Page 1

FD 260-20

Conveyor for FD 260 Tabber

Operator Manual

1/2011 First Edition

Page 2

Page 3

TABLE OF CONTENTS

1. INTRODUCTION .............................................................................................. 1

1.1 FD 260-20 DESCRIPTION ............................................................................... 1

1.2 ITEMS INCLUDED ............................................................................................ 1

1.3 OPERATING MANUAL SAFETY TERMS .............................................................. 2

1.4 SAFETY PRECAUTIONS ................................................................................... 3

1.5 WARRANTY ................................................................................................... 4

1.6 ORDERING ADDITIONAL EQUIPMENT ................................................................ 4

2. SPECIFICATIONS & REQUIREMENTS .......................................................... 5

2.1 SPECIFICATIONS ............................................................................................ 5

2.2 OPERATING REQUIREMENTS ........................................................................... 5

3. POWER CONNECTION ................................................................................... 6

3.1 SAFETY ........................................................................................................ 6

3.2 LINE VOLTAGE ............................................................................................... 6

3.3 LINE FUSES................................................................................................... 8

3.4 POWER CORD ................................................................ ............................... 9

4. SET-UP ........................................................................................................... 10

5. OPERATION ................................................................................................... 12

6. MAINTENANCE .............................................................................................. 14

6.1 CLEANING ................................................................................................... 14

6.2 REPLACING A FUSE ..................................................................................... 14

7. TROUBLESHOOTING ................................................................................... 15

