Page 1

Page 2

FOREWORD

This car maintenance manual provides the Service Technician

with complete information for the maintenance operations on all

1967 Ford, Lincoln and Mercury cars, and the Bronco, Econoline, Falcon Club Wagon and Recreational Vehicles.

The maintenance information is grouped in three parts.. maintenance schedule, maintenance operations, and lubrication charts

and specifications. The maintenance operations include in-vehicle

adjustments.

The descriptions and specifications in this manual were in effect

at the time this manual was approved for printing. The Ford

Motor Company reserves theligh.t to discontinue models at any

time, or change specifications or design, without notice and with-

out incurring obligation.

SERVICE PUBLICATIONS

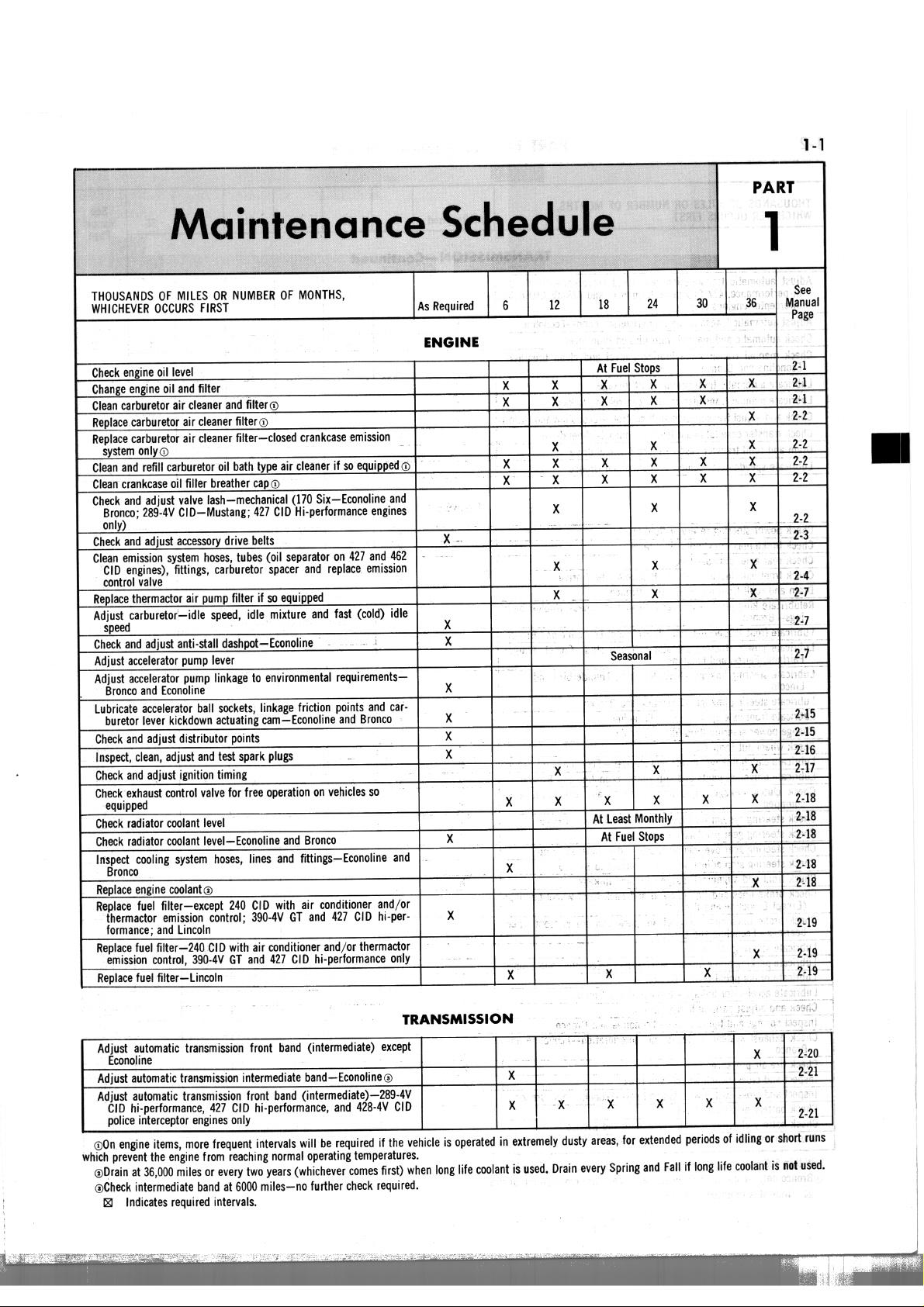

Page 3

Page 4

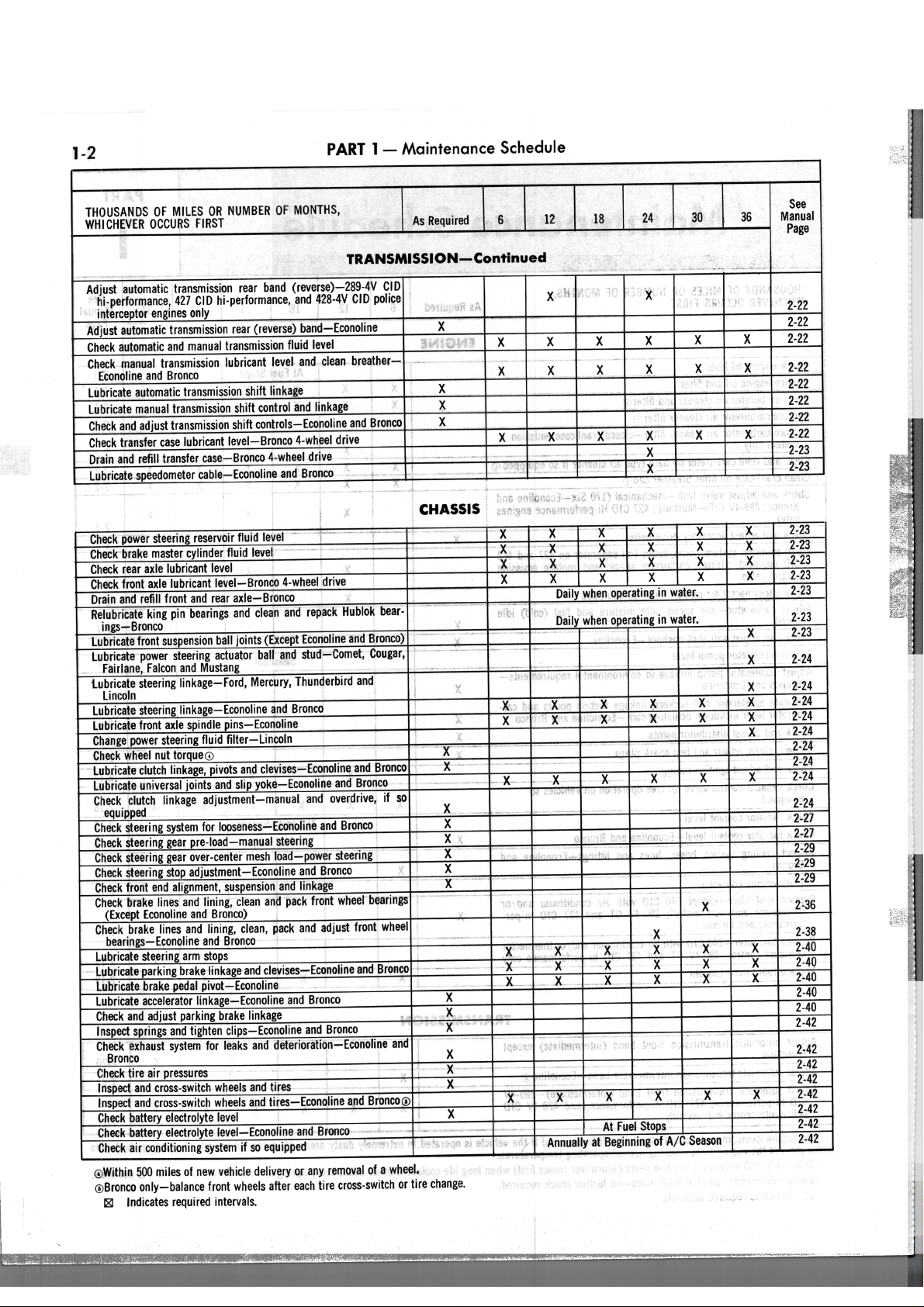

Page 5

Page 6

2-1

Secdoa

1 Engine 2 Transmission...

3 Chassis

Sedioa

4 Body .. 5 Electrical . . . . .

~ ..

