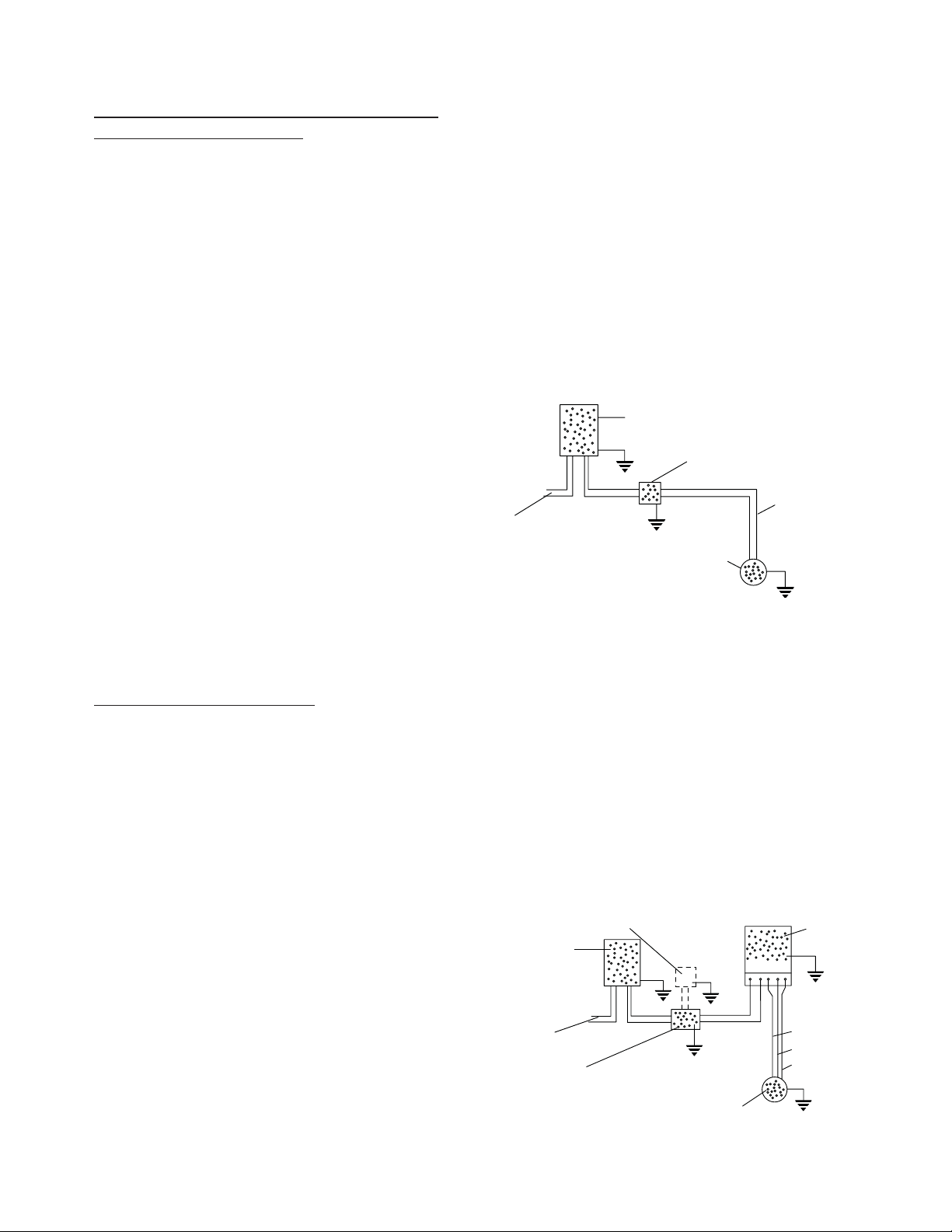

7. A two-wire pump does not require a motor control box,

since all electrical components are built inside the

motor. Fig. 2 shows a typical wiring diagram for a twowire installation.

FIGURE 2 - 2 WIRE, 1 Phase, 1/3 thru 1-1/2 HP

Pump Wiring Diagram

Circuit Breaker or

Fuse Disconnect Switch

Pressure Switch

Incoming 1 Phase Power

1 Phase Submersible Motor

Submersible Cable

8. A three-wire, single-phase pump requires a motor

control box incorporating overload relays. Fig. 3

shows a typical wiring diagram for a three-wire, singlephase installation. Note that a magnetic contactor

must be used if the pressure switch electrical rating

is not suffi cient to handle the submersible motor

electrical rating. The pressure switch would then be

incorporated into a pilot circuit to control the magnetic

contactor. Make the connections at the control box in

accordance with the wiring diagram in the control box

to avoid damage to the motor.

FIGURE 3 - 3-WIRE, 1 Phase, 1/3 thru 15 HP

Pump Wiring Diagram

Note: Order of red, yellow and black may

Pressure Switch (for pilot circuit)

If Magnetic Contactor is used

for starting.

Circuit Breaker

or Fused Disconnect Switch

Incoming 1 Phase Power

Pressure Switch (for direct switching) OR

Magnetic Contactor (w/ pilot circuit)

vary from control box to control box.

Always connect like colors.

L1

1 Phase Sumbersible Motor

L2 R

Y

B

Red

Yellow

Black

Single Phase

Control Box

2

Page 5

9. A three-phase pump does not require a motor control

box . Fig. 4 shows a typical wiring diagram for a 3wire, three-phase installation. A magnetic contractor

with 3-leg protection having quick-trip ambient

compensated overload relays must be used.

