Figure 5 brush assemblyexhaust ports

=

=

Figure 8

®

FOREDOM

Maintenance

motor brushes

The H.MH-170 has permanently lubricated

ball bearings that do not require lubrication. Putting even a small amount of oil

into the handpiece can damage it.

Cleaning Handpiece

Use the Handpiece in as clean and dust

free an environment as possible.

If the Micromotor Handpiece is used

for woodcarving, it should be cleaned

after every use.

cord disconnected from control box, unscrew

the protective cap (see Figure 5) and use a

clean cloth to wipe dirt, chips or dust off

from the exhaust ports and inside the cap.

A cloth with a small amount of alcohol

solution can be used to clean the outside

of the handpiece if necessary.

Do not use any other cleaning fluids

or immerse handpiece in any liquid.

The H.MH-170 Handpiece is

not autoclaveable.

With handpiece power

Checking/Changing

Carbon Brushes

A spare set of carbon brushes is supplied

with each handpiece. Depending on how

long the handpiece is used each day, the

brushes should be checked for wear

periodically (about every

and replaced when the brush is less than

2mm (5/64

1. With handpiece power cord disconnected

from control box, unscrew protective cap

from rear of motor (see Figure 5) by

turning in counterclockwise direction while

gripping the handpiece body. (It has a

standard right hand thread.)

2. With small crosspoint screwdriver remove

screws and brush assemblies one at a time

when reusing existing brushes. Check length

of carbon brush from spring to curved

side of brush.

″) long.

Brushes should be r

eplaced (if less than 2mm in length)

r

one at a time.

Pay careful attention to the orientation of the

brush curve in relation to the curve of the

motor armature. This same orientation must

be maintained when replacing brushes.

200 hours of use)

emoved,

and

=

protective cap

Carbon Brushes continued

3. Reinsert brush assembly or new

assembly into brush tube. Replace and

tighten screws.

4. Screw protective cap back onto rear

of motor housing so that top of brush

assembly is completely tightened.

5. If new brushes were used, run the

handpiece for 30 minutes at half-speed

no load to confirm proper function,

before use.

