Ford Thudenbind 1959 Shop Manual

1

FORD

FORD

DIVISION

PORD

MOTOR

COMPANY

SHOP

MAM

J

Copyright © 2009, Forel Publishing Company, LLC, Woodbridge, Virginia

All Rights Reserved. No part of this book may be used or reproduced in any manner whatsoever

without written permission of Forel Publishing Company, LLC. For information write to Forel

Publishing Company, LLC, 3999 Peregrine Ridge Ct., Woodbridge, VA 22192

1959 Ford Thunderbird Shop Manual

EAN: 978-1-60371-009-1

ISBN: 1-60371-009-4

Forel Publishing Company, LLC

3999 Peregrine Ridge Ct.

Woodbridge, VA 22192

Email address: webmaster@ForelPublishing.com

Website: http://www.ForelPublishing.com

This publication contains material that is reproduced and distributed under a license from Ford

Motor Company. No further reproduction or distribution of the Ford Motor Company material is

allowed without the express written permission of Ford Motor Company.

NNoottee ffrroomm tthhee EEddiittoorr

This product was created from the original Ford Motor Company’s publication. Every effort has

been made to use the original scanned images, however, due to the condition of the material;

some pages have been modified to remove imperfections.

Although every effort was made to ensure the accuracy of this book, no representations or

warranties of any kind are made concerning the accuracy, completeness or suitability of the

information, either expressed or implied. As a result, the information contained within this book

should be used as general information only. The author and Forel Publishing Company, LLC

shall have neither liability nor responsibility to any person or entity with respect to any loss or

damage caused, or alleged to be caused, directly or indirectly by the information contained in

this book. Further, the publisher and author are not engaged in rendering legal or other

professional services. If legal, mechanical, electrical, or other expert assistance is required, the

services of a competent professional should be sought.

Disclaimer

THUNDERBIRD

INDEX

IGNITION,

FUEL,

AND

COOLING

SYSTEMS

CLUTCH

AND

MANUAL-SHIFT

TRANSMISSIONS

CRUISE-O-MATIC

TRANSMISSIONS

REAR

AXLE

AND

DRIVE

LINE

WHEELS,

TIRES,

CHASSIS

SUSPENSION,

AND

UNDERBODY

STEERING

BRAKES

SE

RVICE

DEPARTMENT

FORD

DIVISION

FORD

MOTOR

COMPANY

1958

FORD

MOTOR

COMPANY.

DEARBORN.

MICHIGAN

Reprinted

with

Ford

Motor

Company's

Permission

GENERATING

AND

STARTING

SYSTEMS

LIGHTS,

INSTRUMENTS,

AND

ACCESSORIES

BODY

MAINTENANCE

AND

REPAIR

DOORS,

DECK

LID,

AND

FRONT

SHEET

METAL

INTERIOR

TRIM,

SEATS,

AND

WINDOWS

CONVERTIBLE

TOP

MAINTENANCE,

LUBRICATION,

AND

SPECIAL

TOOLS

FOREWORD

This

manual

provides

information

for

the

proper

servicing

of

the

1959

Thunderbird.

The

descriptions

and

specifications

contained

in

this

manual

were

in

effect

at

the

time

the

manual

was

approved

for

printing.

The

Ford

Division

of

Ford

Motor

Company

reserves

the

right

to

discontinue

models

at

any

time,

or

change

specifications

or

design,

without

notice

and

without

incurring

obligation.

SERVICE

DEPARTMENT

FORD

DIVISION

FORD

MOTOR

COMPANY

I

THUNDERBIRD

SHOP

MANUAL

GROUP

I

ENGINES

AND

EXHAUST

SYSTEM

PAGE

PART

1-1

GENERAL

ENGINE

SERVICE

1-2

PART

1

-2

THUNDERBIRD

352

SPECIAL

V-8

1-23

PART

1-3

THUNDERBIRD

430

SPECIAL

V-8

1-48

PART

1-4

EXHAUST

SYSTEM

1-72

PART

1-5

SPECIFICATIONS

1-74

12

PART

1-1

GENERAL

ENGINE

SERVICE

Section

Page

1

Engine

Trouble

Diagnosis.

1-2

2

Tune-Up

1-8

3

Tests

and

Adjustments

(Engine

Installed)

1-9

Camshaft

Lobe

Lift

1-9

Valve

Timing

1-9

Valve

Clearance

1-9

Manifold

Vacuum

Test.

1-10

Compression

Test

1-10

4

Cleaning,

Inspection,

and

Reconditioning

1-11

Intake

Manifold

1-11

Section

Page

Exhaust

Manifold

1-11

Valve

Rocker

Arm

Shaft

Assembly

1-12

Push

Rods

1-12

Cylinder

Heads

1-12

Valves

1-13

Hydraulic

Valve

Lifters.

1-15

Timing

Chain

1-15

Camshaft

and

Bearings.

1-15

Crankshaft

1-15

Connecting

Rods

1-16

Pistons,

Pins,

and

Rings.

1-16

The

service

procedures

in

this

Part

apply

to

both

the

Thunderbird

352

and

430

Special

V-8

engines.

The

cleaning,

inspection,

and

recondition

ing

of

the

various

component

parts

apply

after

the

parts

have

been

re

moved

from

the

engine,

or

in

the

case

of

a

complete

overhaul,

after

the

engine

has

been

disassembled.

For

removal,

disassembly

,

assem

bly,

and

installation

procedures,

refer

to

Part

1-2

or

1-3.

Section

Page

Main

and

Connecting

Rod

Bearings

1-18

Flywheel

Manual-Shift

Transmissions

1-21

Cylinder

Block

1-21

Oil

Pan

and

Oil

Pump

(and

Vacuum

Booster

430

Engine)

1-22

ENGINE

TROUBLE

DIAGNOSIS

Poor

engine

performance

can

be

caused

by

the

need of

a

general

engine

tune-up,

by

gradual

wear

of

engine

parts,

or

by

a

sudden

parts

failure.

A

good

trouble

diagnosis

will

indicate

the

need

of

a

com

plete engine

tune-up,

individual

ad

justments,

part(s)

replacement

or

overhaul,

or

the

need

of

a

complete

engine

overhaul.

Engine

performance

complaints

usually

fall

under

one

of

the

basic

headings

listed

in

the

"Engine

Trouble

Diagnosis

Guide."

In

addition,

the

"Engine

Trouble

Diagnosis

Guide,"

lists

procedures

and

checks

to

be

performed

to

help

isolate

the

cause

of

the

trouble.

When

a

particular

trouble

can

not

be

traced

to

a

definite

cause

by

a

simple

check,

the

possible

items

that

could

be

at

fault

are

listed

in

the

order

of

their

probable occurrence.

Therefore,

in

most

cases,

the

items

should

be

checked

in

the

order

listed.

For

example,

under

Poor

Ac

celeration,

the

ignition

system

is

listed

as

a

probable

cause

of

the

trouble.

All

the

ignition

system

items

that

affect

acceleration

are

listed.

These

items

should

all

be

checked

before

proceeding

to

the

next

probable

cause

listed

in

the

guide.

For

the

checking

procedures

and

corrections

to

be

made

in

the

var

ious

systems,

refer

to

that

part

of

the

manual

which

covers

the

system

in

detail.

For

example,

refer

to

Part

2-1

for

ignition

system

items.

ENGINE

TROUBLE

DIAGNOSIS

GUIDE

ENGINE

WILL

NOT

CRANK

The

cause

of

this

trouble

is

engine

cranks,

it

indicates

that

water

usually

in

the

starting

system.

is

leaking

into

the

cylinders.

Re-

If

the

starting

system

is

not

at

move

the

cylinder

head(s)

and

in-

fault,

check

forahydrostatic

lock

spect

the

gasket(s)

and/or

head(s)

or

a

seized

engine.

Remove

the

for

cracks.

Also

examine

the

cylin-

spark

plugs,

then

attempt

to

crank

der

block for

cracks.

the

engine

with

the

starter.

If

the

ENGINE

CRANKS

NORMALLY,

BUT

WILL

NOT

START

Check

the

fuel

supply.

If

there

is

proper

sized

metal

rod

in

the

in

sufficient

fuel

in

the

tank,

the

cause

sulator

so

that

it

protrudes

from

the

of

the

trouble

probably

lies

in

either

insulator.

With

the

ignition

on

and

the

ignition

or

the

fuel

system.

the

starter

cranking

the

engine,

hold

To

determine

which

system

is

at

the

end

of

the

rod

approximately

fault,

remove

the

ignition

wire

from

3/16

inch from

the

cylinder

block.

one

spark

plug.

Insert

a

piece

of

\

CONTINUED

ON

NEXT

PAGE

PART

1-1

-GENERAL

ENGINE

SERVICE

1-3

ENGINE

TROUBLE

DIAGNOSIS

GUIDE

(Cont.)

ENGINE

CRANKS

NORMALLY,

BUT

WILL

NOT

START

(CONT.)

ENGINE

STARTS,

BUT

FAILS

TO

KEEP

RUNNING

NO

SPARK

OR

A

WEAK

SPARK

AT

THE

SPARK

PLUGS

The

cause

of

the

trouble

is

in

the

ignition

system.

To

determine

if

the

cause

of

the

trouble

is

in

the

primary

or

the

secondary

circuit,

remove

the

coil

high

tension

lead

from

the

top

of

the

distributor

and

hold

it

approxi

mately

3/16

inch

from

the

cylinder

head,

then

with

the

ignition

on

and

the

engine

turning

over,

check

for

a

spark.

If

the

spark

at

the

coil

high

ten

sion

lead

is

good,

the

cause

of

the

trouble

is

probably

in

the

distributor

cap,

rotor,

or

the

spark

plug

wires.

