Page 1

FD 2094 / FD 2084

AutoSeal

®

Page 2

Page 3

Burster Unpacking & Set-Up

Output Conveyor Installation

Fold Plate Installation

Feed Table Assembly Installation (2094)

Transfer Table Assembly Installation

(2084)

Feed Table Side Guide Adjustment

Vacuum Feed Sheet Separator

Gap Adjustment

Air Blow Adjustment

Feeding Paper

Checking Squareness of Fold

Output Conveyor Stacker Adjustment

Form Set-Up

Form Set-Up with Optional Imprinter

Normal Paper Loading

Powering Up the Folder

Setting a Standard Fold

Setting Custom Folds

Saving Non-Standard Fold into Memory

Recalling a Saved Fold from Memory

Starting Production

Resetting Total Count

Programming the Batch Counter

Resetting the Batch Counter

Rate

Run Time

Start/Stop - Drive Motor

Start/Stop - Pump

Speed

Fold Plates

Changing Dimension Settings

Stacker Wheels

Paper Jams

Shutting Off Jam Detectors

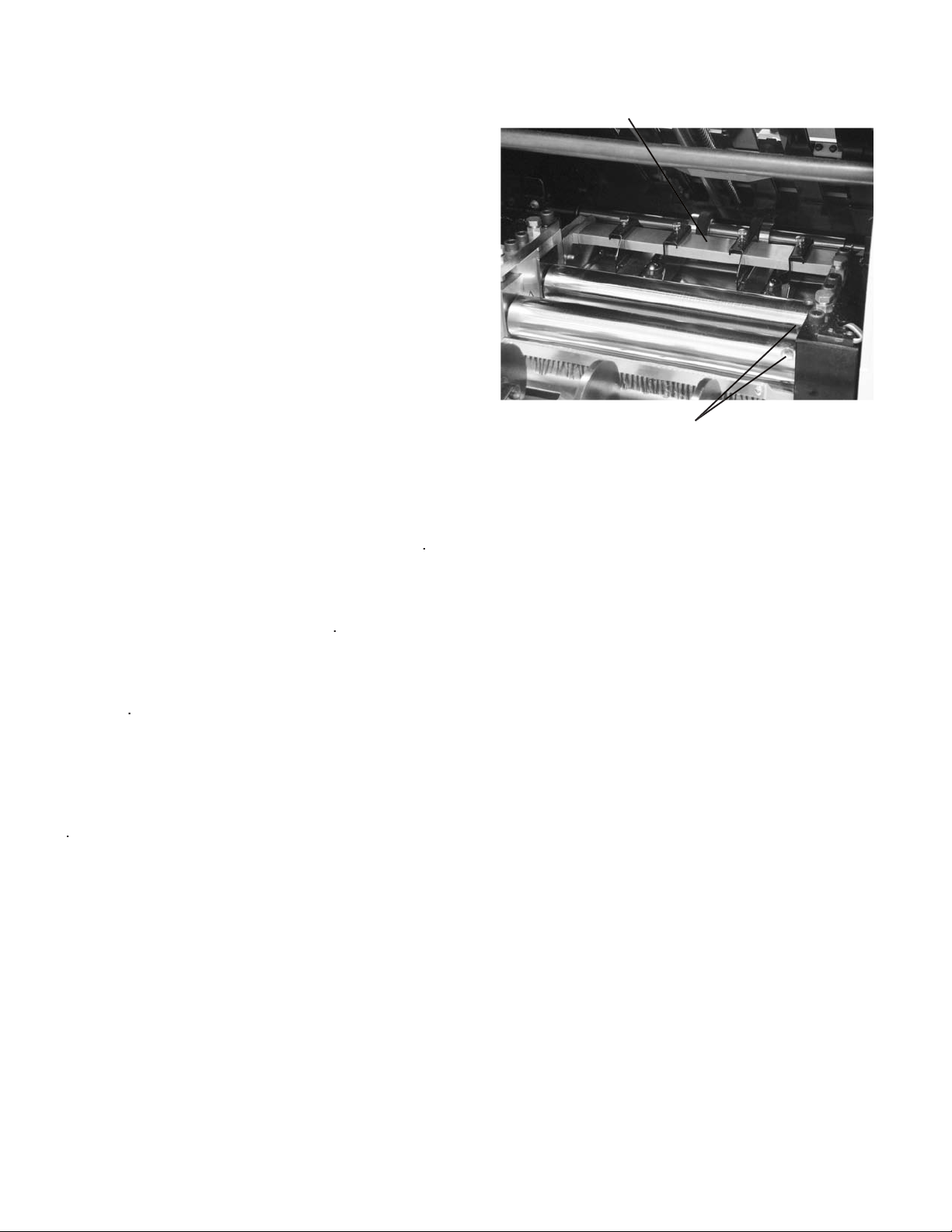

Fold Roller Cleaning

Sealer Roller Cleaning

Cleaning Pump Filters

Photo Eyes

Cleaning Fold Stop Guides

Page 4

Page 5

(193 L x 69 W x 130 H cm)

Approx. 950 lbs.

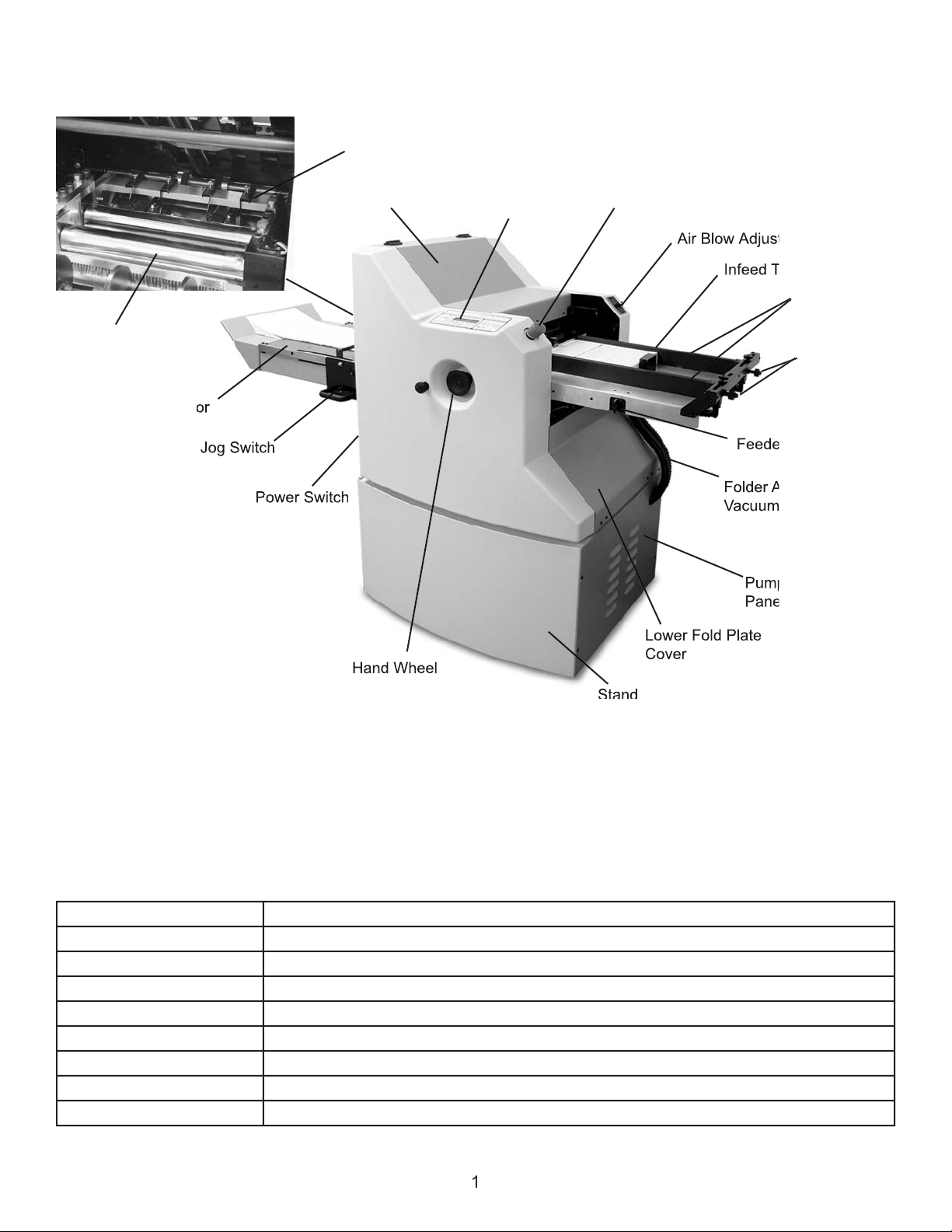

Air Blow Adjustment Knobs

Adjustment Knobs

Page 6

Approx. 1,403 lbs.

