Page 1

FD 280

Double-Head Edge Tabbing System

Operator Manual

10/2011 First Edition

Page 2

Page 3

TABLE OF CONTENTS

1. INTRODUCTION .............................................................................................. 1

1.1 Organization of this Operating Manual ........................................................... 1

1.2 FD 280 Description ......................................................................................... 1

1.3 Items Included ................................................................................................ 3

1.4 Operating Manual Safety Terms ..................................................................... 4

1.5 Safety Precautions .......................................................................................... 5

1.6 Operating Manual Terms ................................................................................ 5

1.7 Warranty ......................................................................................................... 6

2. SPECIFICATIONS & REQUIREMENTS .......................................................... 8

2.1 Specifications .................................................................................................. 8

2.2 Operating Requirements ................................................................................. 8

3. POWER CONNECTION ................................................................................... 9

3.1 Safety .............................................................................................................. 9

3.2 Line Voltage .................................................................................................... 9

3.3 Line Fuses .................................................................................................... 11

3.4 Accessory Fuses........................................................................................... 12

3.5 Accessory Power Outlet ................................................................................ 13

3.6 Power Cord ................................................................................................... 13

4. CONTROLS .................................................................................................... 14

4.1 Power Switch ................................................................................................ 14

4.2 LCD Counter ................................................................................................. 14

4.3 Control Panel

4.3.1 Power Indicator .............................................................................................. 15

4.3.2 Stop ................................................................................................................ 15

4.3.3 Start .............................................................................................................. 15

4.3.4 Tab Ready……………… ……………………………………………………… 15

4.4 Head Position Knob ...................................................................................... 16

4.5 Tab Mode Switch .......................................................................................... 16

5. FEEDING DEVICES ....................................................................................... 17

5.1 Placing the FD 280 In-Line ........................................................................... 17

5.2 ACCESSORY ITEMS ................................................................................... 18

5.2.1 Fan Fold Tab Stand………………………………………………………………...18

5.2.2 FD 280 Short Cart .......................................................................................... 19

5.2.3 FD 280 Long Cart………………………………………………………….………..19

5.2.4 FD 280-20 Label Delivery Module ………….…………………………………….19

Page 4

6. OPERATION ................................................................................................... 20

6.1 Splicing Tabs ................................................................................................ 20

6.2 Threading Tabs……………………………………………………………………21

6.3 Feeding Portrait Mail Pieces ......................................................................... 22

6.4 Feeding Landscape Pieces .......................................................................... 24

6.5 Tabbing Mail Pieces ..................................................................................... 25

6.6 Adjusting Tab Position …………………………………………………………..26

6.7 Remove Waste Backing Paper…………………………………………………27

6.8 Restore Default Tab Settings……………………………………………………27

6.9 Change Piece Size………………………………………………………………27

7. MAINTENANCE .............................................................................................. 28

7.1 General Cleaning & Clearing ........................................................................ 28

7.2 Replacing a Fuse .......................................................................................... 29

7.2.1 Line Fuse........................................................................................................ 30

7.2.2 Accessory Fuse .............................................................................................. 31

8. TROUBLESHOOTING ................................................................................... 32

8.1 Troubleshooting Chart .................................................................................. 32

9. CORRECTING TABBING PROBLEMS ......................................................... 35

9.1 No Tabs Applied To Mail Pieces

9.1.1 Tab Ready Light Off ........................................................................................ 35

9.1.2 Mail Piece Jam ........................................................................................ 35

9.1.3 Torn Backing Paper ........................................................................................ 36

9.2 Incorrect Threading ..................................................................................... 37

9.3 Poor Tab Placement or Appearance…………………………………………...38

9.3.1 Tab Placement Is Inconsistent .................................................................. 38

9.4 Uneven tab Folds……………………………………………………..…………..38

9.5 Restoring factory settings ………………………………………………………..39

10. SERVICE ...................................................................................................... 40

10.1 Service ........................................................................................................ 40

10.2 Repacking Instructions................................................................................ 40

Page 5

1

1. INTRODUCTION

1.1 Organization Of

This Operating

Manual

1.2 ET Description

This manual starts with a description of your FD 280,

then describes its set up, operation and maintenance.

Finally, information is offered to help you determine

what can go wrong and what to do about it. There

are many helpful tips along the way, and it is strongly

suggested that you become familiar with this entire

manual prior to operating the FD 280.

The FD 280 is an automatic tabbing machine used to

seal open mail pieces. Tabs are peeled from rolls or

fan folds of backing paper and applied to mail pieces

such as self-mailers, booklets, brochures, newsletters

and double postcards.

Mail pieces are fed into the FD 280 using a feeding

device such as the Formax FD 260-10 Feeder, a

feeder or labeler from another manufacturer. If the

FD 280 is to work correctly, mail pieces must be fed

into it correctly -- with a gap of about one inch

between mail pieces. This manual does not cover the

operation of the various feeding devices that may be

used to supply the FD 280 with mail pieces. Please

read your feeding device operating manual before

using it in-line with the FD 280.

NOTE

Some feeding devices require a stand

in order to operate in-line with the FD 280.

Check with your Formax dealer.

The FD 280 uses two tabbing heads to advance

pressure-sensitive tabs past a peel bar. Partially

peeled tabs hang from the backing paper, ready to be

peeled at the peel bar before they contact the mail

piece. Tabs are pressed and folded onto mail pieces

between a set of belts and rollers. The tabbed mail

pieces exit the FD 280 and can be collected in an

optional Catch Tray or stacked by a Formax

FD 260-20 Conveyor.

Page 6

2

Tab quality is as important as mail piece quality. Poor

quality tabs and mail pieces take longer to run, jam

often and produce poor results. Only genuine

Formax brand tabs are 100% guaranteed to run on

Formax Tabbers. Imitation tabs can be run on Formax

Tabbers, but are not guaranteed to run problem-free.

The FD 280 depends on a smooth flow of both tabs

and mail pieces. This flow is monitored by a set of

sensors and a microprocessor. As with most

microprocessor-controlled machines, the FD 280

needs a few seconds to get itself ready to run. When

you turn the power on, the FD 280 takes 5 seconds to

boot up. During this time the tab ready light flashes

and the control panel is inoperative.

Signals from sensors and the encoder are fed to the

microprocessor which monitors the length of pieces

fed and calculates the average length of the piece.

Without correct measuring, the FD 280 will not tab.

The FD 280’s sensors work like all other electric eyes.

When an object breaks the beam of light (the

SENSOR BEAM) between them, an electrical signal

is generated. It is imperative that this SENSOR

BEAM PATH be maintained in its proper condition

and alignment at all times.

Debris and stray tabs can become caught in the

paper path and sensor beam. Rough, careless

handling of the FD 280 can cause the sensors to

become mis-aligned. Both of these conditions must

be prevented. The FD 280 requires periodic cleaning

and reasonable handling. Paper dust build-up or

abuse will bring the successful operation of the FD

280 to an end. Take care of your FD 280 by following

the set up, operation and maintenance instructions in

this manual.

