Master

Stone-Setting Kit

Instruction Handbook

AK820 Master Kit with

Foredom®H.30®handpiece

AK825 Master Kit without

Foredom®H.30®handpiece

®

FOREDOM

The Foredom Electric Company

16 Stony Hill Road,

203-792-8622

www

.foredom.com

• fax:

Bethel,

CT 06801

203-796-7861

Master

Stone-Setting Kit

Instruction

Handbook

The Allset prong, pavé and channel-cutting guides in this kit deliver precise,

repeatable accuracy and flexibility whenever they’re used. The result is higher

quality, defect-free stone settings done faster and easier than ever before!

Here’s what you’ll find with your Master Stone-Setting kit:

Non-Rotating Guide Assembly. This lightweight assembly is the heart of the Master kit. It attaches easily to a Foredom

H.30®handpiece and includes body, collar, shaft and L-bracket.

The Easy-Cut Prong Guide. Create level, uniform and precise cuts time after time with this remarkable prong-cutting aid.

Its unique design ensures a level and uniform-height cut on square, round or any other shape of prong. It also includes a new

stop guide that precisely controls the depth of each cut.

Channel-Setting Guides. Create perfectly contoured channel settings for round, square and baguette stones quickly and

easily with these precision guides. Kit includes three guides (small, large and knife-edge).

Prong Guides. Ensure the proper-depth cutting of prongs in single- or multiple-prong settings with these precise guides.

Includes 13 separate guides.

Pavé Guides. Let you create the cobblestone effect of pavé in half the time it would take by hand. Includes seven stainless

steel guides.

Allset Quality. Allset kits and components are made in the USA of highly durable materials and are versatile tools that stand

All of the cutting guides are made of the

up to multiple demands and configurations

highest quality stainless steel for a cleaner finish and a long, rust-free life.

.

Safety Notes

1. Always use eye protection when cutting prongs and channels with your AllSet Master Stone-Setting Kit or

when using any power tool.

2. Some prong and channel-cutting operations may require close placement of the hands to sharp

To avoid injury, please pay careful attention to hand placement, avoid distractions and do not operate

prong-cutting equipment without your full attention.

or safety and effectiveness with any power tool, maintain a clean work surface and general work area.

3. F

cutting edges

,

.

®

2

Introduction

The patented AllSet®guide assembly is a lightweight attachment that becomes part of a standard flexible shaft handpiece.

When properly installed, you can leave the collar and body

attached to the handpiece while doing other work with your

flex shaft. You may even decide to dedicate an extra H.30

handpiece exclusively to the AllSet guide.

To use the AllSet guide, simply slide the shaft and L- bracket

assembly into the body following the assembly instructions on

pages 4 and 5. When the handpiece is needed for another

operation such as polishing, simply loosen the rear shaft

locking screw and slide the shaft out of the body.

Assembling Your AllSet®Guide

The AllSet tool is carefully engineered to adjust for normal

manufacturing tolerance variations in the handpiece.Therefore,

you need to carefully tune the body of the AllSet to your handpiece by adjusting the collar set-screws, using the Allen Key

supplied with your AllSet Master Kit.These minor adjustments

in the collar set-screws will center the hole in the bracket in

front of the handpiece chuck. This procedure is explained in

Steps 6 and 7 of the assembly instructions on pages 4 and 5.

®

A Note About Burs

As a general rule, cutting seats for stones should be done with

low-speed burs. Vanadium steel burs are an excellent choice

because of their fine-vane design. This gives you greater control

while cutting the seat and helps eliminate the tendency of the

bur to grab and skip. As with most drilling operations, use a

low speed.

To achieve precise cuts during prong-setting, we recommend

using a flexible shaft machine with high torque at low speed

such as the Foredom®Series L or TX machine with your AllSet

tool. For cleaner cuts during channel-setting applications, you

will want to use a smaller bur and run it at a higher speed.

For this, we recommend using the Foredom Series SR.

Before You Start

Detach the H.30 handpiece from the flex shaft. Follow Steps 1

through 7 (pages 4 and 5) to install the AllSet guide assembly

on your H.30 handpiece.

