Page 1

福田风景系列轻型客车

使用与维修手册

OPERATION AND MAINTENANCE MANUAL

FOR FOTON VIEW SERIES LIGHT BUS

北汽福田汽车股份有限公司

BEIQI FOTON MOTOR CO.,LTD.

Page 2

内 容 简 介

BRIEF INTRODUCTION

福田风景系列轻型客车是北汽福田汽车股份有限公司生产的主导产品,本《福田风景系

列轻型客车使用与维修手册》较详细地介绍了风景系列轻型客车的技术维护,BJ491EQ1、

BJ483ZQB、BJ486ZQ、YC4F90-21、2RZ-E、4G64S4 等发动机构造、使用、维修、故障排除,

汽车底盘、电器与仪表构造、保养及故障排除、部分车辆主要技术参数等内容。

本书可供风景系列轻型客车使用、维护、修理人员参考。

FOTON VIEW series light bus is the leading product of Beiqi Foton Motor Corporation. This

Operation and Maintenance Manual for FOTON VIEW Series Light Bus introduces in details the

technical maintenance of VIEW series light bus; structure, operation, maintenance and

troubleshooting of BJ491EQ1, BJ483ZQB, BJ486ZQ,YC4F90-21,2RZ-E,4G64S4 engines; main

technical parameters for structure, maintenance and troubleshooting of automobile chassis,

electricals and instruments etc.

This manual offers a reference for user and service personnel of VIEW series light bus.

北汽福田汽车股份有限公司

BEIQI FOTON MOTOR CO., LTD.

福田风景系列轻型客车

使用与维修手册

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW

SERIES LIGHT BUS

北汽福田汽车股份有限公司编

COMPIlED BY BEIQI FOTON MOTOR CO., LTD.

Printed by Chengshun Paper and Plastic Printing House of Langfang City

开本:889mm×1194mm(大 16 开) 22 印张 字数 76.89 千字

Format: 889mm×1194mm (big 16 format) Printing Papers Words Kiloword

2006 年 8 月北京第一版 2006 年 8 月第一次印刷

August , 2006 First Edition, Beijing August, 2006 First Print

印数 0~1000 册

Impression 0~1000 copies

Page 3

前 言

PREFACE

福田风景系列轻型客车是北汽福田汽车股份有限公司在引进日本技术的基础上,根据用

户需求进一步研制开发的系列轻型客车。该系列轻型客车采用 BJ491EQ1、BJ483ZQB、

BJ486ZQ、YC4F90-21、2RZ-E、4G64S4 等汽、柴油发动机;采用了平、半高顶、高顶车身;

淡化仿桃木豪华内饰、动力转向、电动窗、遥控锁、电动后视镜、后照地灯、后组合尾灯、

钻石前大灯、内外温度显示器、高位刹车灯、后暖风、CD/调频一体机、VCD 机、中控锁、

高靠背可调座椅、分体空调等;尾气排放达排放法规的要求,特别适用于各地区城乡使用。

VIEW series light bus has been developed to meet the demands of our customers based on the

technology introduced from Japan. The light buses adopts BJ491EQ1,BJ483ZQB、BJ486ZQ,

YC4F90-21,2RZ-E,4G64S4 gasoline and diesel engines; the buses among the series adopts

flat/half high/ high roof bodies, they equip with peach wood imitated luxury interior trim, power

steering, power window, remote lock, power rear view mirrors, rear floor lamps, rear combination

tail lamps, diamond headlamps, interior and exterior temperature display, high mount brake lamp,

rear warm wind, combination of CD/FM, VCD player, central lock, high back adjustable seat and

individual A/C etc. The vehicles complies with emission regulations, they are ideal vehicles for city

and rural areas.

风景系列轻型客车具有良好的安全性、动力性、经济性、舒适性、操作稳定性和环保性,

自投放市场以来深受广大用户的欢迎。

VIEW series light bus features safety, strong power, economy and comfortability. They also

have good performances such as stable operation and environment friendship. They have been very

popular since the day they were put into market.

汽车性能的保持、发挥以及使用寿命的长短、可靠性等,一方面取决于汽车设计和制造

过程中的质量,另一方面取决于用户的正确使用和精心维护、汽车维修厂正确的修理。为了

使广大用户和维修单位对风景系列轻型客车使用与维修有一个较全面的了解,掌握该车的使

用、维护与修理方法,延长车辆的使用寿命,我们特编写这本《福田风景系列轻型客车使用

与维修手册》。本手册系统地介绍了风景系列轻型客车整车技术性能;几种发动机构造、使用、

维护、修理和故障排除;底盘、电气设备的维护和检修;汽车维护保养制度等。

Maintaining and implementation of vehicle performance and service life / reliability depend on

its orignal quality during design and manufacturing, as well as correct operation and careful

Page 4

maintenance or repair by the user and service garage. This Operation and Maintenance Manual for

VIEW Series Light Bus tends to make the operation and maintenance of VIEW series light bus

known to the users and service stations, so that they could master vehicles’ operation, maintenance

and repair methods to prolong service life of the vehicle. This manual introduces systmatically

VIEW series light bus’s technical performance. It includes the structure, operation, maintenance,

repair and troubleshooting of several engine models; also in this manual are maintenance and repair

of chassis and electrical equipment as well as maintenance system of the vehicle.

本书可供风景系列轻型客车使用、维护、修理人员参考。

This manual offers a reference for user and service personnel of VIEW series light bus.

由于编写时间仓促,资料缺乏,书中难免有不足之处,恳请广大读者批评指正。

Any comment to this manual is highly appreciated.