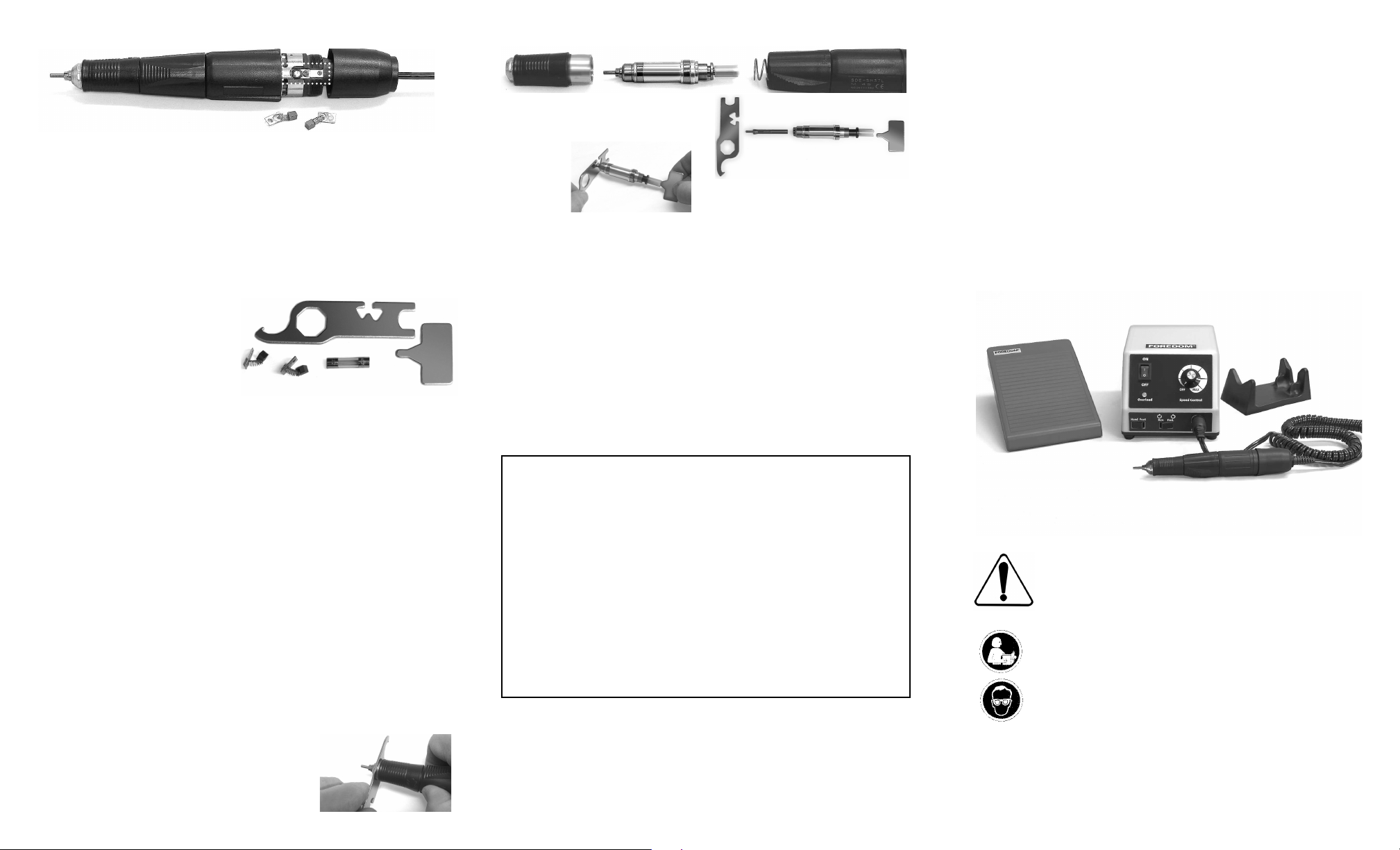

Figure 6

chuck wrench

spare pair

of motor brush-

spare fuse

chuck

joint

wrench

Micromotor Accessories

The K. 1070 Micromotor Kit comes with a

chuck wrench and chuck joint wrench for

changing collets, a spare fuse, and spare

pair of motor brushes as shown in Figure 6.

Installing/Changing Collets

The Handpiece comes with a 2.35mm

collet installed. Optional 1/8

(3/32

″)

3mm collets are available separately . They

can be installed with the collet changing

wrenches, described below.

Caution: Finger tightening is not

enough. A wrench must be used to

tighten the collet fully several turns

beyond the point of initial resistance.

If collet is too loose or absent, spindle

will not turn and damage will occur.

1. With a test bur in the collet, turn the

Locking Ring toward the secure“S” (closed)

position (see Figure 4 on reverse.)

2. Place the octagonal hole of wrench over

the brass nose cone and unscrew the nose

cone assembly from the handpiece body

(shown in

Figure 7.) Do

not remove

locking ring

or spring.

Figure 7

″ and

3. Carefully remove the spindle assembly

from the nose cone, see Figure 8.

4. Insert the

chuck joint

wrench into the

cross section of

the back end of

the spindle

assembly. Insert

the collet head into the appropriate size

triangle hole on the chuck wrench and turn

the chuck wrench counterclockwise to

loosen the collet while holding the chuck

joint wrench with your other hand,

see Figure 9 above.

5. Remove collet and insert new size collet,

with test bur. Use the triangular hole in

chuck wrench to re-tighten collet by turning

clockwise. Make sure to securely tighten

collet or the spindle will not turn. Align

cross-shaped motor drive to spindle by

rotating the collet during installation.

Re-attach and tighten nose cone.

Figure 9

chuck

wrench

test spindle

b

ur assembly

collet

Repair Services

Authorized repair service is available at the

Foredom factory in Bethel, CT. Send items for

repair to the factory marked “Attention:

Repair Department”. Enclose the item(s), a

packing list, and information regarding the

problem or repairs required. Estimates of

repair cost will be made upon request. It is

our policy not to proceed with a repair

without your approval if the cost (labor plus

parts) is more than fifty percent of the cost

for a new replacement. You will be notified

and advised of the cost to repair and to purchase a new replacement. Please allow three

business days for an estimate to be done and

five to seven business days for repair work

to be completed after we receive your

approval to proceed.

Please retain your proof of purchase for warranty repairs.

Warranty

Foredom warrants its product to be free of

defects in material or workmanship for a

period of one year after purchase. During

the warranty period, the defective product

will be repaired or replaced without

charge or, at our option, the purchase price

will be refunded. This warranty does not

cover damage caused in transit or by

accident, misuse, or ordinary wear.

ALL IMPLIED WARRANTIES, INCLUDING

BUT NOT LIMITED TO WARRANTIES OF

FITNESS AND MERCHANTABILITY, ARE

HEREBY LIMITED IN DURATION TO A

PERIOD ENDING ONE YEAR FROM DATE

OF PURCHASE, AND

LIABLE OR RESPONSIBLE FOR ANY

SPECIAL OR CONSEQUENTIAL DAMAGES.

