Forney MAXFire 100 User Manual

MAXFire® Series 100 Gas Igniters

A UTC Fire & Security Company

MAXFire® gas igniters provide the most

reliable source of energy for main flame

ignition, flame stabilization, and boiler

warm-up.

Features & Benefits

Cla ss 1, 2 or 3 Gas IG nIter

•

Capacity range from 0.3 to 50 MBtu/hr.

app lICatIo n Fle xIbI lIty

•

The protected primary combustion zone

ensures reliable operation in multiple

environments.

rel Iable IGnItI on

•

99% ignition rate in most applications.

Coo lInG / Combu stIon aIr

•

Low cooling/combustion air requirements.

low maInte nanCe req uIrem ents

•

No moving parts, a self-cleaning spark tip

and no tools required to perform periodic

inspection.

Dur abIlIty

•

Heavy duty material and no moving parts

to wear out.

Product Overview

e MAXFire® Series 100 gas igniters can be used as a Class 1 , Class 2, or

Class 3 igniter, depending on burner capacity. e MAXFire® igniter is easily

installed as a retrofit into most burner types based on its size, capacity, and reliable

operation.

MAXFire® gas igniters consist of four major components: a guide tube, a

gas transport tube, a spark rod, and a stainless steel diffuser for pilot stabilization.

e guide tube houses the spark rod and the gas transport tube, which are easily

removed from the guide tube for maintenance purposes by releasing a "V" band

retainer, requiring no tools. Cooling/combustion airflow is directed down the guide

tube to support and maintain the primary combustion zone during operation. e

controlled mixture of fuel and air in the primary combustion zone results in a

highly reliable, stable igniter flame. While out of service, airflow cools the igniter

and prevents debris from migrating into the end of the guide tube.

MAXFire® gas igniters come standard with Forney’s High Energy Spark

Com patIbIl Ity

•

Fits most existing mount tubes minimizing

retrofit installation costs.

spa rk sour Ce op tIon s

•

The nonfouling HESI comes standard.

HTSI provides high performance at an

economical price.

Forney Corporation • 3405 Wiley Post Road • Carrollton, TX 75006 • 800-356-7740 • Fax 972-458-6650 • www.forneycorp.com

Igniter (HESI) as the spark source. e HESI produces a powerful 12-joule

spark approximately three times per second at the primary combustion zone. e

HESI spark tip is a nonfouling, surface-gap tip which is replaceable as a unit by

a threaded connection. Optional equipment for the MAXFire® includes a High

Tension Spark (HTSI) source in place of the HESI, mounting hardware, hoses,

flame rod and an integral or externally mounted optical flame detector.