编 者

Author

2006 年 8 月

August, 2006

Page 5

TABLE OF CONTENTS

·1·

目 录

TABLE OF CONTENTS

第一章 风景系列轻型客车主要数据资料

Chapter1 Main data and specification of View series light-bus…………………………………1

1.1 风景系列轻型客车主要数据与规格

1.1 Main data and specification of VIEW series light-bus……………………………………………………… 1

1.2 BJ491EQ1 发动机技术资料

1.2 Technical data of BJ491EQ1 gasoline engine……………………………………………………………… 23

1.3 BJ486ZQ 柴油发动机技术资料

1.3 Technical specification of BJ486ZQ diesel engine………………………………………………………… 29

1.4 YC4F90-21 发动机技术资料

1.4 Technical specification of YC4F90-21 diesel engine……………………………………………………… 31

1.5 2RZ-E 发动机技术资料

1.5 Model 2RZ-E Engine Technical specification………………………………………………………………33

1.6 4G64S4 发动机技术资料

1.6 Technical data of 4G64S4 engine……………………………………………………………………………43

第二章 汽车技术维护

Chapter 2 Vehicle Technical Maintenance………………………………………………………51

2.1 日常维护

2.1 Routine Maintenance………………………………………………………………………………………… 51

2.2 一级维护

2.2 First level maintenance……………………………………………………………………………………… 52

2.3 二级维护

2.3 Second level maintenance…………………………………………………………………………………… 54

2.4 走合期维护

2.4 Run-in maintenance……………………………………………………………………………………………60

2.5 换季维护

2.5 Seasonal Maintenance…………………………………………………………………………………………60

2.6 全车润滑

2.6 Vehicle lubrication…………………………………………………………………………………………… 61

第三章 BJ491EQ1 汽油机构造与调整维修

Chapter 3 Structure, Adjustment and Service of BJ491EQ1 Gasoline Engine…………… 63

3.1 气缸盖部件

3.1 Cylinder head parts ………………………………………………………………………………………… 63

3.2 气缸体部件

3.2 Cylinder block parts ………………………………………………………………………………………… 71

3.3 曲柄连杆机构

3.3 Crank-connecting rod mechanism ……………………………………………………………………………76

3.4 配气机构

3.4 Valve train …………………………………………………………………………………………………… 79

3.5 润滑系统

Page 6

·2·

3.5 Lubrication system ……………………………………………………………………………………………84

3.6 冷却系统

3.6 Cooling system ……………………………………………………………………………………………… 85

3.7 起动系统

3.7 Starting system ……………………………………………………………………………………………… 88

3.8 充电系统

3.8 Charging system ………………………………………………………………………………………………90

3.9 曲轴箱通风装置

3.9 Crankcase ventilator ………………………………………………………………………………………… 91

3.10 离合器

3.10 Clutch ……………………………………………………………………………………………………… 91

FOTON OPERATION AND MAINTENANCE MANUAL FOR VIEW SERIES LIGHT BUS

第四章 BJ491EQ1 汽油机的燃油喷射系统

Chapter 4 BJ491EQ1 Gasoline Engine Fuel Injection System …………………………… 94

4.1 德尔福电控燃油喷射系统简介

4.1 Introduction of Delphi Electronic Control Fuel Injection (EFI) System………………………………………94

4.2 德尔福电控燃油喷射系统零部件

4.2 Parts and Components of Delphi EFI System ……………………………………………………………… 96

第五章 BJ491EQ1 汽油机的使用

Chapter 5 Application of BJ491EQ1 Gasoline Engine ……………………………………112

5.1 安全操作规定

5.1 Regulations for safe operating………………………………………………………………………………112

5.2 油料和冷却液

5.2 Fuel, oil and cooling fluids …………………………………………………………………………………112

5.3 起动前的准备

5.3 Preparations before Startup …………………………………………………………………………………114

5.4 起动步骤

5.4 Startup Proedures ……………………………………………………………………………………………114

5.5 怠速及暖机

5.5 Idle Speed & Warm-up ………………………………………………………………………………………115

5.6 运转期间的检查

5.6 Check during Running ………………………………………………………………………………………115

5.7 停车

5.7 Shutdown ……………………………………………………………………………………………………115

5.8 零件保护

5.8 Component Protection ………………………………………………………………………………………115

5.9 跛行回家

5.9 Limp in ………………………………………………………………………………………………………116

5.10 使用注意事项

5.10 Precautions during Operation ………………………………………………………………………………116

第六章 BJ491EQ1 汽油机的技术保养

Chapter 6 Technical Maintenance of BJ491EQ1 Gasoline Engine ……………………… 117

6.1 技术保养周期

6.1 Technical maintenance interval …………………………………………………………………………… 117

6.2 技术保养内容

Page 7

TABLE OF CONTENTS

6.2 Content of technical maintenance ………………………………………………………………………… 117

6.3 润滑系统的技术保养

6.3 Technical maintenance for lubrication system …………………………………………………………… 118

6.4 冷却系统的技术保养

6.4 Technical maintenance for cooling system …………………………………………………………………119

6.5 燃油系统的技术保养

6.5 Technical maintenance for fuel system………………………………………………………………………119

6.6 进气系统的技术保养

6.6 Technical maintenance for air intake system ……………………………………………………………… 120

·3·

第七章 BJ491EQ1 汽油机故障与排除方法

Chapter 7 BJ491EQ1 Gasoline Engine Faults and Troubleshooting …………………… 121

7.1 汽油机故障排除常识

7.1 Gasoline engine troubleshooting summary …………………………………………………………………121

7.2 汽油机电控燃油喷射系统故障诊断基础

7.2 Diagnosis basics -- gasoline engine electronic fuel injection system…………………………………………121

7.3 汽油机电控燃油喷射系统故障诊断注意事项

7.3 Notes to diagnosis - gasoline engine electronic fuel injection system ………………………………………121

7.4 汽油机故障排除方法

7.4 Gasoline engine troubleshooting procedures ……………………………………………………………… 122

第八章 BJ486ZQ 柴油机的构造与调整维修

Chapter 8 Structure, Adjustment and Service of BJ483ZQB Diesel Engine …………… 131

8.1 柴油机维护调整须知

8.1 Precautions on Service and Adjustment of Diesel Engine ………………………………………………… 131

8.2 柴油机维护与调整

8.2 Service and Adjustment of Diesel Engine ………………………………………………………………… 131

第九章 柴油机故障与排除方法

Chapter 9 Diesel Engine Faults and Troubleshooting………………………………………145

9.1 柴油机起动困难

9.1 Hard start-up…………………………………………………………………………………………………145

9.2 柴油机低温起动困难

9.2 Hard start-up at low temperature…………………………………………………………………………… 146

9.3 柴油机功率不足

9.3 Insufficient power……………………………………………………………………………………………146

9.4 柴油机运转时有异常杂音

9.4 Abnormal noise during operation……………………………………………………………………………147

9.5 柴油机排气烟色不正常

9.5 Abnormal exhaust gas color…………………………………………………………………………………148

9.6 柴油机机油压力不足

9.6 Lower oil pressure……………………………………………………………………………………………148

9.7 柴油机冷却系统冷却液温度失常.缺液

9.7 Abnormal coolant temperature or coolant short…………………………………………………………… 149

9.8 柴油机增压系统故障

9.8 Supercharging system fault …………………………………………………………………………………150

9.9 起动电机不运转.起动无力.发出噪音

Page 8

·4·

9.9 Starter does not run, weak start up or noise…………………………………………………………………151

9.10 发电机不发电.充电电流小或充电电流过大

9.10 Alternator does not work, lower or higher charging current………………………………………………151

9.11 蓄电池容量不足.自放电过大

9.11 Lower battery volume, higher self-discharging……………………………………………………………152

9.12 冷起动预热系统故障

9.12 Cold-start preheating system faults…………………………………………………………………………152

9.13 水泵电磁风扇离合器故障

9.13 Water pump electro-magnetic fan clutch fault………………………………………………………………153

FOTON OPERATION AND MAINTENANCE MANUAL FOR VIEW SERIES LIGHT BUS

第十章 底盘构造与修理

Chapter 10 Chassis Structure and Service …………………………………………………156

10.1 离合器

10.1 Clutch ………………………………………………………………………………………………………156

10.2 变速器

10.2 Transmission ……………………………………………………………………………………………… 163

10.3 传动轴

10.3 Propeller shaft ………………………………………………………………………………………………179

10.4 后桥

10.4 Rear Axle ………………………………………………………………………………………………… 182

10.5 前桥

10.5 Front Axle ………………………………………………………………………………………………… 190

10.6 转向机构

10.6 Steering Mechanism ……………………………………………………………………………………… 199

10.7 悬架

10.7 Suspension …………………………………………………………………………………………………208

10.8 制动系统

10.8. Brake System ………………………………………………………………………………………………214

10.9 车轮

10.9 Wheel ………………………………………………………………………………………………………225

第十一章 电器及仪表结构.使用与修理

Chapter 11 Structure, Application and Serice of Electrical Devices & Instruments …… 232

11.1 电器系统概述

11.1 Electrical System Overview ……………………………………………………………………………… 232

11.2 保险盒

11.2 Fuse Box ……………………………………………………………………………………………………232

11.3 电器系统的故障及修理

11.3 Troubleshooting ……………………………………………………………………………………………232

11.4 电器配件

11.4 Electrical Devices ………………………………………………………………………………………… 235

11.5 组合仪表与辅助电器

11.5 Complex Instrument and Auxiliary Electrical Devices ……………………………………………………259

11.6 汽车空调

11.6 Air Conditioner ……………………………………………………………………………………………262

Page 9

TABLE OF CONTENTS

附录

Appendices

附录 1:匹配 BJ491EQ1 德尔福Ⅲ发动机豪华型整车电气原理图

Appendix:1 Vehicle (Luxury type) Circuit Diagram, with Delphi III BJ491EQ1 engine

附录 2:匹配 BJ483ZQB 发动机经济型整车电气原理图

Appendix:2: Vehicle (Economy type) Circuit Diagram, with BJ486ZQs engine

附录 3:匹配 2RZ-E 发动机整车电气原理图

Appendix3:Vehicle Circuit Diagram, with 2RZ-E engine

附录 4:匹配 BJ483ZQB 发动机整车电气原理图

Appendix4:Vehicle Circuit Diagram, with BJ483ZQB engine

附录 5:匹配 BJ491EQ1 德尔福Ⅲ发动机新电喷系统整车电气原理图

Appendix5;Vehicle (new EFI) Circuit Diagram, with Delphi III BJ491EQ1 engine

附录 6:匹配 BJ486ZQ 发动机整车电气原理图

Appendix6:Vehicle Circuit Diagram, with BJ486ZQ engine

附录 7:匹配 4YC4F90-21 发动机整车电气原理图

Appendix7:Vehicle Circuit Diagram, with 4YC4F90-21engine

附录 8:匹配 4G64S4 发动机整车电气原理图

Appendix8:Vehicle Circuit Diagram, with 4G64S4 engine

附录 9:匹配 4G64S4 发动机经济型整车电气原理图

Appendix 9:Vehicle (Economy type) Circuit Dirgram, with 4G64S4 engine

·5·

Page 10

Chapter 1 Main Data and Specification of VIEW Series Light-bus

Overall length

Overall width

rall hight

Wheel track

Min ground

Wheel base

Rear extension

Min turning

Chapter 1 Main data and specification

of VIEW series light-bus

1.1 Main data and specification of VIEW series light-bus

1.1.1 Main data and specification of VIEW BJ6486、BJ6516

Table 1-1 General data

Model

Drive type 4×2 rear axle drive

BJ6486

FB

BJ6486

HFB

BJ6486

J1F1B

BJ6486

H2F1

BJ6486

J1F2B

BJ6486

H2F2

BJ6486

HJ1F2B

BJ6486

B1DWA

BJ6486

J1FB

·1·

BJ6486

H1F

Seats (include

driver)

(mm)

(mm)

Ove

(mm)

(front

/rear)(mm)

clearance

(mm)

(mm)

Front

extension

(mm)

9~12 ← ← ← ← ← ← 6~15 ← 9~12

4900 ← 4970 ← ← ← ← ← ← 4900

1690 ← ← ← ← ← ← ← ← ←

1935 2205 1935 1995 1935 1995 2225

1450/14

30

165 ← ← ← ← ← ← ← ← ←

2590 ← ← ← ← ← ← ← ← ←

1200 ← 1270 ← ← ← ← ← ← 1200

←

1460/14

40

← ← ← ← ←

1935/19

95

1935 1995

1450/14

30

←

(mm)

diameter (m)

Approach

angle (°)

Departure

angle(°)

1110 ← 1110 ← ← ← ← ← ← ←

≤11.5

21 ← 20 ← ← ← ← ← ← 21

20 ← 20 ← ← ← ← ← ← ←

← ← ← ← ← ← ← ← ←

Page 11

·2·

include

Overall length

Overall width

Overall hight

Wheel track

Min Ground

Wheel base

Min Turning

included

← Overall length

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

Table 1-2 General data

Model

BJ648

HJ1FB

BJ648

H2F

BJ648

H2FB

BJ648J

1FC

BJ648

HJ1FC

BJ648

B1DW

A-8

BJ648

B1DW

A-6

Drive type 4×2 rear axle drive

BJ648

B1DX

A

BJ648

B1DX

A-1

BJ648

B1DX

A-2

BJ648

H1FB

Seats (

driver)

(mm)

(mm)

(mm)

(front/rear)

(mm)

clearance(mm)

(mm)

Front

extension

(mm)

Rear extension

(mm)

6~15 9~12

4970

1690

← ← ← ← 4900 4970

← ← ← ← ← ← ← ← ← ←

2205 1995

1450/1

430

← ← ← ←

← ← ← 6~15 6~12 6~15

← ← ← 4900

1935 2225 1935 2050

1460/1

440

← ← ← ← ←

2225 1995

← ← 9~12

165 ← ← ← ← ← ← ← ← ← ←

2590

1270

1110

← ← ← ← ← ← ← ← ← 1200

← ← ← ← ← ← ← ← ← ←

← ← ← ← ← ← ← ← ← ←

diameter(m)

Approach

angle (°)

Departure

angle (°)

≤11.5 ← ← ← ← ← ← ← ← ← ←

20 ← ← ← ← ← ← ← ← ← 21

20 ← ← ← ← ← ← ← ← ← 20

Note:“←”same as indicated value

Table1-3 General data

Model

BJ648

B1DW

A-1

BJ648

B1DW

A-2

BJ648

B1DW

A-3

BJ648

B1DW

A-4

BJ648

B1DW

A-5

BJ648

B1DW

A-7

Drive type 4×2rear axle drive

Seats (

driver )

(mm)

6~15 6~12 ← ← ← 6~15 6~9 6~15 10~15

4970 ← ← ← ← ← ← ← 5085 ←

BJ648

B1DW

A-9

BJ648

B1DW

C

BJ648

B1DW

A

BJ648

B1DW

A-1

Page 12

Chapter 1 Main Data and Specification of VIEW Series Light-bus

Overall width

Overall hight

Wheel track

Min grond

Min Turning

Approach angle

included

Overall length

Overall width

Overall hight

Wheel track

n Ground

·3·

Model

(mm)

(mm)

front/rear) (mm)

clearance(mm)

BJ648

B1DW

A-1

1690 ← ← ← ← ← ← ← ← ←

2225 1935 1995 2225 1995 2050 1935 1935 2050

1460/14

40

165 ← ← ← ← ← ← ← ← ←

BJ648

B1DW

A-2

BJ648

B1DW

A-3

BJ648

B1DW

A-4

BJ648

B1DW

A-5

BJ648

B1DW

A-7

BJ648

B1DW

A-9

BJ648

B1DW

C

BJ648

B1DW

A

← ← ← ← ← ← ← ← ←

BJ648

B1DW

A-1

Wheel base (mm) 2590 ← ← ← ← ← ← ← ← ←

Front

extension(mm)

