Frank Door T1000 Service Manual

SHOCK HAZARD:

Before opening the controller, wait ve minutes for stored energy to dissipate.

Failure to do so may result in painful electrical shock causing injury and/or death

T1000

Microprocessor Control System

Troubleshooting Guide

This Unit Is Wired For:

120/1/47-63

208/1/47-63

230/1/47-63

400/1/47-63

460/1/47-63

480/1/47-63

(Fuses on Page 8)

1

www.frankdoor.com

Start-Up and

Date:_____________

Customer:_____________

Door Size:_____________

Door S/N:_____________

Controller S/N:_____________

Motor S/N:_____________

_____________

The American Standard for Cold Storage Doors

toll free (888) 833-3667 phone (252) 223-1112 fax (252) 223-1116

Frank Door Company © September 2012-100

Input Voltage 120/208/230/400/460/480 VAC

120 VAC at 16 Amps Max

240 VAC at 8.5 Amps Max

480 VAC at 4.3 Amps Max

Motor Output: 230V 60Hz 3Ph

Motor Load: 370 Watt Max

Technical Data

47-63 Hz, 1Ph

Aux. Voltage: 24 VDC

Aux. Load: 1 Amp Max.

Enclosure NEMA 4

THE BEST IN COLD STORAGE DOOR

AUTOMATION

The T1000 microprocessor-based operator

provides unprecedented control and exibility

in a variety of cold storage applications.

At the push of a button, the T1000 operator

sets its own limits and offers multiple points of

control. Once encoded, the system will never

forget its limits. The microprocessor controls

door position, opening and closing speeds,

partial openings and time-delay closing.

It is fully integrated and does not require

maintenance-prone torque limiters or limit

switches, eliminating constant maintenance

and safety issues.

The system assesses surrounding climate to

intelligently maintain component temperature

enabling applications below 0°C (32 °F). The

system has been designed to handle frequent

openings and closings in the toughest

conditions.

The front-end power factor corrector (PFC)

automatically transforms any voltage from 100

VAC to 230 VAC. A transformer is available

for higher voltages. This conguration allows

for safe installation in facilities where voltage

can uctuate.

Additional features include soft start and stop,

a touch pad display, password protection, a

cycle counter, electronic overload protection

and sophisticated internal diagnostics. There

are no internal control system options to add.

Frank Door Company offers the best drive system

available backed by unprecedented technical

support. Technical support for the system is

available Monday - Friday, 8am - 5pm EST.

2

www.frankdoor.com

The American Standard for Cold Storage Doors

toll free (888) 833-3667 phone (252) 223-1112 fax (252) 223-1116

Frank Door Company © September 2012-100

START-UP ELECTRICAL CONNECTIONS

A/1 Connection of External Devices

Connect all wires from the external devices (loop detectors, pull cords, push buttons, motion detectors,

etc.) to the external leads of the controller per instructions below in Section A/2 & A/9 (leads are located

in service box mounted to controller labeled “24 volts”). This drive system utilizes an encoder, no

additional limit switches are required. The encoder is recognized automatically by the control system.

Make sure there is a lockable switch in the supply line to control the system that will cut off the power

supply completely. Furthermore, a separate fuse must be provided on the site to protect the

supply line and the connection terminals of the control system.

