IMPORTANT INSTRUCTIONS

For Foredom®Handpieces H.25, H.35, and H.35SJ

Before attaching this Handpiece please

read these instructions.

Never use a damaged, bent, vibrating, or

out of balance accessory.

For More Information on Foredom machines, hand-

pieces, or accessories, contact your local dealer. When

no local dealer is available, write The Foredom Electric

Company, 16 Stony Hill Road, Bethel, CT 06801,

email: customerservice@blackstoneind.com, call

(203) 792-8622, visit our website at www.foredom.net.

Always wear proper eye protection

while using this handpiece.

orm 1226 n 12/10 Printed in U.S.A.

F

See your Power Tool Owner's Manual for

complete instructions on use, care and

maintenance.

Repair Service

Factory repairs are done promptly and at reasonable cost.

If you wish, you can send your equipment directly to the

factory marked: “Attention: Service Department”. Include

your street address, daytime phone number and/or email

address, and a brief note describing the problem with the

equipment. Estimates will be made upon request.

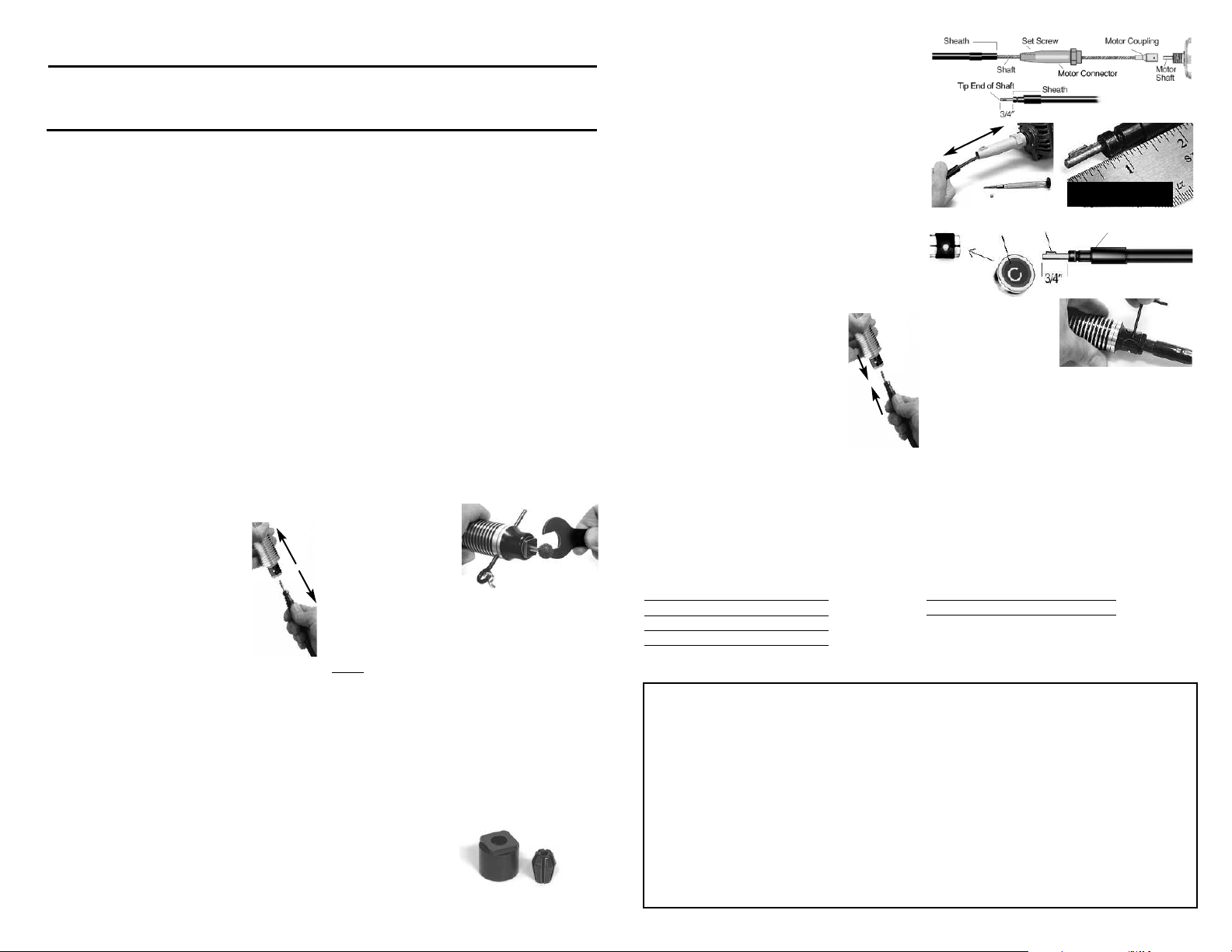

Adjust the Shaft and Sheath

Note: This illustration does not apply to slip joint connections.

It is important to check the sheath and shaft tip and properly

adjust them before attaching this handpiece to your Foredom

flexible shaft tool.