If

there

is

no

spark or

a

weak

spark at

the

coil

high

tension

lead,

the

cause

of

the

trouble

is

probably

in

the

primary

circuit,

coil

to

dis

tributor

high

tension

lead,

or

the

coil.

A

GOOD

SPARK

AT

THE

SPARK

PLUGS

If

the

spark

is

good

at

the

spark

plugs,

check

the

spark

plugs and

the

ignition

timing.

If

the

spark

plugs

or

the

ignition

timing

are

not

at

fault,

check

the

following

items:

FUEL

SYSTEM

Check

the

position

of

the

choke

plate.

If

the

engine

is

warm,

the

plate

should

be

open.

If

the

plate

is

not

open,

the

engine

will

load

up

due

to

the

excessively

rich

mixture

and

will

not

start.

If

the

engine

is

cold,

the

plate

should

be

closed,

if

the

plate

is

not

operating

properly,

check

the

fol

lowing

items:

The

choke

linkage

for

binding.

The

fast

idle

cam

for

binding.

Thermostatic

spring

housing

ad

justment.

Fast

idle

speed

screw

for

proper

adjustment.

Choke

plate

valve

for

proper

op

eration

(Ford

carburetor).

Fuel

Supply

at

Carburetor.

Work

the

throttle

by

hand

several

times.

Each

time

the

throttle

is

actuated

fuel

should

spurt

from

the

acceler

ating

pump

discharge

nozzles.

If

fuel

is

discharged

by

the

ac

celerating

pump,

the

engine

is

prob

ably

flooded,

or

there

is

water

in

the

fuel

system,

or

an

engine

me

chanical

item,

such

as

valves,

is

at

fault.

If

fuel

is

not

discharged

by

the

accelerating

pump,

disconnect

the

carburetor

fuel

inlet

line

at

the

carburetor.

Use

a

suitable

container

to

catch

the

fuel.

Crank

the

en

gine

to

see

if

fuel

is

reaching

the

carburetor.

If

fuel

is

not

reaching

the

carbu

retor,

check:

The

fuel

pump.

The

carburetor

fuel

inlet

line

for

obstructions.

The

flexible

fuel

pump

inlet

line

for

a

collapsed

condition.

The

fuel

tank

line

to

flexible

fuel

line

for

obstructions.

The

fuel

tank

vent.

If

fuel

is

reaching

the

carburetor,

check:

The

fuel

inlet

system

including,

the

fuel

inlet

screen,

the

fuel

inlet

needle

and

seat

assembly,

and

the

float

assembly.

Check

for

dirt

in

the

carburetor,

not

allowing

fuel

to

enter

or

be

dis

charged

from

the

idle

system.

ENGINE

Check

the

valve

timing.

FUEL

SYSTEM

Idle

fuel

mixture

needle(s)

not

properly

adjusted.

Engine

idle

speed

set

too

low.

The

choke

not

operating

properly.

Float

setting

incorrect.

Fuel

inlet

system

not

operating

properly.

Dirt

or

water

in

fuel

lines

or

carburetor.

Carburetor

icing.

Fuel

pump

defective.

IGNITION

SYSTEM

Breaker

points

not

properly

ad

justed.

Defective

spark

plugs.

Open

circuit

at

the

resistor.

Leakage

in

the

high

tension

wiring.

CONTINUED

ON

NEXT

PAGE

14

GROUP

1

-ENGINES

AND

EXHAUST

SYSTEM

ENGINE

TROUBLE

DIAGNOSIS

GUIDE

(Cont.)

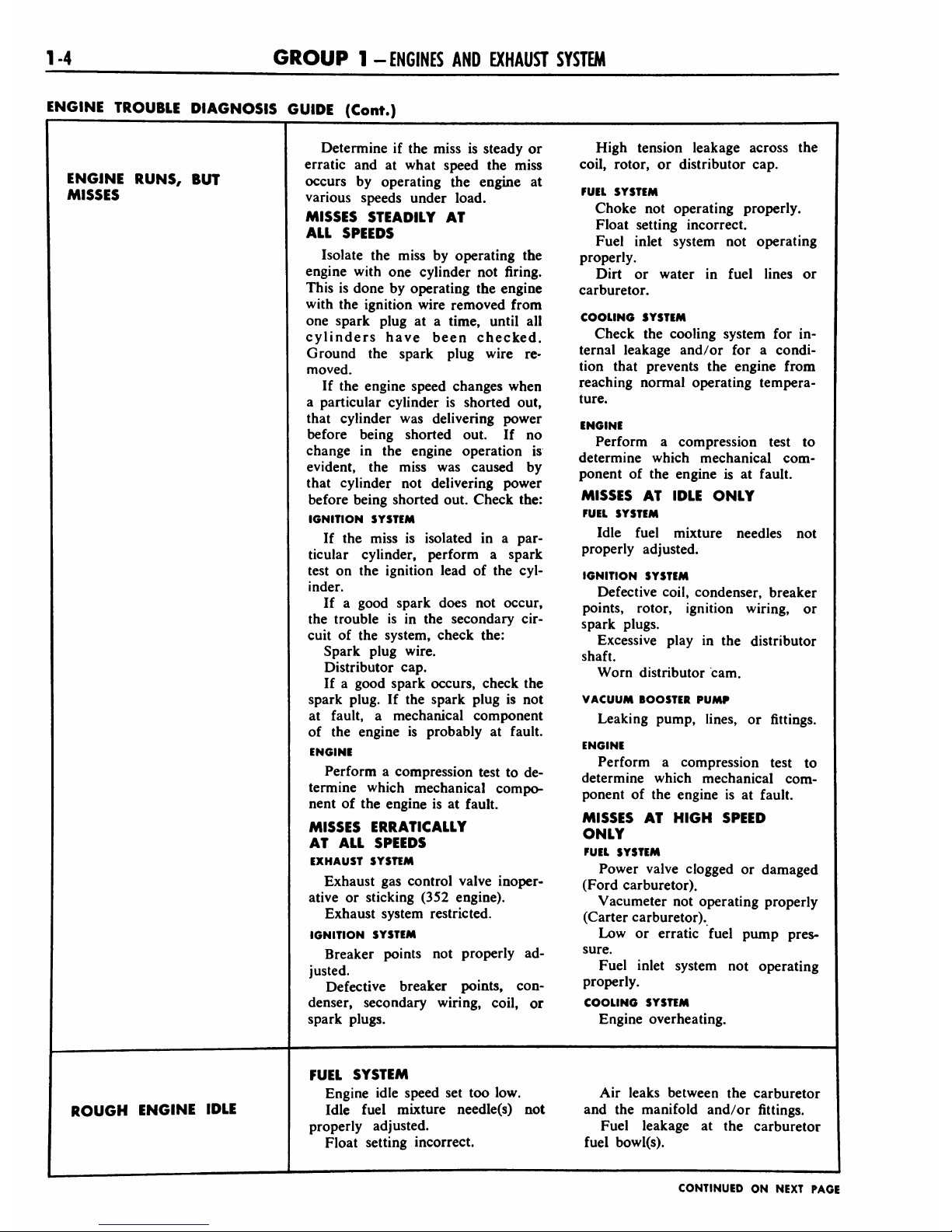

ENGJNE

RUNS,

BUT

MISSES

ROUGH

ENGINE

IDLE

Determine

if

the

miss

is

steady

or

erratic

and

at

what

speed

the

miss

occurs

by

operating

the

engine

at

various

speeds

under

load.

MISSES

STEADILY

AT

ALL

SPEEDS

Isolate

the

miss

by

operating

the

engine

with

one

cylinder

not

firing.

This

is

done

by

operating

the

engine

with

the

ignition

wire

removed

from

one

spark

plug

at

a

time,

until

all

cylinders

have

been

checked.

Ground

the

spark

plug

wire

re

moved.

If

the

engine speed

changes

when

a

particular

cylinder

is

shorted

out,

that

cylinder

was

delivering

power

before

being

shorted

out.

If

no

change

in

the

engine

operation

is

evident,

the

miss

was

caused

by

that

cylinder

not

delivering

power

before

being

shorted

out.

Check

the:

IGNITION

SYSTEM

If

the

miss

is

isolated

in

a

par

ticular

cylinder,

perform

a

spark

test

on

the

ignition

lead

of

the

cyl

inder.

If

a

good

spark

does

not

occur,

the

trouble

is

in

the

secondary

cir

cuit

of

the

system,

check

the:

Spark

plug

wire.

Distributor

cap.

If

a

good

spark

occurs,

check

the

spark

plug.

If

the

spark

plug

is

not

at

fault,

a

mechanical

component

of

the

engine

is

probably

at

fault.

ENGINE

Perform

a

compression

test

to

de

termine

which

mechanical

compo

nent

of

the

engine

is

at

fault.

MISSES

ERRATICALLY

AT

ALL

SPEEDS

EXHAUST

SYSTEM

Exhaust

gas

control

valve

inoper

ative

or

sticking

(352

engine).

Exhaust

system

restricted.

IGNITION

SYSTEM

Breaker

points

not

properly

ad

justed.

Defective

breaker

points,

con

denser,

secondary

wiring,

coil,

or

spark

plugs.

High

tension

leakage

across

the

coil,

rotor,

or

distributor

cap.

FUEL

SYSTEM

Choke

not

operating

properly.

Float

setting

incorrect.

Fuel

inlet

system

not

operating

properly.

Dirt

or

water

in

fuel

lines

or

carburetor.

COOLING

SYSTEM

Check

the

cooling

system

for

in

ternal

leakage

and/or

for

a

condi

tion

that

prevents

the

engine

from

reaching

normal

operating

tempera

ture.