Rear

extension(mm)

diameter(m)

1270 ← ← ← ← ← ← ← 1320 ←

1110 ← ← ← ← ← ← ← 1175 1110

≤11.5

← ← ← ← ← ← ← ← ←

(°)

Departure

angle(°)

20 ← ← ← ← ← ← ← ← 16

20 ← ← ← ← ← ← ← ← ←

Table 1-4 General data

Model

BJ6516

B1DW

A-2

BJ6516

B1DW

A-3

BJ6516

B1DW

A-4

BJ6516

B1DXA

BJ6516

B1DXA

-1

BJ6516

B1DXA

-2

Drive type 4×2rer axle dtive

Seats (

driver )

(mm)

(mm)

(mm)

← 6~9 10~15

← ← ← ← 6~9 10~15 6~9

← 5085 5085 ← ← ← ← ← ← ←

← ← ← ← ← ← ← ← ← ←

1935 ← ← 1935 ← 2050 ← 1995 ← ←

BJ6516

B1DXA

-3

BJ6516

B1DXA

-4

BJ6516

B1DXA

-5

BJ6516

B1DXA

-6

(front/rear)

(mm)

Mi

clearance(mm)

← ← ← ← ← ← ← ← ← ←

← ← ← ← ← ← ← ← ← ←

Page 13

·4·

Wheel base

Min turning

Curb weight

Front axle

Max total

Front axle

Min stable speed in D gear

full load at

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

Model

(mm)

Front

extension(mm)

Rear

extension(mm)

dismeter(m)

Approach angle

°)

Departure

angle(°)

Model

BJ6516

B1DW

A-2

BJ6516

B1DW

A-3

BJ6516

B1DW

A-4

BJ6516

B1DXA

BJ6516

B1DXA

-1

BJ6516

B1DXA

-2

BJ6516

B1DXA

-3

BJ6516

B1DXA

-4

BJ6516

B1DXA

-5

← ← ← ← ← ← ← ← ← ←

← ← ← ← ← ← ← ← ← ←

← 1175 1175 1110 ← ← ← ← ← ←

← ← ← ← ← ← ← ← ← ←

← ← ← 20 ← 16 ← ← ← ←

← ← ← ← ← ← ← ← ← ←

Table 1-5 Mass data

BJ6486

FB

BJ6486

HFB

BJ6486

J1F1B

BJ6486

H1F1

BJ6486

J1F2B

BJ6486

H2F2

BJ6486

HJ1F2B

BJ6486

B1DWA

BJ6486

J1FB

BJ6516

B1DXA

-6

BJ6486

H1F

(kg)

(kg)

Rear axle (kg) 750 760 762 760 700 765 770 700/715

mass (kg)

(kg)

1640 1700 1665 1710 1660 1715 1720 1660/1690 1670 1660

890 940 903 950 960 950 950 960/975

965 960

705 700

2516 2576 2541 2586 2536 2591 2596 2635/2665 2450 2440

1270 1300 1283 1310 1280 1310 1310 1105/1115 1025 1020

Rear axle (kg) 1246 1276 1258 1276 1256 1281 1286 1530/1550 1425 1420

Table 1-6 Operation data

Max speed ≥120 ← ≥130 ← ≥125 ← ← ≥120 ← ←

≤20 ← ← ← ← ← ← ← ← ←

Max climbing slope (%)

Brake distance (

50km/h) (m)

≥30 ← ← ← ← ← ← ← ← ←

≤22 ← ← ← ← ← ← ← ← ←

Fuel consumption

(L/100km)

≤9.5 ← ← ← ← ← ← ← ← ←

(average speed 50km/h)

Page 14

Model

Rear axle

Max total

Front axle

Rear xale

Min stable speed in D

full

Curb weight

Max tatal mass

Curb

weight (kg)

Front

axle(kg)

Chapter 1 Main Data and Specification of VIEW Series Light-bus

·5·

Table 1-7 Mass data

BJ6486

HJ1FB

BJ6486

H2F

BJ6486

H2FB

BJ6486

1FC

BJ6486

HJ1FC

BJ6486

B1DW

A-8

BJ6486

B1DW

A-6

BJ6486

B1DX

A

BJ6486

B1DX

A-1

BJ6486

B1DX

A-12

BJ6486

H1FB

1670 1680 1700 1680 1700 1660 1670 1660 1665 1740 1660

965 980 990 980 990 960 965 960 938 1000 960

(kg)

mass (kg)

(kg)

(kg)

705 700 710 700 710 700 705 700 727 740 700

2405 2556 2576 2556 2576 2635 2450 3635 2640 2715 2440

1025 1086 1096 1086 1096 1150 1070 1335 1300 1315 1020

1425 1470 1480 1470 1480 1530 1380 1300 1340 1400 1420

Table 1-8 Operation data

Max speed ≥120 ← ← ← ← ← ← ≥125 ≥130 ← ≥120

gear

≤20 ← ← ← ← ← ← ← ← ← ←

Max climbing slope (%) ≥30 ← ← ← ← ← ← ← ← ≥38 ≥30

Brake distance (m) (

load at speed 50km/h)

≤22 ← ← ← ← ← ← ← ← ≤19 ≤22

Fuel cansumption

(L/100km)

≤9.5 ← ← ← ← ← ← ← ← ← ←

(average speed 50km/h)

Note :“←” same as indicated value

Table 1-9 Mass data

Model

BJ6486

B1DW

A-1

BJ6486

B1DW

A-2

BJ6486

B1DW

A-3

BJ6486

B1DW

A-4

BJ6486

B1DW

A-5

BJ6486

B1DW

A-7

BJ6486

B1DW

A-9

BJ6486

B1DW

C

BJ6516

B1DW

A

BJ6516

B1DW

A-1

(kg)

1740 1660 1670 1740 1670 1670 1660 1740 1690 1690

Front axle (kg) 1110 960 965 985 965 965 960 985 975 970

Rear axle (kg) 730 700 705 755 705 705 700 755 715 720

(kg)

2715

Front axle (kg) 1145

Rear axle (kg) 1570

2050~2

440

860~11

05

1190~1

530

2060~2

450

865~11

10

1195~1

535

2130~2

520

895~11

40

1235~1

575

2050~2

645

865~11

10

1195~1

535

2615 2227 2715 2665 ←

1110 1140 1120 1135

1505 1575 1545 1530

Page 15

·6·

Min stable speed in D

Max climbing slope

full

average

Curb weight

Max total mass

Min stable speed in

Max climbing slope

full

average speed

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

Table 1-10 Operation data

Max Speed ≥120 ← ← ← ← ← ← ← ← ←

gear

(%)

Brake distance(

load at 50km/h)( m )

≤20

≥30

≤22

← ← ← ← ← ← ← ← ←

← ← ← ← ← ≥38

← ← ←

← ← ← ← ← ← ← ← ←

Fuel consuption

(L/100km)(

≤9.5

← ← ← ← ← ← ← ← ←

speed 50km/ h)

Table 1-11 Mass data

(kg)

Modle

BJ6516

B1DW

A-2

1700 1730 1730 1690 1695 1700 1705 1735 1735 1730

BJ6516

B1DW

A-3

BJ6516

B1DW

A-4

BJ6516

B1DXA

BJ6516

B1DXA

-1

BJ6516

B1DXA

-2

BJ6516

B1DXA

-3

BJ6516

B1DXA

-4

BJ6516

B1DXA

-5

BJ6516

B1DXA

-6

Front axle (kg) 980 900 900 980 978 980 980 905 905 905

Rear axle kg) 720 830 830 720 717 720 725 830 830 830

(kg)

2675 2297 2675 2665 2670 2645 2650 2302 2680 2297

Front axle (kg) 1140 1200 1405 1120 1123 1115 1110 1102 1280 1097

Rear axle (kg) 1530 1097 1270 1545 1547 1530 1540 1200 1400 1200

Table 1-12 Operation data

Max speed ← ← ← ≥125 ≥130 ≥125 ≥130

D gear (km/h)

(%)

Brake distance(

load at 50km/h (m)

← ← ← ← ← ← ≤22 ← ← ←

← ← ← ← ← ≥38 ← ← ← ←

← ← ← ← ← ← ≤19 ← ← ←

← ← ←

Fuel consumption

(L/100km)

(

← ← ← ← ← ← ← ← ← ←

50km/h)

Page 16

Chapter 1 Main Data and Specification of VIEW Series Light-bus

Engine cooling

Transmission oil

Engine cooling

Table 1-13 Volume data

BJ64

BJ64

Model

86

B1D

XA-1

86

B1D

XA-2

BJ64

86

J1F1

B

BJ64

86

H2F1

BJ65

16

BDX

A-1

BJ65

16

BDX

A-3

BJ64

86

J1F2

B

BJ64

86

HJ1F

2B

Fuel tank(L) 65

BJ64

86

H2F2

BJ64

86

B1D

XA

BJ65

16

B1D

XA

BJ65

16

B1D

XA-2

BJ65

16

B1D

XA-4

BJ65

16

B1D

XA-5

·7·

BJ65

16

B1D

XA-6

Used fuel (#)

Better than 93# non-lead gasoline

Engine

lubricating

4.3 5.2

system(L)

Oil SF class 10W/30 or 15W/40

system (L)

10.1

Anti -freezer Ethy lene anti –frezer (or anti –corrosive anti freezer ,do not use alcoholic anti freezer )

Transmission(L)

type

Gear oil GL-5 80W/90 in north (cold )China ,85W/90 for other regions

2.0

Rear axle(L) 1.6

Table 1-14 Volume data

Model

BJ6486

FB

BJ6486

HFB

BJ6486

H1F

BJ6486

H2F

BJ6486

H2FB

BJ6486

HFB

BJ6486

HJ1FB

BJ6486

J1FB

BJ6486

J1FC

BJ6486

HJ1FC

Fuel tank (L)

Used fuel (#)

Better than 93#non-lead gasoline

65

Engine

lubricating

4.2

system(L)

Oil SE class 10W/30 or 15W/40

system(L)

10.1

Anti -freezer Ethylene anti-freezer(or anti- corrosive anti-freezer,do not use alcoholic anti-freezer )

Transmission

(L)

Transmission

oil type

Rear axle (L)

