Formax FD 6102 User Manual

FD 6102

Low-Volume Inserter

|

Operator Manual |

9/2011 |

First Edition |

TABLE OF CONTENTS

1 |

Health, Safety and Environment ...................................................... |

2 |

|

|

1.1 |

Precautions and Safety Issues ................................................... |

2 |

|

1.2 |

Country Specific Conditions ...................................................... |

3 |

|

1.3 |

End of Life .............................................................................. |

4 |

2 |

Functional description ..................................................................... |

5 |

|

|

2.1 |

The Folding and Inserting Process .............................................. |

5 |

|

2.2 |

Operating Controls .................................................................. |

7 |

|

2.3 |

Control Panel .......................................................................... |

8 |

|

2.4 |

User Interface Description ........................................................ |

8 |

3 |

Operating Instructions .................................................................. |

11 |

|

|

3.1 |

Installing the Envelope Catch Tray ............................................ |

11 |

|

3.2 |

Starting Up ............................................................................ |

11 |

|

3.3 |

Loading Documents ................................................................ |

12 |

|

3.4 |

Loading Envelopes .................................................................. |

14 |

|

3.5 |

Filling the Sealing Liquid Reservoir ............................................ |

15 |

|

3.6 |

Run a Job .............................................................................. |

15 |

|

3.7 |

Daily Mail .............................................................................. |

16 |

|

3.8 |

Stopping the system ............................................................... |

16 |

4 |

Job Programming .......................................................................... |

17 |

|

|

4.1 |

Create a Job .......................................................................... |

17 |

|

4.2 |

Edit a Job .............................................................................. |

18 |

|

4.3 |

Delete a Job .......................................................................... |

18 |

5 |

Operator Maintenance ................................................................... |

19 |

|

|

5.1 |

Cleaning or Replacing Moistening Brushes .................................. |

19 |

|

5.2 |

Clean the System ................................................................... |

19 |

6 |

Fault finding .................................................................................. |

20 |

|

|

6.1 |

Error Messages ...................................................................... |

20 |

|

6.2 |

Clearing Stoppages ................................................................. |

20 |

|

6.3 |

Operator Troubleshooting ........................................................ |

22 |

7 |

Specifications ................................................................................ |

27 |

|

|

7.1 |

Technical Specifications ........................................................... |

27 |

|

7.2 |

Dimensions ........................................................................... |

27 |

|

7.3 |

Other Specifications ................................................................ |

27 |

|

7.4 |

Document Specifications ......................................................... |

27 |

|

7.5 |

Envelope and Insert Specifications ............................................ |

28 |

8 |

Terminology .................................................................................. |

29 |

|

|

Index |

.............................................................................................. |

34 |

ENGLISH

1

1.HEALTH, SAFETY AND ENVIRONMENT

1.1Precautions and Safety Issues

Thoroughly read this operator manual, before using this system.

According to the EC declaration (European Commission) following the Low Voltage Directive (2006/95/EC), this operator manual must be available in the national language(s) of the country where the system is delivered. Therefore, if you do not have an operator manual in your country’s language(s), contact your authorized distributor.

Warnings

•Disconnect the mains supply before performing any maintenance.

•Before connecting check if the system is suitable for the local mains voltage. Refer to the type plate.

Safety Precautions

•Only trained personnel should operate this system.

If untrained personnel do operate this system, the manufacturer does not accept responsibility for any resulting accidents or injuries.

•Only service technicians, who are aware of the risks involved, may open the protective covers.

For safety reasons, the system will not function when the covers are open.

•Keep long hair, fingers, jewelry, etc. away from rotating and moving parts.

•The power connection must be easily accessible, preferably close to the system.

•For safety reasons, it is essential that the system is connected to a socket outlet that has a protective earth connection.

•Over-current protection in the equipment also relies on the branch circuit protection (max. 20 A).

•The following part is considered the equipment disconnect device: - Power supply cord plug or appliance coupler

2

Conventions

Warning

This symbol:

•Identifies situations where improper use of the system can result in personal injury or permanent/catastrophic damage to the system.

•Indicates that the operator manual should be consulted.

Note

A note gives additional relevant information.

Caution

Indicates the presence of a hazard that can cause personal injury or property damage, if the hazard is not avoided.

