Ford VSG-411, VSG-413 Service Manual

I

Power

Products

VSG-411 I41 3

ENGINE

SERVICE

MANUAL

FPPO-194-264

REVISED OCT. ‘89

IMPORTANT SAFETY NOTICE

Appropriate service methods and proper repair procedures are essential for the safe, reliable operation of all

motor vehicles as well as the personal safety of the individual doing the work. This Shop Manual provides

general directions for accomplishing service and repair work with tested, effective techniques. Following them

will help assure reliability.

There are numerous variations in procedures, techniques, tools and parts for servicing vehicles, as well as in the

skill of the individual doing the work. This Manual cannot possibly anticipate all such variations and provide

advice or cautions as to each..Accordingly, anyone who departs from the instructions provided in the fvfanual

must first establish that he compromises neither his personal safety nor the vehicle integrity by his choice of

methods, tools or parts.

NOTES, CAUTIONS, AND WARNINGS

As you read through the procedures, you will come across NOTES, CAUTIONS, and WARNINGS. Each one is

there for a specific purpose. NOTES give you added information that will help you to complete a particular

procedure. CAUTIONS are given to prevent you from making an error that could damage the engine. WARNINGS remind you to be especially careful in those areas where carelessness can cause personal injury. The

following list contains some general WARNINGS that you should follow when you work on an engine.

l

Always wear safety glasses for eye protection.

l

Use safety stands whenever a procedure requires you to be under the unit.

l

Be sure that the ignition switch is always in the OFF position, unless otherwise required by the procedure.

l

Set the parking brake when working on a vehicle. If you have an automatic transmission, set it in PARK unless

instructed otherwise for specific operation. If you have a manual transmission, it should be in REVERSE

(engine OFF) or NEUTRAL (engine ON) unless instructed otherwise for a specific operation. Place wood

blocks (4” x 4” or larger) to the front and rear surfaces of the tires to provide further restraint from inadvertent

vehicle movement.

l

Operate the engine only in a well-ventilated area to avoid the danger of carbon monoxide.

l

Keep

belts.

yourself

and your clothing away

from moving parts, when the engine is running, especially the fan and

l

To prevent serious burns, avoid

catalytic converter and muffler.

contact

with hot

metal parts such as the

radiator,

exhaust

manifold, tail

pipe,

l

Do not smoke while working on the vehicle.

l

To avoid

injury, always

a vehicle. Tie work on

remove rings, watches, loose hanging

long hair securely behind the head.

jewelry, and loose clothing

before beginning

0 Keep hands and other objects clear of the radiator fan blades. Electric cooling fans can start to operate at any

time by an increase in underhood temperatures, even though the ignition is in the OFF position. Therefore,

care should be taken to ensure that the electric cooling fan is completely disconnected when working under

the hood.

Introduction

This Service Manual provides the service technician with, information for

the proper servicing of the Valencia industrial Engine.

In general, this manual covers the servicing of the engine and

associated standard equipment. In many cases, engines are supplied

with accessories and equipment that are unique to the application. If

service information is ever required on such unique accessories or

equipment it is suggested that the Ford Power Products Operations of

Ford Motor Company be contacted. The proper information will either be

forwarded or the Service Technician will be advised where it can be

obtained.

The information in this manual is grouped in sections according to the

type of work being performed. The various sections are indicated in the

index. In addition, each section is subdivided to include topics such as

diagnosis and testing, cleaning and inspection, overhaul, removal and

installation procedures, disassembly and assembly procedures, and

service specifications.

Where the terms “Right” or “Left” occur in this publication, they refer to

the respective sides of the engine when viewed from the rear or flywheel

end.

Pistons and valves are numbered from the front or timing cover end of

the engine commencing at Number

1.

FORD MOTOR COMPANY

FORD POWER PRODUCTS OPERATIONS

FORD PARTS AND SERVICE DIVISION

3000 SCHAEFER ROAD

DEARBORN, MICHIGAN

The descriptions and specifications contained in this manual were in effect at the time the book was

released for printing. Ford Motor Company reserves the right to discontinue models at any time, or

change specifications or design, without notice and without incurring obligation.

Note: The recommendations and suggestions contained in this pubiication are made to assist the

distributor in improving his distributorship parts and/or service department operations. These

recommendations and suggestions do not supersede or override the provisions of the

Warranty and Policy Manual and in any cases where there may be a conflict, the provisions

of the Warranty and Policy Manual shall govern.

Litho in U.S.A.

48121

Rev. October, 1989

l-01

VSG GASOLINE ENGINE

PART

1 Basic Engine

PART

2 Ignition System - Breaker Type

PART 2A

PART 2B

PART

Ignition System - Solid State ......

Ignition System - Distributorless

Fuel System

3

.....................

....

...

......................

PART 1 Basic Engine

DIAGNOSIS AND TESTING’ : : : : : :

Camshaft Lobe Lift ......................

Compression Test .......................

Crankshaft End Play .....................

Flywheel Face Runout ...................

Camshaft End Play ......................

OVERHAUL ..............................

Cylinder Head ..........................

Valves .................................

Camshaft. ..............................

Crankshaft. .............................

Pistons, Pins and Rings ..................

Valve Rocker Arm and/or Shaft

Assembly

Push Rods

Cylinder Block

CLEANING AND INSPECTION .............

Intake Manifold

Exhaust Manifolds

Valve Rocker Arm and/or Shaft

Assembly .............................

Push Rods

Cylinder Heads

Tappets ................................

Timing Chain and Sprockets ..............

Camshaft. ..............................

Camshaft Bores

.............................

.............................

..........................

..........................

.......................

.............................

.........................

.........................

..............................

: : : :

......

Basic Engine

PAGE PAGE

l-01

2-01

2A-01 PART

28-01

3-01

PART 4

PART

PART

PART

Connecting Rods

Pistons, Pins and Rings ..................

Main and Connecting Rod Bearings

Cylinder Block ..........................

Oil Pan

Oil Pump ...............................

REMOVAL AND INSTALLATION ............

Valve Rocker Arm Cover, Rocker Arm

Intake Manifold

Exhaust Manifold ........................

Cylinder Head ..........................

Valve Spring, Retainer and Stem Seal

Water Pump

Cylinder Front Cover and Timing Chain, or

Adjusting Valve Clearances ...............

Crankshaft Front Oil Seal

Camshaft and/or Valve Lifters .............

Camshaft Bearings ......................

Oil Pan .................................

Flywheel Ring Gear

Crankshaft Rear Oil Seal

Pistons and Connecting Rods

Oil Filter ................................

DISASSEMBLY AND ASSEMBLY ...........

Charging System .................

5

Starting System ..................

6 Governor ........................

7

Cooling System ...................

8

Specifications and Special Tools ....

...............................

........................

.................................

and/or Shaft

Crankshaft Sprocket

..........................

..........................

............................

...................

................

.....................

.................

.................................

.............

.......

.....

l-01

4-01

5-0’1

6 01

-

7101

8-01

Basic Engine

l-02

IDENTIFICATION

An Identification Decal (Fig. 1) is affixed to the left side of the

rocker cover of each engine. The decal contains the engine serial

number which identifies this unit from all others. Next is the

engine displacement which determines the engine specifications,

then the model number and S .O. or special options which determine the parts or components required on this unit. Use all

numbers when seeking information or ordering replacement parts

for this engine.

FIG. 2 A - Serial Number

B

- Engine Code

C

- Engine Build Date

FIG. 1 Identification Decal

Identification of the cylinder block and therefore of the basic

engine type can be made by reference to the stampings on the left

rear top edge of the cylinder block (Figure 2).

The engine code will begin with a “G.” This will indicate that it

is a 1.1 liter engine.

The engine build date follows the corporate system. Example:

“4K26”. The first number indicates the year. The letter indicates

the month in alphabetical sequence, A January, B February, etc.

omitting I. The last two numbers are the day of the month.

DESCRIPTION

The engine is a water-cooled, 4 cylinder, 4 stroke, in-line

gasoline engine. The cylinder head in which the combustion

chambers are located is of a cross-flow type, the fresh fuel/air

mixture is drawn in on one side and burnt gases are passed into the

exhaust system on the opposite side.

The valves are suspended in the cylinder head and are operated

by means of tappets, pushrods and rocker arms.

The valves are disposed in an alternating pattern in the cylinder

head starting with an exhaust valve by the thermostat housing.

The three-bearing camshaft is located on the right side of the

cylinder block and driven by roller chain from the crankshaft.

The common driving gear shared by the distributor and oil

pump is located behind the second cam on the camshaft, the

eccentric cam driving the fuel pump is located between the sixth

and seventh cams.

The oil pump is bolted onto the outside of the cylinder block

below the distributor. The full-flow oil filter is angled downwards

and mounted directly on the oil pump.

The crankshaft is mounted in three or five bearings (see section

8). The crankshaft end play is determined by thrust half rings at the

center main bearing.

The front crankshaft journal is sealed by means of an oil seal

installed in the timing cover.

The rear crankshaft journal is sealed by means of an oil seal

pressed into an oil seal carrier.

The timing cover has cast ignition timing degree marks or a

TDC reference pointer. A notch on the crankshaft belt pulley is

used in conjunction with either the degree or TDC reference points

when installing the distributor and checking timing. They are

visible on the front, left side of the engine.

The spark plugs have a tapered seat without a sealing ring.

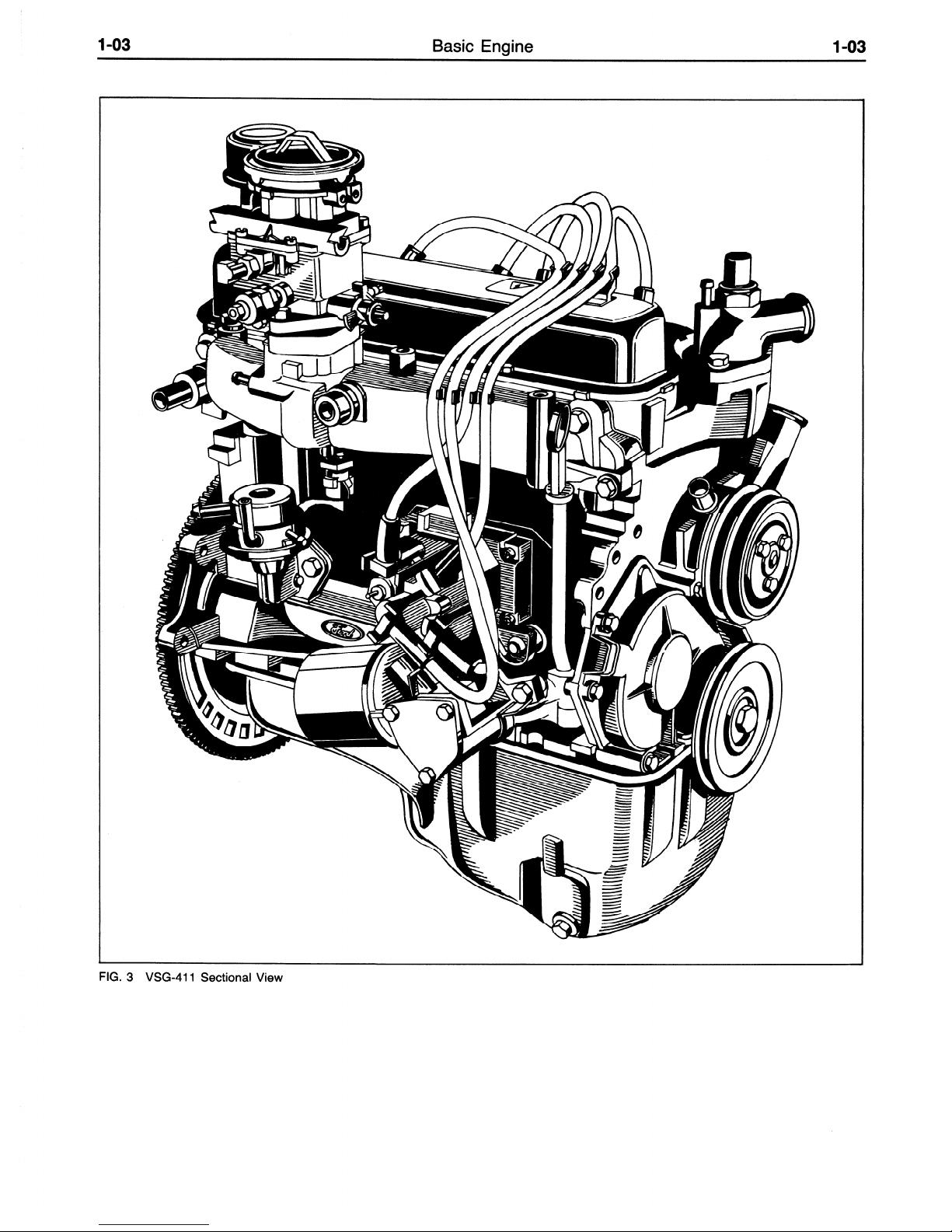

Engine Ventilation, Figure 4.

The ventilation system consists of an oil filler cap with two

connecting hoses, one of which passes to the inlet manifold and

the other to the air cleaner.