®

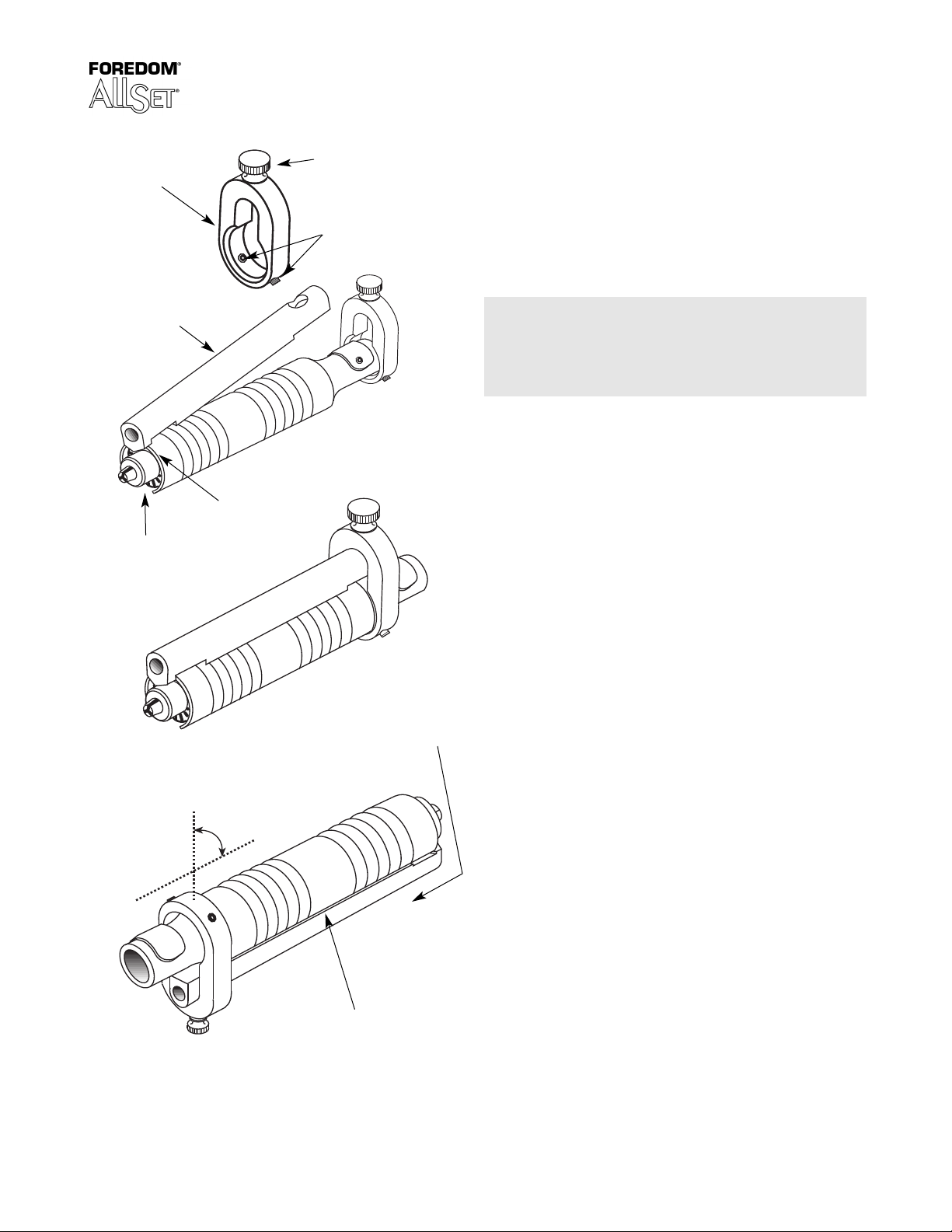

Exploded View

Body

Shaft

Shaft

adjusting nut

L-bracket

H.30®handpiece

(supplied in Kit 820)

L-bracket

Guide

* You’ll need a flexible shaft machine fitted with a Foredom®H.30®handpiece.

(Copies of the Foredom H.30

not allow as good a fit.) Flex shaft machines are available separately.

ront guide

F

locking nut

®

Rear guide

locking nut

may have slight dimensional differences that do

Shaft

locking

screw

Collar

Set-screws

Body

Shaft

Assembled

View

L-bracket

3

90˚

Collar

AllSet®Guide Assembly

Step 1:

Shaft locking screw

Unscrew both set-screws and shaft-locking screw, so none of

them extend into the opening of the collar (Figure 1).

igure 1

F

Figure 2

Figure 3

AllSet body

Chuck key

opening

Housing lip

Set-screws

Step 2:

Hook the front of the AllSet guide body over the front lip of the

handpiece housing, opposite the chuck key opening (Figure 2).

