Page 1

FD 2092 / FD 2082

®

AutoSeal

12/2007

OPERATORS MANUAL

FIRST EDITION

Page 2

TABLE OF CONTENTS

2092 DESCRIPTION / SPECIFICATIONS 1

2082 DESCRIPTION / SPECIFICATIONS 2

ASSEMBLY 3

Conveyor Assembly 3

Folder Assembly 4

Control Panel 7

2092 Power Hookup 8

2082 Power Hookup 9

OPERATION 10

2092 Operation

Squaring 10

Vacuum Feed Sheet Separator 10

Horizontal Separator Adjustment 11

Feeding Paper 11

Bleeder Valve (Vacuum Adjustment) 12

2082 Operation

Form Set-up Procedure 13

Form Set -Up Procedures With Optional Imprinter 15

Normal Loading 15

Burster Operating Hints 16

Fold Plates 16

Roller Caliper Set-Up 17

Safety Covers 18

Fault Detectors 18

DAILY MAINTENANCE 19

General Cleaning 19

Fold Roller Cleaning 19

Sealer Roller Cleaning 19

TROUBLESHOOTING 20

TEST SHEET 23

Page 3

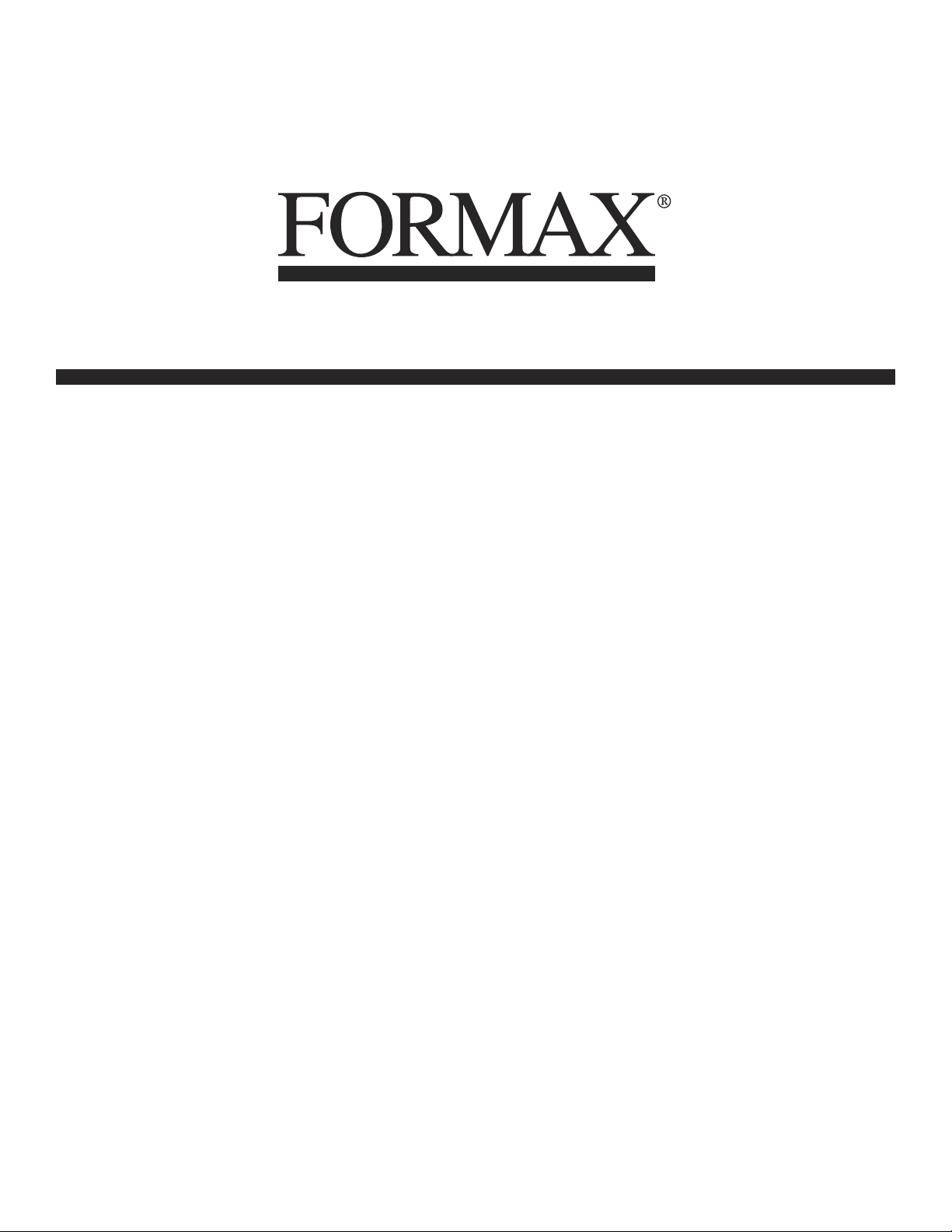

2092 DESCRIPTION

Conveyor

nip wheels

Folder Safety

Cover

Conveyor

Extension

Conveyor

Control Panel

Conveyor

8-ball

transport deck

Sealer safety

cover

Upper fold plate

Folder

Control Panel

Calipers

Infeed table

Folder Air and

vacuum hoses

Sealer power

switch

Sealer housing

and folder stand

Folder power

switch

Folder

Lower Fold plate

FUNCTION

The 2092 folds and seals pressure sensitive forms with pre-applied glue lines into mail ready pieces. Numerous

folds using several different paper sizes can be processed to meet your needs. For confi gurations and paper

sizes see specifi cations.

SPECIFICATIONS

Dimensions 2092: 98” L x 23” W x 51” H (249 L x 84 W x 129.5 H cm)

Paper thickness 20-110 lb. Index

Fold Styles Single, standard letter “C”, accordion “Z”, double parallel, brochure,

half & custom folds

Paper loading capacity 350 Sheets 24# (90 gsm)

Processing speed Up to 30,000 sheets/hr.

