Franke Foodservice FSW908TC BK Service Manual

HANDBOOK HOOD FSW908TC BK/XS 9925072 110.0019.383 updated JANUARY 2010

CONTROLS : Electronic –Low -tension

CONTROLS : PUSH BUTTONS KEY- TOUCH CONTROL

MOTOR : NR 01 330 W

TOTAL POWER : 370 W

FLOW RATE - FREE DELIVERY : 920 M3/H MAX

FLOW RATE IEC 61591 850 M3/H MAX

PRESSURE 440 PA MAX

SOUND POWER(IEC 60704-2-13): 66 DBA

NO SPEED POSITIONS : N0 8 + BOOST

LAMPS : NR 02 HALOGEN LAMPS X 20 W each one

LIGHTING SYSTEM CAN BE MODIFIED UP TO FIVE LEVELS.

GREASE FILTER : METAL CASSETTE

DIAMETER : 150 MM

IMPUT VOLTAGE 230V -50 HZ

CONTENTS:

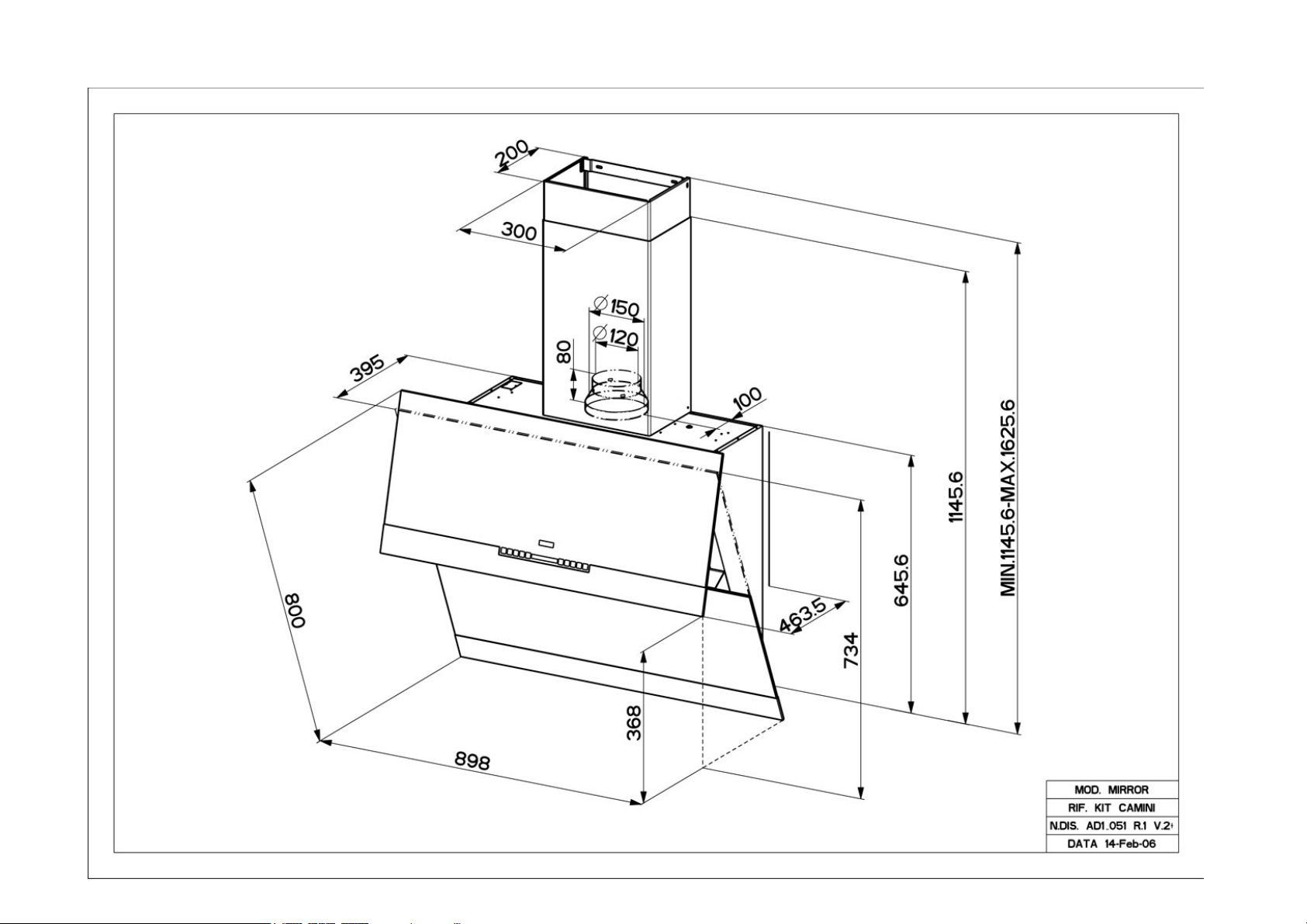

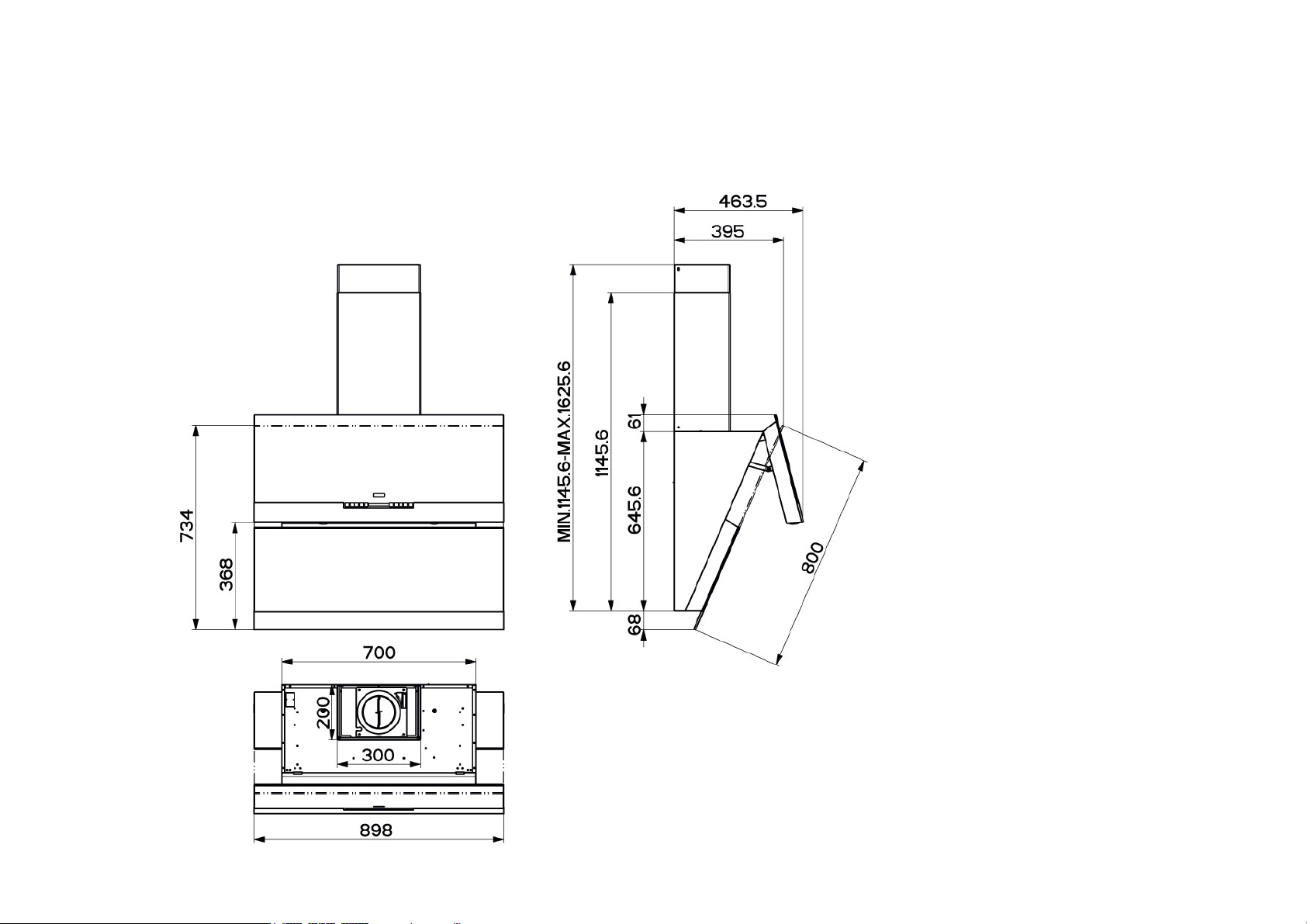

TECHNICAL DATA

DRAWING

ELECTRICAL CONNECTION