Gear oil GL-5 80W/90 in north (cold )China,85W/90 for other area

2.0

2.2

Page 17

·8·

Engine cooling

Rear axle

discharged, max current

Model

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

Table 1-15 Volume data

BJ64

BJ64

BJ64

BJ64

BJ64

BJ64

BJ64

BJ64

BJ64

86

B1D

WA

86

B1D

WA-

1

86

B1D

WA-

2

86

B1D

WA-

3

86

B1D

WA-

4

86

B1D

WA-

5

86

B1D

WA-

6

86

B1D

WA-

7

86

B1D

WA-

8

BJ64

86

B1D

WA-

9

BJ65

16

B1D

WA

BJ65

16

B1D

WA-

1

BJ65

16

B1D

WA-

2

BJ65

16

B1D

WA-

3

BJ65

16

B1D

WA-

4

BJ64

86

B1D

WC

Fuel tank (L)

65

Fuel (#) Better than 93# non lead gasoline

Engine

lubrication

4.2

system (L)

Oil SE class 10W/30or 15W/40

system (L)

10.1

Coolant Ethylene anti-freezer(or anti corrosive anti frezer,do notuse alcoholic anti freezer area)

Transmission

(L)

Transmission

oil type

Rear axle(L)

Gear oil GL-5 80W/90 in north (cold) china,85W/90for other area

2.0 6.5

2.2

Table 1-16 Volume data

BJ6

Model

486

B1D

XA-

1

BJ64

86B1

DXA

-2

BJ64

86J1F

1B

BJ64

86H2

F1

BJ65

16BD

XA-1

BJ65

16BD

XA-3

BJ64

86J1F

2B

BJ64

86HJ

1F2B

BJ64

86H2

F2

BJ64

86B1

DXA

BJ64

86B1

DXA

BJ65

16B1

DXA

-2

BJ65

16B1

DXA

-4

BJ65

16B1

DXA

-5

BJ65

16B1

DXA

-6

oil

Brake

system (L)

Brake fluid

Battery

Refrigerant

(g)

Refrigerant

type

Gera GL-5 80W/90in north (cold )china ,85W/90for other area

1

V -3 –QC/T670 – 2000

At 20℃: concentration 1.28 (full charged);1.16(charged 50%);1.06(

15A during quick charging; 5A during slow charging

1400 1150

R134a

Page 18

Chapter 1 Main Data and Specification of VIEW Series Light-bus

discharged, max current

WA

Rear axle

discharged, max current

Refrigerant

Refrigerant

Spark plug

deflection

Table 1-17 Volume data

Model

BJ6486

FB

BJ6486

FB

BJ6486

H1F

BJ6486

H2F

BJ6486

H2FB

BJ6486

FB

BJ6486

HJ1FB

BJ6486

J1FB

BJ6486

J1FC

Gear oil Gear oil GL-5 80W/90in north (cold china,85W/90 for other aera

·9·

BJ6486

HJ1FC

Brake

system (L)

Brake fluid

Battery

Refrigerant

(g)

Refrigerant

type

Model

oil

Brake

system(L)

1

JG3# composed brake fluid

At 20℃: concentration 1.28 (full charged);1.16(charged 50%);1.06(

15A during quick charging; 5A during slow charging

1500

R134a

Table 1-18 Volume data

BJ648

6

B1D

BJ648

6

B1D

WA-1

BJ648

6

B1D

WA-2

BJ648

6

B1D

WA-3

BJ648

6

B1D

WA-4

BJ648

6

B1D

WA-5

BJ648

6

B1D

WA-6

BJ648

6

B1D

WA-7

BJ648

6

B1D

WA-8

BJ648

6

B1D

WA-9

Rear oil GL-5 80W/90,innorth (cold )china 85W/90 other area

1

BJ651

6

B1D

WA-2

BJ651

6

B1D

WA-3

BJ651

6

B1D

WA-4

BJ648

6

B1D

WC

Brake fluid

Battery

At 20℃: concentration 1.28 (full charged);1.16(charged 50%);1.06(

15A during quick charging,5A during slow charging

(g)

type

Model

clearance (mm)

Belt

(mm)

BJ648

6

B1DX

A-1

BJ64

86

B1D

XA-2

BJ64

86

J1F1

B

V-3-QC/T670-2000

1500

R134a

Table 1-19 Adjustment data

BJ65

BJ65

BJ65

BJ64

86

H2F1

16

BDX

A-1

16

BDX

A-3

BJ651

16

BDX

A-5

6

BDX

A-4

BJ64

86

J1F2

B

BJ64

86

HJ1F

2B

BJ64

86

H2F2

0.7~0.8 1.1

5~7 ←

BJ64

86

B1D

XA

BJ65

16

B1D

XA

BJ651

6

B1D

XA

Page 19

·10·

brake

Free angle of

Free travel of clutch

Free travel of brake

Steering wheel free

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

Model

Free travel -clutch pedal (mm)

Free travel-pedal (mm)

steering wheel (°)

BJ648

B1DX

6

A-1

BJ64

86

B1D

XA-2

BJ64

86

J1F1

B

BJ64

86

H2F1

BJ65

16

BDX

A-1

BJ65

16

BDX

A-3

BJ65

16

BDX

A-5

BJ651

6

BDX

A-4

BJ64

86

J1F2

B

BJ64

86

HJ1F

2B

BJ64

86

H2F2

5~15 ←

1~3 ←

≤20(from center to left) ←

BJ64

86

B1D

XA

Toe-in (mm) 3±1 ←

Camber (°) -0°20’ ±30’ ←

Kingpin

inclination

10°50’ ±30’ ←

Caster (°) 1°15’ ±30’ ←

Engine

Model 4G64S4M 2RZ-E

BJ65

16

B1D

XA

BJ651

6

B1D

XA

Type

Bore × stroke(mm

×mm)

In-line, water cooling ,four cylinders,four strokes, electronic control multi-point injection

gasoline engine

86.5×100 95×86

Displacement 2.350 2.438

Table 1-20 Adjustment data

Model

Spark plug clearance

(mm)

Belt deflection(mm)

pedal (mm)

pedal (mm)

angle (°)

Toe-in (mm)

BJ6486

FB

BJ6486

HFB

BJ6486

H1F

BJ6486

H2F

BJ6486

H2FB

BJ6486

0.8~1.0

5~7

5~15

1~3

≤20(From center to left)

3±1

HFB

BJ6486

HJ1FB

BJ6486

J1FB

BJ6486

J1FC

BJ6486

HJ1FC

Camber(°)

Kingpin inclination

Caster(°)

-0°20’ ±30′

10°50’ ±30′

1°15’ ±30′

Engine

Page 20

Chapter 1 Main Data and Specification of VIEW Series Light-bus

Spark plug clearance

Free travel of clutch

Steering wheel free

Kingpin incliniation

point Injection

Spark plug clearance

·11·

Model

BJ6486

FB

BJ6486

HFB

Model

Vertical ,in-line water cooling .four cylinder ,four strokes, electronic control one-point

Type

Bore×stroke(mm×

mm)

Displacement(L)

Note :“←” same as indicated value

Model

BJ6486

B1DWA

(mm)

Belt deflection (mm)

pedal (mm)

Free travel of brake

pedal(mm)

BJ6486

H1F

Table1-21 Adjustment data

BJ6486

B1DWA-1

BJ6486

H2F

BJ6486

B1DWA-2

BJ6486

H2FB

BJ6486

HFB

BJ6486

HJ1FB

491EQ

injection gasoline engine

91×86

2.237

BJ6486

B1DWA-3

BJ6486

B1DWA-4

0.8~1.0

5~7

5~15

1~3

BJ6486

J1FB

BJ6486

B1DWA-5

BJ6486

J1FC

BJ6486

B1DWA-6

BJ6486

HJ1FC

BJ6486

B1DWA-7

angle (°)

Toe in (mm)

Camber (°)

(°)

Caster (°)

Model

Type

Bore×stroke

(mm×mm)

Displacement(L)

Model

≤20(from center to lift)

3±1

-0°20’ ±30′

10°50’ ±30′

1°15’ ±30′

Engine

491EQ1

In-line, water cooling, four cylinders, four strokes, electronic control multi –

gasoline engine

91×86

2.237

Table1-22 Adjustment data

BJ6486

B1DWA-8

BJ6486

B1DWA-9

BJ6516

B1DWA

BJ6516

B1DWA-1

BJ6516

B1DWA-2

BJ6516

B1DWA-3

BJ6516

B1DWA-4

BJ6486

B1DWC

(mm)

Belt deflection (mm)

0.8~1.0

5~7

Page 21

·12·

Free travel of clutch

Free travel of brake

Steering wheel free

Rated power

Max torque

Idle speed

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

Model

pedal (mm)

pedal (mm)

angle (°)

BJ6486

B1DWA-8

BJ6486

B1DWA-9

BJ6516

B1DWA

BJ6516

B1DWA-1

BJ6516

B1DWA-2

5~15

1~3

≤20(from center to left)

Toe- in (mm) 3±1

Camber (°) -0°20’ ±30′

Kingpin inclination

10°50’ ±30′

Caster (°) 1°15’ ±30′

Engine

Model 491EQ1

Type

Bore ×strok

(mm×mm)

In-line, water cooling, four cylinders, four strokes, electronic control multi –point Injection

gasoline engine

91×86

BJ6516

B1DWA-3

BJ6516

B1DWA-4

BJ6486

B1DWC

Dispencement(L)

Note :“←” same as indicated value

BJ64

BJ64

BJ64

86

86

Model

B1D

XA-1

B1D

XA-2

86

J1F1

B

Compression

ratio

(kW)(r/min)

(N.m)(r/min)

(r/min)

During

Lubri

Idle

catin

speed

g oil

press

During

ure

runnin

(kPa)

g

2.237

Table1-23 Adjustment data

BJ65

BJ65

BJ65

BJ65

BJ64

86

H2F1

16

BDX

A-1

16

BDX

A-3

16

BDX

A-4

BJ648

16

BDX

A-5

6

J1F2

B

BJ64

86

HJ1F

2B

BJ64

86

H2F2

BJ64

86

B1D

XA

9.5 9.0

95/5250 88/5000

196/2750 198/2600

750±50 800/±50

≥20.4

≥170

BJ65

16B1

DXA

BJ65

16B1

DXA

-2

BJ65

16B1

DXA

-6

Drive system

Page 22

Chapter 1 Main Data and Specification of VIEW Series Light-bus

Transmission

Drive

BJ64

BJ64

Model

86

B1D

XA-1

86

B1D

XA-2

BJ64

86

J1F1

B

BJ64

86

H2F1

BJ65

16

BDX

A-1

BJ65

16

BDX

A-3

BJ65

16

BDX

A-4

BJ65

16

BDX

A-5

BJ648

6

J1F2

B

BJ64

86

HJ1F

2B

BJ64

86

H2F2

BJ64

86

B1D

XA

Clutch Single disc, dry diaphram spring,hydraulic operation

Mechanic 5+1,gears with synchronizers

BJ65

16B1

DXA

BJ65

16B1

DXA

-2

·13·

BJ65

16B1

DXA

-6

Ⅰgear

Ⅱgear

ratio

Ⅲgear

Model

Compression ratio

Rated power

[kw(r/min)]