Page 7

3

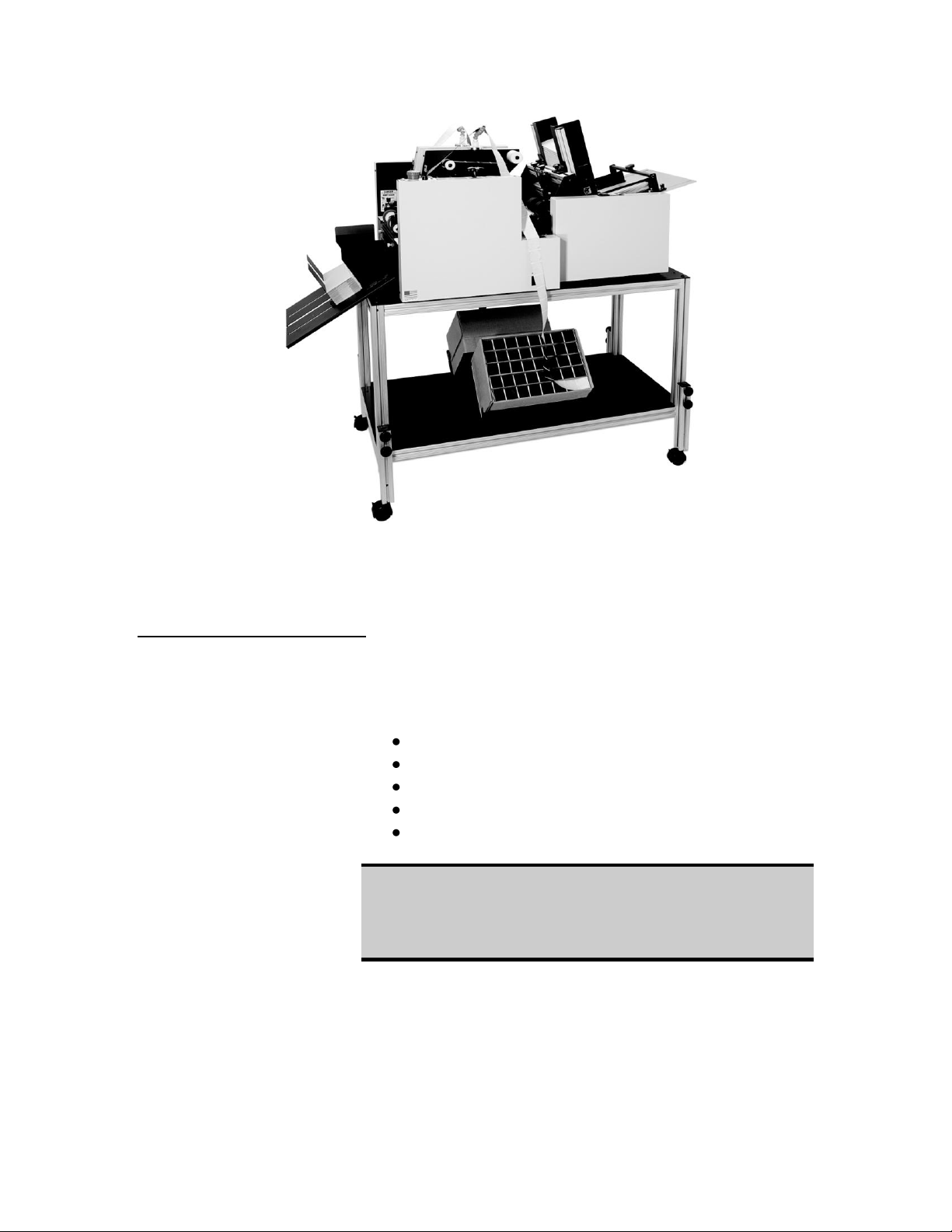

Figure 1.1 – Formax FD 280 with FD 280-10 High Volume Feeder and stand.

1.3 Items Included

The following items are shipped together in one box.

Take note of each as you unpack the box.

FD 280 Tabber with input shafts

Power cord

Catch Tray

2 Magnetic Tab Guides

Operating Manual

WARNING

THE FD 280 IS A HEAVY MACHINE.

USE PROPER LIFTING TECHNIQUES

TO SET IT ON A WORK SURFACE.

Page 8

4

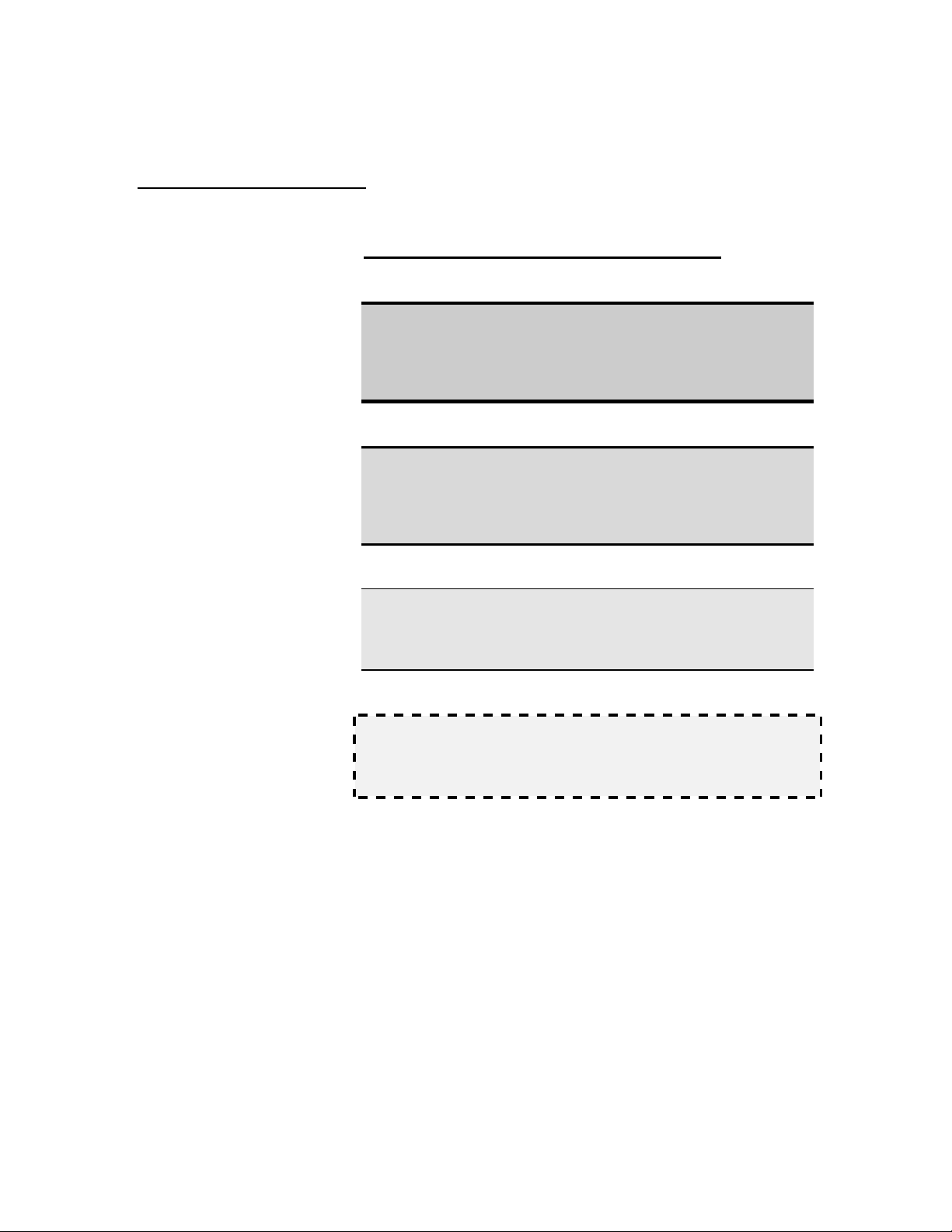

1.4 Operating

Manual Safety

Terms

The following highlighted blocks are used throughout

this manual to emphasize important information.

