Frank Door EFD-DACS User Manual

Model EFD-DACS

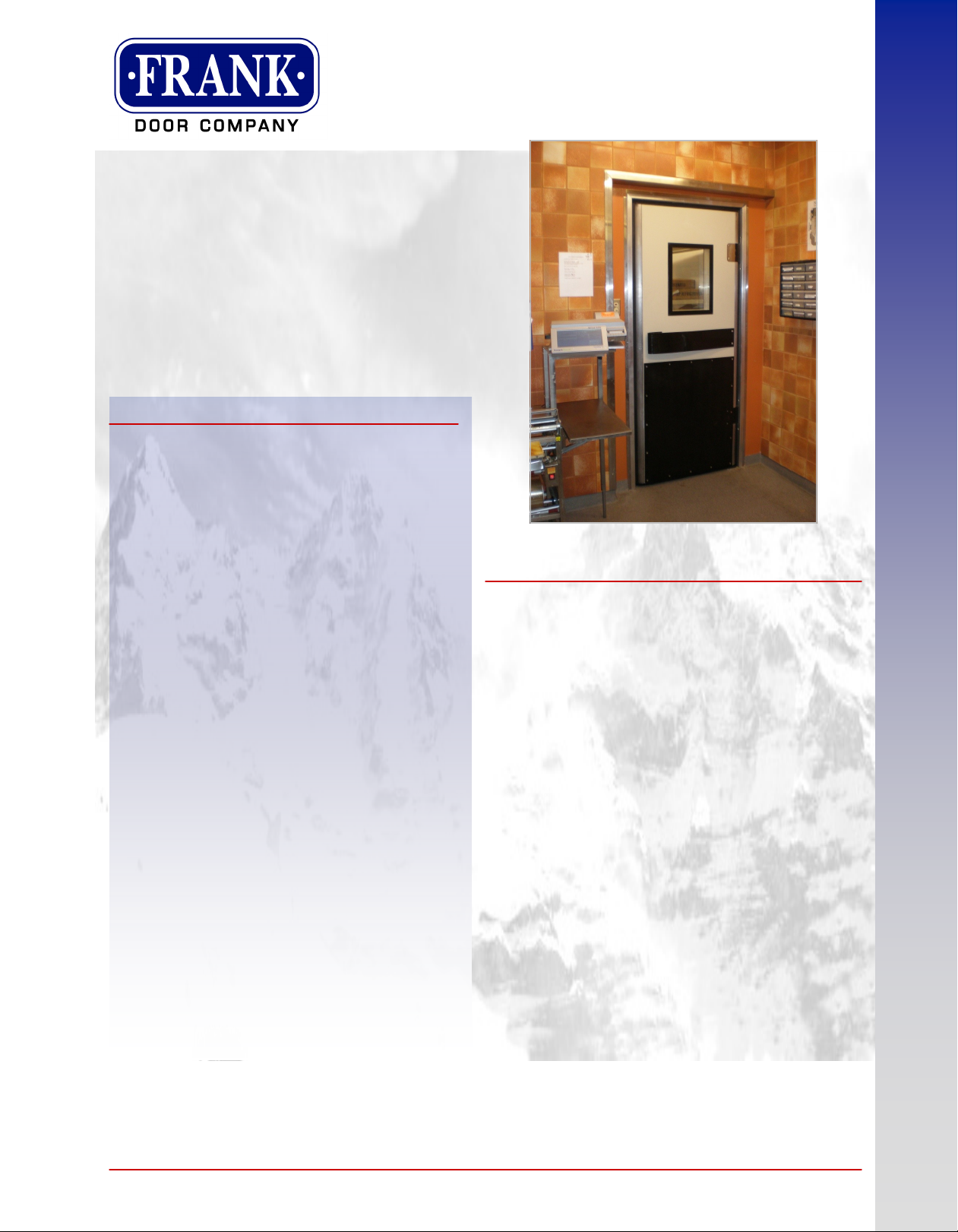

The FRANK ColdSwing Double Acting Cold Storage

Door is used for personnel, hand truck and pallet

jack traffic. It assures quick and easy, hands-free

access between separated environmentally

controlled spaces. It’s an excellent option to

facilitate the continuous movement of personnel,

hand truck and pallet jack traffic in cooler

applications. The door is an excellent visual and

performance match to a traditional cold storage

door.

