FOREDOM M.BL-2CE Owner's Manual

You have purchased a fine quality power tool which will perform a wide variety of tasks

difficult to do with any other kind of power tool. Foredom

®

Power Tools are manufactured to

high standards of precision and performance and, with proper use and maintenance, will

give you years of trouble-free performance.

Safety Instructions

Before using your Foredom Bench Lathe, please read all safety instructions. They are

for your protection and should always be followed to reduce the risk of personal injury or

damage to the tool.

Always wear proper eye and face protection. Safety glasses or face shields should be worn

whenever you operate a Foredom or any power tool to prevent serious eye or face injuries.

Do not wear loose clothing or jewelry and be sure to tie back long hair.

Always use a proper dust collection system or wear a respirator to prevent the

inhalation of dust particles or other debris into your lungs.

Never

operate any accessory at speeds above its maximum speed rating. When

properly used, all of Foredom’s accessories can be operated at the speeds listed in

Foredom accessory catalogs or on the packaging. Only accessories rated for 7,000 RPM or

more should be used with the Bench Lathe.

Always determine the manufacturer’s speed

rating before using accessories other than Foredom’s.

Never use or continue to use any accessory which appears to be damaged, loose, vibrating,

or out of balance. Inspect each accessory for cracks or flaws before using it.

Always insert the shank or arbor of an accessory or mandrel into the collet (or collet holder

chuck or chuck arbor) as far as possible in order to provide proper support. Tighten the collet

or chuck securely.

Always make sure that accessory tightening tools such as the pin and wrench are removed

before the lathe is turned on.

Never use excessive side pressures which may tend to bend or break the shank or arbor or

an accessory. Let the speed of the accessory do the work.

Do not overload the lathe by jamming or using excessive pressure on the polishing wheel,

buff wheel, or accessory. Do not apply long time continuous loading. This can result in

damage to the lathe.

Never operate your power tool during a perceptible power decrease. Turn power tool off and

do not use until power is fully restored.

Use proper fusing procedures. The fuse holder is located on the rear of the base. If a fuse

blows, make sure lathe is not being overloaded, line voltage is not low, and motor shaft turns

freely. Replace fuse with same type and ampere rating. Use type 3AG “slow blow” fuses,

3 Amp for model BL, 1.5 Amp for model BL-2.

Do not use a higher ampere fuse.