ENGINE

Perform

a

compression

test

to

determine

which

mechanical

com

ponent

of

the

engine

is

at

fault.

MISSES

AT

IDLE

ONLY

FUEL

SYSTEM

Idle

fuel

mixture

needles

not

properly

adjusted.

IGNITION

SYSTEM

Defective

coil,

condenser,

breaker

points,

rotor,

ignition

wiring,

or

spark

plugs.

Excessive

play

in

the

distributor

shaft.

Worn

distributor

cam.

VACUUM

BOOSTER

PUMP

Leaking

pump,

lines,

or

fittings.

ENGINE

Perform

a

compression

test

to

determine

which

mechanical

com

ponent

of

the

engine

is

at

fault.

MISSES

AT

HIGH

SPEED

ONLY

FUEL

SYSTEM

Power

valve

clogged

or

damaged

(Ford

carburetor).

Vacumeter

not

operating

properly

(Carter

carburetor).

Low

or

erratic

fuel

pump

pres

sure.

Fuel

inlet

system

not

operating

properly.

COOLING

SYSTEM

Engine

overheating.

FUEL

SYSTEM

Engine

idle

speed

set

too

low.

Idle

fuel

mixture

needle(s)

not

properly

adjusted.

Float

setting

incorrect.

Air

leaks

between

the

carburetor

and

the

manifold

and/or

fittings.

Fuel

leakage

at

the

carburetor

fuel bowl(s).

CONTINUED

ON

NEXT

PAGE

PART

1-1

-GENERAL

ENGINE

SERVICE

1-5

ENGINE

TROUBLE

DIAGNOSIS

GUIDE

(Cont.)

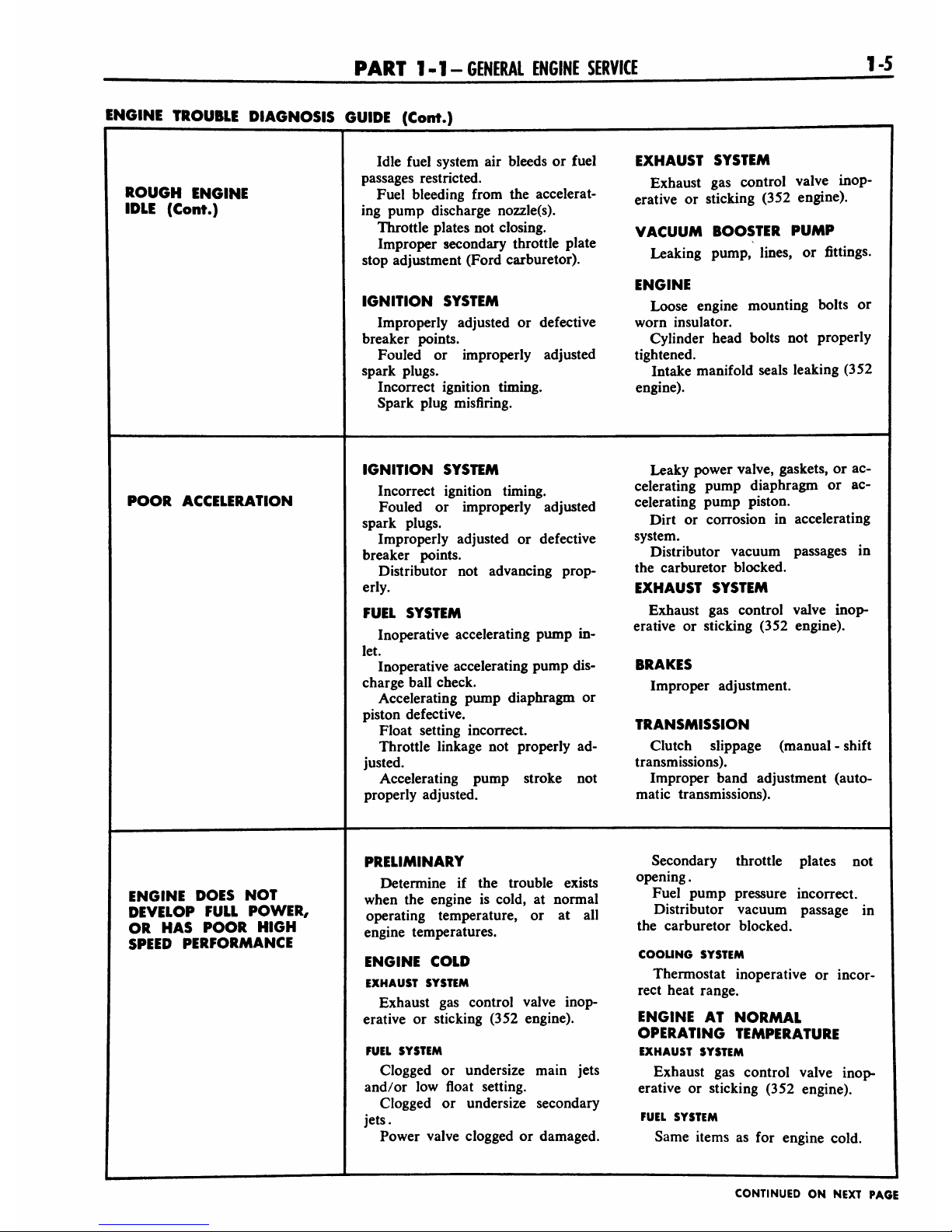

ROUGH

ENGINE

IDLE

(Cont.)

Idle

fuel

system

air

bleeds

or

fuel

EXHAUST

SYSTEM

passages

restricted.

Exhaust

gas

control

valve

inop-

Fuel

bleeding

from

the

accelerat-

erative

or

sticking

(352

engine).

ing

pump

discharge

nozzle(s).

Throttle

plates

not

closing.

VACUUM

BOOSTER

PUMP

Improper

secondary

throttle

plate

,

.

,

*.*.-

stop

adjustment

(Ford

carburetor).

Leak"*

PumP>

,mes>

or

fittm8s-

ENGINE

IGNITION

SYSTEM

Loose

engine

mounting

bolts

or

Improperly

adjusted

or

defective

worn

insulator.

breaker

points.

Cylinder

head

bolts

not

properly

Fouled

or

improperly

adjusted

tightened.

spark

plugs.

Intake

manifold

seals

leaking

(352

Incorrect

ignition

timing.

engine).

Spark

plug

misfiring.

POOR

ACCELERATION

IGNITION

SYSTEM

Leaky

power

valve,

gaskets,

or

ac-

Incorrect

ignition

timing.

celerating

pump

diaphragm

or

ac-

Fouled

or

improperly

adjusted

celerating

pump

piston.

spark

plugs.

Dirt

or

corrosion

in

accelerating

Improperly

adjusted

or

defective

system.

breaker

points.

Distributor

vacuum

passages

in

Distributor

not

advancing

prop-

the

carburetor

blocked.

erly.

EXHAUST

SYSTEM

FUEL

SYSTEM

Exhaust

gas

control

valve

inop-

,

erative or

sticking

(352

engine).

Inoperative

accelerating

pump

in-

&

v

e

let.

Inoperative

accelerating

pump

dis-

BRAKES

charge

ball

check.

Improper

adjustment.

Accelerating

pump

diaphragm

or

piston

defective.

tbammk<iom

Float

setting

incorrect.

iKAnainiaaiuri

Throttle

linkage

not

properly

ad-

Clutch

slippage

(manual

-

shift

justed.

transmissions).

Accelerating

pump

stroke

not

Improper

band

adjustment

(auto-

properly

adjusted.

matic

transmissions).

ENGINE

DOES

NOT

DEVELOP

FULL

POWER,

OR

HAS

POOR

HIGH

SPEED

PERFORMANCE

PRELIMINARY

Secondary

throttle

plates

not

Determine

if

the

trouble

exists

opening.

when

the

engine

is

cold,

at

normal

Fuel

PumP

Pressure

^correct.

operating

temperature,

or

at

all

Distributor

vacuum

passage

in

engine

temperatures.

the

carburetor

blocked.

ENGINE

COLD

COOUNG

SYSTEM

EXHAUST

SYSTEM

Thermostat

inoperative

or

incor-

rect

heat

range.

Exhaust

gas

control

valve

inop

erative

or

sticking

(352

engine).

ENGINE

AT

NORMAL

OPERATING

TEMPERATURE

FUEL

SYSTEM

EXHAUST

SYSTEM

Clogged

or

undersize

main

jets

Exhaust

gas

control

valve

inop-

and/or

low

float

setting.

erative

or

sticking

(352

engine).

Clogged

or

undersize

secondary

jets.

FuEL

SYSTEM

Power

valve

clogged

or

damaged.

Same

items

as

for

engine

cold.

CONTINUED

ON

NEXT

PAGE

1-6

GROUP

1

-ENGINES

AND

EXHAUST

SYSTEM

ENGINE

TROUBLE

DIAGNOSIS

GUIDE

(Cont.)

ALL

ENGINE

TEMPERATURES

ENGINE

IGNITION

SYSTEM

Perform

an

engine

compression

ENGINE

DOES

NOT

DEVELOP

FULL

POWER,

Ignition

timing

not

properly

ad

justed.

Defective

coil,

condenser,

or

test

to

determine

which

mechanical

component

is

at

fault.

OR

HAS

POOR

HIGH

One

or

more

camshaft

lobes

worn

SPEED

PERFORMANCE

(Cont.)

rotor.

beyond

wear

limit.

Distributor

not

advancing

prop

Improper

valve

timing.

erly.

Excessive

play

in

the

distributor

EXHAUST

SYSTEM

shaft.

Restriction

in

system.

Distributor

cam

worn.

Fouled

or

improperly

adjusted

TRANSMISSION

spark

plugs

or

spark

plugs

of

im

Improper

band

adjustment

(auto

proper

heat

range.

matic

transmissions).

