Page 1

FD 2052IL AutoSeal® System

12/2007

OPERATOR MANUAL

FIRST EDITION

Page 2

Page 3

TABLE OF CONTENTS

DESCRIPTION 1

SPECIFICATIONS 1

UNPACKING 1

SETUP 2

Alignment Base Setup 2

Sealer Setup 2-3

Printer Setup 4

Alignment Stoppers 5

CONTROL PANEL 6

OPERATION 7-8

Offline Print Test 8

Normal Operating Conditions 8

Setting Custom Folds 9

TROUBLESHOOTING 10-12

TEST SHEET 13

OPTIONAL CONVEYOR INSTALLATION 14

Page 4

Page 5

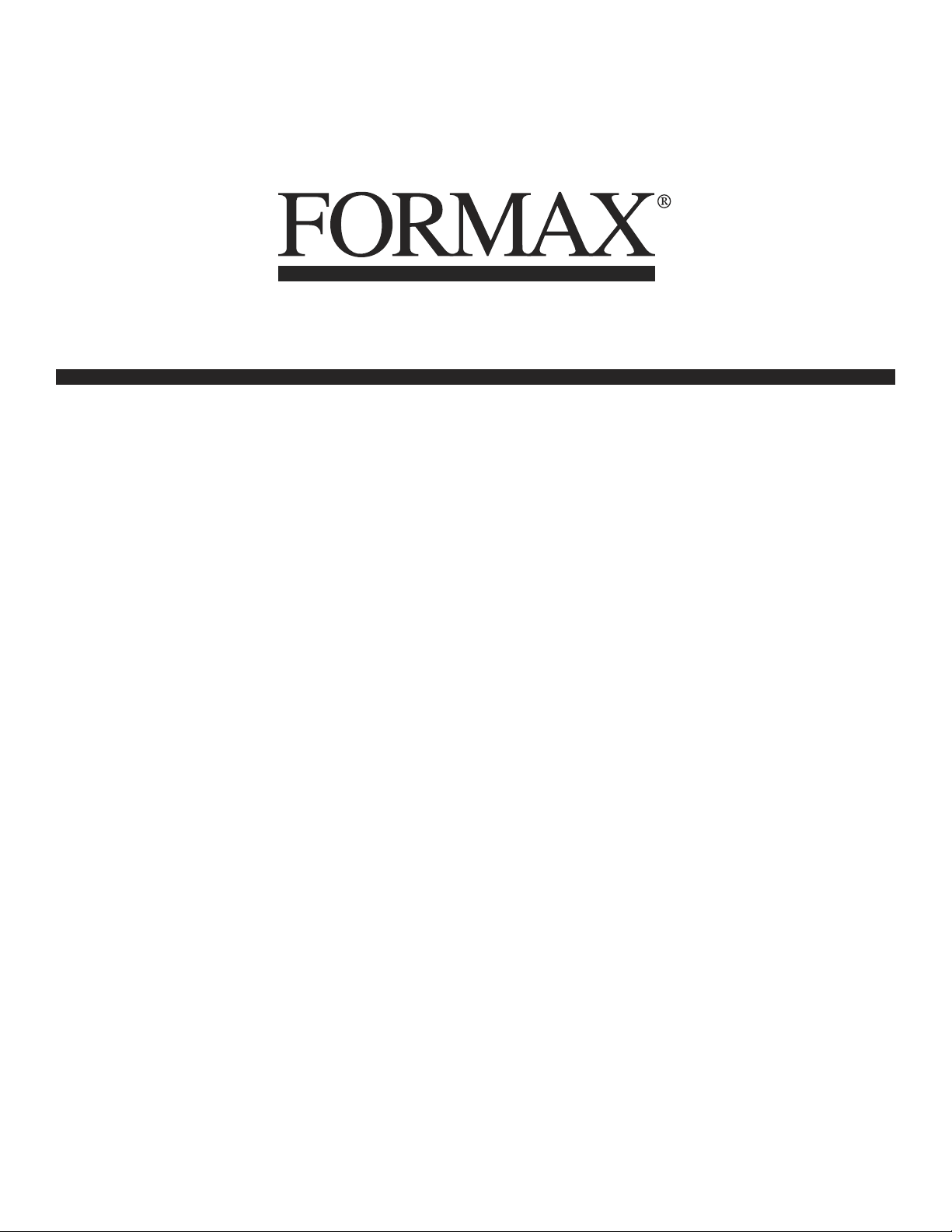

DESCRIPTION

FUNCTION

With the Formax FD 2052IL AutoSeal System operators can print, fold and seal all in one streamlined process.