Lower the back of the AllSet body until it is flat against the

H.30®handpiece.

Please Note:

Be sure the front of the AllSet body is attached to

an unbent, undamaged section of the housing lip.

If the AllSet body does not lie flat on the handpiece,

it is not hook

ed properly over the housing lip.

Step 3:

Slip the collar over the back of the handpiece and AllSet body,

then push forw

ard against the handpiece housing (Figure 3).

Make sure the bevel on the inside edge of the collar is

facing forward.

Step 4:

Turn over the handpiece, body and collar assembly (Figure 4).

Screw in the shaft locking screw just enough to make sure it

is in the hole at the back of the body. Do not tighten it all the

way or the shaft will not slide completely into the body (see

Step 7). This screw is used to lock the shaft in position and does

not function to secure the collar on the body or handpiece.

Collar should be

perpendicular to

the handpiece

Figure 4

.

Push AllSet body firmly back

before tightening set-screws

(see step 5).

Make sure there is no gap

between the

handpiece housing.

AllSet body and the

Step 5:

While holding the body against the handpiece, push the front

of the body toward the collar to be sure it is still hooked over

the front lip of the handpiece housing. Evenly tighten the two

set-screws until the collar is centered from side to side on the

handpiece and the AllSet body is firmly against the handpiece

housing. Snug down the set-screws with the Allen Key included

in the kit. Do not over tighten.

Step 6:

Insert a 3/32″ (2.35mm) shank diameter bur in the handpiece

chuck (F

igure 5).

This bur will act as a reference for aligning the

AllSet guide. Since you will slip a guide over the bur, be sure

the bur head is smaller than the shank which is 2.35mm. A

2mm round bur is suggested.

Step 7:

Assemble the shaft adjusting nut and L-bracket as shown.

Insert the shaft (grooved end first) into the body of the

AllSet

(Figure 5). Loosen the shaft locking screw enough to allow the

shaft to slide past the locking screw. The bur should go through

the center of the hole in the L-bracket. Tighten the shaft

locking screw

.

4

Assembly instructions (continued)

Please Note:

Test for centering by sliding one of the prong stop

guides over the bur and into the hole in the L-bracket.

f the guide slides easily through the hole in the

I

L-bracket, the alignment is correct. The bur does not

need to be perfectly centered, but it should not rub on

the guide. The hole in the L-bracket is slightly larger

than the threaded portion of the guide to adjust for

minor variations in centering.

Installing Accessory Guides

Step 1:

Loosen the shaft locking screw and slide the shaft and

L-bracket assembly out from the bur. Slip the rear guide lock

nut over the bur (Figure 6). Slide the shaft and L-bracket back

into the body and tighten the shaft locking screw. It’s important

to tighten the shaft locking screw before aligning the guide

since the shaft will lift slightly when the screw is tightened.

Step 2:

To install a channel-setting guide or other accessory, slip the

guide over the end of the bur and into the hole in the L-bracket.

Tighten the rear guide lock nut to secure the guide, making sure

the guide is centered around the bur.

Step 3:

Loosen the shaft locking screw which allows the shaft to

slide freely. Adjust the guide using the shaft adjusting nut so

the bur protrudes from the guide (Figure 7). To change the

distance between the guide and the cutting edge of the bur,

adjust the guide using the shaft adjusting nut. Tighten

the shaft locking screw.

Please Note:

The smaller of the two basic channel-setting guides (see

page 12) is designed for use with small burs that have

tapered shafts below the bur head. Because the tip area

of the small channel guide is less than the 3/32

bur shank,

the guide will not allow burs to slip or go deeper

″ (2.35mm)

into the channel. Burs cannot be removed or inserted from

the front of the small guide.

The large channel guide is designed to accommodate larger

such as ball burs

,

burs

, and is especially useful in setting

stones with thicker girdles.

To Install Other Accessories

To install a table guide, the easy-cut prong guide or a pavé

guide, follow steps 2 and 3 (Figure 8).

