Ford Thunderbird 1966 Shop Manual

1966

FORD

SHOP

MA

Copyright © 2009, Forel Publishing Company, LLC, Woodbridge, Virginia

All Rights Reserved. No part of this book may be used or reproduced in any manner whatsoever

without written permission of Forel Publishing Company, LLC. For information write to Forel

Publishing Company, LLC, 3999 Peregrine Ridge Ct., Woodbridge, VA 22192

1966 Ford Thunderbird Shop Manual

EAN: 978-1-60371-016-9

ISBN: 1-60371-016-7

Forel Publishing Company, LLC

3999 Peregrine Ridge Ct.

Woodbridge, VA 22192

Email address: webmaster@ForelPublishing.com

Website: http://www.ForelPublishing.com

This publication contains material that is reproduced and distributed under a license from Ford

Motor Company. No further reproduction or distribution of the Ford Motor Company material is

allowed without the express written permission of Ford Motor Company.

NNoottee ffrroomm tthhee EEddiittoorr

This product was created from the original Ford Motor Company’s publication. Every effort has

been made to use the original scanned images, however, due to the condition of the material;

some pages have been modified to remove imperfections.

Although every effort was made to ensure the accuracy of this book, no representations or

warranties of any kind are made concerning the accuracy, completeness or suitability of the

information, either expressed or implied. As a result, the information contained within this book

should be used as general information only. The author and Forel Publishing Company, LLC

shall have neither liability nor responsibility to any person or entity with respect to any loss or

damage caused, or alleged to be caused, directly or indirectly by the information contained in

this book. Further, the publisher and author are not engaged in rendering legal or other

professional services. If legal, mechanical, electrical, or other expert assistance is required, the

services of a competent professional should be sought.

Disclaimer

GROUP

INDEX

Imrnf^k

mI"**

m^

m^ll

pffllik

liwik

^J5^)SERVICE

PUBLICATIONS

FIRST

PRINTING

AUGUST,

1985

1965

FORD

MOTOR

COMPANY.

DEARBORN,

MICHIGAN

Reproduced

under

License

#

5008

from

Ford

Motor

Company

-

May

2000

CHICLE

IDENTIFICATION

DRIVE

SHAFT

AND

CLUTCH

MANUAL

SHIFT

TRANSMISSION

(Not

Applicable)

AUTOMATIC

TRANSMISSION

mH

ENGINE

.

\WL%\mjB/nKmKKMmmmmMm^

mm.

a

m^^simWimK^aBMkm^iwm^am^mm^mwm^Mmwm^m^mwKM

IGNITION

SYSTEM

BB

FUEL

SYSTEM

ITS1

121

1^

COOLING

SYSTEM

MM

EXHAUST

SYSTEM

J^Mj

CHARGING

SYSTEM

STARTING

SYSTEM

UGHTJNG

SYSTEM,

HORNS

AND

INSTRUMENTS

VENTILATING,

HEATING

AND

ACCESSORIES

BODY,

DOORS

AND

WINDOWS

TRIM,

SEATS

AND

CONVERTIBLE

TOP

fTTI

haWaaal

MAINTENANCE

SCHEDULE

MAINTENANCE

OPERATIONS

LUBRICATION

CHARTS

AND

SPECIFICATIONS

SCHEMATICS

20

SPECIFICATIONS

AND

SPECIAL

SERVICE

TOOLS

AT

END

OF

EACH

GROUP

FOREWORD

This

shop

manual

provides

the

Service

Technician

with

complete

information

for

the

proper

servicing

of

the

1966

Thunderbird

The

information

is

grouped

according

to the

type

of

work

being

performed,

such

as

diagnosis

and

testing,

frequently

performed

adjustments

and

repairs,

in-vehicle

adjustments,

overhaul,

etc.

Specifications

and

recom

mended special

tools

are

included.

Refer

to

the

opposite

page

for

important

vehicle

identi

fication

data.

The

descriptions

and

specifications

in

this

manual

were

in

effect

at

the

time

this

manual

was

approved

for

print

ing.

The

Ford

Motor

Company

reserves

the

right

to

discontinue

models

at

any

time,

or

change

specifications

or

design,

without

notice

and

without

incurring

obligation,

^d

SERVICE

PUBLICATIONS

1-1

\/ri

iif*i

p

IDENTIFICATION

GROUP

1

EXTERIOR

PAINT

COLOR

(WHITE)

BODY

STYLE

\

(2

DOOR

HARDTOP)

\

DATE

CODE

(26TH

DAY

AUGUST)

INTERIOR

TRIM

SILVER

MINK

DETROIT

DISTRICT

AXLE

RATIO

CODE

(3.00:1

AXLE

RATIO)

TRANSMISSION

CODE

(C6

DUAL

RANGE

AUTOMATIC)

BODY//

COLORJ

TRIIVUJ

DATE//

dso/

U

AXLE

ILTRANS

63A

M.'

21

'

26H

33

N

N

j

VEHICLE

WARRANTY

NUMBER

\\OT

\pR

TITLE

Q

>N

PURPOSES

.

,

IEWS

MANUFACTURED

UNDER

UNITED

STATES

D

CTOEI&N

PATENTS

AND

PATENT

APPLICATIONS

A

P\\ODl\VT

OF

lt^^

y

MOTOR

COMPANY

MODEL

YEAR

(1966)

ASSEMBLY

PLANT

(WIXOM)

-\-

CONSECUTIVE UNIT

NUMBER

^ENGINE

CODE

(8

CYL.

390

CID

ENGINE)

BODY

SERIAL

CODE

(2-DOOR

HARDTOP)

Fig.

1

-Thunderbird

Warranty

Plate

M

1087-D

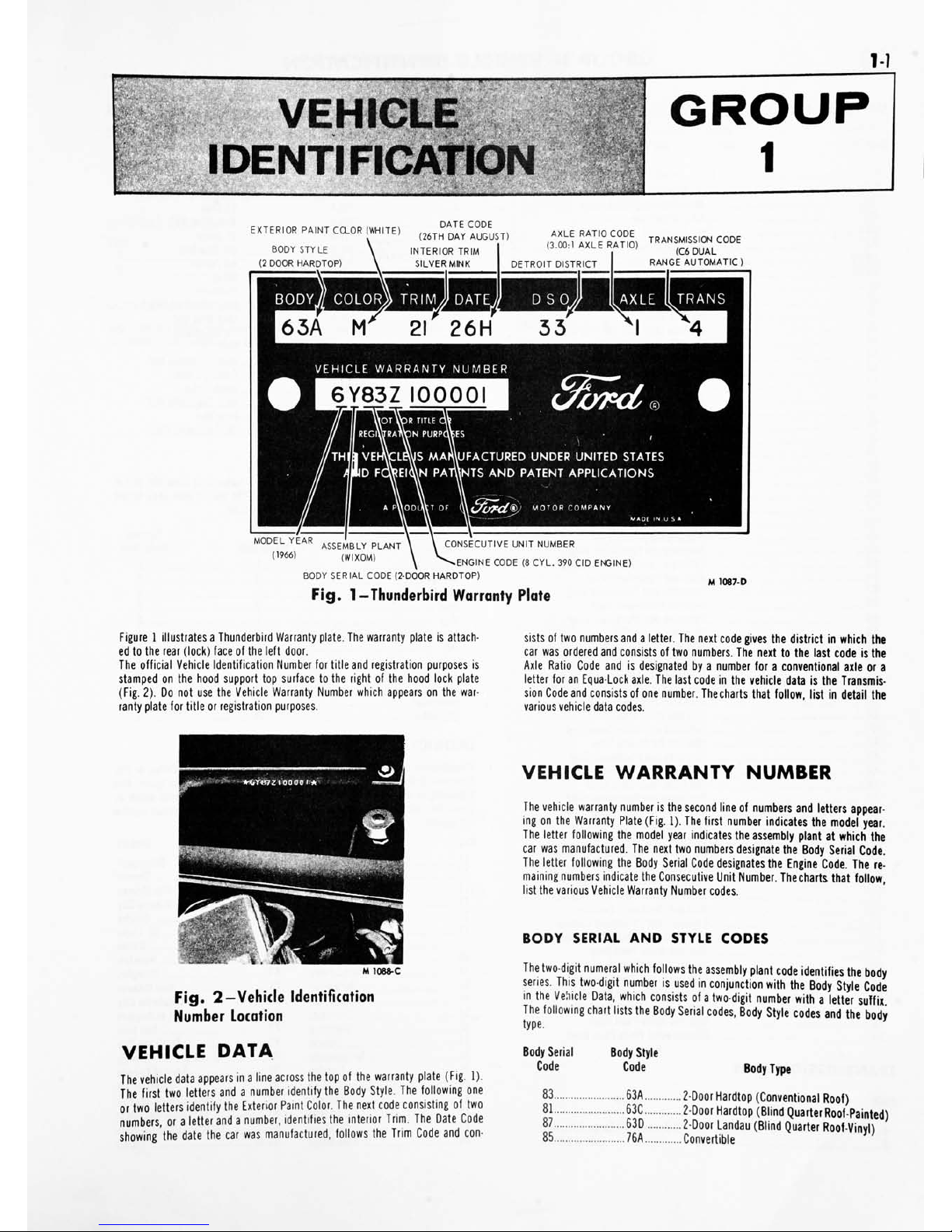

Figure1illustrates

a

Thunderbird

Warranty

plate.

The

warranty

plate

is

attach

ed

to

the

rear

(lock)

face

of

the

left

door.

The

official

Vehicle

Identification

Number

for

title

and

registration

purposes

is

stamped

on

the

hood

support

top

surface

to

the

right

of

the

hood

lock

plate

(Fig. 2).

Do

not

use

the

Vehicle

Warranty

Number

which

appears

on

the

war

ranty

plate

for

title

or

registration

purposes.

sists

of

two

numbers

and

a

letter.

The

next

code

gives

the

district

in

which

the

car

was

ordered

and

consists

of

two

numbers.