1.2Country Specific Conditions

Denmark

In Denmark, certain types of Class 1 appliances may be provided with a plug that does not provide an adequate earth connection when inserted into a Danish socket outlet.

Make sure the system has a good functioning connection that has protective earthing (the plug and socket outlet must match).

Japan

•Establish an earth connection before connecting the mains plug to the power supply.

•First disconnect the power supply before removing the earth connection.

Languages

This manual is also available in other languages. For more information, please contact your local supplier.

ENGLISH

3

1.3End of Life

The objectives of the European Community's environment policy are, in particular, to preserve, protect and improve the quality of the environment, protect human health and utilise natural resources prudently and rationally. That policy is based on the precautionary principle and principles that preventive action should be taken, that environmental damage should as a priority be rectified at source.

Separate collection of waste is the precondition to ensure reuse and recycling of waste that is generated at the disposal of electrical or electronical equipment and is necessary to achieve the chosen level of protection of human health and the environment in the European Community.

More particularly, certain materials and components of waste electrical and electronical equipment needs selective treatment as their injudicious handling or disposing of on or into land, water or air would represent a major threat to the environment and human health.

In order to facilitate collection and treatment separated from normal domestic waste, electrical and electronical equipment is marked with the following logo:

Do not mix with normal domestic waste Please use the subjoined return or collection system dedicated to electrical

and electronical waste.

Equipment produced after August 13, 2005.

Not only are you by law not allowed to dispose of the waste equipment via other wastestreams, but we encourage you to actively contribute to the success of such collection and to the common good and better quality of life of present and future generations.

For more information on the correct disposal of this product please contact your local dealer.

4

2.FUNCTIONAL DESCRIPTION

The system feeds, folds and inserts documents into envelopes and then seals and stacks the envelopes. Automatic monitoring ensures the correct number of inserts per envelope.

The system is a sophisticated folding and inserting system which can process large quantities of mail rapidly and easily.

You can save the settings of the system (document type, envelope type and fold type) as jobs.

2.1The Folding and Inserting Process

The figure shows an overview of the document and envelope flow.

1

3

2

ENGLISH

6 |

5 |

4 |

Feeder Area (1)

The system has a feeder block with two document feeders. The feeder block is equipped with hopper swap. This means that you can link both feeders as pairs. When the first feeder is empty, the system switches to the other feeder. Meanwhile you can refill the other empty feeder without stopping the system.

The front feeder (feeder 1) is equipped with a “daily mail” function to process documents or sets of documents which cannot be processed automatically (e.g. stapled).

5

Double Feed Control (DFC)

Each feeder has double feed control (DFC). In this way the system can detect faulty sets of documents. When a job is started, the first document taken per feeder is used for a reference measurement. When a document is exceeding that reference thickness an error will be displayed.

Note

When Daily mail is selected, the DFC is switched off automatically.

Envelope Hopper (2)

The envelopes are picked up and transported to the insert position inside the system.

Feeder for Business Reply Envelopes (BRE) and Other Enclosures (feeder 3)

Small enclosures or BREs are fed from feeder 3 and added to the folded document set.

Folding area (4)

In the folding area the documents are folded. The following fold types are possible (see “Terminology” on page 29):

•No fold

•V-fold (half fold)

•C-fold (letter fold)

•Double V-fold (double parallel fold)

Inserter (5)

The folded document set is transported to the inserter unit and inserted into a waiting envelope. The inserter can seal the envelope.

Exit (6)

The mail set leaves the system from the exit.