The result is a closed ventilation system in which the fumes

from the crankcase pass back via the inlet manifold into the

cylinders for combustion.

Gas flow is regulated by a calibrated orifice in the oil filler cap.

Lubrication circuit, Figure 5.

An eccentric twin-rotor oil pump draws oil via a strainer from

the sump and forces it into the full-flow oil filter.

Oil pressure is regulated by a relief valve inside the pump. The

filtered oil passes through the center of the filter element, then

along a short passage (right hand side of the engine) to the oil

pressure switch and through a transverse bore to the main oil

gallery (left hand side of the engine).

The crankshaft main bearings are fed directly from the main oil

gallery and the camshaft bearings are linked, in turn for their

lubrication with the front, center and rear main bearings. Each of

the rod journals are supplied with oil by the nearest main bearing

through oblique passages.

An oil hole in the connecting rod ensures splash lubrication of

the piston pins and the trailing side of the cylinders. Timing chain

and sprockets are also lubricated via a splash hole. The camshaft

front bearing journal has a machined groove through which oil is

intermittently forced to the rocker shaft (via passages in cylinder

block and cylinder head).

l-03

Basic Engine

I-03

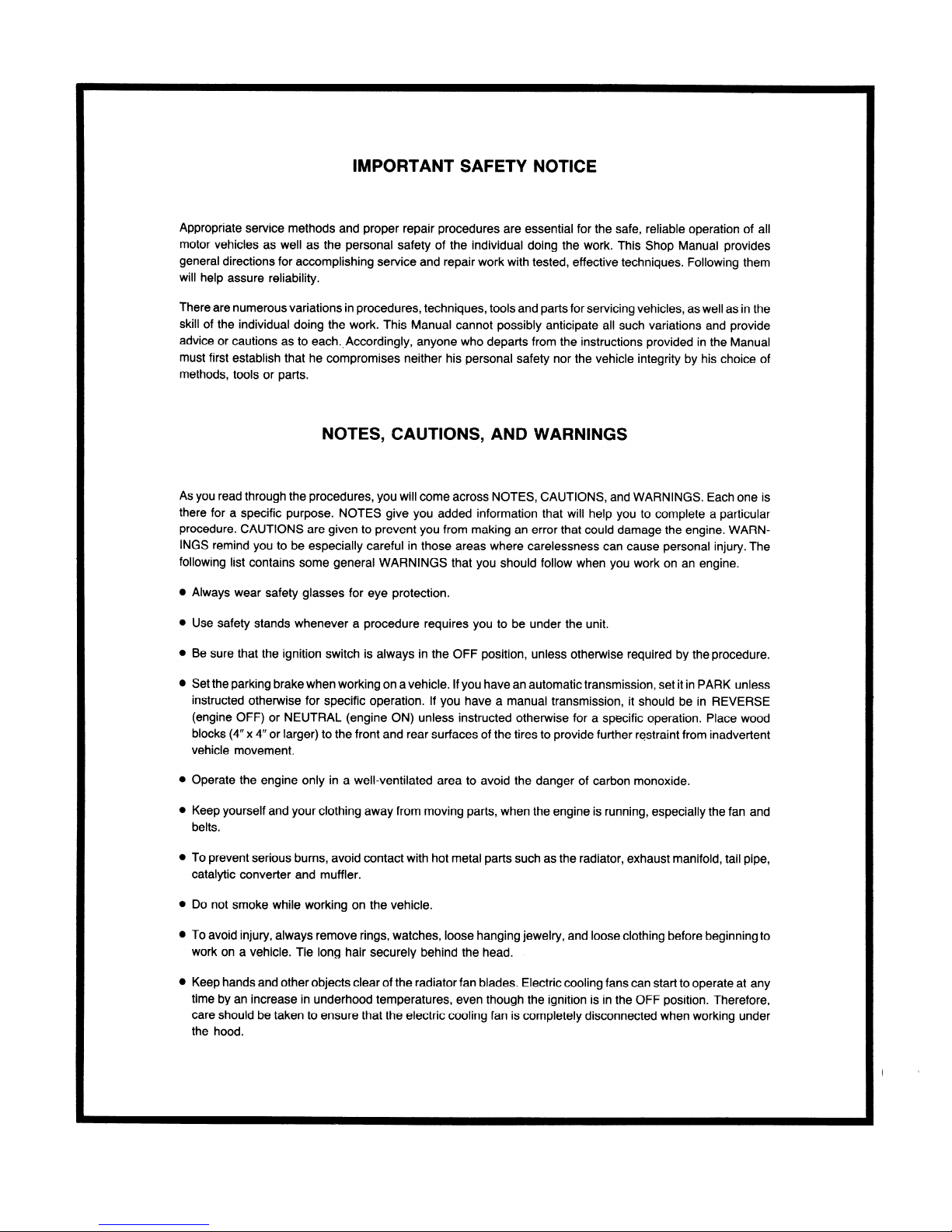

FIG. 3 VSG-411 Sectional View

l-04

Basic Engine

HOSE CONNECTION TO

AIR CLEANER

PRESS IN

ORIFICE

HOSE CX

INNECTION TO

INTAKE MANIFOLD

VACUUM FITTING

FIG. 4 Engine Ventilation System

A - Ventilation at Idle Speed and Half Throttle

B- Ventilation at Full Throttle

FIG. 5 Lubrication Circuit

l-05

Basic Engine

l-05

DIAGNOSIS AND TESTING

CAMSHAFT LOBE LIFT

Check the lift of each lobe in consecutive order and make a note

of the readings.

1. Remove the air cleaner and the valve rocker arm cover.

2. Remove the valve rocker arm shaft assembly as detailed in the

pertinent section.

3. Make sure the push rod is in the valve lifter socket. Install a

dial indicator in such a manner as to have the ball socket

adapter of the indicator on the end of the push rod and in the

same plane as the push rod movement (Figure 6).

FIG. 6 Testing Camshaft Lobe Lift

4. Connect an auxiliary starter switch in the starting circuit.

Crank the engine with the ignition switch OFF. Bump the

crankshaft over until the tappet or lifter is on the base circle of

the camshaft lobe. At this point, the push rod will be in its

lowest position.

5. Zero the ‘dial indicator. Continue to rotate the crankshaft

slowly until the push rod is in the fully raised position (highest

indicator reading).

6. Compare the total lift recorded on the indicator with

specifications.

7. To check the accuracy of the original indicator reading, continue to rotate the crankshaft until the indicator reads zero.

If

the lift on any lobe is below specified wear limits, the

camshaft and the valve lifters operating on the worn

lobe(s) must be replaced.

8. Remove the dial indicator and auxiliary starter switch.

9. Install the rocker arm shaft assembly as detailed under Removal and Installation.

10. Install the valve rocker arm cover and the air cleaner.

COMPRESSION TEST

COMPRESSION GAUGE CHECK

1.

Be sure the crankcase is at the proper level and the battery is

properly charged. Operate the engine for a minimum of 30

minutes at 1200 rpm or until the engine is at normal operating

temperature. Turn the ignition switch off; then remove all the

spark plugs.

2. Set the carburetor throttle plates and chc~ke plate in the wide

open position.

3. Install a compression gauge in No. 1 cylinder.

4. Install an auxiliary starter switch in the starting circuit. Using

the auxiliary starter switch, crank the engine (with the ignition

switch off) at least five compression strokes and record the

highest reading.

Note the approximate number of compression strokes required

d

to obtain the highest reading.

5.

Repeat the test on each cylinder as was required to obtain the

highest reading on the No. 1 cylinder.

TEST CONCLUSION

The indicated compression pressures are considered normal if

the lowest reading cylinder is within 75% of the highest. Refer to

the following example and Figure 7.

Seventy-five percent of 140, the highest cylinder reading, is

105. Therefore, cylinder No. 7 being less than 75% of cylinder

No. 3 indicates an improperly seated valve or worn or broken

piston rings.

If one or more cylinders read low, squirt approximately one (1)

tablespoon of engine oil on top of the pistons in the low reading

cylinders. Repeat compression pressure check on these cylinders.

1. If compresison improves considerably, the piston rings are at

fault.

2. If compression does not improve, valves are sticking or seating poorly.

3. If two adjacent cylinders indicate low compression pressures

’ and squirting oil on the pistons does not increase the compres-

sion, the cause may be a cylinder head gasket leak between the

cylinders. Engine oil and/or coolant in the cylinders could

result from this problem.

It is recommended the following quick reference chart be used

when checking cylinder compression pressures. The chart has

been calculated so that the lowest reading number is 75% of the

highest reading.

EXAMPLE

After checking the compression pressures in all cylinders, it was

found that the highest reading obtained was 196 psi. The lowest

pressure reading was 155 psi. The engine is within specifications

and the compression is considered satisfactory.

CRANKSHAFT END PLAY

1. Force the crankshaft toward the rear of the engine.

2. Install a dial indicator so that the contact point rests against the

crankshaft flange and the indicator axis is parallel to the

crankshaft axis .

3. Zero the dial indicator. Push the crankshaft forward and note

the reading on the dial.

4. If the end play exceeds the wear limit, replace the thrust

washers. If the end play is less than the minimum limit,

inspect the thrust bearing faces for scratches, burrs, nicks, or

dirt.

FLYWHEEL FACE RUNOUT

Install a dial indicator so that the indicator point bears against

the flywheel face. Turn the flywheel, making sure that it is full

forward or rearward so that the crankshaft end play will not be

indicated as flywheel runout.

If the clutch face runout exceeds specifications, remove the

flywheel and check for burrs between the flywheel and the face of

the crankshaft mounting flange. If no burrs exist, check the runout

of the crankshaft mounting flange. Replace the flywheel, or machine the crankshaft-flywheel mounting face sufficiently to true up

the surface if the mounting flange runout exceeds spec”fications.

Replace it or reinstall it on the flywheel.

CAMSHAFT END PLAY

Push the camshaft toward the rear of the engine. Install a dial

indicator so that the indicator point is on the camshaft sprocket

attaching screw or gear hub. Zero the dial indicator. Position a

large screwdriver between the camshaft sprocket and the cylinder

head. Pull the camshaft forward and release it. Compare the dial

indicator reading with specifications. If the end play is excessive,

replace the thrust plate retaining the camshaft. Remove the dial

indicator.