FIGURE 4 - 3-Wire, 3 Phase, 1-1/2 thru 50 HP

Pump Wiring Diagram

Circuit Breaker OR

Fused Disconnect Switch

Incoming 3 Phase Power

Pressure Switch

Magnetic Contactor w/

3-leg protection having

quick-trip ambient

conpensated overload relays

3 Phase Submersible Motor

10. Use an ohmeter to make continuity and insulation

checks after the installation is completed.

11. Place the additional pump nameplate onto the

submersible label and place both onto disconnect

switch or circuit breaker box for future reference.

WELL TEST

Check the pump and well performance before making

the fi nal connection to the discharge system.

1. Install a gate valve on the end of the pipe. Partially

open the valve.

2. Start the pump.

3. Open valve gradually to give full fl ow.

4. If the discharge is not clear, let the pump run until

water clears. If water does not clear in 30 minutes,

stop the pump and take the necessary steps to correct

the condition. After the water has appeared clear,

check for sand by discharging into a clean bucket or

suitable container.

5. Close valve until maximum required system fl ow

rate is obtained (this should correspond to the cutin pressure of the pressure switch). Ensure that

the output of the pump at this setting is not greater

than the yield of the well. This can be checked by

monitoring the well drawdown level and ensuring tht

the level is stable at the maximum required system

fl ow rate.

CAUTION

submerged in water. If run without water, the pump

and motor could be damaged. Note also that air

drawn into the pump can cause an airlock under

certain conditions.

Never run pump unless it’s completely

LOW-YIELDING WELL

A low-yielding well exists when the output from the pump

is greater than the yield of the well. It can reduce the

water level to the suction screen so that a mixture of air

and water enters the pump. Pumping may stop since the

pump cannot generate pressure with insuffi cient water.

In this case, the column of water already in the drop pipe

holds the check valve closed and an airlock may develop

inside the pump. Because the conditions ensure neither

adequate lubrication of the pump nor proper cooling

for the motor, damage can result if power is not cut off

quickly. use one or more of the following methods to

correct and/or protect this installation.

1. Install additional length of drop pipe to place pump

lower in well if possible.

2. Install a Franklin Pumptec or similar electronic

drawdown sensor.

3. Install a fl oatless liquid level control. This device

consists of an electrical relay activated by currents

fl owing through the ground-return circuits of

electrodes hung in the well. The lower(STOP)

electrode, just above the pump, ensures that the

water level can never be pumped down to the suction

screen. The upper(START) electrode, just below

the lowest static water level, ensures that the pump

can start again as soon as the well has recovered.

A fl oatless liquid level control works in series with

the pressure switch. Refer to the manufacturers

instructions provided with control.

4. Install a fl ow control valve in the discharge line

upstream from the pressure switch. This restricts

the output from the pump without affecting the rate

that water can be drawn from the pressure tank.

Nevertheless, a heavy demand for water could

empty the pressure tank, so a tank with a bonded

diaphragm, air cell, or water bag is recommended.

5. Install a smaller pump to avoid over pumping the well.

Have dealer size pump to the well yield.

6. Install a low-pressure cut-off switch. A low pressure

cut off switch, or a pressure switch with such an

arrangement built in, protects a shallow-well pump

from losing its prime, but it does not always provide

satisfactory protection to a submersible pump from

the effects of over pumping the well. This is because

it responds to a loss of pressure at the surface,

which may occur after an air lock has formed inside

the pump. We recommend either a fl oatless liquid

level control or a fl ow control valve, in that order,

in preference to a low-pressure cutoff switch as

protection against over pumping.

3

Page 6

DISCHARGE PLUMBING

Fig. 1 illustrates a typical well installation showing above

ground components. Adhere to the following items when

installing the discharge plumbing.

1. Install an above ground check valve upstream from

the pressure switch.

2. Always install a pressure relief valve in the system.

The relief valve should be capable of discharging the

fl ow rate of the pump at the rated working pressure of

the pressure tank. Locate the relief valve close to the

pressure tank.

3. Install a pressure switch between the check valve and

the pressure tank. Refer to Fig. 2, 3, or 4 for proper

wiring connections of pressure switch.

4. Install a pressure tank as close as possible to

the pressure switch. Refer to manufacturer’s

recommendations for installation.

INSTALLATION IN LAKE OR STREAM

A submersible pump is usually isolated at the bottom of

a well, where electrical leakage from its motor and cable

presents no hazard to life. This natural protection is lost

when you install it in a lake, pond, stream, or fountain

since there is no way to stop people and livestock

from entering or touching the surrounding water.

Consequently we recommend that such an installation

be done by a licensed electrician in conformance with all

applicable national and local electrical codes. Grounding

after the manner already described is a minimum

requirement, and a ground fault circuit interrupter is

advisable. But in the absence of explicit national or local

regulations, ask the local electric utility for guidance. In

any case, support the pump from the shore or bottom,

o

at a 15

Shield the pump from direct physical contact. Protect

and screen the pump intake to prevent blockage by

leaves and weeds, but remember the need for adequate

fl ow over the motor for cooling purposes. In addition,

protect the entire underwater installation from water

currents, ice, boats, anchors, debris, vandalism, and

other hazards.

slant to assure proper motor bearing lubrication.

TROUBLESHOOTING

1. PUMP FAILS TO START

a) Electrical trouble - call dealer or electrician.

b) Drawdown protection device has pump turned off.

c) Overload tripped.

d) Reset low pressure cutoff switch (if installed).

2. PUMP FAILS TO DELIVER WATER

a) Air lock in pump.

b) Clogged intake screen.

c) Insuffi cient well yield.

3. PUMP GIVES REDUCED OUTPUT

a) Insuffi cient well yield.

b) Worn pump.

c) Clogged intake screen.

d) Low voltage.

e) Incorrect rotation (3-phase only).