Pay careful attention to this information.

WARNING

ALERTS YOU TO ACTIONS OR CONDITIONS

THAT MAY PRESENT HAZARDS OR CAUSE

INJURY TO PERSONNEL.

CAUTION

ALERTS YOU TO ACTIONS THAT MAY CAUSE

LOSS OF MATERIALS (MAIL PIECES AND TABS)

OR DAMAGE TO EQUIPMENT.

NOTE

Draws your attention to an important

statement or action.

TIP

A suggestion to enhance the

FD 280’s productivity.

Page 9

5

1.5 Safety

Precautions

Observe the following safety precautions and

warnings when operating, cleaning or repairing the

FD 280. Failure to do so may result in physical injury

or damage to the FD 280. The manufacturer

assumes no liability for your failure to comply with

these requirements.

WARNING

NEVER CLEAN, CLEAR OR DISASSEMBLE THE

FD 280 WITHOUT FIRST UNPLUGGING THE

POWER CORD.

WARNING

KEEP LOOSE CLOTHING, TIES, SCARVES AND

HAIR AWAY FROM ALL MOVING PARTS.

1.6 Operating

Manual Terms

WARNING

DO NOT PLACE FINGERS OR TOOLS BETWEEN

OR NEAR MOVING PARTS.

OBSERVE ALL POSTED WARNING DECALS

The following terms are used throughout this manual:

input end where mail pieces enter

output end where mail pieces exit

operator side side where the controls are

located

non-operator side opposite the operator side

Page 10

6

1.7 Warranty

NOTE

Your FORMAX FD 280 is covered under warranty

by the dealership from which you purchased it.

Formax warrants your FD 280 against defects in

materials and workmanship for a period of six months

from the original ship date when used in accordance

with the operating instructions in this manual. This

warranty covers the cost of parts when the machine is

presented by its original purchaser to an authorized

FORMAX Service Center. Should warranty repairs

become necessary, the service provider, at his/her

option, will repair or replace such parts required to

restore the FD 280 to serviceable condition.

This warranty does not cover consumable parts such

as belts, rollers and sweeps used to contact and

transport mail pieces and tabs. This warranty does

not extend to incidental or consequential damages

arising out of a warranty claim, or to costs associated

with maintenance of the equipment. This warranty

does not cover damages resulting from shipping,

accident, misuse, abuse, neglect, mishandling,

alteration or modification. Your rights under this

warranty may vary from state to state.

Page 11

7

2. SPECIFICATIONS & OPERATING REQUIREMENTS

2.0 Specifications

Size & Weight

20" L x 18" H x 24" W

67 lb. assembled

Power

Possible line voltages are 240V, 230V, 220V,

120V, and 100V at 50-60 Hz

2.1 Operating

Requirements

Mail Piece Size

Height: 31/2" minimum, 9" maximum

Width: 5.5" minimum, 12" maximum

Mail Piece Thickness

Minimum: single sheet of 20 lb. bond paper

tri-folded – 2 tabs.

Maximum: .200”

Tab Specs

Tab width: 1" and 1.5" fan fold or roll

Tab length: 1", 1.5”

Backing paper width: between 1.125" (1" tab) and

1.625 " (1.5" Tabs)

Maximum roll diameter: 10.00" Core Diameter: 3"

Fan Fold: Case Based

Clear or translucent tabs require blacked out tab

areas.

Tab Position Accuracy

1

±

/8" guaranteed when using Formax

their specified shelf life

Mail Piece Fold Quality

Folds in mail pieces should result in flush panels.

Mail piece squareness is important when meeting

USPS tab tenting specifications.

Production

Over 15,000 mail pieces (8.4" long) per hour

®

Tabs within

Page 12

8

3. POWER CONNECTION

BEFORE PLUGGING THE FD 280 INTO AN

OUTLET, CAREFULLY READ THE FOLLOWING

INFORMATION ABOUT VOLTAGES, FUSES AND

3.1 Safety

The FD 280 can connect to any power distribution

system, including the European IT Power System.

Because the European IT Power System does not

have a grounded neutral leg, the FD 280 uses

protective fusing in both the neutral and hot supply

lines of power.

WARNING

THE POWER CORD.

3.2 Line Voltage

WARNING

A BLOWN FUSE IN THE NEUTRAL LEG COULD

MEAN INTERIOR PARTS OF THE FD 280 REMAIN

AT A HAZARDOUS VOLTAGE. ALWAYS UNPLUG

THE POWER CORD BEFORE REMOVING COVERS

FROM THE FD 280.

The FD 280 is rated for continuous operation using a

variety of supply voltages. Possible line voltages are

240V, 230V, 220V, 120V and 100V at 50 or 60 Hz.

The manufacturer configures the FD 280 to operate

with the voltage requested by the customer.

CAUTION

VERIFY THE CORRECT VOLTAGE

SETTING BEFORE PLUGGING THE FD 280

INTO AN OUTLET.