Improperly

adjusted

or

defective

breaker

points.

BRAKES

Improper

adjustment.

FUEL

SYSTEM

Restricted

air

cleaner.

TIRES

Same

items

as

for

engine

cold.

Improper

pressure.

Determine

the

actual

fuel

con

Idle

fuel

mixture

needle(s)

for

sumption

with

test

equipment

in

proper

adjustment.

EXCESSIVE

FUEL

stalled

in

the

car.

Automatic

choke

for

proper

op

CONSUMPTION

If

the

test

indicates

that

the

fuel

eration.

consumption

is

not

excessive,

dem

Fast

idle

speed

screw

for

proper

onstrate

to

the

owner

how

improper

adjustment.

driving

habits

will

affect

fuel

con

Accelerating

pump

stroke

ad

sumption.

justment.

If

the

test

indicates

that

the

fuel

Anti-stall

dashpot

for

proper

ad

consumption

is

excessive,

make

a

justment.

preliminary

check

of

the

following

Air

cleaner

for

restrictions.

items

before

proceeding

to

the

fuel

Float

setting

or

fuel

level.

and

ignition

systems.

Jets

for

wear

and/or

damage.

Power

valve

or

Vacumeter

opera

PRELIMINARY

CHECKS

tion.

Air

bleeds

for

obstructions.

CHASSIS

ITEMS

Accelerating

pump

discharge

noz

Check:

zles

for

siphoning.

Tires

for

proper

pressure.

IGNITION

SYSTEM

Front

wheel

alignment.

Check:

Brake

adjustment.

Ignition

timing.

EXHAUST

SYSTEM

Spark

plug

condition

and

adjust

Check

the

exhaust

gas

control

ment.

Distributor

spark

advance

opera

valve

operation

(352

engine).

tion.

ODOMETER

ENGINE

Check

calibration.

Perform

an

engine

compression

test

to

determine

which

mechanical

IGNITION

SYSTEM

component

of

the

engine

isatfault.

Check

ignition

timing.

COOLING

SYSTEM

FJNAL

CHECKS

Check

thermostat

operation

and

heat

range.

FUEL

SYSTEM

Check:

TRANSMISSION

Fuel

pump

pressure.

Check

band

adjustment

(auto

Engine

idle

speed.

matic

transmissions).

CONTINUED

ON

NEXT

PAGE

PART

1-1

-GENERAL

ENGINE

SERVICE

1-7

ENGINE

TROUBLE

DIAGNOSIS

GUIDE

(Cont.)

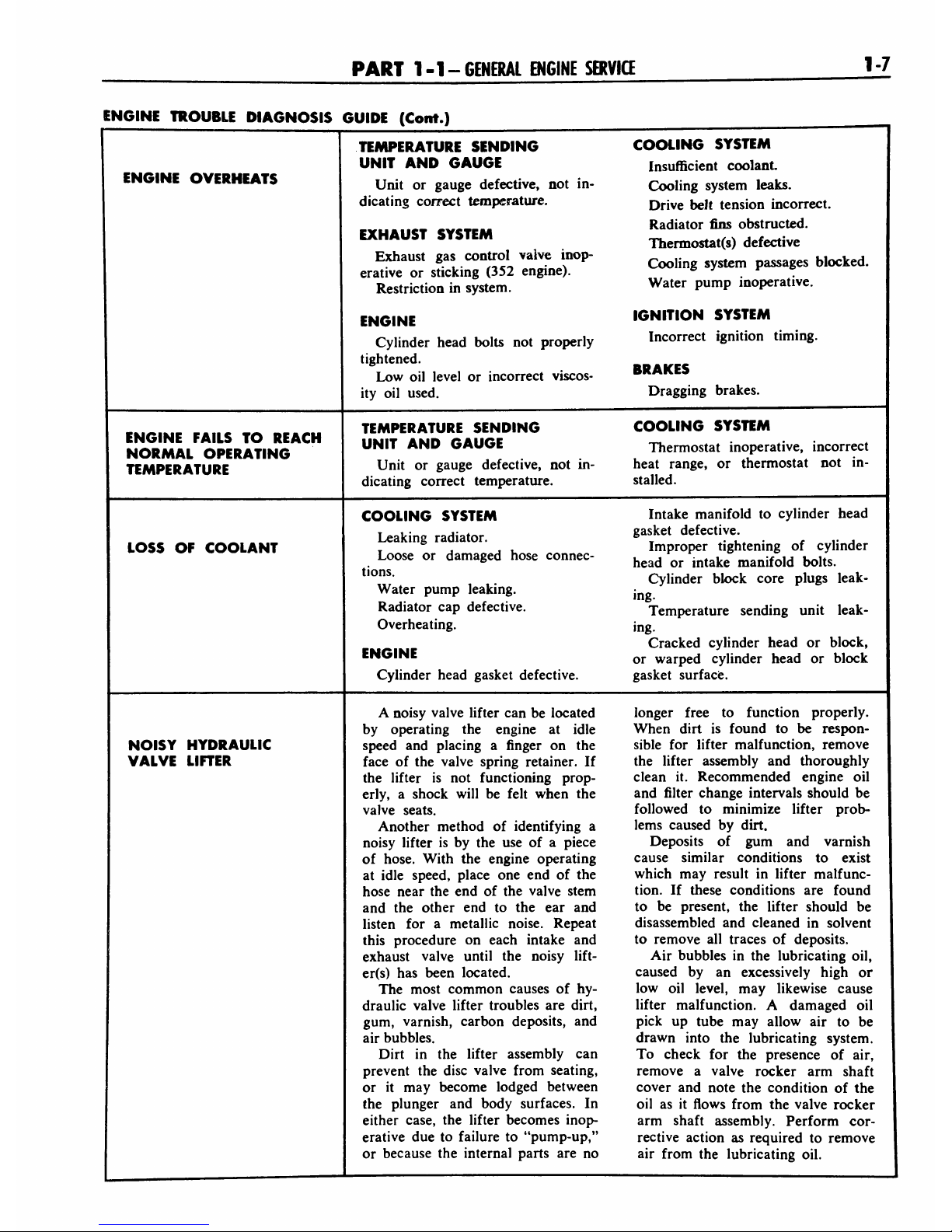

ENGINE

OVERHEATS

TEMPERATURE

SENDING

COOLING

SYSTEM

UNIT

AND

GAUGE

Insufficient

coolant

Unit

or

gauge

defective,

not

in-

Cooling

system

leaks.

dicating

correct

temperature.

Drjve

belt

tension

incorrect.

>~u..e*

.vtfiu

Radiator

fins

obstructed.

EXHAUST

SYSTEM

Therrnostat(s)

defective

Exhaust

gas

control

valvemop-

bhW

erative

or

sticking

(352

engine).

'

.

.

Restriction

in

system.

Water

PumP

^operative.

ENG(NE

IGNITION

SYSTEM

Cylinder

head

bolts

not

properly

Incorrect

ignition

timing.

tightened.

makes

Low

oil

level

or

incorrect

viscos-

""*"

ity

oil

used.

Dragging

brakes.

ENGINE

FAILS

TO

REACH

NORMAL

OPERATING

TEMPERATURE

TEMPERATURE

SENDING

COOLING

SYSTEM

UNIT AND

GAUGE

Thermostat

inoperative,

incorrect

Unit

or

gauge

defective,

not

in-

heat

range,

or

thermostat

not

in

dicating

correct

temperature.

stalled.

LOSS

OF

COOLANT

COOLING

SYSTEM

Intake

manifold

to

cylinder

head

Leaking

radiator.

SasTket

defec^e'

.

f

..

.

,

.

Improper

tightening

of

cylinder

Loose

or

damaged

hose

connec-

head

Qr

mtake

manifold

MtSm

Uom-

Cylinder

block

core

plugs

leak-

Water

pump

leaking.

Radiator

cap

defective.

Temperature

sending

unit

leak-

Overheating.

ing.

Cracked

cylinder

head

or

block,

ENGINE

or

warpe(j

cylinder

head

or

block

j

Cylinder

head

gasket

defective.

gasket

surface.

NOISY

HYDRAULIC

VALVE

LIFTER

A

noisy

valve

lifter

can

be

located

longer

free

to

function

properly.

by

operating

the

engine

at

idle

When

dirt

is

found

to

be

respon-

speed

and

placing

a

finger

on

the

sible

for lifter

malfunction,

remove

face

of

the

valve

spring

retainer.

If

the

lifter

assembly

and

thoroughly

the

lifter

is

not

functioning

prop-

clean

it.

Recommended

engine

oil

erly,

a

shock

will

be

felt

when

the

and

filter

change

intervals

should

be

valve

seats.

followed

to

minimize

lifter

prob-

Another

method

of

identifying

a

lems

caused

by

dirt.

noisy

lifter

is

by

the

use

ofapiece

Deposits

of

gum

and

varnish

of

hose.

With

the

engine

operating

cause

similar

conditions

to

exist

at

idle

speed,

place one

end

of

the

which

may

result

in

lifter

malfunc-

hose

near

the

end

of

the

valve

stem

tion.

If

these

conditions

are

found

and

the

other

end

to

the

ear

and

to

be

present,

the

lifter

should

be

listen

for

a

metallic

noise.

Repeat

disassembled

and

cleaned

in

solvent

this

procedure

on

each

intake

and

to

remove

all

traces

of

deposits.

exhaust

valve

until

the

noisy

lift-

Air

bubbles

in

the

lubricating

oil,

er(s)

has

been

located.

caused

by

an

excessively

high

or

The

most

common

causes

of

hy-

low

oil

level,

may

likewise

cause

draulic

valve

lifter

troubles

are

dirt,

lifter

malfunction.

