FRANKE FDP12004XS, FDP906PXS, FDP904XS, FDP906IXS, FDP12006PXS User Manual

Instructions for use and installation

Istruzioni per l’uso e l’installazione

Mode d’emploi et installation

Bedienungsanleitung und Einrichtung

Kullan

ım ve montaj talimatları

GB

IT

FR

DE

TR

Cooker Hood

Cappa

Hotte de Cuisine

Dunstabzugshaube

Davlumbaz

FDP 904

FDP 12004

FDP 906-P

FDP 12006-P

EN

Instructions Manual

INDEX

RECOMMENDATIONS AND SUGGESTIONS......................................................................................................................7

CHARACTERISTICS..............................................................................................................................................................8

INSTALLATION ......................................................................................................................................................................9

USE.......................................................................................................................................................................................12

MAINTENANCE....................................................................................................................................................................14

2

2

IT

Libretto di Istruzioni

INDICE

CONSIGLI E SUGGERIMENTI ............................................................................................................................................15

CARATTERISTICHE............................................................................................................................................................16

INSTALLAZIONE..................................................................................................................................................................17

USO......................................................................................................................................................................................20

MANUTENZIONE.................................................................................................................................................................22

3

3

FR

Manuel d’Instructions

SOMMAIRE

CONSEILS ET SUGGESTIONS ..........................................................................................................................................23

CARACTERISTIQUES.........................................................................................................................................................24

INSTALLATION ....................................................................................................................................................................25

UTILISATION........................................................................................................................................................................28

ENTRETIEN..........................................................................................................................................................................30

4

4

DE

Bedienungsanleitung

INHALTSVERZEICHNIS

EMPFEHLUNGEN UND HINWEISE....................................................................................................................................31

CHARAKTERISTIKEN..........................................................................................................................................................32

MONTAGE............................................................................................................................................................................33

BEDIENUNG.........................................................................................................................................................................36

WARTUNG............................................................................................................................................................................38

5

5

TR

Kullanim Kilavuku

IÇERIKLER

TAVSIYELER VE ÖNERILER ..............................................................................................................................................39

ÖZELLIKLER........................................................................................................................................................................40

MONTAJ...............................................................................................................................................................................41

KULLANIM............................................................................................................................................................................44

BAKIM...................................................................................................................................................................................46

6

6

EN

RECOMMENDATIONS AND SUGGESTIONS

650 mm min.

The Instructions for Use apply to several versions of this appliance. Accord-

ingly, you may find descriptions of individual features that do not apply to your

specific appliance.

