Foredom H44HT User Manual

Before attaching this handpiece please

read these instructions. They should

always be followed to reduce the risk of

personal injury or damage to

the handpiece.

Always use a proper dust collection

system or wear a respirator to prevent

the inhalation of dust particles, or

other debris into the lungs.

Always wear proper eye protection while

u

sing this handpiece. Wear safety glasses

or a face shield whenever you operate a

Foredom Flexible Shaft machine or any

power tool to prevent serious eye injury.

See your power tool owner’s manual

for complete instructions on use

and maintenance.

Handpiece H.44HT

®

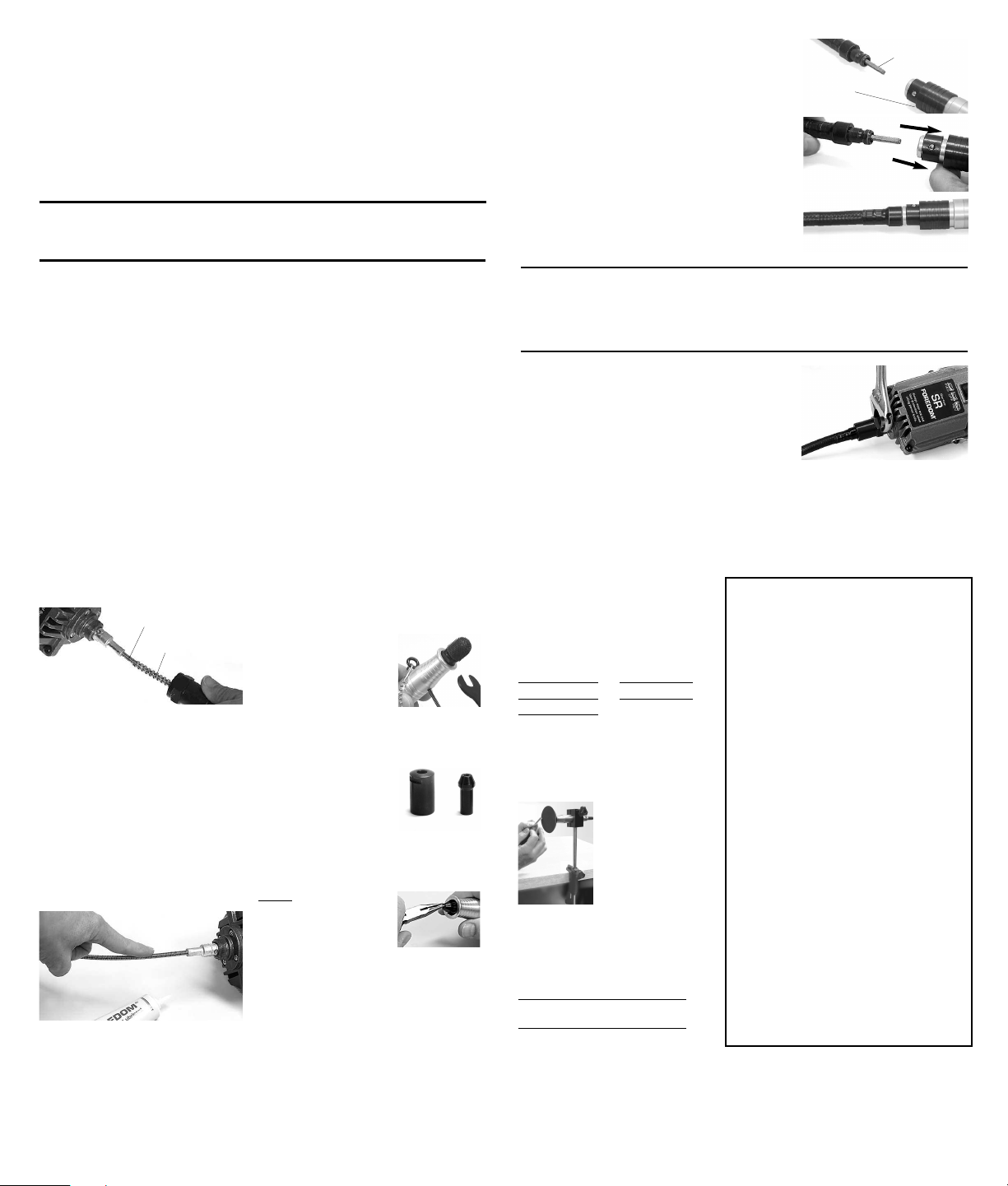

Attaching H.44HT Handpiece to the Flexible Shaft

It takes a fairly strong grasp of the locking ring to

pull it back.

Be careful that your finger or thumb does not get

pinched when you release the locking ring.

P

ull back the black locking ring toward the front end of

t

he handpiece while you insert the tip of the flex shaft.

T

he handpiece has a square slot that the square drive tip

fits into. You may need to rotate the handpiece slightly

until the square drive engages the spindle. Release the

l

ocking ring when you feel the shaft connect to the

For Foredom

h

andpiece. You should hear a click.

To remove handpiece

IMPORTANT INSTRUCTIONS

Pull back the locking ring as described above with a firm

grip and pull the shaft and sheath from the handpiece.

square drive

tip of shaft

locking ring

ocking ring

l

ulled back toward

p

the front end of handpiece

shaft and handpiece connected

Repair Service

Factory repairs are done promptly and at

r

easonable cost. If you wish, you can send

your equipment directly to the factory marked

“

Attention: Repair Department”. Be sure

include a brief note describing the problem

and to give your phone number, email and

street address. Estimates will be made

upon request.