Shaft

adjusting nut

L-bracket

Bur

able guide

T

Shaft

Channel

guide

Handpiece

Shaft

Bur

Body

Chuck

Body

Rear guide

lock nut

Guide

Prong guide

Shaft

locking

screw

urn shaft

T

adjusting nut

to adjust position

of the guide.

L-bracket

Figure 5

Shaft

locking

screw

Figure 6

Figure 7

Figure 8

Rear guide

Rear guide

locking nut

locking nut

5

The Easy-Cut Prong Guide

The AllSet®Easy-Cut Prong Guide helps ensure straight, uniform cuts on

each prong—every time! It’s completely adjustable and it positions the

setting precisely so the bur won’t grab or roll itself around the prongs,

ausing scratches. It adjusts to any stone shape and size. Perfect for 45°,

c

70° and 90° cuts, it allows you to cut perfect seats in the prongs of large

pendants, basket settings, solitaire mountings and much more.An

adjustable guide in back controls the depth of cut as well.

Use the Easy-Cut Prong Guide to:

• cut perfectly level stone seats regardless of the setting shape.

• gain precise, accurate control over the depth of cut so that finished

prongs are stronger.

• reduce stone breakage because you don’t have to force prongs

while setting.

L-bracket

As the bur rotates, it creates a counterclockwise force on the prong. The prong

guide allows movement only along the

guide’s edge.

Top view

stop guide

depth control

adjustment

The prong guide centers the prong for

the bearing cut; align the guide so that

the center of the prong is at the center

of the bur.

range of

adjustment

prong guide

angle adjustment

Side view

Exploded and assembled views of the Easy-Cut

Prong Guide mounted on the L-brack

attached to the H.30®handpiece.

et which is

Assembled view showing guide adjustments.

6

Using the Easy-Cut Prong Guide:

ake sure all prongs are at the same angle. File the tops of the

M

1.

prongs so they are the same height and level with one another.

2. Choose a low-speed bur that will make a cut appropriate for the

stone (usually a 90° hart bur). Fine-cut, low-speed burs will work

the best without chatter and skip.

3. Make the cuts by moving the prongs across the bur, perpendicular

to the inward direction of the cut. Cut about a third of the way

into the prong, depending on how thick the prongs are.

Many large colored stones have extra-thick girdles or some other irregularity. You will have to judge if cuts need to be wider or at different levels. Be

sure to mark the stone and the setting for position as you try the fit and

make adjustments. Well-cut stones benefit from settings made with AllSet

guides because there is little or no unusual torque or pressure from

uneven cuts.

Make sure each prong

s at the same angle

i

and is the same

length. File the top of

the prongs flat.

®

set the depth of cut into

prong with stop guide.

The end of the fence guide should

be positioned slightly underneath

the bur. This will prevent the prong

from slipping between the bur and

the guide.

Prong setting

with prong tips

on the table

Adjust the bur’s height for the

proper stone set (distance of cut

from top of prong).

Check to be sure that the piece sits level on the

table without wobbling.

Position the piece on the table using the prong

guide and depth control guide. Rotate the bur

slowly at first while making the cut into the prong.

Allen bolt

adjustment

When adjusting the guide for

prong width,

that the bur is centered with

the prong for consistent and

straight cuts.

it is very important

The stop guide (depth control) is

not necessary for all settings.

Use it whenever the depth of

the prong cut is critical

to the setting.

Rotational force

Centered prong

7

T

he Easy-Cut Prong Guide offers a wide range of adjustability.

Adjustment for prong height

Adjustment for

prong width

Adjustment

for depth of

cut into prong

same distance from top of prong

Rotational

force

Adjustment for smaller

settings/prongs

llen bolt

A

adjustment

Rotational

force

Adjustment for larger

settings/prongs

Allen bolt

adjustment

Rotational

force

Side view of ring setting showing center-cut prongs

with evenly cut heights.

Top view of ring setting showing center-cut prongs with evenly cut heights.

The Easy Cut Prong Guide produces consistent settings with perfectly even height and depth cuts.

Close-up views of cut prongs

(Easy-Cut Prong Guide vs. freehand cutting)

cut height

cut

depth

correctly

centered cut

cut height

correctly

centered cut

incorrect,

off-center cut

The result—

a perfectly

set stone!

incorrect,

off-center cut

8

Pavé Guide Set

The AllSet®Pavé guides make it quick and easy to create the field-of-

tones effect of pavé.

s

• Includes seven pavé guides, 2–5mm, in 0.5mm increments.