4. PUMP CYCLES TOO FREQUENTLY

a) Excessive pressure drop between pressure switch

and pressure tank.

b) “Cut-in” pressure at pressure tank too high.

c) “Cut-out” pressure at pressure tank too low.

d) Waterlogged pressure tank.

e) Start and stop electrodes of fl oatless liquid level

control set too close together.

f) Tank sized too small to meet system requirements.

5. OVERLOADS TRIP

a) Electrical trouble - call dealer or electrician.

6. PRESSURE SWITCH CYCLES RAPIDLY WHEN

PUMP STARTS

a) Pressure switch too far from pressure tank.

b) Adjust air charge of tank to manufacturer’s

recommendations.

4

Page 7

U.S. LIMITED WARRANTY*

Franklin Pump Systems, Inc.

Franklin Pump Systems, Inc. warrants its new products to be free of defects in material and workmanship for a

period of 1 year from date of installation or 2 years from date of manufacture, whichever comes fi rst, WHEN installed in

a domestic water systems application and pumping potable water only. Warranty does not cover applications pumping

saltwater or other corrosive liquids. Consult and adhere to local codes for all applications. Franklin Pump Systems, Inc.

also provides additional warranty coverage on specifi c products as specifi ed herein.

Franklin Pump Systems’ warranty obligation with regard to equipment not of its own manufacture is limited to the

warranty actually extended to Franklin Pump Systems by its suppliers.

This warranty extends only to the original retail purchaser and only during the time in which the original retail

purchaser occupies the site where the product was originally installed.

Requests for service under this warranty shall be made by contacting the installing Franklin Pump Systems

dealer (point of purchase) as soon as possible after the discovery of any alleged defect. Franklin Pump Systems will

subsequently take corrective action as promptly as reasonably possible.

Franklin Pump Systems at its discretion may replace or repair any product that fails under this warranty after

inspection by an authorized company representative or after Franklin Pump Systems has received the product at our

factory. Replacement or repair cannot be made until after the product is inspected. All charges or expenses for freight

to and from the factory, removal and reinstallation of the product, or installation of a replacement product are the

responsibility of the purchaser.

THIS WARRANTY SUPERSEDES ANY WARRANTY NOT DATED OR BEARING AN EARLIER DATE. ANY

IMPLIED WARRANTIES WHICH THE PURCHASER MAY HAVE, INCLUDING MERCHANT ABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE APPLICABLE WARRANTY PERIOD. Some

states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply

to you. IN NO EVENT SHALL FRANKLIN PUMP SYSTEMS BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES. Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above may not apply to you.

This warranty does not apply to any product which has been subjected to negligence, alteration, accident, abuse,

misuse, improper installation, vandalism, civil disturbances, or acts of God. The only warranties authorized by Franklin

Pump Systems are those set forth herein. Franklin Pump Systems does not authorize other persons to extend any

warranties with respect to its products, nor will Franklin Pump Systems assume liability for any unauthorized warranties

made in connection with the sale of its products.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH

MAY VARY FROM STATE TO STATE.

* Contact Franklin Pump Systems, Inc. Export Division for International Warranty.

E1467 5/06

12401 Interstate 30 • P.O. Box 8903

Little Rock, AR 72219

5

Page 8

Page 9

POMPES SUBMERSIBLES

4” ET 6”

MANUEL DU PROPRIETAIRE

LIRE ET SUIVRE LES INSTRUCTIONS DE

SÉCURITÉ

Voici le symbole d’avertissement de sécurité.

Quand vous verrez ce symbole sur votre pompe ou dans ce

manuel, regardez pour un des mots-clefs ci-dessous et soyez

conscient des dangers potentiels de blessures.

INSPECTION DE L’ÉQUIPEMENT

Sur reception de la pompe verifi er si elle n’a pas ete

endommagee dans le transport. Si un dommage

est apparent, le mentionner immediatement a votre

detaillant la pompe fut achetee. Verifi er si l’ensemble de

pompe inclut: la pompe, le moteur et les conduits pour

moteur (si l’achat de votre pompe inclut un moteur). Ces

unites comprendront soit un clapet integre ou a montage

exterieur a meme la tete de decharge. les modeles

monophases, 3 fi ls, doivent avoir une boite de controle

qui devra etre commandee separement et assortie au

moteur de la pompe (ex: une boite de controle Franklin

pour un moteur Franklin). S’assurer que votre voltage

correspond a celui du moteur.

DANGER

blessures sérieuses, la mort ou des dommages majeurs à la

propriété si ignorés.

AVERTISSEMENT

des blessures sérieuses, la mort ou des dommages majeurs à

la propriété si ignorés.

ATTENTION

causer des blessures mineures à la personne et/ou des

dommages majeurs à la propriété si ignorés.

La vignette À NOTER indique une attention spéciale qui est

importante mais non reliée à la sécurité.

Bien lire et suivre toutes les instructions de sécurité

écrites dans ce manuel et sur la pompe.

Garder les vignettes de sécurité en bonne condition.

Remplacer les vignettes endommagées ou manquantes.

AVERTISSEMENT

Haut Voltage.Pe ut

électrocuter ,brûler ou

causer la mort.

Mettre la pompe à la

masseavant de brancher

au courant principal.

Débrancher le courant

avant de travailler sur

la pompe, le moteur ou

le réservoir.

Avertis des dangers qui vont causer des

Avertis des dangers qui peuvent causer

Avertis des dangers qui peuvent ou vont

Adapter le moteur au

courant utilisé. Voir la section

ÉLECTRIQUE de ce manuel et la

plaque signalétique du moteur.

Mettre le moteur à la masse

avant de brancher au courant

principal.

Se conformer aux codes

électriques nationaux, Canadiens

et locaux pour tout branchement

électrique.

Suivre les instructions de ce

manuel pour le branchement du

moteur au réseau principal.