One-piece pressure sensitive forms are loaded into an existing laser printer where they’re printed and fed directly

into the IL Pressure Sealer where they’re folded, sealed and output as a mail-ready piece.

FD 2052IL System

Printer (not included in IL System)

Upper printer feed tray

Printer power switch

Lower printer feed tray

Printer alignment base

Paper length toggle switch

Printer outfeed / sealer infeed

Lower fold plate

Sealer transport deck

IL Pressure Sealer

Sealer alignment base

SPECIFICATIONS

Printer Compatibility: HP & Troy 4200, only with two 500-sheet trays

HP & Troy 4250, only with two 500-sheet trays

HP & Troy 4350, only with two 500-sheet trays

Consult your Formax dealer for an updated list of additional

FD 2052IL compatible laser printers.

Upper fold plate

Optional 18” conveyor

Sealer power switch

Speed: Printer dependent

Paper Size: Up to 8.5” x 14”

Duty Cycle: Up to 175,000 pieces per month

Power Requirements: FD Model: 120 Volts AC, 50/60 Hz

FE Model: 220 Volts AC, 50/60 Hz

Dimensions (closed) **: 17” W x 43.5” L x 16” H

Dimensions w/18” Conveyor (closed): 17” W x 58.5” L x 16” H

Tabletop Area Required: 19” W x 49” L

Tabletop Area Required

w/18” Conveyor:

Dimensions with Cabinets and

18” Conveyor:

** Dimensions include IL Pressure Sealer and IL Alignment Base.

19” W x 64” L

17” W x 69” L x 45.5” H

UNPACKING

1. Check package for shipping damage. If there is shipping damage do not discard the box.

2. CAUTION: Two people must lift the Pressure Sealer out of the box.

3. Package should contain the IL Pressure Sealer and two piece IL Alignment Base.

1

Page 6

SETUP

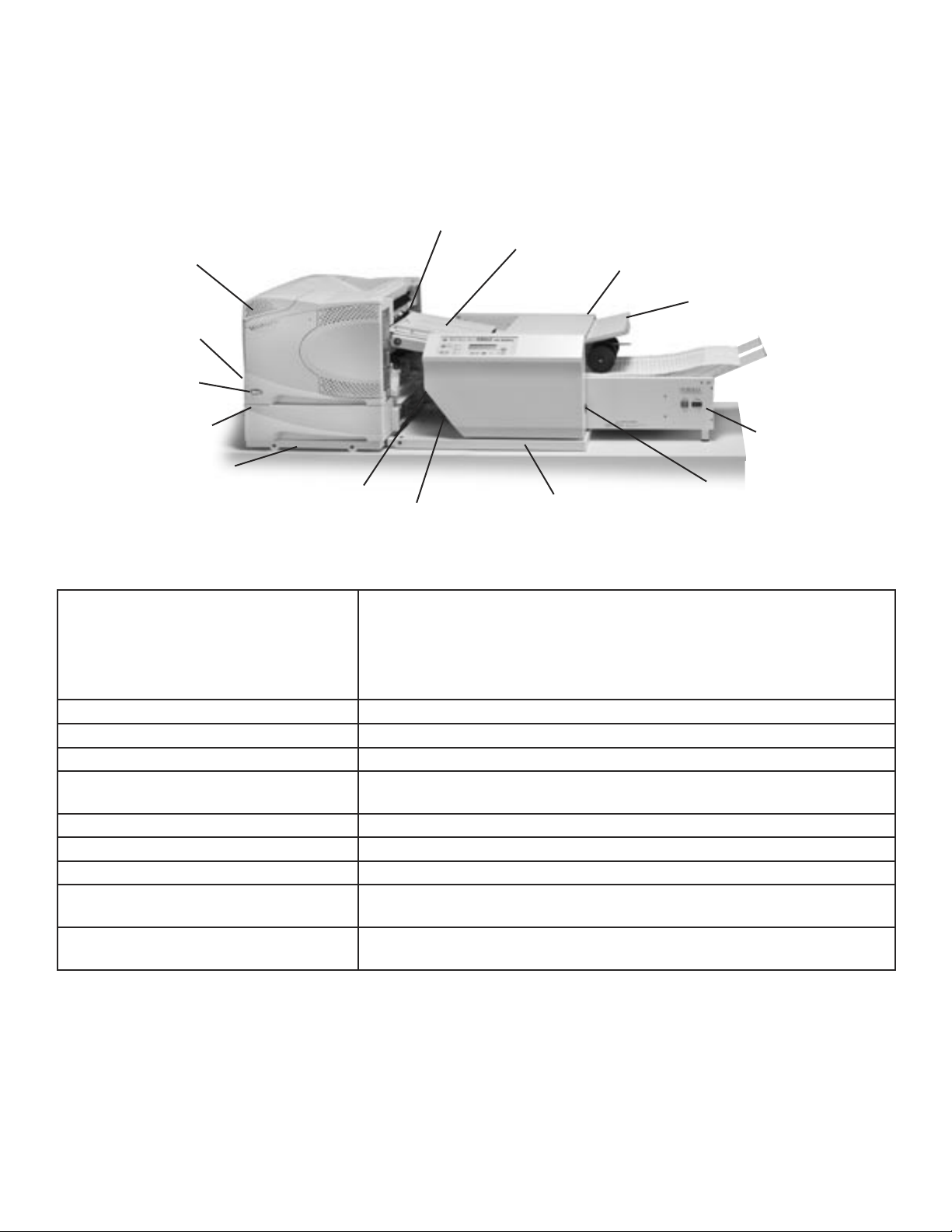

Alignment Base Setup

Connecting slider

1. Place two parts of alignment base face up.

(Fig. 1).

Alignment Base, Pressure Sealer Section

2. Extend connecting slider and slide into slot on

sealer section of base, lining up the screw holes

wih the holes in the top of the base (Fig. 2). Insert

the leading two screws first, do not tighten down at

this point. Align third screw hole in the slider with

the top cover and insert screw. Tighten all three

screws into place.

Sealer Setup

1. Align the 2052IL with the pins located on the

alignment base and lower into position. (Fig. 3)

Caution: Two people should lift and lower the

2052IL.

Fig. 1

Alignment Base, Printer Section

Fig. 2

Fig. 3

2

Page 7

2. Install lower fold plate into pressure sealer.

Match up alignment pins (Fig. 4a) on the pressure

sealer with grooves on the underside of the fold

plate.

Lower fold plate

alignment pins

3. Plug the cord into the fold plate receptacle (Fig.

4b).

4. Install upper fold plate into pressure sealer.

Match up alignment pins (Fig. 5a) on the pressure

sealer with grooves on the underside of the fold

plate.

Fig. 4a

Fig. 4b

Lower fold plate

power connector

Upper fold plate

alignment pins

5. Plug the cord into the fold plate receptacle (Fig.

5b).

CAUTION:

Do not operate the machine without the

fold plates installed and plugged in.

Fig. 5a

Fig. 5b

3

Page 8

Printer Setup

1. Remove back door from the printer. Lower door,

depress the side tabs to release and pull the door

out (Fig. 6).

2. Place printer on alignment base. First align

bottom feed tray with the pins on the printer

alignment base and lower into position. Then align

printer with the bottom feed tray pins and lower into

place. (Fig. 7)

Fig. 6

Side tabs

3. Secure the printer to the bottom feed tray with

the locking mechanism located on the backside of

the printer. (Fig. 8)

Fig. 7

Fig. 8

Locking mechanism

4

Page 9

Alignment Stoppers

The alignment base stoppers are used to keep

the printer from making contact with the sealer

infeed. The exit rollers of the printer and the sealer

infeed throat should not come into contact during

operation. There should be a gap of approximately

1/8” between the rollers and the sealer Infeed

throat.