.,,""",'" .. . . . . . .2-43

:.+;., 2-44

P-ce

2 -1

..2-20

.2-23

hicles cannot be covered in complete

detail here. If a vehicle is found to have

a special component installed that is

not fully covered herein, refer to the

Shop Manual for that vehicle for

complete details.

The maintenance operations described herein are to be considered as

minimum operations on vehicles which

are in operating condition and require

only periodic checkup and service. If,

upon inspection, a component requires

more than adjustment, cleaning or

simple replacement, refer to the applicable Group No. in the appropriate

Shop Manual for complete information.

All variations of all Ford-built ve-

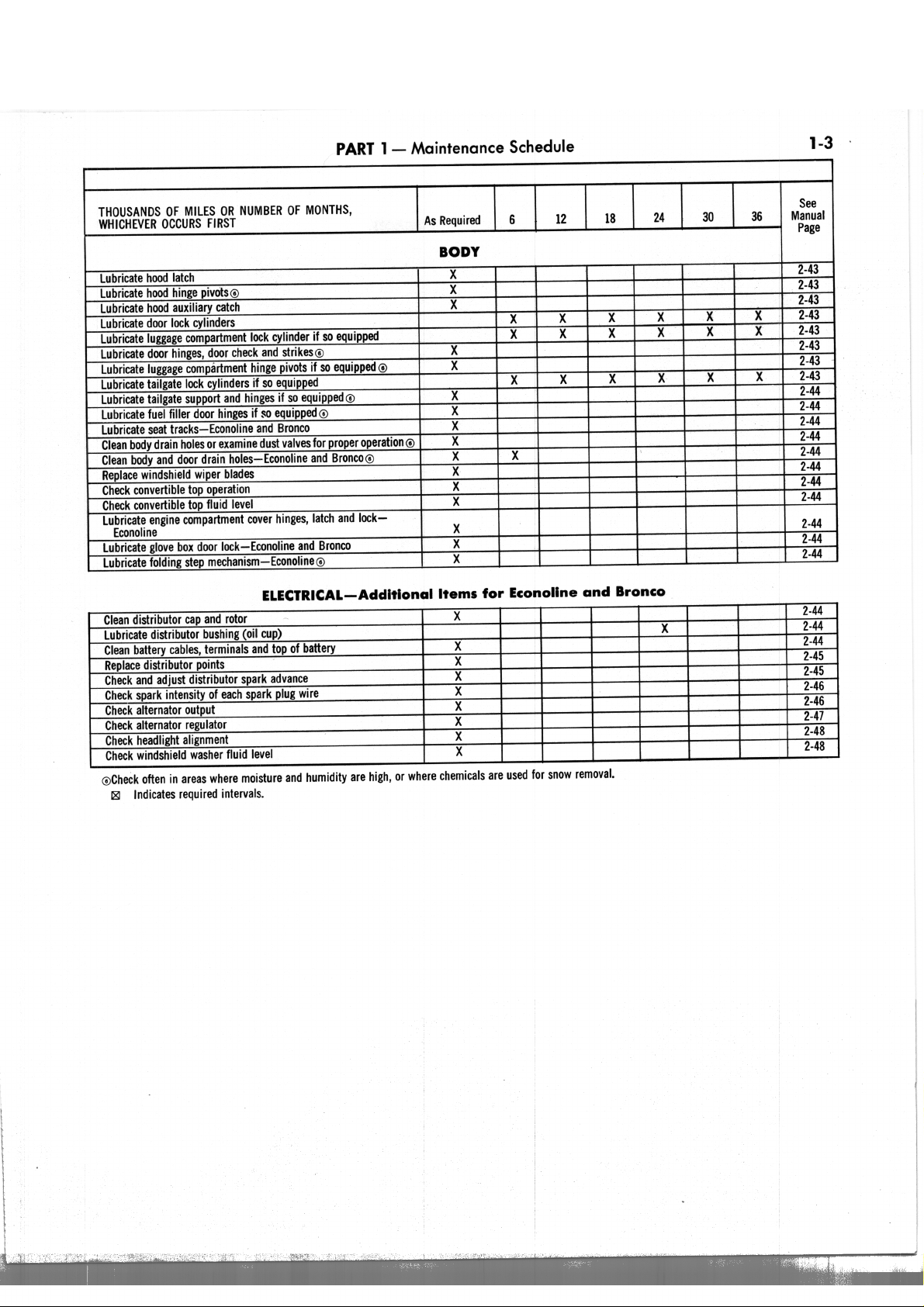

COAT GASKET WITH ENG-..E OIL

filter element. Discard the air cleaner

mounting gasket if it is excessively

worn or damaged-

On a closed crankcase ventilation

system air cleaner, remove the crankcase vent filter aOO gasket from the air

cleaner body, if required.

CLEANING FILTER

ELEMENT

The celluk)Se fiber filter element mlWt

never be cleaned with a solvent or cleaning solution. Also, oil mlWt Dot be added

to the surfaces of the filter element or

air cleaner body.

There are two procedures that can

be used to clean the air filter element.

One method is performed with the use

of compressed air. The other is performed by tapping the element on a

smooth horizontal surface.

Compressed Air Method

Direct a stream of compressed air

through the element in the direction

opposite that of the intake air flow,

that is, from the inside outward. Extreme care m- be exerc8ed to preYeat

rupture of the element material.

Tapping Method

Hold the element in a vertical position and tap it lightly against a smooth,

horizontal surface to shake the dust

and dirt out. Do not deform the element or damage tile gasket surfacs by

tapping too bard. Rotate the filter after

each tap until the entire outer surface

has been cleaned.

the air cleaner assembly to the carburetor and the air duct.

On a closed crank~ ventilation

system equipped car, disconnect the

crankcase ventilation system hose at

the crankcase vent filter.

2.. Remove the air cleaner assembly

from the carburetor. To prevent dirt

from enteriag the carburetor, the filter