l-06

Basic Engine

I-06

Maximum

PSI

I

Minimum

PSI

~~~ T

Maximum

PSI

134

101

174

131

136

102

176

132

138

104 178 133

140

105 180 135

142

107

182

136

144

108

184 138

146 110

186 140

148 111

188

141

150 113

190

142

152 114

192 144

154

115

194 145

156

117

196

147

158 118 198 148

160 120

200 150

162

121

202 151

164 123 204 153

166

124

206

154

168 126 208 156

170

127

210

157

172 129 212 158

Minimum

PSI

I

Maximum

PSI

214

216

218

220

222

224

226

228

230

232

234

236

238

240

242

244

246

248

250

Minimum

PSI

160

162

163

165

166

168

169

171

172

174

175

177

178

180

181

183

184

186

187

FIG. 7 Quick Reference Compression Pressure Limit Chart

CA1

005-A

OVERHAUL

CYLINDER HEAD

Replace the head if it is cracked.

Do not plane or grind more

than 0.010 inch from the cylinder head gasket surface.

Remove

all burrs or scratches with an oil stone.

REAMING VALVE GUIDES

If it becomes necessary to ream the valve guide (Figure 8)) to an

oversize valve always use the reamer in sequence.

Always reface

the valve seat after the valve guide has been reamed, and use a

suitable scraper to break the sharp corner (ID) at the top of the

valve guide.

BREAKSHARP

FIG. 8

Reaming Valve Guides

REFACING VALVE SEATS

Refacing of the valve seat should be closely coordinated with

the refacing of the valve face so that the finished seat and valve

face will be concentric and the specified interference fit will be

maintained. This is important so that the valve and seat will have a

compression-tight fit. Be sure that the refacer grinding wheels are

properly dressed.

Grind the valve seats to a true 45 degree angle (Figure 9).

Remove only enough stock to clean up pits and grooves or to

correct the valve seat runout. After the seat has been refaced, use a

seat width scale or a machinist scale to measure the seat width

(Figure 10). Narrow the seat, if necessary, to bring it within

snecifications.

TO REMOVE STOCK FROM TO REMOVE STOCK FROM

TOP OF SEAT

I

BOTTOM OF SEAT

USE 30” WHEEL

I

USE 60” WHEEL

A7382-1 A

FIG. 9 Refacing

Valve

Seat

If the valve seat width exceeds the maximum limit, remove

enough stock from the top edge and/or bottom edge of the seat to

reduce the width to specifications.

On the

valve seats

of all

engines,

use a 60 degree angle grinding

wheel

to remove stock from the

bottom of the seats (raise the seats)

and use a 30 degree angle

wheel

to remove stock from the top of

the seats (lower

the seats).

The finished valve seat should

contact the approximate center

of the valve face. It is good practice to determine where the valve

l-07

Basic Engine

l-07

seat contacts the face. To do this, coat the seat with Prussian blue

and set the valve in place. Rotate the valve with light pressure. If

the blue is transferred to the center of the valve face, the contact is

satisfactory. If the blue is transferred to the top edge of the valve

face, lower the valve seat. If the blue is transferred to the bottom

edge of the valve face, raise the valve seat.

SEAT WIDTH SCALE

A

FOR DIMENSIONS

CHECK FOR

REFER TO

BENT STEM

SPECIFICATIONS

<

DIAMETER

VALVE

VALVE FACE MARGIN

FACE ANGLE

l/32” MINIMUM

(EDGE OF VALVE HEAD)

THIS LINE PARALLEL

WITH VALVE HEAD

I

AlOOSO-1B

Minor pits, grooves, etc.,

may be removed. Discard valves that

are severely damaged, if the face runout cannot be corrected by

refinishing or stem clearance exceeds specifications. Discard

any

excessively worn or damaged valve train parts.

REFACING VALVES

The valve refacing operation should be closely coordinated

with the valve seat refacing operations so that the finished angles

of the valve face and of the valve seat will be to specifications and

provide a compression-tight fit. Be sure that the refacer grinding

wheels are properly dressed.

Under no circumstances should the faces of aluminized intake

valves be ground or the valves lapped in as this will remove the

diffused aluminum coating and reduce the valves’ wear and heat

resistant properties. If the valve faces are worn or pitted it will be

necessary to install new valves and to resurface the valve seats or,

alternatively, lap the seats using dummy valves. The exhaust

valves may be lapped in or the faces ground if required.

If the valve face runout is excessive and/or to remove pits and

grooves, reface the valves to a true 44 degree angle. Remove only

enough stock to correct the runout or to clean up the pits and

grooves. If the edge of the valve head is less than l/32 inch thick

after grinding (Figure 1 l), replace the valve as the valve will run

too hot in the engine.

The interference fit of the valve and seat

should not be lapped out. Remove all grooves or score marks

from the end of the valve stem, and chamfer it as necessary.

Do not remove more than 0.010 inch from the end of the valve

stem.

If the valve and/or valve seat has been refaced, it will be

necessary to check the clearance between the rocker arm pad and

the valve stem with the valve train assembly installed in the

engine.

SELECT FllTlNG VALVES

If the valve stem to valve guide clearance exceeds the wear

limit, ream the valve guide for the

next

oversize valve stem.

Valves with oversize stem diameter ar’e available for service.

Always reface the valve seat after the guide has been reamed.

Refer to Reaming Valve Guides.

FIG. 11 Critical Valve Dimensions

CAMSHAFT REPAIR

Remove light scuffs, scores or nicks from the camshaft ma-

chined surfaces with a smooth oil stone.

CRANKSHAFT

Dress minor scores with an oil stone. If the journals are severely

marred or exceed the wear limit, they should be refinished to size

for the next undersize bearing.

REFINISHING JOURNALS

Refinish the journals to give the proper clearance with the next

undersize bearing. If the journal will not clean up to maximum

undersize bearing available, replace the crankshaft.

Always reproduce the same journal shoulder radius that existed

originally. Too small a radius will result in fatigue failure of the

crankshaft. Too large a radius will result in bearing failure due to

radius ride of the bearing.

After refinishing the journals, chamfer the oil holes; then polish

the journal with a No. 320 grit polishing cloth and engine oil.

Crocus cloth may also be used as a polishing agent.

FITTING MAIN OR CONNECTING ROD BEARINGS

WITH PLASTIGAGE

1. Clean crankshaft journals. Inspect journals and thrust faces

(thrust bearing) for nicks, burrs or bearing pickup that would

cause premature bearing wear.

When replacing standard

bearings with new bearings, it is good practice to fit the

bearing to minimum specified clearance.

If the desired

clearance cannot be obtained with a standard bearing, try a

0.002 inch undersize in combination with a standard bearing

to obtain the proper clearance.

2. If fitting a main bearing in the chassis,

position a jack under

the counterweight adjoining bearing which is being

checked. Support crankshaft with jack so its weight will

not compress Plastigage and provide an erroneous

reading.

Basic Engine

3. Place a piece of Plastigage on bearing surface across full

width of bearing cap and about l/4 inch off center (Figure 12).

4. Install cap and torque bolts to specifications. Do not turn

crankshaft while Plastigage is in place.

5. Remove cap. Using Plastigage scale, check width of Plastigage at widest point to get minimum clearance. Check at

narrowest point to get maximum clearance. Difference between readings is taper of journals.

6. If clearance exceeds specified limits on the connecting rod

bearings, try a 0.002 inch undersize bearing in combination

with the standard bearings. Bearing clearance must be within

specified limits. If 0.002 undersize main bearings are used on

more than one journal, be sure they are all installed in cylinder

block side of bearing. If standard and 0.002 inch undersize

bearings do not bring clearance within desired limits, refinish

crankshaft journal, then install undersize bearings.

7. After bearing has been fitted, remove Plastigage, apply light

coat of engine oil to journal and bearings. Install bearing cap.

Torque cap bolts to specifications.

8. Repeat procedure for remaining bearings that require

replacement.

PLACE PLASTIGAGE

FULL WIDTH

OF JOURNAL ABOUT

l/4

INCH OFF CENTER

2. Select the proper size piston to provide the desired clearance

(refer to the specifications). The piston should be measured

2-l/4 inches below the dome and at 90’ to the piston pin bore.