Read the current voltage setting through the

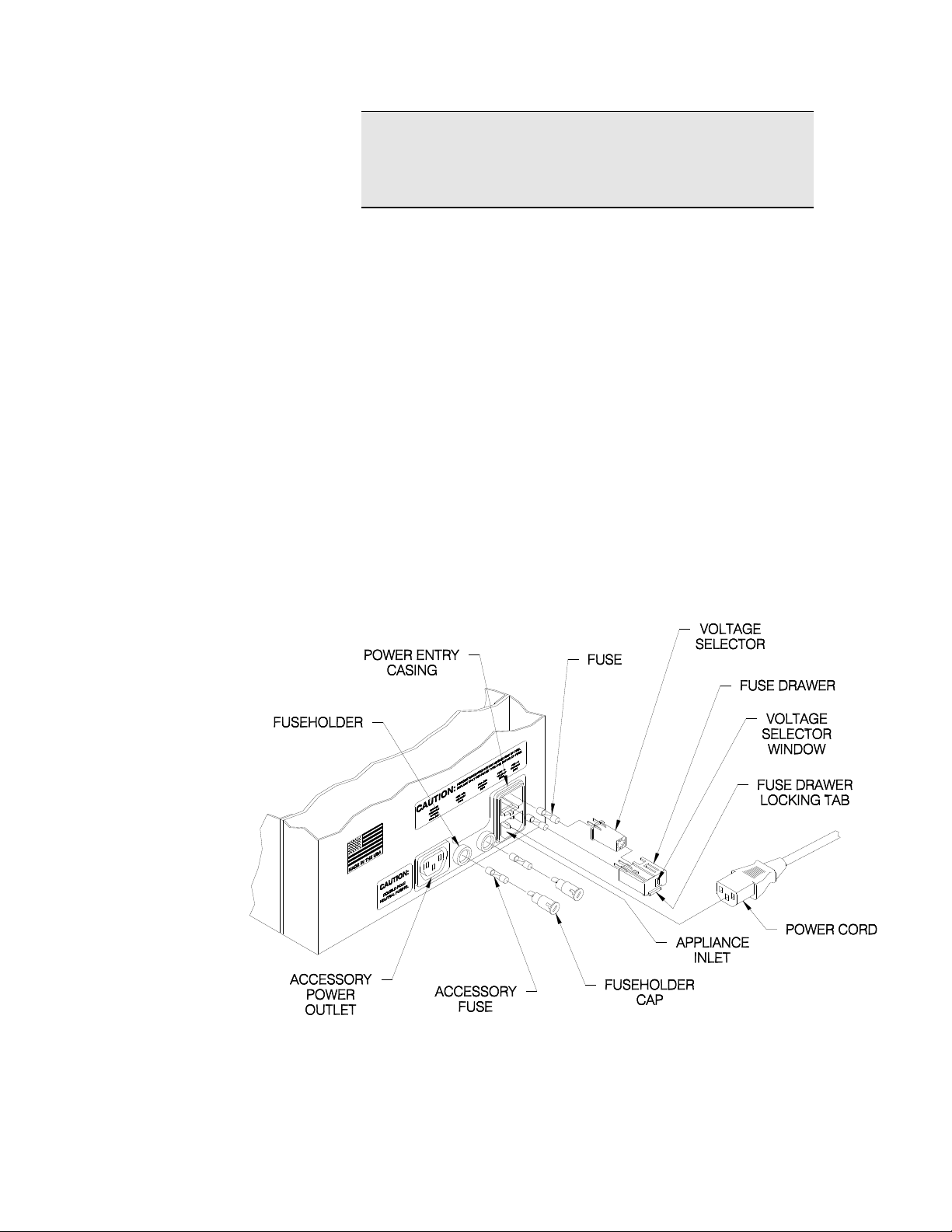

VOLTAGE SELECTOR WINDOW on the nonoperator side of the FD 280. (Refer to Figure 3.1.)

Use the following instructions to change the voltage

setting:

Page 13

9

NOTE

The detachable POWER CORD may need to be

changed to match the particular power-source

output.

1. Unplug the POWER CORD.

2. Use a small screwdriver or similar tool to push up

on and release the FUSE DRAWER LOCKING

TAB.

3. Pull the FUSE DRAWER out of the POWER

ENTRY CASING.

4. Pull the VOLTAGE SELECTOR out of the FUSE

DRAWER.

5. Rotate the VOLTAGE SELECTOR until the correct

voltage is on the same side as the VOLTAGE

SELECTOR WINDOW.

6. Place the VOLTAGE SELECTOR in the FUSE

DRAWER and verify the correct voltage selection.

7. Place the FUSE DRAWER in the POWER ENTRY

CASING.

Figure 3.1 – FD 280 Power Connection

Page 14

10

3.3 Line Fuses

The FUSE DRAWER located on the non-operator

side contains two LINE FUSES. (Refer to Figure 3.1.)

The neutral and hot lines of power are fused. Both

LINE FUSES must be intact for the FD 280 to operate

properly.

CAUTION

VERIFY THAT THE LINE FUSE VALUE IS

CORRECT FOR THE VOLTAGE SETTING.

UNPLUG THE FD 280 BEFORE STARTING THIS

PROCEDURE.

Use the following instructions to verify that the LINE

FUSES installed have the proper fuse value or to

replace a blown fuse:

1. Unplug the POWER CORD.

2. Use a small screwdriver or similar tool to push up

on and release the FUSE DRAWER LOCKING

TAB.

3. Pull the FUSE DRAWER out of the POWER

ENTRY CASING. The LINE FUSES are inside.

4. Determine the proper fuse value as well as the

condition of the LINE FUSE. The fuse value is

shown on the metal tip of the LINE FUSE. The

chart below lists the selected voltage in the left

column followed by the proper fuse value in the

right column.

Selected Voltage Line Fuse Value

100V…………………….1.0A (250V time delay)

120V………………….....1.0A (250V time delay)

220V……………………..0.5A (250V time delay)

240V (or 230V)…………0.5A (250V time delay)

5. Replace the LINE FUSE if necessary. Both LINE

FUSES must be intact for the FD 280 to operate

properly.

6. Install the FUSE DRAWER in the POWER

ENTRY CASING.

Page 15

11

3.4 Accessory

Fuses

Two FUSEHOLDERS are located on the nonoperator side between the APPLIANCE INLET and

the ACCESSORY POWER OUTLET. (Refer to

Figure 3.1.) The FUSEHOLDERS hold two

ACCESSORY FUSES which protect the

ACCESSORY POWER OUTLET. As with the LINE

FUSES mentioned previously, both the neutral and

hot lines are fused. Both ACCESSORY FUSES must

be intact for the FD 280 to properly supply power to

in-line equipment.

WARNING

UNPLUG THE POWER CORD BEFORE STARTING

THIS PROCEDURE.

Use the following instructions to verify that the

ACCESSORY FUSES installed have the proper fuse

value or to replace a blown fuse:

1. Unplug the POWER CORD.

2. Use a small screwdriver or similar tool to press in

and rotate the FUSEHOLDER CAP

counterclockwise to release this cap.

3. Pull the FUSEHOLDER CAP (with the

ACCESSORY FUSE inside) out of the

FUSEHOLDER.

4. Verify the fuse value. Inspect fuses, replace if

blown.

Selected Voltage Line Fuse Value

100V…………………… 6.3A (250V time delay)

120V…………………… 6.3A (250V time delay)

220V…………………… 3.15A (250V time delay)

240V (or 230V)……….. 3.15A (250V time delay)

5. Install the ACCESSORY FUSE and the

FUSEHOLDER CAP in the FUSEHOLDER. Both

ACCESSORY FUSES must be intact for the FD

280 to properly supply power to in-line equipment.

6. Using the screwdriver, press in and turn the

FUSEHOLDER CAP clockwise to lock it.

Page 16

12

3.5 Accessory

Power Outlet

The ACCESSORY POWER OUTLET is located next

to the FUSEHOLDER on the non-operator side.

(Refer to Figure 3.1.) This outlet supplies power to

equipment running in-line with the FD 280.

Typical in-line equipment includes feeders and

labelers. Since the ACCESSORY POWER OUTLET

gets its power from the FD 280, you can control

power to in-line equipment using the FD 280’s

POWER SWITCH. Additionally, the FD 280 features

an automatic interrupt that disables the ACCESSORY

POWER OUTLET in case of a jam. The

ACCESSORY POWER OUTLET is limited to a 6.3A

maximum for 100V and 120V, and 3.15A maximum

for 220V and 240V.

3.6 Power Cord

The FD 280 comes with a three-wire POWER CORD.

The POWER CORD grounds the FD 280 when

connected to an approved three-contact electrical

outlet.

1. Plug the POWER CORD into the APPLIANCE

INLET on the non-operator side. (Refer to Figure

3.1.)