1. Slide the printer up to the sealer infeed throat so

that there is approximately a 1/8" gap between the

printer out feed and the sealer infeed throat. Using

a 1/8” standard allen wrench, loosen the locking pin

of each alignment base stopper. (Fig. 9)

2. Pull the stopper out from the pressure seal

alignment base until it meets the edge of the

printer alignment base, be sure to maintain the gap

between the printer outfeed and the sealer infeed.

(Fig. 10a & 10b)

Fig. 9

Fig. 10a

Alignment base stopper

Locking pins

3. Using the allen wrench, tighten both locking pins

to hold the stopper into place. Now it’s possible to

slide the printer away from the 2052IL infeed throat

and back into place without having to reset the

position. (Fig. 11)

Repeat with the second stopper.

Fig. 10b

Fig. 11

5

Page 10

CONTROL PANEL

2

1

9

8

7

3

4

5

6

1 Standard Fold Menu Press to select standard fold type

2 Fold LED’s Indicates fold type selected

3 Display Screen Displays all current functions

4 Fold Setup Press to automatically set the fold plates

5 Counter Reset Resets counter and resets faults

6 Service Mode Used to perform service diagnostics

7 Custom Fold Selection Push to select custom folds

8 Adjust Tables “-” “+” Adjusts fold plate measurements for programming custom folds

9 Table A / Table B

Toggles between top and bottom fold plate when setting custom

folds

Standard Folds Menu:

The Standard Folds Menu consists of three folds; Letter (C-fold), Zig-Zag (Z-fold), and Single (Half fold). By

pressing the green button in the Standard Folds Menu, you can toggle between the fold settings. An indicator

will light up on the fold type selected. These fold types are standard for 11” and 14” forms.

Set the form length by flipping the 11”/14” toggle switch located on the left of the pressure sealer (fig. )

Custom Folds Menu:

To use a custom fold setting press one of the custom fold buttons (1, 2, 3-9). Press the 3-9 button multiple

times to toggle through the 3rd and the 9th custom folds.

6

Page 11

OPERATION

1. Plug in cord and turn power on for both the

pressure sealer and the laser printer.

2. Set the form length by flipping the 11”/14”

toggle switch located below the feed deck on the

operator side (Fig. 12)

3. Select the fold type from the “Standard Fold

Menu” (Fig.13). If a custom fold is being used

select fold from the Custom fold Menu (see pg 9

to set a custom fold.)

4. Press the “Fold Setup” button to automatically

set the fold plates (Fig. 14).

Fig. 12

Standard Fold

Selection Button

Fig. 13

Form Length Switch

5. Place pressure seal forms in printer paper tray.

Paper should be loaded into the approved HP

printers face down with the glue edge trailing.

Locate the paper orientation guide on the printer

and load accordingly (Fig. 15). The print side

glue edge is considered the top of the document.

Once forms are loaded perform an offline print

test (see pg. 8) to make sure the printer and

sealer are aligned properly. If the print test is

satisfactory begin online operation.

Fig. 14

Fig. 15

Fold Setup Button

Printer Paper

Orientation Guide

7

Page 12

OffLine Print Test

In order to test the system offline follow the directions below to ensure proper alignment and fold setup. For

further printer test mode operation information or if the printer being used is not listed below refer to the printer

operator guide. Note: The sealer is activated when the form passes over the photo-eye located at the mouth of

the sealer transport deck.

Test Mode HP 4350

1. Power up the Printer and Sealer

2. Load forms into printer face down with glue trailing.

3. When “Ready” appears in the printer window press the button.

4. Press the button to highlight “Information” and press the button.

5. Press the button again to print “Menu Map.” Five pages will be printed.

6. To print additional pages repeat steps.

Test Mode HP 4200 / 4250

1. Power up the Printer and Sealer

2. Load forms into printer face down with glue trailing.

3. When “Ready” appears in the printer window press the button.

4. “Information” will be highlighted, press the button.