Max torque

[N.m(r/min)]

Idle speed(r/min)

Lubricati

ng oil

pressure

(kPa)

During

Idle

speed

During

running

BJ6486

FB

BJ6486

HFB

3.967 4.452

2.136 2.619

1.36 1.517

Table 1-24 Adjustment data

BJ6486

H1F

BJ6486

H2F

BJ6486

H2FB

BJ6486

HFB

BJ6486

HJ1FB

BJ6486

J1FB

8.8

70/4600

178/3200

780±50

≥20.4

≥170

BJ6486

J1FC

BJ6486

HJ1FC

Drive system

Clutch Single disc,dry disphram spring,hydraulic operation

Transmission Mechanic 5+1 gears with synchronizer

Ⅰgear

4.452

Drive

ratio

Ⅱgear

Ⅲgear

2.619

1.517

Note :“←” same as indicated value

Table 1-25 Adjustment data

Model

Compression ratio

Rated power /rpm

(kw(r/min))

BJ6486B1

DWA

BJ6486B1

DWA-1

BJ6486B1

DWA-2

BJ6486B1

DWA-3

76/4300~4600

BJ6486B1

DWA-4

8.8

BJ6486B1

Max roque 193/3200

DWA-5

BJ6486B1

DWA-6

BJ6486B1

DWA-7

Page 23

·14·

Rated power /

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

Model

BJ6486B1

DWA

BJ6486B1

DWA-1

BJ6486B1

DWA-2

BJ6486B1

DWA-3

BJ6486B1

DWA-4

BJ6486B1

DWA-5

BJ6486B1

DWA-6

BJ6486B1

DWA-7

[N.m(r/min)]

Idle speed (r/min)

Lubrica

tion oil

pressur

e(kPa)

During

Idle speed

During

running

800±50≥

≥20.4

≥170

Drive system

Torque converter

ratio

Clutch Single disc,dry diaphram spring,hydraulic operation

/ 2.3

/

Transmission Mechanic 5+1 gears with synchronizer Torque converter+Planet gears

Drive

ratio

Ⅰgear

Ⅱgear

4.452 Ⅰgear 2.450

Ⅱgear 1.450

Ⅲgear 1

O/Dgear 0.688

2.619

Planet

Gears

ratio

Ⅲgear

Modle

Compression ratio

Rpm

(kW(r/min))

Max torque

(N.m(r/min))

Idle speed(r/min)

Lubrica

ting oil

pressur

e(kPa)

During

Idle speed

During

running

Torque converter

ratio

BJ6486B1

DWA-8

BJ6486B1

DWA-9

1.517

Table 1-26 Adjustment data

BJ6516B1

DWA

BJ6516B1

DWA-1

BJ6516B1

DWA-2

BJ6516B1D

WA-3

8.8

76/4300~4600

193/3200

800±50

≥20.4

≥170

Drive system

/ 2.3

Rgear 2.222

BJ6516B

1DWA-4

BJ6486B1

DWC

Clutch Single disc,dry diaphram spring ,hydraulic operation

/

Transmission Mechanic 5+1 gears with synchronizers Torque converter+Planet gears

Page 24

Chapter 1 Main Data and Specification of VIEW Series Light-bus

Planet gears

Propeller shaft

Front

·15·

Drive

ratio

Driv

e

ratio

Modle

Ⅰgear

Ⅱgear 2.619

Ⅳgear 1.517

Model

Ⅳ gear

Ⅴ gear

R gear

BJ6486B1

BJ648

6B1D

XA-1o

r -2

DWA-8

BJ64

86

J1F1

B

BJ6486B1

DWA-9

BJ6516B1

DWA

BJ6516B1

DWA-1

BJ6516B1

DWA-2

4.452 Ⅰgear

Table 1-27 Adjustment data

BJ65

BJ65

BJ65

BJ64

86

2F1

16

BDX

A-1

16

BDX

A-3

16

DXA-

4

BJ65

16

DXA-

5

BJ64

86

1F2B

BJ64

86

J1F2

B

1.000 1.000

0.856 0.854

3.578 4.473

BJ6516B1D

WA-3

ratio

BJ64

BJ64

2F2

86

86

1DX

A

BJ6516B

1DWA-4

BJ6486B1

DWC

2.450

Ⅱgear

Ⅲgear

1.450

1

O/Dgear 0.688

Rgear 2.222

BJ65

BJ65

BJ65

16

16

B1D

B1D

B1D

XA

XA-2

XA-6

16

type

Rear axle

Final drive

Final drive

ratio

Differntial

Half shaft

Suspen

tion

Tire

Tire

pressur

e (kPa)

Model

front

rear

rear

BJ6486H

FBor FB

Tubular,exposed needle bearing, universal joint

Integrated banjo type or tubular type

Single hyperbolic bevel gear

4.1 4.27

Symmetric bevel gear type

Semi-floating

Running system

Torsion bar spring,double cross arm independent suspention

Longitudinal leaf spring; non-independent suspension

195/70R15C 195/70R15C or 205/70R15

325 325/250

450 450/250

Table 1-28 Adjustment data

BJ6486H

1F

BJ6486H

2F

BJ6486H

2FB

BJ6486H

FB

BJ6486H

J1FB

BJ6486J

1FB

BJ6486J

1FC

BJ6486H

J1FC

Drive

ratio

Ⅳ gear

Ⅴ gear

R gear

1.000

0.854

4.473

Page 25

·16·

pressure

Drive

ension

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

Model

Prepoller shaft

type

Rear axle

Final drive

Final drive ratio

Differential

Half shaft

Suspens

ion

Front

Rear

Tire

Tire

(kPa)

Front

Rear

Model

BJ64

86B

1DW

A

BJ6486H

FBor FB

BJ64

BJ64

86B1

86B1

DWA

DWA

-1

BJ6486H

1F

BJ6486H

2F

BJ6486H

2FB

BJ6486H

FB

BJ6486H

J1FB

Tubular,exposed needle bearing, universal joint

Integrate bonjo type or tubular type

Single hyperholic bevel rear

4.556

Symmetric bevel gear type

Semi-floating

Running system

Torsion bar spring,double cross arm independent suspension

Longitudinal leaf spring; non-independent suspension

185R14

325

450

Table 1-29 Adjustment data

BJ64

BJ64

BJ64

BJ64

BJ64

-3

86B1

DWA

-4

86B1

DWA

-5

86B1

DWA

-6

86B1

DWA

-7

86B1

DWA

-8

BJ64

86B1

DWA

-9

BJ65

16B1

DWA

BJ65

16B1

DWA

-1

BJ6486J

1FB

BJ65

16B1

DWA

-2

BJ6486J

BJ65

16B1

DWA

-3

1FC

BJ6516

B1DWA

-4

BJ6486H

J1FC

BJ64

86B1

DWC

Ⅳgear

Ⅴgear

ratio

R gear

Propeller

shaft type

Rear axle

Final drive

Tubular,exposed,needle bearing universal joint

Whole banjo type of tubular type

Single hyperbolic bevel gear

Final drive

ratio

Differential

Symmetric bevel gear type

Half shaft

Running system

Susp

Front

Rrear

Torsion bar spring, double cross arm independent suspension

Longtudinal leaf spring non-independent suspension

Tire 185R14 195/70R15C

Tire

Pa)

Front

Rear

press

ure(k

1.000 /

0.854 /

4.473 /

4.556

Semi -floating

185R14

325

450

Page 26

Chapter 1 Main Data and Specification of VIEW Series Light-bus

Max Wheel

body

Wire harness

Table 1-30 Steering gear and brake

Model

BJ648

6B1D

XA-1o

r-2

BJ648

6J1F1

B

BJ648

6H2F

1

BJ651

6XA-

1or -2

BJ651

6XA-

3

BJ648

6J1F2

B

BJ648

6HJ1

F2B

BJ648

6H2F

Steering gear Rack and pinion

Drive ratio 36.42

·17·

BJ65

BJ648

2

6B1D

XA

BJ651

6B1D

XA

BJ651

6B1D

XA-4

16B1

DXA

-5

BJ65

16B1

DXA-

6

Left

37°±0.3°

turning

angle

Right

Steering Wheel

position

34°±0.3°

Left

Service brake Hydraulic,vacuum boosting,dual circuits brake,front disk/rear drum brake

Wire hauness

Vehi

Rated voltage

cle

and

elect

ric

devi

ce

Starter model

Vehicle body

(V)

Battery

model

Alternator

model

Compressor

90A Japanese

Japanese QDY1218(Japanese)

10PC15 10PA17C

Unibody

Negative ground

12

N50Z

Table 1-31 Steering gear and brake

Model

BJ6486

HFB0rFB

BJ6486

H1F

BJ6486

H2F

BJ6486

2FB

BJ6486

HFB

BJ6486

HJ1FB

BJ6486

J1FB

BJ6486

J1FC

BJ6486

HJ1FC

Steering gear Rack and pinion

Drive ratio 36.42

Max wheel

Left 37°±0.3°

truning

angle

Steering wheel position

Right 34°± 0.3°

Left

Running brake Hydraulic, vacuum boosting,dual circuits brake, front disc/rear drum brake

Vehicle

body and

electric

device

Vehecle

body

Ratded

voltage (V)

Unibody

Negative ground

12

Page 27

·18·

Alternator

e body

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

Model

BJ6486

HFB0rFB

BJ6486

H1F

BJ6486

H2F

BJ6486

2FB

Battery

model

Alternator

model

Starter

model

Compressor

Table 1-32 Steering gear and brake

Model

BJ6486B

1DWA

BJ6486B

1DWA-1

BJ6486B

1DWA-1

or-2or-3

BJ6486B

1DWA-4

or –5or-6

BJ6486B1

DWA-7or-8

or-9

Steering gear Rear and rack

Transmission

ratio

Max

Lifut 37°±0.3°

36.42

Wheel

turning

Right 34°± 0.3°

angle

Steering wheel

position

Left

BJ6486

HFB

N50Z

65A

QD121

V50

BJ6486

HJ1FB

BJ6516

B1DWA

BJ6486

J1FB

BJ651

6B1DWA

-10r-2

BJ6486

J1FC

BJ6516

B1DWA-

30r-4

BJ6486

HJ1FC

BJ6486

B1DWC

Running brake

Vehicle

Harness

Rated

Vehicl

and

electri

voltage

Battry

model

c

device

model

Stater

model

compress

body

(V)

or

Hydraulic,vacuum booating ,daul circuits brake ,front disc ,rear drum brake

All load –brearing metal body

Negative prond

12

N50Z

65A

QD121

V50

Page 28

Chapter 1 Main Data and Specification of VIEW Series Light-bus

turbocharger

1.1.2 Main data and specification of VIEW BJ6536

Table1-33

Vehicle model BJ6536B1DBA-2 BJ6536B1DBA-4 BJ6536B1DDA-4

BJ6536B1DW

A-2

Drive Type 4×2 rear axle drive

Persons in cab 6~9 7-9 7-9 6-9 10-12

BJ6536B1DW

·19·

A-1

Overall

dimensions

(mm)