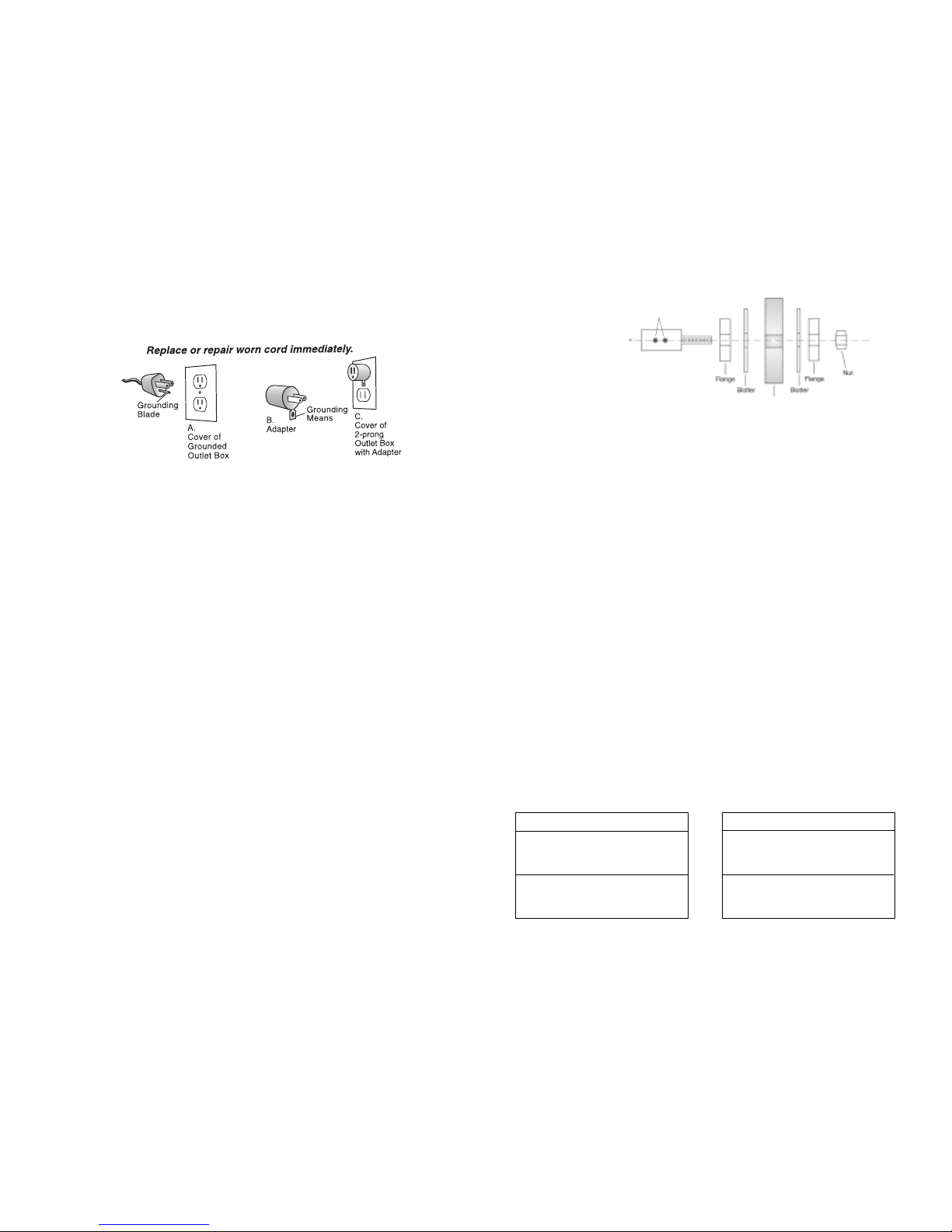

Use proper grounding procedures.

This tool should be grounded while in use to protect

the operator from electric shock. The tool is equipped with an approved 3-conductor cord

and a 3-prong grounding type plug to fit the proper grounding receptacle.

The green (or

green and yellow) conductor in the cord is the grounding wire. Never connect the green (or

green and yellow) wire to a live terminal. If your unit is for use on less than 150 volts, it has a

plug that looks like sketch A in Figure 1. An adapter (sketches B and C) can be used for

connecting plugs as shown in sketch

A

to 2-prong receptacles.

The green colored rigid ear

,

lug, etc., extending from the adapter must be connected to a permanent ground such as a

properly grounded outlet box.

Some jurisdictions, including Canada, prohibit the use of

3 to 2 prong adapters. Where prohibited, they should not be used.

Use only 3-wire

Owner’s Manual

FOREDOM

®

for the

Bench Lathe

M.BL (115v)

M.BL-2CE (230v)

For Your Own Safety–

Read Owner’s Manual before operating

your Foredom Power Tool.

Always wear eye protection while using the

Bench Lathe or other power tools.

Operation

Because of the higher maximum speed (approximately 7,000 RPM) and variable

speed control, the Foredom®Bench Lathe has several advantages over

conventional single or two speed polishing and buffing lathes:

1. The same size buffing wheel can be used to obtain different surface speeds, as

measured in surface feet per minute (SFPM). 3

″ or 4″ diameter buffs can provide

the 1,750 to 3,450 SFPM recommended for polishing and the 3,450 and higher

SFPM recommended for buffing. The chart below shows the SFPM obtained with

different diameter wheels at various speeds.

2. The SFPM can be varied while using the same diameter buff or wheel. This will

give better results on different types of material.

3. The 7,000 RPM maximum speed will enable you to get much higher SFPM with

smaller 1

″ or 2″ buffs or inside ring buffs, than slower single or double

speed equipment.