A

damaged

oil

gum, varnish,

carbon

deposits,

and

pick

up

tube

may

allow

air

to

be

air

bubbles.

drawn

into

the

lubricating

system.

Dirt

in

the

lifter

assembly

can

To

check

for

the

presence

of

air,

prevent

the

disc

valve

from

seating,

remove

a

valve

rocker

arm

shaft

or

it

may

become

lodged

between

cover

and

note

the

condition

of

the

the

plunger

and

body

surfaces.

In

oil

as

it

flows

from

the

valve

rocker

either

case,

the

lifter

becomes

inop-

arm

shaft

assembly.

Perform

cor-

erative

due

to

failure

to

"pump-up,"

rective

action

as

required

to

remove

or

because

the

internal

parts

are

no

air

from

the

lubricating

oil.

1-8

GROUP

1

-ENGINES

AND

EXHAUST

SYSTEM

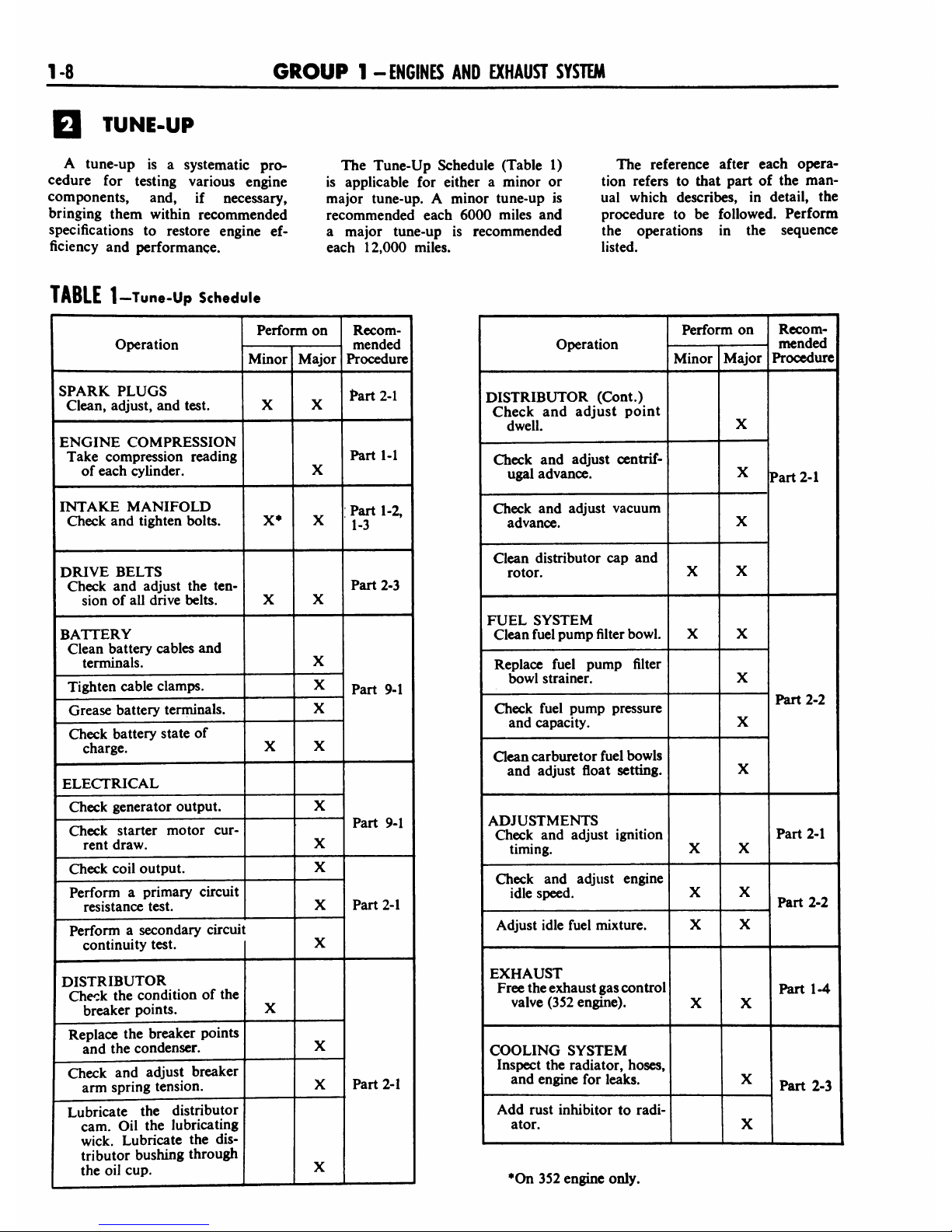

TUNE-UP

A

tune-up

is

a

systematic

pro

cedure

for

testing

various

engine

components,

and,

if

necessary,

bringing

them

within

recommended

specifications

to

restore

engine

ef

ficiency

and

performance.

The

Tune-Up

Schedule

(Table

1)

is

applicable

for

either

a

minor

or

major

tune-up.

A

minor

tune-up

is

recommended

each

6000

miles

and

a

major

tune-up

is

recommended

each

12,000

miles.

The

reference

after

each

opera

tion

refers

to

that

part

of

the

man

ual

which

describes,

in

detail,

the

procedure

to

be

followed.

Perform

the

operations

in

the

sequence

listed.

TABLE

1

-Tune-Up

Schedule

Operation

Perform

on

Recom

mended

Procedure

Minor

Major

SPARK

PLUGS

Clean,

adjust,

and

test.

X

X

Part

2-1

ENGINE

COMPRESSION

Take

compression

reading

of

each

cylinder.

X

Part

1-1

INTAKE

MANIFOLD

Check

and

tighten

bolts.

X*

X

Part

1-2,

1-3

DRIVE

BELTS

Check

and

adjust

the

ten

sion

of

all

drive

belts.

X

X

Part

2-3

BATTERY

Clean

battery

cables

and

terminals.

X

Part

9-1

Tighten

cable

clamps.

X

Grease

battery

terminals.

X

Check

battery

state

of

charge.

X

X

ELECTRICAL

Part

9-1

Check

generator

output.

X

Check

starter

motor

cur

rent

draw.

X

Check

coil

output.

X

Part

2-1

Perform

a

primary

circuit

resistance

test.

X

Perform

a

secondary

circuit

continuity

test.

t

X

DISTRIBUTOR

Check

the

condition

of

the

breaker

points.

X

Part

2-1

Replace

the

breaker

points

and

the

condenser.

X

Check

and

adjust

breaker

arm

spring

tension.

X

Lubricate

the

distributor

cam.

Oil

the

lubricating

wick.

Lubricate

the

dis

tributor

bushing

through

the

oil

cup.

X

Operation

Perform

on

Recom

mended

Procedure

Minor

Major

DISTRIBUTOR

(Cont.)

Check

and

adjust

point

dwell.

X

Part

2-1

Check

and

adjust

centrif

ugal

advance.

X

Check

and

adjust

vacuum

advance.

X

Clean

distributor

cap

and

rotor.

X

X

FUEL

SYSTEM

Clean

fuel

pump

filter

bowl.

X

X

Part

2-2

Replace

fuel

pump

filter

bowl

strainer.

X

Check

fuel

pump

pressure

and

capacity.

X

Clean

carburetor

fuel

bowls

and

adjust

float

setting.

X

ADJUSTMENTS

Check

and

adjust

ignition

timing.

X

X

Part

2-1

Check

and

adjust

engine

idle

speed.

X

X

Part

2-2

Adjust

idle

fuel

mixture.

X X

EXHAUST

Free

the

exhaust

gas

control

valve

(352

engine).

X

X

Part

1-4

COOLING

SYSTEM

!

Inspect

the

radiator,

hoses,

and

engine

for

leaks.

X

Part

2-3

Add

rust

inhibitor

to

radi

ator.

X

*On

352

engine only.

PART

1-1

-GENERAL

ENGINE

SERVICE

1-9

TESTS

AND

ADJUSTMENTS

(ENGINE

INSTALLED)