Page 7

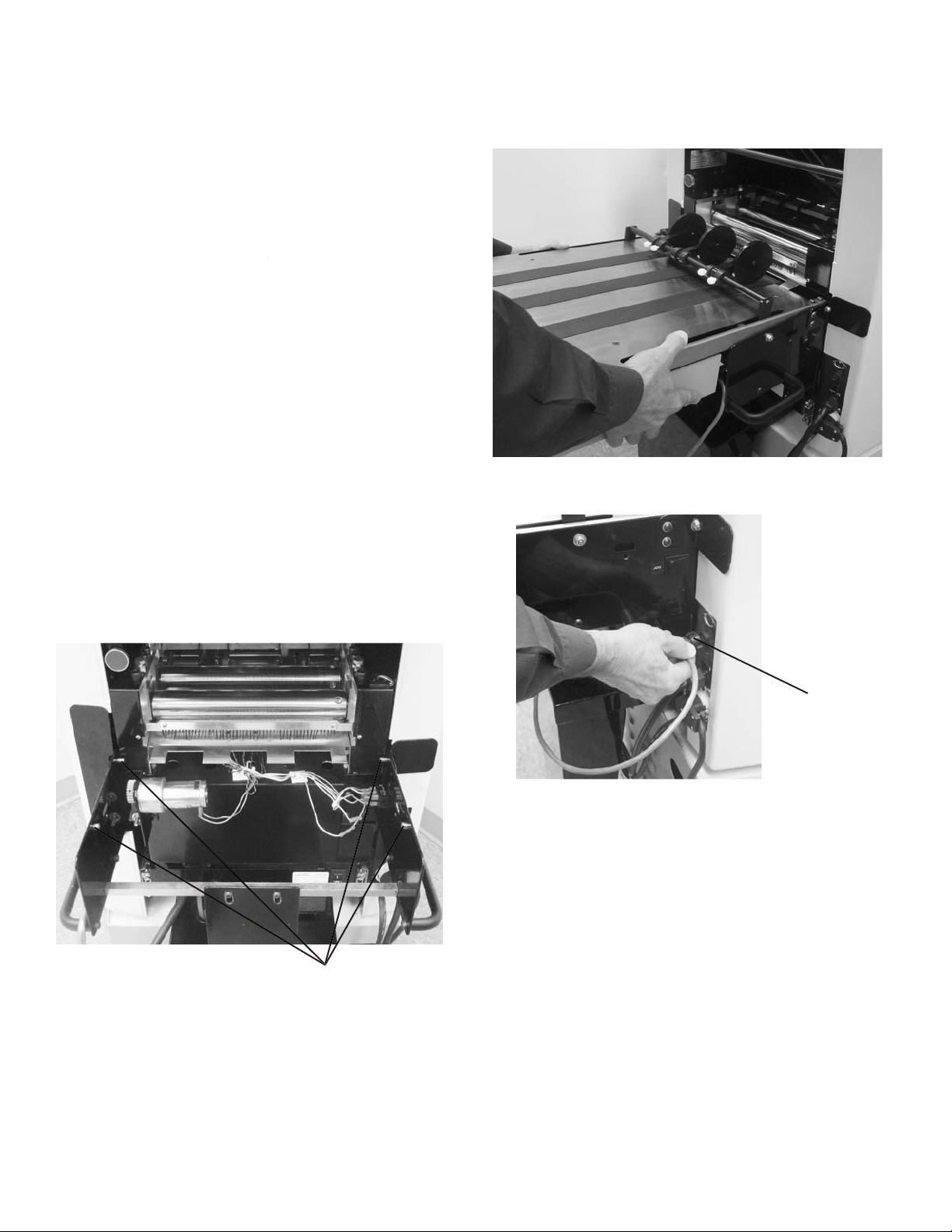