The

next

to

the

last

code

is

the

Axle

Ratio Code

and

is

designated

by

a

number

for

a

conventional

axle

or

a

letter

for

an

Equa-Lock

axle.

The

last

code

in

the

vehicle

data

is

the

Transmis

sion

Code

and

consists

of

one

number.

The

charts

that

follow,

list

in

detail

the

various

vehicle

data

codes.

M

1088-C

Fig.

2

-Vehicle

Identification

Number

Location

VEHICLE

DATA

The

vehicle

data

appears

inaline

across

the

top

of

the

warranty

plate

(Fig.

1).

The

first

two

letters

and

a

number

identify

the

Body

Style.

The

following

one

or

two

letters

identify

the

Exterior

Paint

Color.

The

next

code

consisting

of

two

numbers,

or

a

letter

and

a

number,

identifies

the

interior

Trim.

The

Date

Code

showing

the

date

the

car

was

manufactured,

follows

the

Trim

Code

and

con-

VEHICLE

WARRANTY

NUMBER

The

vehicle

warranty

number

is

the

second

line

of

numbers

and

letters

appear

ing

on

the

Warranty

Plate

(Fig.

1).

The

first

number

indicates

the

model

year.

The

letter

following

the

model

year

indicates

the

assembly

plant

at

which

the

car

was

manufactured.

The

next

two

numbers

designate

the

Body

Serial

Code.

The

letter

following

the

Body

Serial

Code

designates

the

Engine

Code.

The

re

maining

numbers

indicate

the

Consecutive

Unit

Number.

Thecharts

that

follow,

list

the

various

Vehicle

Warranty

Number

codes.

BODY

SERIAL

AND

STYLE

CODES

The

two-digit

numeral

which

follows

the

assembly

plant

code

identifies

the

body

series.

This

two-digit

number

is

used

in

conjunction

with

the

Body

Style

Code

in

the

Vehicle

Data,

which

consists

of

a

two-digit

number

with

a

letter

suffix

The

following

chart

lists

the

Body

Serial

codes,

Body

Style

codes

and

the

body

type.

Body

Serial

Body

Style

Code

Code

Body

Type

83

63A

2-Door

Hardtop

(Conventional

Roof)

81

63C

2-Door

Hardtop

(Blind

Quarter

Roof-Painted)

87

63D

2-Door

Landau

(Blind

Quarter

Roof-Vinvh

85

76A

Convertible

1}

12

GROUP

1-

VEHICLE

IDENTIFICATION

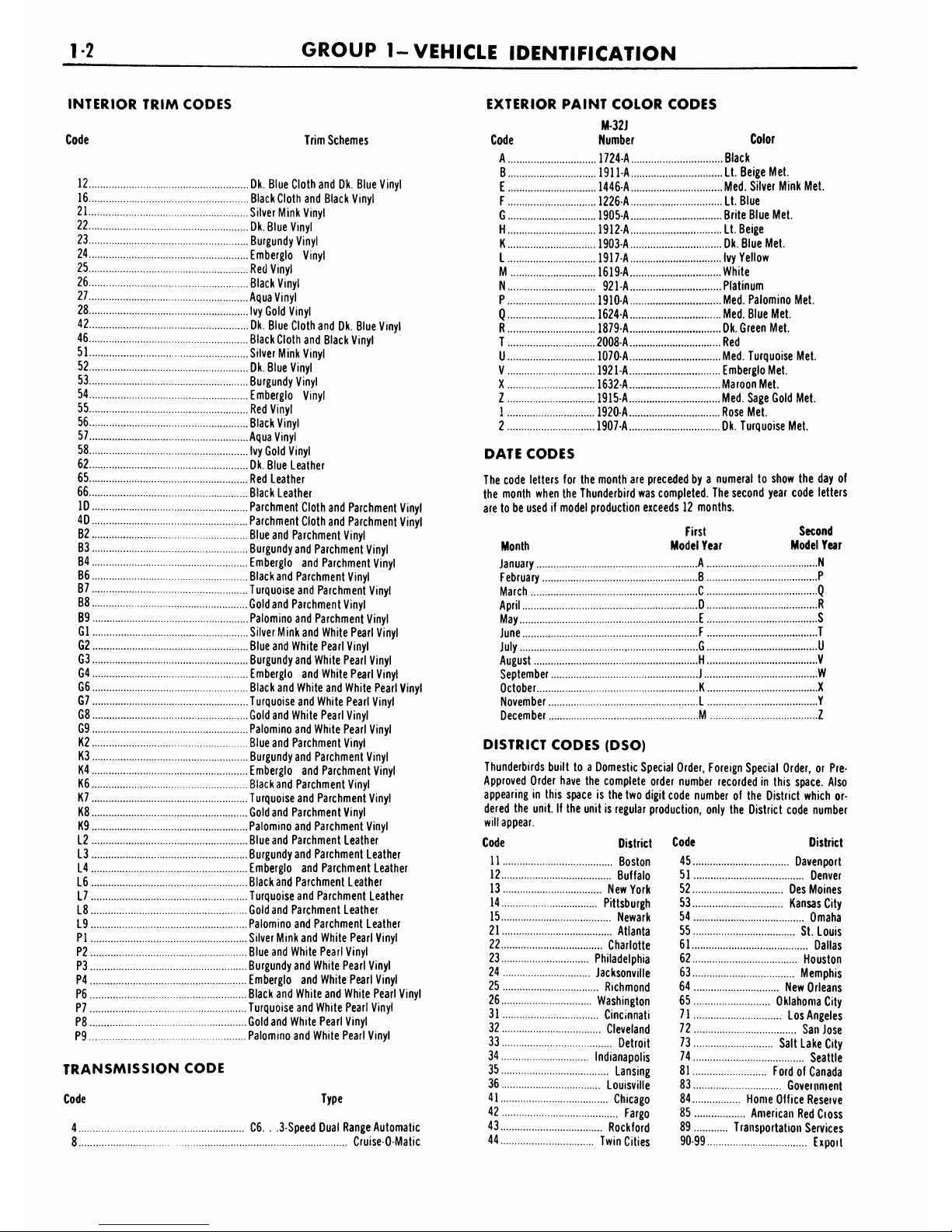

INTERIOR TRIM

CODES

Code

Trim

Schemes

12

Dk.

Blue

Cloth

and

Dk.

Blue

Vinyl

16

Black

Cloth

and

Black

Vinyl

21

Silver

Mink

Vinyl

22

Dk.

Blue

Vinyl

23

Burgundy

Vinyl

24

Emberglo

Vinyl

25

Red

Vinyl

26

Black

Vinyl

27

Aqua

Vinyl

28

Ivy

Gold

Vinyl

42

Dk.

Blue

Cloth

and

Dk.

Blue

Vinyl

46

Black

Cloth

and

Black

Vinyl

51

Silver

Mink

Vinyl

52

Dk.

Blue

Vinyl

53

Burgundy

Vinyl

54

Emberglo

Vinyl

55

Red

Vinyl

56

Black

Vinyl

57

Aqua

Vinyl

58

Ivy

Gold

Vinyl

62

Dk.

Blue

Leather

65

Red

Leather

66

Black

Leather

ID

Parchment

Cloth

and

Parchment

Vinyl

40

Parchment

Cloth

and

Parchment

Vinyl

B2

Blue

and

Parchment

Vinyl

B3

Burgundy

and

Parchment

Vinyl

B4

Emberglo

and

Parchment

Vinyl

B6

Blackand

Parchment

Vinyl

B7

Turquoise

and

Parchment

Vinyl

B8

Gold

and

Parchment

Vinyl

B9

Palomino

and

Parchment

Vinyl

Gl

Silver

Mink

and

White

Pearl

Vinyl

G2

Blue

and

White

Pearl

Vinyl

G3

Burgundy

and

White

Pearl

Vinyl

G4

Emberglo

and

White

Pearl

Vinyl

G6

Black

and

White

and

White

Pearl

Vinyl

G7

Turquoise

and

White

Pearl

Vinyl

G8

Gold

and

White

Pearl

Vinyl

G9

Palomino

and

White

Pearl

Vinyl

K2

Blue

and

Parchment

Vinyl

K3

Burgundy

and

Parchment

Vinyl

K4

Emberglo

and

Parchment

Vinyl

K6

Blackand

Parchment

Vinyl

K7

Turquoise

and

Parchment

Vinyl

K8

Gold

and

Parchment

Vinyl

K9

Palomino

and

Parchment

Vinyl

L2

Blue

and

Parchment

Leather

L3

Burgundy

and

Parchment

Leather

L4

Emberglo

and

Parchment

Leather

L6

Blackand

Parchment Leather

L7

Turquoise

and

Parchment

Leather

L8

Gold

and

Parchment

Leather

L9

Palomino

and

Parchment

Leather

PI

Silver

Mink

and

White

Pearl

Vinyl

P2

Blue

and

White

Pearl

Vinyl

P3

Burgundy

and

White

Pearl

Vinyl

P4 Emberglo

and

White

Pearl

Vinyl

P6

Black

and

White

and

White

Pearl

Vinyl

P7

Turquoise

and

White

Pearl

Vinyl

P8

Gold

and

White

Pearl

Vinyl

P9

Palomino

and

White

Pearl

Vinyl

TRANSMISSION

CODE

Code

4

EXTERIOR

PAINT

COLOR

CODES

M-32J

Code

Number

Color

A

1724-A

Black

B

1911

A

Lt.

Beige

Met.

E

1446-A

Med.

Silver

Mink

Met.

F

1226-A

Lt.

Blue

G

1905-A

Brite

Blue

Met.

H

1912-A

Lt.

Beige

K

1903-A

Dk.

Blue

Met.

L

1917-A

Ivy

Yellow

M

1619-A

White

N

921-A

Platinum

P

1910-A

Med.

Palomino

Met.

Q

1624-A

Med.

Blue

Met.

R

1879-A

Dk.

Green Met.

T

2008-A Red

U

1070-A

Med.

Turquoise

Met.

V

1921

A

Emberglo

Met.

X

1632-A

Maroon

Met.

Z

1915-A

Med.