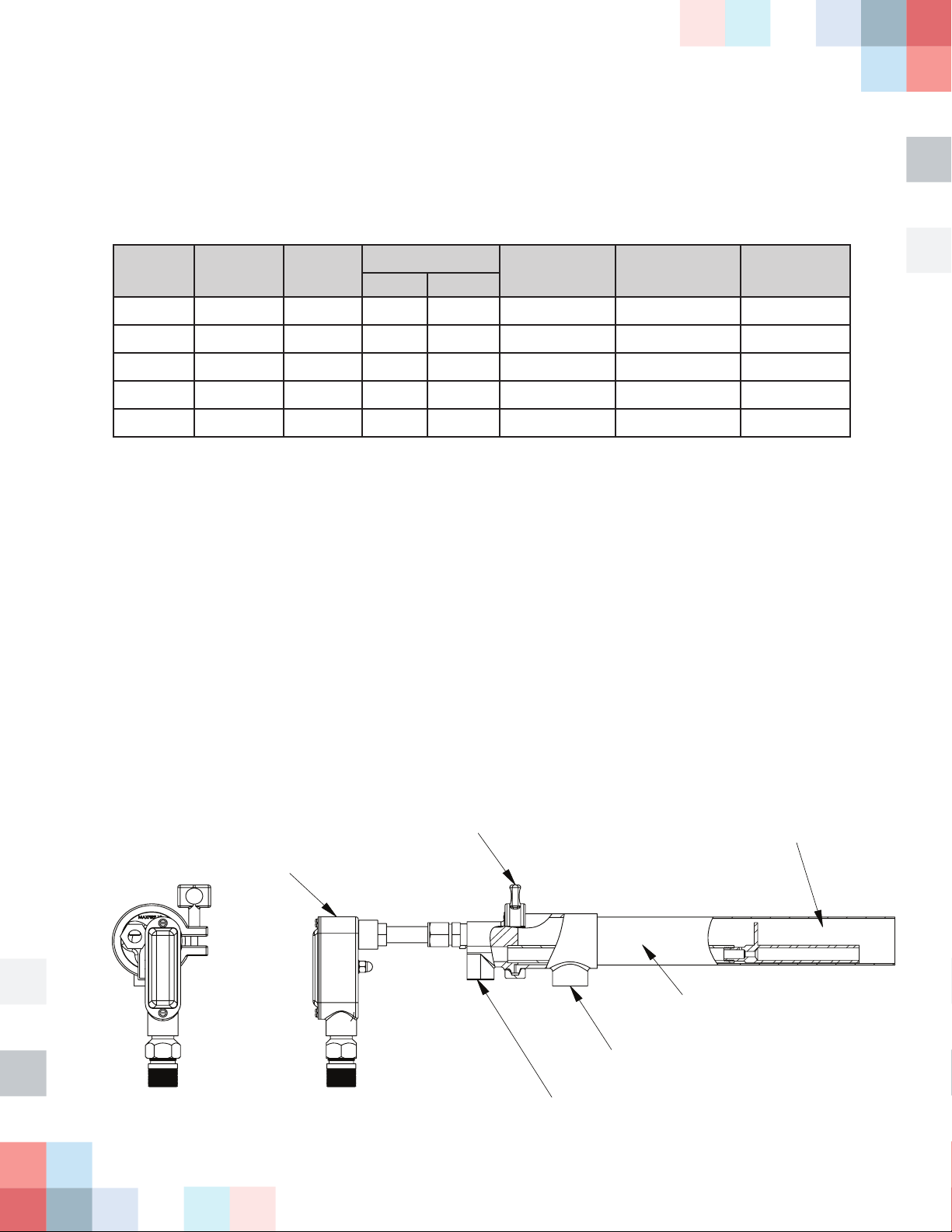

MAXFire® Series 100 Gas Igniters

Primary Combustion Zone

Clamp

Guide Tube

Cooling/combustion Air Inlet

Gas Inlet

HESI

Specications

Fuel: Natural gas or propane

Minimum Length: 14 inches

Guide Tube Material: 10 & 30 - Stainless steel

35, 40 & 50 - Carbon steel with 12” stainless steel at furnace end

Pub # 404006-19

Rev 01/2011

MAXFire

Model

110 0.3 to 1.5 1 7/8” 1/2” 3/4” 23 @ 3 Straight 5-12

130 1.5 to 6.0 2 7/8” 3/4” 3/4” 45 @ 3 Straight or wide 5-12

135 5.0 to 15 3 1/2” 1 1/2” 1 1/2” 50 @ 6 Straight or wide 5-25

140 5.0 to 25 4” 1 1/2” 1 1/2” 80 @ 6 Straight or wide 5-25

150 10 to 50 5” TBD TBD 120 @ 6 Straight or wide 5-25

*scfm@inches w.c. above windbox

Capacity

MBtu/hr

Guide

Tube OD

Connections (NPT) Cooling Air

Gas Air

Requirement*

Nozzle

Type

HESI Specications

Input Voltage: 120 to 240 VAC, 50/60 Hz

Input Power: 120 VAC @ 1.5 A (2-A fuse); 240 VAC @ 0.75A (1-A fuse)

Output Voltage: 2000 VDC

Output Energy: 12 joules per spark

Spark Rate: 3 per second (approximately)

Duty Cycle: 50% at temp 0°F to 135°F (-18°C to 57°C) Ambient

HTSI Specications

Amperage: 20 mA

Input Voltage: 120 to 240 VAC 50/60 HZ

Output Voltage: 6000 VAC

Typical Fuel

Pressure (psig)

Duty Cycle: 100% at temperature rating

Forney Corporation • 3405 Wiley Post Road • Carrollton, TX 75006 • 800-356-7740 • Fax 972-458-6650 • www.forneycorp.com

Loading...

Loading...