2. Plug the POWER CORD into a grounded outlet.

WARNING

TO PREVENT ELECTRICAL SHOCK, ONLY PLUG

THE POWER CORD INTO A GROUNDED OUTLET.

Page 17

13

4. CONTROLS

4.1 Power Switch

4.2 LCD Counter

The POWER SWITCH is located on the bottom of the

operator side panel. Turn the POWER SWITCH on

to supply power to the FD 280.

The LCD COUNTER is located on the right of the

operator side panel. The LCD COUNTER displays

the current number of tabbed mail pieces fed through

the FD 280. Reset the LCD COUNTER by pressing

its reset button.

Figure 4.1 - FD 280 Operator Panel Controls

Figure 4.2 Tab Pressure Controls

Page 18

14

4.3 Control Panel

4.3.1 Power Indicator

Figure 4.3 - FD 280 Control Panel

The orange Power Indicator light illuminates when the

power switch is turned on.

4.3.2 Stop

4.3.3 Start

4.3.4 Tab Ready

The STOP (red pushbutton mushroom) Switch

interrupts the movement of all moving parts and

resets the microprocessor. Once the STOP button

has been pressed, it must be lifted up into the run

position. Lifting the button will not start the machine.

Press the STOP switch to change tab mode settings.

The Start button is a momentary switch that causes

the resumption of movement after the Stop Switch

has been pressed.

Then green Tab Ready light illuminates when enough

(usually 3-4) pieces have been fed regularly through

the machine to allow precise and regular tabbing. If

the Tab Ready light stays unlit, there is a problem

with the feed mechanism as pieces are not being

counted well.

Page 19

15

4.4 Head Position

Knob

4.5 Tab Size Switch

4.6 Tab Mode Touch

Pad

Turning the Head Position Knob moves the tabbing

heads closer together or farther apart. The decal

indicates the direction. Move heads only while

machine is running.

This three position switch indicates 1.0 inch tabs (up,

used for self mailers), 1.5 inch tabs (down used for

booklets) and Set Up (Center – no tabs).

The Tab Mode Touch Pad offers the ability to select

the number, location and type of the tabs as well as

to change location of tabs. Changing mode settings

can only be done with the STOP button pressed.

Figure 4.4 FD 280 Tab Mode Touch Pad

Once the Tab Size Switch has been moved off Set

Up to a tab size, pressing the key pad selects the

tabs to be run as well as their general location on the

piece. There are three buttons per Tab Head - one

for the lead edge, the center and the trail edge.

A typical booklet setting will call for two tabs to be

selected on one head (lead and trail) and one on the

opposite (trail). To do a Booklet, use 1.5 inch tabs.

Page 20

16

To adjust the position of the tabs, press the Stop

Button and hold down the key pad for the tab to be

moved. After a second or two, the tab select light on

that pad will begin to flash. Use the Lead /Trail

arrows on the right of the touch pad to move the tab

toward the lead edge or trail edge. Ten touches of a

position arrow will result in about half an inch in

movement in the direction selected. If corresponding

tabs on the opposite head are selected, both will

move as one. Starting the transport will save your

changes.

5. FEEDING DEVICES

5.1 Placing The

FD 280 In-Line

To operate the FD 280 in-line with your feeding

device, place the output end of the feeding device

next to the input end of the FD 280. Leave about an

1

/8" gap between the machines. Align machines to

place tabs where desired on the mail pieces.

The gap between the feeding device and the FD 280

may need adjusting if the mail pieces are curled or

rigid. If the mail pieces’ leading edge curls up, the

gap should be larger than 1/8" to allow the curled edge

to come down before entering the FD 280. If the

leading edge curls down, the gap should be as small

as possible, so the mail pieces will not fall between

the two machines. A rigid mail piece may require a

larger gap if it hits the bracket above the FD 280

PAPER PATH.

NOTE

Turn on the FD 280 before turning on any feeding

device. If the FD 280 is not turned on first, it will

not accept the fed mail pieces.

Page 21

17

5.2 Accessory

items

5.2.1 FD 280-50 Fan

Fold Tab Stand

NOTE

Some equipment, when run in-line with the

FD 280, requires a stand to raise it to the level of

the FD 280. When ordering additional equipment,

specify which machine you plan to operate in-line

with the FD 280.

The FD 280-50 Tab Stand is a simple accessory that

greatly improves the operation of the machine with

fan fold tabs.

Boxes are placed on the stand – one on each side.

The boxes are tilted at the correct angle to allow for

smooth tab removal from the box. Tab columns are

spliced lead to tail to run continuously. (See Fig. 1.1)

5.2.2 FD 280-30 Stand

The FD 280-30 Adjustable Height Stand holds the

FD 280 and a Fan Fold Tab Stand. It features

adjustable height legs to allow the FD 280 to be used

in line with a number of different machines.

Page 22

18

5.2.3 FD 280-40 Stand

5.2.4 FD 280-20 High

Volume Tab

Delivery Module

The FD 280-40 Adjustable Height Stand holds the

FD 280-20 High Volume Tab Delivery Module Stand.

The FD 280-20

automatically delivers

tabs from high

volume spools to the

FD 280. One per

head is needed.

Page 23

19

6.0 OPERATION

6.1 Splicing Tabs

WARNING

KEEP LOOSE CLOTHING, TIES, SCARVES AND

HAIR AWAY FROM ALL MOVING PARTS. DO NOT

PLACE FINGERS OR TOOLS BETWEEN OR NEAR

MOVING PARTS.

It is highly recommended that splicing one tab strip to

another be the way to add or change strips of tabs.

Splicing is much quicker than threading and the

machine is delivered threaded. Splices can be made

between tab sizes.

When changing tab sizes, make sure that the

backing paper width of the tabs being run is less

than the tab width specification.

To splice tabs:

1. Stop tabbing with at least 12 inches of tab material

between the peel bar and the end of the strip.

2. Trim the last tab so that the end of the strip is

square.

3. Trim the end of the new tab strip square and

attach a tab to the underside of the strip so that it

is half on, half off the strip.

4. Remove the first few tabs from the new strip and

the last few from the old.

5. Attach the new strip to the old strip so that the end

on the old strip is on top of the new strip and in the

place of the first tab that was peeled off the new

strip. Use the tab on the new strip to stick the two

strips together.

Page 24

20

6. When a splice is made correctly no tabs will be

missed.

When running fan

folded tabs, splice

the last tab in one

stack to the first in

the succeeding

stack for continuous

operation. The tabs

are arranged in the

box to allow splicing

at any time.

Two things to

remember with fan

fold tabs. First, run

the stacks in order

from one side of the box to the other, removing stack

separators as stacks are consumed. Second, set the

box at an angle so that the tabs will always tend to fall

away from the tabber. A Formax FD 280-50 tab

stand is a simple means of accomplishing this.

6.2 Threading Tabs

Figure 6.1 – Splicing Tabs

Threading tabs is a more involved process. The tab

peeling mechanism must be removed and replaced.

Before threading take careful note of the threaded

tabs.

1. Peel at least 1-2 feet of tabs from the lead edge of

the strip to be threaded into the machine.

