Frank Door EFD-DSD Installation Manual

SWING DOOR

INSTALLATION INSTRUCTIONS

TRADITIONAL

SWING DOOR

DOOR COMPANY

413 HOWARD BLVD.

NEWPORT, NC 28570

1.888.833.3667

FAX 252.223.1116

WWW.FRANKDOOR.COM

DO NOT DISCARD

11

INSTALLATION GUIDELINES

FOR SWING DOORS

BEFORE YOU INSTALL YOUR DOOR

PLEASE REVIEW THESE BASIC GUIDELINES

Note to Installer: Provide a copy of these

instructions to the building owner. By installing

this product, you acknowledge the terms and

conditions of the limited warranty as part of the

terms of the sale.

Failure to install square, level, plumb and on a

flat plane (without twist or warp) could result

in denial of warranty claims for operational or

performance problems.

ALL DOORS MUST BE INSTALLED

BY EXPERIENCED QUALIFIED COLD

STORAGE DOOR INSTALLERS.

1. All doors & frames must be installed plumb

and square to insure proper operation, seal and

warranty. Any walls out of plumb will require

that the door frames be shimmed back to plumb.

2. All headers and side casings should be

securely fastened to the wall.

3. Doors mounted on insulated panels should

have backup casing frames to help secure the

face casing & door to the opening.

4. Doors mounted on very tall panel walls will

require support steel to be added to the wall

around the door opening. Support steel, if

required, is to be supplied and specified by

others.

TOOLS REQUIRED:

MEASURING TAPE

RATCHET SET

SCREWDRIVERS

PRY BAR

WRENCHES

UTILITY KNIFE

HAMMER

4 LARGE CLAMPS

CAULKING GUN

SILICONE CAULK

BACKER ROD

SHIMS

DRILL

DRILL BITS

SAFETY GLASSES

RECIPROCATING SAW

RUBBER MALLET

FASTENERS FOR WALL TYPE IF NOT

ORDERED WITH DOOR

ELECTRICAL CONNECTIONS FOR

FREEZERS AND HEATED WINDOWS

IMPORTANT: All electrical work must

comply to the National Electric Code as

well as any state or local requirements.

All electrical work must be performed by

a licensed electrician.

NOTICE TO ELECTRICAL CONTRACTOR

5. The exterior and interior edges of the entire

door frame should be caulked with

silicone to prevent any moisture migration

behind the components that may cause frost or

sweating.

DO NOT activate heater cable

before bringing box down to desired

temperature. Doing so will result in

damage to door panel assembly and will

void warranty.

All heaters: Frame Heaters, Bottom Door

Heater and Window heaters are 115 V AC

( unless specified differently) and must

be connected to a DEDICATED 15 AMP

Circuit Breaker.

2

INSTALLATION PROCEDURES FOR

SWING DOORS

1. Check & inspect all crates for damage.

PURCHASER/RECEIVER SHOULD

NOTIFY THE FACTORY IMMEDIATELY OF

ANY DAMAGE, UNLESS DOORS WERE

SHIPPED THIRD PARTY.

2. Measure the opening for the door.

Check the packing slip attached to the

crate to verify that you have ordered

and received the correct size door

for the opening WIC X HIC. (FINISHED

OPENING)