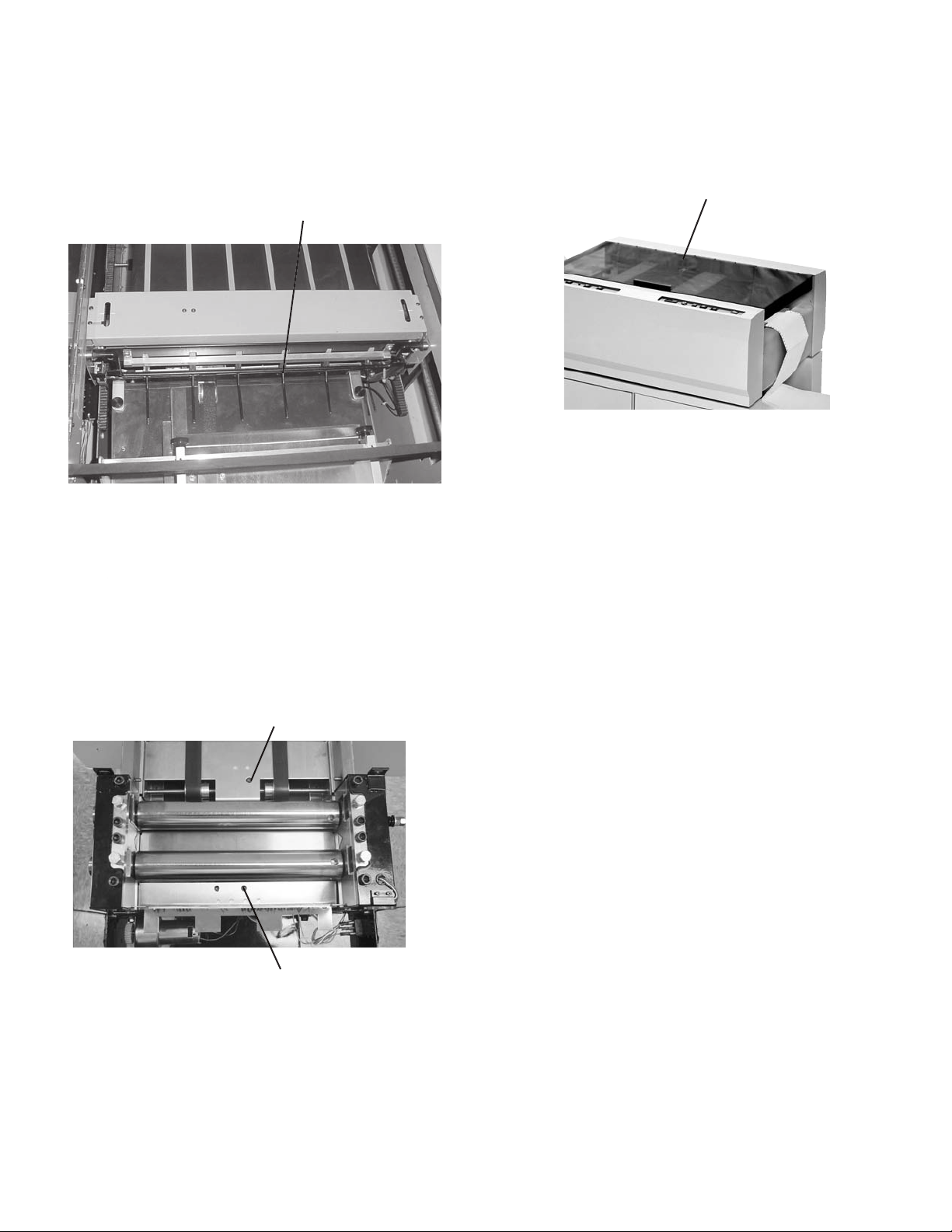

Feed Table and Accessories (Fig. 1b)

