Frank Door EFD-SOM User Manual

Model EFD-SOM

The FRANK Manual Sectional Overhead Door is

used where there is minimum side room and head

room or when several door openings are in close

proximity, such as on warehouse loading docks.

Suitable for interior and exterior applications in

coolers, freezers and industrial buildings. Available

in standard lift or high lift, depending on the amount

of clearance.

Standard Features

Panel

No Wood Construction

24 Gauge Metal

Extruded Aluminum Inner Frame

.040 Embossed Aluminum Skins

Internal Steel Corner Brackets

Insulation

At Least 4” Thick, R32 Foamed In Place Polyurethane

Bulb Style Casing Mounted Gasket

Adjustable Bottom Door Sweep

Track System

12 Gauge Galvanized Steel J Track with 3” Wheels

Heavy Duty Hardware

Side Casings and Header

Insulated Extruded Aluminum

Torsion Spring Counter Balance System

Handles

Stainless Steel / Polymer Exterior Pull Handles

Recessed Interior Pull Handle

Freezer Doors

Three Sided Heat in the Frame

Self Regulating Heated Door Panel

Protected Heat Chase

U.L. Listed Heater

Sectional Overhead

Manual Cold Storage Door

PRODUCT DATA

Options

Panel

Other Metal Finishes And Colors Available

Molded Fiberglass Door Panels Available

Diamond Tread Or Stainless Steel Kickplates

Triple Pane Heated View Window

6” Thick Panels Available

Hardware

Lock

Side Casings and Header

Jamb Caps

Return Jambs

Rain Hood

Extruded Aluminum Back Up Header and Casings

Other Metal Finishes and Colors Available

As the Frank Door Company constantly strives to build the highest quality products for performance and value,

the design, specifications, materials, features and prices are subject to change without notice.

The New American Standard in Cold Storage Doors

Frank Door Company 413 Howard Blvd., Newport, North Carolina USA 28570

www.frankdoor.com Toll Free (888)833-3667 Phone (252)223-1112 Fax (252)223-1116

Sectional Overhead

Manual Cold Storage Door

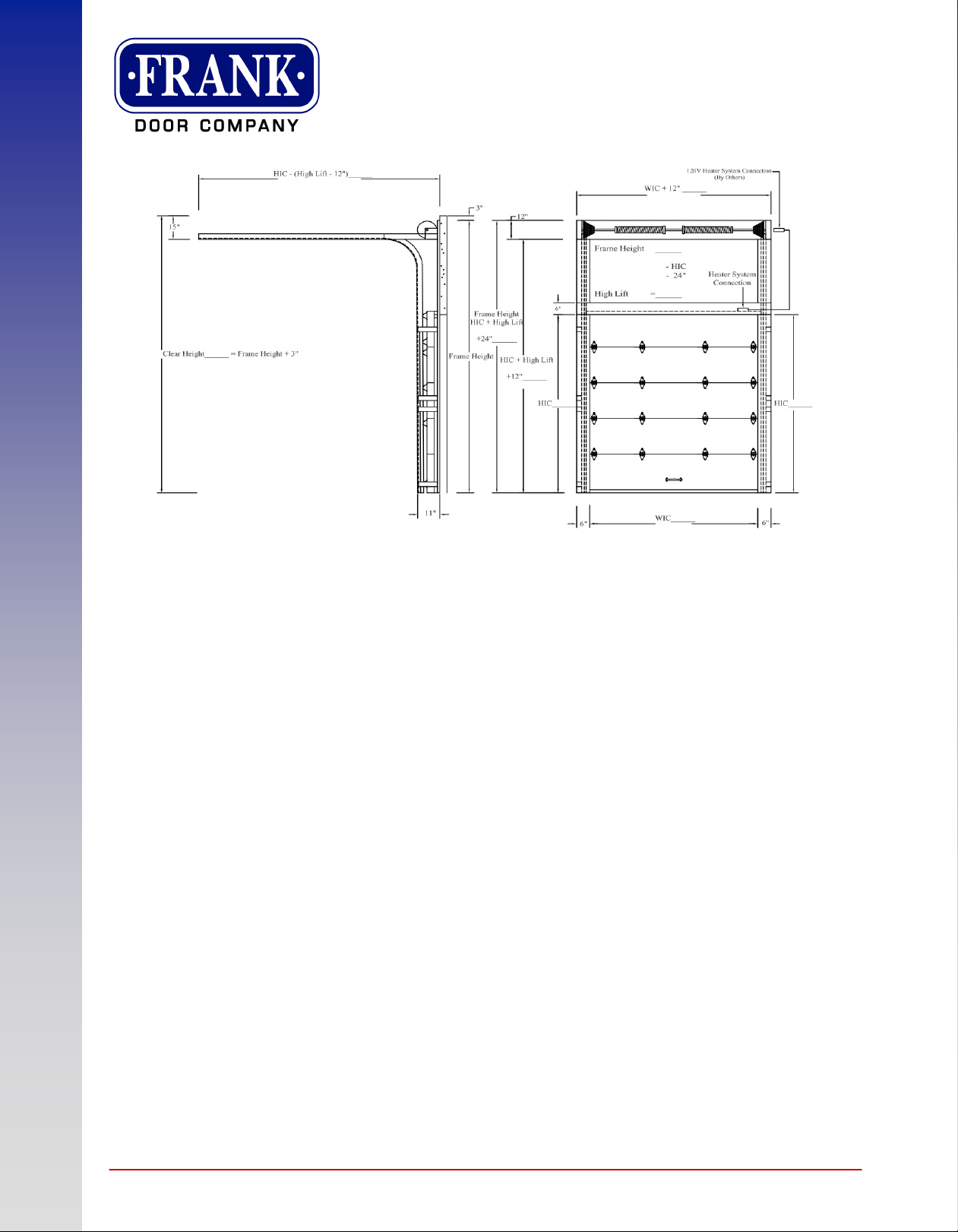

Downloadable drawings and CSI formatted specifications are available at www.frankdoor.com