Duty Cycle 400,000 monthly

Paper Size 4”-11”W x 6” - 17”L (101-279W x 152-508 L mm)

Weight Approx 500 lbs. (227 kg)

Power supply 220 volt single phase, 20 Amp

1

Page 4

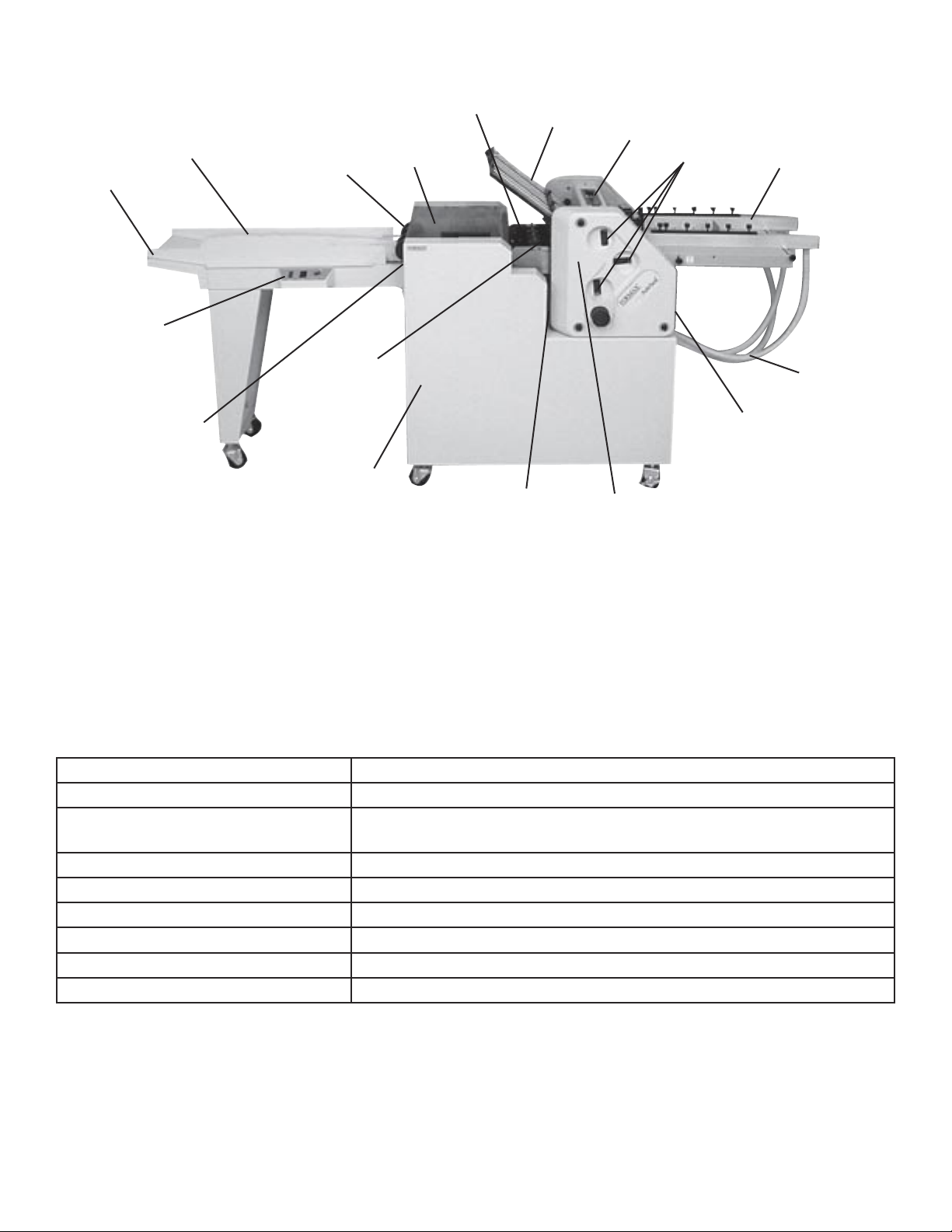

2082 DESCRIPTION

Upper Fold Plate

Conveyor

Conveyor

Extension

Folder Safety

Cover

Conveyor

Control Panel

Sealer power

switch

Conveyor

Nip Wheels

8-ball

transport deck

Manual feed

knob

Sealer Safety

Cover

Sealer housing

and folder stand

Calipers

Folder power

switch

Folder

Lower Fold plate

FUNCTION

The 2082 separates, folds, and seals continuous pressure sensitive forms with pre-applied glue lines into mail

ready pieces. Numerous folds using several different paper sizes can be processed to meet your needs. For

configurations and paper sizes see specifications.

Folder

Control Panel

Burster Controls

Burster

Base

Burster

SPECIFICATIONS

Dimensions 2082: 133” L x 33” W x 51” H (338 L x 58.5 W x 129.5 H cm)

Paper thickness 20-110 lb. Index

Fold Styles Single, standard letter ”C”, accordion “Z”, double parallel, brochure,

half & custom folds

Processing speed Up to 30,000 sheets/hr.

Duty Cycle 400,000 monthly

Paper Size 4”-11”W x 6” - 17”L (101-279W x 152-508 L mm)

Weight Approx 1000 lbs. (454 kg)