METAL GREASE FILT

HOOD BODY MOUNTING

CONTROLS HOW IT WORKS CHARCOAL FILTER

SUBSTIT

REPLACING THE FUSE

LIGHT REPLACEMENT

LIST SPARE PARTS

EXPLODED VIEW

WIRING DIAGRAM

UTION OF T

ERS

HE CHARCOAL FILTER

1

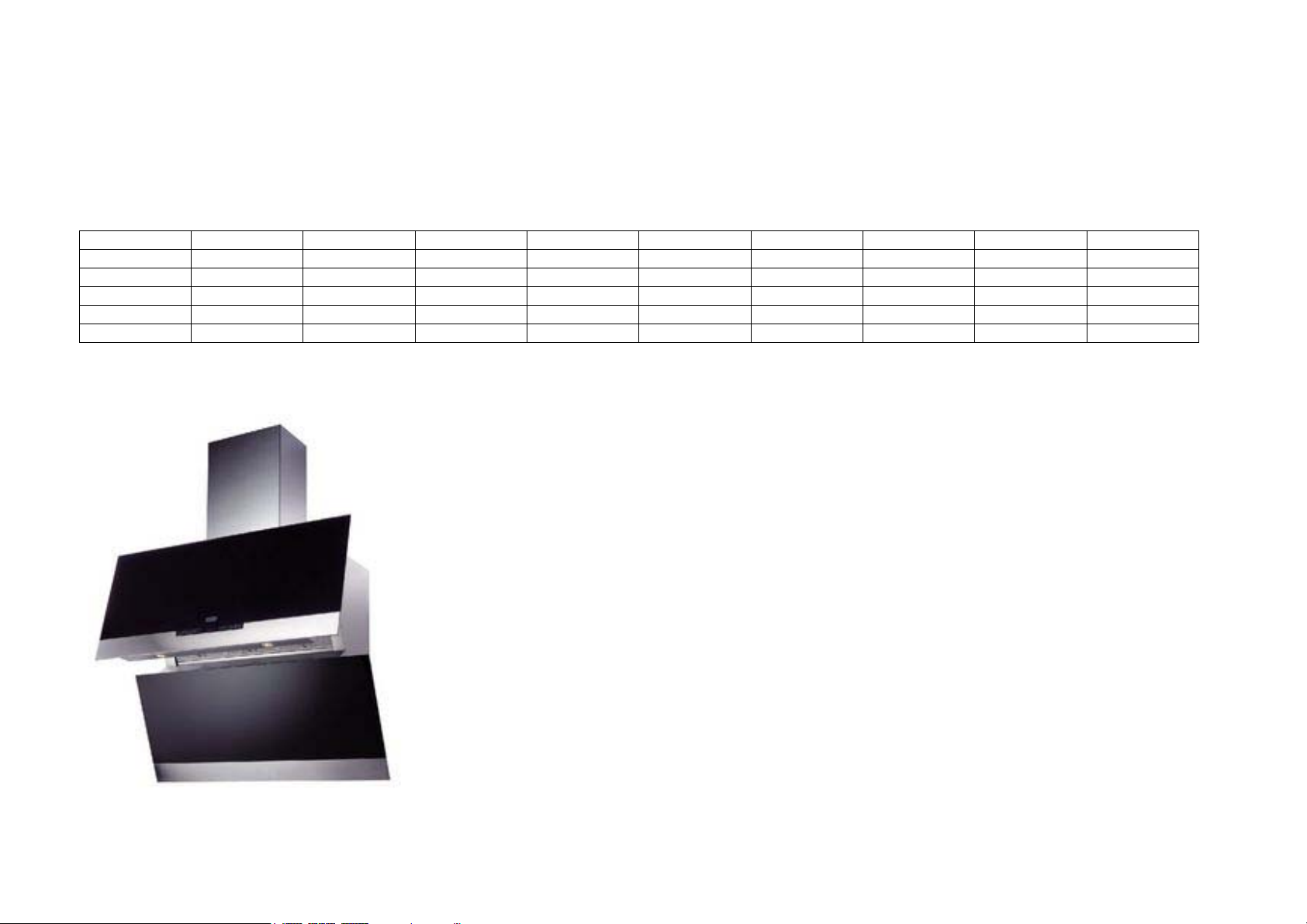

TECHNICAL DATA

SPEED BOOST 8 7 6 5 4 3 2 1

Q MAX 920 750 650 550 480 410 350 280 200

Q IEC 850 700 620 530 460 390 330 265 190

P 440 420 400 390 360 320 280 200 100

W 330 220 180 135 110 90 70 50 35

DBA 66 61 58 55 52 49 46 42 35

2

3

4

ELECTRICAL CONNECTION •

Connect the hood to the mains through a two-pole switch having a contact gap of at least 3

mm.

• Remove the grease filters (see paragraph Maintenance) being sure that the connector of the

feeding cable is correctly inserted in the socket placed on the side of the fan.

Metal grease filters

Metal filters can be washed also in a dish machine. They need to be washed every

time a drop-symbol appears in the display or at least every two months. In case of

very frequent use these have to be washed even more often. Alarm reset • Press

the G-key for at least 2 seconds.

Cleaning

• Open the comfort panel.

• Remove the filters one by one by pushing them backwards and pulling them

down contemporaneously.

• Wash the filters. Pay attention not to bend them. Make sure that filters are

completely dry before putting them into their seat. (a possible modification of the

filter surface doesn’t influence its efficiency).

