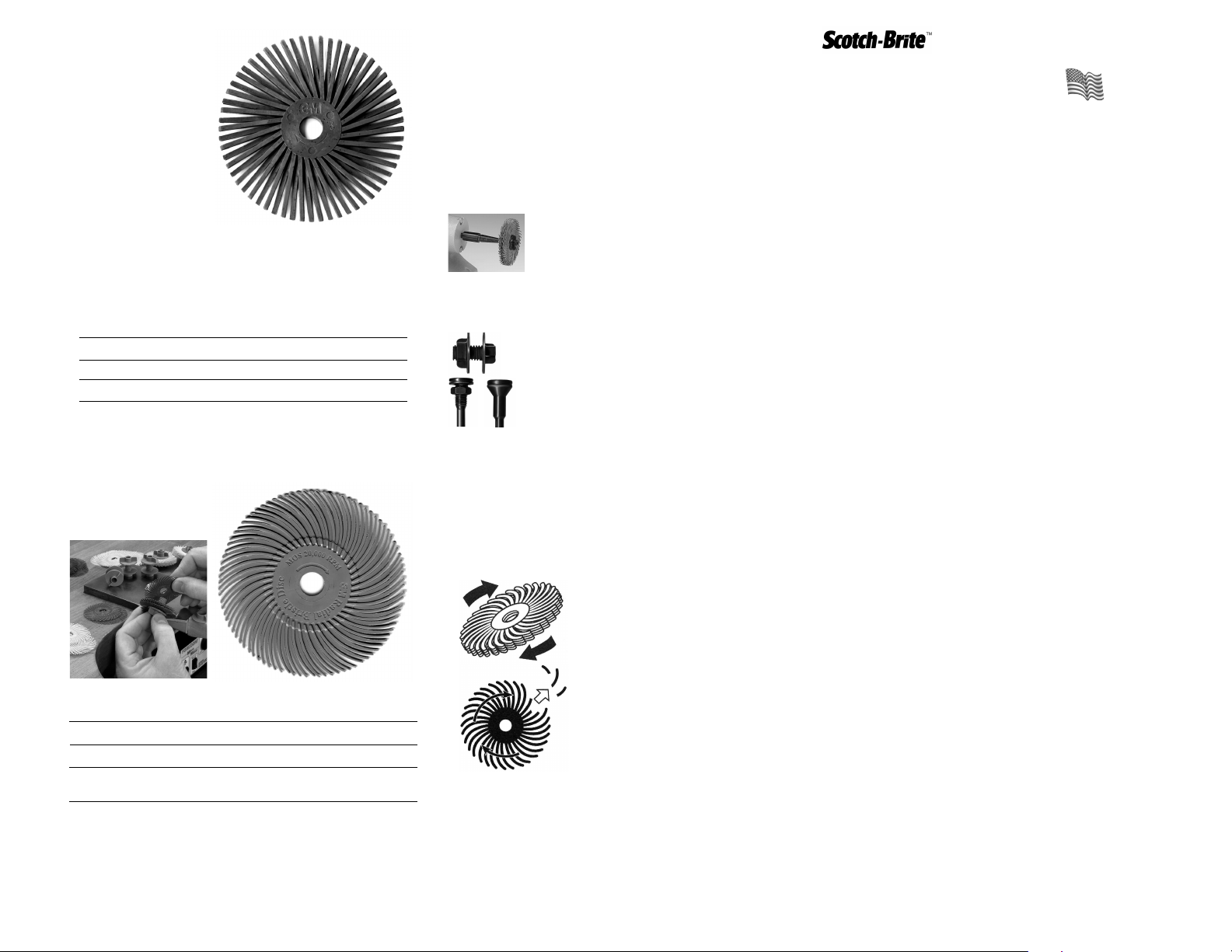

3″

Heavy Duty Radial

Bristle Discs

• Super tough plastic bristle

discs, embedded with

abrasive, wear as they

clean continually exposing

fresh abrasive

• The ideal tool to replace

scrapers, wire wheels and

chemical strippers

• Bristles ride over surface

without gouging

• Use on steel, aluminum,

wood, cast iron

20,000 RPM

Max. Speed

Color Grit Operating Speeds

Green 50 3,000 –10,000 RPM

Yellow 80 3,000 –15,000 RPM

White 120 3,000 –15,000 RPM

Vary the speed to obtain different surface textures and

finishes on different materials.

Recommended

Applications:

Industrial: Clean metal surfaces prior to welding, painting, or other

operations. Weld clean up. Deburr parts. Pre-polish brass, copper,

aluminum, steel, stainless steel, and other metals.

Jewelry: Pre-polish and polish precious metals. Finish pewter and white

metals. Remove scratches and sprue marks. Clean insides of rings.

Clean up solder joints.

