®

FOREDOM

Operation and Maintenance Manual for

K.1030 or K.103018 Portable Micromotor Kit

HP8-306

Charger/Adapter

HP4-310

Control

Unit

HP4-933

Handpiece Cradle

Optional Components

H.MH-130 or H.MH-13018

Handpiece

For Your Safety:

Read this Manual before

operating your Foredom

Micromotor Power Tool.

Always wear eye protection

while using the Foredom

Micromotor Handpiece.

Contact Information

For more information on Foredom machines, handpieces or accessories, contact

your local dealer. When no local dealer is available, write, call, fax, or email:

Foredom Electric Company

16 Stony Hill Road, Bethel, CT 06801

Tel: 203-792-8622 Fax: 203-796-7861 Email customerservice@blackstoneind.com

Visit our website: www.foredom.net

F-1231 n 2/14 Printed in U.S.A.

On/Off

Foot Pedal

HP4-927

Carrying

Case

AP1130

Tool Belt

with Pouch

A-KC300

Safety Instructions

A Micromotor Handpiece is a high speed

rotary power tool which can be dangerous and cause serious injury if it is not

used properly. NEVER operate it without

wearing eye protection.

• ALWAYS wear proper eye and

face protection.

• ONLY use accessories rated for speeds

of 30,000 rpm or higher when operating

this micromotor.

• ALWAYS observe the manufacturer’s maxi-

mum speed rating when using any accessory.

• NEVER use or continue to use any acces-

sory which appears to be damaged, loose,

vibrating, bent, or out of balance. Inspect

each accessory for cracks or aws before use.

• ALWAYS insert the shank or arbor of an

accessory or mandrel into the collet or chuck

of the handpiece as far as possible in order to

provide proper support and close the collet or

chuck securely. DO NOT use accessories with

shanks that are less than 1″ (25mm) long.

• NEVER use excessive side pressures which

may tend to bend or break the shank or arbor

of an accessory. Let the speed of the accessory do the work.

• DO NOT stall the motor by jamming or us-

ing excessive pressure on the mounted point,

buff, wheel or accessory. This can result in

damage to the motor.

• WEAR a dust protector to prevent the inha-

lation of harmful dust or debris from grinding,

carving or other operations performed with

this power tool.

• DO NOT cover the ventilation slots or

handpiece motor with cloth or tape. Air must

pass freely through the intake and exhaust

ventilation slots to properly cool the motor.

If the power cord or plug to the handpiece is

damaged, repair or replace immediately.

• NEVER use a damaged power cord or

adapter. ONLY use the power adapter that

came with the K.1030 Kit.

• USE a dust collector or lter hood to pull

sawdust, grinding dust, or other debris away

from the work area and the micromotor

intake vents.

• NEVER wear open shoes or sandals. Use

foot-wear that is tough enough to protect

your feet from falling tools.

• ALWAYS keep both hands and ngers

away from the cutting edge.

• NEVER cut or exert pressure, toward your

hand or any other part of your body.

• DO NOT wear loose tting clothing or

jewelry. Loose clothing or jewelry can become entangled in the tool. Do not wear

items such as neckties, necklaces, or

bracelets when operating power tools.

Secure or tie back long hair.

• NEVER turn on or start the Handpiece

while the collet is in open (unlocked) position. This can damage the handpiece.

• ALWAYS operate and store it with a bur

or other accessory in the collet and with the

collet in the closed position.

• NEVER plug the Handpiece into the On/

Off Foot Control Connection Port on the side

of the Control Unit. ONLY plug the Hand-

piece into the Handpiece Connection Port on

the Top of the Control Unit.

• DO NOT operate the handpiece in the

presence of any ammable liquid or gas.

• NEVER drop the Control Unit or Micromo-

tor Handpiece.

• NEVER plug or unplug the power cord

with wet hands.

• NEVER allow water or liquids to spill onto

any parts of the K.1030 Micromotor Kit.

• DO NOT operate or store the unit in a

high heat environment such as direct sun,

a parked car in hot weather, near a ame

or stove. Minimum and maximum working

environment temperatures are 32°F – 104°F

(0°C – 40°C).