Sage

Gold

Met.

1

1920-A

Rose

Met.

2

1907-A

Dk.

Turquoise

Met.

DATE

CODES

The

code

letters

for

the

month

are preceded

by

a

numeral

to

show

the

day

of

the

month

when

the

Thunderbird

was

completed.

The

second

year code

letters

are

to

be

used

if

model

production

exceeds

12

months.

First

Second

Month

Model

Year

Model

Year

January

A

N

February

B

P

March

C

Q

April

D

R

May

E

S

June

F

T

July

G

U

August

H

V

September

J

W

October

K

X

November

L

Y

December

M

Z

DISTRICT

CODES

(DSO)

Thunderbirds

built

to

a

Domestic Special

Order,

Foreign

Special

Order,

or

Pre-

Approved

Order

have

the

complete

order

number

recorded

in

this

space.

Also

appearing

in

this

space

is

the

two

digit

code

number

of

the

District

which

or

dered the

unit.

If

the

unit

is

regular

production,

only

the

District

code

number

will

appear.

Code

District

Code

District

C6.

Type

3

Speed

Dual

Range

Automatic

Cruise-O-Matic

11

Boston

12

Buffalo

13

New

York

14

Pittsburgh

15

Newark

21

Atlanta

22

Charlotte

23

Philadelphia

24

Jacksonville

25

Richmond

26

Washington

31

Cincinnati

32

Cleveland

33

Detroit

34

Indianapolis

35

Lansing

36

Louisville

41

Chicago

42

Fargo

43

Rockford

44

Twin

Cities

45

Davenport

51

Denver

52

Des

Moines

53

Kansas

City

54

Omaha

55

St.

Louis

61

Dallas

62

Houston

63

Memphis

64

New

Orleans

65

Oklahoma

City

71

Los

Angeles

72

San

Jose

73

Salt

Lake

City

74

Seattle

81

Ford

of

Canada

83

Government

84

Home

Office

Reseive

85

American

Red

Cioss

89

Transportation

Services

90-99

Expoit

PART

1-VEHICLE

IDENTIFICATION

1-3

REAR

AXLE

RATIO

CODE

Code

Ratio

1

3.00:1

3

3.20:1

6

2.80:1

ENGINE

CODES

Code

Type

Z

8

Cylinder

390

Cubic

Inch

(4

barrel)

Q

8

Cylinder

428

Cubic

Inch

(4

barrel)

CONSECUTIVE

UNIT

NUMBER

The

assembly

plant,

with

each

model

year,

begins

with

consecutive

unit

num

ber

100001

and

continues

on

for

each

unit

built.

ASSEMBLY

PLANT

CODES

Code

Letter

Assembly

Plant

A

Atlanta

B

Oakville

Passenger

C

Ontario

Truck

D

Dallas

E

Mahwah

G

Chicago

H

Lorain

J

Los

Angeles

K

Kansas

City

L

Michigan

Truck

MODEL

YEAR

The

number

6

designates

1966

Code

Letter

Assembly

Plant

N

Norfolk

p

Twin

Cities

R

San

Jose

S

Pilot

Plant

T

Metuchen

U

Louisville

W

Wayne

Y

Wixom

Z

St.

Louis

2-1

GROUP

PART

2-1

GENERAL

BRAKE

SERVICE

PART

2-2

BRAKE

SYSTEM

PAGE

PART

2-3

. .

2-1

SPECIFICATIONS

PAGE

.

2.22

2-7

PART

2-1

GENERAL

BRAKE

SERVICE

Section

Page

1

Diagnosis

and

Testing

2-1

Preliminary

Tests

2-1

Road

Test

2-1

Disc

Brake

Trouble

Symptoms

and

Possible

Causes

2-2

Drum

Brake

Trouble

Symptoms

and

Possible

Causes

2-3

2

Common

Adjustments

and

Repairs

2-4

Section

Page

Parking

Brake

Linkage

Adjustment

2-4

Power

Brake

Master

Cylinder

Push

Rod

Adjustment

2-4

Hydraulic

System

Bleeding

2-4

3

Cleaning

and

Inspection

2-5

Disc

Brakes 2-6

Drum

Brakes

2-6

Booster

Unit

2-6

DIAGNOSIS

AND

TESTING

PRELIMINARY

TESTING

1.

Check

the

fluid

level

in

the

master

cylinder,

and

add

Rotunda

R103-A

Super

Heavy

Duty

brake

fluid

(B7AZ-19542-A)

if

required.

2.

Push

the

brake

pedal

down

as

far

as

it

will

go

while

the

engine

is

running

or

vacuum

is

in

the

system

and

the

car

is

standing

still.

If

the

pedal

travels

to

a

point

less

than

1

inch

from

the

floor

pan,

check

the

brake

adjustment

and

the

automatic

adjusters.

To

check

rear

brake

adjuster

opera

tion,

check

the

shoes

and

the

adjuster

components

for

binding

or

improper

installation

and

follow

the

procedure

described

under

Brake

Shoe

Ad

justments

in

Part

2-2,

Section

2.

Make

several

reverse

brake

stops

to

ensure

uniform

adjustment

at

the

rear

wheels.

On

front

disc

brakes,

the

automatic

adjustment

is

a

permanent

built-in

feature.

3.

With

the

transmission

in

neutral,

stop

the

engine

and

apply

the

parking

brake.

Depress

the

service

brake

pedal

several

times

to

exhaust

all

vacuum

in

the

system.

Then,

depress

the

pedal

and

hold

it

in

the

applied

position.

Start

the

engine.

If

the

vacuum

system

is

operating,

the

pedal

will

tend

to

fall

away

under

foot

pressure

and

less

pressure

will

be

required

to

hold

the

pedal

in

the

applied

position.

If

no

ac

tion

is

felt,

the

vacuum

booster

system

is

not

functioning.

4.

With

the

engine

shut

off,

ex

haust

all

vacuum

in

the

system.

Depress

the

brake

pedal

and

hr'd

it

in

the

applied

position.

Ifthepc

ually

falls

away

under

thi?

the

hydraulic

system

is

lea!.

all

tubing,

hoses,

calipers,

cylinders,

and

connections

for

leaks.

If

the

brake

pedal

movement

feels

spongy,

bleed

the

hydraulic

system

to

remove

air

from

the

lines

and

cylinder.

See

Hydraulic

System

Bleed

ing,

Section

2.

Also,

check

for

leaks

or

insufficient

fluid.

5.

Should

one

of

the

brakes

be

locked

and

the

car

must

be

moved,

open

the

bleeder

screw

long

enough

to

let

out

a

few

drops

of

brake

fluid.

This

bleeding

operation

will

release

the

brakes,

but

it

will

not

correct

the

cause

of

the

trouble.

ROAD

TEST

The

car

should

be

road

tested

only

if

the

brakes

will

safely

stop

the

car.

Apply

the

brakes

at

a

speed

of

25-30

mph

to

check

for

the

existence

of

the

trouble

symptoms

listed

in

Table

1,

with

the

exception

of

brake

chatter

and

those

symptoms

resolved

in

the

preliminary

tests.

For

each

of

the

symptoms

encountered,

check

and

eliminate

the

causes

which

are

also

listed

in

Table

1.

To

check

for

brake

chatter

or

surge,

apply

the

brakes

lightly

at

approximately

50

mph.

Chatter

or

surge

will

apply

almost

en

tirely

to

rear

brakes

only.

For

booster

removal

and

installa

tion

procedures,

refer

to

Part

2-2,

Sec

tion

3.

No

service

repairs,

other

than

adjustment

of

the

push

rod,

are

made

onjhfcrfco-oster.

Replace

the

assembly

Avlien

the

booster

is

determined

to

be

defective.

2-2

GROUP

2

-BRAKES

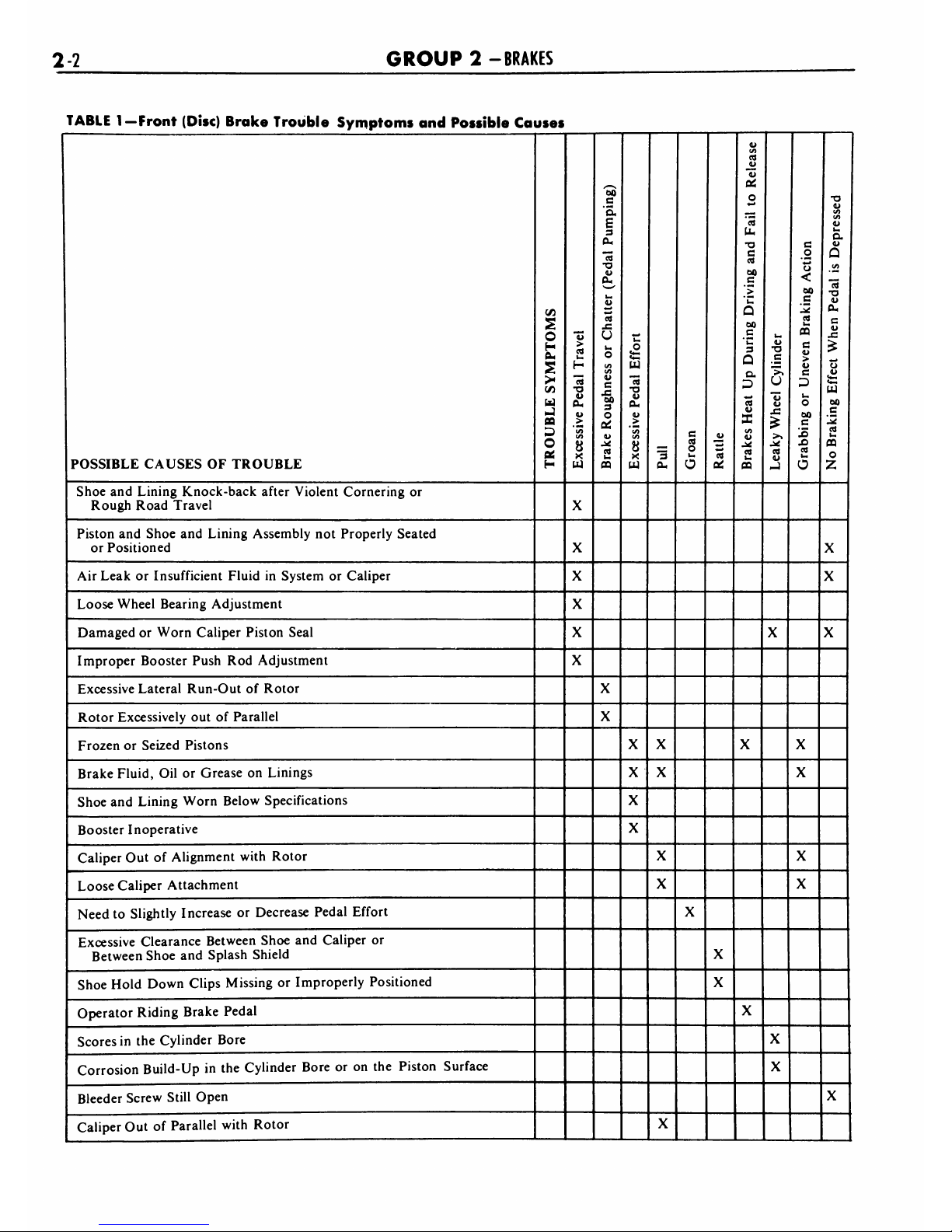

TABLE

1

Front

(Disc)

