Page 1

Formax FD 314 Office

Desktop Folder

Instruction Manual

Page 2

FD 314

Tabletop Paper Folder

1/2015

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

OPERATOR MANUAL

FIRST EDITION

Page 3

TABLE OF CONTENTS

TOPIC PAGE

SPECIFICATIONS 1

SAFETY GUIDELINES 1

UNPACKING AND SETUP 2

INSTALLING FOLD PLATES 3 - 4

SETTING FOLD PLATES 4

SETTING OUTFEED STACKER WHEELS 5

LOADING PAPER & ADJUSTING SIDE GUIDES 5

CONTROL PANEL 6

COUNTER 6

AUTOBATCH COUNTING 6

AUTOBATCH LAST FORM ADJUSTMENT 6

SETTING CUSTOM FOLDS 7

TROUBLESHOOTING 8

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 4

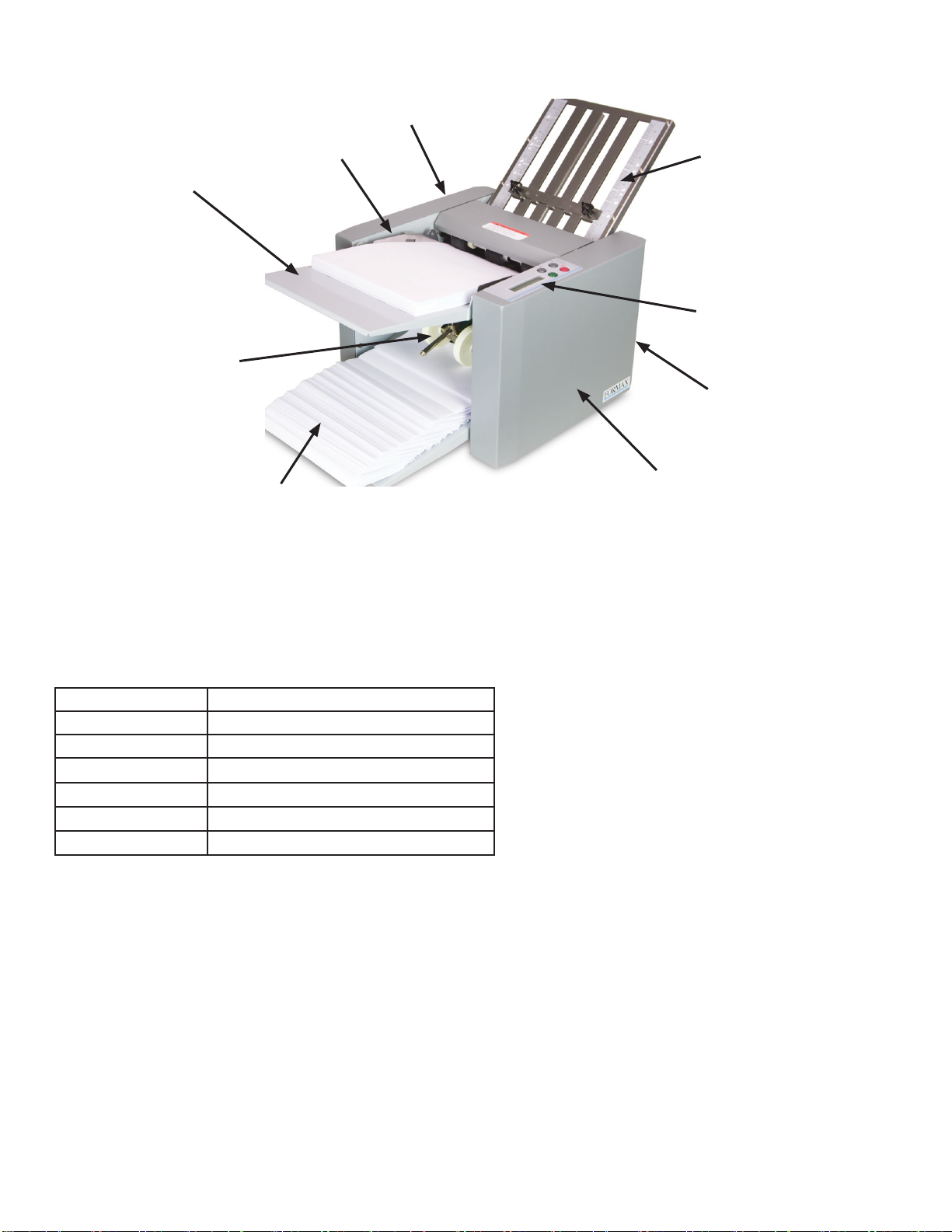

DESCRIPTION

Back Cover

Paper Guides

Upper Fold Plate

Infeed Tray

Control Panel

Outfeed Tires

Lower Fold Plate

Outfeed Conveyor

Front Cover

FUNCTION

The Formax FD 314 Low-Volume Document Folder is designed to fold various paper sizes. The fold plates are

manually adjusted for C, V, Z and double parallel folds.

SPECIFICATIONS

Hopper Capacity Up to 250 sheets 20#

Speed: Up to 7,700 sheets per hour

Paper Size: Up to 8.5” x 14”

Fold Types: C, Z, V, Double Parallel

Dimensions: 24” L x 14” W x 16.5” H

Machine weight 25 lb.

Power supply 120V, 50/60 Hz .6A

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

SAFETY GUIDELINES

• The FD 314 is designed only to fold paper.

• Use the FD 314 in indoor locations only.

• Discontinue use if power cord is frayed or damaged. Contact Formax for assistance.

• Discontinue use if the machine makes unusual noise. Contact Formax for assistance.

• Use only the voltage specied, 120V. Do not attempt to alter this.

• Before using the machine, read all instructions carefully.

• To reduce the possibility of injury, children should not be allowed to operate the machine.

• Keep ngers, hands, loose sleeves, jewelry, hair away from the machine.

• If paper is jammed, switch off power and unplug from outlet. Remove fold plates from the machine and

remove jammed paper.

• When replacing the fuse, use the same type specied. Disconnect machine from power supply then replace

fuse. (Remove the front cover to access the fuse).

1

Page 5

UNPACKING & SETUP

1. Inspect package for damage.

2. Inspect packing to ensure all components are included: FD 314, upper & lower fold plates, power cord.

Lower Fold Plate

Upper Fold Plate

