Frank Door TS723 Installation Manual

TS723 Power Operator Instructions

413 HOWARD BLVD.

NEWPORT, NC 28570

252.223.1112

888.833.DOOR (3667)

FAX: 252.223.1116

TS723

(Model Years 12/06 thru current)

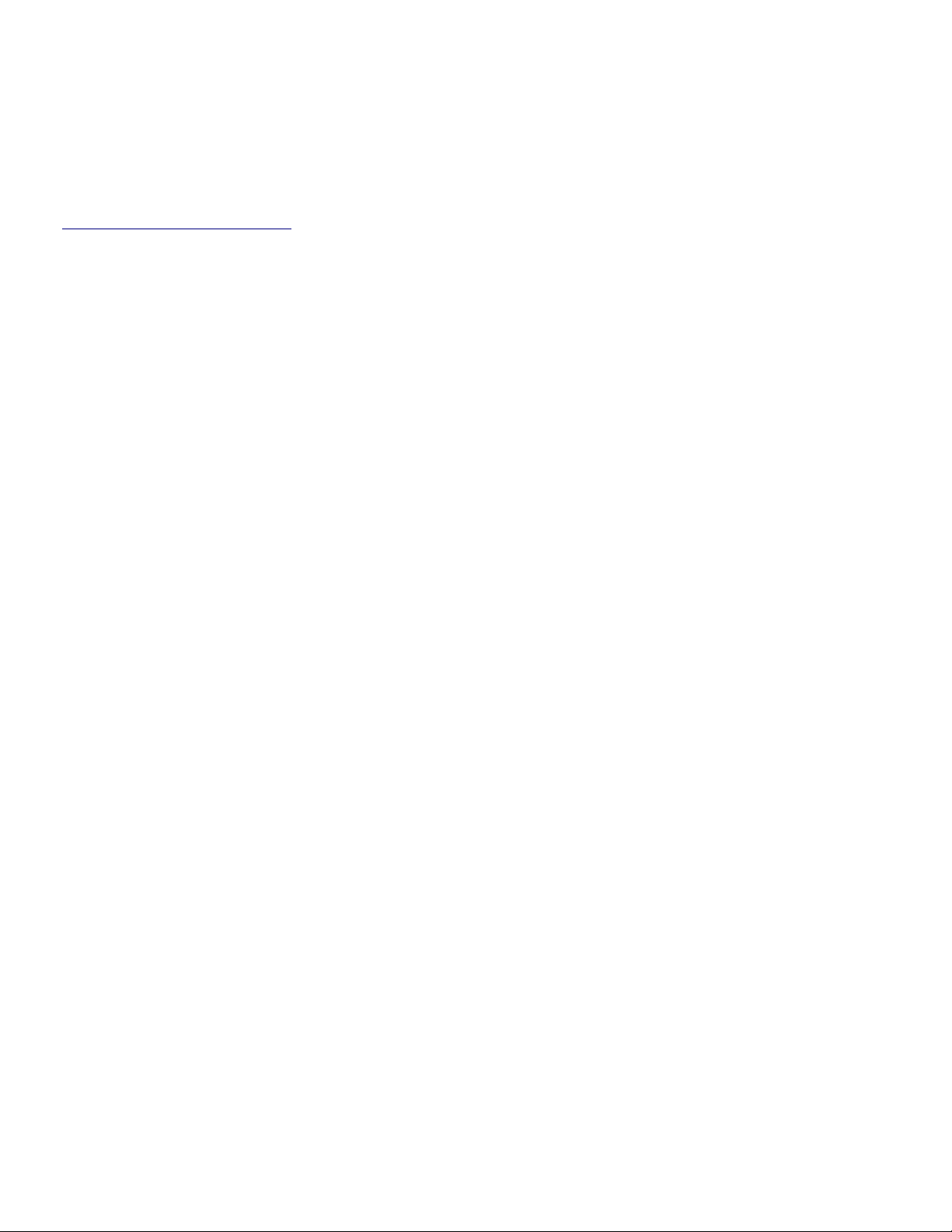

Microprocessor Control System for three-phase drive units

The TS723 self-positioning control system is designed for three-phase motors to open

and close sliding doors and is to be used for industrial applications only. The acceleration

and deceleration of the motor is adjustable as well as the travel speed of the door. The

positions of the door are controlled by an integrated position control system (encoder). As

the drive unit is equipped with a position control system, the TS723 control system

recognizes this automatically. Both drive unit and control system are electronically

protected against damage from overload or a short circuit. All programming and

adjustments are carried out with membrane keys located on the outside of the closed

case - after all connections have been done. For safety reasons, no adjustments are

possible within the case.

http://www.frankdoor.com/TS723_PowerOperator_Instructions.htm (1 of 16)3/17/2008 8:24:17 AM