3. Make sure the piston and cylinder block are at room temperature (70 degrees F.).

After any refinishing operation

allow the cylinder bore to cool, and make sure the piston

and bore are clean and dry before the piston fit is checked.

FITTING PISTON RINGS

Three piston rings are fitted, two compression and one oil

control ring.

1. Select the proper ring set for the size cylinder bore.

2. Position the ring in the cylinder bore in which it is going to be

used.

3. Push the ring down into the bore area where normal ring wear

is not encountered.

4. Use the head of a piston to position the ring in the bore so that

the ring is square with the cylinder wall.

Use caution to avoid

damage to the ring or cylinder bore.

5. Measure the gap between the ends of the ring with a feeler

gauge (Figure 13). If the ring gap is less or greater than the

specified limits, try another ring set.

P

IN

PLASTIGAGE

FIG. 12 Installing and Measuring Plastigage

\ -1

. I

-CHECK WIDTH

1 CLEARANCE

OF PLASTIGAGE

A2868-B

PISTONS, PINS AND RINGS

FITTING PISTONS

Pistons are available for service in standard sizes and the over-

sizes shown in the parts list.

Measure the piston diameter to ensure that the specified clearance is obtained. It may be necessary periodically to use another

piston that is either slightly larger or smaller to achieve the specified clearance.

provide the proper clearance for the piston. When a piston has

been fitted, mark it for assembly in the cylinder to which it was

fitted. If the taper, out-of-round and piston to cylinder bore

clearance conditions of the cylinder bore are within specified

limits, new piston rings will give satisfactory service. If new

rings are to be installed in a used cylinder that has not been

refinished, remove the cylinder wall glaze (Refer to Cylinder

Block, Refinishing Cylinder Walls). Be sure to clean the cylinder bore thoroughly.

1. Calculate the size piston to be used by taking a cylinder bore

check. Follow the procedures outlined under Cleaning and

Inspection.

If none can be fitted, refinish the cylinder to

FIG. 13 Checking Piston Ring Gap

6. Check the ring side clearance of the compression rings with a

feeler gauge inserted between the ring and its lower land

(Figure 14). The gauge should slide freely around the entire

ring circumference without binding. Any wear that occurs will

form a step at the inner portion of the lower land.

If the lower

lands have high steps, the piston should be replaced.

FIG. 14 Checking Piston Ring Side Clearance

l-09

Basic Engine

l-09

FllTlNG PISTON PINS

The piston pins are selected to give the correct fit in the piston

pin bore and bushing in the connecting rod. Pistons are only

supplied in service complete with the piston pin, to ensure the

correct fit. The piston pins should not be interchanged.

VALVE ROCKER ARM AND/OR SHAFT

ASSEMBLY

Dress up minor surface defects on the rocker arm shaft and in the

rocker arm bore with a hone.

If the pad at the valve end of the rocker arm has a grooved

radius, replace the rocker

arm. Do not attempt to true this

surface by grinding.

PUSH RODS

Following the procedures under Push Rod Inspection, check the

push rods for straightness.

If the runout exceeds the maximum limit at any point, discard

the rod.

Do not attempt to straighten push rods.

CYLINDER BLOCK

REFINISHING CYLINDER WALLS

Honing is recommended for refinishing cylinder walls

only

when the walls have minor scuffs or scratches, or for fitting pistons

to the specified clearance. The grade of hone to be used is determined by the amount of metal to be removed. Follow the instructions of the hone manufacturer. If coarse stones are used to start the

honing operation, leave enough material so that all hone marks can

be removed with the finishing hone which is used to obtain the

proper piston clearance. Cylinder walls that are severely marred

and/or worn beyond the specified limits should be refinished.

Before any cylinder is refinished, all main bearing caps must

be in place and tightened to the proper torque so that the

crankshaft bearing bores will not become distorted from the

refinishing operation.

Refinish only the cylinder or cylinders that

require it. All pistons are the same weight, both standard and

oversize; therefore, various sizes of pistons can be used without

upsetting engine balance. Refinish the cylinder with the most wear

first to determine the maximum oversize. If the cylinder will not

clean up when refinished for the maximum oversize pistonrecommended, replace the block. Refinish the cylinder to within approximately 0.0015 inch of the required oversize diameter. This will

allow enough stock for the final step of honing so that the correct

surface finish and pattern are obtained. For the proper use of the

refinishing equipment follow the instructions of the manufacturer.

Only experienced personnel should be allowed to perform this

work. Use a motor-driven, spring pressure-type hone at a speed of

300500 rpm. Hones of grit sizes 180-220 will normally provide

the desired bore surface finish of 15/32 RMS. When honing the

cylinder bores use a lubricant mixture of equal parts of kerosene

and SAE No. 20 motor oil. Operate the hone in such a way to

produce a cross-hatch finish on the cylinder bore. The cross-hatch

pattern should be at an angle of approximately 30 degrees to the

cylinder bore. After the final operation in either of the two refinishing methods described and prior to checking the piston fit,

thoroughly clean and oil the cylinder walls. Mark the pistons to

correspond to the cylinders in which they are to be installed. When

the refinishing of all cylinders that require it has been completed

and all pistons are fitted, thoroughly clean the entire block and oil

the cylinder walls.

REPAIRING SAND HOLES OR

POROUS ENGINE CASTINGS

Porosity or sand hole(s) which will cause oil seepage or leakage

can occur with modem casting processes. A complete inspection

of engine and transmission should be made. If the leak is attributed

to the porous condition of the cylinder block or sand hole(s),

repairs can be made with metallic plastic (part No. C6AZ- 19554A).

Do not repair cracks with this material.

Repairs with this

metallic plastic must be confined to those cast iron engine component surfaces where the inner wall surface is not exposed to engine

coolant pressure or oil pressure. For example:

1. Cylinder block surfaces extending along the length of the

block, upward from the oil pan rail to the cylinder water jacket

but not including machined areas.

2. Lower rear face of the cylinder block.

3. Intake manifold casting.

4. Cylinder head, along the rocker arm cover gasket surface.

The following procedure should be used to repair porous areas

or sand holes in cast iron.

a.

Clean the surface to be repaired by grinding or rotary filing

to a clean bright metal surface. Chamfer or undercut the

hole or porosity to a greater depth than the rest of the

cleaned surface. Solid metal must surround the hole.

Openings larger than l/4 inch should not be repaired using

metallic plastic. Openings in excess of l/4 inch can be

drilled, tapped and plugged using common tools. Clean

the repair area thoroughly. Metallic plastic will not stick to

a dirty or oily surface.

b. Mix the metallic plastic base and hardener as directed on

the container. Stir thoroughly until uniform.

c.

Apply the repair mixture with a suitable clean tool, (putty

knife, wood spoon, etc.) forcing the epoxy into the hole or

porosity.

d. Allow the repair mixture to harden. This can be accom-

plished by two methods, heat cure with a 250 degree lamp

placed 10 inches from the repaired surface, or air dry for

lo- 12 hours at temperatures above 50 degrees F.

e. Sand or grind the repaired area to blend with the general

contour of the surrounding surface.

f. Paint the surface to match the rest of the block.

l-10

Basic Engine

CLEANING AND INSPECTION

The cleaning and inspection procedures are for a complete

engine overhaul; therefore, for partial engine overhaul or parts

replacement, follow the pertinent cleaning or inspection

procedure.

INTAKE MANIFOLD

Cleaning

Remove all gasket material from the machined surfaces of the

manifold. Clean the manifold in a suitable solvent and dry it with

compressed air.

l-10

CYLINDER HEADS

Cleanlng

With the valves installed to protect the valve seats, remove

deposits from the combustion chambers and valve heads with

a scraper and a wire brush. Be careful not to damage the

cylinder head gasket surface.