Page 10

RECORD D’INSTALLATION

C’est une bonne idée de garder un record exact de votre

installation. Voir à completer les données suivantes.

Acheté de:

Date d’installation:

No. de modèle de la pompe*

Code de date de la pompe*

Dia. int. du puits:

Profondeur du puits:

Profondeur jusqu’au niveau d’eau:

Dimension du tuyau de descente:

Dimension du fi l:

De la pompe à la boîte de contrôle:

De la boîte de cont. à l’alim. élec.:

Tuyauterie horizontale distante:

Marque de moteur*

Amp C.V. Volts Ph

Marque de la boîte de contrôle

C.V. Volts

Alimentation électrique

Volts Ph

* Cette information est sur l’étiquette de la pompe

ou moteur. Ceci nous aidera à identifi er la pompe, si

nécessaire.

rapidement l’interrupteur de ligne à la position

marche et arrêt. Si, en regardant par la décharge de

la pompe, la coquille se déplace dans le sens des

aiguilles d’une montre, la rotation est bonne. our

modifi er la rotation, interchanger deux des conduits

pour moteur du démarreur magnétique.

5. Activer la pompe pour quelques secondes afi n de

vérifi er si elle fonctionne bien.

FIGURE 1 - Diagramme D’installation

Réservoir à pression

Joint d’étanchéite hygiénique ou

adapteur pour puits sans fosse

Tuyan de

refoulement

Tuyau de décharge

Soupape de retenue à

ressort (recommande à tous

les 100’/30m.)

Cáble de sécurité

Cáble

(fixé au tuyau avec du ruban

ou collier de serrage tous les

10 pieds/3 mètres)

Intercepteur de couple

Paro du puits

Soupape de retenue à

ressort à la décharge de la pompe

Pompe submersible

Tamis d’aspiration

Moteur

Tamis du puits ou perforations

de la paroi

Cáble submersible

Soupape de retenue

Voir shéma

de câblage

Soupape de sûreté

à pression

Note: Installer la pompe au moins à 5 pieds

au-dessus du fond du puits et au-dessus du

tamis ou les perforations de la paroi.

Manomètre à pression

Interrupteur à pression

Tuyau de service

Vanne

EXAMINEZ LE FONCTIONNEMENT

Si un essai doit ètre fait avant l’installation, verser 1

gallon d’eau dans la décharge, pour s’assurer que la

pompe ne demarre pas à sec.

1. Vérifi er si l’alimentation en courant électrique

correspond aux indication données sur les plaques

d’indentifi cation du moteur et de la boîte de contrôle

(si requise)

2. Installer la pompe et les composantes appropriées

pour effectuer l’essai, tel qu’illustré à la fi gure 1.

3. S’assurer que l’alimentation électrique est à la position

arrêt et que le coupe-circuit ou disjoncteur est ouvert.

Faire les raccords électriques qui correspondent à

votre moteur, tel qu’illustré aux fi gures 2,3, et 4.

4. MODÈLES TRIPHASÉS. Un moteur requiert un

démarreur magnétique équipé d’éléments chauffants

à déclenchement rapide, compensé pour température

ambiante, correspondant à la force du moteur.

Pour vous assure de la bonne rotation des modèles

triphasés, soutenir la coquille de pompe solidement et

y donner momentanément du courant en mettant

8

CONVENANCE DE PUITS

Installer la pompe seulement quand le puits à été

préparé adéquatement. L’eau d’un puits qui n’a pas

été developpé comme il se doit contient beaucoup de

sable, saletés et matières abrasives qui pourraient

endommager la pompe. Vérifi er si le puits est

assez grand pour pouvoir y installer la pompe à la

profondeur voulue. Ne pas installer la pompe en bas

des perforations de la paroi ou du tamis du puits, à

moins que l’installation soit faite pour assurer un debit

d’eau adequat audessus du moteur, pour les besoins

de refroidissement. Déterminer, d’apres les records

d’installation du foreur, où la pompe doit être installée en

tenant compte du niveau statique de l’eau et du niveau

de tirage d’eau, au taux de pompage proposé. Installer

la pompe au moins à 5 pieds au-dessus du fond du puits

foré.

RACCORDEMENT DU CÂBLE ÉLECTRIQUE

Suivre les instructions incluses avec la trousse de

raccordement pour câble.

Page 11

TUYAU DE DESCENTE

Il est recommandé d’installer du tuyay galvanisé

pour les pompes submersibles installées dans le

puits. Si du tuyau de plastique est utllisé, suivre les

recommandations du fabricant de la tuyauterie de

plastique, en tenant compte de la profondeur et de la

pression. Cependant, s’assurer d’avoir en main les items

suivants:

1. Un câble de sécurité pour éviter de perdre la pompe,

en cas de bris de tuyau.

2. Amortisseur de couple placé juste au-dessus de la

pompe pour prévenir le frottement du fi l, quand la

pompe et le tuyau se tordent lors du démarrage et

l’arrêt de la pompe.

Du tuyau galvanisé de type 40 est approprié pour

les installations jusqua’à 600 pieds (180m). Pour des

installations plus en profundeur, utiliser du tuyau type 40

pour les premiers 600 pieds (180m) et du type 80 pour la

balance qui se trouve au-dessus de 600 pieds (180m).

Prende soin de garder les tuyaux propres et libres de

cailloux, dépôts calcaires, etc... Assurer une étanchéité

compléte à tous les raccords. Un enduit étanche pour

tuyaux est recommandé.

SOUPAPES DE RETENUE

Plusieurs pompes ont une soupape à retenue à ressort,

soit qu’elle est déjà incorporée, soit qu’elle est installée.

Pour une pompe qui n’a pas de soupape de retenue à

ressort, en installer une immédiatement au-dessus de

la pompe. Installer une soupape de retenue à ressort

additionnelle à la surface.