7.1 TROUBLESHOOTING CHART .......................................................................... 15

8. SERVICE ........................................................................................................ 16

8.1 SERVICE ..................................................................................................... 16

8.2 REPACKING INSTRUCTIONS ........................................................................... 16

i

Page 4

Page 5

1. INTRODUCTION

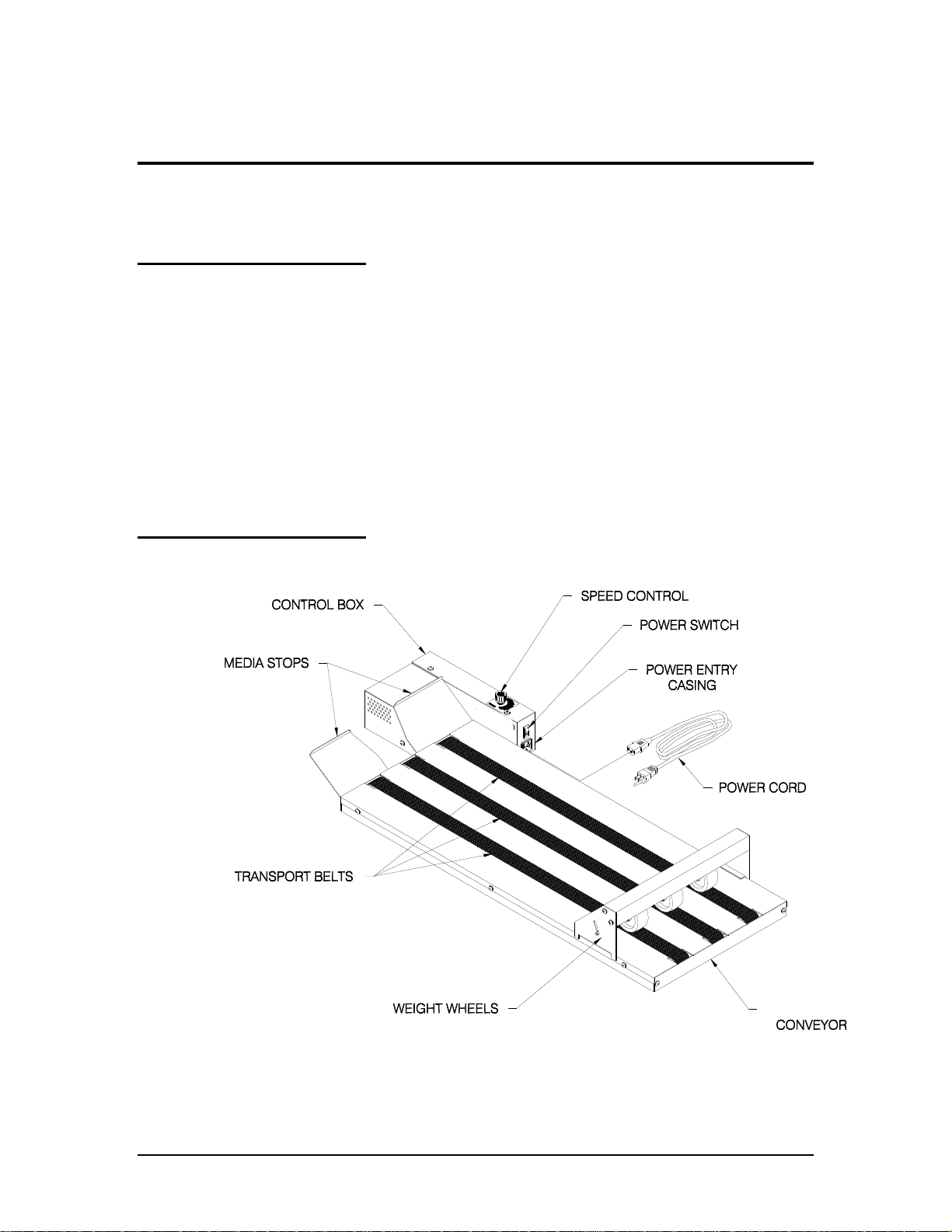

1.1 FD 260-20

Description

The Formax FD 260-20 is a variable speed conveyor that

moves finished mail pieces away from mail processing

equipment.

A DC motor drives three rubberized transport belts which

carry mail pieces to the end of the conveyor where they are

stacked against the media stop. Weight wheels ensure mail

pieces shingle neatly and consistently.

1.2 Items Included

Figure 1.1 – FD 260-20 with Components

1

Page 6

1.3 Operating

Manual Safety

Terms

The following items are shipped together in one box. Take

note of each as you unpack the box. (Refer to Figure 1.1.)

FD 260-20 Conveyor

power cord

weight wheels (disassembled)

Operating Manual

WARNING

THE FD 260-20 IS A HEAVY MACHINE.

USE CORRECT LIFTING TECHNIQUES

TO SET IT ON A WORK SURFACE.

The following highlighted blocks are used throughout this

manual to emphasize important information. Pay careful

attention to this information.

WARNING

ALERTS YOU TO ACTIONS OR CONDITIONS

WHICH MAY PRESENT HAZARDS OR CAUSE

INJURY TO PERSONNEL.

CAUTION

ALERTS YOU TO ACTIONS WHICH MAY CAUSE

LOSS OF MAIL PIECES OR DAMAGE TO

EQUIPMENT.

NOTE

Draws your attention to an important statement or

action.

2

Page 7

1.4 Safety

Precautions

Observe the following safety precautions and warnings

when operating, cleaning or repairing the FD 260-20.

Failure to do so may result in physical injury or damage to

the FD 260-20. The manufacturer assumes no liability for

your failure to comply with these requirements.

WARNING

NEVER CLEAN, CLEAR OR DISASSEMBLE THE

FD 260-20 WITHOUT FIRST UNPLUGGING THE

POWER CORD.

WARNING

KEEP LOOSE CLOTHING, TIES, SCARVES AND

HAIR AWAY FROM ALL MOVING PARTS.

WARNING

DO NOT PLACE FINGERS OR TOOLS BETWEEN

OR NEAR MOVING PARTS.

3

Page 8

1.5 Warranty

NOTE

Your Formax FD 260-20 is covered under warranty

by the dealership from which you purchased it.

If you have any questions about

the FD 260-20 or its warranty,

contact your authorized FORMAX dealer.