The tip of the flexible shaft should extend 3/4

the sheath. This adjustment is made by loosening the set screw

in the motor connector and moving the sheath in or out while the

motor and shaft and sheath are hanging fully extended or laying

on a flat surface. When the shaft is adjusted correctly, tighten the

set screw in the motor connector.

Always make sure your power tool is unplugged

during any maintenance procedure.

″ beyond the end of

Attach Handpiece to Flexible Shaft

Before attaching the handpiece, connect the motor to the

speed control and plug into power source.

To Attach Handpiece:

outer sheath tip facing upward, turn on the control so that the

motor is running at about half speed and then

turn it off. While the inner key tip is still rotating, grip the handpiece and push it onto the

sheath tip with one firm motion until it snaps

into place (shown at right). This procedure will

align the key tip into the keyway slot (shown

above). To verify this, insert and tighten an

accessory into collet or chuck, turn on control

to a low speed and observe that the accessory

rotates smoothly. Finally retighten locking

screw to secure handpiece on sheath.

while holding the black colored metal

IMPORTANT!

key tip end

eyway

k

of shaft

slot

inside,

back end of

handpiece

Handpiece Locking

Screw on H.25,

H.35 & H.35SJ

The locking screw on the

bottom of your handpiece

prevents unintended release from the shaft and sheath and

keeps the handpiece from rotating on the sheath. Some

users who make frequent handpiece changes, prefer to use

this handpiece with locking screw removed since it is easier to switch out handpieces.

etal sheath tip

m

To Remove Handpiece from Flexible Shaft:

1. First make sure your power tool

is unplugged.

If the handpiece has a locking screw in

2.

place remove it –

3. To remove, simply pull the handpiece

off the shaft and sheath with a firm grip.

instructions on reverse.

14,000 RPM is the recommended

maximum speed for the H.35 handpiece.

The bearings in the H.35 will overheat and may

cause damage if you operate your motor at full

speed (generally

18,000 RPM).

Maintenance and Lubrication

Handpieces: no lubrication is required. Putting oil or grease

into the front or back of these handpieces will damage their

pre-lubricated ball bearings. The collet seat and threads of

the handpiece should be kept free of dirt, chips, dust

or debris.

Flex Shafts: Follow the instructions for cleaning and lubrication that came with your flexible shaft machine or view the

online maintenance videos at www.foredom.net

To Change an Accessory

Be sure the shank size of the accessory is paired with the

same size collet. Inserting an accessory which is too small or

too large may damage the collet.

To change an accessory

insert the pin provided into

the pilot hole and through

the spindle hole (turn spindle to align holes).

Apply wrench and loosen

chuck nut slightly by turning

counterclockwise. Insert shank of accessory into collet.

Tighten chuck nut with wrench, keeping pin in pilot hole.

Test for a secure hold by pulling on accessory. Remove

pin.

Never screw the chuck nut back on too tightly.

If you tighten an empty collet or insert an

accessory which is too small or too large

you may damage the collet.

Changing Collets

Foredom offers additional collets for holding burs and

other accessories with different shank sizes.

To Change a Collet insert pin provided into the pilot hole

and through the spindle hole (turn spindle to align holes).

Apply wrench and unscrew chuck nut by turning

counterclockwise.

Remove chuck nut to

expose collet and pull collet

out of handpiece shaft. Slip

new collet in place and

screw on chuck nut with

pin and wrench.

chuck nut and collet

Handpiece Accessories and Spare Parts

Pins and wrenches that are lost or damaged can be

ordered from your dealer or the factory.

Collets for H.25, H.35 and H.35SJ

P/N Nominal Capacity P/N Nominal Capacity

HP103116 1/16″ HP103124 3mm

HP103115 3/32″ HP103126 4mm

″

HP103114 1/8

HP103113 3/16

HP103112* 1/4″

Foredom®warrants its product to be free of defects in material or workmanship for a period of 90 days after purchase. During

the warranty period, the defective product will be repaired or replaced without charge or, at our option, the purchase price will

be refunded. This warranty does not cover damage caused in transit or by accident, misuse, or ordinary wear.

ALL IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO WARRANTIES OF FITNESS AND MERCHANTABILITY, ARE

HEREBY LIMITED IN DURA

OR RESPONSIBLE FOR ANY SPECIAL OR CONSEQUENTIAL DAMAGES. Repair or replacement will be made at our option if

the product is returned post-paid to:

All warranty repairs must be done at the factory at the address above. We will not pay any shipping or transportation charges.

This warranty covers the original purchaser of the product only. Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to you. This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

(comes with H.25 & H.35)

″

(comes with H.25)

LIMITED WARRANTY

TION TO A PERIOD ENDING 90 DA

The Foredom Electric Company

16 Stony Hill Road, Bethel CT 06801

P/N HP103117– Pin and Wrench for handpieces H.25,

H.35, and H.35SJ

HP103000 5 Collet Set

includes: 1/16″, 3/32″, 1/8″, 3/16″, and 1/4″* collets.

(comes with H.35SJ)

HP103119* 6mm

*Not recommended for handpiece H.35

YS FROM DA

TE OF PURCHASE, AND WE WILL NOT BE LIABLE

Loading...

Loading...