Power supply 220 volt single phase, 20 Amp

2

Page 5

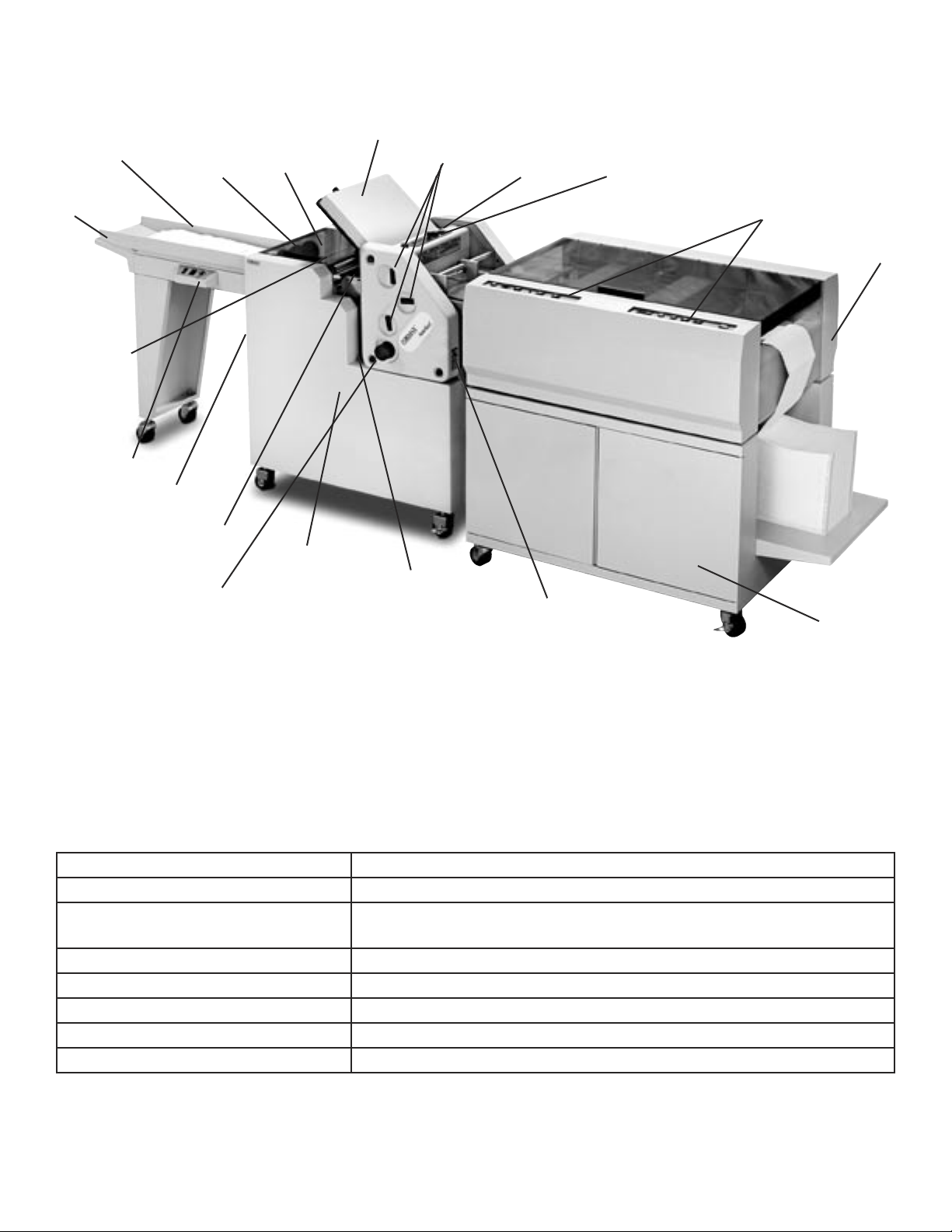

ASSEMBLY

Steps for assembling the conveyor:

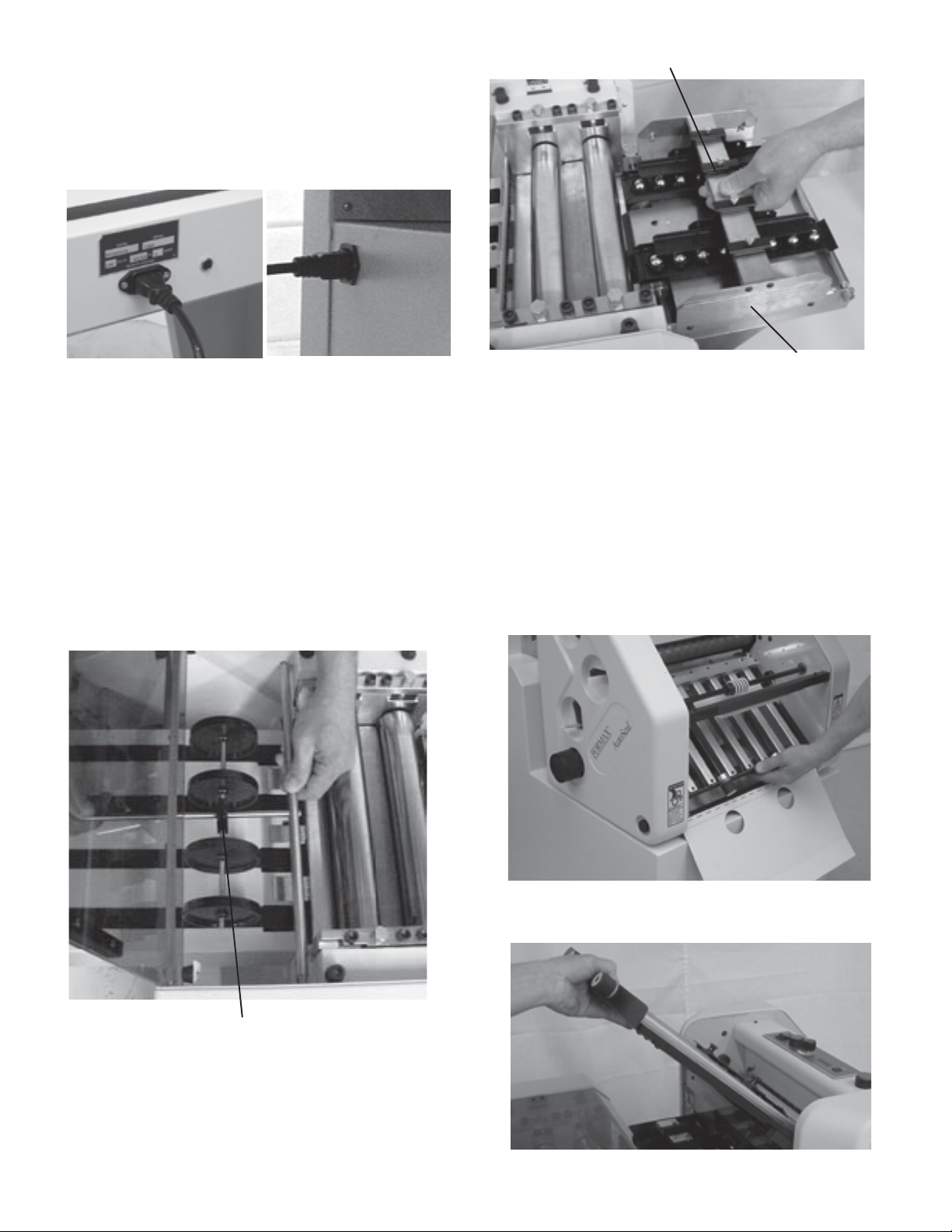

1. Turn conveyor over and remove the four screws to

the far left of the control panel with a 3/8” allen wrench.

Then attach the conveyor leg using the same four

screws (Fig 1).

Step 1

Fig 4

5. Once the conveyor is securely mounted, the bracket

can be adjusted up or down to level the conveyor.

Loosen the allen screws and slide up or down and

retighten (Fig 5).

Fig 1

Step 2

2. With the conveyor still turned over remove the

second to last set of screws that are located to the

right of the control panel (These screws will be used to

attach the conveyor to the mounting bracket) (Fig1).

3. Turn the conveyor to its upright position and roll

it up to the sealer so that holes on the underside of

the conveyor line up with the holes in the mounting

bracket. The conveyor should fit up tight against the

sealer outfeed (Fig 2).

Fig 5

Step 5

6. Attach conveyor extension to the end of the

conveyor using the six 3/8” allen screws provided

(Fig 6).

Fig 2

4. Secure the conveyor to the mounting bracket

using the two screws removed form the bottom of the

conveyor (Fig. 4).