Sectional Overhead Manual Cold Storage Door

Division 13

Section 13010

Cold Storage Doors Section 08 38 00

Part 1 - General

1.0.1 Scope

Work required under this section shall include the furnishing of all labor, materials, tools, and

equipment necessary to complete all work as detailed on the drawings and/or as specified herein.

1.0.2 Product

Supply, where indicated on the plans, a Frank Door Model EFD-SOM (sectional overhead

manual cold storage door). Door panel frames shall be constructed of an aircraft grade aluminum extrusion with steel corner reinforcements and clad with a choice of metal skins. Door

panels shall contain at least 4” of foamed-in-place polyurethane insulation (R32). Insulated wall

casings and header shall be aircraft-grade aluminum extrusions. Track shall be “J” style track

with torsion spring counterbalance system. Gasketing shall be casing-mounted bulb gasket seal.

Panel shall have exterior and interior pull handles. All hardware and mechanisms shall be

corrosion resistant materials. All freezer doors shall be equipped with a full perimeter, regulated

heater cable. No organics such as wood or wood composites shall be used in the door panel,

casings or header. Doors shall be built to NSF standards.

1.0.3 Substitutions

This specification is written with Frank Door Company EFD-SOM as the basis of acceptable

materials, construction and performance. No substitutions will be considered unless written

request for approval is received in the architect’s office at least 14 days prior to the release of the

bids.

DRAWINGS & SPECIFICATIONS

1.0.4 Submittals

In compliance with the specification requirements, submit detailed shop drawings for each door,

showing in clear detail of all mounting requirements and accessories.

1.0.5 Quality Assurance

Doors shall be installed in accordance with the architect's plans and specifications and the door

manufacturer's written installation instructions, drawings and recommendations. Doors shall

carry a 5 year limited warranty for the door panel, door frame, trim, vertical casings and header

and a 2 year limited warranty on all other Frank Door Company manufactured components with

the exception of typical wear components. Frank Door Company also warrants all products or

component parts not manufactured by Frank Door Company to the same extent that they were

warranted by the original manufacturer to the Frank Door Company.

Part 2 - Product

2.0.1 Material

Casings/Header

Extruded aluminum profiles with insulated with polystyrene inserts. (Matching back up headers and

casings are optional. Return jambs are optional. Jamb caps are optional.) Gaskets shall be casing

mounted bulb style. No organics such as wood or wood composites shall be accepted. All sweep

bottom freezer doors shall be equipped with a heater cable in the three sided casing frames. All high

sill freezer doors shall be equipped with a full perimeter heater cable in the casing frames.

Track System

12 gauge, galvanized steel J track with 3 inch diameter panel mounted rollers and torsion spring

counter balanced assembly. Gasketing shall be a casing mounted bulb gasket.

Door Panel

The door panel shall be constructed aircraft grade aluminum inner frame with steel corner brackets

and clad with two USDA approved 24 gauge steel or .040 aluminum face sheets (Smooth white and

stainless steel face sheets are optional). Backup blocking is used at all hinge, roller, and handle

attachment points. The panel is foamed-in-place with at least 4” of polyurethane insulation (R32).

Threshold gasket to be bottom mounted bulb style compression seal. (Optional triple pane window

shall be sealed, heated, heat reflective and made with tempered safety glass with metal frame. Aluminum diamond plate and stainless steel kick plates are optional.) No organics such as wood or wood

composites shall be used for the door panel structure or blocking. All freezer doors shall be equipped

with a full perimeter, regulated heat cable.

Door Hardware

Exterior and interior pull handles. Locking provision provided. All hardware and mechanisms shall

be corrosion resistant materials.

Part 3 - Execution

3.0.1 Installation

Doors shall be mounted in full accord with the door manufacturer installation instructions and contract documents. When mounting the door casings, header and track, the mounting surfaces shall be

set true and level, be shimmed and caulked to assure tightness and fit, securely lagged or through

bolted to the wall structure. After the doors are hung, they shall be checked for mechanical operation

and adjusted to insure a tight and uniform perimeter gasket seal. Connection of any panel or window

heating is the responsibility of the electrical contractor.

3.0.2 Product Delivery, Storage and Handling

Each cold storage door shall be securely crated so as to protect the door from damage during shipment

and handling. Door identification number shall be clearly marked on the outside of each crate.

3.0.3 Cleaning and Adjustment

Clean all doors of excess sealant, grease, stains, fingerprints and construction dust prior to final

inspection to the satisfaction of the architect/owner. Adjust all doors for smooth, proper operating

condition, including proper sealing and lubrication, prior to turnover of facility to owner.

The New American Standard in Cold Storage Doors

Loading...

Loading...