3. Place the FD 314 on a sturdy, level surface. Lower the output conveyor into its fully open position.

4. Open the paper infeed tray

Power Cord

5. Attach power cable to receptacle, and plug into appropriate wall outlet.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

2

Page 6

INSTALLING FOLD PLATES

Upper Fold Plate Lower Fold Plate

Fold stop

Fold stop knobs

Fold stop

Half fold diverter

Upper Fold Plate

Install the upper fold plate at an angle, as shown. Align the notches on each side of the fold plate with the pins

on each side of the machine body. Push gently on the fold plate to lock it into position.

Upper fold plate

Upper fold plate pinsUpper fold plate notches

Upper fold plate seated on pins

3

Page 7

Lower Fold Plate

Install the lower fold plate at an angle, as shown. Align the notches on the fold plate with the lower fold plate

pins. Push gently on the fold plate to lock it into position.

Lower fold plate

Lower fold plate notches

Lower fold plate pins

Lower fold plate seated on pins

Setting Fold Plates

1. Determine the fold type and paper size.

2. Refer to the guides on each side of the upper and lower fold plates and set each one to correspond with

the desired fold type and paper size.

3. To adjust the fold stops, loosen the two thumbscrews, slide the fold stop up or down to the correct position and tighten the thumbscrews. The fold stop notch should be centered on the white line matching the

selected fold type and paper size.

Note: To process a Half Fold, set the upper fold plate stop to the proper position then remove the lower

fold plate, rotate it 180

To set custom folds, refer to the chart on page 7.

Fold stop position decal on upper

fold plate.

o

and re-install it.

Align the fold stop notch

with the icon that

matches the fold type

and paper size.

Loosen the thumbscrews to adjust

the fold stop position.

4

Page 8

Setting Outfeed Stacker Wheels

1. A zip tie is used to hold the outfeed wheels in place during shipping. Cut and remove the tie before

proceeding. Adjust outfeed wheels to match the fold type and paper size. NOTE: This is important for

proper outfeeding. Loosen the thumbscrew and slide the tires up or down to the correct position.

Refer to the guide at right for the correct position. Tighten the thumbscrew to hold the tires in place.