Brake

Trouble

Symptoms

and

Possible

Causes

POSSIBLE

CAUSES

OF

TROUBLE

C/3

2

o

H

>

u

J

ca

S3

o

a.

H

>

CC

ha

H

"5

o

<l>

0-

V

>

</>

a

X

UJ

/S5

c

"S.

3

CU

"c5

T3

CL,

t-

U

ed

U

u

O

</>

</>

ii

c

_c

00

3

o

cQ

a

CO

u

o

<

.

<

UJ

"5

"O

V

da

>

8

X

UJ

3

a.

c

CQ

o

o

rt

CKJ

</>

CQ

JL>

*4>

a!

o

'3

U,

T3

C

d

oo

C

>

a

00

c

3

Q

o.

08

V

X

(/>

u

CQ

Urn

a>

c

">

U

13

u

>>

_:

CQ

-J

c

o

o

<

00

cQ

la)

OQ

c

>

u

c

ha

o

oo

c

15

X)

CQ

>

O

T3

u

(/>

</)

V

u

a

Q

(/>

"cQ

TJ

<1>

Oa

C

i>

Ua

00

c

12

CQ

Ua

CQ

O

Z

Shoe

and

Lining

Knock-back

after

Violent

Cornering

or

Rough

Road

Travel

X

Piston

and

Shoe

and

Lining

Assembly

not

Properly

Seated

or

Positioned

X

X

Air

Leak

or

Insufficient

FluidinSystem

or

Caliper

X

X

Loose

Wheel

Bearing

Adjustment

X

Damaged

or

Worn

Caliper

Piston

Seal

X

X X

Improper

Booster

Push

Rod

Adjustment

X

Excessive

Lateral

Run-Out

of

Rotor

X

Rotor

Excessively

out

of

Parallel

X

Frozen

or

Seized

Pistons

X X

X X

Brake

Fluid,

Oil

or

Grease

on

Linings

X X

X

Shoe

and

Lining

Worn

Below

Specifications

X

Booster

Inoperative

X

Caliper

Out

of

Alignment

with

Rotor

X

X

Loose

Caliper

Attachment

X

X

Need

to

Slightly

Increase

or

Decrease

Pedal

Effort

X

Excessive

Clearance

Between

Shoe

and

Caliper

or

Between

Shoe

and

Splash

Shield

X

Shoe

Hold

Down

Clips

Missing

or

Improperly

Positioned

X

Operator

Riding

Brake

Pedal

X

Scores

in

the

Cylinder

Bore

X

Corrosion

Build-Up

in

the

Cylinder

Bore

or

on

the

Piston

Surface

X

Bleeder

Screw

Still

Open

X

Caliper

Out

of

Parallel

with

Rotor

X

PART

2-1

-GENERAL

BRAKE

SERVICE

2-3

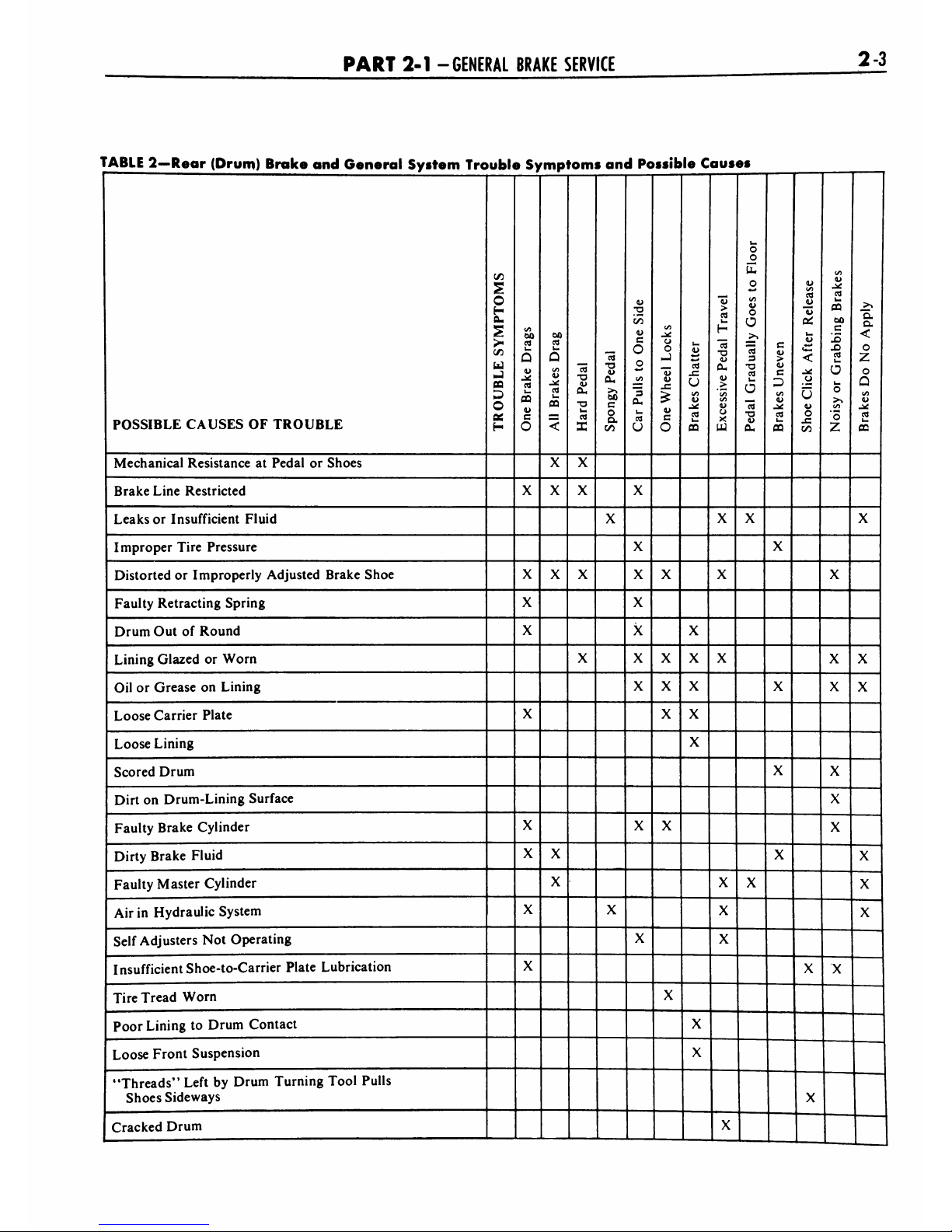

TABLE

2

Rear

(Drum)

Brake

and

General

System

Trouble

Symptoms

and

Possible

Causes

POSSIBLE

CAUSES

OF

TROUBLE

C/5

O

H

a.

>

u.

J

CC

O

ft.

H

00

ca

ha

Q

ha

CQ

c

O

00

C9

ha

Q

</i

u

rt

ha

ca

<

rt

-a

u

0-

T3

ha

X

T3

0-

>

00

c

o

a

on

u

.12

i/5

u

c

O

o

(/I

"3

ft.

ha

rt

u

10

.X

0

0

-J

"w

u

x:

c

0

u

u

<u

ca

ha

CQ

>

rt

ha

H

"rt

-0

u

Oa

cu

>

(/5

un

u

0

X

UJ

ha

0

u_

0

00

cu

0

0

>>

"rt

3

0

ca

ha

0

"rt

0

u

Oa

c

>

c

</)

rt

ha

CQ

(U

c/l

rt

s

ha

CU

<*-

<

0

0

(U

0

-n

00

00

u

-X

rt

CQ

00

c

IS

X)

ca

ha

0

ha

0

>-.

CO

'5

z

>>

a

a

<

0

z

0

a

I/)

u

J*

rt

ha

CC

Mechanical

Resistance

at

Pedal

or

Shoes

X

X

Brake

Line

Restricted

X X

X

X

Leaks

or

Insufficient

Fluid

X X

X

X

Improper

Tire

Pressure

X

X

Distorted

or

Improperly

Adjusted

Brake

Shoe

X X

X

X

X

X

X

Faulty

Retracting

Spring

X

X

Drum

Out

of

Round

X

X

X

Lining

Glazed

or

Worn

X X

X

X

X

X X

Oil

or

Grease

on

Lining

X

X

X

X

X

X

Loose

Carrier

Plate

X

X

X

Loose

Lining

X

Scored

Drum

X

X

Dirt

on

Drum-Lining

Surface

X

Faulty

Brake

Cylinder

X

X X

X

Dirty

Brake

Fluid

X

X

X

X

Faulty

Master

Cylinder

X

X

X

X

Air

in

Hydraulic

System

X

X

X

X

Self

Adjusters

Not

Operating

X

X

Insufficient

Shoe-to-Carrier

Plate

Lubrication

X

X

X

Tire

Tread

Worn

X

Poor

Lining

to

Drum

Contact

X

Loose

Front

Suspension

X

Threads"

Left

by

Drum

Turning

Tool

Pulls

Shoes

Sideways

X

Cracked

Drum

X

.