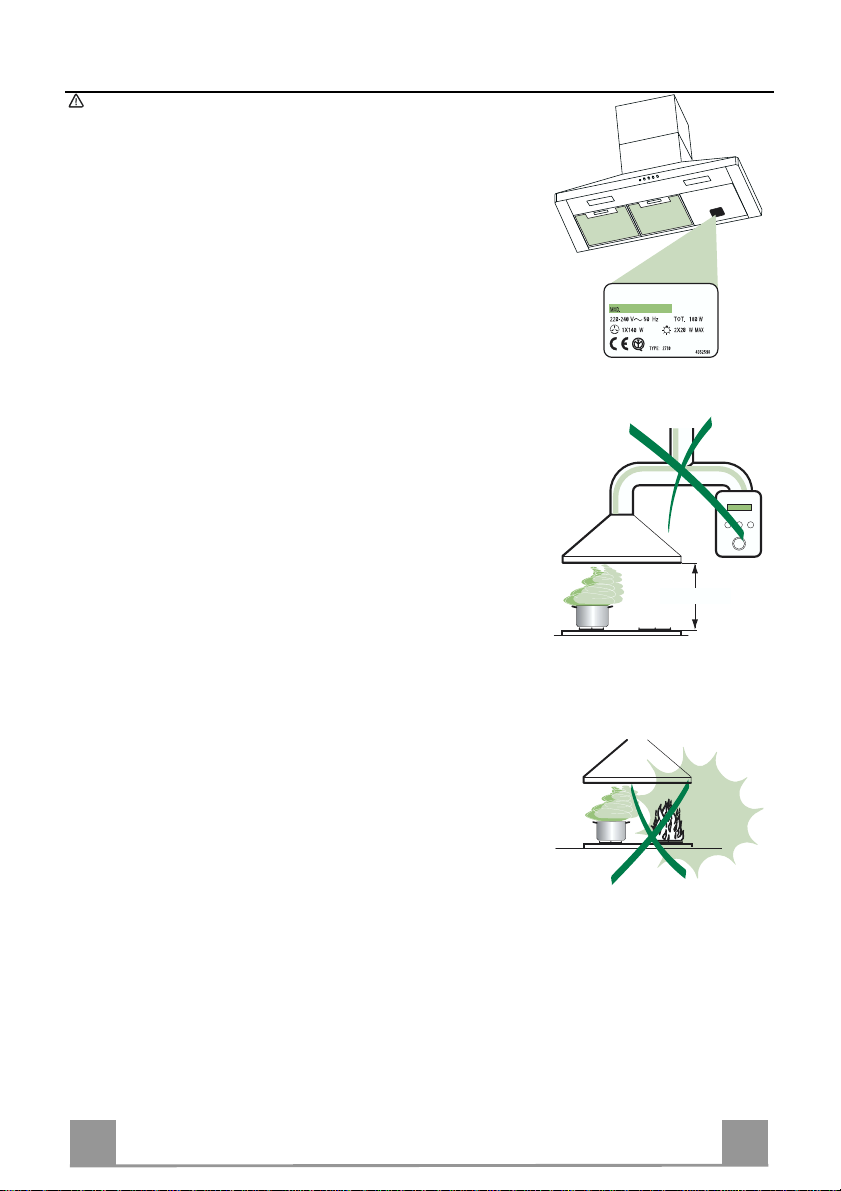

INSTALLATION

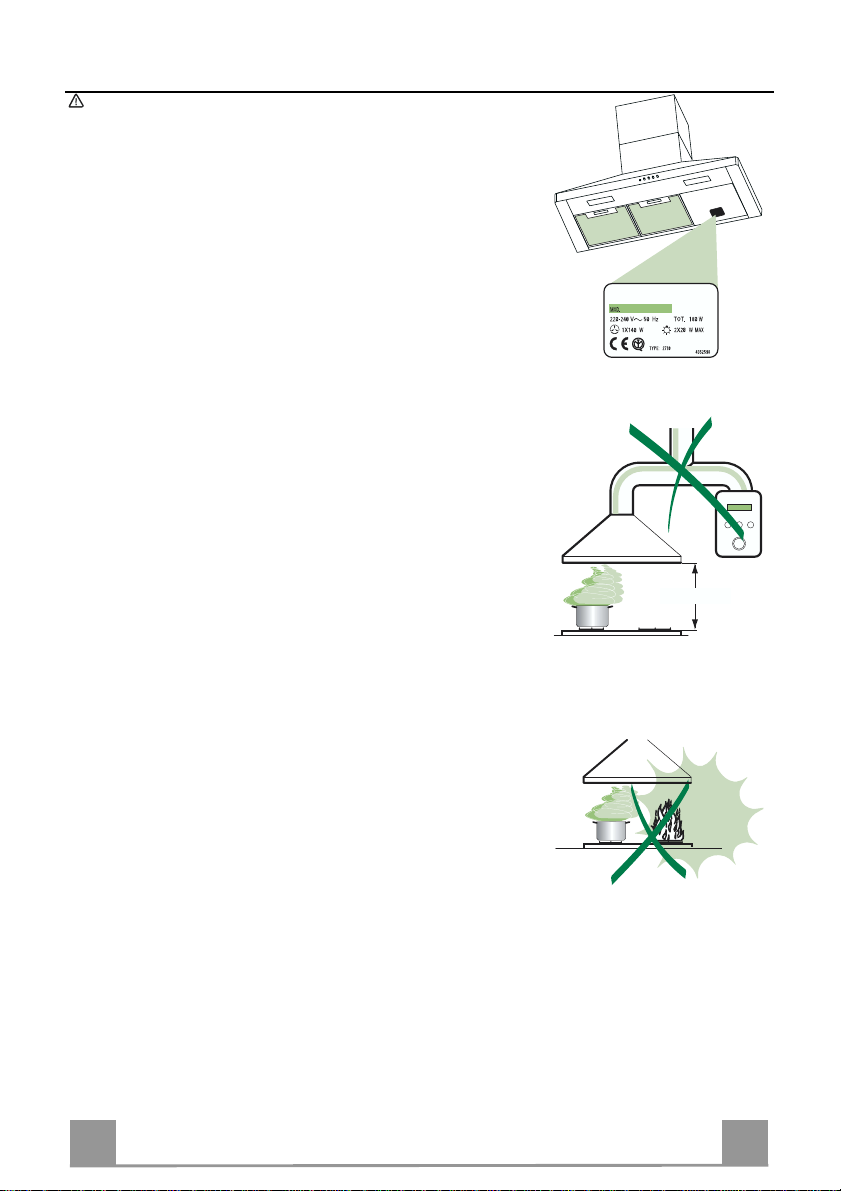

• The manufacturer will not be held liable for an y damages resulting fro m incorrect or impro per installat ion.

• The minimum safety distance between the cooker top and the extractor hood

is 650 mm.

• Check that the mains voltage corresponds to that indicated on the rating plate

fixed to the inside of the hood.

• For Class I appliances, check that the domestic power supply guarantees adequate earthing.

Connect the extractor to the exhaust flue through a pipe of minimum diameter

120 mm. The route of the flue must be as short as possible.

• Do not connect the extractor hood to exhaust ducts carrying combustion fumes

(boilers, fi replaces, etc.).

• If the extractor is used in conjunction with non-electrical appliances (e.g. gas

burning appliances), a sufficient degree of aeration must be guaranteed in the

room in order to prevent the backflow of exhaust gas. The kitchen must have

an opening communicating directly with the open air in order to guarantee the

entry of clea n air.

USE

• The extractor hood has been designed exclusively for domestic use to eliminate kitchen smells.

• Never use the hood f or purposes other than for which it has ben designed.

• Never leave high naked flames under the hood when it is in operation.

• Adjust the flame intensity to direct it onto the bottom of the pan only, making

sure that it does not engulf the sides.

• Deep fat fryers must be continuously monitored during use: overheated oil can

burst into flames.

• Do not flambè under the range hood; risk of fir e

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the appliance.

MAINTENANCE

• Switch off or unplug the appliance from the mains supply before carrying out

any maintenance work.

• Clean and/or replace the Filters after the specified time p eriod.

• Clean the hood using a damp cloth and a neutral liquid deter gent.