Fig 6

3

Page 6

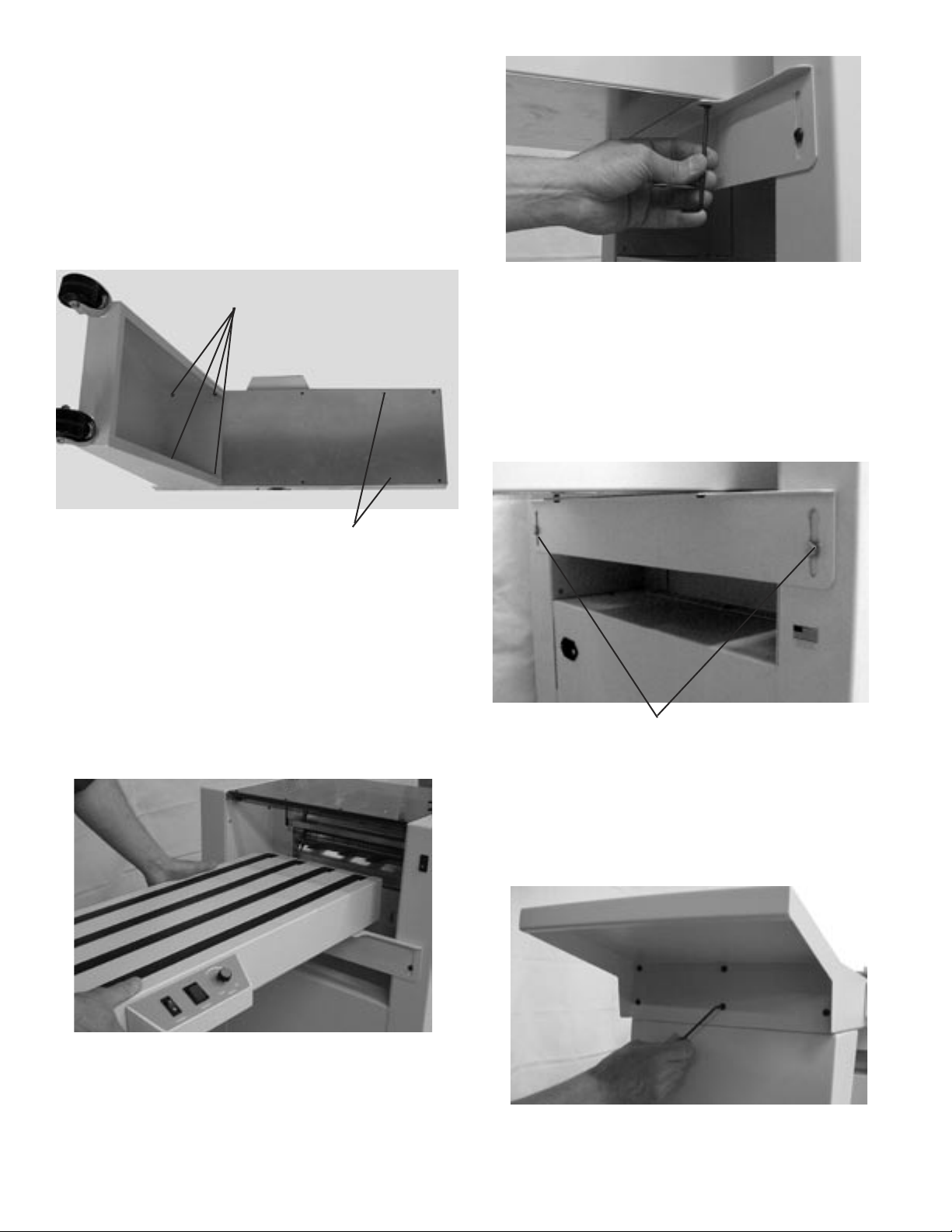

7. Plug one end of the conveyor plug into the conveyor

and the other into the sealer. The conveyor inlet is on

the non operator side of the conveyor and the sealer

inlet is located on the non-operator side of the sealer

outfeed (Fig 7a & 7b).

Eight-ball track

Fig 7bFig 7a

8. Install the conveyor nip rollers to sealer. Insert

the spring-loaded end (right side – viewed from rear

of the sealer) of the shaft into the locator hole in the

side frame, compress the spring against the side

frame and swing the opposite end into position in the

other side frame (Fig. 8).

The nip wheels can be adjusted in or out to

accommodate different size forms. This is done by

grasping (Fig. 8) the black slide handle attached to

the shaft and sliding it closer to the sealer or away

from the sealer.

Fig 9

Transfer deck

Steps for assembling the 2092/2082 folder:

1. Set the folder on the cabinet and line it up with the

recessed holes. Attach the folder to the cabinet from

the underside with the two screws provided.

2. Install the #2 (lower) fold plate. Lower the cover and

insert #2 fold plate making sure the pins latch into the

rail guides and tighten the eccentric plate locks. Note:

Both plates have two sets of locating holes in the plate

rails. The fi rst set is used when the plate defl ector is

down, the other when the plate is open (Fig 10).

Fig 8

Black Slide Handle

9. Place the eight ball track onto the folder/sealer

transfer deck. Line the notches in the track up with

the studs on the deck and set the deck into place

(Fig. 9).

Fig 10

3. Install the #1 (upper) fold plate (Fig 11).

Fig 11

4

Page 7

4. Make sure the fold plate pins are located in the

guide rails, then lower the plate locks. Place the sound

cover on top of the #1 fold plate (Fig. 12).

Fig 12

5. Install the feed table

(follow these steps for

the 2092 for the 2082 skip to steps 5a through

5b on page 5 for transfer table install and burster

attachment)

. Insert the table between the folder side

frames. Install the feed table so the holes in the side

brackets mate with the mounting holes inside the

folder side frames (Fig 13a). Insert mounting pins

(Fig 13b).

NOTE: Mounting pins should be located in the

UPPER SET of threaded holes.