Dental: Smooth and clean hard alloys. Remove oxides and

contaminants. Prepare surfaces. Polish acrylics.

Woodworking: Sand and smooth flat or irregular surfaces on soft or

hard wood. Remove fuzz and burs from carvings. Sand inside grooves.

pered Spindle

Ta

Tapered Spindle

Adapters P/N:

(right hand)

A-4561

(left hand)

A-4562

A-M30 and A-M31

Mandrels

Mounting Discs: For tapered spindles on bench

lathes (Foredom BL lathe or other) use a Tapered Spindle

Adapter which will hold 1 to 12 of the discs.A wheel

mandrel with 3/8″ arbor can also be used on bench

grinders or lathes. Use 2 or 3 discs for small grooves and

recessed areas and 6 to 12 discs for wider areas.

2″ Discs can be used in hand held grinders or flex shaft

handpieces with an A-M30 or A-M31 Foredom Mandrel.

Be sure to mount them so that the arrow

molded into the hub of the disc is pointing in

the direction of rotation of the spindle.

Authorized 3M Distributor

FOREDOM

Foredom Electric Company

16 Stony Hill Road, Bethel, CT 06801

www.foredom.com

Form No.1306 n 4/08 Printed in USA

®

2″and 3″Radial Bristle Discs

2″ O.D. (51mm) X 3/8″ Arbor Hole (9.5mm)

3

″ O.D. (76mm) X 3/8″ Arbor Hole (9.5mm)

Maximum Operating Speed (MOS):

30,000 RPM for 2″discs 20,000 RPM for 3″discs

20,000 RPM for Heavy Duty 3

Product Features: Scotch-Brite™ patented radial bristle discs are

molded plastic discs embedded with a blend of patented 3M Cubitron

and aluminum oxide mineral. Cubitron is a tough, long lasting ceramic

aluminum oxide mineral with sharper edges than regular aluminum

oxide.The abrasive filled bristles apply a continuous fresh supply of

mineral to the work piece eliminating the need for compounds.The

flexible bristles will reach into grooves and contours on irregular

surfaces or work on flat areas.They can clean and remove dirt, rust,

and oxidation without damage to the underlying surface.They run

cool and will not load up with removed material. Because no

compounds are required these discs generate far less dust.

Scotch-Brite™ Heavy Duty Discs have thick

rugged construction and are available in coarse grits: 50, 80 and

120. They quickly remove many types of tough coatings including

rust and paint from a wide variety of metals and can carve wood.

Scotch-Brite™ is a trademark of 3M 3M

″

discs

er bristles, more

Made

in USA

™

2″and 3″Radial

Bristle Discs

Color Grit Operating Speeds

Yellow 80 3,000 – 15,000 RPM

White, Red & Blue 120, 220 & 400 3,000 – 18,000 RPM

Pink, Peach 1,200 (pumice), 3,000 (6 micron)

& Lt. Green & 14,000 (1 micron)

Vary the speed to obtain different surface textures and

finishes on different materials.

Always wear eye and face pr

Recommended

1,750 – 7,500 RPM

otection.

Safety Information:

Read this insert before mounting brush/disc on tool or

machine. Post this insert in the work area.

Improper use can cause product to break apart and may

cause injury. Take precautions indicated below.

Exceeding maximum operating

speed or abusive operation can

cause product to break apart

and may cause injury.

exceed the maximum

Never

operating speed (MOS).

Be sure you check the maximum

operating speed (MOS) of the

product against the machine speed.

Be sure you check direction of

brush/disc rotation. Running in the

Discs can break apart

Do not jam the work piece into the product.

Do not press hard on the side of the product.

Sparks flying off some products can cause fire.

Particles flying off products can cause injury.

Remove flammable materials

ect

Dir

sparks aw

wrong direction can cause bristles

to break off.

from the work area.

ay from face and body

.

For Dangerous Operations, use the proper machine

Safety Guards.

Consult your plant Safety Engineer for safe work set-up.

Wear face, hand and/or body protection when appropriate.

Make sure no one is standing in front or back of the product

when starting machine.

Provide appropriate local exhaust. If exhaust

ventilation is not adequate, wear dust protection respirator

or face mask to prevent inhalation of dust particles.

A damaged, vibrating, or wobbling brush or disc

can break apart and may cause injury.

Do Not

enlarge or change the shape of the center hole.

Stop the product if vibrating or wobbling occurs during use.

Damage or Wobbling can be caused by:

• Forcing the product onto a spindle that is too large.

• Over-Tightening the mounting nut.

• Using side support washers with brushes/discs that are

smaller than 1/3 product diameter, unequal in diameter

or warped.

Incorrect storage can cause bristles to break off

during use and may cause injury

.

Store product at temperatures between 40ºF (5ºC) and

150ºF (65ºC) for at least 24 hours before using.

Store in a Dry, Cool Place.

Loading...

Loading...