5. Press the button again to print “Menu Map.” Five pages will be printed.

6. To print additional pages repeat steps.

Normal Operating Conditions

1. Steam may be present when the form comes out of the printer and enters the sealer transport deck. This is

a normal operating condition if the transport deck is cool when operation begins. The steam should go away

after 5 - 10 forms run through the system allowing the transport deck to warm up.

2. Moisture present on the transport deck. When forms are printed moisture is released from the forms. Due

to the enclosed IL system setup the moisture is present on the transport deck, it should lessen as the transport

deck warms up. Environmental conditions may affect the amount of moisture present as well.

8

Page 13

SETTING CUSTOM FOLDS

The Custom Folds Menu allows you to program custom folds into memory. The 2052IL can store up to nine

custom folds. To store a custom fold into memory, follow these steps:

1. Measuring Fold Lengths

Example 1: Uneven “Z”

a. Measure the length of panel “A”.

b. Measure the length of panel “B”

c. Enter these measurements according to the

instructions below.

Example 2: Uneven “C”

a. Measure the length of panel “A” + “B”

b. Measure the length of panel “B”

c. Enter these measurements according to the

instructions below.

Panel A

Panel B

Panel A

Panel B

1. Select the custom fold number you want to program.

2. Press the green button next to the Table A and Table B lights.

Note: The display will read “Tbls A: #.## B: #.## CUSTOM #”.

Table A adjusts the upper fold plate.

Table B adjusts the lower fold plate.

The “-“ and “+” buttons decrease and increase the fold numbers.

3. Press the “-” and/or “+” button to enter the length of the fold. Fine adjustments can be made with the

adjustment screw at the end of the plate.

4. Press the “Fold Setup” button and run the printer test mode to ensure the proper folds have been entered.

5. Once the folds are correct, press and hold the “Custom Fold” green arrow button until the machine sounds

a tone. The fold has been memorized.

9

Page 14

TROUBLESHOOTING

TROUBLE POSSIBLE CAUSE REMEDY

Control panel lights are

not illuminated.

No power at the wall outlet.

No power to the machine inlet.

Check wall outlet.

Check power cord for frayed/broken

wires.

Fold plate stop not

moving when “Fold

Setup” is pressed.

Sealer does not turn on

when the form enters

the throat of the sealer

transport deck.

Standard fold is

misfolding

No power to the control panel.

Internal electrical failure

Fold plate is not plugged in.

Electrical or mechanical failure

Sealer is not turned on

Sealer reset button has not

been pressed after a paper jam

Sealer breaker has popped

Photo eye is not detecting the

form

Fold plate is not plugged in.

Wrong fold is selected

Press the black breaker reset button

located on the backside of the sealer,

see pg. 12 Fig. 17.

Call for service

Plug fold plate in.

Call for service.

Check that the sealer is plugged in and

turned to the on position.

Press the “counter reset” button to reset

the sealer

Press the black breaker reset button

located on the backside of the sealer,

see pg. 12 Fig. 17.

Wipe sensor with dry cloth.

Call for service

Plug fold plate in.

Check to make sure the correct fold is

selected from the “Standard fold menu”

Fold plates are not inserted

correctly.

Piece of paper or other material

is stuck in the fold plate.

10

A custom fold may need to be created

if the fold varies from the standard fold

setting, see pg 9 for custom fold setup.

Remove and reinstall fold plates. Be

sure they’re properly positioned.

Remove object from the fold plate.

Page 15

Custom fold is misfolding Fold plate is not plugged in.

Plug fold plate in.

Wrong fold is selected

Fold plates are not inserted

correctly.

Piece of paper or other material

is stuck in the fold plate.

Fold settings are off

“Cover Open” is

displayed.

“Paper out “ is displayed. In-feed tray is empty. Place documents on the in-feed tray.

“Paper Jam” is displayed. Paper misfeed between printer

Cover open

Magnetic switch is broken.

outfeed and sealer infeed

Check to make sure the correct fold is

selected from the “Custom fold menu”

Remove and reinstall fold plates. Be

sure they’re properly positioned.

Remove object from the fold plate.

Check that the fold settings match the

actual fold lengths, see pg 9 for custom

fold setup.