Locating mounting holes

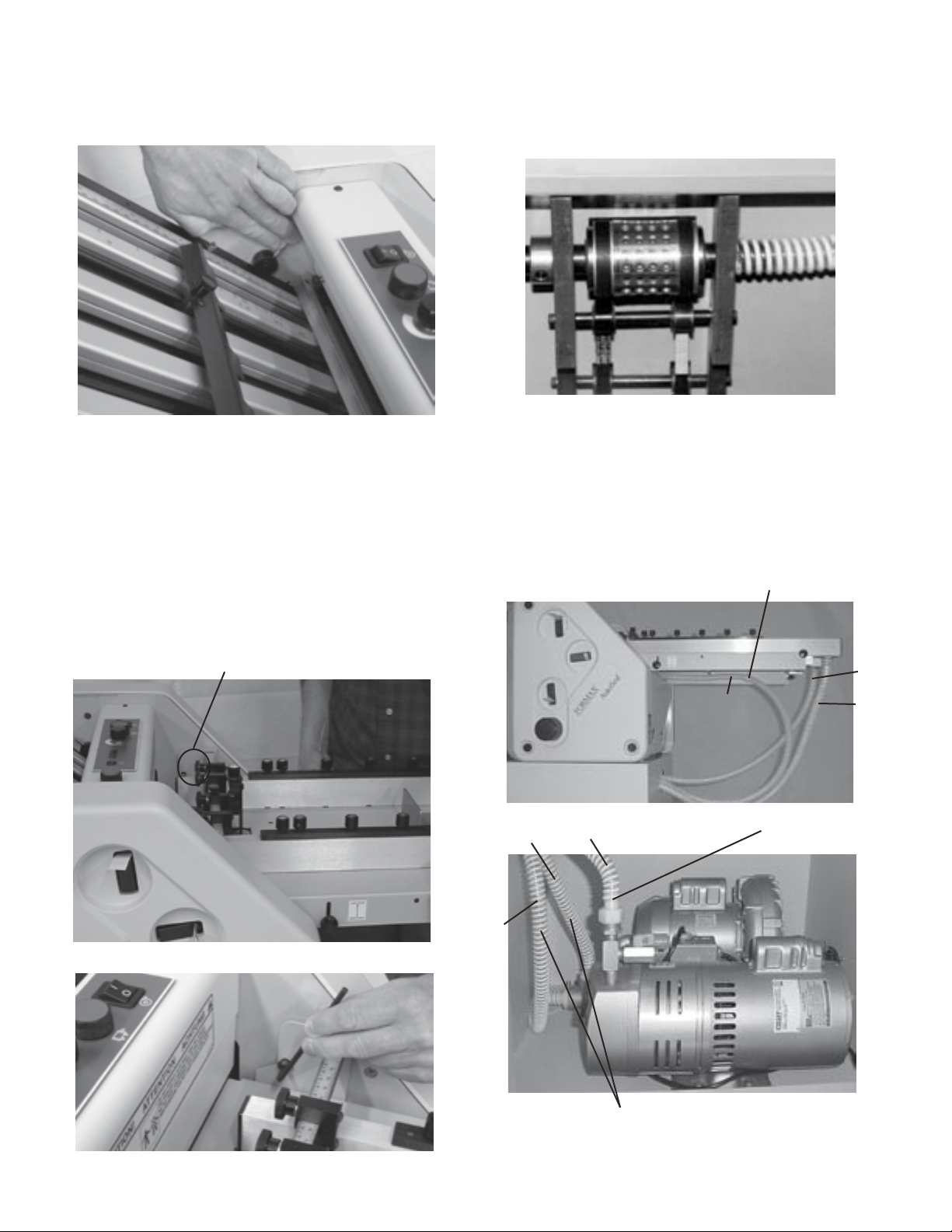

6. Connect the compressor hoses to the feed

table assembly. The sucker wheel hose threads

through the plastic hose clamp and table support,

underneath the feed table, then onto the end of the

sucker wheel tube (Fig. 15).

Fig 14

7. Attach the air hoses from the ends of the pile

guides to the double hose fi ttings of the blower. The

single hose from the sucker wheel fi tting attaches to

the vacuum fi tting (Fig 15a & Fig 15b).

NOTE Make sure all shipping plugs are removed

from the pump openings before attaching the hoses.

Plastic Hose Clamp

1

Fig 13a

Fig 15a

1

Fig15b

3

2

3

Blower hoses

Vacuum Fitting

2

Fig 13b

5

Page 8

5a. Install the transfer table for the 2082. Insert the

table between the folder side frames and set the

notches on to the mounting pins (Fig 16).

Locating mounting pins

Fig 16

5b. Align the outfeed of the burster with the transfer

table and push the burster forward until the mounting

holes of the transfer table and the burster line up.

Slide mounting pins into holes to lock the table in

place (Fig 17).

Fig 17

Locating mounting pins

6

Page 9

CONTROL PANELS

Conveyor control panel

No. NAME FUNCTION

1 Power Switch Press to turn the conveyor on (I) and off (O)

2 Runout Press to gather forms

3 Speed Control Knob Select the speed to run the conveyor

Folder control panel: located on top of the roller guard cover

1

Fig 18

1

Fig 17

2

2

3

3

4

5

6

No. NAME FUNCTION

1 Roller Stop Button Press to stop the rollers.

2 Counter Reset Button Resets the counter

3 Counter Counts number of forms processed

4 Speed Control Knob Select the speed to run the folder

5 Roller Start Button Press to start the rollers

6 Compressor On/Off Press to turn the compressor on (I) and off (O)

Burster control panel

(2082)

3

1

Fig 19

No. NAME FUNCTION

1 Counter Counts number of forms processed

2 Counter Reset Key Resets the counter

3 Stop Button Press to stop the burster at infeed or outfeed

4 Speed Control Dial Select the speed to run the burster

5 Start Button Press to start the burster at infeed and outfeed

6 Interlock Indicates cover upen, jam grill in up position, folder not running

7 Jog Switch Advances forms forward or backward at infeed and outfeed

8 Form Length Sets the length of the form to be bursted

9 Power Turns burster on and off

2

4

75

6

8

7

9

Page 10

2092 POWER & INTERLOCK HOOKUP

Folder

Fig 18a

Sealer

7

6

4

5

2

Fig 18b

3

1

No. NAME FUNCTION

1 & 2 Interlock Shuts down the sealer from the folder

3 Interlock Shuts down the folder from the sealer

4 Compressor Power Cord Connects power from compressor to folder

5 Folder Power Cord Connects power from folder to sealer

6 Folder Power Switch Press to turn folder on (I) or off (O)

7 Main Power Cord Supplies power to folder

8

Page 11

2082 POWER & INTERLOCK HOOKUP

Burster

Sealer

4

Folder

1

3

2

5

6

7

8

No. NAME FUNCTION

1 Interlock Shuts down the burster from the folder

2 Burster Power Cord Connects power from burster to sealer

3 Folder Power Cord Connects power from folder to sealer

4 Main Power Cord Supplies power from wall to machine

5 Bypass plug Bypasses

6 Interlock Shuts down the sealer from folder

7 Interlock Shuts down the folder from sealer

8 Folder Power Switch Press to supply power to folder

9

Page 12

OPERATION

2092 Operation

Squaring

In order for your machine to fold squarely, it must be fed

into the rollers square. Your 2092 has been adjusted

at the factory and should only require periodic checks.

The 2092 has a unique feed table adjustment feature to

quickly and easily adjust it if needed.

Fig 20

1. Adjust the feed table squaring screw and align the

center line of the scale with the center mark on the

feeder table (Fig 20).

Front Guide Adjusting Knob

3. Raise the sheet separator counter clockwise (ccw)

so it is away from the sucker wheel (fig. 22). Place

a sheet of the paper to be folded on the feed table.

Slide the sheet forward into the rollers. The sheet

must contact the rollers evenly and not touch the side

guides. Turn the hand wheel so about 1/2” (3mm) is

pulled into the rollers.

4. Position the operator side guide so it is just

touching the sheet but not pushing it. The side guide

must be even to the sheet from end to end. Tighten

the front lock knobs then the rear knobs, (fig 20 &

21).