Si la pompe est plus que 100 pieds (30m) en bas de la

tête de puits, installer une autre soupape de retenue

dans le tuyau de descente 10 pieds (30m). Au-dessus

de la pompe. Pour les installations au-delà de 200 pieds

(60m), installer une soupape de retenue additionnelle

aux intervalles de 100 pieds (30m).

INSTALLATION DE LA POMPE, TUYAU DE

DESCENTE ET L’EQUIPMENT S’YRATTACHANT

La fi gure 1 illustre une installation typique d’un puits

avec les composantes installées dans le sol. A

l’installation de la pompe et du tuyau de descente, suivre

les instructions suivantes:

1. Attacher le câble au tuyau de descente avec des

colliers de serrage ou du ruban approprié a tous

les 10 pieds (3m) pour éviter qu’il ne s’entortille et

ne s’endommage. Le câble doit étre lâche quand

l’installation set faite avec du tuyau de plastique, afi n

d’obtenir une installation sécuritaire dans le puits.

2. Prendre soin de ne pas égratigner ou pincer le câble

contre la paroi du puits.

3. Vous servir d’un ohmmétre ou d’un mégahmètre pour

procéder à des essais de continuité et d’isolation sur

le câble, une fois la pompe installée. Ceci permettra

de déceler toute défaillance dans le câble.

4. S’assurer d’installer une soupape de retenue

immédiatement au-dessus de la pompe. Installer des

soupapes de retenue additionnelles aux intervalles de

100 pieds (30m).

5. Si recommandé par votre marchand, installer un

amortisseur de couple juste au-dessus de la pompe,

pour prévenir le frottement du câble quand la pompe

et le tuyau se tordent lors du démarrage et de l’arrêt

de la pompe.

6. Attacher un câble de sécurité à la pompe, pour éviter

de perdre celle-ci en cas de bris de tuyau.

7. Installer un joint d’étanchéité hygiénique ou un couvert

d’adapteur pour puits sans fosse au-dessus du puits,

en suivant les recommandations du manfacturier.

8. Installer la pompe au moins à 5 pieds (1.5m) audessus du fonds du puits et au-dessus du tamis ou les

perforations de la paroi.

INFORMATION ÉLECTRIQUE

1. Utiliser les services d’un électricien compétent pour

l’installation du câblage. Tous les raccordements

doivent être faits selon le code national et local

d’électricité.

2. Vérifi er si l’alimentation électrique correspond avec

les indications donnees sur le moteur et la boîte de

contrôle (se requise). S’assurer que les données de

la boîte de contrôle correspondent avec les données

électriques du moteur.

3. Chaque installation requiert un sectionneur à fusibles

ou un coupe-circuit.

4. Chaque installation doit avoir une mise à la terre.

Il doit y avoir un raccord effi cace de mise à la terre

entre la pompe et le panneau de distribution. le

conduit pour moteur est incorporé d’un conducteur de

mise à la terre vert.

5. Des paratonnerres sont recommandés pour

chaque installation. Tous les moteurs jusqu à 5 c.v.

monophasés 4” sont incorporés de paratonnerres.

Tout moteur triphasé, soit 4” ou 6”, requiert un

paratonnerre séparé, installé le plus près possible de

la tête de puits. (Note: une boîte de contrôle 5 c.v.,

monphasé raccordée à un moteur 5 c.v. 6” requiert

un paratonnerre séparé.) Installer le paratonnerre

in suivant les recommandations du manufacturier.

Un paratonnerre protège contre les surcharges des

lignes secondaires mais ne protège pas contre les

coups directs.

9

Page 12

6. Installer la boîte de contrôle dans un endroit

protégé de la pluie, neige, lumière directe du soleil

ou des températures élevées qui pourraient faire

déclencher le protecteur de surcharge. Aussi,

protéger la boîte de contrôle des températures

extrêmes de froid (sous 25 degres F/ -32 degres

C) qui pourraient affecter le condensateur de

démarrage.

7. Une pompe 2 fi ls ne nécessite pas une boîte

de contrôle, les composantes électriques étant

incorporées en dedans du moteur. La fi gure 2 vous

montre un shéma typique de câblage pour une

installation 2 fi ls.

FIGURE 2 - Schéma Câblage Pompe

Coupe-circuit ou

disjoncteur à fusible

9. Une pompe triphasée 3 fi ls ne requiert pas une

boîte de contrôle. La fi gure 4 bous montre un

schéma typique de câblage pour une installation

triphasée, 3 fi ls. Un contacteur magnétique avec

protection à tous les 3 conducteurs possédant

des relais de surcharge à déclenchement rapide

(compensés pour la température) doit être utilisé.

FIGURE 4 - Schéma De Câblage Pour Pompe

1-1/2 c.v. à 5 c.v. 3 Fils Triphasée

Coupe-circuit ou

disjoncteur à fusibles

Arrivée alimentation

électrique triphasée

Interrupteur à pression

Contacteur magnétique avec

protection à tous les 3 conducteurs,

possédant des rèlais de surcharge à

déclenchement rapide (compensés

pour la température)

Interrupteur à pression

Arrivée alimentation

électrique monophasée

Moteur submersible monophasé

Câble submersible

8. Une pompe monophasée 3 fi ls requiert une boîte

de contrôle comprenant des relais de surcharge. La

fi gure 3 vous montre un schéma typique du câblage

pour une installation monophasée, 3 fi ls. Prendre

note d’utiliser un contacteur magnétique si la

capacité électrique de l’interrupteur à pression n’est

pas suffi sante pour la capacité électrique du moteur

submersible. L’interrupteur à pression serait alors

incorporé dans un circuit pilote afi n de côntroler le

contacteur magnétique. Faire les raccordements à

la boîte de contrôle, selon le schéma de câblage,

dans la boite de contrôle, ceci afi n d’éviter

d’endommager le moteur.