Check that all covers are closed

Call for service

Slide printer back to gain access to

the printer outfeed and remove forms.

Lift top cover of printer, remove toner

cartridge and remove forms. Reinstall

toner, close printer cover, slide printer

back into position and press the “counter

reset” button on sealer to reset sealer.

Paper jammed at steel sealer

rollers.

Black marks on the folded

forms.

Fold is skewed. Printer and sealer are out of

Transport table belts do

not turn.

Documents are wrinkled

or crunched.

Fold rollers and/or steel sealer

rollers are dirty.

alignment.

Transport deck belts are dirty

Broken drive belt, worn drive

gear.

Fold plates are not inserted

correctly.

Piece of paper or other material

is stuck in the fold plate.

Remove paper and press “Counter

Reset” button, see pg 12 for clearing

instructions.

Clean the rollers with approved roller

cleaner and rejuvenator.

Check to make sure the printer and

sealer are set properly on the alignment

pins

Adjust rear pin on the printer alignment

base, see pg 12 for adjustment

procedure)

Clean belts with approved cleaner

Call for service

Remove and reinstall fold plates. Be

sure they’re properly positioned.

Remove object from the fold plate.

11

Page 16

A. Clearing paper jams from the steel pressure seal rollers:

WARNING: Turn off machine and unplug cord from its receptacle.

If a jam occurs in between the metal sealing rollers open the top cover and remove the upper fold table.

Remove the jam-clearing tool (located under the top fold table), apply the tool to the upper metal roller (Fig.

16) and turn clockwise until the paper jam is clear. (Caution: Do not apply excessive force or rollers may be

damaged.) (Caution: Do not turn counter-clockwise and force the form(s) to exit the machine or the rollers

may be damaged.) Remove the jammed form, return tool to holder and reinstall the upper fold table. Reinstall

cover and press the reset button.

Note: Press the black button (Fig. 17) near the power cord inlet to reset the breaker if necessary.

Fig. 16

Fig. 17

B. Adjusting printer alignment base pin:

The rear printer alignment base pin can be adjusted to properly align the printer with the sealer. Loosen the

rear pin using an adjustable wrench to hold the pin while using a 7/16” socket to loosen the nut. Slide the pin

forward to move the front outfeed corner of the printer forward toward the front edge of the alignment base and

slide the pin back to move the front corner of the printer back away from the edge of the alignment base. The

printer will pivot on the front alignment pin (Fig. 18).

Rear alignment pin

Back position

Forward position

Front alignment pin

Front edge

Fig. 18

12

Page 17

Leading Edge

Make copies of this page on copy paper for fine tuning folds

Instruction For Lining Up Folds

1. Place a stack of these sheets into the feeder and fold

one (1) or two (2) sheets.

2. Take a folded sheet from the catch tray and lay it on

top of a pressure seal form lining the leading edge of

this sheet up with leading edge of the pressure seal

form.

3.

If the folds on this test sheet do not line up with the

perforated folds on the form, the fold plates need to

be adjusted up or down to make the folds line up.

Refer to Fig. 1 for a “Z” fold and Fig. 2 for a “C” fold.

-

If fold “A” on the test form is right of the perforation on

the pressure seal form move the top fold plate

stop up. If fold ”A” is below move the top fold plate

stop fold stop down.

-

If fold “B” on the test form is right of the perforation

on the pressure seal form move the bottom fold plate

stop down. If fold ”B” is to the left move the bottom

fold plate stop up.

Fold “A” Fold “B”