Formax warrants your FD 260-20 against defects in

materials and workmanship for a period of six months from

the original ship date when used in accordance with the

operating instructions in this manual. This warranty covers

the cost of parts when the machine is presented by its

original purchaser to an authorized Formax Dealer. Should

warranty repairs become necessary, the service provider, at

his/her option, will repair or replace such parts required to

restore the FD 260-20 to serviceable condition.

This warranty does not cover consumable parts such as

belts, rollers and sweeps used to contact and transport mail

pieces and tabs. This warranty does not extend to

incidental or consequential damages arising out of a

warranty claim, or to costs associated with maintenance of

the equipment. This warranty does not cover damages

resulting from shipping, accident, misuse, abuse, neglect,

mishandling, alteration or modification. Your rights under

this warranty may vary from state to state.

1. 6 Ordering

Additional

Equipment

To order, or find out about, additional Formax equipment,

contact an authorized Formax dealer.

4

Page 9

2. SPECIFICATIONS & REQUIREMENTS

2.1 Specifications

Size

44" l x 51/2" h x 181/2" w

Transport Length

38"

Weight

40 lb. assembled

Production (Speed)

Adjustable

Power

Possible line voltages are 240V, 230V, 220V, 120V,

and 100V at 50-60 Hz

2.2 Operating

Requirements

Mail Piece Size

Length: no limit

Height: no limit

Width: up to 16"

5

Page 10

3. POWER CONNECTION

BEFORE PLUGGING THE FD 260-20 INTO AN

OUTLET, CAREFULLY READ THE FOLLOWING

INFORMATION ABOUT VOLTAGES, FUSES AND

3.1 Safety

The FD 260-20 can connect to any power distribution

system, including the European IT Power System. Because

the European IT Power System does not have a grounded

neutral leg, the FD 260-20 uses protective fusing in both

the neutral and hot supply lines of power.

WARNING

THE POWER CORD.

3.2 Line Voltage

WARNING

A BLOWN FUSE IN THE NEUTRAL LEG COULD

MEAN INTERIOR PARTS OF THE FD 260-20

REMAIN AT A HAZARDOUS VOLTAGE. ALWAYS

UNPLUG THE POWER CORD BEFORE REMOVING

COVERS FROM THE FD 260-20.

The FD 260-20 is rated for continuous operation using a

variety of supply voltages. Possible line voltages are 240V,

220V, 120V and 100V at 50 or 60 Hz. The manufacturer

configures the FD 260-20 to operate with the voltage

requested by the customer.

CAUTION

VERIFY THE CORRECT VOLTAGE SETTING

BEFORE PLUGGING THE FD 260-20 INTO AN

OUTLET.

Read the current voltage setting through the VOLTAGE

SELECTOR WINDOW on the CONTROL BOX. (Refer to

6

Page 11

Figure 3.1.) Use the following instructions to change the

voltage setting:

NOTE

The detachable POWER CORD may have to be

changed to match the particular power-source

output.

1. Unplug the POWER CORD.

2. Use a small screwdriver or similar tool to push up on

and release the FUSE DRAWER LOCKING TAB.

3. Pull the FUSE DRAWER out of the POWER ENTRY

CASING.

4. Pull the VOLTAGE SELECTOR out of the FUSE

DRAWER.

5. Rotate the VOLTAGE SELECTOR until the correct

voltage is on the same side as the VOLTAGE

SELECTOR WINDOW.

6. Place the VOLTAGE SELECTOR in the FUSE

DRAWER and verify the correct voltage selection.

7. Place the FUSE DRAWER in the POWER ENTRY

CASING.

Figure 3.1 -- FD 260-20 Power Connection

7

Page 12

3.3 Line Fuses

The FUSE DRAWER located on the CONTROL BOX

contains two LINE FUSES. (Refer to Figure 3.1.) The

neutral and hot lines of power are fused. Both LINE

FUSES must be intact for the FD 260-20 to operate

properly.

CAUTION

VERIFY THAT THE LINE FUSE VALUE IS

CORRECT FOR THE VOLTAGE SETTING.