• The K.1030 Micromotor has a Lithium

Ion battery that should NEVER be

thrown in the trash. Recycle Lithium Ion

batteries in accordance with local laws.

www.call2recycle.org is a good source of

recycling locations in the US and Canada.

NEVER throw the battery into a re as

it could explode. Should the electrolytic

chemicals spill and get in your eyes wash

immediately with water. Remove and wash

any clothing or article that has spilled battery

chemicals with water.

On/Off

Button

2-digit

Power

Adapter

Outlet

RPM

Indicator

LED

Display

Overload

Battery

Charge

Assembly

Before attaching the handpiece or adapter

with power cord to the control box turn the

Speed Selection Knob down to MIN. Make

sure that the power is off by conrming

that the Speed Indicator LED Light is off by

pushing in the On/Off button located on the

upper left side of the control box for at least

2 seconds.

Attaching the

Micromotor Handpiece

Be sure that the handpiece collet is secure

with an accessory in it. Attach the micromotor handpiece by plugging in the handpiece

cord into the Motor connection port on the

top of the Control Box.

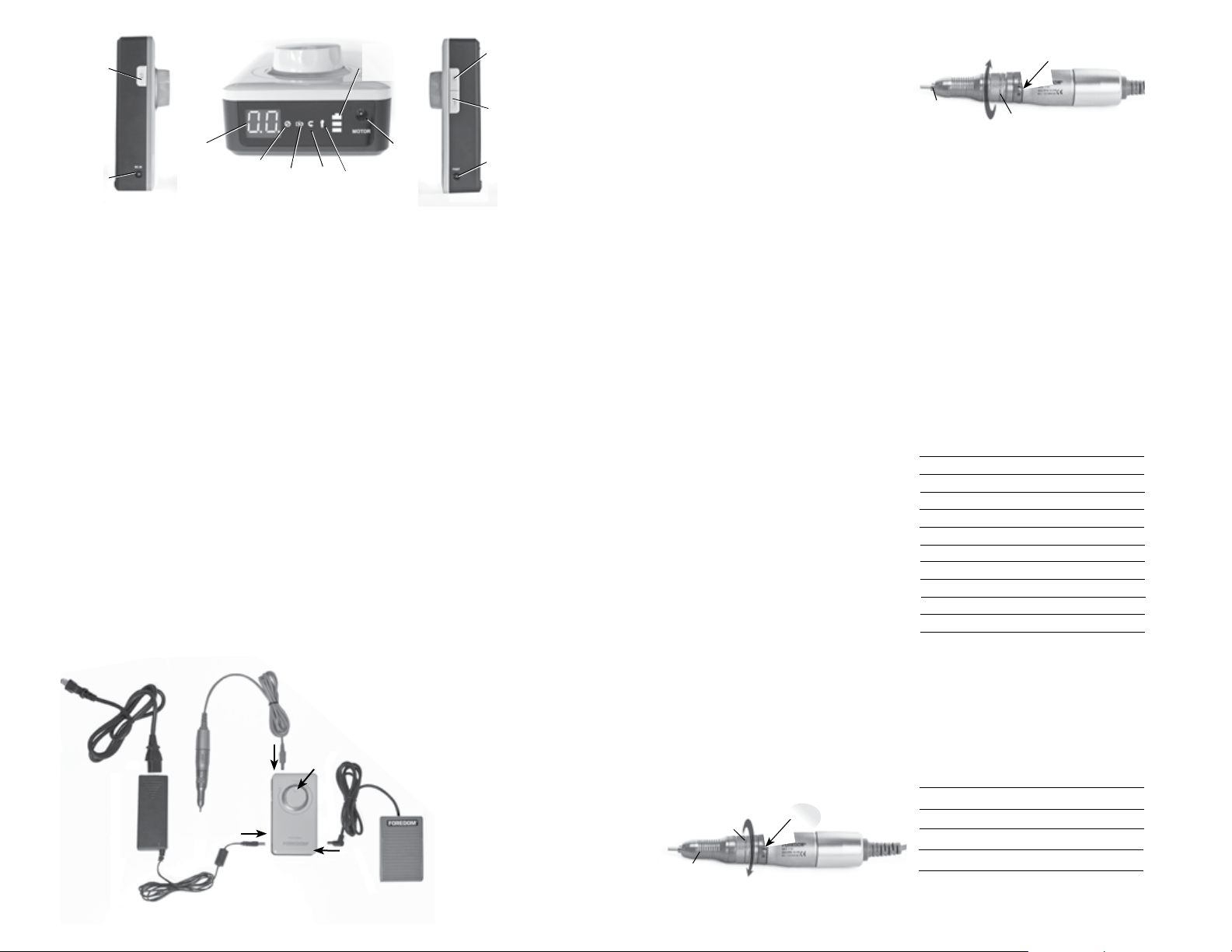

Connecting AC Power Adapter

First, make sure the power to the handpiece

is turned off by pushing in the On/Off button

on the upper left side of the control unit for

at least 2 seconds. Then, plug the adapter

plug into the DC IN port located on the

lower left side of the control box. Next, plug

the power cord receptacle into the 3-prong

power cord port in the adapter. Finally,

plug the power cord into an electrical

outlet to charge the battery or to use

the micromotor without battery drain.

Power Cord Plugs

into electrical outlet

Micromotor

Handpiece

plugs into

Control

AC Power

Adapter

and

Battery

Charger

Unit

Power

Adapter plugs

into control

unit

Forward/

Reverse

Button

Optional

Foot Pedal

Button

Optional

On/Off Foot

Pedal

Outlet

Fwd/

Rev

Battery

Level

Display

Foot

Pedal

Micromotor

Handpiece

Outlet

Operating Instructions

for the HP4-310 Control Unit

1. Charging the Battery: Once the power

cord and adapter are connecting the control

unit to the electrical outlet, the Battery

Charge LED light will blink on and off. When

the battery is fully charged the light will