CAMSHAFT

LOBE

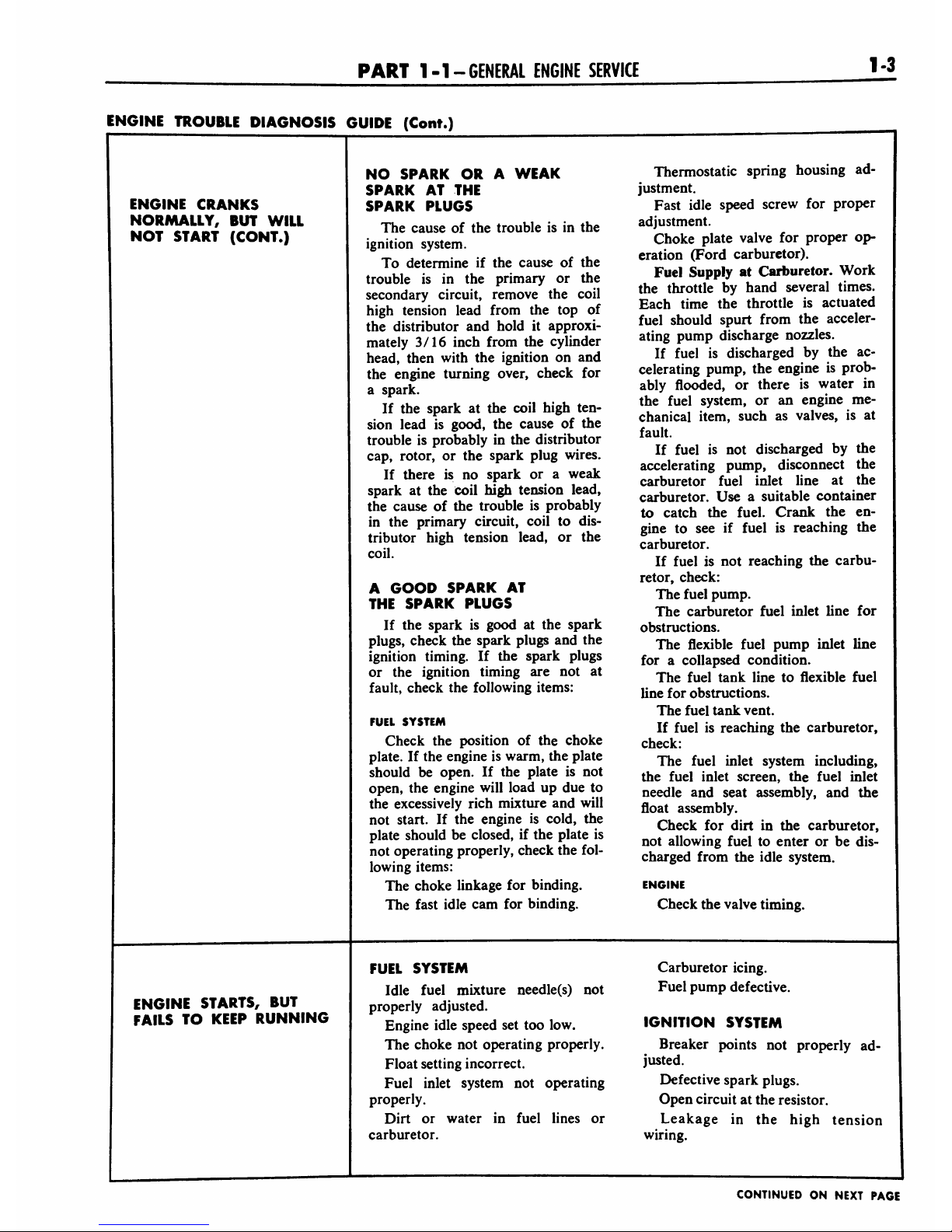

LIFT

1.

Remove

the

valve

rocker

arm

shaft

assembly

and

install

a

solid

tappet-type

push

rod

in

the

push

rod

bore

of

the

camshaft

lobe

to

be

checked.

2.

Make

sure

the

push

rod

is

in

the

lifter

push

rod

cup,

then

install

a

dial

indicator

in

such

a

manner

as

to

have

the

actuating

point

of

the

indi

cator

in

the

push

rod

socket

and

in

the

same

plane

as

the

push

rod

move

ment

(Fig.

1).

3.

Rotate

the

crankshaft

slowly

in

the

direction

of

rotation

until

the

lifter

is

on

the

base

circle

of

the

cam

shaft

lobe.

At

this

point,

the

push

rod

will

be

in

its

lowest

position.

Zero

the

dial

indicator,

then

continue

to

rotate

the

damper

slowly

until

the

push

rod

is

in

the

fully

raised

position.

Com

pare

the

total

lift

recorded

on

the

indicator

with

specifications.

4.

Continue

to

rotate

the

crank

shaft

until

the

indicator

reads

zero.

This

is

a

check

on

the

accuracy

of

the

original

indicator

reading.

VALVE

TIMING

The

valve

timing

should

be

checked

when

poor

engine

performance

is

noted

and

all

other

checks,

such

as

carburetion,

ignition

timing,

etc.

fail

to

locate

the

cause

of

the

trouble.

Before

the

valve

timing

is

checked,

check

for

a

bent

timing

pointer.

Bring

the

No.

1

piston

to

T.D.C.

on

the

compression

stroke

and

see

if

the

timing

pointer

is

aligned

with

the

T.D.C.

mark

on

the

damper.

If

the

valve

timing

is

not

within

specifications,

check

the

timing

chain,

camshaft

sprocket,

crankshaft

sprock

et,

camshaft,

and

crankshaft

in

the

order

of

accessibility.

To

check

the

valve

timing

with

the

engine

installed,

proceed

as

follows:

1.

Install

a

quadrant

on

the

crank

shaft

damper.

BE

SURE

TO

PLACE

Indicator

TIP

IN

CENTER

OF

PUSH

ROD

SOCKET

1748-B

FIG.

1

Camshaft

Lobe

Lift

Typical

Remove

the

right

valve

rocker

arm

shaft

assembly

and

remove

the

No.

1

intake

valve

push

rod

(the

second

push

rod)

and

install

a

solid

tappet-

type

push

rod

in

its

place.

2.

Make

sure

the

push

rod

is

in

the

lifter

push

rod

cup,

then

install

a

dial

indicator

in

such

a

manner

as

to

have

the

actuating

point

of

the

in

dicator

in

the

push

rod

socket

and

in

the

same

plane

as

the

push

rod

move

ment

(Fig.

1).

3.

Rotate

the

crankshaft

slowly

in

the

direction

of

rotation

until

the

lifter

is

on

the

base

circle

of

the

cam

shaft

lobe.

At

this

point

the

push

rod

will

be

in

its

lowest

position.

Zero

the

dial

indicator

and

continue

rotat

ing

the

crankshaft

slowly

in

the

direc

tion

of

rotation

until

the

dial

indicator

registers

the

specified

camshaft

lobe

lift (Table

2).

4.

Compare

the

crankshaft

degrees

indicated

on

the

quadrant

with

speci

fications

(Table

2).

After

the

valve

opening

is

checked,

continue

to

ro

tate

the

damper

to

check

the

valve

closing.

VALVE

CLEARANCE

A

0.060-inch

shorter

push

rod

(color

coded

white)

or

a

0.060-inch

longer

push

rod

(color

coded

yel

low)

is

available

for

service

to

pro

vide

a

means

of

compensating

for

dimensional

changes

in

the

valve

mechanism.

Valve

stem

to

valve

rocker

arm

clearance

should

be

0.078-0.218

inch

(352

engine)

or

0.126-0.226

inch

(430

engine)

with

the

hydraulic

lifter

completely

col

lapsed.

Repeated

valve

recondition

ing

operations

(valve

and/or

valve

seat

refacing)

will

decrease

this

clear-

TABLE

2

Valve

Timing

Specifications

Engine

Intake

Valve

Exhaust

Valve

Opens

Closes

Opens

Closes

Crankshaft

Degrees

(BTDC)

Camshaft

Lobe

Lift

(Inch)

Crankshaft

Degrees

(ABDC)

Camshaft

Lobe

Lift

(Inch)

Crankshaft

Degrees

(BBDC)

Camshaft

Lobe

Lift

(Inch)

Crankshaft

Degrees

(ATDC)

Camshaft

Lobe

Lift

(Inch)

352

22

0.002

68

0.005

68

0.002

22

0.005

430

22

0.002

68

0.005

63

0.002

27

0.005

MO

GROUP

1-

ENGINES

AND

EXHAUST

SYSTEM

1883-A

Mb.

2

Valve

Clearance

Typical

ance

to

the

point

that

if

not

com

pensated

for,

the

hydraulic

valve

lifter

will

cease

to

function.

The

correct

operating

range

of

the

hydraulic

valve

lifter

plunger

must

be

maintained

because:

If

the

plunger

travel

is

excessive,

the

lifter

pump-up

time

will

be

pro

longed

resulting

in

excessive

valve

train

noise

following

engine

start-up.

If

the

travel

is

insufficient

to

com

pensate

for

normal

expansion

of

the

valve

operating

components,

the

valve

would

not

be

permitted

to

seat

properly

resulting

in

a

rough

engine

and/or

premature

valve

failure.