WILL NOT BE

WE

Contact Information

If you have a warranty issue with your

Foredom power tool please use the

contact information below

information on Foredom machines, handpieces or accessories, contact your local

dealer. When no local dealer is available,

F-1278 n 6/22

.

or more

F

Printed in U.S.A.

Repair or replacement will be made at our

option if the product is returned postpaid

to:

The Foredom Electric Company,

16 Stony Hill Road, Bethel, CT 06801

All warranty repairs must be done at the

factory at the address above. We will not

pay any shipping or transportation charges.

This warranty only covers the original purchaser of the product. Proof of purchase

may be requested. Some states do not allow

limitations on how long an implied warranty lasts, so the above limitation may not

apply to you. This warranty gives you specific legal rights, and you may also have

other rights which v

call,

,

write

The Foredom Electric Company

16 Stony Hill Road, Bethel, CT 06801

203-792-8622 F

el:

T

customerservice@blackstoneind.com

ary from state to state

or email:

fax,

ax:

203-796-7861

Visit our website:

www.foredom.com

c

huck joint

wrench

Operation and

Maintenance Manual for

K.1070 Micromotor Kit

HP4-917

Control

HP4-933

Cradle

HP4-960

Foot Control

H.MH-170

Handpiece

For Your Safety:

Read this Manual before operating your

Foredom Micromotor Power Tool.

.

Always wear eye protection while using

the Foredom Micromotor Handpiece.

Safety Instructions

A Micromotor Handpiece is a high

speed rotary power tool which can

be dangerous and cause serious

injury if it is not used properly.

NEVER operate it without wearing

eye protection.

• ALWA YS wear proper eye and

face protection.

• ONLY use accessories rated for

speeds of 38,000 rpm or higher

when operating this micromotor.

• ALWAYS observe the manufacturer's

maximum speed rating when using any

accessory other than Foredom’s.

• NEVER use or continue to use any

accessory which appears to be damaged,

loose, vibrating, bent, or out of balance.

Inspect each accessory for cracks or flaws

before use

• ALWAYS insert the shank or arbor of

an accessory or mandrel into the collet or

chuck of the handpiece as far as possible

in order to provide proper support and

close the collet or chuck securely.

NOT

less than 1

• NEVER use excessive side pressures

which may tend to bend or break the

shank or arbor of an accessory. Let the

speed of the accessory do the work.

• DO NOT stall the motor by jamming or

using excessive pressure on the mounted

point, buff, wheel or accessory. This can

result in damage to the motor.

• WEAR a dust protector to prevent the

inhalation of harmful dust or debris from

grinding, carving or other operations

performed with this power tool.

• DO NOT cover the ventilation slots or

handpiece motor with cloth or tape. Air

must pass freely through the intake and

exhaust ventilation slots to properly cool

the motor. If the power cord or plug to

the handpiece is damaged,

replace immediately.

• NEVER operate with a damaged

power cord.

• USE a dust collector (v

to pull sawdust, grinding dust, or other

debris aw

micromotor intak

.

DO

use accessories with shanks that are

″ long.

repair or

acuum system)

ay from the work area and the

e vents

.

• NEVER turn on or start the

Handpiece while chuck is in open

(unlocked) position.

the handpiece. Always operate and store

it with a bur or other accessory in the

chuck and with the chuck in the

closed position.

• NEVER plug the Handpiece into

This can damage

the Variable Speed Foot Control

Connection Port on the back of

the Control Box.

• ALWAYS plug the Handpiece into

the Handpiece Connection Port on

the Front of the Control Box.

• DO NOT operate the handpiece in the

presence of any flammable liquid or gas.