7

7

EN

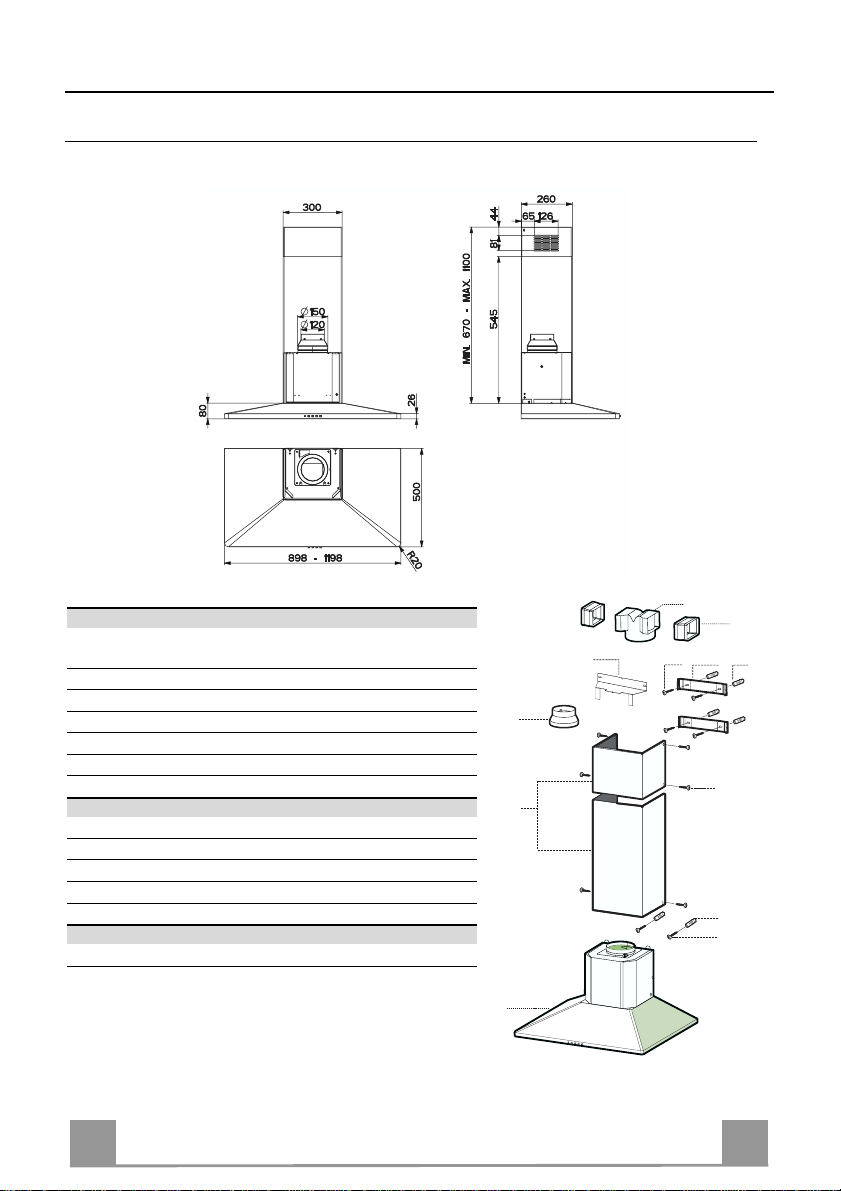

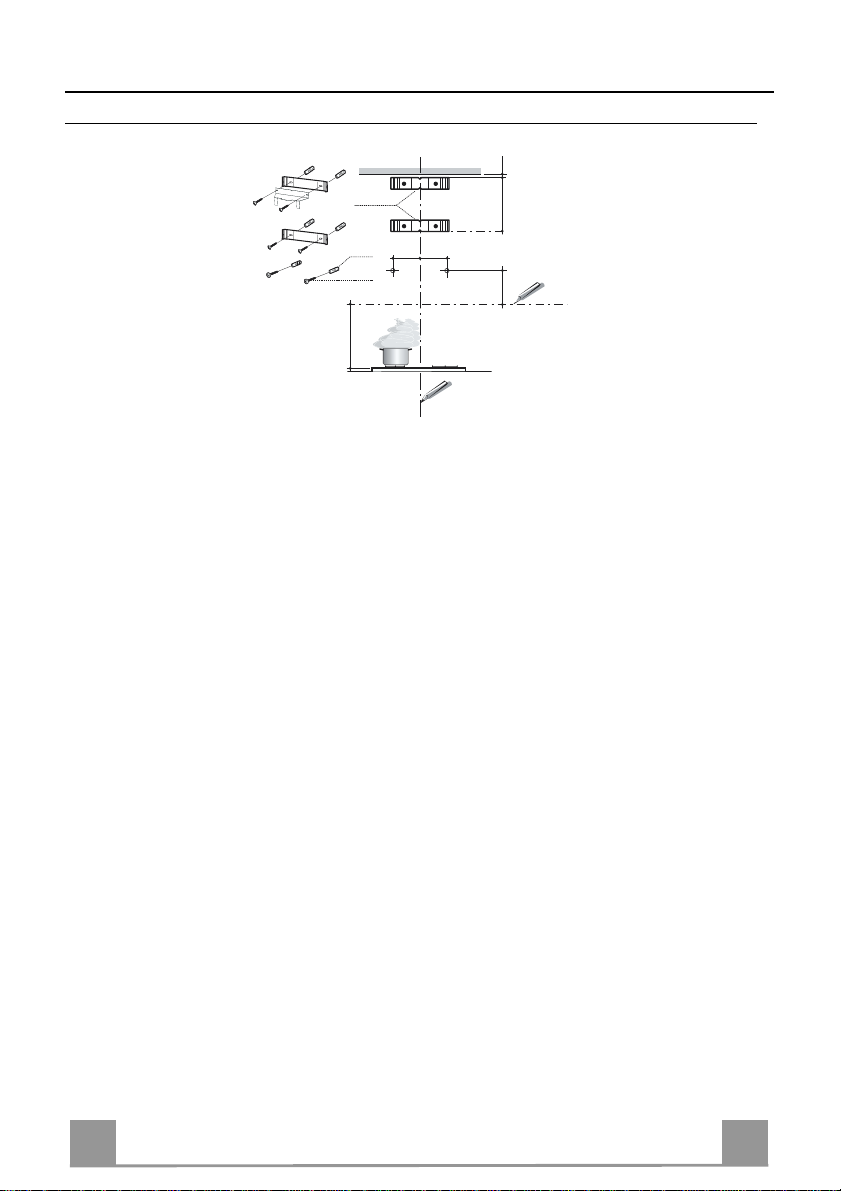

CHARACTERISTICS

Dimensions

Components

Ref. Q.ty Product Components

1 1 Hood Body, complete with: Controls, Light, Blower,

2 1 Telescopic Chimney comprising:

2.1 1 Upper Section

2.2 1 Lower Section

9 1 Reducer Flange ø 150-120 mm

14.1 2 Air Outlet Connection Extension

15 1 Air Outlet Connection

Ref. Q.ty Installation Components

7.2.1 2 Upper Chimney Section Fixing Brackets

7.3 1 Air Outlet Connection Supp ort

11 6 Wall Plugs

12a 6 Screws 4,2 x 44, 4

12c 6 Screws 2,9 x 9, 5

Q.ty Documentation

1 Instruction Manual

Filters

15