clean the valve guide bores with a valve guide cleaning tool. Use

cleaning solvent to remove dirt, grease and other deposits. Clean

all bolt holes. Remove all deposits from the valves with a fine wire

brush or buffing wheel.

After the valves are removed,

Inspection

Inspect the manifold for cracks, damaged gasket surfaces, or

other defects that would make it unfit for further service. Replace

all studs that are stripped or otherwise damaged.

Remove all

filings and foreign matter that may have entered the manifold

as a result of repairs.

EXHAUST MANIFOLDS

Cleaning

Remove all gasket material from the manifolds.

Inspection

Inspect the cylinder head joining flanges of the exhaust mani-

fold for evidence of exhaust gas leaks.

Inspect the manifolds for cracks, damaged gasket surfaces, or

other defects that would make them unfit for further service.

VALVE ROCKER ARM AND/OR SHAFT

ASSEMBLY

Cleaning

Clean all the parts thoroughly. Make sure all oil passages are

open.

Make sure the oil passage in the rocker arm is open.

Inspection

On rocker arm shaft assemblies, check the clearance between

each rocker arm and the shaft by checking the ID of the rocker arm

bore and the OD of the shaft. If the clearance between any rocker

arm and the shaft exceeds the wear limit, replace the shaft and/or

the rocker arm. Inspect the shaft and the rocker arm bore for nicks,

scratches, scores or scuffs.

Inspect the pad at the valve end of the rocker arm for indications

of scuffing or abnormal wear. If the pad is grooved, replace the

rocker arm.

Check the adjusting nut(s) torque. If not within specifications,

replace the nut(s). Check the rocker arm pad and fulcrum seat for

excessive wear, cracks, nicks or burrs.

Do not attempt to true this surface by grinding.

Inspection

Check the cylinder head for cracks and inspect the gasket

surface for burrs and nicks. Replace the head if it is cracked.

The following inspection procedures are for a cylinder head that

is to be completely overhauled. For individual repair operations,

use

only the pertinent inspection procedure.

When a cylinder head is removed because of gasket leaks,

check the flatness of the cylinder head gasket surface (Figure 15)

for conformance to specifications. If necessary to refinish the

cylinder head gasket surface,

than 0.010 inch.

I

I

FIG.

@@CHECK DIAGONALLY

@CHECK ACROSS CENTER

15

Typical Cylinder Head Flatness

Check the valve seat runout with an accurate gauge (Figure 16).

Follow the instructions of the gauge manufacturer. If the runout

exceeds the wear limit, reface the valve and valve seat. Measure

the valve seat width (Figure 10). Reface any valve seat whose

width

is not within specifications.

RUNOUT GAUGE

do not plane or grind off more

A2895 1 C

PUSH RODS

Cleaning

Clean the push rods in a suitable solvent. Blow dry the pushrod

with compressed air.

Inspection

Check the ends of the push rods for nicks, grooves, roughness

or excessive wear.

The push rods can be visually checked for straightness while

they are installed in the engine by rotating them with the valve

closed. They also can be checked with a dial indicator.

If the push rod is visibly bent, it should be replaced.

A9624-1 A

FIG. 16 Checking Valve Seat Runout

l-11

Basic Engine

l-11

Inspect the valve face and the edge of the valve head for pits,

grooves, scores or other damage. Inspect the stem for a bent

condition and the end of the valve head for pits, grooves, scores

or other wear. Inspect the stem for a bent condition and the end

of the stem for grooves or scores. Check the valve head for

signs of burning, erosion, warpage and cracking. Minor pits,

grooves, etc., may be removed. Discard valves that are severely

damaged.

Inspect the valve spring, valve spring retainers, locks and

sleeves for wear or damage. Discard any visually damaged parts.

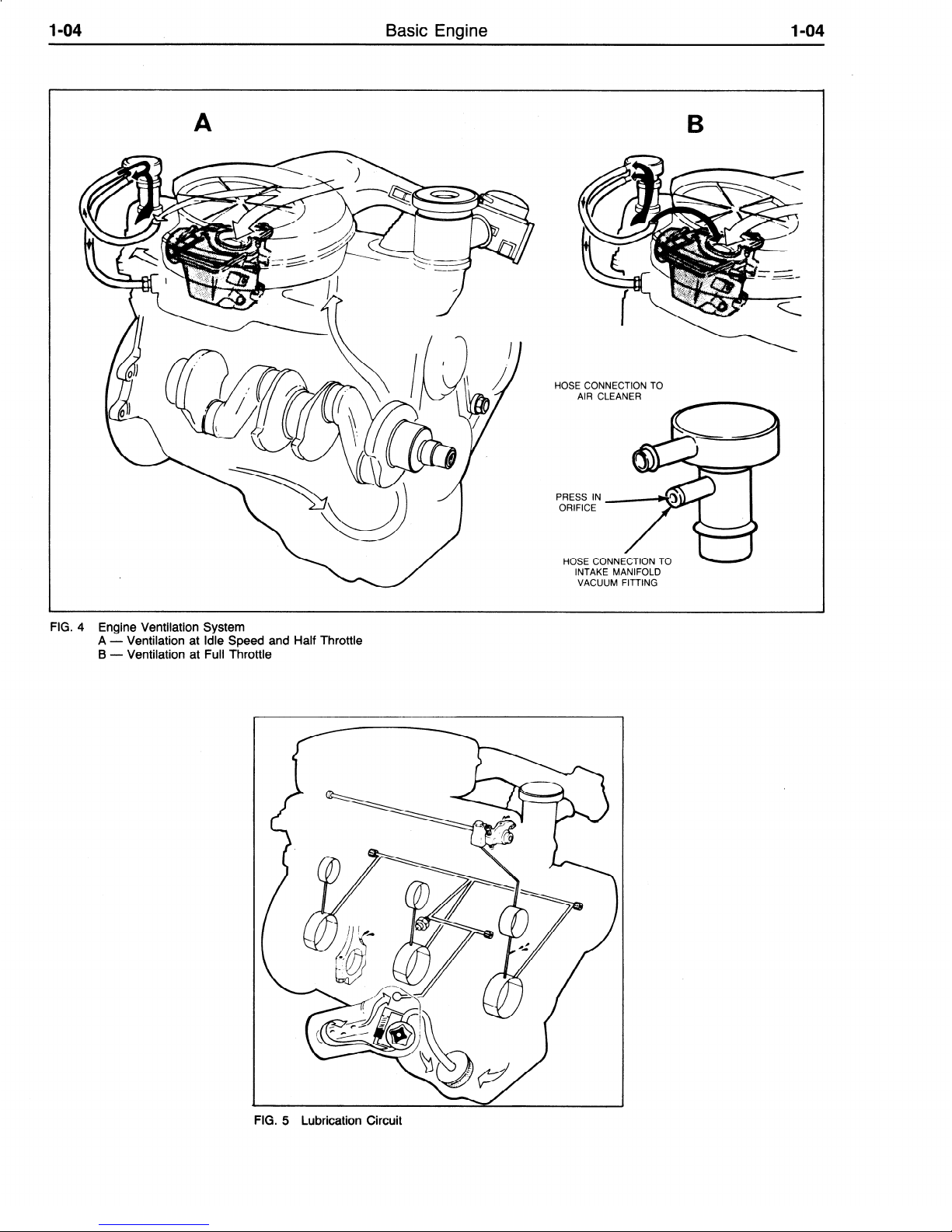

Check the valve stem to valve guide clearance of each valve in

its respective valve guide with the tool shown in Figure 17 or its

equivalent. Use a flat end indicator point.

With the cylinder head gasket face up, slide a new standard

intake or exhaust valve into the valve guide to be checked until the

tip of the valve stem is flush with the top of the valve guide.

Mount a dial test indicator on the cylinder head by the valve to

be checked (Figure 17).

FIG. 17 Checking Valve Stem Clearance

Position the plunger of the dial test indicator on the edge of the

valve head and measure the valve head movement by applying

lateral pressure to the valve. If the valve head movement is greater

than the values given below, the valve guide in question must be

reamed using the appropriate reamer, and a new oversize valve

installed.

Maximum permissible valve head movement values for the

above test procedure:

Intake valve

0.50 mm (0.020 in.)

Exhaust valve

0.60

mm (0.024 in.)

Check the springs for proper pressure (Figure 18) at the spec-

ified spring lengths. (Tool 65 13-DD.)

Manually rotating the

valve spring assemblies while installed in the engine, must not

be used to determine good and/or bad valve springs.

Weak

valve springs cause poor engine performance. Replace any spring

not within specifications.

APPLY TORQUE UNTIL

CLICK IS HEARD, READ

TORQUE WRENCH AND

MULTIPLY READING

BY TWO

SPRING TESTE

TOOL-6513-DD

SET KNOB TO

COMPRESSED

A9077-1C

FIG. 18 Checking Valve Spring Pressure

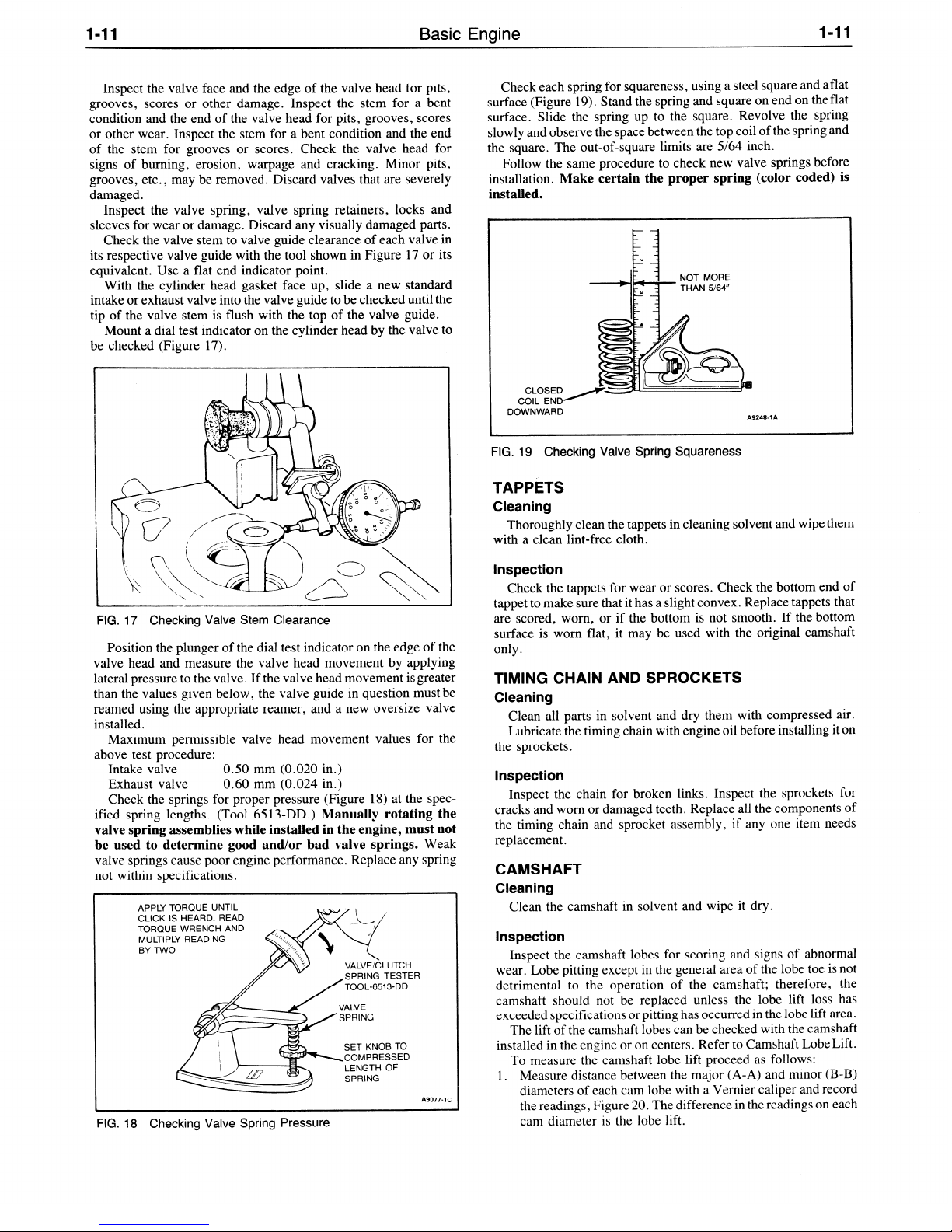

Check each spring for squareness, using a steel square and aflat

surface (Figure 19). Stand the spring and square on end on the flat

surface. Slide the spring up to the square. Revolve the spring

slowly and observe the space between the top coil of the spring and

the square. The out-of-square limits are 5/64 inch.

Follow the same procedure to check new valve springs before

installation.

Make certain the proper spring (color coded) is

installed.

CLOSED

COIL END

DOWNWARD

A9248-1 A

Thoroughly clean the tappets in cleaning solvent and wipe them

with a clean lint-free cloth.

Inspection

Check the tappets for wear or scores. Check the bottom end of

tappet to make sure that it has a slight convex. Replace tappets that

are scored, worn, or if the bottom is not smooth. If the bottom

surface is worn flat, it may be used with the original camshaft

only.

TIMING CHAIN AND SPROCKETS

Cleaning

Clean all parts in solvent and dry them with compressed air.

Lubricate the timing chain with engine oil before installing it on

the sprockets.

Inspection

Inspect the chain for broken links. Inspect the sprockets for

cracks and worn or damaged teeth. Replace all the components of

the timing chain and sprocket assembly, if any one item needs

replacement.

CAMSHAFT

Cleaning

Clean the camshaft in solvent and wipe it dry.

Inspection

Inspect the camshaft lobes for scoring and signs of abnormal

wear. Lobe pitting except in the general area of the lobe toe is not

detrimental to the operation of the camshaft; therefore, the

camshaft should not be replaced unless the lobe lift loss has

exceeded specifications or pitting has occurred in the lobe lift area.

The lift of the camshaft lobes can be checked with the camshaft

installed in the engine or on centers. Refer to Camshaft Lobe Lift.

To measure the camshaft lobe lift proceed as follows:

1. Measure distance between the major (A-A) and minor (B-B)

diameters of each cam lobe with a Vernier caliper and record

the readings, Figure 20. The difference in the readings on each

cam diameter is the lobe lift.

Basic Engine

l-12

NO PITTING

ALLOWED IN

THIS AREA

DIMENSION A MINUS

DIMENSIO

N B EQUALS

LOBE LIFT

A64898

FIG.

l/4”

l/4”

t J

A

20

Camshaft Lobe Lift Measurement Camshaft Removed

2. If the readings do not meet specification, replace the

camshaft.

CAMSHAFT BORES

Inspection

Check camshaft bores for size, taper, roundness, runout, and

finish. If any of these dimensions exceeds the limits given in

Specifications, install new camshaft bearings.

CRANKSHAFT

Cleaning

Handle the crankshaft with care to avoid possible fractures or

damage to the finished surfaces. Clean the crankshaft with solvent, then blow out all oil passages with compressed air.

Inspection

Inspect the main and connecting rod journals for cracks,

scratches, grooves or scores. Inspect the crankshaft oil seal surface

for nicks, sharp edges or burrs that might damage the oil seal

during installation or cause premature seal wear.

Measure the diameter of each journal in at least four places to

determine an out-of-round, taper or undersize condition (Figure

21).

AVSB=