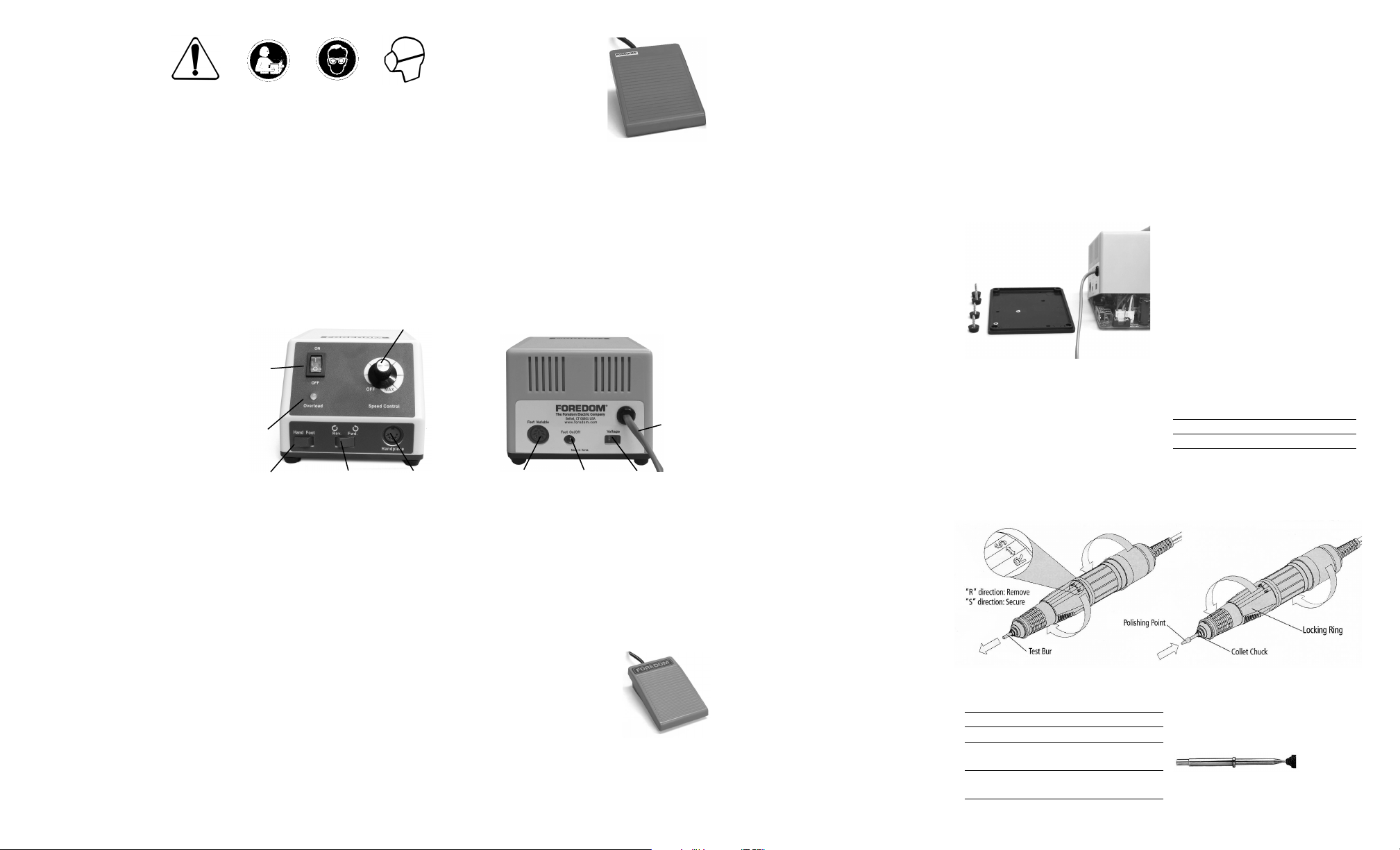

Figure 1 Front Panel

Illuminated

Power

On/Off

Switch

Overload

Indicator

Light

Speed Control Selector

Switch (Hand or Foot)

Dial Speed Control

Rotation

Selection Switch

Handpiece

Connection

Port

Assembly Instructions

Do not plug into a power outlet

before connecting the handpiece or

foot pedal. Check to see that the

voltage selector switch on the

back of the control box, is set to

the voltage to be used–110 or

220 volt.

Connecting Handpiece

Attach the micromotor handpiece to the

control box by plugging the coiled cord

into the Handpiece Connection Port on

the lower right side of the front control

panel (Figure 1). Use keyway for proper

alignment when plugging in the cord.

NEVER plug the handpiece into the

Variable Speed Foot Control

Connection P

ort.

Connecting the Variable

Speed Foot Control

The Variable Speed Foot Control is suitable for either 110 or 220 volt operation.

Attach it by inserting

the connector into the

Variable Speed Foot

C

ontrol connection

port on the rear panel

of the control (Figure

2) using keyway for

proper alignment. It is

not necessary to have

the foot pedal connected to the control

box to operate the dial speed control. The

Micromotor control and handpiece are

now ready to operate.

Connecting Power Cord

Before connecting the power cord plug

(Figure 2) to a power outlet, select the

proper voltage (110 or 220v) on the back

of the control box. Put the On/Off Selector

Switch in the OFF position and turn the

Figure 2 Rear Panel

Power

Cord

Variable Speed

Foot Control

Connection Port

dial speed control to the OFF speed position.

Be sure that the handpiece chuck is

On/Off Foot

Connection

Port

closed with (or without) an accessory in

Operating the handpiece with the

it.

chuck in the open position can

cause severe damage to the motor.

Now plug in the power cord to an AC

current outlet. See Figure 2 to select the

Hand/Foot and Forward/Reverse switches.