stay on. The rst time the battery is charged

it will take about 3 hours. After that, it will

take about 2 hours to fully charge a low

battery. When fully charged the micromotor

will run for 3 to 5 hours depending on the

workload. Charging should be done in a

cool dry place 32°F – 104°F (0°C – 40°C).

The motor will shut down on its own when

the battery charge is too low.

2. The Power On/Off Button located on

the upper left side of the control box must

be pushed in at least 2 seconds to either

turn on or off the micromotor. When it is on

the red LED two digit speed indicator light

will light up as well as the battery indicator/

charge light. 00 rpm is not the same as

OFF. Use the Power On/Off Button to

turn the unit off.

The unit will power off automatically

after 3 minutes if it is not in use.

3.

Each time the unit is turned on

the speed control dial must be

reset to MIN for the micromotor

handpiece to work.

Control Dial varies the speed from

Speed

Control

Dial

MIN (minimum) to MAX (maxi-

mum). The Speed Indicator LED

light shows the speed in two

digits 00 = zero rpm and

Optional

On/Off

Foot

Pedal plugs into

control unit

The Speed

30 = 30,000 rpm.

Optional

On/Off Foot

Pedal

4. The Forward/Reverse Button located

on the upper right side of the control box is

Close

for operating the micromotor handpiece in

reverse rotation. Rotation direction

always resets to Forward when power

is stopped and restarted. The Fwd/Rev

LED on top of the control unit will light up

when reverse rotation is selected. The light

goes off when Forward rotation is engaged.

Forward is the most commonly used setting.

Right-handed people will get the most control

in forward rotation. Forward motor rotation

means that the motor is turning an accessory

(bur, bit, drill, cutter, etc.) counterclockwise

when holding the handpiece upright in your

hand and you are looking down on to the

front of the accessory. When the handpiece/

collet

knurled locking ring

shanks less than 1″ (25mm) long. To tighten

the new bur twist the knurled locking ring

counterclockwise toward the S (Secure) until

it stops and locks the collet closed.

Never turn the power on to the handpiece when the collet is open or in the R

(Release) position.