CVSD= HORIZONTAL TAPER

A

CHECK FOR OUT-OF-ROUND AT EACH END OF JOURNAL

VS C AND

VERTICAL TAPER

B VS D

= OUT OF ROUND

FLYWHEEL

Inspection

Inspect the flywheel for cracks, heat check, or other damage

that would make it unfit for further service. Machine the friction

surface of the flywheel if it is scored or worn. If it is necessary to

remove more than 0.045 inch of stock from the original thickness,

replace the flywheel.

Inspect the ring gear for worn, chipped, or cracked teeth. If the

teeth are damaged, replace the ring gear.

With the flywheel installed on the crankshaft, check the

flywheel face runout, following the procedure under Diagnosis

and Testing.

CONNECTING RODS

Cleaning

Removing the bearings from the rod and cap. Identify the

bearings if they are to be used again. Clean the connecting rod in

solvent, including the rod bore and the back of the inserts.

use a caustic cleaning solution.

Blow out all passages with

Do not

compressed air.

Inspection

The connecting rods and related parts should be carefully in-

spected and checked for conformance to specifications. Various

forms of engine wear caused by these parts can be readily

identified.

A shiny surface on either pin boss side of the piston usually

indicates that a connecting rod is bent.

Abnormal connecting rod bearing wear can be caused by either

a bent connecting rod, worn or damaged crankpin, or a tapered

connecting rod bore.

Twisted connecting rods will not create an identifiable wear

pattern, but badly twisted rods will disturb the action of the entire

piston, rings and connecting rod assembly and may be the cause of

excessive oil consumption.

Inspect the connecting rods for signs of fractures and the bearing

bores for out-of-round and taper. If the bore exceeds the recommended limits and/or if the connecting rod is fractured, it should

be replaced. Check the ID of the connecting rod piston pin bore. If

the pin bore in the connecting rod is larger than specifications,

install a 0.002 inch oversize piston pin. First, prefit the oversize

piston pin to the piston pin bore by reaming or honing the piston.

Then, assemble the piston, piston pin and connecting rod follow-

ing the procedures for assembly.

It is not necessary to ream or

hone the pin bore in the connecting rod. Replace damaged

connecting rod nuts and bolts. Check the connecting rods for

bend or twist on a suitable alignment fixture. Follow the

instructions of the fixture manufacturer. If the bend and/or

twist exceeds specifications, the connecting rod must be

straightened or replaced.

PISTONS, PINS AND RINGS

Cleaning

Remove deposits from the piston surfaces. Clean gum or var-

nish from the piston skirt, piston pins and rings with solvent.

not use a caustic cleaning solution or a wire brush to clean

pistons.

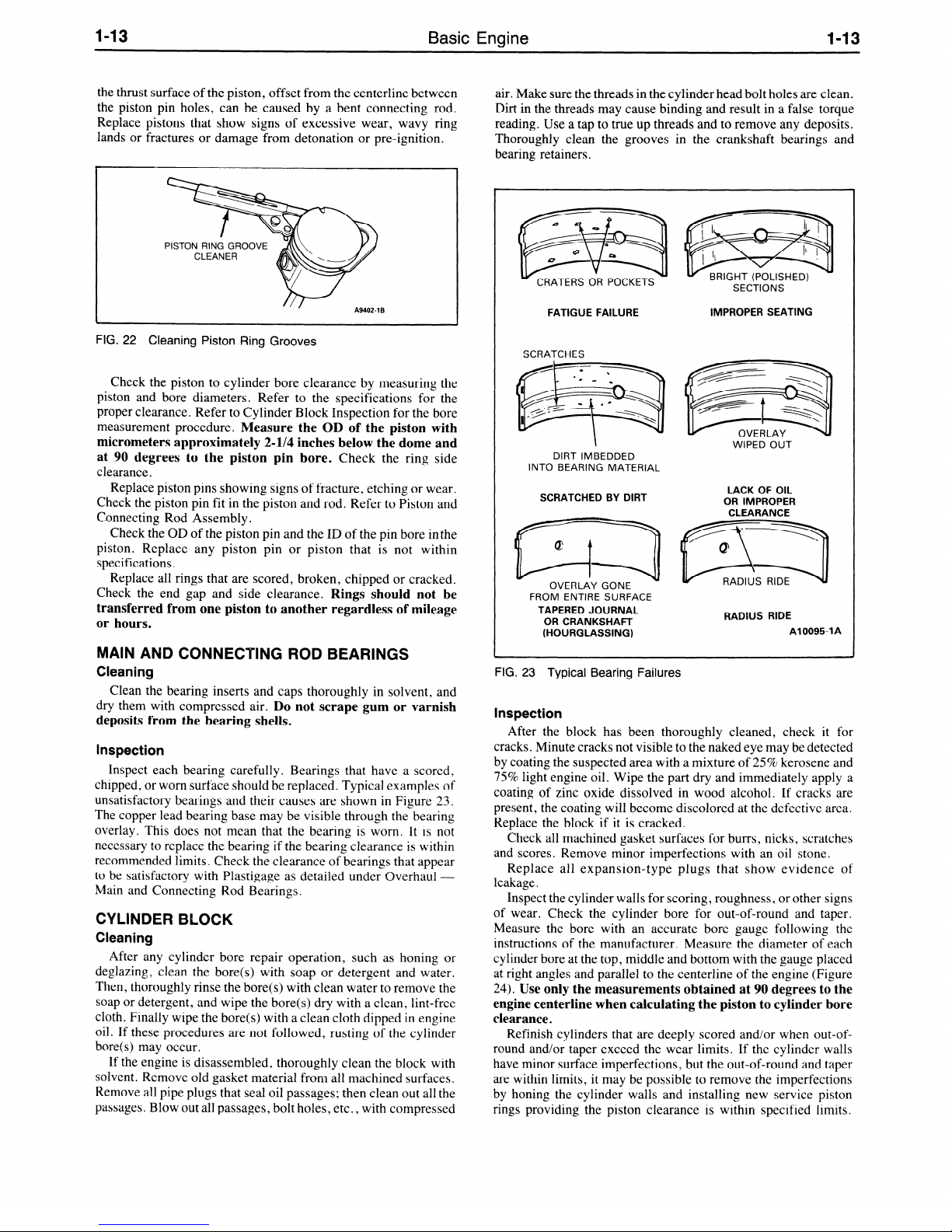

Clean the ring grooves with a ring groove cleaner (Figure 22).

Make sure the oil ring slots (or holes) are clean.

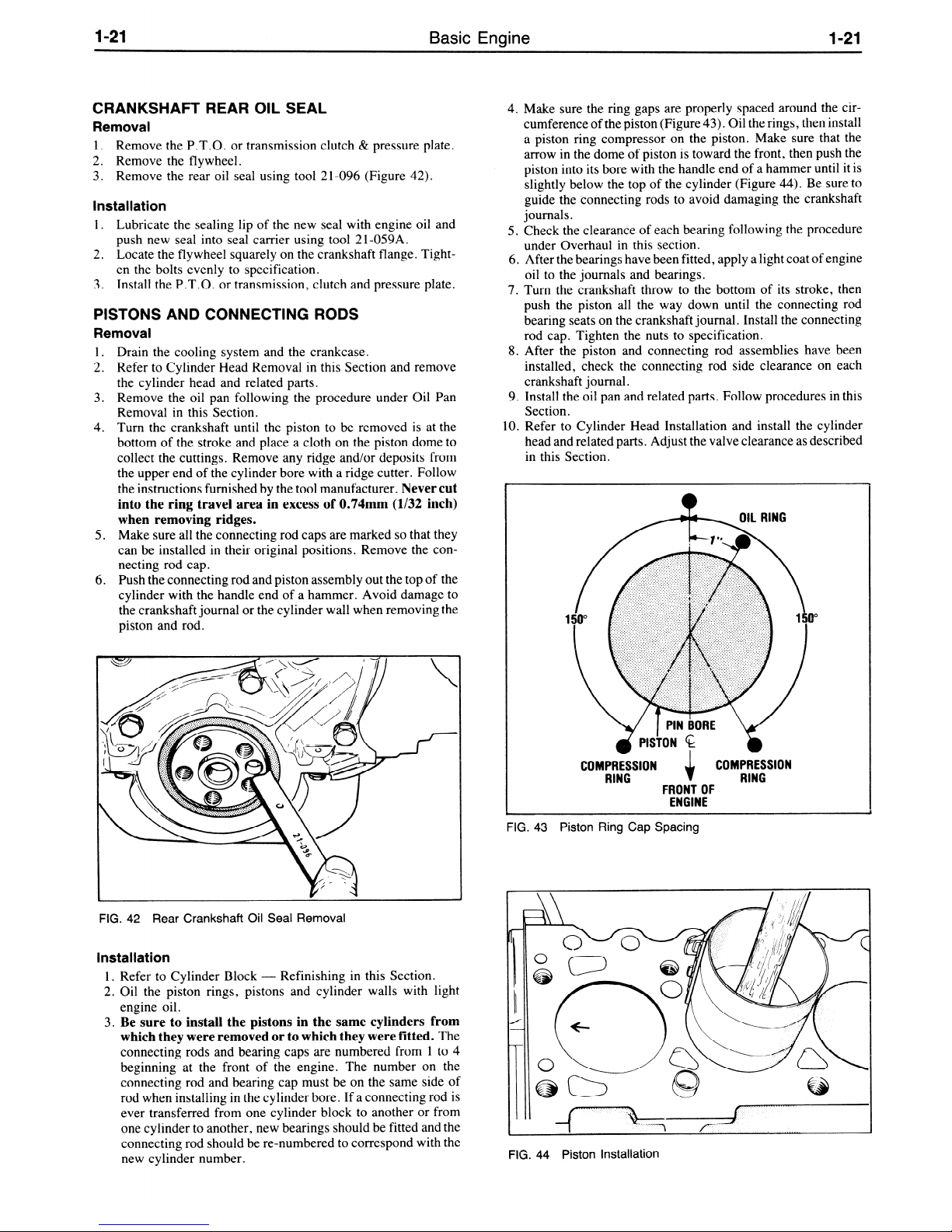

Do

FIG. 21 Crankshaft Journal Measurement

A2901-1B

Inspection

Carefully inspect the pistons for fractures at the ring lands,

skirts and pin bosses, and for scuffed, rough or scored skirts. If the

lower inner portion of the ring grooves has a high step, replacethe

piston. The step will interfere with ring operation and

excessive ring side clearance.

Spongy, eroded areas near the edge of the top of the piston are

usually caused by detonation or pre-ignition. A shiny surface on

cause

Basic Engine

1-13

the thrust surface of the piston, offset from the centerline between

the piston pin holes, can be caused by a bent connecting rod.

Replace pistons that show signs of excessive wear, wavy ring

lands or fractures or damage from detonation or pre-ignition.

air. Make sure the threads in the cylinder head bolt holes are clean.

Dirt in the threads may cause binding and result in a false torque

reading. Use a tap to true up threads and to remove any deposits.

Thoroughly clean the grooves in the crankshaft bearings and

bearing retainers.

CLEANER

FIG. 22 Cleaning Piston Ring Grooves

Check the piston to cylinder bore clearance by measuring the

piston and bore diameters. Refer to the specifications for the

proper clearance. Refer to Cylinder Block Inspection for the bore

measurement procedure.

Measure the OD of the piston with

micrometers approximately 2-I/4 inches below the dome and

at 90 degrees to the piston pin bore.

Check the ring side

clearance.

Replace piston pins showing signs of fracture, etching or wear.

Check the piston pin fit in the piston and rod. Refer to Piston and

Connecting Rod Assembly.

Check the OD of the piston pin and the ID of the pin bore inthe

piston. Replace any piston pin or piston that is not within

specifications.

Replace all rings that are scored, broken, chipped or cracked.

Check the end gap and side clearance.

Rings should not be

transferred from one piston to another regardless of mileage

or hours.

MAIN AND CONNECTING ROD BEARINGS

Cleaning

Clean the bearing inserts and caps thoroughly in solvent, and

dry them with compressed air.

Do not scrape gum or varnish

deposits from the bearing shells.

Inspection

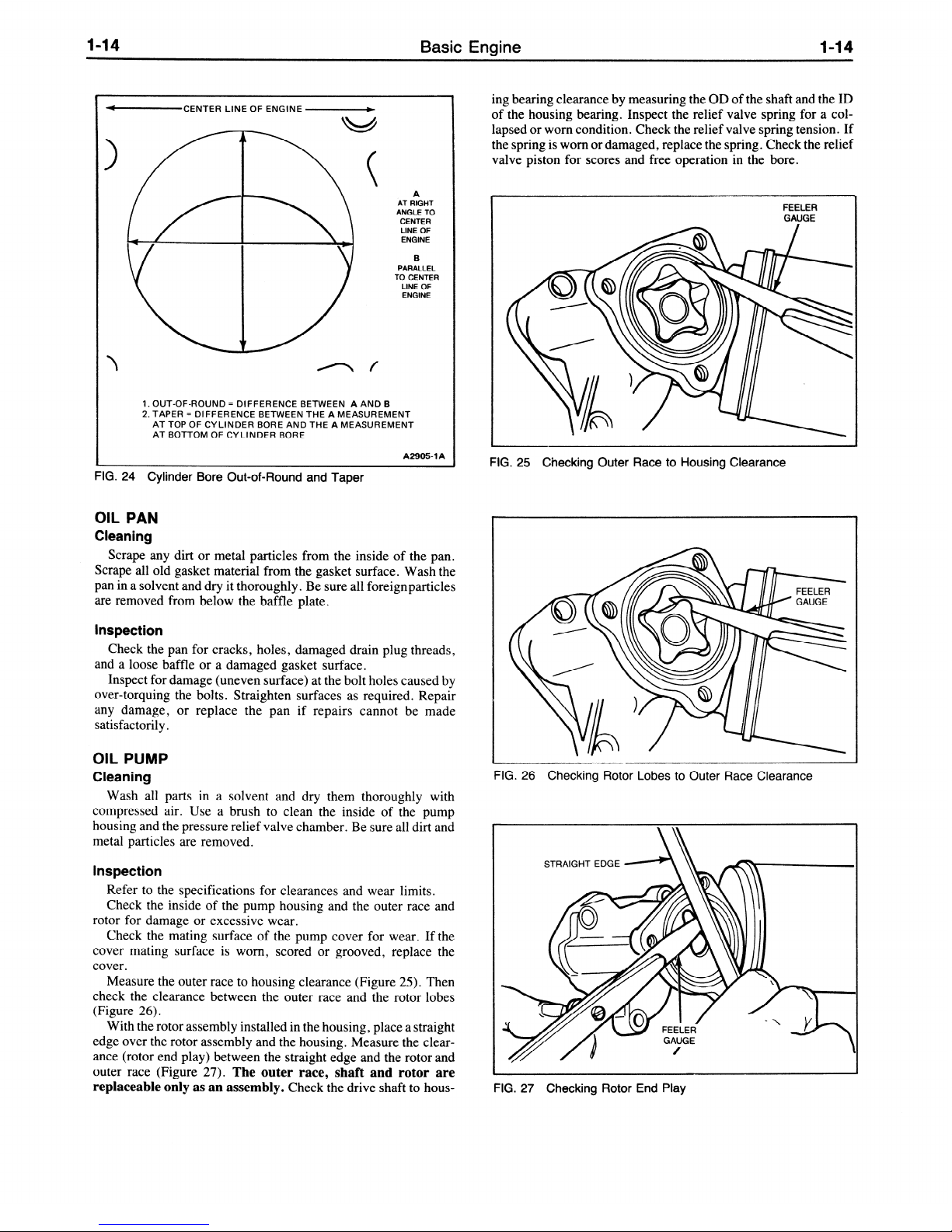

Inspect each bearing carefully. Bearings that have a scored,

chipped, or worn surface should be replaced. Typical examples of

unsatisfactory bearings and their causes are shown in Figure 23.

The copper lead bearing base may be visible through the bearing

overlay. This does not mean that the bearing is worn. It is not

necessary to replace the bearing if the bearing clearance is within

recommended limits. Check the clearance of bearings that appear

to be satisfactory with Plastigage as detailed under Overhaul Main and Connecting Rod Bearings.

CYLINDER BLOCK

Cleaning

After any cylinder bore repair operation, such as honing or

deglazing, clean the bore(s) with soap or detergent and water.

Then, thoroughly rinse the bore(s) with clean water to remove the

soap or detergent, and wipe the bore(s) dry with a clean, lint-free

cloth. Finally wipe the bore(s) with a clean cloth dipped in engine

oil. If these procedures are not followed, rusting of the cylinder

bore(s) may occur.

If the engine is disassembled, thoroughly clean the block with

solvent. Remove old gasket material from all machined surfaces.

Remove all pipe plugs that seal oil passages; then clean out all the

passages. Blow out all passages, bolt holes, etc. , with compressed

CRATERS OR

POCKETS

FATIGUE FAILURE

IMPROPER SEATING

SCRATCHES

WIPED OUT

DIRT IMBEDDED

INTO BEARING MATERIAL

SCRATCHED BY DIRT

LACK OF OIL

OR IMPROPER

CLEARANCE

ww

OVERLAY GONE

FROM ENTIRE SURFACE

TAPERED JOURNAL

OR CRANKSHAFT

(HOURGLASSING)

RADIUS RIDE

A10095-1A

FIG. 23 Typical Bearing Failures

Inspection

After the block has been thoroughly cleaned, check it for

cracks. Minute cracks not visible to the naked eye

may

be detected

by coating the suspected area with a mixture of 25% kerosene and

75% light engine oil. Wipe the part dry and immediately apply a

coating of zinc oxide dissolved in wood alcohol. If cracks are

present, the coating will become discolored at the defective area.

Replace the block if it is cracked.

Check all machined gasket surfaces for burrs, nicks, scratches

and scores. Remove minor imperfections with an oil stone.

Replace all expansion-type plugs that show evidence of

leakage a

Inspect the cylinder walls for scoring, roughness, or other signs

of wear. Check the cylinder bore for out-of-round and taper.

Measure the bore with an accurate bore gauge following the

instructions of the manufacturer. Measure the diameter of each

cylinder bore at the top, middle and bottom with the gauge placed

at right angles and parallel to the centerline of the engine (Figure

24). Use only the measurements obtained at 90 degrees to the

engine centerline when calculating the piston to cylinder bore

clearance.

Refinish cylinders that are deeply scored and/or when out-ofround and/or taper exceed the wear limits. If the cylinder walls

have minor surface imperfections, but the out-of-round and taper

are within limits, it may be possible to remove the imperfections

by honing the cylinder walls and installing new service piston

rings providing the piston clearance is within specified limits.

Basic Engine

l-14

-CENTER LINE OF ENGINE -

\

n f

A

AT RIGHT

ANGLE

TO

CENTER

LINE OF

ENGINE

B

PARALLEL

TO CENTER

LINE OF

ENGINE

1. OUT-OF-ROUND = DIFFERENCE BETWEEN A AND B

2. TAPER = DIFFERENCE BETWEEN THE A MEASUREMENT