Connecting Optional

On/Off F

This switch (p/n HP4-927)

is available separately and

attaches by inserting the

connector into the On/Off

foot connection port on

the rear panel of the control (Figure 2) using keyway for proper

alignment.

the motor on and off without changing

the speed set by the dial.

oot Switch

his switch allows you to turn

T

Voltage Selector

Switch-110 or 220

volt

HP4-927

Operating Instructions

for HP4-917 Control Box

1. Power On/Off Switch:

When the Power On/Off Switch is in the

ON position the switch lever will light up.

This switch must be in the ON position for the handpiece to run with

either the dial speed control or the

foot speed control selected.

Always turn the Dial and Power

On/Off Switch to the Off position

when not in use.

2. Hand or Foot Selector Switch:

With the Dial and Power On/Off Switch in

the OFF position, select either foot or hand

speed control.

• With the Speed Control Selector Switch in

the Hand position, the handpiece will run

at the speed set by the Dial Speed Control.

• With the Speed Control Selector Switch in

the Foot position, the handpiece will not

operate until the Foot Pedal is depressed.

3. Forward/Reverse Rotation

Selection Switch:

On/Off Switch in OFF position, select the

desired handpiece rotation by moving the

switch to Fwd.

REVERSE rotation.

piece rotation direction while in

operation is not recommended.

4. Regulating Speed:

• The Dial Speed Control varies the speed

of the handpiece from minimum to

maximum when the Speed Control

Selector Switch is in the Hand position.

• The Dial also controls the maximum

speed that can be reached when using

a foot pedal.

To achieve maximum speed with a

foot pedal, the dial speed control

must be turned all the way to the

Max setting.

5. Handpiece Overload Protection:

If the Handpiece is used with a locking

ring left in the

in an overload condition caused by excessive workload, it will trigger the overload

circuit protector. The red overload light

will come on with an audible alarm,

the handpiece will stop. Immediately turn

off control by putting the P

switch in OFF position.

in ON position again when overload

condition is corrected. There may be a

time delay of several seconds before

the overload trip resets.

With the Power

for FORWARD or Rev. for

Changing hand-

“R”position (see F

Put power switch

ig.4), or

and

ower ON/OFF

6. Fuse Protection: The internal circuit

is protected by a 3.15 Amp, 5mm x

20mm, Bussman Type GDC-3.15A or

equivalent fuse.A blown fuse usually

indicates a short circuit condition on the

circuit board. The blown fuse should

require that the board be checked by a

qualified technician. Disconnect the

power cord, unscrew the four feet and

remove the baseplate. The fuse is located

in the top left corner of the circuit board.

Replace fuse and reassemble the

baseplate with four feet. Re-connect the

power cord and test unit operation.

Figure 3

4-feet baseplate fuse

=

H.MH-170

Micromotor

This Handpiece is intended only for

fine finishing and detailing work. It

should not be used to remove large

amounts of material in carving or

other applications. If the handpiece

is misused or abused, it will not be

covered under warranty.

Figure 4

Collet Size

3/32″(2.35mm) to 1⁄16″ 1⁄16″ HPL4-3233

1⁄8″ to 1⁄16″ 1⁄16″ HPL4-3234

3mm to 3/32″(2.35mm)

1/8″ to 3/32″(2.35mm) 3/32″(2.35mm)

3mm to 1.6mm

Handpiece

Accessory

Shank Size

3/32

″(2.35mm)

1.6mm

Part No.

HPL4-3235

HPL4-3236

HPL4-3237

Changing Accessories

Burs and other accessories can be

inserted or removed from the handpiece

collet when the collet is open.

To open the collet–

1. Put the power switch on control box in

OFF position and wait for handpiece to

stop rotating.

2. Twist locking ring toward “R” or

Remove (See Figure 4 below) by turning

clockwise until collet snaps open.

3. Insert shank of accessory fully into

collet for maximum support.

use accessories with shanks less

than 1

″ long.

4. Twist knurled grip toward “S” or

Secure (See Figure 4) by turning counterclockwise until it snaps to lock collet.

Never turn power on to handpiece

when collet is open.

a locked position and will not turn which

will result in damage to the motor.

Collets Available for the

H.MH-170 Handpiece

Collet Size Part No.

2.35mm(3/32″) Collet (supplied) HP4-117

3.18mm 1/8″) Collet (optional) HP4-117B

3mm Collet (optional) HP4-117C

Instructions for changing collets

on reverse.

Collet Adapters

(listed at left)

Use collet adapters with different shank

size accessories without having to

change collets

.

Do not

The spindle is in

Loading...

Loading...