Fig. 1 “Z” fold Form

Fold “A” Fold “B” Leading Edge

Leading Edge

13

Fig. 2 “C” Fold Form

Page 18

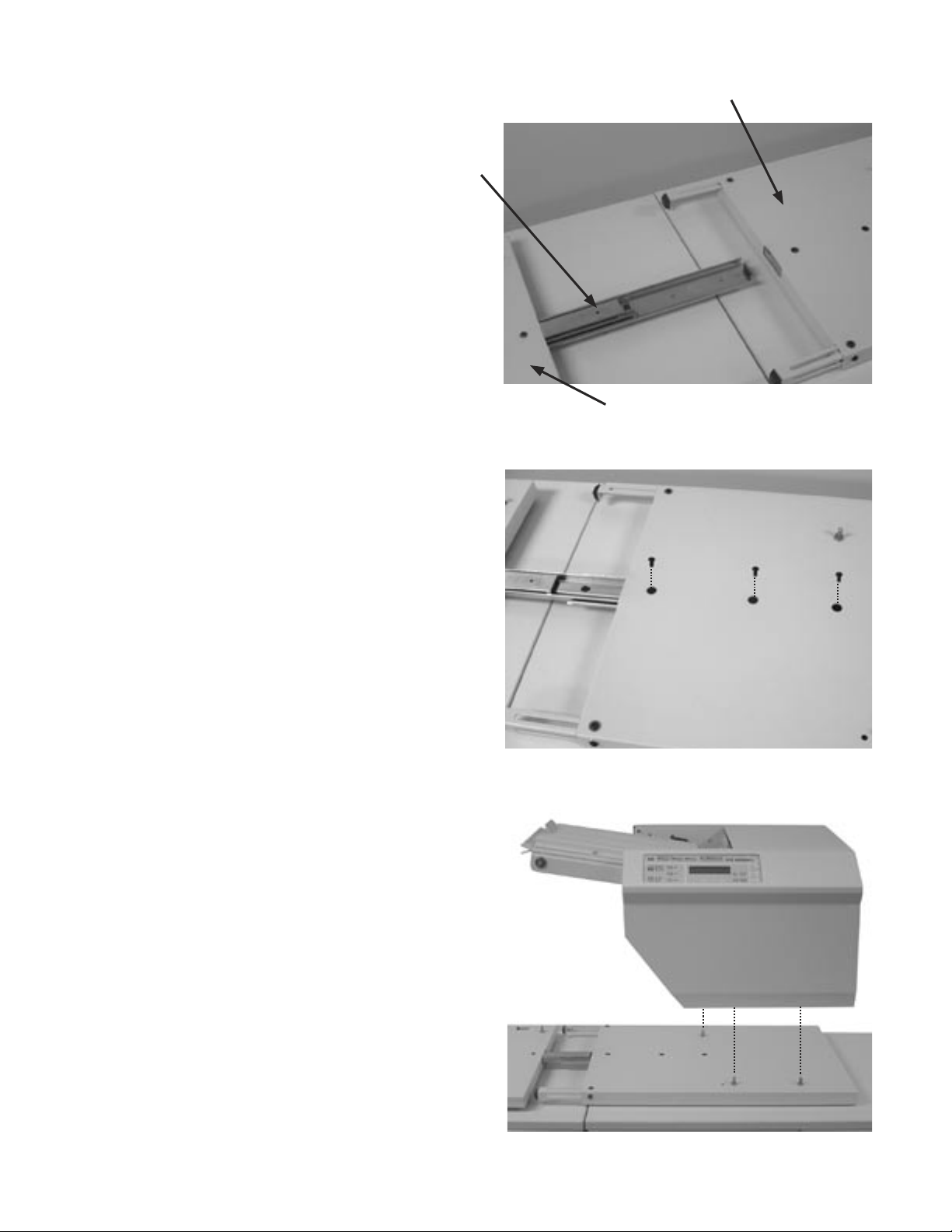

OPTIONAL CONVEYOR INSTALLATION

To install the 18” conveyor, follow these steps:

1. Unplug the pressure sealer from the wall outlet.

2. Remove the catch tray from machine.

3. Remove the upper fold table.

4. Plug the power cord into the underside of the conveyor.

5. Install the conveyor mounting bolts. (Fig. 19)

6. Attach the conveyor to the pressure sealer.

7. Install the stacker wheel assembly into the holes indicated below. (Fig. 20)

8. Adjust the stacker wheels to conveyor decal.

9. Plug the conveyor power cord into the power outlet on the pressure sealer.

10. Reinsert the upper fold table.

11. Plug the pressure sealer into the wall outlet.

Fig. 19

Mounting Bolts

Holes For Stacker Wheel

Assembly

Stacker Wheels

Fig. 20

Loading...

Loading...