Foredom M402 User Manual

Cleaning, Maintenance & Parts

continued

T

® B

yphoon

carbide burs with unique, structurally aligned points,

easily cleaned with supplied

ing brush, a steam cleaner or ultrasonic cleaner.

M.400 comes with 2– 1/4″ shank coarse (red) burs–

Taper (5°) p/n A-KB14198 and Ball Nose A-KB14734.

M.402 comes with 2– 6mm shank coarse (red) burs–

Taper (5°) p/n A-KB66198 and Ball Nose A-KB66734.

Other 1/4″ and 6mm shank burs available.

Sanding Bands: M.400 and M.402 are supplied with

3/4″ x1

ing bands, rubber drum mandrel (A-SD145 with

M.400, A-SD345 with M.402) Replacement bands

with finer grits also available.

Cylinder Sanding Bands 10-packs

60 grit coarse A-4942-10

80 grit medium A-4943-10

120 grit fine A-4944-10

220 grit extra fine A-4946-10

urs:Long lasting, non-clogging tungsten

A-HB58 brass bur clean-

1

⁄2″ (19 x 38mm) 5 coarse, 5 extra fine sand-

Carbon Brush Wear: Disconnect power cord before

checking for brush wear. Check for brush wear

a

bout every 1000 hours or after approximately one

year of continuous operation. To access the motor,

the cover of the unit needs to be removed. Turn the

unit over and remove the screws embedded in the

four rubber feet. The brush tubes are located under

the two protective caps on the motor. Remove them

with a standard screw driver blade, unscrew the

brush tube caps, check the brush length, and install

new brushes if the old ones are less then 1/4

(6mm) in overall length. Be sure the radius in the

end of the brush is in line and conforms to the commutator surface. Replacement brushes are available

from your dealer or the factory. To order the correct

replacement motor brushes, find the part number

on your Arch Trimmer’s motor. See listing below:

Motor No. Volts Part No.

90-953 115V

90-954 230V

33-1711 115V

33-1712 230V

Motor Brush

MP319P

MP2039P

″

(Includes 2)

®

FOREDOM

Owner’s Manual

Repair Service

Factory repairs are done promptly and at

reasonable cost. If you wish, you can send your

equipment directly to the factory marked Attention:

Service Dept. Be sure to give your street address

and phone number. The equipment should be

accompanied by a brief note describing the problem with the equipment. Estimates will be made

upon request.

Please retain your proof of purchase for

warranty repairs.

LIMITED W

The Foredom Electric Company warrants the Arch T

workmanship for a period of 2 years after purchase. During the warranty period, the defective

product will be repaired or replaced without charge or, at our option, the purchase price will be refunded. This

warranty does not cover damage caused in transit or by accident, misuse, or ordinary wear.

ALL IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO WARRANTIES OF FITNESS AND

MERCHANTABILITY, ARE HEREBY LIMITED IN DURATION TO A PERIOD ENDING ONE YEAR FROM DATE OF

PURCHASE, AND WE WILL NOT BE LIABLE OR RESPONSIBLE FOR ANY SPECIAL OR CONSEQUENTIAL

DAMAGES.

All warranty repairs must be done at the factory at the above address. We will not pay any shipping or

transportation charges. This warranty only covers the original purchaser of the product. Some states do not allow

limitations on how long an implied warranty lasts, so the above limitations may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state.

Repair or replacement will be made at our option if the product is returned post-paid to:

The Foredom Electric Company, 16 Stony Hill Road, Bethel, CT USA 06801

®

Contact Information

If you have a warranty issue with your Foredom

power tool please use the contact information

below. For more information on Foredom

machines, handpieces or accessories, contact

your local dealer. When no local dealer is

available contact Foredom at:

The Foredom Electric Company

16 Stony Hill Road, Bethel, CT 06801

Tel.: (203) 792-8622

Email: customerservice@blackstoneind.com

ARRANTY

rimmer to be free of defects in material or

• Fax: (203) 796-7861

FOREDOM The Foredom Electric Company www.foredom.com

Form 513A 3/10 n

Printed in USA

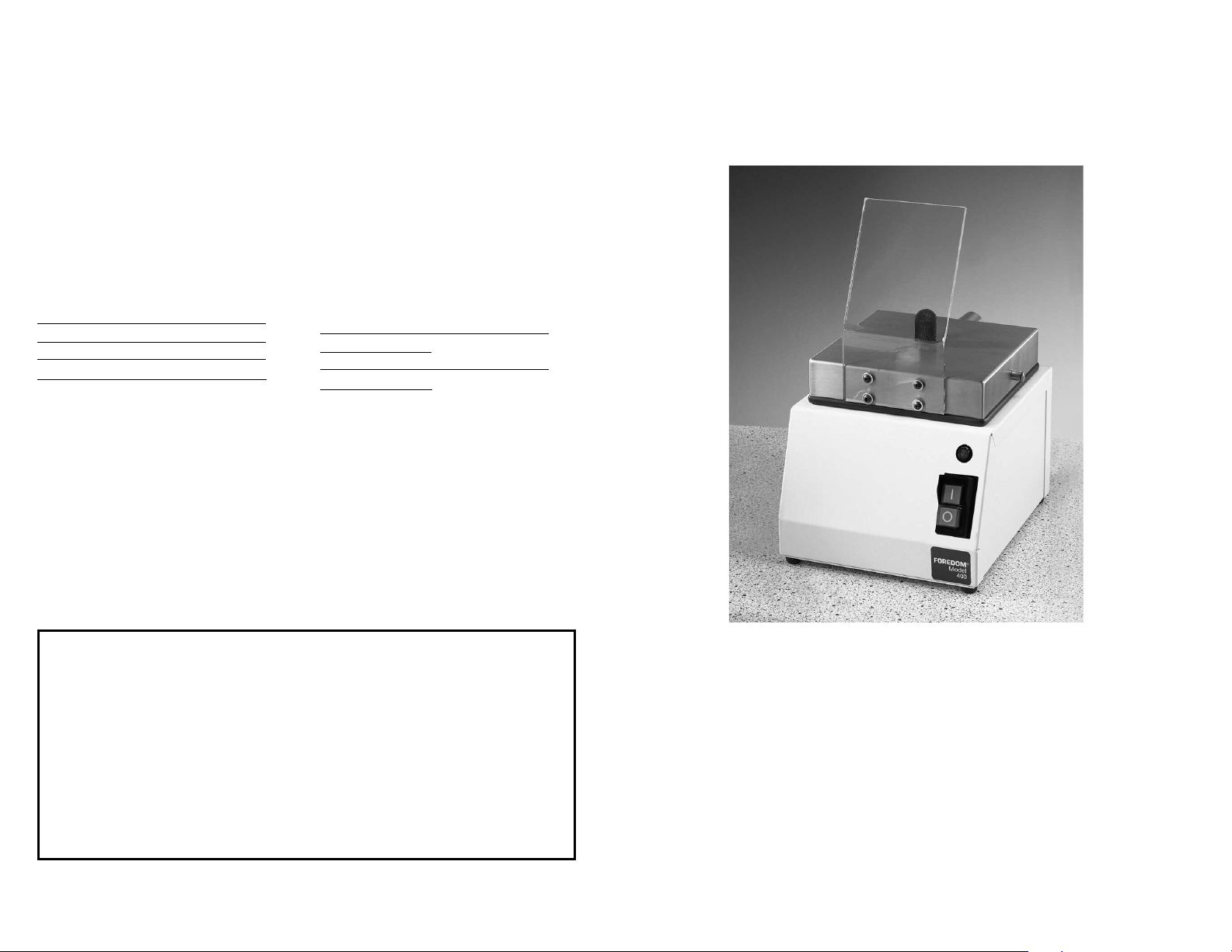

Arch Trimmer

M.400 (115 Volt) and M.402 (230 Volt)

For Your Own Safety–

Read the Owner’s Manual before operating

your Foredom Power Tool.

Always use the safety shield and wear eye protection

while using the Arch Trimmer or other power tools.

Safety Instructions

The Foredom®Arch Trimmer is manufactured to

high standards of precision and performance and,

with proper use and maintenance, will give you

years of trouble-free operation.

Before

using your Foredom Arch Trimmer,

read all safety instructions

protection and should always be followed to reduce

the risk of personal injury or damage to the tool.

Always use the safety shield.

Always wear proper eye and face protection. Safety

glasses or face shields should be worn whenever

you operate a Foredom or any power tool to

prevent serious eye or face injuries.

Do not wear loose clothing or jewelry, and be sure

tie back long hair.

to

Never operate any accessory at speeds above its

maximum speed rating. When properly used, all of

Foredom’s accessories can be operated at the

speeds listed in the Foredom Rotary Accessories

catalog or on the packaging. Never use or continue

to use any accessory which appears to be damaged, loose, vibrating, or out of balance. Inspect

each accessory for cracks or flaws before using it.

Always insert the shank or arbor of an accessory

into the collet as far as possible in order to provide

proper support. Tighten the collet or

chuck securely.