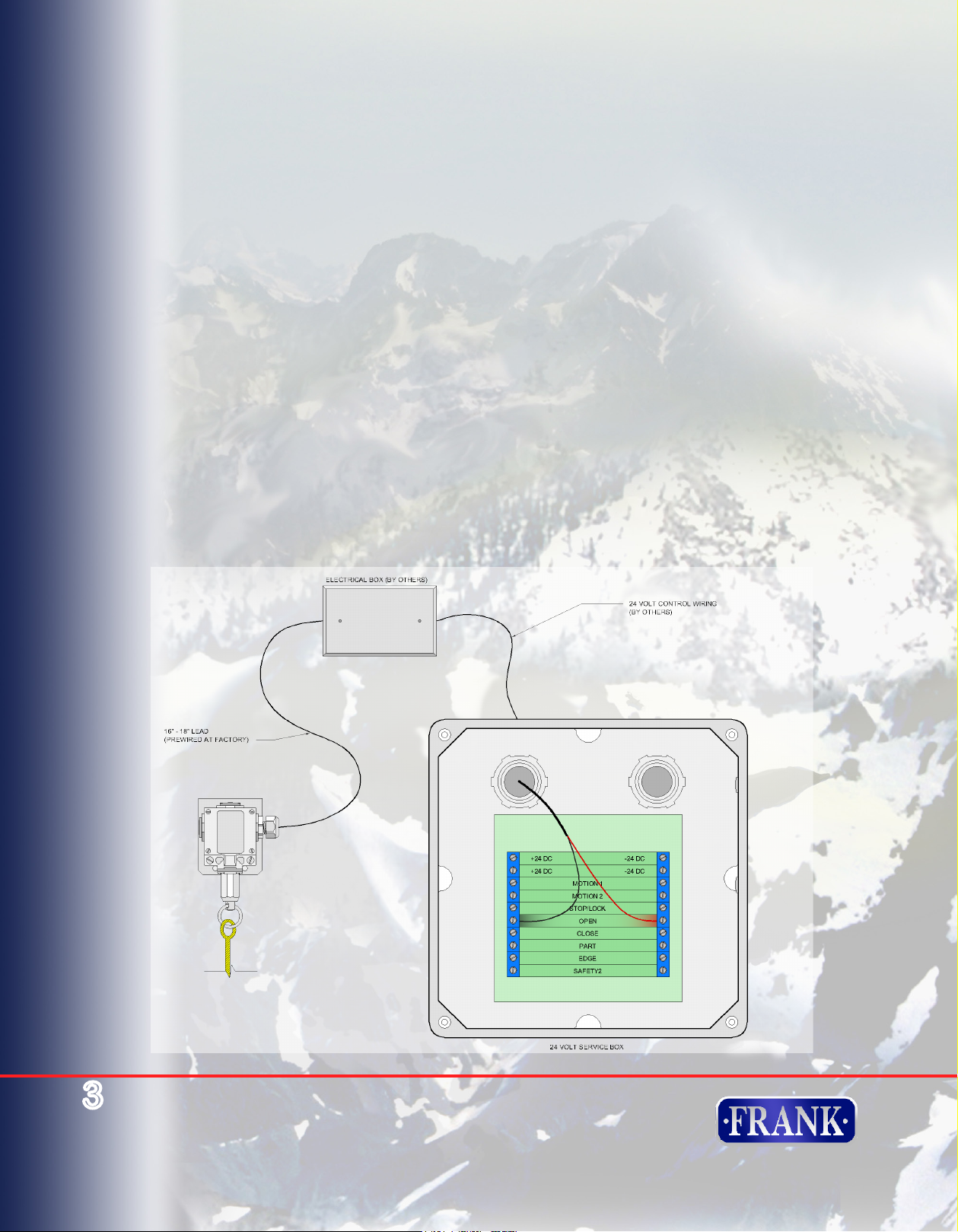

A/2 Wiring Connections for Pull Cord

Note: Pull switch stations & 2-button switches (if supplied) must be wired normally open & in

parallel.