6

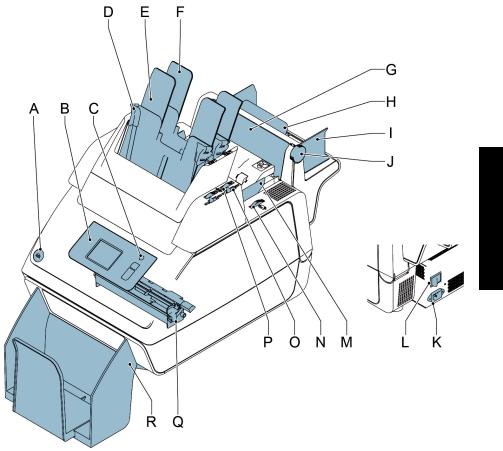

2.2Operating Controls

ENGLISH

A |

button to open the system |

K |

power inlet |

B |

control panel with touch screen |

L |

power switch |

C |

standby button |

M |

side guides envelope hopper |

D |

paper guides |

N |

thumb wheel for adjusting side guides |

E |

document feeder 1 |

|

envelope hopper |

F |

document feeder 2 |

O |

locking lever for side guides of document |

G |

flap, for access to document path |

|

feeder tray 2 and for filling tray 2 |

|

of feeder 3 |

P |

thumb wheel for adjusting side guides |

H |

support feeder 3 |

|

document feeder tray 2 |

I |

side guides feeder 3 |

Q |

sealing liquid reservoir |

J |

thumb wheel to adjust side guides |

R |

catch tray |

|

feeder 3 |

|

|

7

2.3Control Panel

The system has a touch screen (D).

There are three buttons next to the touch |

A |

||

screen: |

|||

|

|||

• Standby button A to switch the system |

B |

||

|

on or off. |

||

|

|

||

• |

: the stop key (B) |

C |

|

|

|||

|

When the stop key is pressed, the |

D |

|

|

system completes the current set and |

|

|

stops.

• : the start key (C)

: the start key (C)

When the start key is pressed the system starts processing.

Caution

The touch screen is covered with a thin pressure-sensitive layer. To avoid permanent damage of the touch screen, do not use sharp objects to press on the touch screen.

2.4User Interface Description

2.4.1Explanation of Buttons and icons

Buttons

Opens a selection menu with |

Back: return to the previous menu |

language settings and supervisor |

|

menu |

|

Home: return to the ‘job selection’ |

Save: save changes to a job |

menu |

|

New job: create a new job |

OK or Yes: confirm choice |

Edit: open the ‘job settings’ menu |

No: reject choice |

Meaning of Icons in Upper Left Corner of Touch Screen

The icons in the upper left corner indicate the menu type you are working in.

Home menu or ‘job selection’ menu |

Settings |

‘job settings’ menu |

Wizard |

8

2.4.2Home (Job Selection)

When you start up the system, the home menu ‘job selection’ appears. With the arrows you can scroll through the jobs. If you want more information on a job, select the job (see

2.4.3 ”Job Description (Current Job)” on page 9).

The Menu button opens a selection menu (see 2.4.4 ”Menu” on page 10).

With the New Job button you can define a new job (see “Create a Job” on page 17).

2.4.3Job Description (Current Job)

If you want more information on a job, select the job in the ‘job selection’ menu.

The ‘current job’ menu shows the following information of the selected job:

•Job name.

•Job counter: total number of mail sets that have been processed with this job.

If you want to set the job counter to zero,

press the edit button  and Reset job counter.

and Reset job counter.

Note

The counter settings are job related.

ENGLISH

ENGLISH

•A picture of the system with symbols for the selected features. The following symbols can be used:

Feeder 1 is set for daily mail.

Sealing is on.

With the home button  you get back to the home menu (‘job selection’).

you get back to the home menu (‘job selection’).

9

2.4.4Menu

When you press the Menu button a selection menu appears. This menu allows you to change system settings and define jobs. The screen shows the following functions:

•Language settings: change the language of the user interface.

•Supervisor menu: define envelope settings (see “Supervisor Menu” below, only for authorized personnel).

2.4.5Supervisor Menu

When you press the Supervisor menu button in the selection menu, a login menu opens. Enter the PIN-code 2546 to access the ‘supervisor menu’.

When you enter the correct pin code the ‘supervisor menu’ appears. This menu enables you to:

•Define custom envelope sizes (press the

Adjust stop position button).

•Adjust the envelope stop position (see “Envelope Position” on page 26).

•Adjust the sealing position (see “Sealing position” on page 26).

•Switch off popups, like the popup that tells you to press the 1x button.

2.4.6Job Settings Menu

When you press on a job and press the edit button

, the ‘job settings’ menu opens. This menu enables you to:

, the ‘job settings’ menu opens. This menu enables you to:

•Edit a job (see 4.2 ”Edit a Job” on page 18).

•Delete a job (see 4.3 ”Delete a Job” on page 18).

•Reset the job counter: sets counter to zero.

•Switch the double feed control (DFC) on or off, per feeder. For example, if you have a document with an address sticker on it,

switch the DFC off. The DFC sees the sticker as a double feed and generates an error message.

10

Loading...

Loading...