element m1Bt never be removed when

the air cleaner body is m(Mlnted on the

carburetor.

3. Remove the air cleaner cover and

CHECK ENGINE OIL LEVa

Check the oil level dipstick to be

sure it indicates the correct quantity

of oil in the crankcase. Be sure the

oil is clean.

CHANGE ENGINE OIL

AND FILTER

REMOVAL

1. Raise the car.

2. Remove the oil pan drain plug,

and allow the engine oil to drain into

a container.

3. Place a drip pan under the filter

assembly (Fig. 1).

4. Turn the filter counterclockwise

and remove it from the adapter.

INSf ALLA nON

1. Clean the gasket surfaces at the

adapter.

2. Coat the gasket on the filter with

a light film of oil. Screw the filter onto

t~ adapter until the gasket contacts

the sealing surface, then advance it II,.

turn. Do not overtighten the filter.

3. Remove the drip pan and lower

the car.

4. Fill the crankCase to its required

level with the proper type and grade

of lubricant.

5. Start the engine. Operate the engine at fast idle and check for oil

leakage.

6. Add additional lubricant if required.

CLEAN CARBURETOR AIR

CLEANER AND FILTER ELEMENT

REMOVAL

1. Remove the wing nuts retaining

Page 7

2.2

PART 2

Maintenance Operations

CLEAN CRANKCASE OIL

FILLER aREA THER CAP

Remove the cap and wash it in a

low-volatility, petroleum-base solvent.

Probe the breather hole(s) to assure

removal of any accumulated deposits.

Shake the cap dry and install it. Do not

dry with compressed air as air pressure

may damage the filter element.

INSPEcriNG FILTER

ELEMENT

Hold the filter in front of a back-up

light and carefully inspect it for any

splits or cracks. If the filter is split or

cracked, replace it.

CLEANING BODY AND COVER

Clean the air cleaner body and cover

with a solvent or compressed air. Wipe

the air cleaner dry if a solvent is used.

Inspect the air cleaner body and cover

for distortion or damage at the gasket

mating surfaces. Replace the cover or

body if they are damaged beyond

repair.

the carburetor so that the word Front

faces the front of the car.

3. Place the air cleaner filter element

in the air cleaner body.

Make sure the filter is prolK!rly

seated. If the word TOP is ilMlicated on

the filter element, make sure the word

TOP faces up.