If the power is on when the collet is open, it

will damage the motor because the spindle is

locked and it will not turn. Always keep a

bur in the collet when it is not in use.

accessory is applied to the workpiece, your

viewpoint changes to the back end of the

handpiece and accessory and the forward

rotation direction can be described as

clockwise.

5. The Optional On/Off Foot Pedal will not

vary the speed and only turns the micromotor

on or off. It plugs into the port marked FOOT

on the lower right side of the control box. To

select the on/off foot pedal you must press

the foot control button located just below the

Forward/Reverse Button on the right side of

the control box. With the on/off foot pedal

you can select and keep a specic speed

setting and return to it without turning the

speed control dial. This is useful when accessories require an optimal speed or a lower

maximum speed (<30,000rpm) than the full

speed range of the micromotor.

6. To Change an Accessory or bur, rst open

the collet. To open the collet, rst turn off the

unit by holding down the on/off button for

Maintenance

The handpiece has permanently lubricated

ball bearings, which require no lubrication.

Putting even a small amount of oil or grease

in the handpiece will damage it and void

the warranty.

Replacement & Optional Parts

2.35mm (3/32″) Collet HP4-117

3.18mm (1/8″) Collet HP4-117B

3mm Collet HP4-117C

Lithium Ion Battery HP8-B1800

Motor Brushes (2) HP8-163

Set of 2 Wrenches HP4-993

Charger/ Adapter HP8-306

Optional Parts

On/Off Foot Pedal

Carrying Case

Tool Belt with Pouch

(shown at left) HP4-927

(shown on front) AP1130

(shown on front) A-KC300

Part No.

at least 2 seconds– until the indicator light

is off. The collet snaps open when the

knurled locking ring on the handpiece is

turned clockwise toward the R (Remove or

Release). You can now remove an accessory

or bur and insert another. Insert the new bur

shank fully into the collet for maximum

support. Do not use accessories with

Open

R

I

Knurled

Locking Ring

Collet

S

Collet Adapters are used to ‘step down’ a

collet size without actually having to change

the collet. It is a faster and easier way to use

smaller diameter shank accessories without

the effort of changing a collet.

Collet Accessory

Adapter Size Shank Size Part No.

3/32″ (2.35mm)– 1/16″ 1/16″ HPL4-3233

1/8″ to 1/16″ 1/16″ HPL4-3234

3mm – 3/32″ (2.35mm) 3/32″ (2.35mm) HPL4-3235

1/8″ – 3/32″ (2.35mm) 3/32″ (2.35mm) HPL4-3236

3mm to 1.6mm 1.6mm HPL4-3237

Maintenance continued

Micromotor Supplies

K.1030 Micromotor Kit comes with a chuck

wrench and chuck joint wrench for changing

collets (Wrench Set p/n HP4-993), and spare

pair of motor brushes (p/n HP8-163) as

shown at right.

Checking and

Changing Carbon Brushes

A spare set of carbon brushes is supplied

with each handpiece. They come packed in

the handpiece box. Depending on how long

the handpiece is used each day, the brushes

should be checked for wear about every 200

hours of use and replaced when the brush is

less than 1mm (1/16″) long.

1. With handpiece power cord disconnected

from control box, unscrew protective cap

from rear of motor by turning counterclockwise while gripping the handpiece body. (It

has a standard right hand thread.)

motor brush

installed

spare

motor brush

crosspoint

screwdriver

2. With small crosspoint screwdriver remove

screws and brush assemblies one at a time.

Check length of carbon brush from spring to

end of brush.

New motor brush

Brushes should be replaced if they are less

than 1mm long. Replace both motor

brushes with new ones even if only one

of them looks worn.

protective

cap

Worn

motor brush

REPLACE!

Set of 2 wrenches HP4-993 and spare

motor brushes come packed in handpiece box.

chuck

joint

wrench

triangular

holes

motor brushes HP8-163

chuck

wrench

Installing/Changing Collets

Important Note: Always keep a test

bur or accessory in both collets when

changing collets.

1. The Handpiece has either a 2.35mm

(3/32″) or 1/8″collet installed. 2.35mm

(3/32″), 1/8″ and 3mm collets are available

separately. They can be installed with the

collet changing wrenches, described below.