Page 25

21

2. Remove the peel bar mechanism by unscrewing the

knurled stainless steel knob located on the side of the

assembly.

3. Thread the strip of backing paper down through the

assembly behind the round bar and over the edge of

the peel bar.

4. Holding the backing paper up against the back of the

mechanism, replace it on the machine using the long

Stainless Steel knob.

5. Run the backing paper up and over the black rubber

roll from behind the roller. To allow space between

the black roller and the red rollers, press the

threading release lever.

6. Bring the backing paper up over the front of the red

roller, taking the slack out of the strip and squaring it

under the various rollers in the paper path. Take care

that the edge of the strip is not caught in the peel bar.

7. Take the strip back over the top plastic guide roller

and attach it to the take up spool. Check for

squareness.

Figure 6.2 Threaded Formax FD 280

Page 26

22

6.3 Feeding Portrait

Mail Piece

1. Switch the Tab Size Switch to Set-Up

2. Turn FD 280’s POWER SWITCH on. Push Stop

3. Place a sample of the piece to be tabbed between

button.

the input guides and lock the guides tight to the

edge of the piece without binding the piece.

Figure 6.3 Setting up Input Guides on the FD 280

4. Take the same sample piece and set it between the

vertical tab indicator plates on the exit side of the tab

heads. Run the transport and rotate the Head

Position control to bring the heads close (to within a

sixteenth of an inch) to both edges of the piece.

Some pieces are not folded square. Use the widest

part of the piece to set the distance between the

heads.

5. Stop the transport and slide a feeder up into position.

Start the transport and send sample pieces through.

Make sure that guides are set and locked and that the

heads are not too close together to jam pieces.

Pieces must travel smoothly through the machine.

Page 27

23

6.4 Feeding

Landscape Mail

Pieces

Figure 6.4 Setting the heads to match a piece on the FD 280

The FD 280 is capable of accepting pieces in either

Portrait or Landscape orientation. Booklets are

typically edge tabbed in Portrait direction while self

mailers are often top tabbed in landscape. The

typical folded self mailer is narrower than the

minimum space between the self centering input

guides. In order to top tab accurately the piece needs

to be registered against the operator side input guide

and the operator side head set to apply either 1 or 2

tabs to the piece.

1. Press the Stop Button and select SET UP on the

Tab Size Switch. Tab Ready Light will be off.

2. Set the feeder to the width of the narrow piece to

be run.

3. Set the Input Guides about 1 inch wider than their

narrowest setting.

4. Adjust the space between the heads to about 1

inch. This will put the Operator side head wider

than it should be for good top tabbing.

5. Feed pieces. Carefully bring the tab heads

together so that the edge of the piece to be

tabbed runs just free of the tab fold mechanism.

The edge should be just under the edge of the tab

fold belt.

6. Press the Stop Button

7. Select the correct tab mode (see Sec. 6.5).

Page 28

24

8. Lift the Stop button, Press start and feed pieces.

Three will feed before tabbing begins.

TIP

To register the narrow piece against the operator

side input guide, try to offset the guide bar(s) in

their mounting holes. Thin material may require a

single bar to be offset, thick material may require

both to be offset. Run the material under one of

the set of rollers only. See Figure 6.5

6.5 Tabbing Mail

Pieces

Figure 6.5 Roller Offset for stiff self mailers.

1. Make sure tabs are threaded correctly and peel

point area is clear.

2. Turn the POWER SWITCH on.

CAUTION

TO AVOID A JAM, TURN THE FD 280 ON BEFORE

TURNING ON THE FEEDING DEVICE.

Page 29

25

Figure 6.6 Tab Selection Key Pad

3. Stop the machine with the Stop Switch

4. Select the correct tab size on the Tab Size Switch

5. Press the Tab Selection Key Pad to set the

number of tabs per head. Typically there will be at

least one tab selected (lit) per head.

6. Double check to be sure that the paper guides

and the tab guides are set for the correct piece

width.

7. Lift the Stop Button and press Start.

8. Feed pieces through the machine until the tab

ready light comes on (usually three).

9. The FD 280 begins tabbing in the mode selected.

Tabs are placed and folded per the USPS

regulations.

6.6 Adjusting Tab

Position

TIP

When finishing a tabbing job, leave tabs threaded

in the machine and press the Stop Button before

turning off the Power.

1. Press the STOP button.

2. Determine which tab or pair of tabs that need to

be moved and in which direction.

3. Press on the Tab Selection Key Pad

corresponding to the tab(s) that need to be

moved. Hold it for a second or two until the light

flashes.

Page 30

26

6.7 Removing Waste

Backing Paper

4. Press the Lead or Trail arrows to move the tab (s).

Two presses of the arrow will move the tabs

almost one eighth of an inch.

5. Lift the Stop Button and run tabs.

6. Repeat as needed to place tabs where desired.

7. If tab placement is drastically altered, tab positions

are interfering with one another (ex. Lead tab in

Center area). Stop and move tabs clear of one

another or restore factory settings (Section 6.8)

and begin the adjustment process again.

1. Tear the waste backing paper, leaving enough to

reach and wrap around the TAKE-UP SPINDLE.

2. Pull the waste backing paper off the TAKE-UP

SPINDLE.

3. Place backing paper under the TAKE-UP

SPINDLE from the input end.

4. Secure the backing paper to the underside of the

SPINDLE with tape.

6.8 Restore Default

Tab Settings

All FD 280’s are set at the factory to meet USPS

recommended settings. Each “C” tab is set to the

center of a piece. To quickly restore these settings.

1. Press Stop.

2. Press and hold Head 1 and 2 “L” keys plus both

the Lead and Trail keys until the lights begin to

flash.

3. Release keys and wait until all lights stop flashing.

Lift Stop and resume tabbing by selecting the correct

tab positions for the piece being run.

Page 31

27

6.9 Change Piece

Size

NOTE: It is always advisable to go through

the set up procedure when changing the size

of the piece being tabbed.

Feeding and transport are critical to good tabbing.

When changing piece sizes, use the SET UP mode

first.

1. Press the RED Stop Button

2. Switch to the SET UP mode on the size selection

switch.

3. Make all mechanical adjustments to the feeder,

input guides and tab plates.

4. Send as many pieces through as necessary to

achieve smooth operation.

5. Press Stop and switch to the tab size and location

6. Lift Stop and feed three pieces. The TAB READY

light will come if the three pieces have fed regularly

and have been measured correctly by the machine.

7.0 MAINTENANCE

7.1 General

Cleaning

Your FD 280 will need regular cleaning. How often

you’ll need to clean it depends on the amount of

paper dust your mail pieces generate. Wipe surface

dust or debris from the FD 280 with a damp cloth as

necessary.

TIP:

It is easier to move heads apart and together

when the rollers are turning.

Periodically check for peeled tabs stuck on the roller

near the bottom of the PEEL PLATE.

Page 32

28

7.2 Replacing Fuses

To remove tabs and debris from peel point area:

WARNING

DO NOT PLACE FINGERS OR TOOLS BETWEEN

OR NEAR MOVING PARTS.

1. Spread the heads as far apart as possible to

expose the transport rollers.

2. Hit the Stop Button

3. Turn the POWER SWITCH off and/or uplug the

unit.