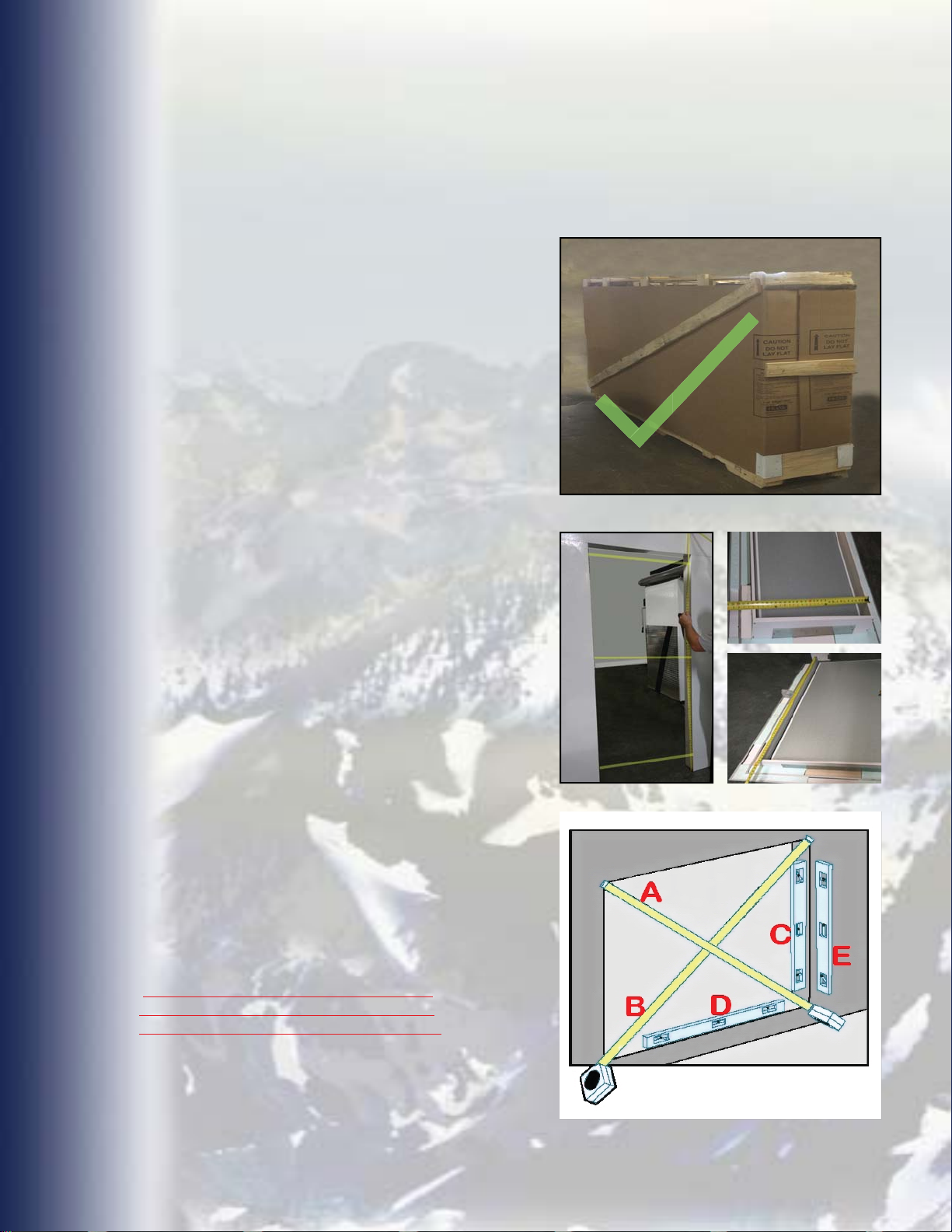

3. Verify the finished / rough opening is

square. The (A) and (B) measurements

should be the same. Verify the rough

opening is level and plumb (C) and (D).

The maximum allowable deviation is 1/8”.

The exterior face of the box wall must be

in a single plane (E) with less than 1/8”

deviation from corner to corner.

Any walls out of plane will require that

the door frame’s casing be shimmed to

the same plane to achieve a proper seal.