Caution: Finger tightening is not enough.

A wrench MUST be used to tighten the

collet fully several turns beyond the

point of initial resistance. If collet is too

loose or absent, the spindle will not turn

and it will damage the motor.

Close

collet

A bur or test bur MUST be in the

collet when changing collets!

2. With a test bur in the collet, turn the

Locking Ring toward the secure “S” (closed)

position. Do NOT remove the locking

ring or spring!

3. Place the Chuck Wrench hook into the

notch on the H.MH-130 handpiece nose

cone and unscrew it counterclockwise (see

photo above).

Do NOT remove

the locking ring or spring.

R

I

S

knurled locking ring

hook

notch

nose cone

chuck

joint

wrench

spindle assembly

4. Carefully remove the spindle assembly

from the nose cone. Be sure to place the

nose cone

washer

collet with bur

chuck joint

wrench

spindle

assembly

collet

bur

thin washer back on the collet end of

the spindle assembly before reassembling the handpiece. Don’t misplace it!

spindle

assembly

chuck

wrench

chuck joint

wrench

6. Remove collet and insert new size collet,

with a test bur inserted. Use the triangular

hole in chuck wrench to re-tighten collet by

turning clockwise. Be sure to securely

tighten collet! Rotate the collet to align

the cross-shaped end of the spindle assembly with the cross-shaped motor drive inside

collet

with bur

5. Insert the chuck joint wrench into the cross

section of the back end of the spindle assem-

the handpiece. Carefully review steps 4, 3,

2, and 1 to reassemble the handpiece with

the changed collet. Re-attach and tighten

nose cone.

bly. Insert the collet head into the collet size

triangle hole on the chuck wrench and turn

the chuck wrench counterclockwise to loosen

the collet while holding the chuck joint wrench

Please retain your proof of purchase

for warranty repairs.

with your other hand.

Limited Warranty

Foredom warrants all parts of this product (except the

has a one year warranty)

after purchase. Blackstone Industries, LLC d/b/a The Foredom Electric Company warrants, to the original

purchaser only, that its products will be free from defects in material or workmanship for the applicable

period of time indicated above following the purchase date. During the warranty period, the defective

product will be repaired or replaced without charge or, at our sole option, the purchase price will be refunded. This warranty does not cover damage caused in transit or by accident, misuse or ordinary wear

ALL IMPLIED WARRANTIES INCLUDING, WITHOUT LIMITATION, IMPLIED WARRANTIES OF FITNESS FOR

A PARTICULAR PURPOSE AND MERCHANTABILITY, ARE LIMITED IN DURATION TO THE APPLICABLE

WARRANTY PERIOD. IN NO EVENT WILL WE BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES. Some states do not allow limitations on how long an implied warranty lasts or the exclusion

or limitation of incidental or consequential damages, so the above limitations or exclusion may not

apply to you.

At our sole option, repair, replacement or refund will be made if the product is returned postage

prepaid to:

All warranty repairs must be done at the factory at the address above. We will not pay any shipping

or transportation charges. This warranty only covers the original purchaser of the product. Proof of

purchase may be requested. Some states do not allow limitations on how long an implied warranty

lasts, so the above imitation may not apply to you. This warranty gives you specic legal rights, and you

may also have other rights which vary from state to state.

Foredom Electric Company, 16 Stony Hill Road, Bethel, CT 06801

to be free of defects in material or workmanship for a period of two years

Repair Services

Authorized repair service is available at the

Foredom factory in Bethel, CT. Send items

for repair to the factory marked “Attention:

Repair Department”. Enclose the item(s), a

packing list and description of the problem

or repairs required plus your daytime phone

number and email address. Estimates of

Lithium Ion Battery p/n HP8-B1800 which

repair cost will be made upon request. It

is our policy not to proceed with a repair

without your approval if the cost (labor plus

parts) is more than fty percent of the cost

for a new replacement. You will be notied

and advised of the cost to repair and to

purchase a new replacement.

Loading...

Loading...