AT TOP OF CYLINDER BORE AND THE A MEASUREMENT

AT BOTTOM OF CYLINDER BORE

A29051 A

FIG. 24

Cylinder Bore Out-of-Round and Taper

OIL PAN

Cleaning

Scrape any dirt or metal particles from the inside of the pan.

Scrape all old gasket material from the gasket surface. Wash the

pan in a solvent and dry it thoroughly. Be sure all foreignparticles

are removed from below the baffle plate.

Inspection

Check the pan for cracks, holes, damaged drain plug threads,

and a loose baffle or a damaged gasket surface.

Inspect for damage (uneven surface) at the bolt holes caused by

over-torquing the bolts . Straighten surfaces as required. Repair

any damage, or replace the pan if repairs cannot be made

satisfactorily.

OIL PUMP

Cleaning

Wash all parts in a solvent and dry them thoroughly with

compressed air. Use a brush to clean the inside of the pump

housing and the pressure relief valve chamber. Be sure all dirt and

metal particles are removed.

Inspection

Refer to the specifications for clearances and wear limits.

Check the inside of the pump housing and the outer race and

rotor for damage or excessive wear.

Check the mating surface of the pump cover for wear. If the

cover mating surface is worn, scored or grooved, replace the

cover.

Measure the outer race to housing clearance (Figure 25). Then

check the clearance between the outer race and the rotor lobes

(Figure 26).

With the rotor assembly installed in the housing, place a straight

edge over the rotor assembly and the housing. Measure the clearance (rotor end play) between the straight edge and the rotor and

outer race (Figure 27).

The outer race, shaft and rotor are

replaceable only as an assembly.

Check the drive shaft to hous-

ing bearing clearance by measuring the OD of the shaft and the ID

of the housing bearing. Inspect the relief valve spring for a col-

lapsed or worn condition. Check the relief valve spring tension. If

the spring is worn or damaged, replace the spring. Check the relief

valve piston for scores and free operation in the bore.

FEELER

GAUGE

FIG. 25 Checking Outer Race to Housing Clearance

FIG. 26 Checking Rotor Lobes to Outer Race Clearance

STRAIGHT EDGE

FIG. 27 Checking Rotor End Play

l-15

Basic Engine

REMOVAL AND INSTALLATION

VALVE ROCKER ARM COVER, ROCKER ARM

AND/OR SHAFT

Removal

1. Remove the air cleaner from the carburetor.

2. Disconnect the spark plug leads, remove them from the clip on

the rocker cover and position aside.

3. Remove the rocker cover attaching screws, remove the rocker

cover and discard the gasket.

4. Remove the rocker arm shaft attaching bolts evenly and lift off

the rocker arm shaft assembly.

5. Remove the cotter pin from one end of the shaft and slip the

flat washer, crimped washer and second flat washer off the

shaft. The rocker arm shaft supports, rocker arms and springs

can now be removed from the shaft.

6. Remove the plugs from the rocker shaft ends by drilling a hole

in one plug. Insert a long rod through the drilled plug and

knock the opposite plug out of the shaft. Remove the drilled

plug in the same manner.

7. Clean the component parts of the shaft assembly in any suit-

able degreasing fluid.

l-15

INTAKE MANIFOLD

Removal

1. Partially drain the cooling system.

2. Remove the air cleaner.

3. Disconnect the throttle rod from the carburetor throttle lever.

4. Disconnect the fuel line and the distributor vacuum line from

the carburetor.

5. Disconnect the water outlet hose and the crankcase ventilation

hose from the intake manifold.

6. Remove the attaching nut and bolts and remove the intake

manifold.

7. Remove the gasket.

8. If a new manifold is to be installed, transfer all necessary

components to the new manifold.

Installation

1. Apply a water resistant sealer to both sides of the gasket

around the water port and position it on the cylinder head.

2. Install the intake manifold and tighten the nuts and bolts

evenly to specifications.

3. Connect the water hose and the crankcase ventilation hose to

the intake manifold.

4. Connect the distributor vacuum line and the fuel supply line to

the carburetor.

5. Connect the throttle rod.

6. Install the air cleaner.

7. Refill the cooling system with the recommended coolant.

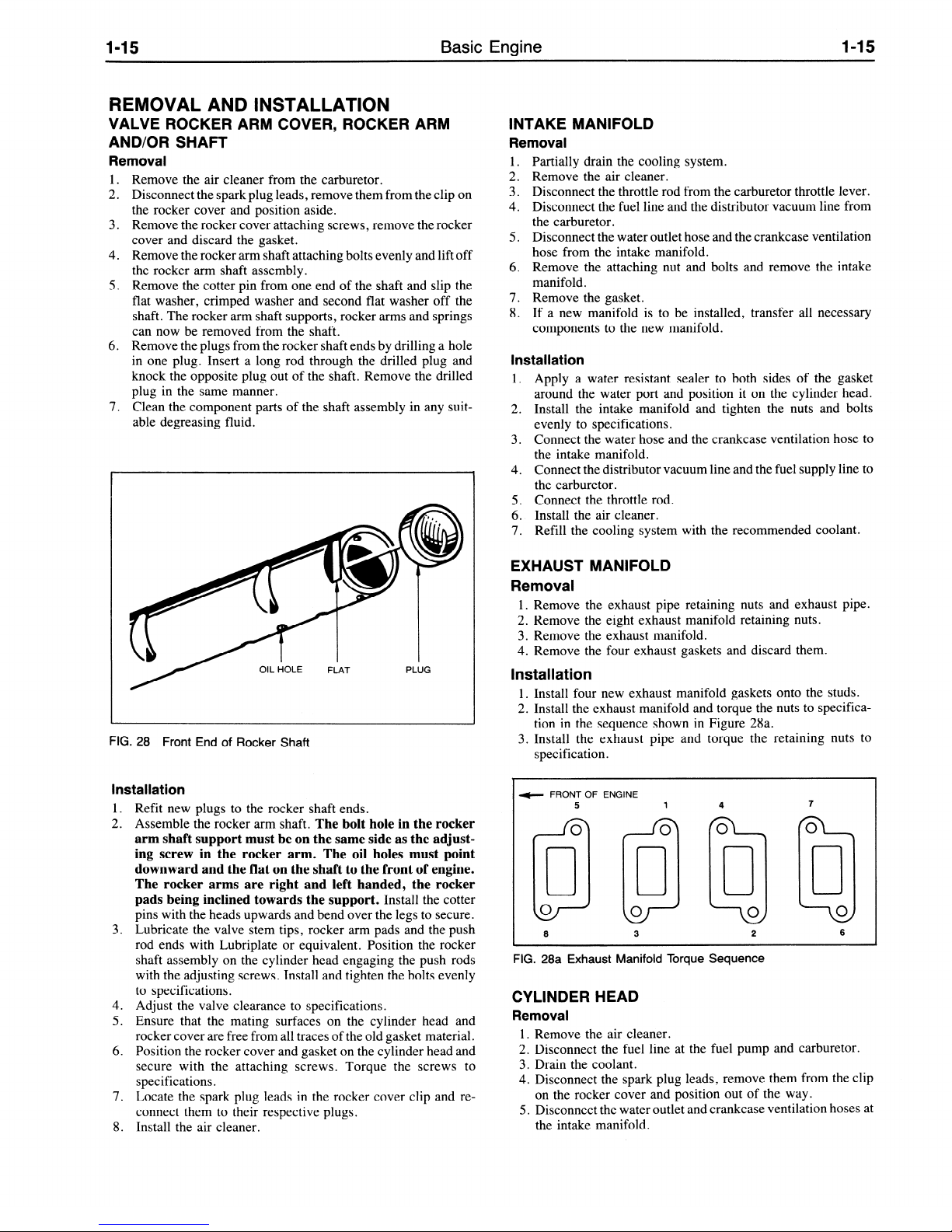

FIG. 28

Installation

1.

2.

3.

4.

5.

6.

7.

8.

Front End of Rocker Shaft

Refit new plugs to the rocker shaft ends.

Assemble the rocker arm shaft.

arm shaft support must be on the same side as the adjusting screw in the rocker arm. The oil holes must point

downward and the flat on the shaft to the front of engine.

The rocker arms are right and left handed, the rocker

pads being inclined towards the support.

pins with the heads upwards and bend over the legs to secure.

Lubricate the valve stem tips, rocker arm pads and the push

rod ends with Lubriplate or equivalent. Position the rocker

shaft assembly on the cylinder head engaging the push rods

with the adjusting screws. Install and tighten the bolts evenly

to specifications.

Adjust the valve clearance to specifications.

Ensure that the mating surfaces on the cylinder head and

rocker cover are free from all traces of the old gasket material.

Position the rocker cover and gasket on the cylinder head and

secure with the attaching screws. Torque the screws to

specifications.

Locate the spark plug leads in the rocker cover clip and reconnect them to their respective plugs.

Install the air cleaner.

The bolt hole in the rocker

Install the cotter

EXHAUST MANIFOLD

Removal

1. Remove the exhaust pipe retaining nuts and exhaust

2. Remove the eight exhaust manifold retaining nuts.

3. Remove the exhaust manifold.

4. Remove the four exhaust gaskets and discard them.

Installation

1. Install four new exhaust manifold gaskets onto the studs.

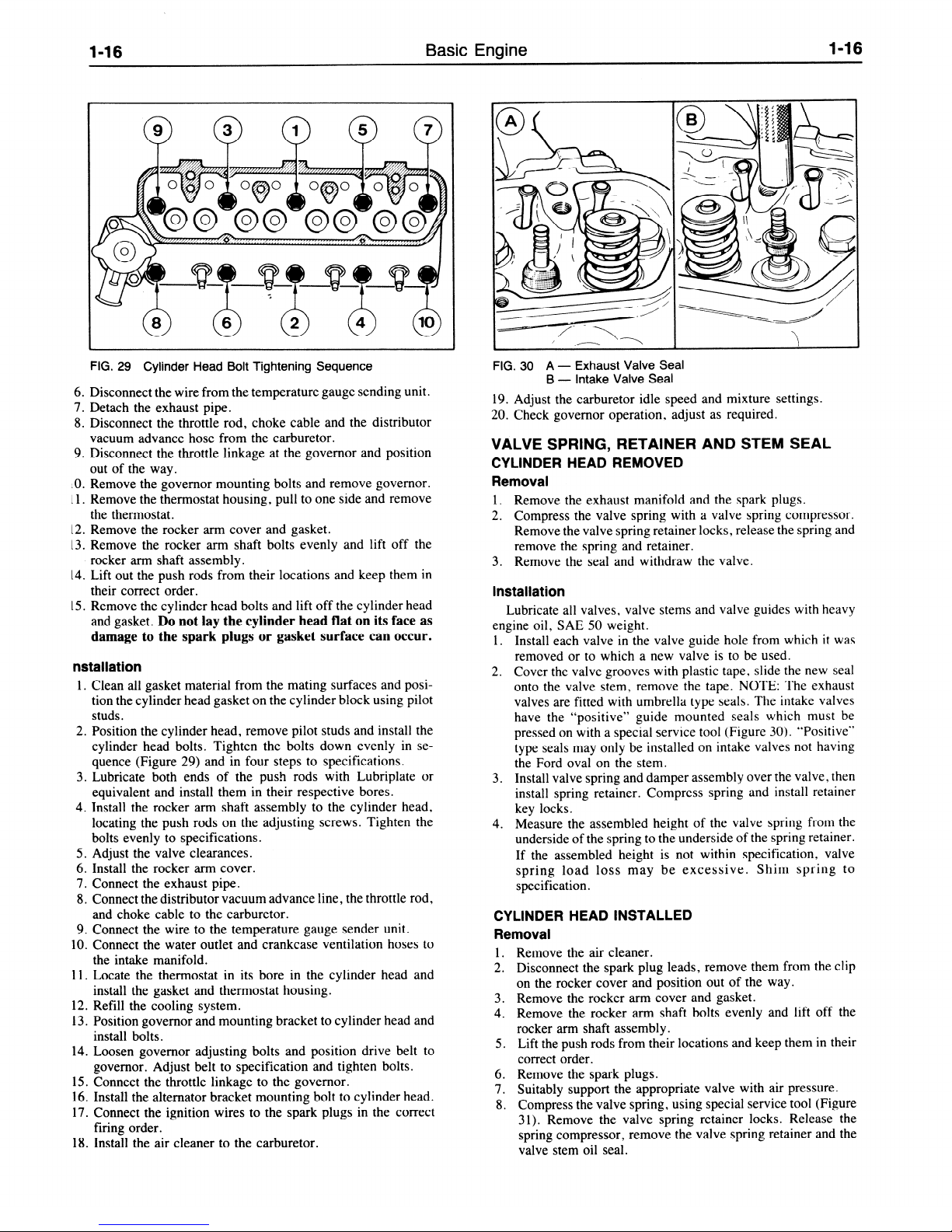

2. Install the exhaust manifold and torque the nuts to specification in the sequence shown in Figure 28a.

3. Install the exhaust pipe and torque the retaining nuts to

specification.

L

e FRONT OF ENGINE

L

FIG. 28a Exhaust Manifold Torque Sequence

CYLINDER HEAD

Removal

1. Remove the air cleaner.

2. Disconnect the fuel line at the fuel pump and carburetor.

3. Drain the coolant.

4. Disconnect the spark plug leads, remove them from the clip

5. Disconnect the water outlet and crankcase ventilation hoses at

5

0

cl

0

0

8

on the rocker cover and position out of the way.

the intake manifold.

1 4

0

cl

0

0

3

0

cl

0

0

2

pipe.

7

0

cl

0

0

6

l-15

Basic Engine

REMOVAL AND INSTALLATION

VALVE ROCKER ARM COVER, ROCKER ARM

AND/OR SHAFT

Removal

1. Remove the air cleaner from the carburetor.

2. Disconnect the spark plug leads, remove them from the clip on

the rocker cover and position aside.

3. Remove the rocker cover attaching screws, remove the rocker

cover and discard the gasket.

4. Remove the rocker arm shaft attaching bolts evenly and lift off

the rocker arm shaft assembly.

5. Remove the cotter pin from one end of the shaft and slip the

flat washer, crimped washer and second flat washer off the

shaft. The rocker arm shaft supports, rocker arms and springs

can now be removed from the shaft.

6. Remove the plugs from the rocker shaft ends by drilling a hole

in one plug. Insert a long rod through the drilled plug and

knock the opposite plug out of the shaft. Remove the drilled

plug in the same manner.

7. Clean the component parts of the shaft assembly in any suit-

able degreasing fluid.

l-15

INTAKE MANIFOLD

Removal

1. Partially drain the cooling system.

2. Remove the air cleaner.

3. Disconnect the throttle rod from the carburetor throttle lever.

4. Disconnect the fuel line and the distributor vacuum line from

the carburetor.

5. Disconnect the water outlet hose and the crankcase ventilation

hose from the intake manifold.

6. Remove the attaching nut and bolts and remove the intake

manifold.

7. Remove the gasket.

8. If a new manifold is to be installed, transfer all necessary

components to the new manifold.

Installation

1. Apply a water resistant sealer to both sides of the gasket

around the water port and position it on the cylinder head.

2. Install the intake manifold and tighten the nuts and bolts

evenly to specifications.

3. Connect the water hose and the crankcase ventilation hose to

the intake manifold.

4. Connect the distributor vacuum line and the fuel supply line to

the carburetor.

5. Connect the throttle rod.

6. Install the air cleaner.

7. Refill the cooling system with the recommended coolant.

FIG. 28

Installation

1.

2.

3.