5. Repeat step 4 on the non operator side guide.

6. The paper will now feed square into the rollers.

Now that the side guides are square, the feed table

squaring screw, (Fig. 20), can be adjusted for fine

tuning the overall squareness.

Vacuum Feed Sheet Separator

The sheet separator will have to be adjusted for the

weight of paper you are folding. Ideal adjustment

will feed only one sheet without marking the paper or

feeding doubles. Use the following procedure to get

started.

Fine tune these adjustments according to the

condition of the paper and the environmental

conditions of your particular work area.

Adjustment Procedure

Raise the separator (ccw) to avoid marking the

sucker wheel.

NOTE: DO NOT MAKE SEPARATOR

ADJUSTMENTS WHILE THE FOLDER IS

RUNNING.

Fig 21

Scale

Side Guides

2. Loosely position the feed table side guides to the

scales on the feed table, (fig 20 & 21). Read the front

scale at the inside edge of the side guide clamp block.

The rear scale will line up with the inside edge of the

side guide. The scales are set up to center the paper

on the sucker wheel. Initially set each guide 1/4” (6mm)

wide. Do not tighten the lock knobs.

1. Raise the separator (ccw) to avoid marking the

sucker wheel.

Fig 22

Separator Guide

Adjusting Knob

Separator Guide

Plate

10

Page 13

2. Turn the hand wheel until the separator tip is

positioned over a solid portion of the sucker wheel,

i.e. between the rows of holes.

3. Place a one inch wide (25mm), double thickness

piece of paper to be folded under the tip of the

separator plate. Lower the separator clockwise (cw)

until there is a slight drag on the paper as it is pulled

from the separator.

Fig 23

4. The vacuum advance knob is located on the side

of the feed table (Fig. 23). Adjusting the knob will

position where the vacuum contacts the stock of

paper. Raising the knob will move the vacuum away

from the lift and toward the rollers (light papers).

Lowering the knob will move the vacuum contact

toward the lift and away from the rollers (heavy

papers).

Horizontal Separator Adjustment

1. Raise the separator (ccw) to avoid marking the

sucker wheel.

2. Loosen knob (ill. 2).

3. As a starting reference, turn the hand wheel until

a set of sucker wheel holes is at the 12 o’clock

position.

Feeding Paper

NOTE: Set folds with standard copy paper so that

the folds line up with the perfs on the pressure seal

forms.

1. Load a stack of paper onto the feed table. The

stack should be no higher than the side guides , 2”

(51mm). Position the backstop up against the lift.

2. Turn on the air/vacuum pump. The air should float

the bottom of the lift approximately 1/16 to 1/8” (16 to

32mm). Air blast can be controlled by adjusting the

valve located at the end of each side guide (Fig. 24).

4. Adjust separator assembly so that the plate is 1/16”

forward of the 12 o’clock position, measure from the

feed side of the plate.

5. Tighten knob (ill. 2).

Fig 24

11

Page 14

Separator Guide Lock

Set Screw

Air Blast

Openings

Fig 25

3. Turn the speed control to ½ or full speed. Place

your thumb on the back of the stack to keep paper

from feeding. Press the green button, the sucker

wheel will start to turn. Reduce the pressure of your

thumb to feed only 3 to 4 sheets. Press your thumb

down to stop the feeding again. Press the red button

to stop the sucker from turning. If the paper did not

feed, adjust the position of the vacuum advance,

bleeder valve, or sheet separator.

There is a bleeder valve on the vacuum pump,

(Fig 26), which allows for vacuum adjustment from

completely off to completely on. General settings for

the bleeder valve are half open for 20# stock, and

closed for 80# and heavier stock. If your machine

is feeding doubles, this can be opened slightly to

“relieve” some of the vacuum and stop the double

feeding.

4. Check the accuracy of the 3 or 4 sheets fed. It

may be necessary to adjust the fold stop, or the

squareness of the fold stop, or the squareness of

the side guides. Try only one adjustment at a time

then repeat step 3

5. If the folds look good, the job may now be run.

The speed of the folder will affect the accuracy of the

folds. Folds set up at slow speed will be difficult at

high speed and will need to be fine tuned.

NOTE: All of the controls mentioned above contribute

to smooth and accurate folding. There are many

combinations possible depending on the condition of

the paper and environment.

Bleeder Valve (Vacuum Adjustment)

Fig 26

12

Page 15

2082 Operation

Slitter Adjustment

Edge Slitters

8-Pin Tractor, OP 8-Pin Tractor, DrCenter Paper Guide

Wedger

Screw

4. Center leading edge of form at infeed end of the

burster.

Alignment Mark

5. Position tractors to proper form width by releasing

thumbscrews on top of tractors and sliding tractors to

proper width. Raise tractor gates.

6. Lay margin holes of form over feed pins. (Fig. 29)

Fig 27

Form Set-up Procedure

1. Turn on the machine. Measure form length.

2. Press the form length switch on the burster to

align the alignment mark with the form length on form

length scale. (Fig. 28)

Form Length Scale

Fig 28

Alignment Mark

NOTE: Do not stretch form too tightly between

pins; pins should be centered in margin holes.

Fig 29

7. Close tractor gates and lock tractors by tightening

thumbscrews.

8. If using edge slitters, position alignment mark

where you wish to slit. (Fig. 27)

9. If slitting, be sure that slitter blades are engaged.

This is accomplished by rotating wedger in a

counterclockwise direction as far as they will go

without force. (Fig. 27)

10. Lock edge slitters in place by tightening

thumbscrews clockwise. (Fig. 27)

NOTE: If you do not want to slit, push edge slitters

away from form and tighten thumbscrews.

3. Place form stack on pull down tray on front of the

burster.

11. By pressing jog switch in forward position,

advance form through feed rollers until snap rollers

grab the form.

13

Page 16

12. If necessary, adjust form length so that form

starts to burst when perforation is just under tear

points.

NOTE: Tear points can be moved to allow operator

to position them at any location along tear bar. Tear

points should be set between perforations that run

vertically the length of the form. (Fig. 30)

13. The tear bar is adjustable to accommodate

characteristics of various forms. To adjust height

bar must be pushed to compress spring and lift out.

Rotate 180 degrees (turned over) and replaced

making sure that square end of bar locks into

brackets. (Fig. 31, shown in HIGH position)

Fig 31

Fig 30

14

Page 17

Form Set -Up Procedures With Optional

Imprinter

10. Move timing collar so that mark on collar aligns

with mark on side frame. Tighten setscrews.

NOTE: It is recommended that numbered forms or

checks fed into imprinter should be last form first,

right side up.

1. Center leading edge of form at infeed end of

machine so that outer edges of form extend equally

beyond guide straps on each side. If you find that

edges come within about 1/4” of guide straps, offset

form in either direction to avoid this condition.