4. Install the cover and connect the

air in~t duct and valve assembly, if so

equipped, to the air cleaner with the

wing-type retaining screws. Tighten

the screws.

S. On a closed crankcase ventilation

system air cleaner, install the crankcase

vent filter and gasket in tlM: air cleaner

body, if it was previously removed.

Connect the crankcase vent hose to the

crankcase vent filter and tighten the

hose retaining clamp.

CLEAN AND REFILL OIL BATH

AIR CLEANER-ECONOLINE

AND BRONCO

INSfAUADON

1. Install a new air cleaner mount-

ing gasket on t~ carburetor. if nec-

essary .

2. Install the air cleaner body on

t~ carburetor so that t~ word Front

faces t~ front of t~ car.

3. Place the air cleaner filter element

in the air cleaner body. Make sure the

element is ..-opeIty leafed. Install the

cover and connect t~ air duct to the

air cleaner. Tighten the retaining wing

DUts.

On a closed crankcase ventilation

system air cleaner. install t~ crankcase vent filter and gasket in the air

cleaner body. if it was previously removed. Connect the crankcase vent

hose to t~ crankcase vent filter and

tighten t~ hose retaining clamp.

REMOVAL

1. Remove the carburetor to air

cleaner retaining wing nut.

On a cl~ crankcase ventilation

equipped engine, loosen the hose clamp

at the air cleaner body and disconnect

the hose.

On a 240 Six engine, remove the

bolts securing the air cleaner body to

the support brackets.

2. Remove the air cleaner. Use care

to prevent on spillage.

CLEANING AND INSPECflON

1. Drain the air cleaner reservoir.

Wash the air cleaner components and

duct (if so equipped) in cleaning solvent, and dry them with compressed

air.