14.1

7.3

9

2.1

2

2.2

1

12a

7.2.1 11

12c

11

12a

8

8

EN

INSTALLATION

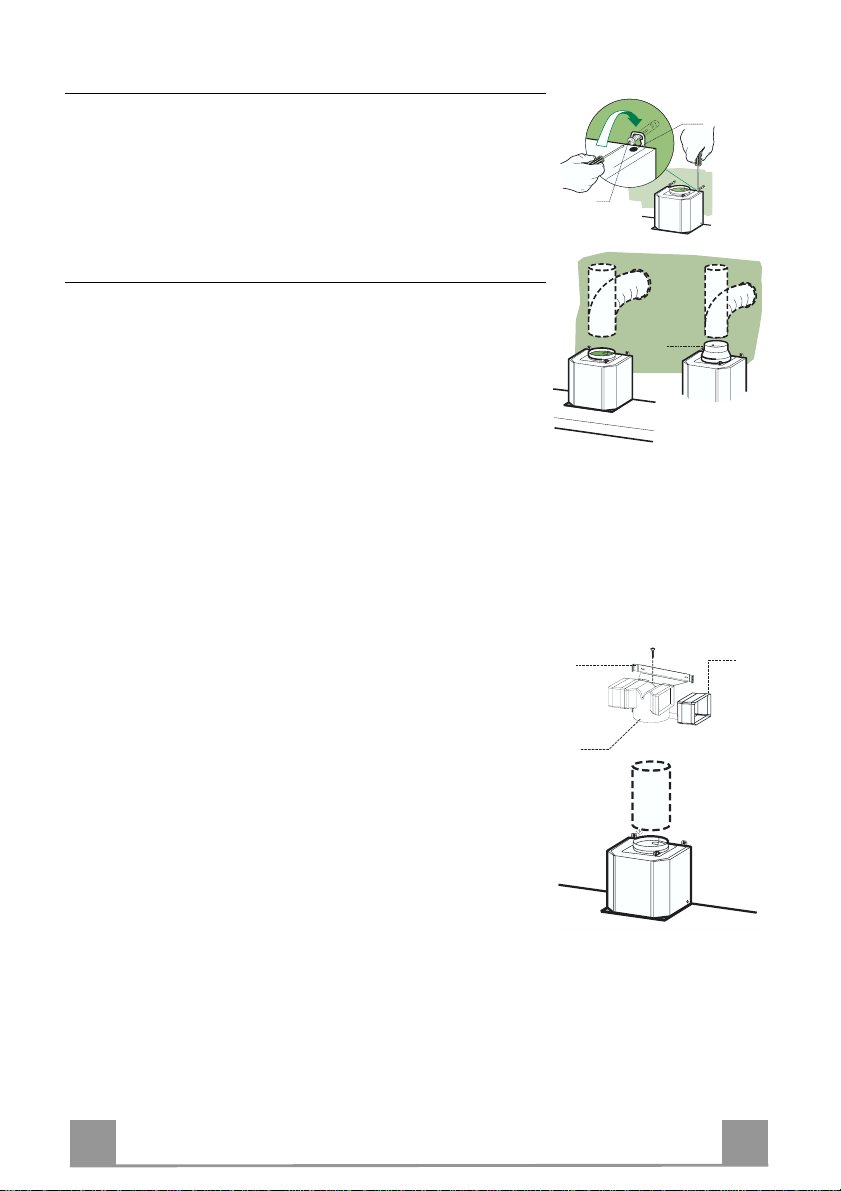

Wall drilling and bracket fixing

7.2.1

11

12a

116

116

1÷2

X

340

650 min.

Wall marking:

• Draw a vertical line on the supporting wall up to the ceiling, or as high as practical, at the

centre of the area in which the hood will be installed.

• Draw a horizontal line at 650 mm above the hob.

• P l ace bracket 7.2.1 on the wall as shown about 1-2 mm from the ceiling or upper limit aligning the centre (notch) with the vertical reference line.

• Mark the wall at the cent r es of the holes in the bracket.