UNPLUG THE FD 260-20 BEFORE STARTING THIS

PROCEDURE.

Use the following instructions to verify that the LINE

FUSES installed have the proper fuse value or to replace a

blown fuse:

1. Unplug the POWER CORD.

2. Use a small screwdriver or similar tool to push up on

and release the FUSE DRAWER LOCKING TAB.

3. Pull the FUSE DRAWER out of the POWER ENTRY

CASING. The LINE FUSES are inside.

4. Determine the proper fuse value as well as the condition

of the LINE FUSE. The fuse value is shown on the

metal tip of the LINE FUSE. The chart below lists the

selected voltage in the left column followed by the

proper fuse value in the right column.

Selected Voltage Line Fuse Value

100V………………………...1.0A (250V time delay)

120V………………………...1.0A (250V time delay)

220V………………………...0.5A (250V time delay)

240V (or 230V)…………….0.5A (250V time delay)

5. Replace the LINE FUSE if necessary. Both LINE

FUSES must be intact for the FD 260-20 to operate

properly.

6. Install the FUSE DRAWER in the POWER ENTRY

CASING.

8

Page 13

3.4 Power Cord

The FD 260-20 comes with a three-wire POWER CORD.

The POWER CORD grounds the FD 260-20 when

connected to an approved three-contact electrical outlet.

1. Plug the POWER CORD into the APPLIANCE INLET

on CONTROL BOX. (Refer to Figure 3.1.)

2. Plug the POWER CORD into a grounded outlet.

WARNING

TO PREVENT ELECTRICAL SHOCK, ONLY PLUG

THE POWER CORD INTO A GROUNDED OUTLET.

9

Page 14

4. SET-UP

WARNING

KEEP LOOSE CLOTHING, TIES, SCARVES AND

HAIR AWAY FROM ALL MOVING PARTS. DO NOT

PLACE FINGERS OR TOOLS BETWEEN OR NEAR

MOVING PARTS.

The FD 260-20 is shipped assembled, except for the

WEIGHT WHEELS.

To assemble the WEIGHT WHEELS:

1. Fasten one SIDE FRAME to the SUPPORT. Line up

the holes in one end of the SUPPORT with the holes in

one SIDE FRAME. (Refer to Figure 4.1.)

2. Secure 1 BUTTONHEAD SCREW through each hole.

Keep these BUTTONHEAD SCREWS slightly loose.

(Refer to Figure 4.1.)

Figure 4.1 -- Assembling the Weight Wheels

10

Page 15

3. Place 1 HAIRPIN CLIP on the WHEEL SHAFT. Place

1 WHEEL on the WHEEL SHAFT next to the

HAIRPIN CLIP. Continue until all 3 WHEELS are on

the WHEEL SHAFT with a HAIRPIN CLIP on each

side of the WHEEL. (Refer to Figure 4.1.)

4. Place one end of the WHEEL SHAFT through the

SLOT in the fastened SIDE FRAME.

5. Fasten the other SIDE FRAME to the SUPPORT.

Place the other end of the WHEEL SHAFT in the

SLOT. Line up the holes in the SUPPORT with the

holes in the SIDE FRAME. (Refer to Figure 4.1.)

6. Secure 1 BUTTONHEAD SCREW through each hole.

Keep these BUTTONHEAD SCREWS slightly loose.

7. Place the WEIGHT WHEELS on the CONVEYOR as

shown in Figure 4.2. The TABS at the bottom of each

SIDE FRAME fit over the sides of the CONVEYOR,

and the MAGNETS rest on the CONVEYOR.

8. Make sure the MAGNETS are flat on the

CONVEYOR. Tighten all 4 BUTTONHEAD

SCREWS. (Refer to Figure 4.2.)

9. Position the WHEELS over the TRANSPORT BELTS.

Slide the HAIRPIN CLIPS against the sides of the

WHEELS to hold the WHEELS in place.

