Page 1

1

By Appointment to

Her Majesty Queen Elizabeth II

Suppliers of Commercial Refrigeration

Foster Refrigerator, King’s Lynn

Call: +44 (0)843 216 8800 Fax: +44 (0)843 216 4700 Email: support@foster-uk.com

www.fosterrefrigerator.co.uk

A Division of ITW Ltd

Foster Refrigerator

Oldmedow Road

King’s Lynn

Norfolk, PE30 4JU

United Kingdom

ISO 9001 ISO 14001

Original Operation Instructions

Controlled Thaw

CT75

Surf navigation Click Wheel Controller

00-570084 August 2014 Issue 2

English

Page 2

GB

1

If not disposed of properly all refrigerators have components that can be harmful to the

environment.

All old refrigerators must be disposed of by appropriately registered and licensed waste

contractors, and in accordance with national laws and regulations.

Foster Refrigerator recommends that the equipment is electrically connected via a Residual

Current Device; such as a Residual Current Circuit Breaker (RCCB) type socket, or through a

Residual Current Circuit Breaker with Overload Protection (RCBO) supplied circuit.

Time

Phase

Phase

Storag

P1 Set

P1Hysteres

Storage

Storage Set

Start

Temperature

Controller Operation

If the cabinet has been laid on its back at any time DO NOT switch on immediately but leave

in the upright position for at least 60 minutes.

Important: Ensure a minimum clearance of 150mm above the unit and adequate ventilation

for efficient operation. Where possible, ensure the unit is away from a heat source.

Unpacking: The unit is delivered on a pallet and shrink-wrapped. Documentation is inserted

into a clear pocket inside the unit. Carefully remove the protective plastic film and cardboard

from the unit exterior and from the door opening surround making sure that any sharp

instrument used does not cause damage, plus remove any quality labels.

Cabinet removal from the pallet: Remove the shelf holding the package containing the

castors. Remove the retaining bolts which secure the unit to the pallet. Move the unit over the

front of the pallet fit the lockable castors in the mounting holes. To fit the rear castors, lock

the front castors, tilt the unit forwards, remove the pallet and fit the castors in the mounting

holes. Ensure that all are tightened firmly into position.

Ensure during installation the unit is level if not the door may not close correctly.

Adjust castors by inserting spacers, supplied separately, under the appropriate castor and the

base of the unit until level.

When mains electrical power is first applied to the controller it will carry out a self-test

function, for approximately 3 seconds.