• P l ace br acket 7.2.1 on the wall as shown at X mm below the first bracket (X = height of the

upper chimney section supplied), aligning the centre (notch) with the vertical line.

• Mark the wall at the cent r es of the holes in the bracket.

• Mark a reference point as in dicated at 116 mm from the vertical reference li ne and 340 mm

above the horizontal reference l ine.

• Repeat this operation on the other side.

• Drill ø 8 mm holes at all the centre points marked.

• Insert the wall plugs 11 in the holes.

• Fix the lower bracket 7.2.1 using the 12a screws (4,2 x 44,4) supplied.

• Fix the upper bracket 7.2.1 and the air outlet co nnection support 7.3 together using the 2

screws 12a (4,2 x 44,4) supplied.

• Insert the two screws 12a (4,2 x 44,4) supplied in the hood body fixing holes, leaving a gap

of 5-6 mm between the wall and the head of the screw.

9

9

EN 110

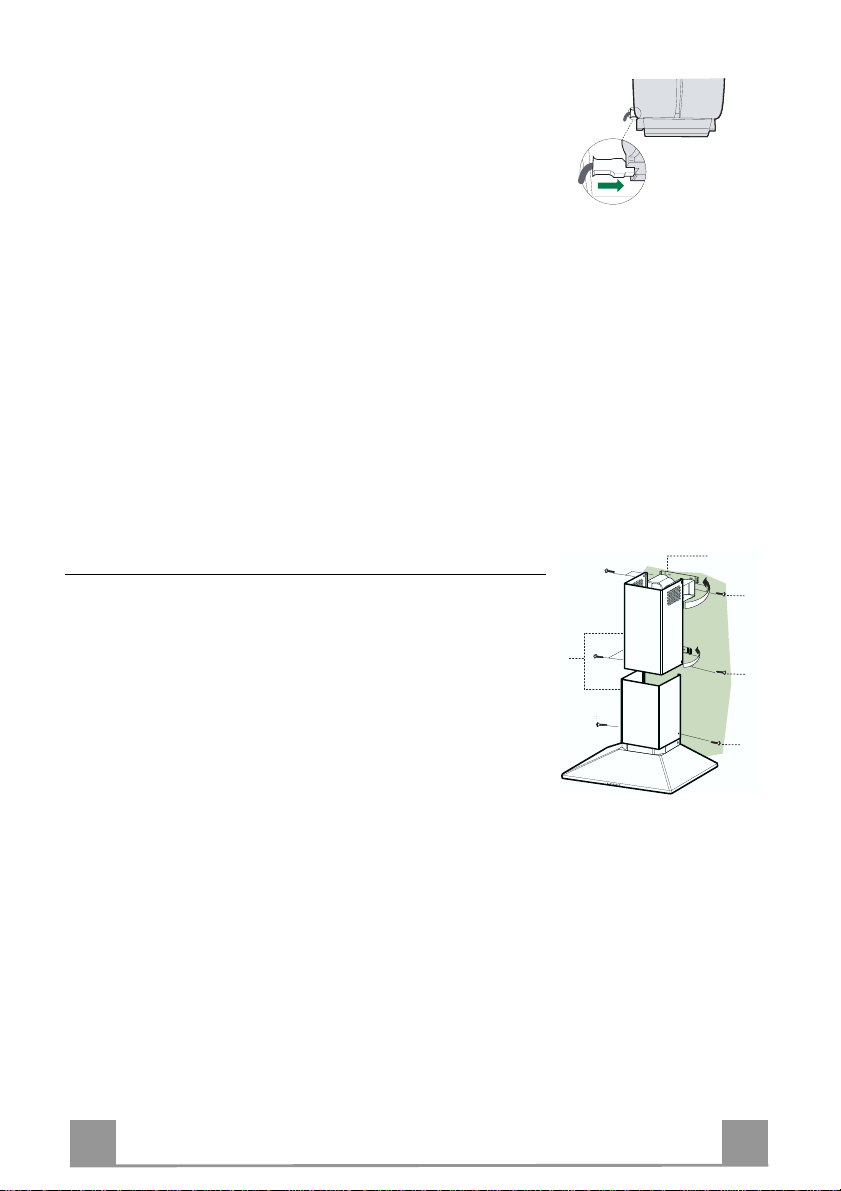

Mounting the hood body

9

ø 120ø 150

ø 150

15

14.1

7.3

• Before attaching the hood body, tighten the two screws Vr located on the hood body mounting points.

• Hook the hood body onto the screws 12a.

• Fully tighten support screws 12a.

• Adjust screws Vr to level the hood body.

Connections

DUCTED VERSION AIR EXHAUST SYSTEM

When installing the ducted version, connect the hood to the

chimney using either a flexible or rigid pipe ø 150 or 120 mm,

the choice of which is left to the installer.

• To install a ø 120 mm air exhaust connection, insert the reducer flange 9 on the hood body outlet.

• Fix the pipe in position using sufficient pipe clamps (not supplied).

• Remove any activated charcoal filters.

Vr

12a

RECIRCULATION VERSION AIR OUTLET

• Insert the con nection extensio n pieces laterall y 14.1 in conn ection 15.

• Insert the Connector 15 i nto the Suppor t bracket 7.3 and fix it

with a screw.

• Make su re that the outlet of the extension pieces 14.1 is horizontally and vertically aligned with the chimney outlets.

• Connect the ai r outlet connection 15 to the hood body outlet

using either a flexible or rigid pipe ø 150 mm, the choice of

which is left to the installer.

• Ensure that the activated charcoal filters have been inserted.