• Place the filters again into their seats and make sure that the handle of the filter

remains outside.

• Close the comfort panel.

5

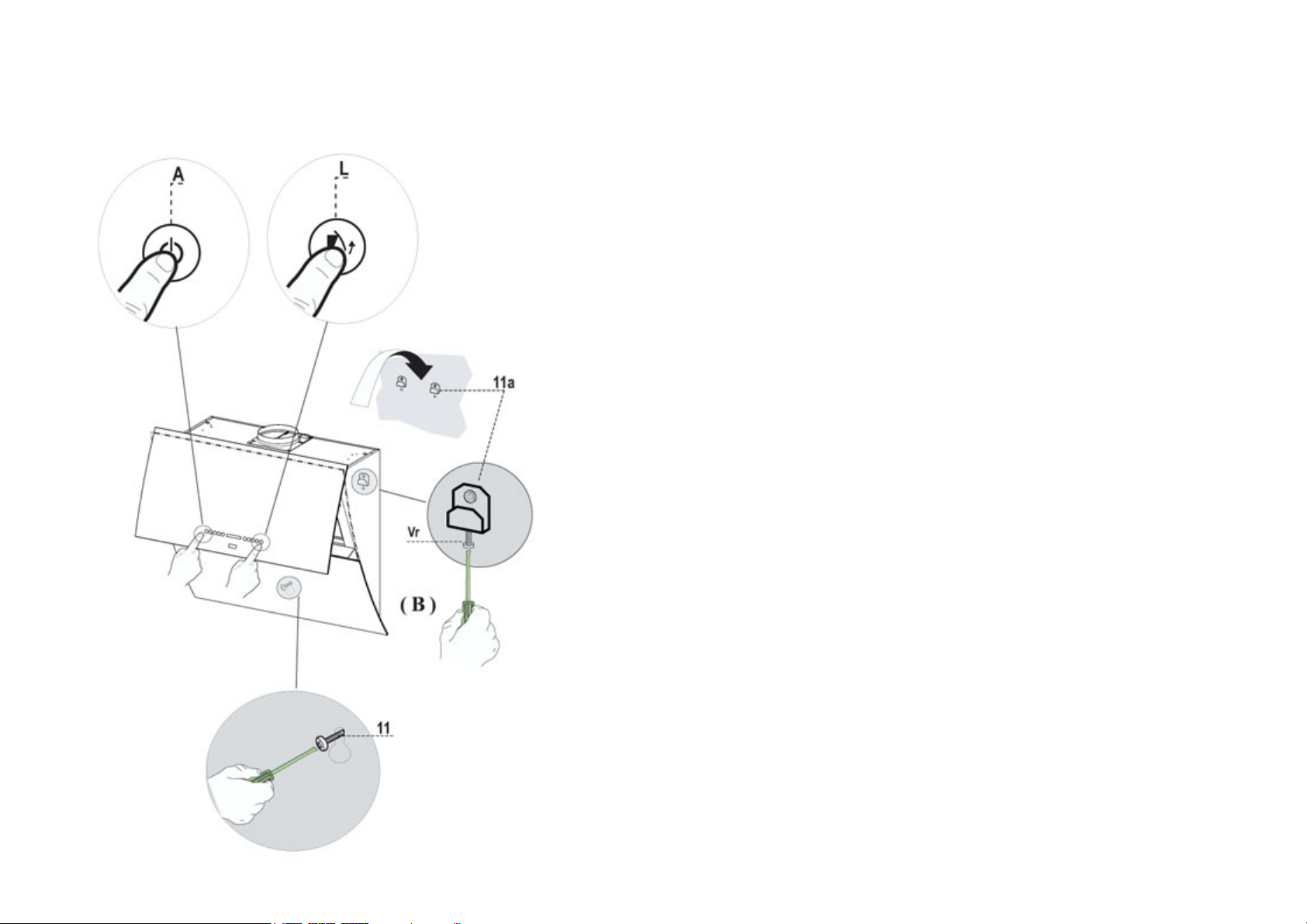

Hood body mounting

Firstly, it is necessary to adjust the two Vr-screws of the 11abrackets, at minimun (B).

• Hang the hood body on the two brackets 11a.

• Connect the hood to the mains supply by means of a bipolar switch

with at least 3 mm contact gap.

• Press the “A”-key for one second (see Part USE) to open the upper

panel.

• Remove the metal filters.

• In order to align the hood it is necessary to adjust the Vr-screws

from inside the hood.

• Fasten the safety screw 11.

• Fit again the metal filters into their seats and close the upper panel

by pressing “L”-key for one second (see Part USE).

• Disconnect the hood from the mains supply. Attention: the upper

panel stops if any barrier occurs in its way during the panel opening

or closing.

To open the panel it is enough to remove the barrier and press the

key once again.

6