Never wear open shoes or sandals. Use

footwear that is tough enough to protect

your feet from falling tools.

Keep both hands and fingers away from

the cutting edge at all times.

Form 1290 n 1/12 Printed in USA

Lubrication of Flexible Shaft

continued:

shaft

silencer

spring

Slide both the outer sheath and the

silencer spring off of the flexible shaft.

Usually the silencer spring remains

inside the sheath when you remove it.

Every 200 hours the flexible shaft should

be thoroughly cleaned with a solvent.

light film of Foredom grease

Apply a

(MS10006) to entire length of inner

Reattach outer sheath and run

shaft.

motor for ten minutes before reconnecting handpiece. T

excess grease from tip of drive shaft and

reconnect to handpiece per instructions

on revers

urn off motor

e.

, wipe off

Do not wear loose fitting clothing or

ewelry. Loose clothing or jewelry can

j

be come entangled in the tool. Do not

wear items such as neckties or jewelry

when operating power tools. Secure or

tie back long hair.

Use both hands whenever possible to

hold and guide the tool.

Never use a damaged, bent, vibrating,

or out of balance accessory.

Avoid knots, imperfections in the wood

or metal objects like nails, which could

catch or damage the tool bit. Let the

speed of the tool

do the work.

Changing Accessories

Be sure the shank size of the accessory is

paired with the same size collet. Inserting

an accessory which is too small or too large

may damage the collet.

Insert the pin provided into

the pilot hole and through the

spindle hole (turn spindle to

align holes). Apply wrench

and loosen chuck nut slightly by turning

clockwise. Insert shank of the accessor

counter

into the collet. T

keeping pin in pilot hole. Test for a secure hold

by pulling on accessory.

Remove pin.

Changing Collets

The collets that come with

your handpiece are for holding burs and other accessories with

1/4

or

the accessor

Never

ighten chuck nut with wrench,

Chuck Nut and Collet

″ shank sizes.

Be sure the shank size of

y is paired with the same size collet.

screw the chuck

3/32″,

1/8

nut back on too tightly.

To change a collet insert pin

into the pilot hole and

through the spindle hole

(turn spindle to align holes).

Apply wrench and unscrew

chuck nut by turning counterclockwise. Remove

chuck nut to expose collet and pull collet out of

handpiece spindle. Slip new collet in place and

screw on chuck nut with pin and wrench.

Pliers are useful for

removing collets

For more information on this handpiece and other Foredom tools , contact your local

dealer. When no local dealer is available, write: The Foredom Electric Co.,

16 Stony Hill Rd., Bethel, CT 06801, call (203) 792-8622, fax (203) 796-7861,

o

r email: customerservice@blackstoneind.com.

Visit www.foredom.net for the latest information and how-to videos!

Maintenance and Lubrication

Handpieces: no lubrication is required. Putting oil or grease

i

nto the front or back of these handpieces will damage their

pre-lubricated ball bearings. The collet seat and threads of

the handpiece should be kept free of dirt, chips, dust

or debris.

Flexible Shaft: Every 50 hours of use the flexible shaft

should be be checked, wiped clean and relubricated. Unscrew outer sheath connector nut

(left hand thread) and remove inner drive shaft.

silencer spring and the outer sheath.

If you tighten an empty collet or insert

an accessory shank which is too small

or too large you may damage the collet.

Collets for H.44HT

P/N Capacity

HP442 3/32″ ∗

HP443 1/8″ ∗

HP444 5/32″

HP445 3/16″

y

∗

Supplied with handpiece

HP440 Set Includes all seven collets.

MAHH-30

P/N Capacity

HP447 1/4″ ∗

HP448 3mm

HP449 6mm

Handpiece

Accessories and

Spare Parts

″

handpiece can be swiveled and locked

into position. Pins and wrenches that

are lost or damaged can be ordered

from your dealer or the factory.

Part No. Description

MAHH-30 Handpiece

HP103117 Pin and Wrench

A Handpiece Holder is

available that clamps

to work benches up to

1

/4″ thick. The height

2

above the bench can

be adjusted and the

Holder

The shaft is threaded through both a

LIMITED WARRANTY

Warranty period is 90 days for handpieces.

Blackstone Industries, Inc. d/b/a The Foredom Electric

Company warrants, to the original purchaser only

its products will be free from defects in material or

workmanship for the applicable period of time indicated

above following the purchase date. During the warranty

period, the defective product will be repaired or replaced

without charge or, at our sole option, the purchase price

will be refunded. This warranty does not cover damage

caused in transit or by accident, misuse or ordinary wear.

ALL IMPLIED WARRANTIES INCLUDING, WITHOUT

LIMITATION, IMPLIED WARRANTIES OF FITNESS FOR

A PARTICULAR PURPOSE AND MERCHANTABILITY,

ARE LIMITED IN DURATION TO THE APPLICABLE

WARRANTY PERIOD. IN NO EVENT WILL WE BE

LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES. Some states do not allow limitations on how

long an implied warranty lasts or the exclusion or

limitation of incidental or consequential damages, so the

above limitations or exclusion may not apply to you.

At our sole option, repair, replacement or refund will be

made if the product is returned postage prepaid to:

The Foredom Electric Company

16 Stony Hill Road, Bethel, Connecticut 06801

All warranty repairs must be done at our factory at the

above address. W

transportation charges. Shafts, sheaths and duplex

springs are not covered by this warranty

This warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

e will not pay any shipping or

Continued on reverse

, that

.

Loading...

Loading...