2. If form length is 3 1/2”, 7”, 10 1/2” or 14”, rollers

must be timed. Time rollers by activating jog switch

until timing marks on the rollers are vertical and in

view in cutouts in feed and snap roller covers.

3. Position tractors by releasing and sliding to proper

form width. Raise tractor gates. Place forms on feed

pins as shown in. Close tractor gates and secure in

position.

4. Loosen thumbscrew on ink roller unit and slide unit

away from signature area on form.

5. Loosen setscrews on plate cylinder. If setscrews

are not in view, rotate free wheeling cylinder until

they are in view.) Horizontally align plate cylinder with

signature area on form. Tighten setscrews.

6. Loosen setscrews on imprint cylinder. (If setscrews

are not in view, use jog switch to bring them into

view.)

11. Remove forms from tractors. Install signature

patches on imprint cylinder.

12. Move ink roller directly over signature patch on

imprint cylinder. Jog forward, if necessary, so that

imprint cylinder turns to a point where signature patch

should touch ink roller. Adjust ink roll thumbscrews so

ink roll turns when signature patch makes contact.

For darker impression, turn adjustment thumbscrews

clockwise.

NOTE: The signature saddle has been factory

adjusted to fit a .092 thick signature patch. If

adjustment is required to lower or raise the height

of signature saddle for a different signature patch

thickness, release imprinter side plates from their

locked positions. Pull back latch finger to release

plates. Loosen side setscrews to free top setscrew

Turn top setscrew in at half-turn increments until

required height is reached. Tighten side setscrews

and slide imprinter module back into position.

Normal Loading

NOTE: Imprinter must be timed each time you load a

different form into Burster for imprinting.

1. Jog machine forward until timing collar mark is

aligned with side panel mark.

2. Place forms to leading edge to timing mark.

7. With no signature saddles on imprint cylinder,

move forms forward so signature area is centered

over plate cylinder shaft.

8. Center signature cylinder over signature area

(NOTE: Setscrews should be facing you.) and center

signature plate locator pins directly over imprint area

on form. Tighten setscrews.

9. Advance forms forward so that next horizontal

perforation aligns at top edge of plastic tractor or

alignment mark on metal tractor.

3. Advance (jog) forms forward through imprint area.

Stop leading edge of form in front of slitters.

4. Move slitters to trim proper amount of trim

and engage slitter blades by turning wedgers

counterclockwise. Lock down slitters.

5. Advance forms through slitters and check for

proper slitting. Advance on through to Tear Bar.

15

Page 18

6. Set up tear bar as before. (Fig. 33)

7. Close Safety covers. Machine is now ready to

burst and imprint. Press the Start Button and adjust

machine speed to speed desired.

Burster Operating Hints

1. To stop the machine just push on either one of

two stop buttons. Opening safety cover or lifting jam

detection grill will also stop machine.

2. To restart machine start button must be pressed.

CAUTION: Machine will restart at same speed that it

was running at unless speed control thumbwheel is

turned down.

3. Some paper has a natural curve. Sometimes this

curve tends to catch air and sail. If this occurs, try

running them upside down.

4. Perforations vary in strength. If forms are bursting

hard, tearing, or breaking behind tear bar, vary form

length setting up to 1/2”ahead or behind actual form

size setting, and/or put tear bar in low position.

Fold Plates

(2092 & 2082)

Plate set up will depend on the type of stock and type

of fold you require. The fold plate design on the folder

allows changing from open or closed deflector (up

and/or down folds) without removing or turning the

plates.

A good understanding of the roller/plate

configuration will help you decide which plate to

open or close for up or down folds. Illustration 3

shows the paper path for a common “Z”-fold.

A self-adhesive folding guide label has been

conveniently placed on the conveyor extension tray.

Used along with scales on the fold plates, the guide

will help you quickly establish a rough set up for

some of the most common folding jobs.

Plate Stop

Inch/mm

Scale

Fig 32

Quick Setup Scales (read at

these points)

16

Page 19

Coarse adjustments are made by loosening the lock

screws on the plate stops, then moving the stop (Fig.

26). The plate stop lines up with the scale marks

along its front edge (not where the paper contacts

the stop). Fine adjustments are made with the micro

adjust knobs on the ends of the fold plates (Fig 27).

Fig 33

Roller Caliper Set Up

To provide the proper clearance between rollers,

¾” wide paper strips are inserted into the calipers.

Simply press the caliper lever and insert the correct

number of strips into the open gap. Put the same

number of strips into both sides of the folder. Do not

use folded or torn strips of paper (they may give false

readings).

Adjustable calipers are used on the folder to obtain

clean crisp folds on a variety of stock (Fig 28). The

proper amount of paper strips (of the same material

being folded) in each caliper on both sides of the

folder will give the best grip for a good fold. As the

paper is folded, the thickness of the paper passing

between the rollers increases. The number of paper

strips placed in the calipers should be equal to the

minimum thickness of the paper passing between the

rollers (tail end of the sheet).

Roller Calipers

Illustration 4 diagrams the position of rollers, fold

plates, feed table, calipers and the correct number

of paper strips to be placed into the calipers for a

common “Z” fold.

Roller Caliper Quick Set Up Guide

The chart below gives the set ups for calipers for several

common folds.

Fold Type # 1 Caliper # 2 Caliper # 3 Caliper

Letter “C” 1 1 3

“Z” 1 1 3

Half 1 2 2

Double Parallel 1 2 4

Uneven “Z” 1 1 3

Uneven “C” 1 1 3

Fig 34

17

Page 20

Safety Covers

Fault Detectors

The burster (2082), folder and sealer are equipped

with plexi safety covers (Fig. 35a, 35b & 35c).

The 2092 and 2082 will not run unless plexi-safety

covers are in the lowered position.

Burster Safety Cover

Fig 35a

Folder Safety Cover

Burster (2082) - The burster is equipped with on

outfeed jam detector grill. This device senses jams

between the burster and the transfer table and stops

the burstor until the jam is removed and the machine

is restarted (Fig 36).

Burster Jam Grill

Fig 36

Folder - The folder is equipped with a delivery area

jam detector. This device senses jams at the eight

ball transfer deck and immediately stops the burster,

folder, and sealer until the jam is removed and the

machine is restarted. The jam detector is mounted

on the center of the tie bar and looks similar to a third

stacker spring, it may be reformed for best operation

(Fig. 37).

Fig 35b

Fig 35c

Sealer Safety Cover

Sealer - A photo-eye sensor is located on the Eight

ball transfer deck before entering the sealer unit.

This device senses jams and immediately stops

the sealer, burstor (2082) and folder until the jam is

removed and the machine is restarted (Fig. 37).

Folder Jam Detector

Sealer Photo-eye

18

Page 21

DAILY MAINTENANCE

General Cleaning

Take a few minutes at the end of each day to wipe off accumulations of paper dust. Cover your machine when

not in use. These practices will keep your machine clean and in tip-top operating condition.