33

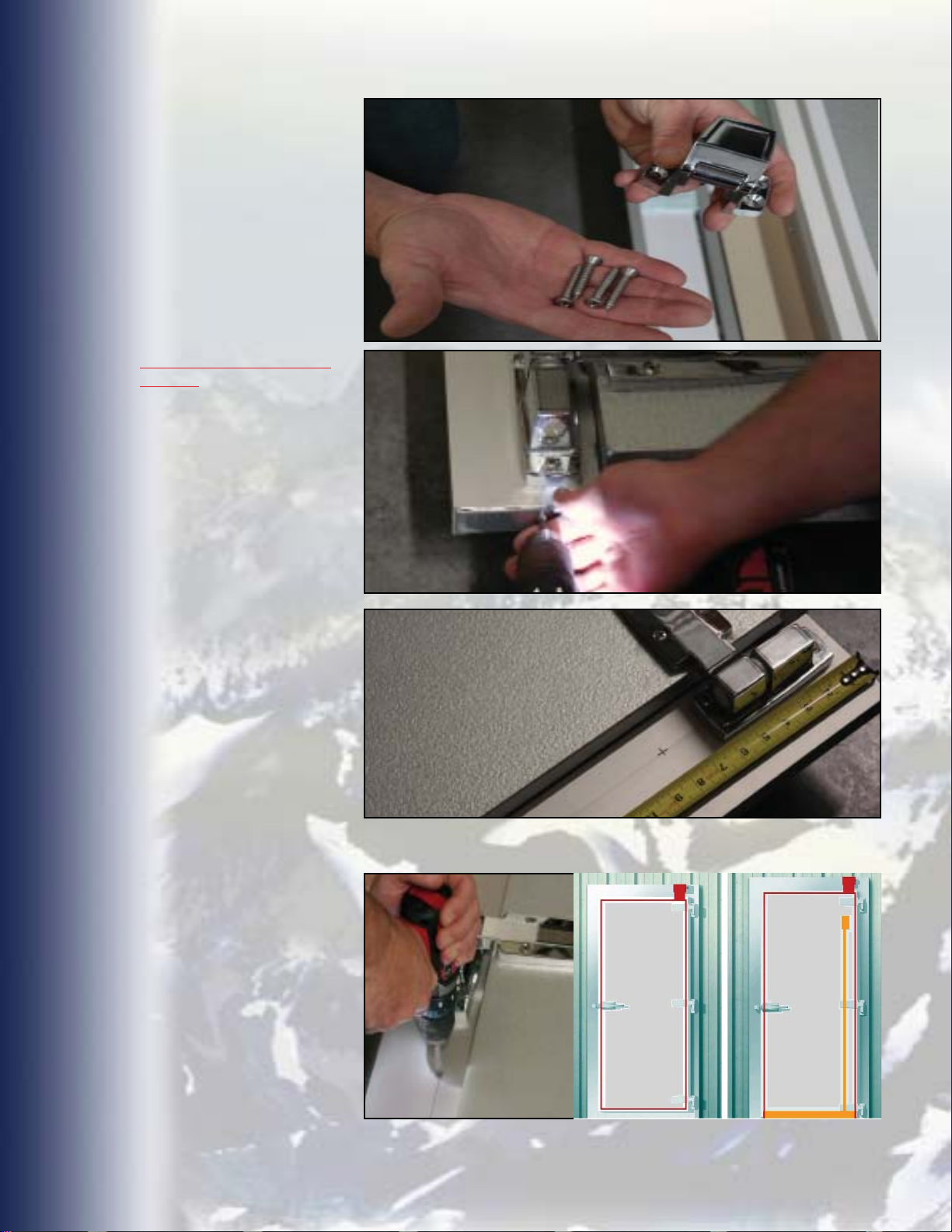

4. Lay uncrated door face

up. If assembly has a three

sided frame, remove only

the screws from the bottom

shipping strap using a #2

Philips Head. (On a swing

door with a chrome latch,

locate strike on back of

hinge side casing. With a #3

Philips Bit or Screw driver,

remove screws holding

strike assembly to blocking

without stripping heads.

Do not misplace strike or

screws!

5. It is recommended that

pilot holes be drilled in

casing frame.

6. Mark the height locations

for fasteners on your frame.

The first should be approx.

8” - 10” above the floor.

They should then be

spaced approx. 24” - 30”

apart.

Once you have marked the

height locations on your

side casings, go to each

mark:

Remove Screws & Strike from Back

of the Face Casing. DO NOT MISPLACE

STRIKE OR SCREWS!

Remove Screws From Shipping Strap

6” Wide Casings

From the

in 3 1/4” and mark.

4” Wide Casings

From the

in 1 1/4” and mark.

outer edge

outer edge

7. Using a 1/8” drill bit, drill

pilot holes at marks.

ON FREEZER DOOR

ASSEMBLIES : DO NOT

DRILL FRAME IN AREA

UNDER JUNCTION BOX!

Before drilling any holes,

check area around opening

(on exterior and interior

sides of walls) and insure

there are no obstructions,

electrical conduit or

junction boxes in way of

entire door and frame

assembly.

measure

Mark Location of Fastener

measure

Drill Out Pilot Hole

Marks, Using an

1/8” Drill Bit.

DO NOT DRILL FRAME IN AREA

UNDER JUNCTION BOX.

4

Loading...

Loading...