Wheel base (mm)

Wheel

L 5320 5320、5385 5320、5385 5320 5320

W

1690 1690 1690 1690 1690

H 2050 2050、2225 2050、2225 2050 2050

2590 2890 2890 2890 2890

Front 1460 1460 1460 1460 1460

track

(mm)

Max Speed

(km/h)

Max Climbing slope

Min ground

clearance(mm)

Curb weight(kg)

Total weight(kg)

Rear 1440 1440 1440 1440 1440

≥95 ≥100 ≥110 ≥110 ≥120

(%)

≥22 ≥22 ≥30 ≥30 ≥38

≥160 ≥160 ≥160 ≥165 ≥160

1785 1785、1825 1840、1865 1695

2484 2484 2425、2450 2628

Engine BJ483ZQB BJ486ZQ YC4F90-21 BJ491EQ1 BJ491EQ1

Type

Four cylinders,in-line, water

cooling,direct injection,

diesel engine

Four cylinders,

in-line water

cooling,Turbo

charger diesel

engine

In-line,water cooling,four

cylinders,four strokes,

electronic control multi-point

injection gasoline engine

Bore×Stroke(mm)

Compression ratio

Reted power/Rpm

(kw/rpm)

Max torque/Rpm

(N.m/rpm)

83×100 86×100 92×100 91×86 91×86

17.5 18.1 17.5 8.8 8.8

46/3300 52/3300 65/3400 76/4300-4600 76/4300-4600

150/2200 175/1900-2300 215/1900-2200 193/2000-2600 193/2000-2600

Diaplacement(L) 2.164 2.324 2.66 2.237 2.237

Engine Lubricating

system (L)

Engine coolanting

system (L)

Fuel tank volume(L)

4.5 4.5 7.5 4.2 4.2

10.1

65 65/70 65/70 65 65

Page 29

·20·

Fuel consumption(at

alignment

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

Vehicle model BJ6536B1DBA-2 BJ6536B1DBA-4 BJ6536B1DDA-4

50km/h,full

payload,good road)

≤9 ≤8.5 ≤9.5 ≤ ≤9.5

L/100km)

Transm

ission

Model ZSY08 ZSY08 035H 5RYA

Type Mechanic 5+1 gears with synchronizer

Clutch Single plate, dry type diaphragm spring

Type Whole banjo type, punch axle housing

Rear

axle

Steerin-

g gear

Final drive

ratio

Rear axle

(L)

4.1 4.556 4.1

2.2(85W/90)

Type Pinion and rack

Transmissi

on (L)

1

BJ6536B1DW

A-2

Final drive

ratio

BJ6536B1DW

A-1

4.556

Sevice brake Hydraulic,vacuum boosting , dual circuits front disk,rear drum brake,

King

–pin

inclinati

Front

wheel

on

Caster 1°15′±30′ 1°15′±30′ 1°15′±30′

Camber 0°20′±30′ 0°20′±30′ 0°20′±30′

Toe-in

Max Wheel turning

angle(°)

Free travel of brake

pedal(mm)

Parking brake type

Suspenti

Front

on

system

Rear

-10°50′±30′ -10°50′±30′ -10°50′±30′

1~5 mm 1~5 mm 1~5 mm 1~5 mm 3±1 mm

34~37 34~37 34~37 34~37 34~37

1~3 1~3 1~3 1~3 1~3

Steel cable(Wheel brake)

Torsion bar spring,double crose arm independent suspension,hydraulic two –way

telescopic shock absorber

Longitudinal half –elliptic leaf spring ,non –independent suspension

Hydraulic two –way telescopic shock absorber

-10°50′±

30′

1°15′±30′ 1°15′±30

0°20′±30′ 0°20′±30

-10°50′±

30′

′

′

Electrica

l device

Type Negative ground

Rated

voltage

12V

Type of Tire and 185R14: 325 185R14C:325 185R14C:325 185R14C:325 185R14C:325

Page 30

Chapter 1 Main Data and Specification of VIEW Series Light-bus

dimensions

·21·

Vehicle model BJ6536B1DBA-2 BJ6536B1DBA-4 BJ6536B1DDA-4

Tire pressure (kPa)

Type of Tire and

Tire pressure(kPa)

185R14:450

195/70R15:250 195/70R15:250 195/70R15:250

185R14C:450

195/70R15:300

185R14C:450

195/70R15:300

BJ6536B1DW

A-2

185R14C:450

195/70R15:300

185R14C:450

Type of Rim 7JJ×15

Table1-34

Vehicle model BJ6536B1DBA-1 BJ6536B1DBA-5

BJ6536B1DDA

-5

BJ6536B1DBA-4

BJ6536B1DDA

Drive Type 4×2 Rear axle drive

Persons in cab 10~12 10-14 10-15 6-9 6-9

Over all

L 5320 5320、5385 5320、5385 5320、5385 5320、5385

W 1690 1690 1690 1690 1690

(mm)

Wheel base (mm)

H 2050 2050、2225 2050、2225 2050、2225 2050、2225

2890 2890 2890 2890 2890

BJ6536B1DW

A-1

-4

Wheel

front 1460 1460 1460 1460 1460

track

(mm)

Max Speed(km/h)

Max Climbing slope

Min ground

clearance(mm)

Curb weight(kg)

Gross weight(kg)

rear 1440 1440 1440 1440 1440

≥95 ≥100 ≥110 ≥100 ≥110

(%)

≥22 ≥25 ≥30 ≥25 ≥30

≥160 ≥160 ≥160 ≥160 ≥160

1785 1785、1825 1865、1890 1785、1825 1840、1865

2718 2952 3032、3057 2484 2425、2450

Engine BJ483ZQB BJ486ZQ YC4F90-21 BJ486ZQ YC4F90-21

Type

Four cylinders,

in-line, water

cooling,

supercharging,

diesel engine、

Four cylinders,

in-line, water

cooling,direct

injection,diesel

engine

Four cylinders,

in-line, water

cooling,direct

injection,diesel

engine

Four cylinders,

in-line, water

cooling,direct

injection,diesel

engine

Four ylinders,

in-line, water

cooling,direct

injection,diesel

engine

Bore×Stroke(mm) 83×100 86×100 92×100 86×100 92×100

Compression ratio

Reted power/Rpm

(kw/rpm)

Max torque/Rpm

(N.m/rpm

17.5 18.1 17.5 18.1 17.5

46/3300 52/3300 65/3400 52/3300 65/3400

150/2200 175/1900-2300 215/1900-2200 175/1900-2300 215/1900-2200

Diaplacement 2.164(L) 2.324(L) 2.66(L) 2.324(L) 2.66(L)

Page 31

·22·

Fuel consumption(at

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

Vehicle model BJ6536B1DBA-1 BJ6536B1DBA-5

BJ6536B1DDA

-5

BJ6536B1DBA-4

BJ6536B1DDA

Engine oil (L) 4.5 4.5 7.5 4.5 7.5

Engine coolant (L)

10.1 10.1 10.1 10.1 10.1

Fuel tank (L) 65 65/70 65 65 65

50km/h,full

payload,good road)

≤9 ≤8.5 ≤9.5 ≤8.5 ≤9.5

L/100km)

Transm

ission

Model

Type Mechanic 5+1 gears with synchronizer

Clutch Single disc dry, diaphram spring, hydraulic operration

Type Whole banjo type , punch axle housing

Rear

axle

Final drive

ratio

Rear axle

(L)

4.1 4.556 4.1 4.556 4.1

2.2(85W/90) 2.2(85W/90) 2.2(85W/90) 2.2(85W/90) 2.2(85W/90)

-4

Steerin

g gear

Type Rear and rack

Transmissi

on (L)

Brake system

King

–pin

inclinati

Front

on

wheel

alignment

Caster 1°15′±30′ 1°15′±30′ 1°15′±30′ 1°15′±30′

date

Camber 0°20′±30′ 0°20′±30′ 0°20′±30′ 0°20′±30′

Toe-in

Max Wheel turning

angle(°)

Free travel of brake

pedal(mm)

1

Hydraulic,vacuum boosting ,dual circuits front

disk,rear drum brake

-10°50′±30′ -10°50′±30′

-10°50′±30

′

-10°50′±30′

-10°50′±

1°15′±30

0°20′±30

1~5 mm 1~5 mm 1~5 mm 1~5 mm 1~5 mm

34~37 34~37 34~37 34~37 34~37

1~3 1~3 1~3 1~3 1~3

30′

′

′

Parkong brake type

Suspenti

Front

on

system

Rear

Steel cable (Wheel brake)

Torsion bar spring,double cross arm independent suspension, hydraulic two –way

telescopic shack absorber

Longitudinal half –elliptic leaf spring,non –independent suspension,

hydraulic two –way telescopic shack absorber

Page 32

Chapter 1 Main Data and Specification of VIEW Series Light-bus

Type of Tire andTire

·23·

Vehicle model BJ6536B1DBA-1 BJ6536B1DBA-5

Electrica

l device

pressure (kPa)

Type of Tire and

Tire pressure (kPa)