FIGURE 3 - Schéma De Cablage Pour Pompe 3 Fils

Monophasée 1/3 c.v. à 1.5 c.v.

Note: L’ordre des couleurs rouge, jaune et noir

peut varier d’une boîte de contrôle à l’autre.

Interrupteur à pression (pour circuit pilote)

si un contacteur magnétique est utilisé

pour le démarrage.

Coupe-circuit ou

disjoncteur à fusibles

Boìte de contrôle monophasée

Interrupteur à pression (pour interruption directe)

ou un contacteur magnetique avec circuit pilote

Toujours raccorder les fils avec la couleur équivalente.

Moteur monophasé

submersible

L2 R

L1

B

Y

Rouge

Jaune

Noir

Arrivée alimentation

électrique monophasé

10

Moteur submersible triphasé

10. Utiliser un ohmmètre ou un mégahmètre pour

procéder à des essais de continuité et d’isolation,

après que l’installation est complétée.

11. Apposer la plaque d’identifi cation de la pompe sur

l’étiquette de la pompe submersible FPS, Inc. et

placer les deux sur le disjoncteur ou sur la boîte du

coupe-circuit, pour références futures.

VÈRIFICATION DU PUITS

Vérifi er la pompe et le rendement du puits, avant

de faire le dernier raccordement au systéme de

décharge.

1. Installer une vanne à l’extrémité du tuyau et ouvrir

partiellement la vanne.

2. Démarre la pompe.

3. Ouvrir graduellement la vanne pour obtenir le débit

maximal.

4. Si l’eau à la décharge n’est pas claire, laisser la

pompe fonctionner jusqu’à ce qu’elle devienne

claire. Si dans 30 minutes l’eau n’est pas claire,

arrêter la pompe et prendre les moyens nécessaires

pour corriger la situation. Après avoir obtenu une

eau claire, vérifi er le sable en déchargeant dans un

seau propre ou tout autre contenant.

5. Fermer la vanne jusqu’à l’obtention maximale du

débit d’eau requis. S’assurer qua la sortie de la

pompe à ce niveau de réglage n’est pas supérieure

au rendement du puits; en faire la vérifi cation en

surveillant le niveau de tirage d’eau et s’assurer

que le niveau reste stable au débit d’eau maximal

requis.

CAUTION

Ne pas faire fonctionner la pompe

si elle n’est pas complétement subergée dan

l’eau, autrement la pompe et le moteur pourraient

s’endommager. Prende note également que l’air

formé dans la pompe peut causer une poche d’air,

à certaines conditions.

Page 13

FAIBLE RENDEMENT DU PUITS

Un puits à faible rendement existe quand la sortie

de la pompe est supérieure au rendement du puits.

Il en résulte une diminution du niveau d’eau au

tamis d’aspiration faisant entrer un mélange d’air et

eau dans la pompe. Dans ce cas, la colonne d’eau

qui se trouve déjà dans le tuyau de descente tiens

la soupape de retenue fermée et développe ainsi

une poche d’air à l’intérieur de la pompe. Dans ces

conditions, la pompe n’est pas lubrifi ée adéquatement

et le moteur n’est pas refroidi proprement; et it pourrait

en résulter des dommages si l’alimentation électrique

n’est pas arrêtée rapidement. Suivre une ou plusieurs

des recommandations suivantes pour corriger et/ou

protéger l’installation:

1. Installer une longueur additionnelle de tuyau pour

descendre la pompe plus bas dans le puits se

possible.

2. Installer un mécanisme sensitif Pumptec mc

de Franklin ou tout autre appareil électronique

similaire.

3. Installer un contrôle pour niveau de liquide sans

fl otteur. Ce dispositif consiste en un relais électrique

activé par des courants passant au travers des

circuits de retour des électrodes suspendus dans

le puits, L’électrode inférieur (arrêt) qui se trouve

juste au’dessus de la pompe, permet au neveau

d’eau de ne pas descendre plus bas que le tamis

d’aspiration. L’électrode supérieur (démarrage),

situé juste en-dessous du plus bas niveau d’eau

statique, fait démarrer la pompe de nouveau,

aussitôt que le puits à récupéré. Un contrôle pour

niveau de liquide sans fl otteur travaille en série

avec l’interrupteur à pression. Vous référer aux

instructions du manufacturier fournies avec le

contrôle.

4. Installer une soupape de contrôle du débit dans la

ligne de décharge avant l’interrupteur à pression.

Ceci limite la sortie à partir de la pompe, sans

affecter le rendement de l’eau tirée du réservouir

à pression. Néanmoins, use forte demande d’eau

pourrait vider le reservoir a pression; donc un

réservoir à diaphragme ou tout autre dispositif

est recommandé, car il empêche l’air d’être

êvacué dans la ligne de service. Non seulement la

décharge d’air dans les robinets serait désagréable,

mais l’air évacué du réservoir à pression devrait

être remplacé.

5. Installer une pompe plus petite, poue éviter

un surpompage au puits. Vous référer à votre

dépositaire pour le bon choix de la pompe.

6. Installer un interrupteur de basse pression. Un

interrupteur de basse pression ou un interrupteur à

pression avec un dispositif intégré protège la pompe

pour puits peu profund contre la perte d’amorçage,

mais ne donne pas toujours un rendement

satisfaisant sur les pompes submersibles contre

les effets de surpompage au puits; c’est parce qu’il

réagit à une perte de pression à la surface, qui

se produit lorsqu’une poche d’air s’est formée à

l’intérieur de la pompe. Nous recommandons, soit

un controle de niveau pour liquide sans fl otteur ou

une soupape de contrôle du débit, dans cet ordre,

de preférénce à un interrupteur à pression d’arrêt,

comme protection contre le surpompage.