Figure 4.2 -- FD 260-20 with Weight Wheels

11

Page 16

5. OPERATION

1. Position the FD 260-20 in-line with other mail

processing equipment.

2. Turn POWER SWITCH on. (Refer to Figure 5.1.)

NOTE

Turn on the FD 260-20 before turning on any other

machines. If you process mail pieces before

turning the FD 260-20 on, those mail piece will not

stack properly.

3. Adjust the speed of the TRANSPORT BELTS using the

SPEED CONTROL KNOB. (Refer to Figure 5.1.)

Turn the knob toward FAST to increase the speed, or

counterclockwise to decrease the speed. Turning this

knob counterclockwise as far as it will go stops the

TRANSPORT BELTS.

Figure 5.1 -- Adjusting Speed

4. Process several mail pieces and temporarily adjust the

FD 260-20’s speed so it runs slightly slower than the

other processing machines.

12

Page 17

5. Process more mail and adjust the FD 260-20’s speed so

mail pieces shingle neatly as in Figure 5.2.

Figure 5.2 – FD 260-20 in-line with Formax

FD 260 Tabber and FD 260-10 Feeder.

13

Page 18

6. MAINTENANCE

6.1 Cleaning

Your FD 260-20 will need regular cleaning. How often,

depends on the amount of paper dust your mail pieces

generate.

Wipe surface dust or debris from the FD 260-20 with a

damp cloth as necessary. While cleaning, inspect the

FD 260-20 periodically for damage or worn parts.

Wipe the transport belts using a cloth and isopropyl

alcohol. Rotate each transport belt with your hand to reach

and clean the entire belt.

6.2 Replacing a

Fuse

When one or both FUSES are blown, the FD 260-20 will

appear to have no power. If the machine has blown a

FUSE, you need to replace it. (Refer to Section 3.3.)

14

Page 19

trouble

cause

solution

1. Nothing works.

POWER SWITCH is

off.

POWER CORD is not

plugged in.

No power in outlet.

LINE FUSE is blown.

FD 260-20 keeps

blowing FUSES.

Turn POWER

SWITCH on.

Plug POWER CORD

in.

Check circuit source

for blown fuse or

circuit breaker.

Replace blown LINE

FUSE. (Section 3.3)

Contact authorized

FORMAX dealer.

2. Mail pieces do not

stack properly.

Mail pieces jammed

between

TRANSPORT BELT

and MEDIA STOP.

TRANSPORT BELTS

are not flat.

Turn POWER

SWITCH off and

remove jammed mail

pieces.

Contact authorized

FORMAX dealer.

7. TROUBLESHOOTING

UNPLUG THE POWER CORD BEFORE

REMOVING, ADJUSTING OR REPAIRING ANY

7.1 Troubleshooting

Chart

WARNING

PARTS IN THE FD 260-20.

15

Page 20

8. SERVICE

8.1 Service

8.2 Repacking

Instructions

If any problems occur with this equipment or if you need

assistance installing or operating your FD 260-20, contact

an authorized Formax dealer.

When calling for service, have your FD 260-20’s serial

number handy.

If it is necessary to ship your FD 260-20 to your authorized

FORMAX dealer for service, pack it in the original

shipping container and packaging material. If the original

container is not available, the FD 260-20 should be

carefully packed so that it will not be damaged in transit.

NOTE

If the FD 260-20 is packed correctly, your

Shipping Carrier is liable for any damages that

occur during shipping.

Use the following instructions to pack the FD 260-20 with

commercially available materials.

1. Double wrap the machine in heavy plastic.

2. Use a heavy duty, double-walled container of 350-

pound test material.

3. Surround the FD 260-20 on ALL sides with at least 4 to

5 inches of shock absorbing packaging material. This

will provide firm cushioning and prevent movement

inside the container.

4. Seal the top and bottom of the shipping container with

strong tape or banding material.

5. Clearly and legibly mark the shipping container

FRAGILE.

6. Contact your authorized FORMAX dealer.

16

Page 21

Loading...

Loading...