24

GROUP

2

-BRAKES

COMMON

ADJUSTMENTS

AND

REPAIRS

PARKING

BRAKE

LINKAGE

ADJUSTMENT

Check

the

parking

brake

cables

when

the

brakes

are

fully

released.

If

the

cables

are

loose,

adjust

them

as

follows:

1.

Fully

release

the

parking

brake

pedal

by

pushing

down

the

manual

release

lever.

2.

Raise

the

car.

3.

Adjust

the

equalizer

lever

against

the

cable

spring

on

the

pedal

cable

to

the

dimension

shown

in

Fig.

1.

4.

Loosen

the

adjusting

nut

on

the

equalizer

rod,

and

then

turn

the

lock

nut

in

front

of

the

equalizer

several

turns

forward.

5.

Depress

the

parking

brake

pedal

1

3/4

inches

from

its

normal

released

position.

6.

While

turning

the

rear

wheels

in

a

rearward

direction,

turn

the

ad

justing

nut

against

the

equalizer

until

a

moderate

drag

is

felt

(Fig.

1).

7.

When

the

cables

are

properly

adjusted,

tighten

the

lock

nut

against

the

equalizer.

8.

Release

the

parking

brake,

and

check

to

make

sure

that

the

brake

shoes

return

to

the

fully

released

position.

9.

Depress

the

parking

brake

pedal

two

inches.

Under

normal

conditions,

this

will

satisfactorily

hold

the

car.

10.

Release

the

parking

brake

again,

and

then

depress

the

pedal

1/2

inch.

The

brakes

should

not

drag

with

the

pedal

depressed

1/2

inch.

If

the

rear

brakes

do

not

fully

release,

check

the

cables

for

kinks

or

binds.

Free

the

cables

as

required.

MASTER

CYLINDER

PUSH

ROD

ADJUSTMENT

The

push

rod

is

designed

with

a

self-locking

adjustment

screw

to

provide

the

correct

relationship

between

the

booster

piston

and

the

master

cylinder

piston.

The

ad

justment

screw

is

set

to

the

correct

height

at

the

time

of

original

assembly

of

the

power

unit.

Under

normal

service

the

adjustment

screw

does

not

require

any

further

attention

providing

the

push

rod

assembly

re-

U-CLIP

CABLE

HOUSING

END

SPRING

SEAT

CABLE

SPRING

LEVER-TO-CABLE

ADJUSTING

NUT

EQUALIZER

ROD

EQUALIZER

LEVER

CABLES

TO

REAR

WHEELS

H1307-A

FIG.

1

Parking

Brake

Adjustments

mains

in

the

original

unit.

However,

when

a

new

push rod

is

used

or

the

push

rod

assembly

is

transferred to

another

unit,

the

distance

from

the

end

of

the

adjustment

screw

to

the

mounting

surface

of

the

booster

body

should

be

rechecked

either

with

a

micrometer

depth

gauge

to

a

dimen

sion

of

0.380

0.995

inch,

or

with

a

height

gauge

as

shown

in

Fig.2.The

details

for

making

a

height

gauge

are

given

in

Fig.

3.

ADJUSTMENT

SCREW

Push

Rod

Gauge

HI

086-

A

FIG.

2

-Push

Rod

Adjustment

#15

OR

#16

U.S.S.

GAUGE

SHEET

STEEL

2-7/8".

H1087-C

FIG.

3-Push

Rod

Gouge

Dimensions

To

adjust

the

push

rod,

hold

the

serrated

end

of

the

rod

with

cross-

milled

pliers

and

turn

the

adjustment

screw

in

to

shorten,

or

out

to

lengthen.

After

assembly

of

the

master

cylinder

to

the

power

section,

the

pis

ton

cup

in

the

hydraulic

cylinder

should

just

clear

the

compensating

port

hole

when

the

unit

is

in

the

fully

released

position.

This

can

be

checked

by

placing

a

few

drops

of

brake

fluid

over

the

compensating

port

and

ap

plying

light

air

pressure

to

the

output

port

of

the

master

cylinder.

If

air

bub

bles

appear,

the

port

is

open.

If

the

primary

piston

cup

overlaps

the

com

pensating

port,

there

will

be

no

flow

of

air

through

the

compensating

port.

If

this

condition

exists,

the

ad

justment

screw

should

be

turned

into

the

push

rodaslight

amount

or

until

the

compensating

portisopen.

HYDRAULIC

SYSTEM

BLEEDING

When

any

part

of

the

hydraulic

sys

tem

has

been

disconnected

for

repair

or

replacement,

air

may

get

into

the

lines

and

cause

spongy

pedal

action.

Bleed

the

hydraulic

system

after

it

has

been

properly

connected

to

be

sure

that

all

air

is

expelled

from

the

brake

cylinders,

disc

brake

calipers,

and

lines.

PART

2-1

-GENERAL

BRAKE

SERVICE

25

The

hydraulic

system

can

be

bled

manually

or

with

pressure

bleeding

equipment.

With

disc

brakes,

more

pumping

of

the

pedal

is

required

and

more

frequent

checking

of

the

master

cylinder

may

be

necessary

while

bleeding.

Remove

the

front

wheel

and

tire

as

semblies

in

order

to

gain

access

to

the

bleeder

fittings

on

the

disc

brake

calipers.

MANUAL

BLEEDING

Bleed

the

longest

lines

first.

Keep

the

master

cylinder

reservoir

filled

with

new

Rotunda

R103-A

Extra

Heavy

Duty

brake

fluid

during

the

bleeding

operation.

Never

use

brake

fluid

which

has

been

drained

from

the

hydraulic

sys

tem.

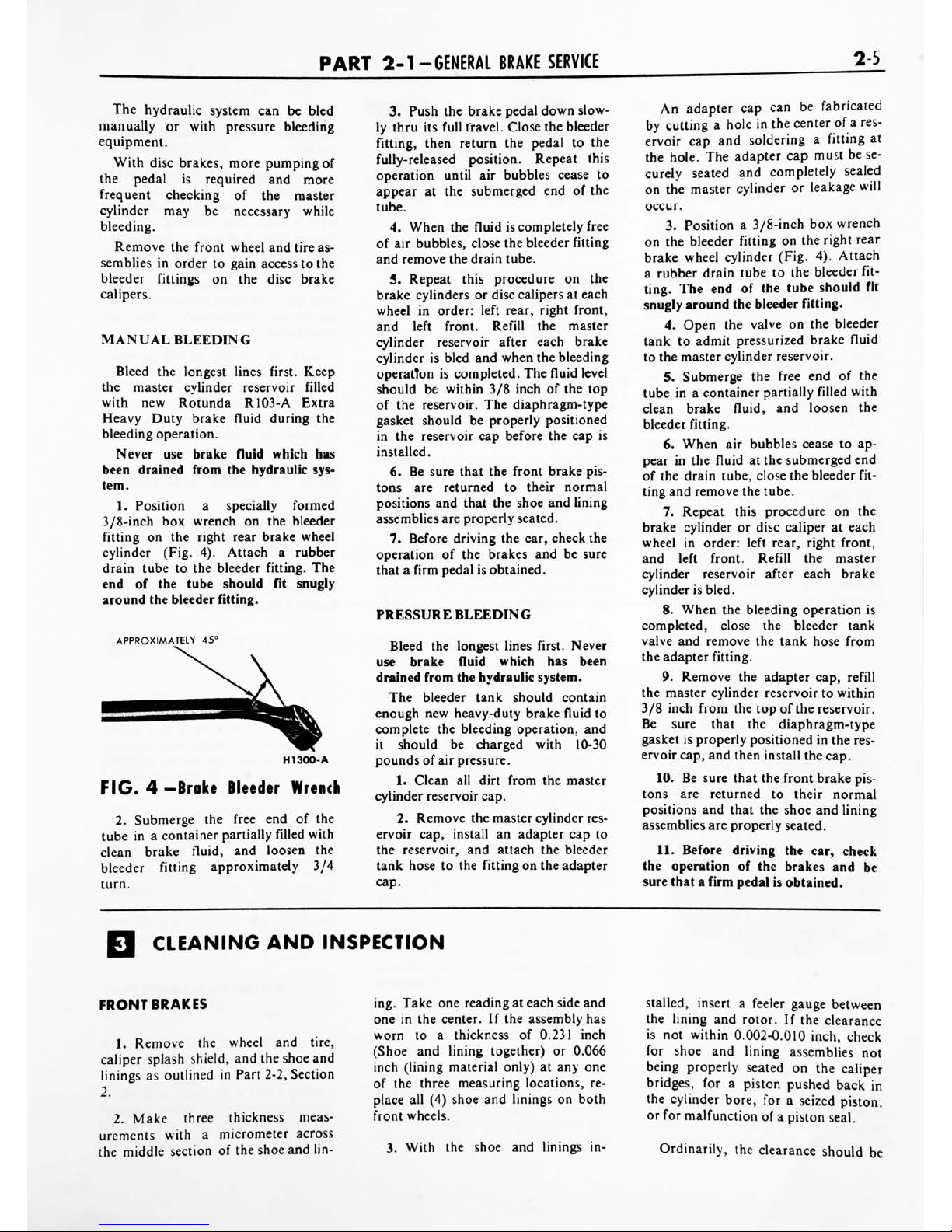

1.

Position

a

specially

formed

3/8-inch

box

wrench

on

the

bleeder

fitting

on

the

right

rear

brake

wheel

cylinder

(Fig.

4).

Attach

a

rubber

drain

tube

to

the

bleeder

fitting.

The

end

of

the

tube

should

fit

snugly

around

the

bleeder

fitting.