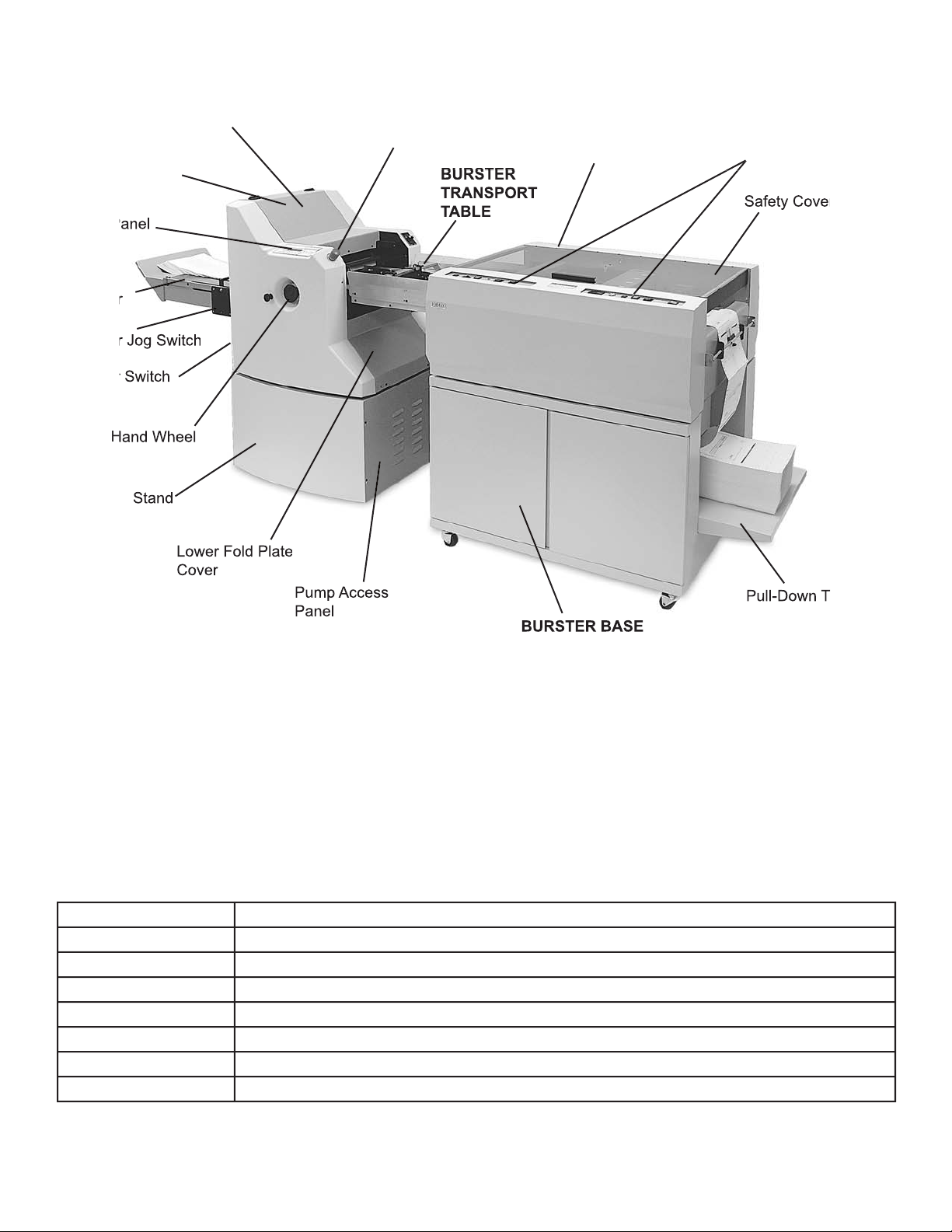

Transfer Table and Accessories (Fig. 1b)

Burster (Fig. 2a)

Burster Base (Fig. 2b)