4. Gently remove the tabs from the roller using a

roller cleaning solvent.

When one or both LINE FUSES are blown, the

FD 280 will appear to have no power and the LINE

FUSE must be replaced. Press the STOP Button and

turn Power OFF before replacing a fuse.

7.2.1 To replace a LINE

FUSE:

WARNING

UNPLUG THE POWER CORD BEFORE OPENING

THE FUSE DRAWER.

1. Use a small screwdriver or similar tool to push up

on the FUSE DRAWER LOCKING TAB to release

this locking tab. (Refer to Figure 7.1.)

Page 33

29

2. Pull the FUSE DRAWER out of the POWER

ENTRY CASING. (Refer to Figure 7.1.)

Figure 7.1 Replacing FD 280 Fuses

3. Inspect the FUSES; look for blackened glass,

melted wire or a disconnected wire between the

ends of the tube. If you find any of these

problems in either FUSE, that FUSE is blown and

must be replaced.

4. Pull the blown FUSE from its slot.

WARNING

REPLACE ONLY WITH SAME TYPE AND RATING

OF FUSE. (REFER TO CHART BELOW.)

Selected Voltage Line Fuse Value

100V…………………….1.0A (250V time delay)

120V………………….....1.0A (250V time delay)

220V……………………..0.5A (250V time delay)

240V (or 230V)…………0.5A (250V time delay)

Page 34

30

7.2.2 To replace an

ACCESSORY FUSE:

5. Place the new FUSE into the same slot.

6. Install the FUSE DRAWER. (Refer to Figure 7.1.)

Accessory Fuse

When one or both ACCESSORY FUSES are blown,

the ACCESSORY POWER OUTLET and the

machine plugged into this outlet lose power.

WARNING

UNPLUG THE POWER CORD BEFORE OPENING

THE FUSE DRAWER.

1. Use a small screwdriver or similar tool to press in

and slightly rotate the FUSEHOLDER CAP

counterclockwise. (Refer to Figure 7.1.)

2. Inspect the FUSE; look for blackened glass,

melted wire or a disconnected wire between the

ends of the tube. If you find any of these

problems in the FUSE, it is blown and must be

replaced. If the first FUSE is fine, repeat steps 1

and 2 for the second FUSE.

3. Pull the blown FUSE from its slot.

WARNING

REPLACE ONLY WITH SAME TYPE AND RATING

OF FUSE. (REFER TO CHART BELOW.)

Selected Voltage Line Fuse Value

100V…………………… 6.3A (250V time delay)

120V…………………… 6.3A (250V time delay)

220V…………………… 3.15A (250V time delay)

240V (or 230V)……….. 3.15A (250V time delay)

4. Place the new FUSE into the same slot.

5. Install the FUSEHOLDER into the same slot.

Refer to Fig. 7.1

Page 35

31

Trouble

Cause

Solution

1. Nothing works,

no orange Power

Indicator light

Power switch is not

on.

Turn power switch on.

Power cord is

damaged or not

plugged into proper

outlet.

Replace power cord if

damaged or plug into

proper outlet if

necessary.

Outlet does not have

power present.

Check circuit source

for a blown fuse or

circuit breaker.

2. Not tabbing -TAB READY light

is on but no tabs

at peel point.

Tabs not threaded

correctly

Tab motor failure,

Microprocessor

Failure

Out of tabs or tab

sensor blocked

Check and re-thread.

Toggle Power Off and

on waiting 5-10

seconds to reset

processor.

Remove tabs from

the sensor if present

and re-thread.

3. Not Tabbing

Tab Ready Light

is OFF

Transport Failure

Tab Mode Switch

Inconsistent tab

length counts due to

slippage in transport,

jamming pieces.

Poor Feeding.

Tab Mode Switch on

Setup

Processor. Toggle

off and on to reset

4. FD 280 stops.

Power entry fuse is

blown.

Replace blown line

fuse. Refer to

Section 3.3.

FD 280 keeps blowing

fuses after you

replace them.

Contact authorized

Formax dealer.

8.0 TROUBLESHOOTING

REMOVING, ADJUSTING OR REPAIRING ANY

WARNING

UNPLUG THE POWER CORD BEFORE

PARTS IN THE FD 280.

Page 36

32

Mail piece has

jammed in machine.

Clear the jam. Refer

to Section 9.1.3.

Backing paper has

torn before the drive

roll.

Thread tabs from that

point on. Refer to

Section 9.1.4.

5. Feeding stops.

Accessory fuse is

blown.

Replace blown

accessory fuse. Refer

to Section 3.4. If the

fuse is not blown,

refer to your feeding

device manual.

6. Backing paper

slack.

Backing paper is

threaded under the

drive roll.

Re-thread tabs.

Refer to Section 6.1.

7. Tabbing

incorrectly

Peel plate assembly is

not latched.

Debris and tab residue

at peel and fold point.

Tabs set too close

together

Piece size has

changed without

resetting tab

placement locations

Insert and latch peel

plate assembly.

Thoroughly clean tab

fold and seal rollers

and belts. Remove

all tab debris.

Move lead tab closer

to lead edge.

Reset tab placements

see sec. 6.9

8. Multiple tabs on

mail piece.

Incorrect TAB MODE

selection.

Make Mode selection

for tabs and forms

being run. Section

9.1.2.

9. Tab placement is

inconsistent.

Mail pieces are

feeding crooked.

Make sure mail

pieces feed straight

into FD 280. Refer to

Section 9.2.1.

Backing paper has

torn after the drive roll.

Re-thread backing

paper from drive roll.

Refer to Section

9.1.4.

Tabs Hanging up on

way to tabber.

Make sure that tabs

are being pulled from

the tab source freely.

The FD 280 works

best with no

resistance (slack)

from the tabs.

Tilt the box of tabs.

Remove stack

separators.

Page 37

33

10. Tab fold is

uneven.

Head position needs

adjustment.

With 1 inch tabs, the

tabs are not centered

Adjust head position.

Refer to Section

9.2.2.

Make sure that the

tab strip is between

the hinged guides on

the peel bar.

Tab Size Wrong

Power Off, select tab

size

11. Leading edge of

mail piece tears

at the tab.

Head position needs

adjustment.

Mail pieces are poorly

folded.

Mail pieces are too

thin.

Spread the heads

apart slightly.

If tenting is too great,

move heads closer

together slightly.

12. Mail pieces jam

upon entering FD

280.

Input Guides are too

close together

Spread guides.

Input device and

tabber are misaligned.

Correct alignment is

critical. Carefully

position the input

device for correct

feeding and

transport.

Feeding device is too

fast.

Reduce speed of

feeding device until

tabs are being

applied correctly.

Skew at the feeder.

Pieces MUST feed

straight to tab

straight. Consult

feeder manual to

eliminate skew at the

output of the feeder.

Page 38

34

9.0 CORRECTING TABBING PROBLEMS

9.1 No Tabs on

Pieces

9.1.1 Tab Ready Light

doesn’t come on

Make sure that pieces are being fed through the FD

280 smoothly and consistently. The FD 280

measures the first three pieces through the machine

after set up and if these three are not close in

measurement, the ready light will not come on.

Clean the product sensor.

Turn the machine off and on after waiting for 10

seconds.