APPROXIMATELY

45

HI

300-

A

FIG.

4

-Brake

Bleeder

Wrench

2.

Submerge

the

free

end

of

the

tube

in

a

container

partially

filled

with

clean

brake

fluid,

and

loosen

the

bleeder

fitting

approximately

3/4

turn.

3.

Push

the

brake

pedal

down

slow

ly

thru

its

full

travel.

Close

the

bleeder

fitting,

then

return

the

pedal

to

the

fully-released

position.

Repeat

this

operation

until air

bubbles

cease

to

appear

at

the

submerged

end

of

the

tube.

4.

When

the

fluid

is

completely

free

of

air

bubbles,

close

the

bleeder

fitting

and

remove

the

drain

tube.

5.

Repeat

this

procedure

on

the

brake

cylinders

or

disc

calipers

at

each

wheel

in

order:

left

rear,

right

front,

and

left

front.

Refill

the

master

cylinder

reservoir

after

each

brake

cylinder

is

bled

and

when

the

bleeding

operation

is

completed.

The

fluid

level

should

be

within

3/8

inch

of

the

top

of

the

reservoir.

The

diaphragm-type

gasket

should

be

properly

positioned

in

the

reservoir

cap

before

the

cap

is

installed.

6.

Be

sure

that

the

front

brake

pis

tons

are

returned

to

their

normal

positions

and

that

the

shoe

and

lining

assemblies

are

properly

seated.

7.

Before

driving

the

car,

check

the

operation

of

the

brakes

and

be

sure

that

a

firm

pedal

is

obtained.

PRESSURE

BLEEDING

Bleed

the

longest

lines

first.

Never

use

brake

fluid

which

has

been

drained

from

the

hydraulic

system.

The

bleeder

tank

should

contain

enough

new

heavy-duty

brake

fluid

to

complete

the

bleeding

operation,

and

it

should

be

charged

with

10-30

pounds

of

air

pressure.

1.

Clean

all

dirt

from

the

master

cylinder

reservoir

cap.

2.

Remove

the

master

cylinder

res

ervoir

cap,

install

an

adapter

cap

to

the

reservoir,

and

attach

the

bleeder

tank

hose

to

the

fitting

on

the

adapter

cap.

An

adapter

cap

can

be

fabricated

by

cutting

a

hole

in

the

center

of

a

res

ervoir

cap

and

soldering

a

fitting

at

the

hole.

The

adapter

cap

must

be

se

curely

seated

and

completely

sealed

on

the

master

cylinder

or

leakage

will

occur.

3.

Position

a

3/8-inch

box

wrench

on

the

bleeder

fitting

on

the

right

rear

brake

wheel

cylinder

(Fig.

4).

Attach

a

rubber

drain

tube

to

the

bleeder

fit

ting.

The

end

of

the

tube

should

fit

snugly

around

the

bleeder

fitting.

4.

Open

the

valve

on

the

bleeder

tank

to

admit

pressurized

brake

fluid

to

the

master

cylinder

reservoir.

5.

Submerge

the

free

end

of

the

tube

in

a

container

partially

filled

with

clean

brake

fluid,

and

loosen

the

bleeder

fitting.

6.

When

air

bubbles

cease

to

ap

pear

in

the

fluid

at

the

submerged

end

of

the

drain

tube,

close

the

bleeder

fit

ting

and

remove

the

tube.

7.

Repeat

this

procedure

on

the

brake

cylinder

or

disc

caliper

at

each

wheel

in

order:

left

rear,

right

front,

and

left

front.

Refill

the

master

cylinder

reservoir

after

each

brake

cylinder

is

bled.

8.

When

the

bleeding

operation

is

completed,

close

the

bleeder

tank

valve

and

remove

the

tank

hose

from

the

adapter

fitting.

9.

Remove

the

adapter

cap,

refill

the

master

cylinder

reservoir

to

within

3/8

inch

from

the

top

of

the

reservoir.

Be

sure

that

the

diaphragm-type

gasket

is

properly

positioned

in

the

res

ervoir

cap,

and

then

install

the

cap.

10.

Be

sure

that

the

front

brake

pis

tons

are

returned

to

their

normal

positions

and

that

the

shoe

and

lining

assemblies

are

properly

seated.

11.

Before

driving

the

car,

check

the

operation

of

the

brakes

and

be

sure

that

a

firm

pedal

is

obtained.

CLEANING

AND

INSPECTION

FRONT

BRAKES

1.

Remove

the

wheel

and

tire,

caliper

splash

shield,

and

the

shoe

and

linings

as

outlined

in

Part

2-2,

Section

2.

2.

Make

three

thickness

meas

urements

with

a

micrometer

across

the

middle

section

of

the

shoe

and

lin

ing.

Take

one

reading

at

each

side

and

one

in

the

center.

If

the

assembly

has

worn

to

a

thickness

of

0.231

inch

(Shoe

and

lining

together)

or

0.066

inch

(lining

material

only)

at

any

one

of

the

three

measuring

locations,

re

place

all

(4)

shoe

and

linings

on

both

front

wheels.

3.

With

the

shoe

and

linings

in

stalled,

insert

a

feeler

gauge

between

the

lining

and

rotor.

If

the

clearance

is

not

within

0.002-0.010

inch,

check

for

shoe

and

lining

assemblies

not

being

properly

seated

on

the

caliper

bridges,

for

a

piston

pushed

back

in

the

cylinder

bore,

for

a

seized

piston,

or

for

malfunction

of

a

piston

seal.

Ordinarily,

the

clearance

should

be

2-6

GROUP

2

-BRAKES

0.002-0.010

inch.

However,

if

the

car

was

stopped

by

a

brake

application

just

prior

to

checking

the

clearance,

the

brakes

may

drag

slightly.

4.

To

check

rotor

runout,

first

eliminate

the

wheel

bearing

end

play

by

tightening

the

adjusting

nut.

After

tightening

the

nut

check

to

see

that

the

rotor

can

still

be

rotated.

5.

Clamp

a

dial

indicator

to

the

caliper

housing

so

that

the

stylus

con

tacts

the

rotor

at

a

point

approximate

ly

1

inch

from

the

outer

edge.

Rotate

the

rotor

and

take

an

indicator

read

ing.

If

the

reading

exceeds

0.002

inch

total

indicator

runout,

replace

the

rotor.

Do

not

attempt

to

refinish

a

rotor

that

indicates

runout

in

excess

of

specification.

When

the

runout

check

is

finished

be

sure

to

adjust

the

bearings

as

outlined

in

Group

3,

in

order

to

prevent

bearing

failure.

6.

Check

the

rotor

for

scoring.

Minor

scores

can

be

removed

with

a

fine

emery

cloth.

If

the

rotor

is

exces

sively

scored

replace

it.

7.

Visually

check

the

caliper.

Ifitis

cracked

or

if

excess

leakage

is

evident,

it

should

be

replaced.

Slight

leakage

or

seized

pistons

indicate

removal

and

disassembly.

8.

If

upon

disassembly

the

caliper

is

found

to

be

distorted

or

damaged,

or

if

the

cylinder

bores

are

scored

or

excessively

worn,

replace

the

as

sembly.

The

two

halves

of

the

caliper

as

sembly

should

never

be

separated.

Damage

or

failure

of

one

requires

re

placement

of

both

as

a

unit.

REAR

BRAKES

1.

Remove

the

wheel

from

the

drum,

and

remove

the

drum

as

out

lined

in

Part

2-2,

Section

2.

Wash

all

the

parts

except

the

brake

shoes

in

a

cleaning

fluid

and

dry

with

com

pressed

air.

2.

Brush

all

dust

from

the

carrier

plate

and

interior

of

the

brake

drum.

3.

Inspect

the

brake

shoes

for

ex

cessive

lining

wear

or

shoe

damage.

If

the

lining

is

worn

to

within

1/32

inch

of

the

rivet

heads

or

if

the

shoes

are

damaged,

they

must

be

replaced.

Rep

lace

any

lining

that

has

been

oil

satu

rated.

Replace

the

lining

in

axle

sets.

Prior

to

replacement

of

the

lining,

the

drum

diameter

should

be

checked

to

determine

if

oversize

linings

must

be

installed.

4. Check

the

condition

of

the

brake

shoes,

retracting

springs,

and

drum

for

signs

of

overheating.

If

the

shoes

have

a

slight

blue

coloring,

or

if

the

springs

show

a

change

in

free

length,

indicating

overheating,

replacement

of

the

retracting

and

hold

down

springs

is

necessary.

Overheated

springs

lose

their

pull and

could

cause

the

new

lin

ing

to

wear

prematurely

if

they

are

not

replaced.

5.

If

the

car

has

30,000

or

more

miles

of

operation

on

the

brake

lin

ings,

or

signs

of

overheating

are

pres

ent

when

relining

brakes,

the

wheel

cylinders

should

be

disassembled

and

inspected

for

wear

and

dirt

in

the

cylinder.

The

cylinder

cups

and

other

parts

contained

in

the

overhaul

kit

should

be

replaced,

thus

avoiding

future

problems.

6.

Inspect

all

other

brake

parts

and

replace

any

that

are

worn

or

da

maged.

7.

Inspect

the

brake

drums

and,

if

necessary,

refinish.

Refer

to

Part

2-2,

Section

4

for

refinishing.