• Solid, non-rotating guides let you complete rows of settings in a

very short time and at the perfect depth for the material.

• Guides accept all 3/32″ (2.35mm) shank burs such as ball burs,

setting burs and hart burs.

Pavé Setting

Step 1:

Determine the diameter of the stones you will be using, making sure all

stones are the same size. Scribe the material with a crosshatch of lines

that are only slightly further apart than the diameter of the stones. This

pattern is usually a 60° offset design (Figure 9) but can be a square pattern. In any case, each line intersection must be slightly more than the

diameter of the stone from the closest adjacent intersection.

Figure 9

Figure 10

Step 2:

At each line intersection, drill through the material with a small drill

(smaller than the stone). This hole will provide a guide for the bur you use

to make the seat.

Step 3:

The AllSet pavé guide will provide a stop for the bur, making all the seats

exactly the same depth. Select a bur (usually a setting bur) the same size

as the stone. Choose one of the pavé guides that is a little larger than the

bur head.

handpiece. Adjust the pavé guide for the depth you need to make the seat

(Figure 10). This depth should allow the stone girdle to sit slightly below

the surface of the material.

drilled hole to guide the start of the bur

perpendicular to the work.

Step 4:

Place the stones in their seats to be sure they all fit. Finish the setting by

using a beading tool to push the material down between the stones

square pattern or any other spacing where there is material around the

stones, you will need to raise beads over the stones with a graver and

then finish each bead with a beading tool.

Mount the pavé guide in the

Mak

AllSet and then the bur in the

e all the seats in the material using the

Be sure to k

.

eep the tool

.

F

or a

9

Prong Guide Set

The AllSet®prong guides ensure proper depth cutting on all prongs in a

ingle setting with one quick cut. This allows you to produce more settings

s

with greater accuracy. Each prong is cut to precisely the same depth so the

stone will be absolutely level.

• 13 adjustable depth prong-setting guides allow you to use bur

sizes from 2.5mm to 8.5mm in 0.5mm graduated increments.

• Solid, non-rotating guides lets you hold settings firmly in place

with no twisting or grabbing as you cut.

• Guides accept all

Prong Setting

Step 1:

Make sure all prongs on the setting are evenly spaced and angled the

same. The distance between opposing prongs should be adjusted to

slightly less than the diameter of the stone at the height on the prongs

where you intend to cut the seat.

3

/32″ (2.35mm) shank burs.

Figure 11

Step 2:

Choose a setting bur that is just slightly smaller than the stone’s

diameter (too small a bur increases the chance that the bur will grab

and skip). The best burs are non-aggressive, fine cut burs. Select the prong

guide closest to the bur size that allows the head of the bur to fit down

inside the guide.

Step 3:

Mount the prong guide in the AllSet L-bracket (Figure 11). Insert the bur

through the guide and into the handpiece chuck. Tighten the chuck to

secure the bur.

Step 4:

Loosen the shaft locking screw and adjust the shaft with the shaft

adjusting nut so the shoulder of the bur is at the desired cut-depth below

the guide (Figure 12). You can always cut deeper, so set the depth less

rather than more for the first cut. The depth of the cut should end up

being a little deeper if the stone has a thick girdle.

Step 5:

Hold the setting securely and make sure you approach the prongs as

straight in as possible. Holding the setting with your fingers allows the

setting to move and align itself as the prongs come in contact

with the guide.

L-bracket

Figure 12

Prongs stop

flush against

guide for

a perfectly

level cut.

10

Channel-Setting Guides

Figure 13

Cut continuous channels on

straight or contoured pieces.

The AllSet®channel-setting guides allow you to cut perfect channels with

precisely the same depth on each side of the channel for level stone

setting. The set includes three adjustable depth channel-setting guides

for all channel-setting applications.

• The rounded tips of the two basic guides (small and large) make it

easy to cut continuous channels on straight or contoured pieces

(Figure 13).

• The new double knife-edge guide ensures perfect spacing of

separated stones.

Please Note: The smaller of the two basic channel setting guides

is designed for use with small burs that have tapered shafts below

the bur head. Because the tip area of the small channel guide is less

than the 3/32

″ (2.35mm) bur shank, the guide will not allow burs to

slip or go deeper into the channel. Burs cannot be removed or inserted

from the front of the small guide.