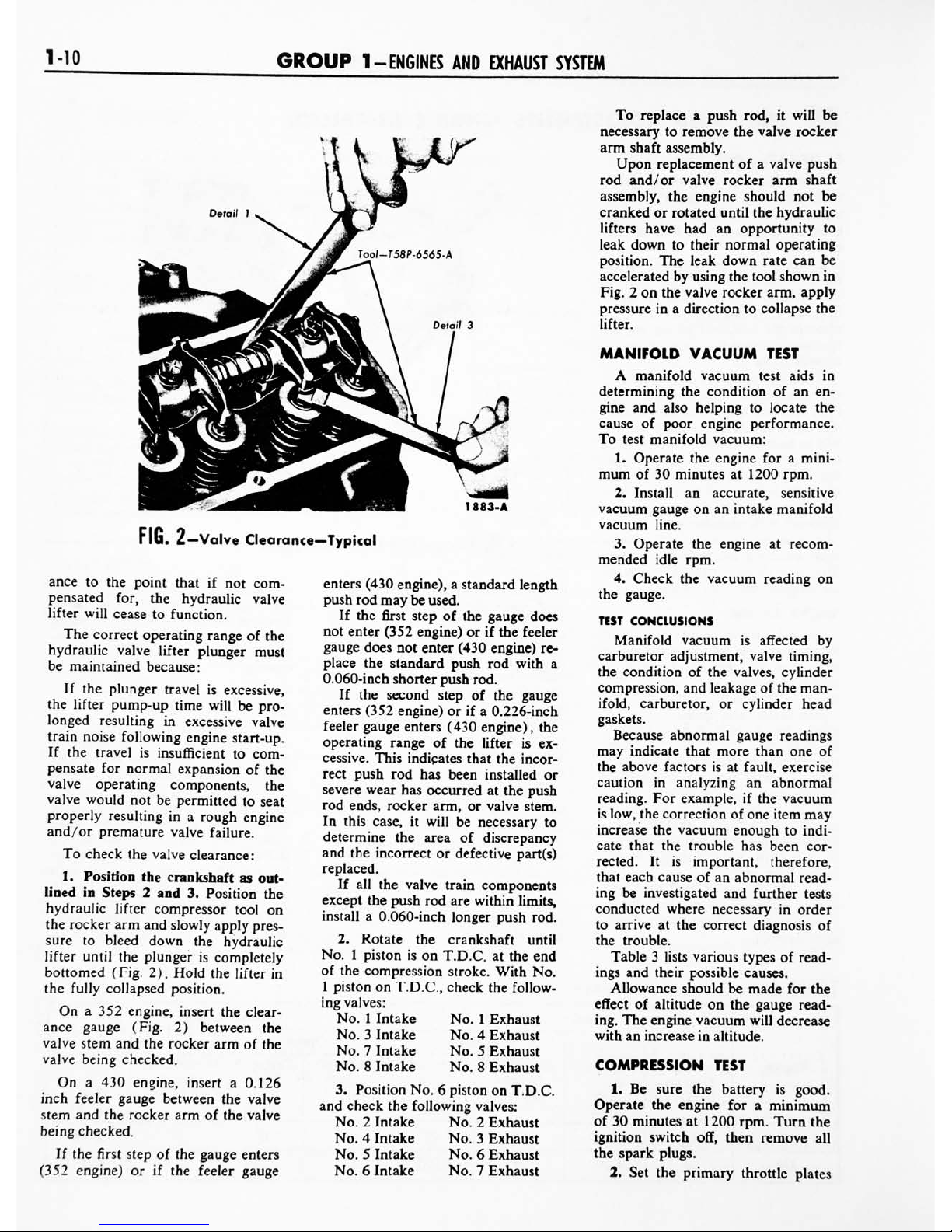

To

check

the

valve

clearance:

1.

Position

the

crankshaft

as

out

lined

in

Steps

2

and

3.

Position

the

hydraulic

lifter

compressor

tool

on

the

rocker

arm

and

slowly

apply

pres

sure

to

bleed

down

the

hydraulic

lifter

until

the

plunger

is

completely

bottomed

(Fig.

2).

Hold

the

lifter

in

the

fully

collapsed

position.

On

a

352

engine,

insert

the

clear

ance

gauge

(Fig.

2)

between

the

valve

stem

and

the

rocker

arm

of

the

valve

being

checked.

On

a

430

engine,

insert

a

0.126

inch

feeler

gauge

between

the

valve

stem

and

the

rocker

arm

of

the

valve

being

checked.

If

the

first

step

of

the

gauge

enters

(352

engine)

or

if

the

feeler

gauge

enters

(430

engine),

a

standard

length

push

rod

may

be

used.

If

the

first

step

of

the

gauge

does

not

enter

(352

engine)

or

if

the

feeler

gauge

does

not

enter

(430

engine)

re

place

the

standard

push

rod

with

a

0.060-inch

shorter

push

rod.

If

the

second

step

of

the

gauge

enters

(352

engine)

or

if

a

0.226-inch

feeler

gauge

enters

(430

engine),

the

operating

range

of

the

lifter

is

ex

cessive.

This

indicates

that

the

incor

rect

push

rod

has

been

installed

or

severe

wear

has

occurred

at

the

push

rod

ends,

rocker

arm,

or

valve

stem.

In

this

case,

it

will

be

necessary

to

determine

the

area

of

discrepancy

and

the

incorrect

or

defective

part(s)

replaced.

If

all

the

valve

train

components

except

the

push

rod

are

within

limits,

install

a

0.060-inch

longer

push

rod.

2.

Rotate

the

crankshaft

until

No.

1

piston

is

on

T.D.C.

at

the

end

of

the

compression

stroke.

With

No.

1

piston

on

T.D.C,

check

the

follow

ing

valves:

No.

1

Intake

No.

1

Exhaust

No.

3

Intake No.

4

Exhaust

No.

7

Intake

No.

5

Exhaust

No.

8

Intake

No.

8

Exhaust

3.

Position

No.

6

piston

on

T.D.C.

and

check

the

following

valves:

No.

2

Intake

No.

2

Exhaust

No.4Intake

No.

3

Exhaust

No.

5

Intake

No.

6

Exhaust

No.6Intake

No.

7

Exhaust

To

replace

a

push

rod,

it

will

be

necessary

to

remove

the

valve

rocker

arm

shaft

assembly.

Upon

replacement

of

a

valve

push

rod

and/

or

valve

rocker

arm

shaft

assembly,

the

engine

should

not

be

cranked

or

rotated

until

the

hydraulic

lifters

have had

an

opportunity

to

leak

down

to

their

normal

operating

position.

The

leak

down

rate

can

be

accelerated

by

using

the

tool

shown

in

Fig.

2

on

the

valve

rocker

arm,

apply

pressure

in

a

direction

to

collapse

the

lifter.

MANIFOLD

VACUUM

TEST

A

manifold

vacuum

test

aids

in

determining

the

condition

of

an

en

gine

and

also

helping

to

locate

the

cause

of

poor

engine

performance.

To

test

manifold

vacuum:

1.

Operate

the

engine

for

a

mini

mum

of

30

minutes

at

1200

rpm.

2.

Install

an

accurate,

sensitive

vacuum

gauge

on

an

intake

manifold

vacuum

line.

3.

Operate

the

engine

at

recom

mended

idle

rpm.

4.

Check

the

vacuum

reading

on

the

gauge.

TEST

CONCLUSIONS

Manifold

vacuum

is

affected

by

carburetor

adjustment,

valve

timing,

the

condition

of

the

valves,

cylinder

compression,

and

leakage

of

the

man

ifold,

carburetor,

or

cylinder

head

gaskets.

Because

abnormal

gauge

readings

may

indicate

that

more

than

one

of

the

above

factors

is

at

fault,

exercise

caution

in

analyzing

an

abnormal

reading.

For

example,

if

the

vacuum

is

low,

the

correction

of

one

item

may

increase

the

vacuum

enough

to

indi

cate

that

the

trouble

has

been

cor

rected.

It

is

important,

therefore,

that

each

cause

of

an

abnormal

read

ing

be

investigated

and

further

tests

conducted

where

necessary

in

order

to

arrive

at

the

correct

diagnosis

of

the

trouble.

Table

3

lists

various

types

of

read

ings

and

their

possible

causes.

Allowance

should

be

made

for

the

effect

of

altitude

on

the

gauge

read

ing.

The

engine

vacuum

will

decrease

with

an

increase

in

altitude.

COMPRESSION

TEST

1.

Be

sure

the

battery

is

good.

Operate

the

engine

for

a

minimum

of

30

minutes

at

1200

rpm.

Turn

the

ignition

switch

off,

then

remove

all

the

spark

plugs.

2.

Set

the

primary

throttle

plates

PART

1-1

-GENERAL

ENGINE

SERVICE

Ml

and

the

choke

plate

in

the

wide

open

position.

3.

Install

a

compression

gauge

in

No.

1

cylinder.

4.

Crank

the

engine

several

times

and

record

the

highest

reading

reg

istered.

Note

the

number

of

compres

sion

strokes

required

to

obtain

the

highest

reading.

5.

Repeat

the

test

on

each

cylin

der,

cranking

the

engine

the

same

number

of

times

for

each

cylinder

as

was

required

to

obtain

the

highest

reading

on

No.

1

cylinder.

TEST

CONCLUSIONS

A

variation

of

20

pounds

from

specified

pressure

is

satisfactory.

However,

the

compression

of

all

cyl

inders

should

be

uniform

within

10

pounds.

A

reading

of

more

than

the

allow

able

tolerance

above

normal

indicates

excessive

deposits

in

the

cylinder.

A

reading

of more

than

the

allow

able

tolerance

below

normal

indicates

leakage

at

the

cylinder

head

gasket,

piston

rings,

or

valves.

A

low

even

compression

in

two

adjacent

cylinders

indicates

a

cylin

der

head

gasket

leak.

This

should

be

checked

before

condemning

the

rings

or

valves.

To

determine

whether

the

rings

or

the

valves

are

at

fault,

squirt

the

equivalent

of

a

tablespoon

of

heavy

TABLE

3

Manifold

Vacuum

Gauge

Readings

Gauge

Reading

Engine

Condition

19-20

inches

(352

engine).

17-18

inches

(430

engine).

Normal.

Low

and

steady.

Loss

of

power

in

all

cylinders

caused

possibly

by

late

ignition

or

valve

timing,

or

loss

of

compression

due

to

leakage

around

the

piston

rings.

Very

low.

Manifold,

carburetor,

or

cylinder

head

gasket

leak.

Needle

fluctuates

steadily

as

speed

increases.

A

partial

or

complete

loss

of

power

in

one

or

more

cylinders

caused

by

a

leaking

valve,

cyl

inder

head

or

intake

manifold

gasket

leak,

a

defect

in

the

ignition

system,

or

a

weak

valve

spring.

Gradual

drop

in

reading

at

engine

idle.

Excessive

back

pressure

in

the

exhaust

system.

Intermittent fluctuation.

An

occasional

loss

of

power

possibly

caused

by

a

defect

in

the

ignition

system

or

a

sticking

valve.

Slow

fluctuation

or

drifting

of

the

needle.

Improper

idle

mixture

adjustment,

carburetor

or

intake

manifold

gasket

leak,

or

possibly

late

valve

timing.

oil

into

the

combustion

chamber,

then

crank

the

engine

to

distribute

the

oil

and repeat

the

compression

test.

The

oil

will

temporarily

seal

leakage

past

the

rings.

If

approximately

the

same

reading

is

obtained,

the

rings

are

satisfactory,

but

the

valves

are

leak

ing.

If

the

compression

has

increased

10

pounds

or

more

over

the

original

reading,

there

is

leakage

past

the

rings.