ASSEMBLY

Page 8

Page 9

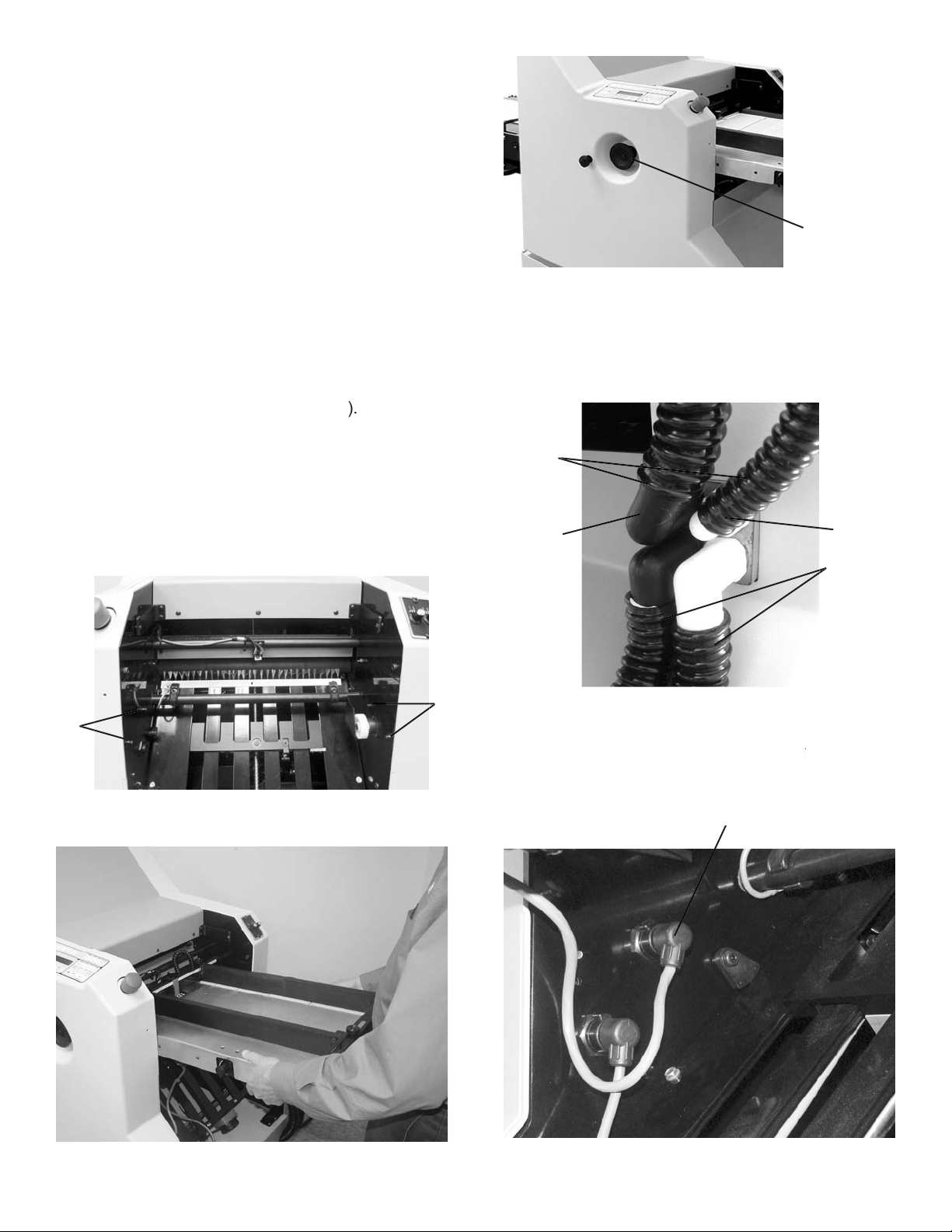

INSTALLATION

over both sets of locating

table

(Fig. 5b).

conveyor into the table receptacle

Do not operate machine without

Page 10

Do not operate machine without

Page 11

Do not operate machine without

table in

10

Page 12

Page 13

Advances forms forward or backward at infeed and outfeed

Page 14

Adjust these guides to correspond with the different

widths of paper being processed.

on the feed table.

19

18

VACUUM FEED SHEET SEPARATOR

weight of paper you are folding. Ideal adjustment

will feed only one sheet without marking the paper

Page 15

AIR BLOW ADJUSTMENT

20a

21

20b

Page 16

with an Allen wrench. Align the center of the

Page 17

where

advance

starts

Tear points can be moved to position them at

Alignment Mark

Alignment Mark

Page 18

was running at unless speed control thumbwheel is

Page 19

with mark on side frame. Tighten setscrews.