Fold Roller Cleaning

Keep fold rollers clean. Most folding problems are the result of material accumulations on the fold rollers.

Although designed to minimize accumulations, over a period of time, ink and dust buildup will prevent the

rollers from gripping the stock evenly. Rollers must be cleaned on a regular basis to maintain optimum folding

performance.

Disconnect the power, remove the fold plates and clean rollers with Formax approved cleaner designed for the

type of rollers your machine is equipped with. Turn the rollers with the hand wheel never attempt to clean rollers

with the machine running.

Check rollers periodically for wear. During normal use fold rollers will gradually wear. Worn rollers will be evident

by increased setup times, increased spoilage, inaccurate folding and inability to control the sheet. If one or more

of these conditions are noted, contact your authorized Formax folder dealer to inquire about inspection and/or

possible roller replacement.

Sealer Roller Cleaning

Keep sealer rollers clean. Sealing problems may occur if printer toner builds up on the steel rollers.

Disconnect the power, lift the sealer safety cover and wipe the rollers down with Formax approved lint free cloth

and roller cleaner.

19

Page 22

TROUBLESHOOTING

TROUBLE POSSIBLE CAUSE REMEDY

Machine not running Is the power on?

Make sure the power to the folder, sealer

and conveyor are in the on position.

Check to make sure the wall outlet has

power

Is the machine plugged in?

Are the safety covers lowered?

No power even with machine

turned on, plugged in and wall

power is on?

Double feeding forms Is the feeder set properly?

Is paper stuck together?

Using paper other than

specified?

Sealer jams Double feeding? Turn power off, insert jam clearing bar

Folder Jams Double feeding?

Paper stuck in fold plate?

Metal rollers dirty Toner is on metal rollers of

sealer?

Paper fold gets out of

place

Paper stops have moved?

Make sure all the plugs are plugged in

properly

Make sure the safety covers for the

folder and sealer are lowered.

Call Service

See pages 7,8 & 9.

Separate paper from each other.

Paper other than specified may cause

mechanical trouble.

into sealer roller and turn back counter

clockwise until jam is cleared.

Turn power off, turn hand wheel counter

clockwise and clear jam.

Turn power off, remove fold plate and

clear paper.

Unplug machine and clean with

approved cleaner.

Rotate the fine adjustment knobs to

correct movement.

Is folding roller dirty?

Paper jam occurs often Is folding roller dirty?

Is inside of machine dirty?

Are conveyor nip rollers in

proper positions?

Is paper curled?

If paper jamming continues.

Clean with approved cleaner.

Clean with approved cleaner.

Clean inside of machine.

Set rollers to proper position.

Let paper sit curl side down with weight

on top to eliminate curl.

Call for service.

20

Page 23

Forms Creasing Form is not exiting the folder

straight?

Check to make sure the forms are being

fed squarely.

Check to make sure the eight ball track

is sitting properly.

Check to see if the fold rollers are clean.

Documents are wrinkled

or crunched

Forms in burster creep to

one side.

Burster stalls or tears

forms

Form is not entering the sealer

straight?

Creasing continues

Fold plates are not inserted

correctly?

Piece of paper or other material

is stuck in the fold plate?

Infeed guides not set properly.

Roller tension not uniform

across roller.

Tear bar in high position.

Burster not running fast

enough.

Incorrect form length setting.

Tear points not adjusted

properly across face of form.

Tough form perforations.

Check to make sure the eight ball track

is sitting properly.

Call service.

Remove and reinstall fold plates. Be

sure they’re properly positioned.

Remove object from the fold plate.

Reset Guides

Check and adjust roller tension, Call

Service

Put bar in low position pg. 14

Increase burster speed

Reset paper length pg. 13

Adjust tear points pg. 14

Adjust tear points pg. 14

Burster rollers don’t

rotate / machine runs.

Won’t burst properly.

Poor slitting. Slitter blades not making

Slipped belt, Broken drive belt,

Loose pulley.

Incorrect roller tension.

Carriage not properly

positioned.

Tear point not set correctly.

Tear bar not set correctly.

contact with one another.

Worn blades.

21

Call Service

Check and adjust roller tension, Call

Service

Reset carriage position

Adjust tear points pg. 14

Adjust tear bar position pg. 14

Adjust slitter blade position

Replace blade, Call service

Page 24

Forms pull out of burster

tractors.

Roller timing off.

Incorrect form length setting.

Call service.

Reset form length pg. 13

Large variations in trim

accuracy

Snap roller carriage will

NOT move

Loop forming between

the slitter and the infeed

roller.

Incorrect feed roller tension.

Tractor drive pulley bound up.

Tractors binding internally.

Tractor pins not centered in

margin holes.

Dull slitter blades.

Tractor timing is off.

Paper not centered to slitter

feed.

Margin slitter setscrew not

tightened down.

Defective switch or motor.

Broken carriage drive chain.

Loose setscrew on carriage

advance shaft or on motor.

Obstruction on rack.

Obstruction at the pivot arm.

Obstruction between the

infeed and snap rollers.

Broken flow strap.

Check and adjust roller tension, Call

Service

Check for paper jam and clear, Call

service.

Call service.

Adjust tractors pg. 13

Replace blade, Call service

Call service.

Realign paper

Tighten setscrew

Call Service

Call Service

Tighten setscrew, Call service

Remove obstruction

Remove obstruction

Remove obstruction

Call Service

Bent infeed finger.

Tear bar in low position.

Too many tear points.

Need Anti-tenting bracket.

22

Call Service

Put bar in high position pg. 14

Adjust tear points pg. 14

Call Service

Page 25

Leading Edge

Make copies of this page on copy paper for fine tuning folds

Instruction For Lining Up Folds

1. Place a stack of these sheets into the feeder and fold

one (1) or two (2) sheets.

2. Take a folded sheet from the catch tray and lay it on

top of a pressure seal form lining the leading edge of

this sheet up with leading edge of the pressure seal

form.

3.

If the folds on this test sheet do not line up with the

perforated folds on the form, the fold plates need to

be adjusted up or down to make the folds line up.

Refer to Fig. 1 for a “Z” fold and Fig. 2 for a “C” fold.

-

If fold “A” on the test form is right of the perforation on

the pressure seal form move the top fold plate

stop up. If fold ”A” is below move the top fold plate

stop fold stop down.

-

If fold “B” on the test form is right of the perforation

on the pressure seal form move the bottom fold plate

stop down. If fold ”B” is to the left move the bottom

fold plate stop up.

Fold “A” Fold “B”

Fig. 1 “Z” fold Form

Fold “A” Fold “B” Leading Edge

Leading Edge

23

Fig. 2 “C” Fold Form

Loading...

Loading...