During

a

compression

test,

if

the

pressure

fails

to

climb

steadily

and

remains

the

same

during

the

first

two

successive

strokes,

but

climbs

higher

on

the

succeeding

strokes,

or

fails

to

climb

during

the

entire

test,

it

in

dicates

a

sticking

or

stuck

valve.

CLEANING,

INSPECTION,

AND

RECONDITIONING

INTAKE

MANIFOLD

Clean

the

manifolds

in

a

suitable

solvent,

then

dry

them

with

com

pressed

air.

On

the

352

engine,

scrape

all

car

bon

deposits

from

the

center

exhaust

passage

below

the

carburetor

heat

riser.

This

carbon

acts

as

an

insu

lator

restricting

the

heating

action

of

the

hot

exhaust

gases.

Inspect

the

manifold

for

cracks,

leaks,

or

other

defects

that

would

make

it

unfit

for

further

service.

Re

place

all

studs

that

are

stripped

or

otherwise

damaged.

Remove

all

fil

ings

and

foreign

matter

that

may

have

entered

the

manifold

as

a

result

of

repairs.

On

the

352

engine,

check

the

baffle

plate

on

the

underside

of

the

mani

fold

for

looseness

and

be

sure

the

maze

screen

is

in

place.

Clean

off

any

varnish

accumulation.

EXHAUST

MANIFOLD

Inspect

the

manifolds

for

cracks,

leaks,

or

other

defects

that

would

make

them

unfit

for further

service.

On

the

right

exhaust

manifold

of

the

352

engine,

clean

out

the

auto

matic

choke

air

heat

chamber

(Fig.

3).

Make

sure

the

air

inlet

and

outlet

holes

are

completely

open

and

the

cover

does

not

leak.

Blow

out

the

AIR

INLET'

1S09-A

FIG.

3

Automatic

Choke

Air

Heat

Chamber

352

Engine

M2

GROUP

1-

ENGINES

AND

EXHAUST

SYSTEM

Runout

Gauge

Holding

fixture'

PUSH

ROD

FIG.

4

Push

Rod

Runout

Typical

1003-A

(D

(3)

CHECK

DIAGONALLY

(|)

CHECK

ACROSS

CENTER

FIG.

5

Cylinder

Head

Flatness

Typical

73S-A

1729-A

FIG.

6

Valve

Seat

Runout

Typical

automatic

choke

air

heat

tube

with

compressed

air.

VALVE

ROCKER

ARM

SHAFT

ASSEMBLY

Clean

all

the

parts

thoroughly.

Make

sure

that

all oil

passages

are

open.

Check

the

clearance

between

each

rocker

arm

and

the

shaft

by

checking

the

I.D.

of

the

rocker

arm

bore

and

the

O.D.

of

the

shaft.

If

the

clear

ance

between

any

rocker

arm

and

the

shaft

exceeds

the

wear

limit,

replace

the

shaft

and/

or

the

rocker

arm.

In

spect

the

shaft

and

the

rocker arm

bore

for

nicks,

scratches,

scores,

or

scuffs.

Dress

up

minor

surface

defects

with

a

hone.

Inspect

the

pad

at

the

valve

end

of

the

rocker

arms

for

a

grooved

radius.

If

the

pad

is

grooved,

replace

the

rocker

arm.

Do

not

attempt

to

true

this

surface

by

grinding.

Check

for

broken

locating

springs.

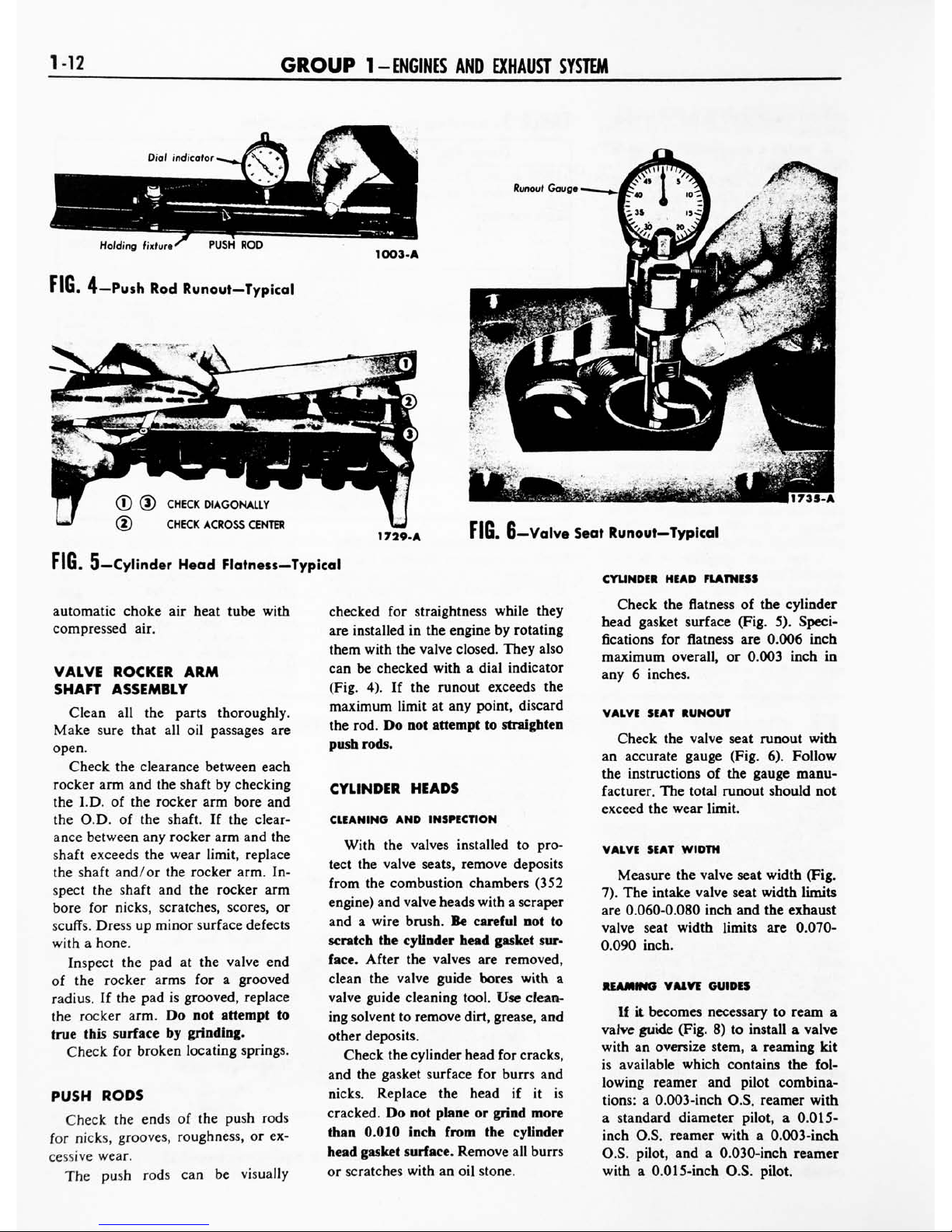

PUSH

RODS

Check

the

ends

of

the

push

rods

for

nicks,

grooves,

roughness,

or

ex

cessive

wear.

The

push

rods

can

be

visually

checked

for

straightness

while

they

are

installed

in

the

engine

by

rotating

them

with

the

valve

closed.

They

also

can

be

checked

with

a

dial

indicator

(Fig.

4).

If

the

runout

exceeds

the

maximum

limit

at

any

point,

discard

the

rod.

Do

not

attempt

to

straighten

push

rods.

CYLINDER

HEADS

CLEANING

AND INSPECTION

With

the

valves

installed

to

pro

tect

the

valve

seats,

remove

deposits

from

the

combustion

chambers

(352

engine)

and

valve

heads

with

a

scraper

and

a

wire

brush.

Be

careful

not

to

scratch

the

cylinder

head

gasket

sur

face.

After

the

valves

are

removed,

clean

the

valve

guide

bores

with

a

valve

guide

cleaning

tool.

Use

clean

ing

solvent

to

remove

dirt,

grease,

and

other

deposits.

Check

the

cylinder

head

for

cracks,

and

the

gasket

surface

for

burrs

and

nicks.

Replace

the

head

if

it

is

cracked.

Do

not

plane

or

grind

more

than

0.010

inch

from

the

cylinder

head

gasket

surface.

Remove

all

burrs

or

scratches

with an

oil

stone.

CYLINDER

HEAD

FLATNESS

Check

the

flatness

of

the

cylinder

head

gasket

surface

(Fig.

5).

Speci

fications

for

flatness

are

0.006

inch

maximum

overall,

or

0.003

inch

in

any

6

inches.

VALVE

SEAT

RUNOUT

Check

the

valve

seat

runout

with

an

accurate

gauge

(Fig.

6).

Follow

the

instructions

of

the

gauge

manu

facturer.

The

total

runout

should

not

exceed

the

wear

limit.

VALVE

SEAT

WIDTH

Measure

the

valve

seat

width

(Fig.

7).

The

intake

valve

seat

width

limits

are

0.060-0.080

inch

and

the

exhaust

valve

seat

width

limits

are

0.070-

0.090

inch.

REAMING

VALVE

GUIDES

If

it

becomes

necessary

to

ream

a

valve

guide

(Fig.

8)

to

install

a

valve

with

an

oversize

stem,

a

reaming

kit

is

available

which

contains

the

fol

lowing

reamer

and pilot

combina

tions:

a

0.003-inch

O.S.

reamer

with

a

standard

diameter

pilot,

a

0.015-

inch

O.S.

reamer

with

a

0.003-inch

O.S.

pilot,

and

a

0.030-inch

reamer

with

a

0.015-inch

O.S.

pilot.

Loading...

Loading...