EN 111

ELECTRICAL CONNECTION

12c

12c

12c

2.1

2.2

2

7.2.1

• Connect the hood to the mains through a two-pole switch having a contact gap of at least 3 mm.

• Re move the grease filters (see paragraph Maintenance) being

sure that the conn ector of the feeding cable is correctly inserted

in the socket placed on th e side of the fan.

Flue assembly

Upper exhaust flue

• Slightly widen the two sides of the upper flue and hook them

behind the brackets 7.2.1, making sure that they are well

seated.

• Secure the sides to the brackets using the 4 screws 12c (2,9 x

9,5) supplied.

• Make sure that the ou tlet of the extensions pieces is align ed

with the chimney outlets.

Lower ex haust flue

• Slightly widen the two sides of the flue and hook them between the upper flue and t he wall, makin g sure that they are

well seated.

• Fix the lower part laterally to the hood body using the 2 screws

12c (2,9 x 9,5) supplied.

EN 112

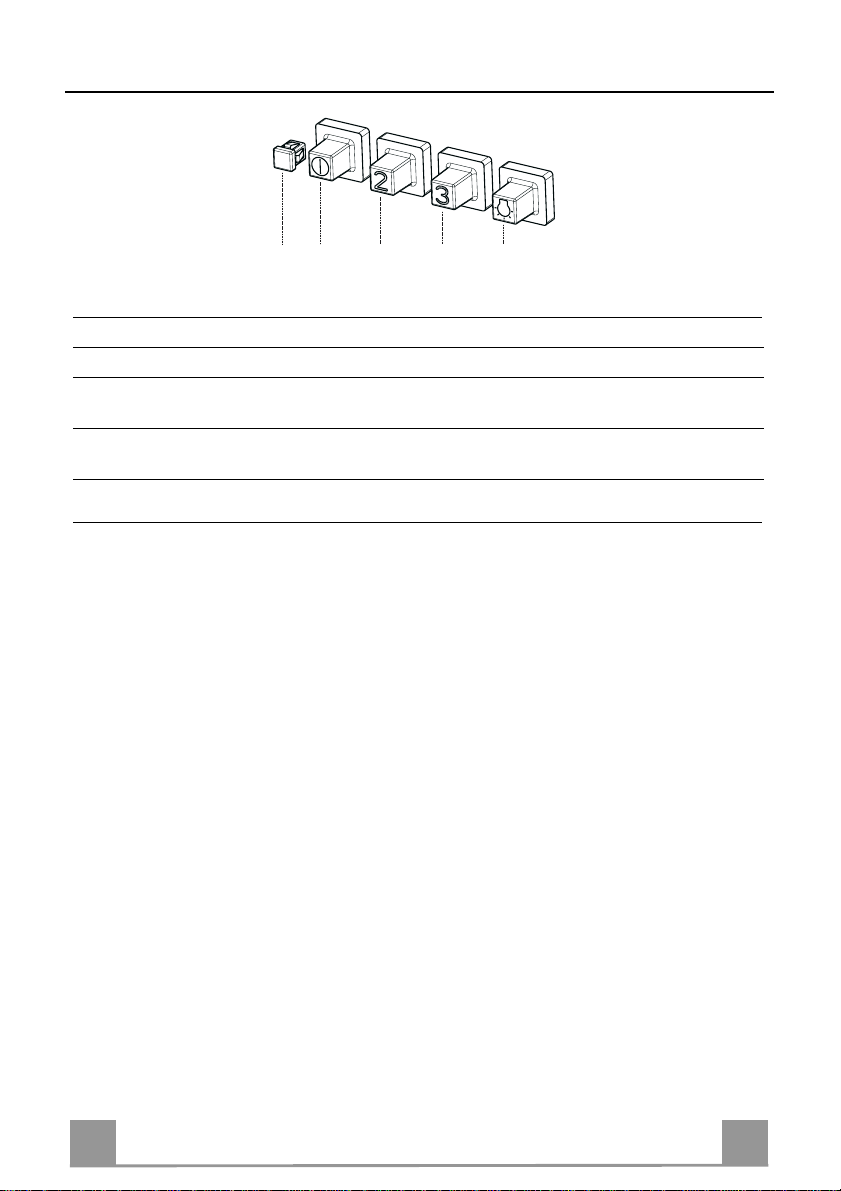

USE

V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1V1

S

V2

V3

L

L Light Switches the lighting system on and off.

S Led Motor running led.

V1 Motor Switches the extractor motor on and off at low speed. Used to provide a

contin-uos and silent air change in the presence of light cooking vapours.

V2 Speed Medium speed, suitable for most operating conditions given the optimum

treated air flox/noise level ratio.

V3 Intensive Maximum speed, used for eliminating the highest cooking vapour emission,

including long periods.