2-7

PART

2-2

BRAKE

SYSTEM

Section

Page

Section

Page

Description

and

Operation

2-7

Disc

Brake

Assemblies

2-7

Hydraulic

Self-

Adjusting

Brake

System

2-8

Booster

System

2-9

Parking

Brake

2-9

In-Car

Adjustments

and

Repairs

2-10

Disc

Brake

Caliper

Assembly

2-11

Front

Wheel

Hub

and

Rotor

Assembly

-

Disc Brakes

2-11

Disc

Brake

Rotor

Splash

Shield

2-12

Proportioning

Valve

2-12

Brake

Shoe

Adjustments

2-12

Rear

Brake

Drum

2-13

Brake

Shoes

and

Adjusting

Screw

2-13

Disc

Brake

Shoe

and

Lining

Replacement

2-13

Wheel Cylinder

Repair

2-14

Wheel

Cylinder

Replacement

2-15

Brake

Carrier

Plate

Replacement

2-15

Hydraulic

Lines

2-15

Brake

Tube

Replacement

2-15

Brake

Hose

Replacement

2-15

Removal

and

Installation

2-16

Master

Cylinder

-

Power

Brakes

2-16

Booster

Unit

2-17

Brake

Pedal

-

Automatic

Transmission

2-17

Parking

Brake

Control

Assembly

2-18

Parking

Brake

Vacuum

Power

Unit

2-19

Parking

Brake

Equalizer

to

Control

Cable

2-19

Parking

Brake

Equalizer

to

Rear

Wheel

Cable

2-19

Major

Repair

Operations

2-20

Brake

Drum

Refinishing

2-20

Brake

Shoe

Relining

2-20

Master

Cylinder

2-20

DESCRIPTION

AND

OPERATION

The

1966

Thunderbird

brake

system

employs

disc

brakes

on

the

front

wheels

and

single

anchor,

internal

ex

panding

and

self-adjusting

brake

as

semblies

on

the

rear

wheels.

The

sys

tem

is

powered

by

a

vacuum

booster

as

standard

equipment.

The

master

cylinder

converts

physi

cal

force

from

the

brake

pedal

and

booster

into

hydraulic

pressure

against

the

pistons

in

the

calipers

(front

wheels)

or

in

the

wheel

cylinders

(rear

wheels).

The

pistons

in

turn

convert

hydraulic

pressure

back

into

physical

force

at

the

discs

and

brake

shoes.

DISC

BRAKE

ASSEMBLIES

-FRONT

WHEELS

RELATION

AND

FUNCTION

OF

COMPONENT

PARTS

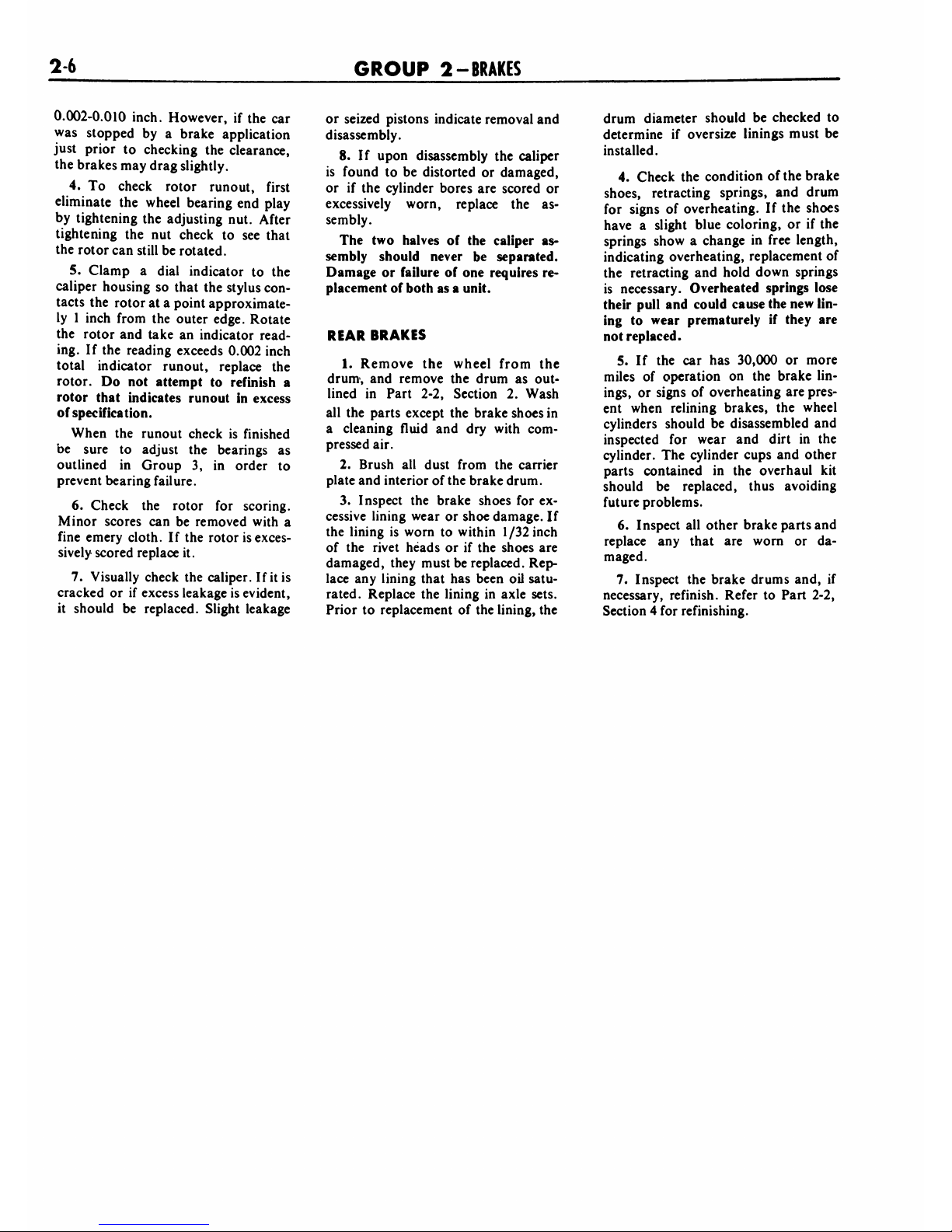

The

disc

brake

is

a

fixed

caliper,

opposed

piston,

non-energized,

ven

tilated

disc

type,

actuated

by

a

hy

draulic

system

(Fig.

1).

There

is

no

lateral

movement

of

either

the

disc

(rotor)

or

the

caliper.

The

caliper

as

sembly

consists

of

two

caliper

housings

bolted

together

with

each

half

containing

two

cylinder

bores

of

1

15/16

inch

diameter.

Each

cylinder

bore

contains

a

piston

with

an

at

tached

molded

rubber

dust

boot

to

seal

the

cylinder

bore

from

con

tamination*

(Fig.

2).

Square-section

rubber

piston

seals

are

positioned

in

grooves

in

the

cylinder

bores.

The

piston

seals

perform

three

im

portant

tasks:

1.

They

provide

hydraulic

sealing

between

the

cylinders

and

pistons.

2.

They

return

the

pistons

to

released

position,

when

hydraulic

pressure

is

released.

3.

They

maintain

the

shoes

in

cor

rect

adjustment

at

all

times

(compar

able

to

the

automatic

adjusters

in

drum-type

brakes.

The

cylinders

are

connected

hy-

draulically

by

means

of

internal

pas

sages

in

the

caliper

housings

and

an

external

transfer

tube

between

the

two

halves

of

the

caliper

assembly.

One

CALIPER

SPLASH

SHIELD

EXTERNAL

TRANSFER

HUB

AND

ROTOR

ASSEMBLY

DER

SCREW

H1368-B

FIG.

1

Disc

Brake

Assembly

bleeder

screw

and

fluid

inlet

fitting

is

provided

on

each

caliper

assembly.

The

shoe

and

lining

assemblies

are

located

in

between

parallel

machined

abutments

within

the

caliper,

and

are

supported

radially

by

tabs

on

the

2-8

GROUP

2

-BRAKES

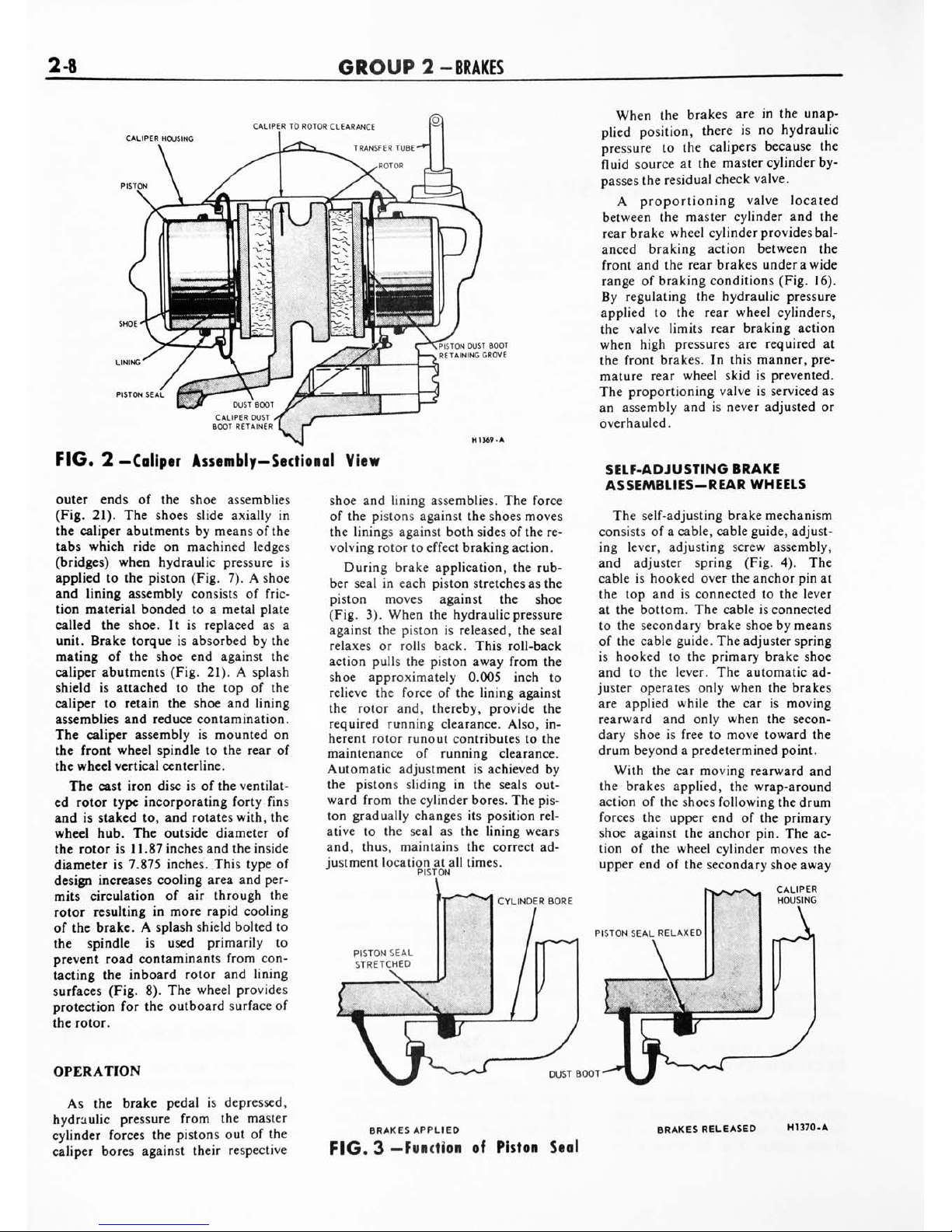

CALIPER

HOUSING

CALIPER

TO

ROTOR

CLEARANCE

TRANSFER

TUBE

-ROTOR

PISTON

OUST

BOOT

RETAINING

GROVE

PISTON

SEAL

FIG.