PLOMBERIE DE DÉCHARGE

La fi gure 1 illustre une installation typique d’un puits

avec les composantes installées à la surface. A

l’installation de la plomberie de décharge, suivre les

instructions suivantes:

1. Installer une soupape de retenue à ressort sur ligne

de decharge avant l’interrupteur à pression.

2. Toujours installer une soupape de sûreté à pression

dans le système. La soupape de sûreté devrait

pouvoir être capable de décharger le débit d’eau

de la pompe à la pression demandée du réservoir à

pression.

3. Installer un interrrupteur à pression entre la soupape

de retenue et le réservoir à pression, mais près du

reservoir à pression. Vous réferer aux fi gures 2,3,

ou 4 pour le raccordement adéquat de l’interrupteur

à pression.

INSTALLATION DANS UN LAC OU UNE

RIVIÈRE

Une pompe submersible est habituellement isolée

dans le fond du puits, où des pertes électriques du

moteur ou du câble ne présentent aucun danger pour

la vie humaine. Vous n’avez plus cette protection

quand la pompe est installeé dans un lac, un étang,

une rivière ou une fontaine, car il n’est pas possible

d’empêcher les gens d’aller aux alentours. Cependant,

nous recommandons qu’une telle installation soit faite

par un électricien qualifi é, selon le code national et

local d’électricité. Une mise à la terre est le minimum

requis; un interrupteur de circuit de mise à la terre est

recommandable. Dans toute installation, supporter

la pompe à partir du bord de l’eau ou le fond, avec

une inclinaison de 15 degrés pour assurer une bonne

lubrifi cation des roulements du moteur. Mettre la

pompe à l’abri de tout contact physique. Protéger et

mettre un tamis à l’aspiration de la pompe pour éviter

le blocage par les feuilles et les herbes, mais ne pas

oublier qu’il faut un débit d’eau adéquat au-dessus

du moteur, pour les besoins de refroidissement. En

plus, protéger l’installation faite sous l’eau contre les

courants d’eau, glaces, bateaux, les ancres, débris,

vandalisme ou autres dangers.

11

Page 14

GUIDE DE DÉPANNAGE

1. La pompe refuse de démarrer:

a) Problème d’électricité - appeler le détaillant ou

l’électricien.

b) Dispositif de protection a nis la pompe en

position arrêt.

c) Surcharge se déclenche.

d) Remettre en marche l’interrupteur de basse

pression (si installé).

2. La pompe ne donne pas d’eau.

a) Poche d’air dans la pompe.

b) Écran du succion obstrué.

c) Rendement insuffi sant du puits.

3. L’interrupteur de surcharge se déclenche.

a) Problème d’électricité - appeler le détaillant ou

l’électricien.

4. Le débit de la pompe est réduit.

a) Rendement insuffi sant du puits.

b) Pompe usée.

c) Écran du succion obstrué.

d) Bas voltage.

e) Rotation inexacte (triphasé seulement).

5. La pompe s’arrête et se remet en marche trop

souvent.

a) Baisse de pression excessive entre l’interrupteur

à pression et le réservoir.

b) Pression de mise en marche trop haute.

c) Pression d’arrêt trop faible.

d) Le réservoir est surchargé d’eau.

e) Les électrodes d’arrêt et de démarrage du

contrôle pour niveau de liquide sans fl otteur

réglés trop prés.

f) Réservoir trop petit pour rencontrer les exigences

du système.

6. L’interrupteur à pression arrête et se remet en

marche rapidement quand la pompe démarre.

a) L’interrupteur à pression trop éloigné du resérvoir

à pression.

b) Ajuster le chargeur d’air du réservoir, en suivant

les recommandations du manufacturier.

ATTENTION!

INFORMATIONS IMPORTANTES POUR LINSTALLATEUR DE

CET EQUIPEMENT

CET EQUIPEMENT DOIT ETRE INSTALLE PAR UN

TECHNICIEN QUALIFIE. SI L’INSTALLATION N’EST PAS

CONFORME AUX LOIS NATIONALES OU LOCALES

AINSI QU’AUX RECOMMANDATIONS DE FRANKLIN

ELECTRIC, UN CHOC ELECTRIQUE, LE FEU, UNE

PREFORMANCE NON ACCEPTABLE, VOIRE MEME

LE NON’FONCTIONNEMENT PEUVENT SURVENIR.

UN GUID D’INSTALLATION DE FRANKLIN ELECTRIC

EST DESPONIBLE CHEZ LES MANUFACTURIERS

DE POMPES, LES DISTRUBUTEURS, OU

DIRECTEMENTCHES FRANKLIN. POUR DE PLUS

AMPLES RENSEIGNEMENTS, APPELEZ SANS FRAIS

LE 1-800-348-2420. CONSERVEZ CETTE FEUILLE

D’INFORMATION AVEC L’EQUIPEMENT POUR

CONSULTATION FUTURE

AVERTISSEMENT

UN CHOC ELECTRIQUE SERIEUZ OU MEME MORTEL

EST POSSIBLE, SI L’ON NEGLIGE DE CONNECTER LE

MOTEUR, LA PLONBERIE METALLIQUE, BOITES DE

CONTROLE ET TOUT METAL PROCHE DU MOTEUR A UN

CABLE ALLANT VERS UNE ALIMENTATION D’ENERGIE

AVEC BORNE DE MISE A LA TERRE UTILISANT AU

MOINS LE MEME CALIBRE QUE LES FILS DU MOTEUR.

POUR REDUIRE LE RISQUE DE CHOC ELECTRIQUE.