Page 3

GB

2

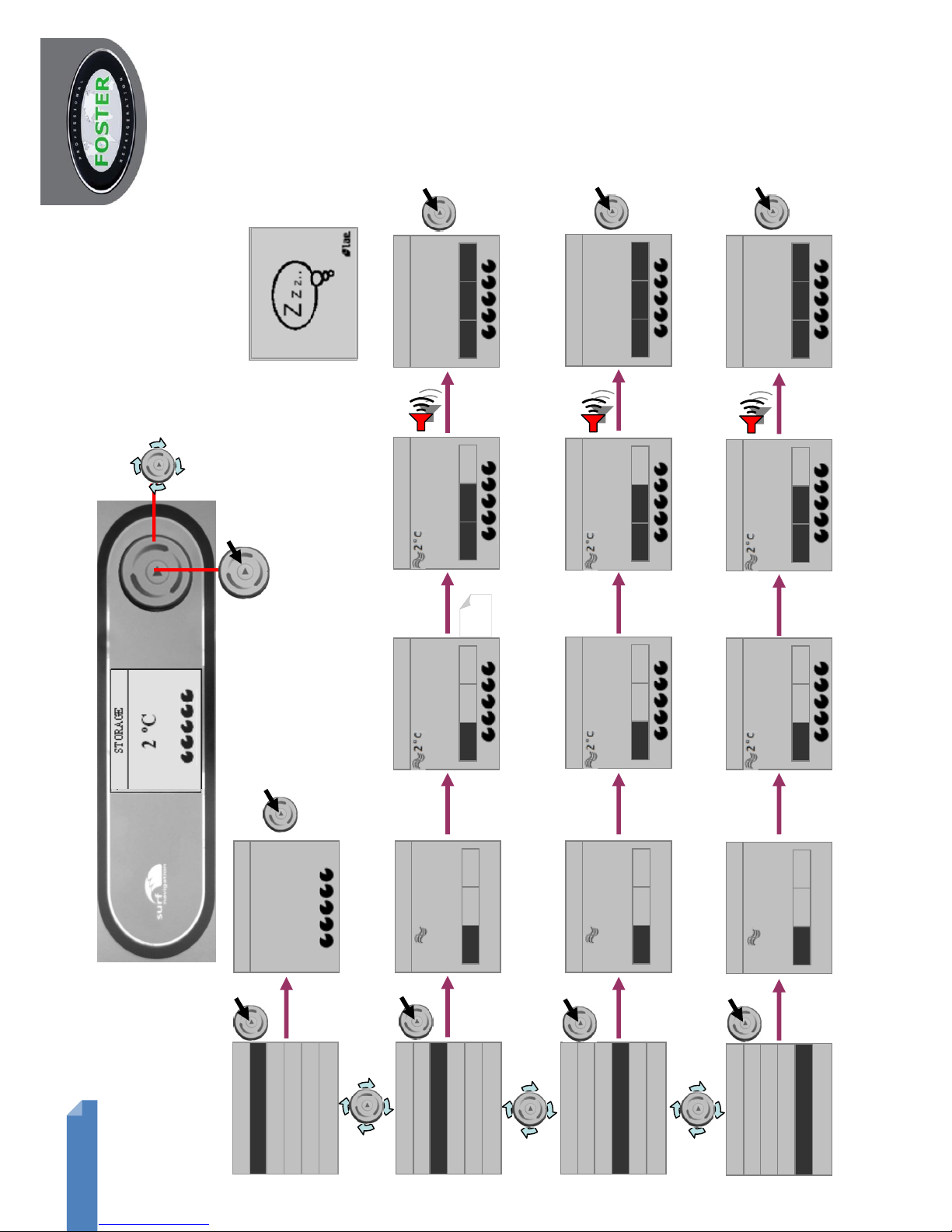

Programme 1 is a programme to thaw up to 35Kgs of frozen product in 5 hours 30 minutes.

Programme 2 is a programme to thaw up to 70Kgs of frozen product 7 hours.

Programme 3 is a programme to thaw up to 70Kgs of denser frozen product in 9 hours.

NOTE: the above are for guidance only as the programme times may vary for different products. There is a fourth programme on the controller but this does not have a set programme.

‘SLEEP’ mode

TURN TO SELECT- PRESS TO ST ART

STORAGE

PROGRAM 1

PROGRAM 2

PROGRAM 3

2 ºC

STORAGE

2 Secs

TURN TO SELECT- PRESS TO ST ART

STORAGE

PROGRAM 1

PROGRAM 2

PROGRAM3

5: 30

PROGRAM 1

PHASE 1

PHASE 2

HOLD

59: 59

PROGRAM 1

PHASE 2

HOLD

2 ºC

PROGRAM 1

HOLD

5: 30

PROGRAM 1

PHASE 1

PHASE 2

HOLD

-10°C

2 Secs

TURN TO SELECT- PRESS TO ST ART

STORAGE

PROGRAM 1

PROGRAM 2

PROGRAM 3

7: 00

PROGRAM 2

PHASE 1

PHASE 2

HOLD

59: 59

PROGRAM 2

PHASE 2

HOLD

2 ºC

PROGRAM 2

HOLD

7: 00

PROGRAM 2

PHASE 1

PHASE 2

HOLD

-10°C

2 Secs

TURN TO SELECT- PRESS TO ST ART

STORAGE

PROGRAM 1

PROGRAM 2

PROGRAM 3

9: 00

PROGRAM 3

PHASE 1

PHASE 2

HOLD

59: 59

PROGRAM 3

PHASE 2

HOLD

2 ºC

PROGRAM 3

HOLD

9: 00

PROGRAM 3

PHASE 1

PHASE 2

HOLD

-10°C

2 Secs

Move your finger lightly around

the click wheel, either clockwise

or counter clockwise to select

the programme you require.

Press and release the centre button to

start the program

Press and hold for 2 seconds to stop

the Program

Page 4

GB

3

The cabinet has fixed positions for the shelving incorporated in the side air ducts.

Door Open Alarm

The door alarm will sound if the door is left open for more than 5 minutes when the

programme is running.

The display will continue to display the alarm message until cancelled by shutting the door.

If the alarm cannot be cancelled by doing this call your Foster Authorised Service

Company.

High Temperature Alarm

If the cabinet temperature remains above 10°c for more than 90 minutes whilst in the

storage mode the alarm will

Air Probe Alarm

In the event of the probe failing the alarm will sound and the display will show probe fault.

Contact your Foster Authorised Service Company.

Power Failure

If the power fails for up to five minutes the unit will re-start on the resumption of the

power supply without affecting the selected cycle.

If the power is off for longer than five minutes the controller will enter the hold mode.

It is at the user’s discretion whether the stock is kept or disposed of depending on the

length of the time the cabinet had no power

Important: Before cleaning the power supply should be turned off at the mains.

Cared for correctly, stainless steel has the ability to resist corrosion and pitting for many

years.

The following weekly cleaning regime is recommended:

a. Exterior: use a proprietary stainless steel cleaner following the manufacturer’s

instructions.

b. Interior: Wash with soapy water, rinse with clean water and dry thoroughly.

WARNING:

High alkaline cleaning agent or those containing bleaches, acids and chlorines are very

harmful to stainless steel. Corrosion and pitting may result from their accidental or

deliberate application. If any of these liquids should come into contact with the unit during

general cleaning, wipe down the affected area with clean water and rub dry.

Never use wire wool or scouring powders on stainless steel or aluminium surfaces.

After cleaning allow the unit to reach its normal operating temperature before reloading

with product. During usage all spills should be wiped clean immediately.

Door Gaskets

These should be inspected on a regular basis and replaced if damaged. To clean, wipe with

a warm damp soapy cloth followed by a clean damp cloth and finally thoroughly dry before

shutting the door.