2

Caliper

Assembly

Sectional

View

outer

ends

of

the

shoe

assemblies

(Fig.

21).

The

shoes

slide

axially

in

the

caliper

abutments

by

means

of

the

tabs

which

ride

on

machined

ledges

(bridges)

when

hydraulic

pressure

is

applied

to

the

piston

(Fig.

7).

A

shoe

and

lining

assembly

consists

of

fric

tion

material

bonded

to

a

metal

plate

called

the

shoe.

It

is

replaced

as

a

unit.

Brake

torque

is

absorbed

by

the

mating

of

the

shoe

end

against

the

caliper

abutments

(Fig.

21).

A

splash

shield

is

attached

to

the

top

of

the

caliper

to

retain

the

shoe

and

lining

assemblies

and

reduce

contamination.

The

caliper

assembly

is

mounted

on

the

front

wheel

spindle

to

the

rear

of

the

wheel

vertical

centerline.

The

cast

iron

disc

is

of

the

ventilat

ed

rotor

type

incorporating

forty

fins

and

is

staked

to,

and

rotates

with,

the

wheel

hub.

The

outside

diameter

of

the

rotor

is

1

1

.87

inches

and

the

inside

diameter

is

7.875

inches.

This

type

of

design

increases

cooling

area

and

per

mits

circulation

of

air

through

the

rotor

resulting

in

more rapid

cooling

of

the

brake.

A

splash

shield

bolted

to

the

spindle

is

used

primarily

to

prevent

road

contaminants

from

con

tacting

the

inboard

rotor

and

lining

surfaces

(Fig.

8).

The

wheel

provides

protection

for

the

outboard

surface

of

the

rotor.

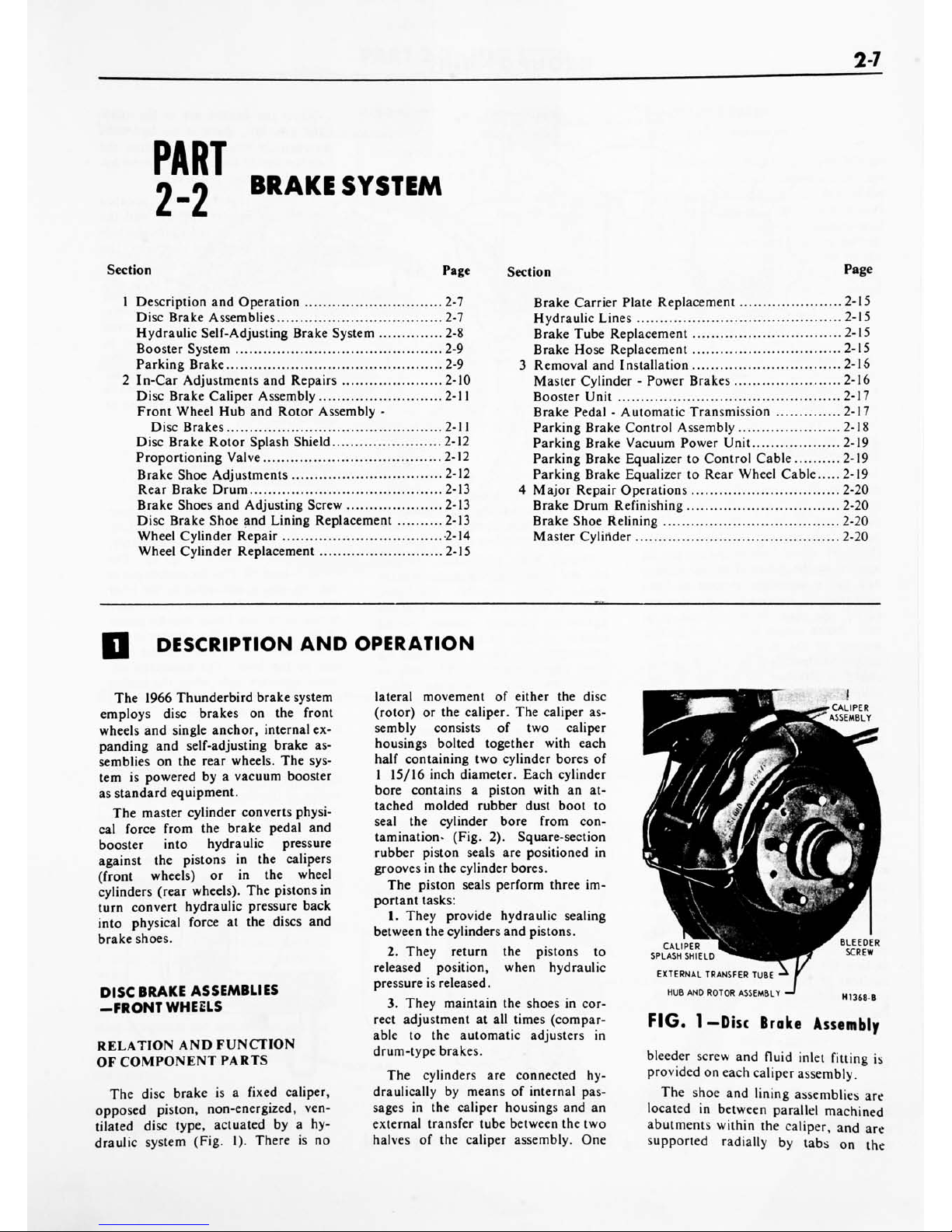

OPERATION

As

the

brake

pedal

is

depressed,

hydraulic

pressure

from

the

master

cylinder

forces

the

pistons

out

of

the

caliper

bores

against

their

respective

shoe

and

lining

assemblies.

The

force

of

the

pistons

against

the

shoes

moves

the

linings

against

both

sides

of

the

re

volving

rotor

to

effect

braking

action.

During

brake

application,

the

rub

ber

seal

in

each

piston

stretches

as

the

piston

moves

against

the

shoe

(Fig.

3).

When

the

hydraulic

pressure

against

the

piston

is

released,

the

seal

relaxes

or

rolls

back.

This

roll-back

action

pulls

the

piston

away

from

the

shoe

approximately

0.005

inch

to

relieve

the

force

of

the

lining

against

the

rotor

and,

thereby,

provide

the

required

running

clearance.

Also,

in

herent

rotor

runout

contributes

to

the

maintenance

of

running

clearance.

Automatic

adjustment

is

achieved

by

the

pistons

sliding

in

the

seals

out

ward

from

the

cylinder

bores.

The

pis

ton

gradually

changes

its

position

rel

ative

to

the

seal

as

the

lining

wears

and,

thus,

maintains

the

correct

ad

justment

location

at

all

times.

PISTON

t

When

the

brakes

are

in

the

unap

plied

position,

there

is

no

hydraulic

pressure

to

the

calipers

because

the

fluid

source

at

the

master

cylinder

by

passes

the

residual

check

valve.

A

proportioning

valve

located

between

the

master

cylinder

and

the

rear

brake

wheel

cylinder

provides

bal

anced

braking

action

between

the

front

and

the

rear

brakes

under

a

wide

range

of

braking

conditions

(Fig.

16).

By

regulating

the

hydraulic

pressure

applied

to

the

rear

wheel

cylinders,

the

valve

limits

rear

braking

action

when

high

pressures

are

required

at

the

front

brakes.

In

this

manner,

pre

mature

rear

wheel

skid

is

prevented.

The

proportioning

valve

is

serviced

as

an

assembly

and

is

never

adjusted

or

overhauled.

SELF-ADJUSTING

BRAKE

ASSEMBLIES-REAR

WHEELS

The

self-adjusting

brake

mechanism

consists

of

a

cable,

cable

guide,

adjust

ing

lever,

adjusting

screw

assembly,

and

adjuster

spring

(Fig.

4).

The

cable

is

hooked

over

the

anchor

pin

at

the

top

and

is

connected

to

the

lever

at

the

bottom.

The

cable

is

connected

to

the

secondary

brake

shoe

by

means

of

the

cable

guide.

The

adjuster

spring

is

hooked

to

the

primary

brake

shoe

and

to

the

lever.

The

automatic

ad

juster

operates

only

when

the

brakes

are

applied

while

the

car

is

moving

rearward

and

only

when

the

secon

dary

shoe

is

free

to

move

toward

the

drum

beyond

a

predetermined

point.

With

the

car

moving

rearward

and

the

brakes

applied,

the

wrap-around

action

of

the

shoes

following

the

drum

forces

the

upper

end

of

the

primary

shoe

against

the

anchor

pin.

The

ac

tion

of

the

wheel

cylinder

moves

the

upper

end

of

the

secondary

shoe

away

CALIPER

HOUSING

BRAKES

APPLIED

BRAKES

RELEASED

HI

370-

A

FIG.

3

-Function

of

Piston

Seal

Loading...

Loading...