Standard Features

Panel

24 Gauge Metal Skins

.040 Embossed Aluminum Skins

Extruded Aluminum Full Radius Nose Guard

Extruded Aluminum Full Radius Jamb Gaurd

Full Perimeter Thermal Break

42” Black HDPE Impact Plates

20” Black HDPE Impact Plates with 6” Spring Bumpers

Insulation

At Least 3.5” Thick, R25 Foamed In Place Polyurethane

Dual Blade, Full Perimeter, Panel Mounted Santoprene Gasket

Hardware

Stainless Steel and UHMWPE Full Washdown No-Rise Hinges

Sealed, Heat Reflective, Argon Filled, Safety Glass Window

Door Frame

Extruded Aluminum with Integrated Thermal Break

3 Piece Knock Down Frame

ColdSwing

Double Acting Cold Storage Door

PRODUCT DATA

Options

Panel

Other Metal Finishes and Colors Available

Spring Bumpers

As the Frank Door Company constantly strives to build the highest quality products for performance and value,

the design, specifications, materials, features and prices are subject to change without notice.

The New American Standard in Cold Storage Doors

Frank Door Company 413 Howard Blvd., Newport, North Carolina USA 28570

www.frankdoor.com Toll Free (888)833-3667 Phone (252)223-1112 Fax (252)223-1116

ColdSwing

Double Acting Cold Storage Door

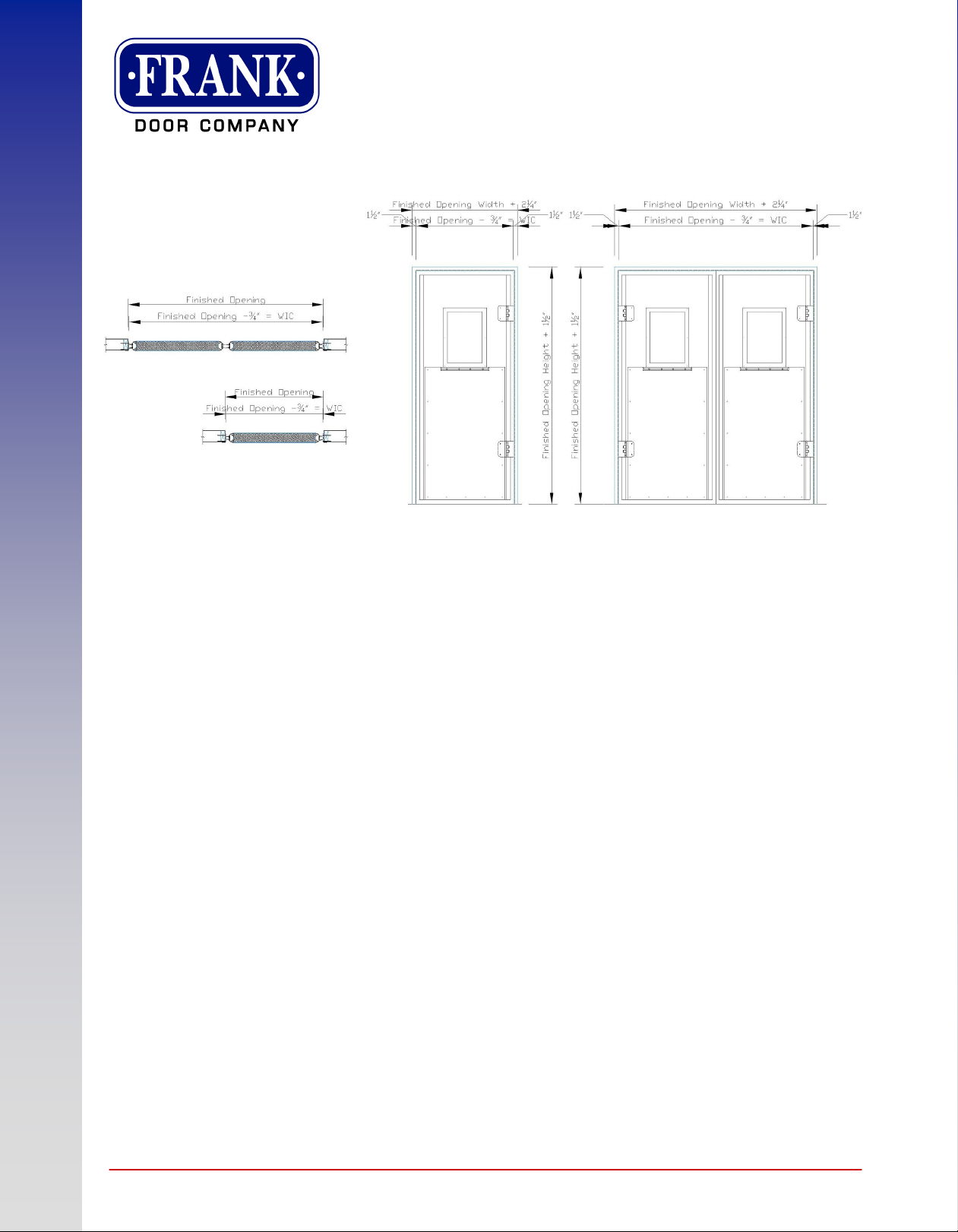

Downloadable drawings and CSI formatted specifications are available at www.frankdoor.com