1) Mount pull cord switch at desired location

2) Mount electrical box near pull cord switch

3) Run pre-wired lead into electrical box

4) Connect pre-wired lead to 24 volt control wiring inside electrical box

5) Run low voltage (24v) control wire from electrical box to 24 volt service box

6) Run red wire to open right bus

7) Run black wire to open left bus

3

www.frankdoor.com

The American Standard for Cold Storage Doors

toll free (888) 833-3667 phone (252) 223-1112 fax (252) 223-1116

Frank Door Company © September 2012-100

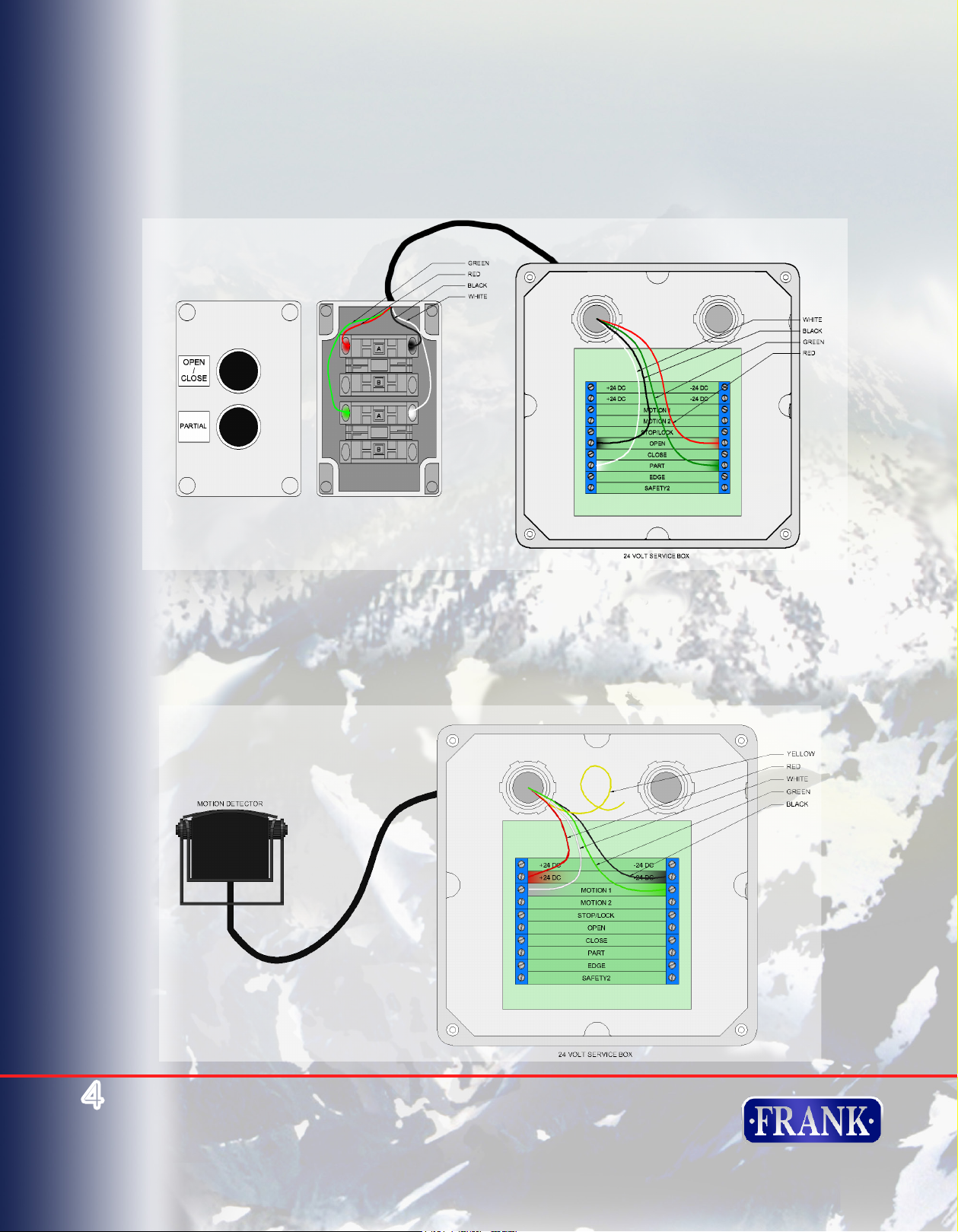

A/3 Wiring Connections for Pull Switch Stations, 2-button switch

Note: Pull switch stations & 2-button switches (if supplied) must be wired normally open & in parallel.

Connect pull switch stations to terminals labeled “OPEN”

Connect “Open/Close” feature of 2-button switch (if supplied) to terminals labeled “OPEN”

Connect “Partial Open” feature of 2-button switch (if supplied) to terminals labeled “PARTIAL OPEN”

A/4 Wiring Connections for Motion Detector (if supplied)

Connect RED to +24VDC left bus

Connect BLACK to -24VDC right bus

Connect WHITE to Motion 1 left bus

Connect GREEN to Motion 1 right bus

If using 2 motion detectors, wire extra WHITE and GREEN wire to Motion 2

4

www.frankdoor.com

The American Standard for Cold Storage Doors

toll free (888) 833-3667 phone (252) 223-1112 fax (252) 223-1116

Frank Door Company © September 2012-100

A/5 Wiring Connections for Radio Receiver (if supplied)

Radio receiver is pre-wired in the factory. If a radio receiver is added after initial installation:

Connect RED wire from radio receiver to terminal labeled “+24 VDC” on left bus

Connect BLACK wire from radio receiver to terminal labeled “-24 VDC” on right bus

Connect GRAY wires from radio receiver to terminals labeled “OPEN”

A/6 Hasp Lock

Connect BLACK wire from Hasp Lock to terminal labeled “Stop/Lock” on right bus

Connect RED wire from Hasp Lock to terminal labeled “Edge” on right bus

Connect WHITE wires from Hasp Lock to terminal labeled “Edge” on left bus

5

www.frankdoor.com

The American Standard for Cold Storage Doors

toll free (888) 833-3667 phone (252) 223-1112 fax (252) 223-1116

Frank Door Company © September 2012-100

Loading...

Loading...