Page 20

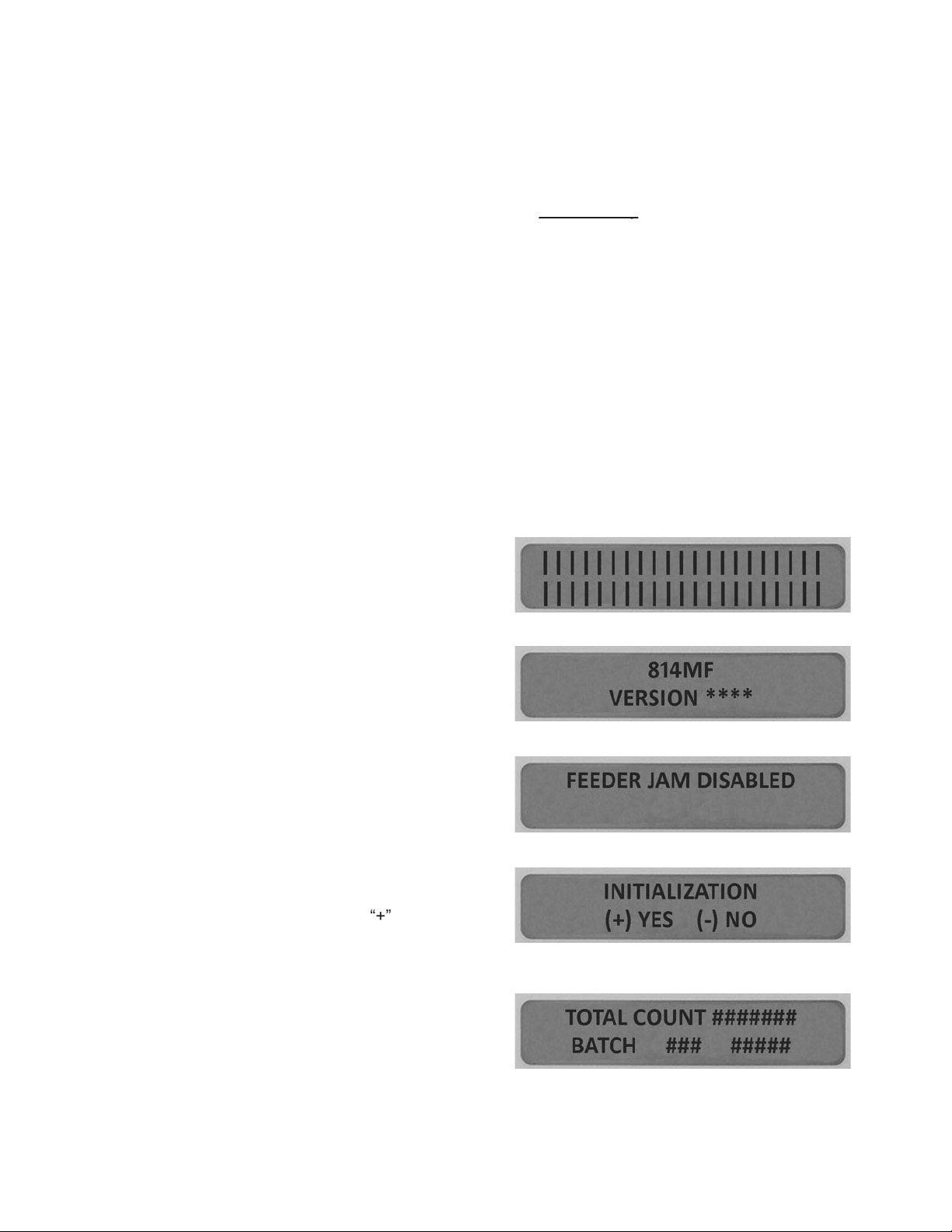

After the self diagnostic phase, the display will show

will go to the initialization screen. The initialization

activated when a function requires

•

• Batch Size

Page 21

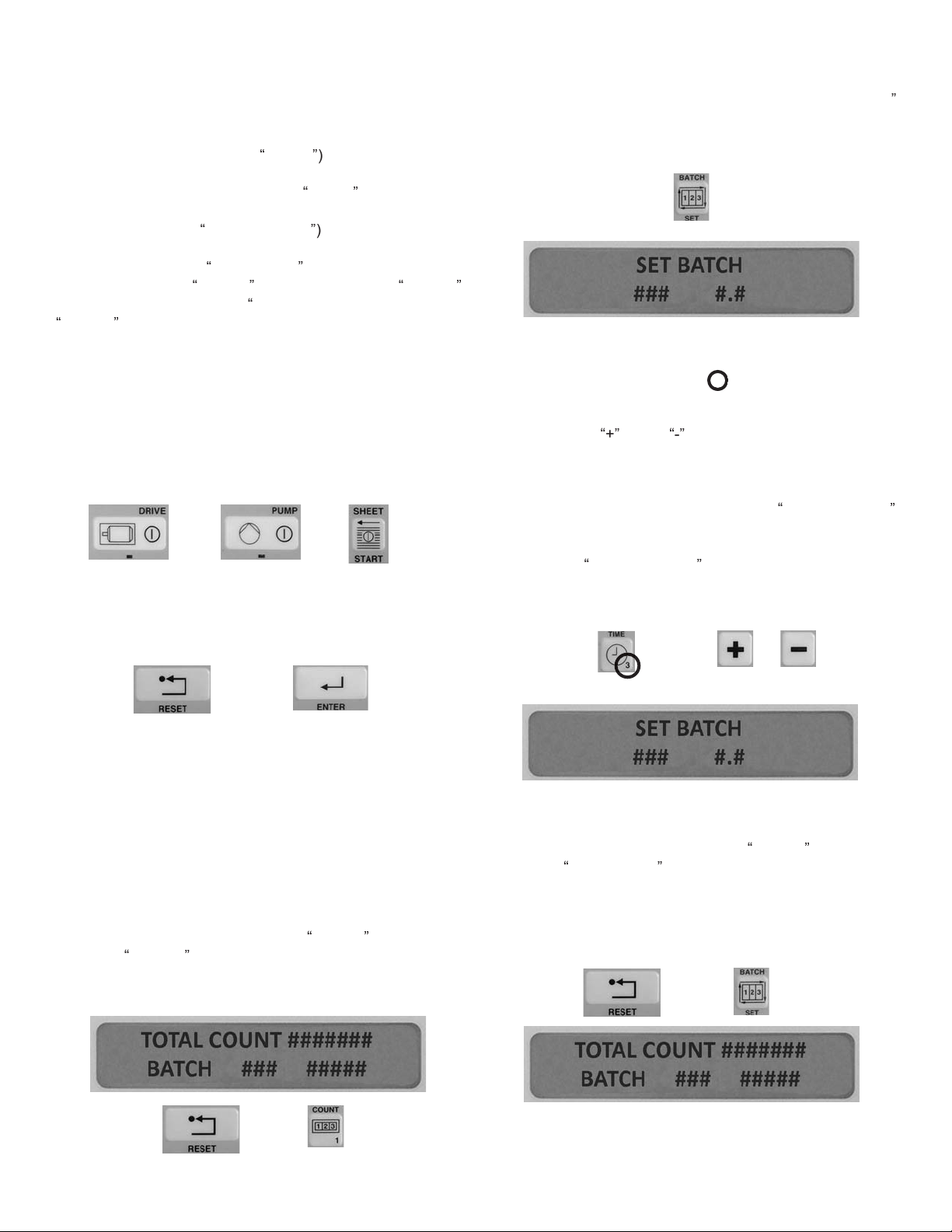

will be displayed.

You have the following two options:

A)

Enter a new sheet

Page 22

DO NOTHING:

After 5 seconds, the count screen will be displayed.

A)

ENTERING A NEW SHEET LENGTH:

will appear.

Page 23

After the

After every new set up the machine speed will always be

button to process the next

SET

Page 24

If a button is not pressed within 2 minutes, the

will increment only when the folder is running. The pump

will light. Pressing the

If a button is not pressed within 2 minutes, the

will activate the pump motor, and the LED below the button

will light. Pressing the

Page 25

Page 26

wheels hit the home position. Once the stacker wheels

After the stacker wheels are in position press the

Any time a jam indication is showing in the display you can

jammed paper.

will clear the jam message, return the stacker wheels to

Page 27

jam detectors on.

when not in use. These practices will keep your

Although designed to minimize accumulations, over a

will gradually wear. Worn rollers will be evident by

wipe the rollers down with Formax-approved lint free

with a dry cloth to keep the plate moving properly.

Page 28

Page 29

Page 30

will form along the surface of the sheet.

Page 31

Page 32

surface of the sheet is folded into contact

with itself).

surface of the

Page 33

jams between the burster and the transfer table and

- A photo-eye sensor is located on the eight

Page 34

AM OCCURS BETWEEN THE METAL SEALING

to exit the machine

or the rollers may be

Page 35

Page 36

wall outlet has power

Are conveyor nip rollers in

Page 37

Adjust tear points pg. 13

Adjust tear points pgs. 13 - 14

Adjust tear points pgs. 13 - 14

Adjust tear bar position pg. 14

Adjust slitter blade position, pg. 12

Page 38

Adjust tractors pg. 13

Need Anti-tenting bracket

Adjust tear points pgs. 13 - 14

Page 39

Loading...

Loading...