If this doesn’t remedy the problem, the difficulty lies

with a sensor, an encoder or the processor or their

related electrical connections.

9.1.2 Mail Piece Jam

Mail pieces usually jam during set up. The cause of a

set up jam is usually obvious. Any of the piece width

adjustments is not made correctly. Carefully set-up

the machine and check the width of the heads and

input guides. Make sure that the feed device is lined

up correctly and precisely before feeding pieces. A

feeder must deliver the piece as square and as

straight as possible into the FD 280.

If a piece jams during tabbing, it is most likely the

result of a poorly folded piece being introduced

between closely set heads or skew introduced at the

feeder.

Occasionally, an interruption in tab delivery will cause

a partially dispensed tab to hang up a piece. Make

sure that tabs flow into the machine with little or no

resistance.

Page 39

35

To clear mail pieces from the transport tray:

WARNING

DO NOT PLACE FINGERS OR TOOLS BETWEEN

OR NEAR MOVING PARTS.

1. Press the STOP switch quickly

2. Leave the heads in place.

3. Reverse the piece through the FD 280 by turning

the transport rolls by hand. Pull the jammed mail

pieces out of the input area of the transport.

4. If the jam happens upstream from the tab heads, it

may be necessary to remove the transport rolls.

Each set of rolls is spring loaded and is mounted

on a spring loaded shaft. Release spring pressure

and slide the entire roll assembly out of the

machine by compressing the spring on the shaft

and lifting the shaft out once one end is free from

its mounting hole. Note one mounting hole is

shaped like s “D” to prevent the shaft from turning.

Make sure to replace the shaft as you have

removed it.

9.1.3 Torn Backing

Paper

WARNING

DO NOT PLACE FINGERS OR TOOLS BETWEEN

OR NEAR MOVING PARTS.

If the backing paper tears before the drive roll, the

FD 280 will stop tabbing but continue feeding.

To start tabbing:

WARNING

DO NOT PLACE FINGERS OR TOOLS BETWEEN

OR NEAR MOVING PARTS.

1. Turn the POWER SWITCH off.

2. Thread the FD 280 from the point where the

backing paper tore. (Refer to Section 6.1.)

Page 40

36

NOTE

When backing paper is pulled, tabs will peel at the

PEEL PLATE until pulling is stopped.

3. Remove any tabs or debris from the peel point

area

4. Turn the POWER SWITCH on.

5. Toggle ON/OFF until a tab advances to the peel

point and the TAB READY light illuminates.

If the backing paper tears after the drive roll, the

backing paper may fall away from the FD 280 and

tabbing will continue. If the backing paper wraps

around rolls in the threading path, tabbing may

continue, but tab placement may not be accurate. To

continue tabbing accurately:

9.2 Incorrect

Threading

WARNING

DO NOT PLACE FINGERS OR TOOLS BETWEEN

OR NEAR MOVING PARTS.

1. Turn the POWER SWITCH off.

2. Secure the backing paper around the TAKE-UP

SPINDLE with the CLIP. You may need to pull the

backing paper a little to reach the TAKE-UP

SPINDLE.

Threading a tab strip incorrectly can prevent tabbing.

Three examples are listed below. See Sec. 6.1

PEEL PLATE ASSEMBLY is not latched. The

backing paper will pull the PEEL PLATE assembly

out of its slot, tabs will peel in the wrong place,

and the PEEL PLATE assembly will block any mail

pieces entering the FD 280.

Backing paper is threaded under the DRIVE

ROLL. The backing paper will pull backward and

no tabs will peel.

Page 41

37

9.3 Poor Tab

Placement Or

Appearance

9.3.1 Tab Placement Is

Inconsistent

Tabs are in front of steel bar at the bottom of the

peel bar assembly. Make sure that you see the

steel bar at the top of the peel plate when tabs are

threaded.

If tab placement on mail pieces varies during the

same run, check to see if mail pieces are feeding

straight. Make sure the paper guides on your feeding

device are set against the sides of the stack of mail

pieces. If mail pieces can move sideways between

the paper guides, they will not feed straight.

To check your tab placement:

1. Hold a stack of tabbed mail pieces. Make sure all

edges are straight and even, and all tabs are on

the same side.

2. Look at the tabbed side of the stack. If the tabs

do not form a straight line down the stack, the mail

pieces are moving sideways as they enter the

FD 280.

3. Set paper guides correctly and securely on the

feeding device.

Also make sure that the tabs are freely moving from

the tab supply into the FD 280. If tabs hang up, they

will be misplaced. Do not feed the FD 280 from rolls

that do not consistently run freely and/or are not

advanced to keep slack between the roll and the

FD 280.

Page 42

38

9.4 Tab Fold Is

Uneven

If tabs are folding poorly, the piece may be folded

badly.

The tab heads may be too tight (tearing of the tab) or

too far apart (tenting). Make position adjustments

very carefully. Be sure that the space between the

tab heads is NEVER smaller than the space between

the input guides.

Tabs may be wandering in the tab guides indicating

that something in the tab path is applying too much

pressure to one side of the tab web.

Tabs are made of different materials and will fold

differently. For example, paper tabs may fold

differently than foil tabs. Colored tabs may fold

differently than white tabs because ink adds moisture

and density.

Genuine Formax tabs are tested with machines and

will work in the most consistent manner.

Contact an authorized Formax dealer for supplies.

9.5 Restoring

Factory Settings

The FD 280 affords the operator great flexibility in tab

selection and placement. For example, a delayed

center position tab may be set and selected instead

of the opposite trailing edge tab when it is necessary

to have the tab miss important text on the piece.

The net result may be confusing at the outset of a

different job and factory settings will need to be

restored.

To restore these settings:

1. Stop the transport by pressing the RED Stop

Switch.

Page 43

39

2. Depress the two Lead position keys (L’s) and the

two tab placement keys (arrows), holding all four

down until the light flashes stabilize.

3. Release and wait until lights go out.

4. Resume set up by selecting positions appropriate

for the job being run.

NOTE: When changing from a piece to one

of another dimension, go through the set

up process to avoid misplaced tabs.

10. SERVICE

10.1 Repacking

Instructions

If any problems occur with this equipment or if you

need assistance installing or operating your FD 280

contact an authorized Formax dealer.

If it is necessary to ship your FD 280 to your

authorized Formax dealer for service, pack it in the

original shipping container and packaging material. If

the original container is not available, the FD 280

should be carefully packed so that it will not be

damaged in transit.

When calling for service, have your FD 280’s serial

number handy.

NOTE

If the FD 280 is packed correctly, your

Shipping Carrier is liable for any damages

that occur during shipping.

Page 44

40

Use the following instructions to pack the FD 280 with

commercially available materials.

1. Double wrap the machine in heavy plastic.

2. Use a heavy duty, double-walled container of 350pound test material.

3. Surround the FD 280 on ALL sides with at least 4

to 5 inches of heavy duty shock absorbing

packaging material (peanuts or wadded up

newspaper do not qualify as “heavy duty”. This

will provide firm cushioning and prevent

movement inside the container.

4. Seal the top and bottom of the shipping container

with strong tape or banding material.

5. Clearly and legibly mark the shipping container

FRAGILE.

Loading...

Loading...