EN 113

T

T1T

3

2

T4T

5

L

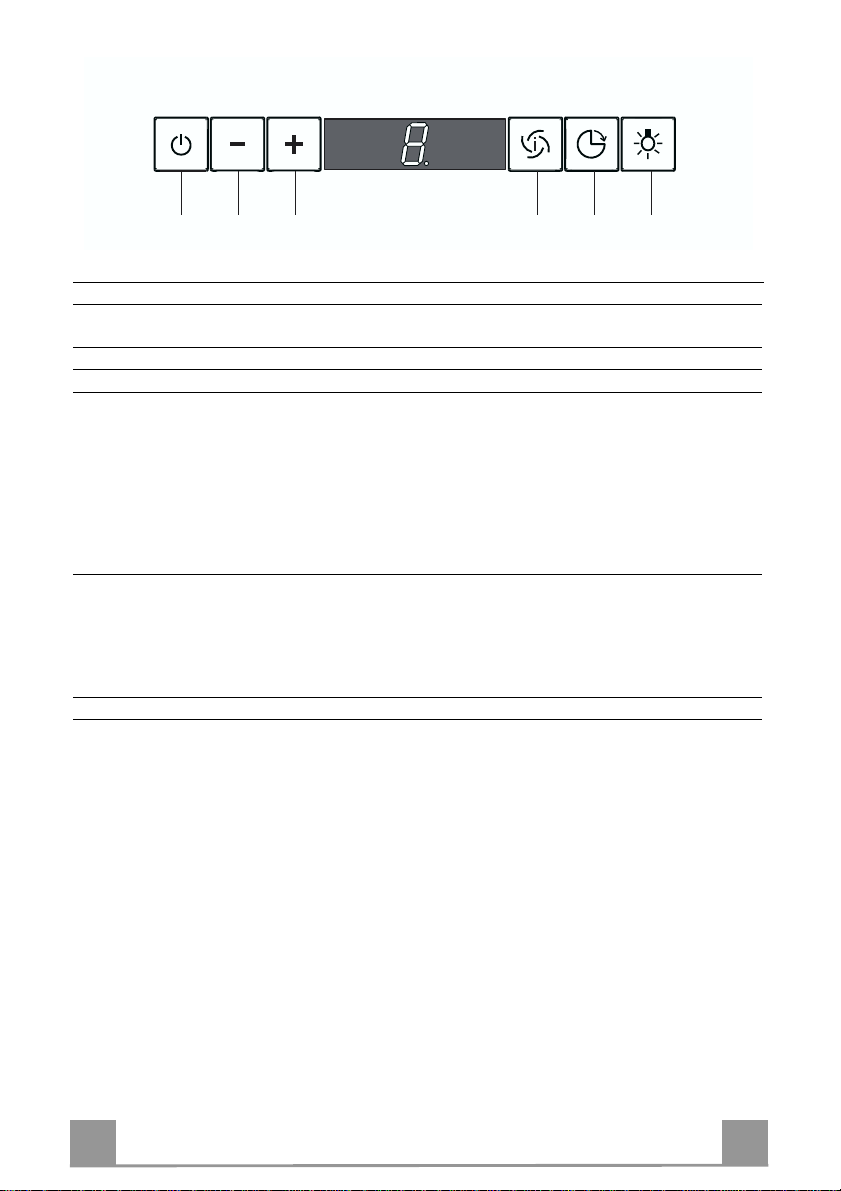

Control panel

TOUCH CONTROL FUNCTION

T1 ON/OFF Motor Switches the hood motor on and off. The latest selected

speed appears on the displ ay.

T2 Speed - Decreases the suction speed: V3 → V2 → V1

T3 Speed + In creases the suction speed: V1 → V2 → V3

T4 In tensive speed Activates the intensive sp eed from any previously selected

speed. The intensive sp eed can be activated even when the

motor is OFF. By pressing the same touch control once again

or by switching off the motor this function can be deactivated. Intensive speed cannot be activated when the delay

function is on. Intensive speed has been timed at 10 minutes:

H appears on the display and a spot down on the right side

flashes once a second. After 10 minutes the system activates

automatically the latest select ed speed.

T5 Delay Activates and deactivates the delayed shutdown of the hood

(motor + lighting) at 30 minutes: the selected speed o f the

hood appears on the display and a spot down on the right

side flashes once a second. By pressing the same touch control once again or by switching off the motor delay function

can be deactivated.

L Lighting Turns light on and off.