Double Acting Cold Storage Traffic Door.

Division 13

Section 13010

Cold Storage Doors Section 08 38 00

Part 1 - General

1.0.1 Scope

Work required under this section shall include the furnishing of all labor, materials, tools, and

equipment necessary to complete all work as detailed on the drawings and/or as specified herein.

1.0.2 Product

Supply, where indicated on the plans, a Frank Door ColdSwing EFD-DACS (double acting

insulated cold storage door). Door leaf shall have leading and rear edge protection constructed

of aircraft-grade aluminum extrusions with integrated thermal break. The door panel shall be

clad with choice of metal skins. Door panel shall contain at least 3.5” (R28) of foamed-in-place

polyurethane insulation. Impact or kick plates are standard. Full perimeter gasket seal and

double pane window is standard. Hinges shall be no rise and double acting. Knock-down frame

shall be aircraft-grade aluminum extrusions with integrated thermal break. All hardware and

mechanisms shall be corrosion resistant materials. Doors shall be built to NSF standards and

come complete with all components required for installation.

1.0.3 Substitutions

This specification is written with Frank Door Company’s EFD-DACS as the basis of acceptable

materials, construction and performance. No substitutions will be considered unless written

request for approval is received in the architect’s office at least 14 days prior to the release of the

bids.

DRAWINGS & SPECIFICATIONS

1.0.4 Submittals

In compliance with the specification requirements, submit detailed shop drawings for each door,

showing in clear detail all mounting requirements and accessories.

1.0.5 Quality Assurance

Doors shall be installed in accordance with the architect's plans and specifications and the door

manufacturer's written installation instructions, drawings and recommendations. Doors shall

carry a 5 year limited warranty on the door panel, door frame and trim and 2 year limited

warranty on all other Frank Door Company manufactured components with the exception of

typical wear components. Frank Door Company also warrants all products or component parts

not manufactured by Frank Door Company to the same extent that they were warranted by the

original manufacturer to the Frank Door Company.

Part 2 - Product

2.0.1 Material

Frame Jamb and Header

Half-wrap, extruded aluminum frame with integrated thermal break. Door leaves come pre-mounted

to jambs.

Door Panel

Full radius leading and jamb edges are aircraft-grade aluminum extrusions with integrated thermal

break. The panel shall have at least 3.5” of foamed-in-place polyurethane insulation (R28) between

two USDA approved 24 gauge steel or .040 aluminum face sheets. (Stainless steel face sheets are

optional.) Gasketing shall be a panel mounted, full perimeter, dual blade Santoprene gaskets. Double

pane window shall be sealed, argon gas filled, heat reflective, tempered safety glass with metal frame.

HDPE impact plate or stainless steel kick plate is standard. All hardware and mechanisms shall be

corrosion resistant materials.

Hinges

No-rise, full wash-down, dual internal compression spring double acting hinges are constructed from

stainless steel and UHMWPE.

Part 3 - Execution

3.0.1 Installation

Doors shall be mounted in full accord with the door manufacturer installation instructions and contract documents. The mounting surfaces shall be set true and level, be shimmed and caulked to assure

tightness and fit, securely lagged or through bolted to the wall structure. After the doors are hung,

they shall be checked for mechanical operation and adjusted to ensure a tight and uniform perimeter

gasket seal.

3.0.2 Product Delivery, Storage and Handling

Each cold storage door shall be securely crated so as to protect the door from damage during shipment

and handling. Door identification number shall be clearly marked on the outside of each crate.

3.0.3 Cleaning and Adjustment

Clean all doors of excess sealant, grease, stains, fingerprints and construction dust prior to final

inspection to the satisfaction of the architect/owner. Adjust all doors for smooth, proper operating

condition, including proper sealing and lubrication, prior to turnover of facility to owner.

The New American Standard in Cold Storage Doors

Loading...

Loading...