TS723 Power Operator Instructions

TECHNICAL DATA

Mains voltage 208 / 230 / 400 / 460 / 480 VAC / 1 / 60

Power consumption 4.0 amps

Output voltage (secondary) 24VDC

Power supply (secondary) max. 1020 mA

Output voltage to motor 230 VAC (3-phase)

Motor rating max. 370 watts

Dimensions HxWxD = 6 1/2" x 20 1/2" x 4 5/8"

I. Electrical Connection

I/1 Connection of external devices

Connect all wires (maximum length: 90 feet) from the external devices (operating

switches, reversing edges, etc.) to the external leads of the controller per instructions

below in Section I/2 & I/3. When using the control system together with drive units with an

electronic position control system (encoder), no additional limit switches are required. The

encoder is recognized automatically by the control system. Make sure there is a lockable

switch in the supply line to control system that will cut off the power supply completely.

Furthermore, a separate fuse must be provided on the site to protect the supply line

and the connection terminals of the control system.

I/2 Wiring connections for pull switch stations, 2-button switch, locks

Note: Pull switch stations & 2-button switches (if supplied) must be wired normally

open & in parallel. Locking device (if supplied) must be wired normally closed & in

series with reversing edge.

Connect pull switch stations to leads labeled "Pull Switch/Push Button" (Wires 1 & 2)

Connect "Open/Close" feature of 2-button switch (if supplied) to leads labeled "Pull Switch/

http://www.frankdoor.com/TS723_PowerOperator_Instructions.htm (2 of 16)3/17/2008 8:24:17 AM

TS723 Power Operator Instructions

Push Button" (Wires 1 & 2)

Connect "Partial Open" feature of 2-button switch (if supplied) to leads labeled "Partial

Open" (Wires 7 & 8)

Connect locking device (if supplied) to leads labeled "Lock/Stop"

I/3 Wiring connections for reversing edge

Plug in leads from reversing edge to connector on trailing edge side of header. On

biparting doors, there is a connector on each side of header.

I/4 Wiring connections for photocell (if applicable)

Run wires from terminals 1 & 3 (in photocell) to leads labeled "Reversing Edge" (Wires 5

& 6)

Run wires from power supply terminals (in photocell) to leads labeled "24 Volt/Aux

Power" (Wires 9 & 10. Note that wire #9 is the hot lead)

Make sure that photocell switch is set to "LIGHT"

Note: If using a photocell & reversing edge together, they MUST be wired in series

I/5 Wiring connections for radio receiver (if applicable)

Radio receiver is pre-wired in the factory. If a radio receiver is added after initial

installation:

Connect RED wire from radio receiver to lead labeled "24 Volt/Aux Power" (Wire 9)

Connect BLACK wire from radio receiver to lead labeled "24 Volt/Aux Power" (Wire 10)

Connect GRAY wires from radio receiver to leads labeled "Pull Switch/Push

Button" (Wires 1 & 2)

I/6 Wiring connections for D38 motion detector (if applicable)

#1 wire from motion detector to a 24 volt transformer

http://www.frankdoor.com/TS723_PowerOperator_Instructions.htm (3 of 16)3/17/2008 8:24:17 AM

TS723 Power Operator Instructions

#2 wire from motion detector to a 24 volt transformer

#3 wire from motion detector to lead labeled "Pull Switch/Push Button"

#4 wire from motion detector to lead labeled "Pull Switch/Push Button"

Dips on motion detector

#1 - on

#2 - off

#3 - off

#4 - on

Note: Both "Open" & "Close" Controls must be set at "Full Travel"

"Automatic Closing" must be set to "On"

Please follow manufacturer's instructions for all other motion detectors.

I/7 Location of fuses

FUSE F1: T 4.0 A Main fuse (time-lag fuse)

(Complete 230V AC supply)

http://www.frankdoor.com/TS723_PowerOperator_Instructions.htm (4 of 16)3/17/2008 8:24:17 AM

TS723 Power Operator Instructions

II. Adjustment/Programming

All adjustments and programming are carried out with the membrane keys and the LCD

display on the lid of the control system. On the following page, you will find the adjustment

menu with all adjustable functions and values. Please mark in the right hand column, the

values you adjusted in your control system. Detailed information on how to adjust the

speeds and the positions of the door can be found on pages 8 and 9.

WARNING: Never make any adjustments when the door is moving!

II/1 Operation

1) Switch on the mains power supply. The LCD display on the lid will show for a short

time, the number of the software update used in this control system. Afterwards, it

switches to "Find Encoder Limits Automatically - ENT". (Do not press "ENTER" at this

time. See Section II/3 Adjustment/Programming on the following page.)

2) You can choose between English, German, Franch, Italian, and Spanish (the default is

set to English).

http://www.frankdoor.com/TS723_PowerOperator_Instructions.htm (5 of 16)3/17/2008 8:24:17 AM

Loading...

Loading...