COUPER LE COURANT AVANT DE TRAVAILLER PRES

OU UNE ZONE DE BAIGNADE.

ATENTION!

INFORMACION PARA EL INTALADO

DE ESTE EQUIPO

PARA LA INSTALACION DE ESTE EQUIPO, SE

REQUIERE DE PERSONAL TECNICO CALIFICADO.

EL NO CUMPLIR CON LAS NORMAS ELECTRICAS

NACIONALES Y LOCALES, ASI COMO CON LAS

RECOMENDACIONES E FRANKLIN ELECTRIC DURANTE

SU INSTALACION, PUEDE OCASIONAR: UN CHOQUE

ELECTRICO, PELIGRO DE UN INCENDIO, OPERACION

DEFECTUOSA E ESTAN DISPONIBLES CON LOS

DISTRIBUIDORES, FABRICANTES DE BOMBAS O

DIRECTAMENTE CON FRANKLIN ELECTRIC. PUEDE

LLAMAR GRATUITAMENTE PARA MAYOR INFORMACION

AL TELEFONO 800-348-2420. GUARDAR ESTA

INFORMACION JUNTO AL EQUIPO PARA FUTURAS

CONSULTAS.

ADVERTENCIA

PUEDE OCURRIR UN CHOQUE ELECTRICO, SERIO

O FATAL DEBIDO A UNA ERRONEA CONECCION DEL:

MOTOR O POR NO UTILIZAR UN CABLE PARA TIERRA

DE CALIBRE IGUAL O MAYOR AL DE LA ALIMENTACION.

PARA REDUCIR EL RIESGO DE CHOQUE ELECTRICO.

DESCONECTAR LA ALIMENTACION ELECTRICA ANTES

DE INICIAR A TRABAJAR EN EL SISTEMA HIDRAULICO.

NO UTILIZAR ESTE MOTOR EN ALBERCAS O AREAS EN

DONDE SE PRACTIQUE NATACION.

12

Page 15

GARANTIE LIMITÉE États-Unis*

Franklin Pump Systems Inc.

Franklin Pump Systems Inc. garantie que ses produits neufs sont libres de tout défaut de matériaux et de

fabrication pour une période de 1 an à compter de la date d’installation ou de 2 ans à compter de la date de

fabrication, le premier atteint, quand installés dans un système d’eau domestique qui pompe de l’eau potable

seulement. La garantie ne couvre pas les systèmes pompant de l’eau salée ou d’autres liquides corrosifs. Consultez

et suivez les codes locaux pour tous les systèmes.

Les obligations de garantie de Franklin Pump Systems en ce qui concerne l’équipement fabriqué par d’autres

manufacturiers sont limitées à la garantie qui est donnée à Franklin Pump Systems par ses fournisseurs.

Cette garantie s’applique seulement à l’acheteur original et seulement au moment où il occupe l’endroit où le

produit a été installé originalement.

Les demandes de services couverts par cette garantie seront faites en contactant le dépositaire installateur (endroit

d’achat du produit) aussitôt que possible après la découverte des présumés défauts. Franklin Pump Systems prendra

subséquemment les actions correctives aussi promptement que raisonnablement possible.

Franklin Pump Systems peut remplacer ou réparer à sa discrétion tout produit qui brise pendant la couverture

de cette garantie après une inspection par un représentant autorisé de la compagnie ou après que Franklin Pump

Systems ait reçu le produit à la compagnie. Le remplacement ou la réparation du produit ne pourront être faits

qu’après son inspection. Tous les frais et dépenses de transport (aller et retour), démontage et réinstallation, ou

l’installation d’un produit de remplacement sont la responsabilité de l’acheteur.

CETTE GARANTIE PRÉVAUT SUR TOUTE GARANTIE NON DATÉE OU AYANT UNE DATE PLUS ANCIENNE.

TOUTE GARANTIE IMPLICITE QUE L’ACHETEUR POURRAIT AVOIR, INCLUANT L’HABILETÉ ET L’APTITUDE

D’UN MARCHAND POUR UN BUT PARTICULIER, NE DEVRA PAS S’ÉTENDRE AU-DELÀ DE LA PÉRIODE

DE GARANTIE APPLICABLE. Certains états ne permettent pas de limiter la durée d’une supposée garantie,

donc les limites ci-haut peuvent ne pas s’appliquer à vous. EN AUCUN CAS FRANKLIN PUMP SYSTEMS NE

SERA TENU RESPONSABLE DE DOMMAGES FORTUITS OU CONSÉCUTIFS. Certains états ne permettent pas

l’exclusion ou la limitation des dommages fortuits ou consécutifs, donc ceci peut ne pas s’appliquer à vous.

Cette garantie ne s’applique pas aux produits ayant été sujets de négligence, de modifi cations, d’accident,

d’abus, de mauvaise utilisation, d’installation incorrecte, de vandalisme, de dérangements civils ou d’actes de Dieu.

Les seules garanties autorisées par Franklin Pump Systems sont celles mentionnées ici. Franklin Pump Systems

n’autorise personne à prolonger les garanties en ce qui concerne ses produits et Franklin Pump Systems ne sera pas

tenu responsable d’aucune garantie non autorisée faite en union avec la vente de ses produits.

CETTE GARANTIE VOUS DONNE DES DROITS LÉGAUX PRÉCIS. VOUS POUVEZ AUSSI AVOIR D’AUTRES

DROITS QUI PEUVENT VARIER D’UN ÉTAT À L’AUTRE.

*Contactez Franklin Pump Systems Inc. Export Division pour les garanties internationales.

E1467 5/06

12401 Interstate 30 • P.O. Box 8903

Little Rock, AR 72219

13

Page 16

Loading...

Loading...