4.

5.

6.

7.

8.

Front End of Rocker Shaft

Refit new plugs to the rocker shaft ends.

Assemble the rocker arm shaft.

arm shaft support must be on the same side as the adjusting screw in the rocker arm. The oil holes must point

downward and the flat on the shaft to the front of engine.

The rocker arms are right and left handed, the rocker

pads being inclined towards the support.

pins with the heads upwards and bend over the legs to secure.

Lubricate the valve stem tips, rocker arm pads and the push

rod ends with Lubriplate or equivalent. Position the rocker

shaft assembly on the cylinder head engaging the push rods

with the adjusting screws. Install and tighten the bolts evenly

to specifications.

Adjust the valve clearance to specifications.

Ensure that the mating surfaces on the cylinder head and

rocker cover are free from all traces of the old gasket material.

Position the rocker cover and gasket on the cylinder head and

secure with the attaching screws. Torque the screws to

specifications.

Locate the spark plug leads in the rocker cover clip and reconnect them to their respective plugs.

Install the air cleaner.

The bolt hole in the rocker

Install the cotter

EXHAUST MANIFOLD

Removal

1. Remove the exhaust pipe retaining nuts and exhaust

2. Remove the eight exhaust manifold retaining nuts.

3. Remove the exhaust manifold.

4. Remove the four exhaust gaskets and discard them.

Installation

1. Install four new exhaust manifold gaskets onto the studs.

2. Install the exhaust manifold and torque the nuts to specification in the sequence shown in Figure 28a.

3. Install the exhaust pipe and torque the retaining nuts to

specification.

L

e FRONT OF ENGINE

L

FIG. 28a Exhaust Manifold Torque Sequence

CYLINDER HEAD

Removal

1. Remove the air cleaner.

2. Disconnect the fuel line at the fuel pump and carburetor.

3. Drain the coolant.

4. Disconnect the spark plug leads, remove them from the clip

5. Disconnect the water outlet and crankcase ventilation hoses at

5

0

cl

0

0

8

on the rocker cover and position out of the way.

the intake manifold.

1 4

0

cl

0

0

3

0

cl

0

0

2

pipe.

7

0

cl

0

0

6

l-16

Basic Engine

l-16

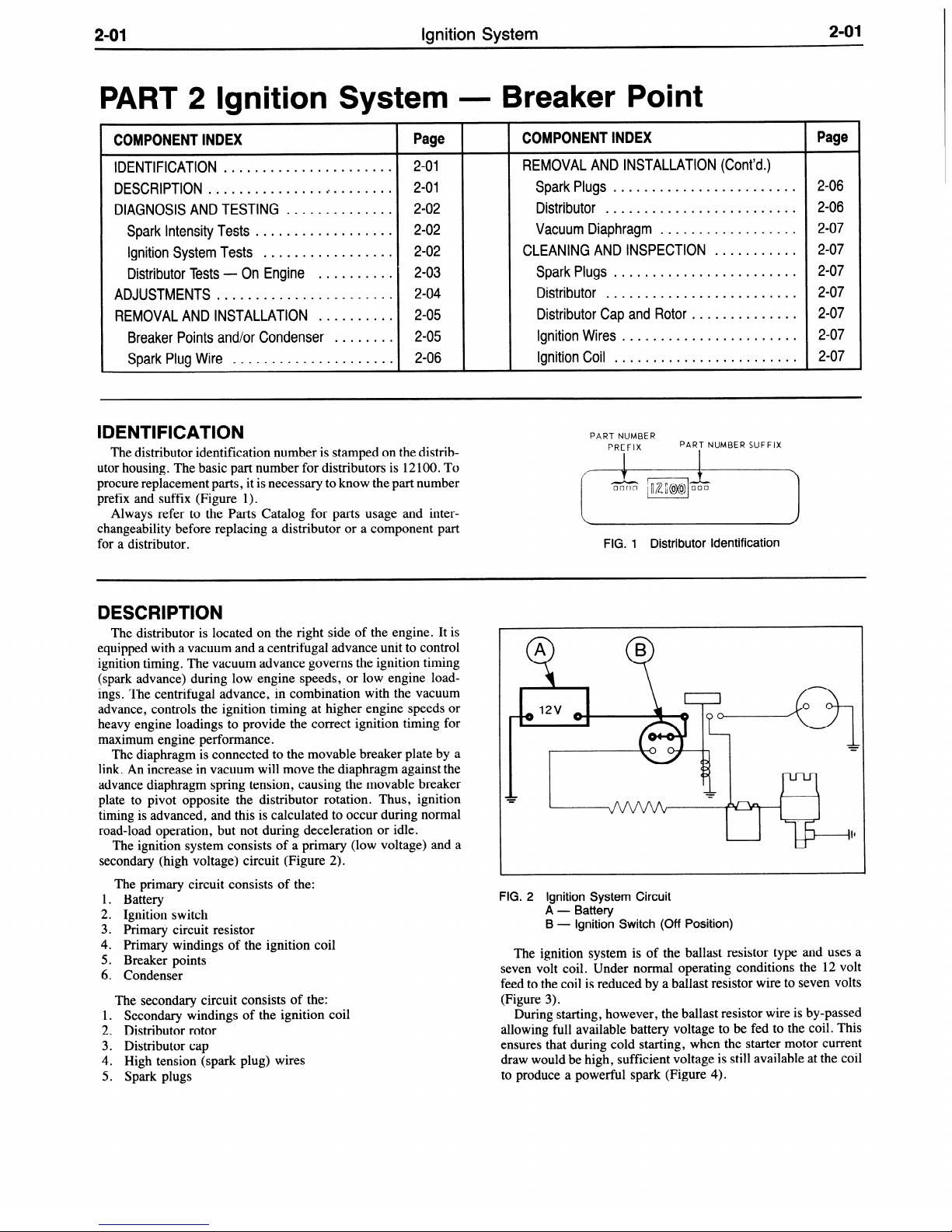

FIG. 29 Cylinder Head Bolt Tightening Sequence

6. Disconnect the wire from the temperature gauge sending unit.

7. Detach the exhaust pipe.

8. Disconnect the throttle rod, choke cable and the distributor

vacuum advance hose from the carburetor.

9. Disconnect the throttle linkage at the governor and position

out of the way.

kO. Remove the governor mounting bolts and remove governor.

Il. Remove the thermostat housing, pull to one side and remove

the thermostat.

12. Remove the rocker arm cover and gasket.

13. Remove the rocker arm shaft bolts evenly and lift off the

rocker arm shaft assembly.

14. Lift out the push rods from their locations and keep them in

their correct order.

15. Remove the cylinder head bolts and lift off the cylinder head

and gasket.

damage to the spark plugs or gasket surface can occur.

Do not lay the cylinder head flat on its face as

nstallation

1. Clean all gasket material from the mating surfaces and position the cylinder head gasket on the cylinder block using pilot

studs.

2. Position the cylinder head, remove pilot studs and install the

cylinder head bolts. Tighten the bolts down evenly in sequence (Figure 29) and in four steps to specifications.

3. Lubricate both ends of the push rods with Lubriplate or

equivalent and install them in their respective bores.

4. Install the rocker arm shaft assembly to the cylinder head,

locating the push rods on the adjusting screws. Tighten the

bolts evenly to specifications.

5. Adjust the valve clearances.

6, Install the rocker arm cover.

7. Connect the exhaust pipe.

8. Connect the distributor vacuum advance line, the throttle rod,

and choke cable to the carburetor.

9. Connect the wire to the temperature gauge sender unit.

10. Connect the water outlet and crankcase ventilation hoses to

the intake manifold.

11. Locate the thermostat in its bore in the cylinder head and

install the gasket and thermostat housing.

12. Refill the cooling system.

13. Position governor and mounting bracket to cylinder head and

install bolts.

14. Loosen governor adjusting bolts and position drive belt to

governor. Adjust belt to specification and tighten bolts.

15. Connect the throttle linkage to the governor.

16. Install the alternator bracket mounting bolt to cylinder head.

17. Connect the ignition wires to the spark plugs in the correct

firing order.

18. Install the air cleaner to the carburetor.

FIG. 30 A -

19. Adjust the carburetor idle speed and mixture settings.

20. Check governor operation, adjust as required.

Exhaust Valve Seal

Intake Valve Seal

B-

VALVE SPRING, RETAINER AND STEM SEAL

CYLINDER HEAD REMOVED

Removal

1. Remove the exhaust manifold and the spark plugs.

2. Compress the valve spring with a valve spring compressor.

Remove the valve spring retainer locks, release the spring and

remove the spring and retainer.

3. Remove the seal and withdraw the valve.

Installation

Lubricate all valves, valve stems and valve guides with heavy

engine oil, SAE 50 weight.

1. Install each valve in the valve guide hole from which it was

removed or to which a new valve is to be used.

2. Cover the valve grooves with plastic tape, slide the new seal

onto the valve stem, remove the tape. NOTE: The exhaust

valves are fitted with umbrella type seals. The intake valves

have the “positive” guide mounted seals which must be

pressed on with a special service tool (Figure 30). “Positive”

type seals may only be installed on intake valves not having

the Ford oval on the stem.

3. Install valve spring and damper assembly over the valve, then

install spring retainer. Compress spring and install retainer

key locks.

4. Measure the assembled height of the valve spring from the

underside of the spring to the underside of the spring retainer.

If the assembled height is not within specification, valve

spring load loss may be excessive. Shim spring to

specification.

CYLINDER HEAD INSTALLED

Removal

1. Remove the air cleaner.

2. Disconnect the spark plug leads, remove them from the clip

on the rocker cover and position out of the way.

3. Remove the rocker arm cover and gasket.

4. Remove the rocker arm shaft bolts evenly and lift off the

rocker arm shaft assembly.

5. Lift the push rods from their locations and keep them in their

correct order.

6. Remove the spark plugs.

7. Suitably support the appropriate valve with air pressure.

8. Compress the valve spring, using special service tool (Figure

3 1). Remove the valve spring retainer locks. Release the

spring compressor, remove the valve spring retainer and the

valve stem oil seal.

l-17

Basic Engine

l-17

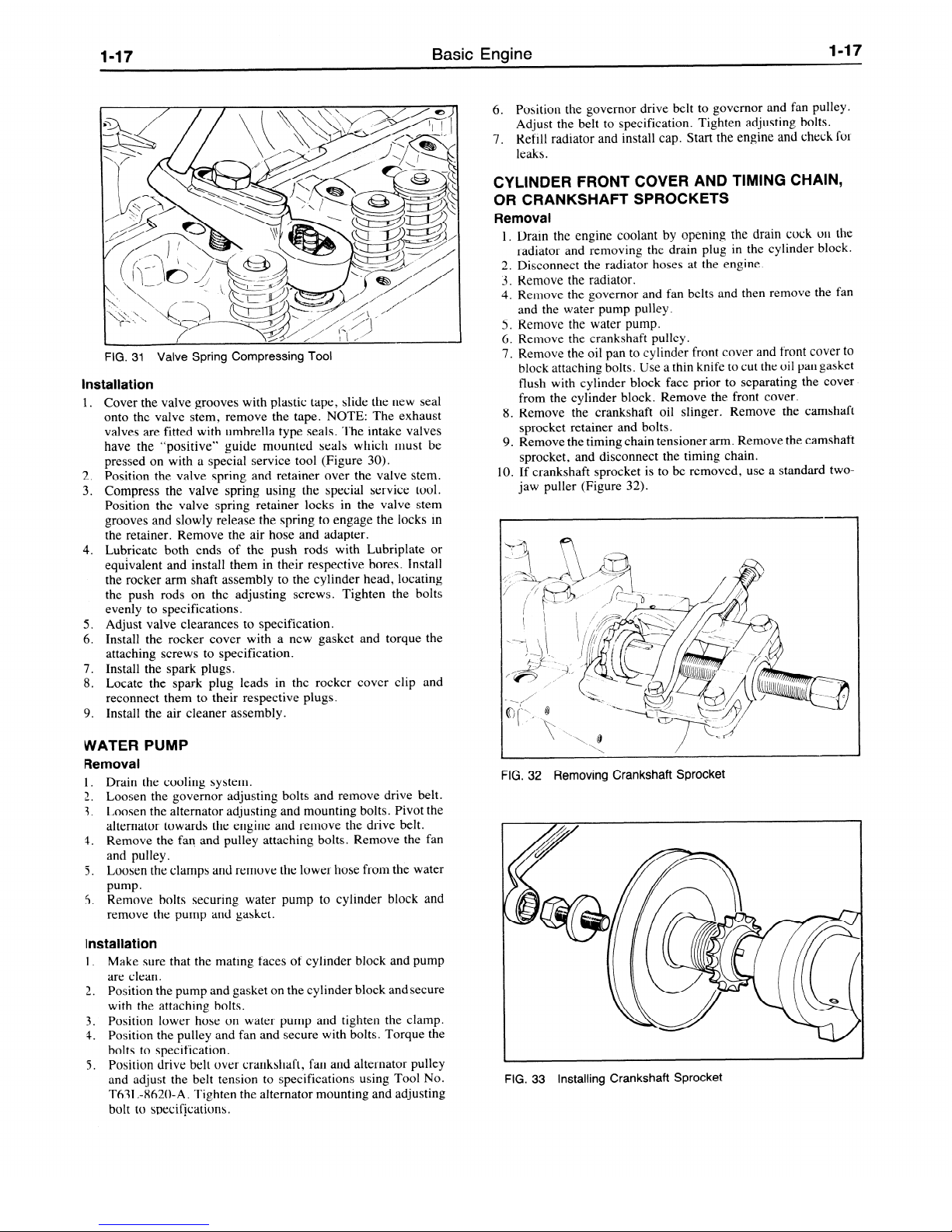

FIG. 31 Valve Spring Compressing Tool

Installation

1.

Cover the valve grooves with plastic tape, slide the new seal

onto the valve stem, remove the tape. NOTE: The exhaust

valves are fitted with umbrella type seals. The intake valves

have the “positive” guide mounted seals which must be

pressed on with a special service tool (Figure 30).

Position the valve spring and retainer over the valve stem.

Compress the valve spring using the special service tool.

Position the valve spring retainer locks in the valve stem

grooves and slowly release the spring to engage the locks in

the retainer. Remove the air hose and adapter.

Lubricate both ends of the push rods with Lubriplate or

equivalent and install them in their respective bores. Install

the rocker arm shaft assembly to the cylinder head, locating

the push rods on the adjusting screws. Tighten the bolts

evenly to specifications.

Adjust valve clearances to specification.

Install the rocker cover with a new gasket and torque the

attaching screws to specification.

Install the spark plugs.

Locate the spark plug leads in the rocker cover clip and

reconnect them to their respective plugs.

Install the air cleaner assembly.

2.

3.

4.

5.

6.

7.

8.

9.

WATER PUMP

Removal

1. Drain the cooling system.

2. Loosen the governor adjusting bolt,s and remove drive belt.

3. Loosen the alternator adjusting and mounting bolts. Pivot the

alternator towards the engine and remove the drive belt.

4. Remove the fan and pulley attaching bolts. Remove the fan

and pulley. .

5. Loosen the clamps and remove the lower hose from the water

Pump*

5. Remove bolts securing water pump to cylinder block and

remove the pump and gasket.

Installation