EN 114

MAINTENANCE

Grease filters

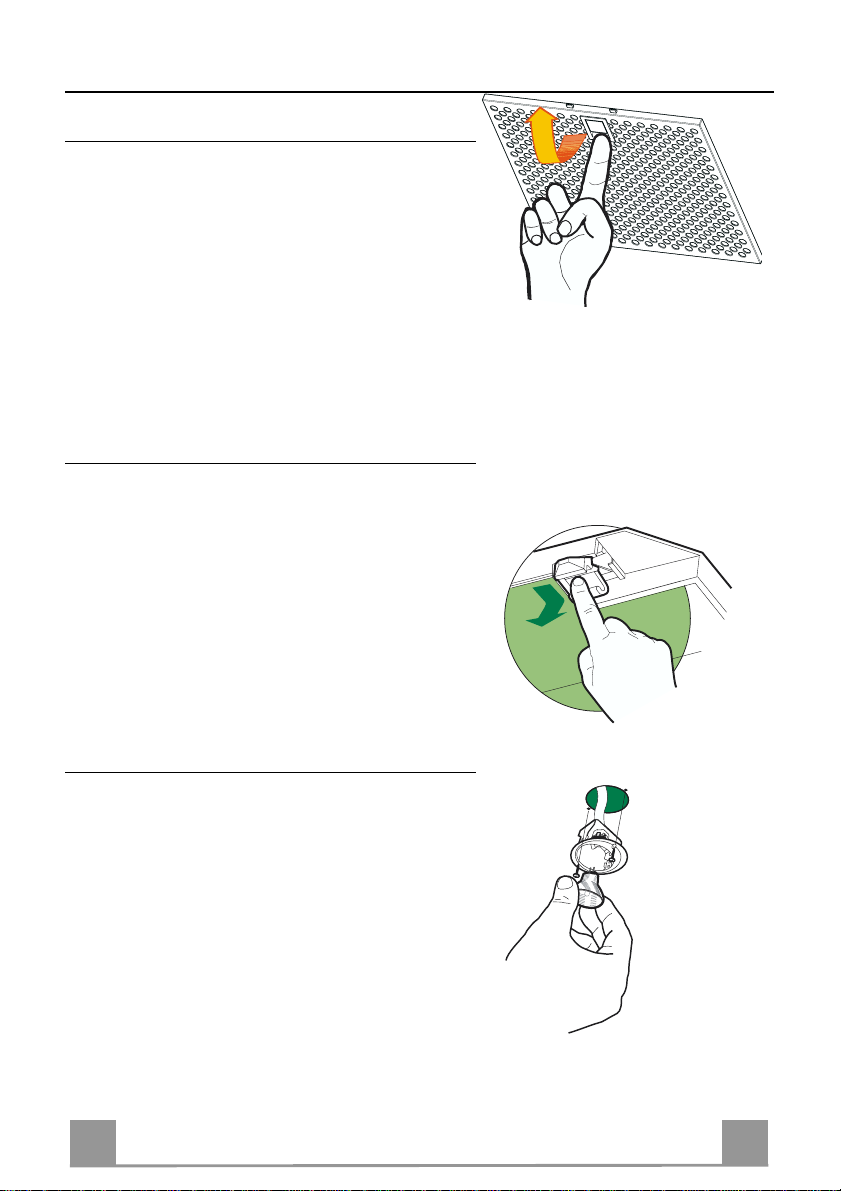

CLEANING META L SELF- SUPPO RTING GREASE FILTERS

• The filters must be cleaned every 2 months of operation, or more frequently for particularly heavy usage,

and can be washed in a dishwasher.

• Remove the filters one at a time holding them up

with one hand and pulling the handle downwards

with the other hand at the same time.

• Wash the filters, taking care not to bend them. Allow

them to dry before refitting.

• When refitting the filters, make sure that the handle

is visible on the outside.

Activated charcoal filter (Recirculation version)

REPLACING THE ACTIVATED CHARCOAL FILTE R

• The filter is not washable and cannot be regenerated,

and must be replaced approximat ely every 4 months

of operation, or more frequently for particularly

heavy usage.

• Remove the metal grease filters

• Remove the saturated activated carbon filter by releasing the fixing hooks

• Fit the new filter by hooking it into its seating

• Replace the metal grease filters.

Lighting

LIGHT REPLACEMENT

20 W halogen light.

• Remove the 2 screws fixing the Lighting support, and

pull it out of from the Hood.

• Extract the lamp from the Support.

• Replace with another of the same type, making sure

that the two pins are properly inserted in the lamp

holder socket holes.

• Replace the Su pport, fixing it in place with the two

screws removed as above.

IT 115

CONSIGLI E SUGGERIMENTI

650 mm min.

Questo libretto di istruzioni per l'uso è previsto per più versioni dell' apparec-

chio. É possibile che siano descritti singoli particolari della dotazione, che non

riguardano i l Vostro apparecchio.

INSTALLAZIONE

• Il produttore declina qualsiasi responsabilità per danni dovuti ad installazione

non corretta o non conforme alle regole dell’arte.

• La distanza minima di sicurezza tra il Piano di cottura e la Cappa deve essere

di 650 mm.

• Verificare che la tensione di rete corrisponda a quella riportata nella targhetta

posta all’interno della Cappa.

• Per Apparecchi in Classe Ia accertarsi che l’impian to elettrico domestico garantisca un corretto scarico a terra.

• Collegare la Cappa all’u scita dell’a ria aspirata con tuba zione di d iametro pari o

superiore a 120 mm. Il percorso della tubazione deve essere il più breve possibile.

• Non collegare la Cappa a condotti di scarico dei fumi prodotti da combustione

(caldaie, caminetti, ecc.).

• Nel caso in cui nella stanza vengano utilizzati sia la Cappa che apparecc hi non

azionati da energia elettrica (ad esempio apparecchi utilizzatori di gas), s i deve

provvedere ad una aerazione sufficiente dell’ambien te. Se la cucina ne fosse

sprovvista, praticare un’apertura che comunichi con l’esterno, per garantire il

richiamo d’ari a pulit a.

USO

• La Cappa è stata progettata esclusivamente per uso domestico, per abbattere

gli odori della cucina.

• Non fare mai uso improprio della C appa.

• Non lasciare fiamme libere a forte intensità sotto la Cappa in funzione.

• Regolare sempre le fiamme in modo da evitare una evidente fuoriuscita laterale delle stesse rispetto al f ondo delle pe ntole.

• Controllare le friggitrici durante l’uso: l’olio surriscaldato potrebbe infiammarsi.

• Non preparare alimenti flambè sotto la cappa da cucina; pericolo d'incendio.

• Questo apparecchio non deve essere utilizzato da persone (bambini inclusi)

con ridotte capacità psichiche, sensoriali o mentali, oppure da persone senza

esperienza e conoscenza , a meno che non siano controllati o istruiti all’uso

dell’apparecchio da persone responsabili della loro sicurezza.

• I bambini devono essere supervisionati per assicurarsi che non giochino con

l’apparecchio.

MANUTENZIONE

• Prima di procedere a qualsiasi operazione di manutenzione, disinserire la

Cappa togliendo la spina elettrica o spegnendo l’interruttore generale.

• Effettuare una scrupolosa e tempestiva manutenzione dei Filtri secondo gli

intervalli consigliati.

• Per la pulizia delle supe rfici della Cappa è sufficiente utilizzare un pan no umido e detersivo liquido neut ro.

Loading...

Loading...