Zip Tie

Fold Type LT (11”) LGA (14”)

Letter “C”

Accordion “Z”

Double Parallel

Half “V”

Loading Paper and Adjusting Side Guides

1. Load the paper by pressing down on the spring-loaded infeed guide. Be sure the leading edge of the

paper is under the feed tires.

Stacker Wheel Position

3 2

3 2

4 3

1 0

2. After loading the paper, adjust the side guides by gently pinching them and sliding them inward toward

the paper stack. Be sure they are snug against the paper stack, then loosen slightly to leave a gap of

approximately 1mm on each side. The paper should lie at.

5

Page 9

Control Panel

1 LCD Screen Displays status, counter, batch counter, any faults

2 START Button Press to start operation

3 STOP Button Press to stop operation

4 BATCH Button Press to change batch counting quantity and interval

54

5 CLEAR/RESET Button Press to clear counter

Counter:

The FD 314 has a 3 digit resettable counter that will count up as the paper is folded. To reset the counter

press and hold the “C” button for 3 seconds.

AutoBatch Counting:

To fold a set number of sheets with a pause between sets, use the AutoBatch Counter. Press the Batch

button repeatedly to set the number of sheets to be folded, then press the red Stop button to set

the number of seconds between each set (up to 30 seconds). Press the Batch button to adjust the time

delay (the delay will cycle up to 30 seconds and then go back to 0).

1

2

3

,

AutoBatch Last Form Adjustment:

The speed of the last three forms can be adjusted when using AutoBatch for accurate sets. For example, if 10

sheets are programmed in AutoBatch and 11 are pulled, the speed of the last three forms needs to be reduced,

if only 9 sheets are pulled the speed of the last three forms needs to be increased. T

ment mode press and hold the Stop button for 3 seconds, the screen will read “M_Count: ### MS”, note

the number shown, then press the Batch button to adjust the speed (the speed will cycle up to 495 MS and

then go back to 005). To increase the speed, set to a higher number and to decrease the speed, set to a lower

number. To exit press the Stop button one time.

o enter the last form adjust

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

6

Toll Free: 1-800-944-4573

Local: 503-640-5920

-

Page 10

Paper Out:

If the control panel reads “NO PAPER”, check the infeed tray and reload paper. The screen will reset when

paper is loaded.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Setting Custom Folds

Example 1: Uneven “C”

1. Measure the length of panel “A”

2. Adjust the upper fold plate so that the stop plate lines

up with the measurements of the panel “A” i.e. if panel

“A” is 5 1/4” long slide the stop plate up or down so that

it lines up with the 5 1/4” mark on the fold plate.

3. Measure the length of panel “B”

Panel A

Panel B

4. Adjust the lower fold plate so that the stop plate lines

up with the measurement of panel “B”

5. Load forms and press test. If folds are too long or too

short adjust accordingly.

Example 2: Uneven “Z”

1. Measure the length of panel “A” & “B”

2. Adjust the upper fold plate so that the stop plate lines up

with the measurements of panel “A” & “B”. i.e. if panel

“A” & “B” are 9” long slide the stop plate up or down so

that it lines up with the 9” mark on the fold plate.

3. Measure the length of panel “B”

4. Adjust the lower fold plate so that the stop plate lines up

with the measurement of panel “B

5. Load forms and press test. If folds are too long or too

short adjust accordingly.

Panel A

Panel B

7

Page 11

Troubleshooting

PROBLEM: SOLUTION:

Folder will not start Check that power cord is plugged into the folder and an electrical outlet

Check that the power switch is ON

Paper will not feed Adjust the paper guides so a single sheet of paper slides freely

between the guides without excessive play

Check to be sure the paper is properly loaded in the infeed tray, with the

leading edge under the feed tires.

Paper folding incorrectly Check that fold plates are inserted correctly (upper on top, lower on bottom)

and that they’re properly seated on their alignment pins

Check the fold stops to be sure they match the positions show on the guide

(see page 3) and that the thumbscrews have been tightened

Overload Check outfeed wheels to be sure they are properly adjusted for fold type and

paper size. Turn folder off and on to reset.

“PAPER ERR” displayed on

control panel

Turn off power and check the fold plates to see if paper is jammed. If it is,

remove the fold plate(s), remove the jammed paper and re-install the fold

plate(s).

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

8

Loading...

Loading...