Figure 14

Front

iew

v

Knife

guide

Remove just enough of the corner edge to allow the stone to

pass as it is set into the channel. For deep or thick-girdled

stones, the lower corner edge may also be removed (use a

bur or graver to preserve smooth edges on the bearing cut).

Choose a bur

that is slightly

smaller than

your channel

width.

Secure stones in the

channel temporarily

with red sprue wax

before hammering.

ide

S

view

Move the knife guide

along the scribe marks

to create the stone

bearing-cut. Cut one

side at a time and

cut one side deeper

to allow access for

the stone.

Hammer the inside

edge of the channel

with a flat punch

or hammer

piece

hand

.

Figure 15

The large channel guide is designed to accommodate larger burs, such

as ball burs, and is especially useful in setting stones with thicker girdles.

Channel-Setting Tips:

Square Stones

For setting stones that will touch, you can cut a continuous channel

(Figure 13):

Step 1: Choose a hart bur with a diameter that will cut a channel to the

proper depth in the material for the diameter of the stones you are using.

Step 2: Select one of the two basic channel guides (small and large ) for

the size bur you are using (see note above).

Step 3: Adjust the distance between the guide tip and cutting edge of

the bur to the desired position of the channel.

Step 4: Cut each channel, making sure to keep the handpiece

perpendicular to the material.

Round Stones (using the knife guide)

For a setting where there will be space between round stones:

Step 1: Choose a hart bur that is slightly smaller than the

diameter of the stone (Figure 14).

Step 2: Scribe deep center marks on top of the channel w

use the knife-edge channel setting guide as illustrated (side view).

Step 3: Cut individual seats for each stone by sliding the knife

edge guide from one side to the other in the groove made by the

When setting the depth of the seat, be sure to allow a little

.

scribe

extra wall height for filing out the scribe marks (file out the scribe

°

30

marks before hammering).

Step 4: Set the stones in the channel (Figure 15). F

angle and hammer the top inside edge (not

channel w

all at a 30

°

the outside) to tighten the material over the stones.

ile the outside

all and

Set the leading

edge of the stone

into the first bearing

cut and lower the

opposite edge into

the opened

bearing cut.

he stone should

T

only just touch

the edge.

File a 30° angle

into the outside

edge of the

channel.

Hint:

Be sure to thoroughly clean shavings and metal debris from

out of the setting before putting the stone in place.

11

Customize Your Own Setting Operation with Allset®Kits!

Customize your AllSet just the way you want it! Choose exactly what you need to maximize your efficiency and

guarantee great results. If you already have a Foredom®handpiece or some of the equipment included in the kits,

just add the AllSet components you want from the selection described below.

Master Kit AK820

Quickly and easily achieve perfect results in all your stone-setting operations.

Includes a H.30®handpiece, AllSet handpiece attachments, complete set of

guides and video.

Master Kit AK825 Without Foredom H.30®handpiece.

Channel-Setting Kit AK828

AllSet handpiece

Cut perfect channels and maximize your production.

attachment for the H.30

knife-edge),

Channel Set Guides Only AK-829

guide locking nut,

®

three channel-setting guides

,

Allen wrench and instructions—in a fitted box.

Includes

, (small, large for baguette and

Prong-Setting Kit AK826

Produce consistent settings nearly 10 times faster than by hand! Includes AllSet

handpiece attachment for the H.30

locking nut, Allen wrench and instructions—all in a fitted box.

Prong Guides Only AK827

®

handpiece, 13 prong-setting guides, guide

Pavé-Setting Kit AK832

Allset handpiece attachment for the H.30®handpiece, seven pavé guides (for

setting a number of stones in a pattern to produce a field-of-stones effect),

guide locking nut,

Pavé Set Guides Only AK833

Allen wrench and instructions—all in a fitted box.

The Allset Accessory Video A-DVD125

Allset co-inventor, award-winning jeweler and tool designer, Jeffrey

Mathews, shows you how to use this revolutionary system to speed

stone- setting and increase accuracy.

orm 1270B n 5/08 Printed in USA.

F

31 minutes.

Easy-Cut Prong Guide Kit AK847

Allset milling table, guide locking nuts, Allen wrench and instructions—

in a fitted box.

Handpieces and guides sold separately

.

Loading...

Loading...