Never use excessive side pressures which may

tend to bend or break the shank or arbor or an

accessory. Let the speed of the accessory

do the work.

. They are for your

Figure 1

please

Do not stall the motor by jamming or using

e

xcessive pressure on the Typhoon

accessory. This can result in damage to the motor.

Never operate your Arch Trimmer during a perce

tible power decrease. Turn power tool off and do

not use until power is fully restored.

Always replace or repair a worn cord immediately.

Use proper grounding procedures. This tool should

be grounded while in use to protect the operator

from electric shock. The tool is equipped with an

approved 3-conductor cord and a 3-prong grounding type plug to fit the proper grounding receptacle.

The green (or green and yellow) conductor in the

cord is the grounding wire. Never connect the green

(or green and yellow) wire to a live terminal. If your

unit is for use on less than 150 volts, it has a plug

that looks like sketch A in Figure 1. An adapter

(sketches B and C) can be used for connecting

plugs as shown in sketch A to 2-prong receptacles.

The green colored rigid ear, lug, etc., extending from

the adapter must be connected to a permanent

ground such as a properly grounded outlet box.

Some jurisdictions, including Canada, prohibit the

use of 3 to 2 prong adapters. Where prohibited,

they should not be used.

cords that have 3-prong grounding type plugs and

3-pole type plugs and 3-pole receptacles that accept

the tool’s plug. Always disconnect the power cord

before servicing the lathe. Never use in an area

where flammable vapors are present.

Use only 3-wire extension

®

b

ur or other

1

″ (25mm) dust collection port

connects to central dust collector.

Adapter for hose is included.

stainless steel

work surface 7

(178mmx 178mm) with

two captive thumb screws

″ x 7″

pin and

wrench

safety

shield

collet and

chuck nut

Assembly and Operating Instructions

The Foredom Arch Trimmer includes two

Typhoon®Carbide Burs, sanding bands with a

rubber drum mandrel, a brass bur cleaning brush,

1/4″ collet and chuck nut (6mm for Model 402),

pin and wrench for changing burs, and an adapter

for connecting the dust port to a 21⁄2″ (64mm)

diameter hose for 110V. and 11⁄4″ (31.75mm)

diameter hose for 220V.

1. Attach the safety shield to stainless steel work

surface using the four screws & washers supplied.

2. Plug the molded cord set into the three-poled

receptacle located in the back of the cabinet. Now

connect the unit to the power supply.

3. Use the hook on the back of the cabinet for

hanging the pin and wrench.

4. Push the green “on” button to start motor.

Green power light will go on. The electromagnetic

on/off switch will shut off power to motor if there

is a power failure or power cord is unplugged.

Restart by pushing green “on” button.

Fuse Protection: The Arch Trimmer is protected

from power line current surges or shorts by a 2

amp fuse (p/n CP10540) for the 115 volt model,

and a 1.5 amp fuse (p/n

model. It can be checked or replaced by unscrewing the cap in the back of the cabinet.

Installing and Changing Burs:

unplug the machine before changing burs.

Always

1. Remove the stainless steel cover by loosening

the 2 thumb screws.

CP10543) for the 230 volt

m

otor

shaft

cross hole

in motor

shaft

HB58 brass bur cleaning brush

2.Insert bur shank as far as possible into

the collet.

3. Use the pin and wrench to tighten the bur.

First insert pin into cross hole in motor shaft, then

place wrench on chuck nut flats to tighten the

bur—turning

clockwise.

on/off

light

push

button

on/off

switch

4. Follow the same procedure to remove a bur,

turning

counter-clockwise to loosen it.

5. Return pin and wrench to hook.

6.

Mount stainless steel work surface on cabinet

and tighten thumb screws.

Always use the safety shield when operating the

Arch Trimmer.

Always make sure the bur is properly secured into

motor shaft before turning the machine back on.

Cleaning, Maintenance, and Parts

Cleaning: At least once a week you should remove

and clean the area beneath the stainless steel work

surface to insure proper air flow and prevent

build-up of dust or powder around the motor shaft.

If you do more than 5 models a day you should

rimmer at the end of

clean the Model 400 Ar

each day. Remove the stainless steel work surface

and vacuum the dust. Remove the collet or chuck

and vacuum the collet holder socket in the spindle.

Clean the chuck nut and collet. Wipe the Collet with

light lubricating oil before replacing.

Lubrication: The Foredom Ar

pre-lubricated ball bearings and a sealed dust-proof

motor housing that do not require any lubrication.

ch T

rimmer has

ch T

Loading...

Loading...