Type Negative ground

Rated

voltage

185R14: 325

185R14:450

185R14C:325

195/70R15:250

185R14C:450

195/70R15:300

BJ6536B1DDA

-5

12V

185R14C:325

195/70R15:250

185R14C:450

195/70R15:300

BJ6536B1DBA-4

185R14C:325

195/70R15:250

185R14C:450

195/70R15:300

BJ6536B1DDA

-4

185R14C:325

195/70R15:25

0

185R14C:450

195/70R15:30

0

1.2 Technical data of BJ491EQ1 gasoline engine

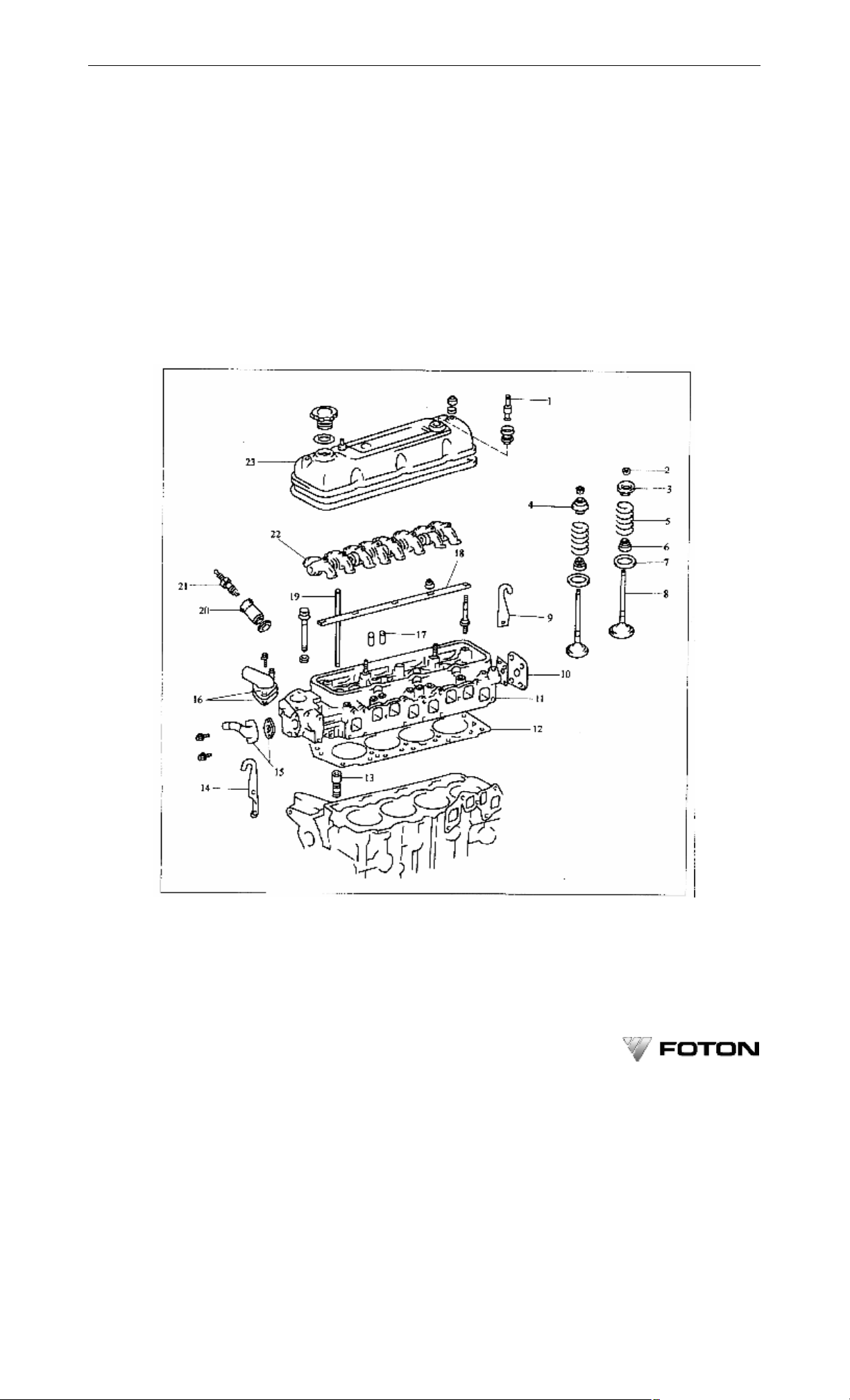

1.2.1 General structure of gasoline engine

Gasoline engine is a type of complicated machine that transforms heat energy of fuel into mechanical

operation. A gasoline engine contains the following mechanisms and systems:

1.2.11 Crank-connecting rod mechanism

The function of crank-connecting rod mechanism is to change reciprocating motion of piston into rotation

movement of crankshaft, and change gas pressure on top of piston into torque, producing output through

crankshaft.

Crank-connecting rod mechanism contains piston / connecting rod assemblies and crankshaft/flywheel

assemblies.

1.2.1.2 Cylinder block and cylinder head

Cylinder block and cylinder head form piston motion space and gasoline engine combustion chamber in

which air-fuel mixture is burning. The cylinder block and cylinder head are the framework of a gasoline engine,

on which all moving parts and auxiliary systems are supported and installed.

1.2.1.3 Valve train

Valve train discharges exhaust gas and sucks in air at specified timing to help combustion inside the engine.

Valve train includes valves and driving assemblies (tappet, push rod, rocker arm, rocker arm shaft, camshaft,

timing chain sprocket and timing chain etc.)

Air intake/exhaust system is composed of air cleaner, intake/exhaust manifolds/pipes, throttle body, muffler

and three-way catalytic converter etc.

1.2.1.4 Fuel supply system

Fuel supply system turns gasoline into combustible mixture according to the working requirement of gasoline

engine, and continuously supplies cylinder to meet the needs during combustion process.

Fuel supply system is mainly composed of fuel tank, electric fuel pump, fuel filter, fuel injector, pressure

regulator and fuel pipeline etc.

1.2.1.5 Lubrication system

Lubrication system is to deliver engine oil (lubricant) to friction surfaces of moving parts to perform

antifriction, cooling, cleaning and antirust functions, so as to reduce friction resistance and wear, take away the

heat generated during friction that ensure normal working of gasoline and prolong its service life.

BJ491EQ1 multi point electronic fuel injection gasoline engine combines to use pressure and splash

lubrication methods.

The lubrication system is mainly composed of oil strainer, oil pump, oil filter and lubricant oil passages etc.

Page 33

·24·

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

1.2.1.6 Cooling system

Cooling system is to radiate heat from excessive heat parts, so as to ensure a normal working temperature of

engine and avoid damage to its mechanical parts and other adverse influences.

BJ491EQ1 multi point electronic fuel injection gasoline engine adopts a forced water-cooling method.

The cooling system is mainly composed of cylinder block and water jacket in cylinder head, water pump, fan,

radiator, thermostat and silicon oil fan clutch etc.

1.2.1.7 Ignition system

Ignition system is to generate electric sparks to ignite the air-fuel mixture inside cylinder timely.

The ignition system is composed of battery, spark plug, ignition coil and high resistance cable.

1.2.1.8 Starting system

Starting system is to rotate crankshaft to a certain speed so as to suck combustible mixture into cylinder to

enable ignition and combustion.

The starting system is composed of starter, battery and other devices.

1.2.1.9 Electronic control fuel injection system

Through various sensors, electronic fuel injection system input signals of air intake volume, crankshaft

rotation / position and other auxiliary components to ECM. ECM processes these singals and commads auctators

to get uptimum air-fuel ratio and proper ignition timing, and ignite the combustible mixture to obtain an ideal

engine power performance, economical efficiency and emission index.

1.2.2 Specifications of gasoline engine

Description BJ491EQ1

Type

4-stroke ,in-line,water cooling,wedge combustion chamber,

EFI

Number of Cylinders 4

Cylinder bore [mm] 91

Piston stroke [mm] 86

Displacement[L] 2.237

Rated output[kW/(r/min)] 76/4600~4600

Idle rpm [r/min] 800±50

Max torque[N·m/(r/min)] 193/2000~2600

Fuel rate RON93 or better ,non-leaded super gasoline

Min fuel consumption [g/(kW·h)] ≤275

Oil rate SF or better 10W/30or 15W/40,and 5W/30 in winter

Oil /fuel consumption rate [%] <0.8

Average piston speed [m/s] 13.19

Rotating direction of crankshaft Counter- clockwise

Compression ratio 8.8:1

Anti-freezer Ethylene anti-freezer

Oil volume (dry)[L] 4.2

Page 34

Chapter 1 Main Data and Specification of VIEW Series Light-bus

Description BJ491EQ1

Coolant volume [L] 7.9(With out worm pipe capacity)

·25·

Firing sequence

Intake open advance angle 12ºBTDC

Intake close delayed angle 48ºABDC

Valve timing

Exhaust open advance 54ºBBDC

Exhaust close delayed angle 10ºATDC

Coolant type

Lubricating

Starting type

Net weight [kg]

Spark plug clearance[mm]

Max oil temperature [℃]

Coolant temperature [℃]

At idle ≥30

Oil pressure [kPa]

2000r/min ≥170

3000r/min 245~490

1-3-4-2

Forced cooling

Combine to use pressure and splash lubrication

Electric starting

145

1.1±0.1

110

85~105(For high pressure cooling system )

1.2.3 Specifications of gasoline engine main components

Description Type Specifications

ECM ITMS-6F

O2 sensor 25327985 Heat style

Spark plug F6RTC or F5RTC M14×1.25, 3~9kΩ resistance

Starter QDY1253 U=12V,P=1kW

Alternator U=14V,I=65A/90A

Fuel injector 25343351

Oil pump Rotor type

Water pump Centrifugal type

Thermostat

Oil pressure sensor ZM10,Alarm pressure 39.2kPa

Oil filter Paper element

491-FT01 for van;491-FT02 for pick-up;

491-FT03for SUV

Valve opening temperature ;76℃,or more at 88℃,valve

lift≥8mm

Ignition coil 19005252

Clutch Diaphragm spring type

Page 35

·26·

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

1.2.4 The fitting clearance of main components

Description Data

Warpage -- cylinder block side 0.15mm

Warpage -- manifold side 0.10mm

Culinder head

Valve guide

bushing

Valve

Refacing angle

Intake 45º,75º

Exhaust 45º

Valve seat

Connecting angle 45º

Connecting width 1.2~1.4mm

Inner diameter(mm) 8.010~8.030

STD(mm) 13.040~13.051

Outer dirmeter

O/S0.05(mm) 13.090~13.101

Intake 108.2

Overall length STD(mm)

Exhaust 108.5

Intake 44.5º

Valve face angle

Exhaust 44.5º

Intake(mm) 7.970~7.985

Stem diameter

Exhaust(mm) 7.965~7.980

Intake 0.025~0.060

STD(mm)

Exhaust 0.030~0.065

Stem oil clearance

Intake 0.10

Limit (mm)

Exhaust 0.12

Valve spring

Rocker arm and

shaft

Valve lifter and

lifter hole

Valve stem end face

polishing limit(mm)

Margin thickness

Limit(mm)

Installed tension at 40.6mm(N) 292~336

Squareness(mm)

Oil clearance

(mm)

Oil clearence

(mm)

Intake 0.5

Exhaust 0.5

Intake 1.0~1.4

STD

Exhaust 1.3~1.7

Intake 0.5

Limit

Exhaust 0.8

Free length (mm) 47

Limit 2.0

STD 0.02~0.051

Limit 0.08

STD 0.017~0.056

Limit 0.10

Leak down test at196N 7~50s/1mm

Page 36

Chapter 1 Main Data and Specification of VIEW Series Light-bus

Description Data

Manifold Warpage Limit(mm) 0.4

Chain slackness at 98N Limit(mm) 13.5

·27·

Timing chain and

timing sprocket

Chain tensioner

and vibration

damper

Camshaft

Camshaft

Chain elongation Limit(mm) 291.44

Cranshaft sprocket wear Limit(mm) 59(Measure with chain)