4. The new 3M Scotch-brite

™

Radial Bristle Discs in 2

″ and 3″ diameters also

require 5,000 or higher RPM for optimum performance.

5. The maximum speed of 7,000 RPM is also fast enough to permit the use of small

mounted abrasive points, brushes, cutters, or other accessories in the A-CHA-5

collet holder, S.BO-516 flexade or A-JCA-2 chuck holder.

For additional information on buffing and polishing procedure, wheel selection,

and Foredom buffing and polishing compounds, please refer to the Foredom

Buffing and Polishing Guide (Form No. 1234).

Assembly Instructions

BL Bench Lathes have 5/16” (8mm) straight motor shafts and come with A-TM5 (left hand)

and A-TM6 (right hand) tapered spindles. These precision made spindles are suitable for

speeds of 500 to 7,000 RPM. Similar accessories, supplied for slower speed polishing

motors, often do not run as true which can cause vibration and be a potential hazard.

Using

spindles and other precision accessories supplied for slower speed motors is not

recommended with this bench lathe.

Mounting Base:

The Bench Lathe comes with suction cup feet that help to secure the lathe

to a smooth work surface. To further prevent movement while pressure is being applied to a

buff or wheel, the base should be bolted or screwed down to a solid work bench or table.

Use the four mounting holes in the base for this purpose.

Attaching Accessories: The supplied A-TM6 tapered spindle, and optional A-CHA-5 collet

holder, A-JCA-2 chuck arbor, A-WM6 wheel mandrel and S.BO flexades

®

are right hand

side

accessories, intended for use on the right hand side of the lathe as you face it. Do not

use them on the left side

as buff, wheel or tool may unscrew under load. The supplied

A-TM5 tapered spindle is intended

for use on the left side only. An optional A-WM-5

wheel mandrel is available for use on the left side of the lathe. (Every spindle and mandrel

is marked with an R or L to indicate left or right hand.)

Attach the spindles or mandrels by sliding them onto the motor shaft until there is only a

1/8

″ space between the motor housing and inside edge of the spindle or mandrel. Be

sure that the two set screws line up with the flat on the motor shaft.

Tighten both screws securely with supplied hex key.

See Figure 2 for mounting rubber wheels or other accessories with 1/4″ diameter

center holes on A-WM-6 wheel mandrel.

Use only 115 Volt AC 60 Hz for BL and use only 230 Volt AC 50 Hz for a BL-2. Run the

lathe at slow speed without a buff (or wheel) to see that the spindles, mandrel, or collet

holder on the lathe are running true.

Never use a buff, brush, abrasive wheel, or any other accessory that is not rated

for at least 7,000 RPM and never use one that appears to wobble or vibrate.

It could

damage the lathe or injure you.

Buffs over 4″ in diameter should not be used on the

Bench Lathe.

Never use a grinding wheel over 2

″ diameter nor rubber bonded wheels

over 3

″ in diameter. Please refer to Figure 2 for the proper mounting procedure for wheels

or brushes on the A-WM-6 (or A-WM-5) mandrel.

Figure 1

Figure 2

A-WM-6

Assemble

all components in

proper sequence.

(A-WM-5 left side

wheel mandrel has

same components in

opposite sequence)

Cotton, chamois or felt buffs over 4″ in diameter should not be used with

the Bench Lathe.

SPEED SFPM

1

″ Dia. Buff

Full 7,000 RPM 1,750

Med

4,000 RPM

1,000

2″ Dia. Buff

Full

7,000 RPM

3,500

Med 4,000 RPM 2,000

SPEED SFPM

3

″ Dia. Buff

Full 7,000 RPM 5,250

Med

4,000 RPM 3,000

4″ Dia. Buff

Full 7,000 RPM 7,000

Med 4,000 RPM 4,000

M

otor Shaft

s

et screws

R

ubber

Wheel

extension cords that have 3-prong grounding type plugs and 3-pole type plugs and 3-pole receptacles that accept the tool’s plug. Always disconnect the power cord before servicing the lathe.

Never use in an area where flammable vapors are present.

Loading...

Loading...