Page 5

GB

4

Condenser Cleaning

Clean the condenser, located in the unit compartment, when it becomes dirty.

Important: Disconnect the mains electrical supply to the machine prior to

cleaning the condenser.

Clean the condenser using a soft brush or vacuum cleaner.

NOTE: if there are any stubborn grease deposits etc. left on or through the condenser call

your Foster Authorised Service Company to carry out a full service.

Once the condenser has been cleaned switch the unit on.

Failure to carry out this action may invalidate the warranty of the condensing unit.

Airflow

Do not obstruct the airflow throughout the cabinet interior.

Air inlet and outlet duct should not be obstructed with cardboard boxes etc. as this may result in

loss of performance.

Page 6

GB

5

>Page Left Blank Intentionally<

Page 7

GB

6

>Page Left Blank Intentionally<

Page 8

FOSTER REFRIGERATOR (a division of ITW Ltd.)

Oldmedow Road, King’s Lynn, Norfolk. PE30 4JU United Kingdom

GB DECLARATION OF CONFORMITY

D ÜBEREINSTIMMUNGSERKLÄRUNG

DK OVERENSSTEMMELSES - ERKLÆRING

E DECLARACIÓN DE CONFORMIDAD

F DECLARATION DE CONFORMITE

FIN VAATIMUSTENMUKAISUUSVAKUUTUS

GR ΔΗΛΩΣΗ ΙΙΡΟΔΙΑΓΡΑΦΗΣ

I DICHIARAZIONE DI CONFORMITA’

NL CONFORMITEIT’S VERKLARING

P DECLARAÇÃO DE CONFORMIDADE

PL DEKLARACJA ZGODNOŚCI CE

S GARANTI

GB We declare the following equipment:

D Man erklärt, daß folgendes Gerät mit den nachstehend aufgefürten Europäischen

DK Man erklærer, at det følgende apparatur:

E Se declara que el siguiente equipo:

F Nous déclarons que les appareils suivants:

FIN Täten vakuutamme, että seuraava laite:

GR Δηλωνεται οτι η παρεβουσα συσκευη:

I Si dichiara che la seguente apparecchiatura:

NL De volgende machines:

P Se declara que a seguente maquina:

PL Deklarujemy że następujące urządzenie:

S Härmed udertygas att följande apparatur:

GB comply with the following European Directives:

D richtlinien übereinstimmt:

DK er I overensstemmelse med de følgende europæiske direktivers forskrifter:

E es en conformidad a cuanto establecen las siguientes Normas Europeas:

F sont conformes aux Directives Européennes:

FIN vastaa seuraavien Euroopan yhteisön direktiivien vaatimuksia:

GR τηρει τις προδιαγραφες των εξης Ευροπαϊκων Оδηγων:

I è conforme a quanto prescritto dalle seguenti Direttive Europee:

NL conform met de Europeese Wetgeving:

P è feita siguendo as prescrições das siguentes diretinas eu:

PL Spelnia wymogi następujących Dyrektyw Europejskich:

S ä normriktig och utformad enligt fölande Europeiska direktiv:

GB and have been designed, realised and controlled according to the following regulations:

D das Gerät ist folgenden Normen gemäß entworfen, angfertigt und geprüft worden:

DK er blevet projekteret, realiseret og kontrolleret i følge neden for beskrevne normer:

E y estuvo proyectado, realizado y controdado segùn las siguentes normas:

F et ont été conçus, réalisés et contrôlés suivant les norms:

FIN ja että se on suunniteltu, valmistettu ja tarkistettu seuraavien säännösten mukaisesti:

GR και σχεδιαστηκε, καταστευαστηκε και ελεγχτηκε:

I ed è stata progettata, realizzata e controllata secondo le seguenti norme:

NL die volgens de volgende normen warden gecontrueerd, uitgevoerd en gecontroleerd:

P e foi projectada, realizada e controlada Segundo as siguentes normas:

PL Oraz że zostala zaprojektowana, wyprodukowana I skontrolowana zgodnie

z nastęepującymi przepisami:

S projekerad, realiserad och kontrollerad enligt föliande normregler:

On behalf of Foster Refrigerator:

C.M. Playford

(Market & Development Director)

January 2014

2006/42 EC

(Machinery Directive)

2004/108 EC

(EMC Directive)

REG.1935/2004 EC

(Food Equipment Directive)

2006/95 EC

(Low Voltage Directive)

2002/95 EC

(RoHS / WEEE Directive)

97/23 EC

(Pressure Equipment Directive)

CEI EN 61000-1 … 4

(EMC Test Standards)

CEI EN 60335-1 / 2-89

(Electrical Appliance Standards)

CEI EN 60204-1

(Electrical Machinery Standard)

UNI EN 378-1

(Refrigeration System / Test Standards)

UNI EN ISO 13857

(Safety Distance Standard)

UNI EN ISO 12100-2

(Machinery Safety Standard)

UNI EN ISO 12100-1

(Design Safety Standard)

FOSTER CONTROLLED THAW CABINET

CT75

Loading...

Loading...