Camshaft sprocket wear Limit(mm)

Tensioner head thickness Limit(mm) 12.5

Damper thinckness Limit(mm) 5

Thrust clearance(mm)

Journal oil clearance

(mm)

Journal diameter STD

(mm)

Out of round limit(mm) Limit 0.06

114(Measure with

chain)

STD 0.07~0.22

Limit 0.3

STD 0.025~0.111

Limit 0.14

No.1 46.459~46.475

No.2 46.209~46.225

No.3 45.959~45.975

No.4 45.709~45.725

No.5 45.459~45.475

Cylinder block

Piston and piston

ring

Cam lobe height

(mm)

Top surface warpage(mm) 0.05

Bore diameter(mm)

Diameter of piston

(mm)

Piston oil clearance(mm) 0.032~0.092

STD

Intake 38.620~38.720

Exhaust 38.629~38.729

Intake 38.26

Limit

Exhaust 38.27

STD 91.00~91.03

Limit 91.23

O/S 0.5(mm) 91.73

O/S0.75(mm) 91.98

O/S1.00(mm) 92.23

STD 90.938~90.968

O/S 0.5(mm) 91.438~91.468

O/S0.75(mm) 91.688~91.718

O/S1.00(mm) 91.938~91.968

Page 37

·28·

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

Description Data

NO.1 0.27~0.39

Piston ring end gap

(mm)

Piston ring groove clearance 0.03~0.07

Thrust clearance(mm) 0.160~0.312

Connecting –rod

Flyweel Runout (mm) 0.10

Thrust clearence(mm)

Crankshft

Benting per 100mm Limit 0.05

Twisting per100mm Limit 0.05

Thrust washer

thickness

(mm)

Main jounral oil

clearence(mm)

Main journal diameter

(mm)

NO.2 0.40~0.55

Oil side rail 0.20~0.70

STD 0.02~0.20

Limit 0.35

STD 2.450~2.490

O/S0.125mm 2.565~2.615

O/S0.250mm 2.69~2.89

STD 0.020~0.051

limit 0.10

STD 57.985~58.00

Crank pin oil

clearence(mm)

Crank pin diameter (mm) STD 47.985~48.00

Circle runout(mm) Limit 0.06

Main journal taper and out –of round(mm)

Crank pin taper and out –of round(mm)

STD 0.020~0.051

Limit 0.10

Limit 0.02

Limit 0.02

1.2.5 Tightening torque of main fasteners

1.2.5.1 Tightening torque for mechanical parts of gasoline engine

Parts

Rocker arm shaft×Cylinder head 25~32 Water pump ×cylinder block 39~48

Cylinder head

bolts

Manifold ×cylinder head 49~55 Connecting cap ×rod 49~55

Spark plug ×cylinder head 25~30

M12 93~105

M8 20~25

Tightening torque

(N.m)

Parts

Chain case 20~25

Mainbearing cap × cylinder

block

Tightening torque

(N.m)

78~88

Chain sprocket ×camshaft 90~100 Crankshaft pilley ×crankshaft 155~165

Page 38

Chapter 1 Main Data and Specification of VIEW Series Light-bus

·29·

Parts

Camshaft thrust washer ×cylinder

block

Water pump×chain case 20~25 Oil pan ×cylinder block 10~13

Oil pan drain plug 38~45 Head cover ×cylinder head 6~8

1.2.5.2 Tightening torque for EFI parts

NO Parts

1 Throttle body 10~15 5 Ignition coil 10~15

2 MAP sensor 7~12 6 O2 sensor 38~46

3 Coolant temperature sensor 20~25 7 Upper and lower ports 20~25

4 Crankshaft 7~9

1.2.5.3 Tightening torque for other parts

NO Parts

Tightening torque

(N.m)

20~25 Flywheel×crankshaft 83~90

Tightening

torque(N.m)

Tightening torque

(N.m)

Parts

NO Parts

NO Parts

Tightening torque

(N.m)

torque(N.m)

Tightening torque

(N.m)

Tightening

1 M6 9~11 3 M10 41~591

2 M8 20~25 4 M12 73~

1.3 Technical specification of BJ486ZQ diesel engine

1.3.1 Technical specification of BJ486ZQ diesel engine

No Description Unit Specifications

1 Type

2 Shape of combustion chamber

3 Cylinder number 4

4 Cylinder bore mm 86

5 Piston stroke mm 100

6 Compression ratio 18

7 Diplacement L 2.324

8 Firing sequence 1-3-4-2

9 Output /rpm Kw/r/min 52/3300

DI A type

4-stroke ,water cooling ,in line、DI

supercharging,diesel engine

10 Max torque /rpm N.m/r/min 175/1900~2300

11 Min fuel consumption rate G/kw/h 225

12 Adjustable velocity % ≤10

Page 39

·30·

8º,Intake valve closes(after

No Description Unit Specifications

13 Idle rpm r/min 800~850

14 Smoke m-1 ≤1.8

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

15

16 Method of lubrication Pressure and splash

17 Starting method Electric

18 Net weight Kg ≤215

19 Overall dimensions mm 754×592×671

Rotating directon of

crankshaft

Clockwise(see from front of diesel engine)

1.3.2 Main technical parameters of BJ486ZQ diesel engine

Description Parameters

Intake valve opens(before T.D.C)

B.D.C)44º

Exhaust valve opens (before BDC) 44º ;

Exhaust valve closes (after TDC) 8º

Intake valve 0.35mm, Exhaust valve 0.35mm

≤550℃

≤95℃(use high pressure water tank ≤105℃)

0.30~0.42MPa

Valve timing

Advance angle 8º~10ºCA(before T.D.C)

The range of

temperature and

pressure

Intake valve

Exhaust valve

Valve clearance

(cold)

Exhaust gas temperature

Coolant outlet

temperature

Oil temperature 80℃~105℃

Idling oil pressure ≥0.07MPa

Nominal speed oil

pressure

Camshaft gear bolt 45~55

Main bearing cap bolt 160~180

Tightening

torque(N.m)

Connecting –rod nut 55~65

Cylinder head bolt

Flywheel bolt 80~90

Crankshaft pulley bolt 250~280

170~190(bolt,Cylinder head)55~65(Small bolt,Cylinder

1.3.3 Main fitting specification of BJ486ZQ diesel engine

Description Specifications

Type of oil pump Gear type

Lubrication system

Type of oil filter Integral canister type

Alarm oil pressure 80kPa

head)

Page 40

Chapter 1 Main Data and Specification of VIEW Series Light-bus

Description Specifications

Fuel filter Rotor type

Fuel pump Piston

·31·

Fuel supply sistem

Cooling system

Electronic sistem

Type of fuel injection

pump

Type of injector “P”multi –hole type ,ZP20 type

Injector open pressure 22~23MPa

Water pump Centrifugal type

Water pump flow ≥130L/min/4800r/min

Thermostat Wax type

Fan Silicon oil clutch and plastic fan

Glow plug relay 12V

Starter 12V,2.8kw

Alternator 14V,900W

Alternator rotating

direction

Type SJ44 or JP40S

BHF4P090213 type

Clockwise (viewing from front)

Turbeocharger

Max rpm 18000r/min

Rated rpm 15000r/min

1.4 Technical specification of YC4F90-21 diesel engine

1.4.1 The technical specifications

NO Description Specifications

1 Engine type 4-stroke ,water cooling,in line,supercharging

2 Shape of combustion chamber DI ω shape

3 Cylinder bore × Piston stroke (mm)

4 Displacement(L) 2.66

5 Compression ratio 17.5:1

6 Rated power/rpm kW(r/min) 65±5%/3400

7 Max torque /rpm (N.m/rpm) 210/1900~2200

8 Min fuel consumption〔g/(kW.h)〕

4-92×100

≤215

9 (Oil/fuel )consumption rate ≤0.2%

Page 41

·32·

full load

Transmission connecting

e end face to transmission connecting

release lever:

OPERATION AND MAINTENANCE MANUAL FOR FOTON VIEW SERIES LIGHT BUS

NO Description Specifications

10 Max rpm ( r/min) ≤3630

11 Min steady idle rpm 700~800

12 Firing order 1-3-4-2

13 Rotating direction of crankshaft Clockwise(viewing from front of diesel engine)

14 Starting method Electric

15 Starting performance

Startup at -10℃ w/o glow plug device, startup at-35℃ with

glow plug device; successful startup after 3 crankings

16 Smoke at free acceleration ( Rb) ≤2.0

Maximum smoke under

17

FSN

≤3.5

18 Noise (dB) (A) ≤116

19 Oil pan volume 7.5(L)

20 Oil temperature 90~115℃

Oil pressure at steady idling speed:>0.1MPa

21 Lubricating oil pressure

Working pressure: 0.3-0.6MPa

22 Coolant temperature 80~95℃

23 Exhaust gas temperature ≤650℃

24 Net weight(kg) 260(excl. clutch)

Overall dimensions

25

(L×W×H)mm

723.6×568.3×666

1.4.2 Main components specifications

NO Description Specifications

1 Type of fule injection pump BHF4PL090

2 Type of injector CKBAL63P967

3 Turbocharger JP50

4 EGR controller (ECU) Max environment temperature<80℃

Fraction face of flywheel and clutch to transmission connecting plate :

5

plate

6 Type of clutch

52mm ; Input shaft bearing

plate : 25mm

ф225 diaphragm spring clutch,ajusting height of clutch

36.4mm; Clutch is of involute spline type

7 Flywheel 108teeth,speed signal output from flywheel

8 Speed sensor Mounting location aligns with flywheel gear ring center,

9 Input shaft bearing 6201 bearing,Input shaft front φ12mm

Page 42

Chapter 1 Main Data and Specification of VIEW Series Light-bus

intake

ront fuel tank

Cleanness from air filter to

ment

NO Description Specifications

10 Oil pan volume 7.5L,Engine w/o oil from factory

11 Starting motor DC reducer motor QDJ1303/3kW/12V

12 Generator 14V/90A,built-in voltage regulator

13 Air filter flow ≥600m3/h

14 Air filter resistance ≤2.5 kPa, with double stage elements

Air intake resistance –

15

system

16 Radiating area -- radiator ≥16M2

17 Expansion tank ≥15% of total cooling system volume

18 Fuel filter flow ≥0.7L/min,particles after filter<0.005mm

Cleanness of f

19

to fuel pump inlet pipe

≤4 kPa,Negative pressure alarm on air filter assembly

<10mg

·33·

20