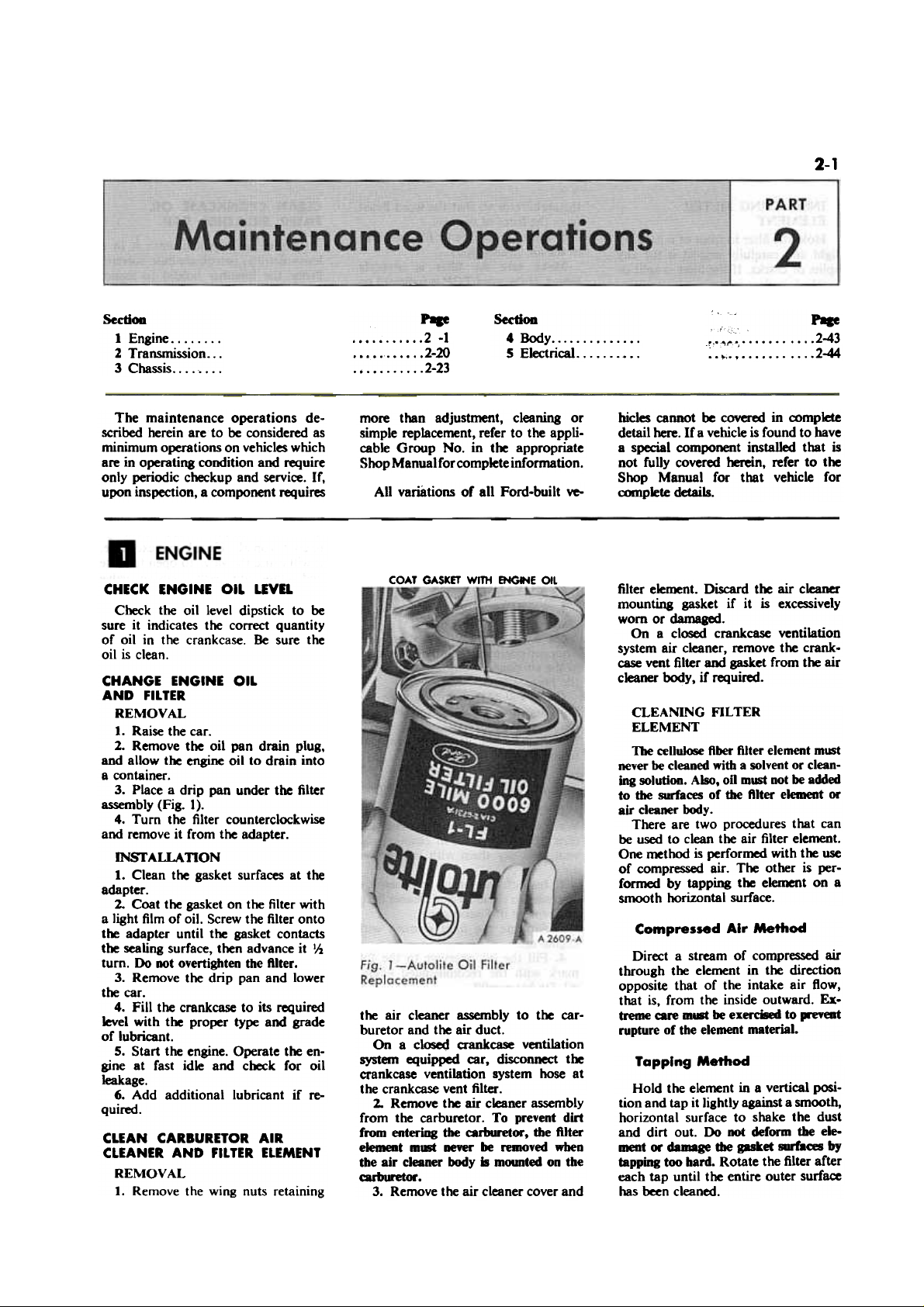

CHECK AND ADJUST VALVE

LASH-MECHANICAL TAPPETS

It is very important that the valve

lash be held to the correct specifications because:

If the lash is set too close, the valve

will open too early and close too late,

resulting in rough engine idle. Burning

and warping of the valves will occur

also because the valves cannot make

firm contact with the seats long enough

to cool properly. If the lash is excessive,

it will cause the valve to open too late

and close too early causing valve

bounce. In addition, damage to the

crankshaft lobe is likely because the

tappet foot will not follow the pattern

of the camshaft lobe, causing a shock

contact between these two parts.

1. Be sure the engine is at normal

operating temperature before attempting to set the valve lash.

If the engine is cold, start and operate it for a minimum of 30 minutes at

1200 rpm to stabilize engine temperatures.

2. Remove the air cleaner and other

obstructing hardware.

3. Remove the valve rocker arm

cover and gaskets.

4. With the engine idling, set the

valve lash (Figs. 2, 3 or 4) .-i8g . step.

type feeler: gauge only (go and no go).

The final (hot) intake and exhaust valve

lash settings are listed in the Specifications Section in Group 8 of the

appropriate Shop Manual.

For example, to obtain the correct

2. Inspect the gasket between the

oil reservoir chamber and cleaner body

and replace it if necessary.

3. Saturate the filter element wittl

engine oil.

4. Fill the oil reservoir to the full

mark with the recommended engine

oil. Do not overfill.

STEP-TYPE fEELER GAUGE

REPLACE CARBURnOR

AIR CLEANER FILTER

REMOVAL

1. Remove the wing nuts retaining

the air cleaner assembly to the carburetor and the air duct, if so equipped.

On a closed crankcase ventilation

system equipped car, disconnect the

crankcase ventilation system hose at

the crankcase vent filter.

2. Remove the air cleaner assembly

from the carburetor. To prevent dirt

fnMII enteriDg the cariMlretor, the filter

element mlBt never be removed when

the air cleaner body is mounted on the

carburetor.

3. Remove the air cleaner cover and

filter element. Discard the air cleaner

mounting gasket if it is excessively worn

ordarnaged.

On a closed crankcase ventilation

system air cleaner, remove the crankcase vent filter and gasket from the air

cleaner body, if required.

INSI' ALLA nON

1. Install a new air cleaner mounting

gasket on the carburetor, if necessary.

2.. Install the air cleaner body on

INST ALLA nON

1. Position the air cleaner on the

carburetor and install the retaining

wing nut. UR care to ..-eveat oil

spillage.

On a 240 Six engine, ~re the air

cleaner to the support brackets with

the retaining bolts.

On a closed crankcase ventilation

system air cleaner, connect the ventilation system hose to the air cleaner body

and tighten the retaining clamp.

Fig. 2-Valve lash Adjustment-

170 Six Engine

Page 8

PART 2 - Maintenance Operations

2-3

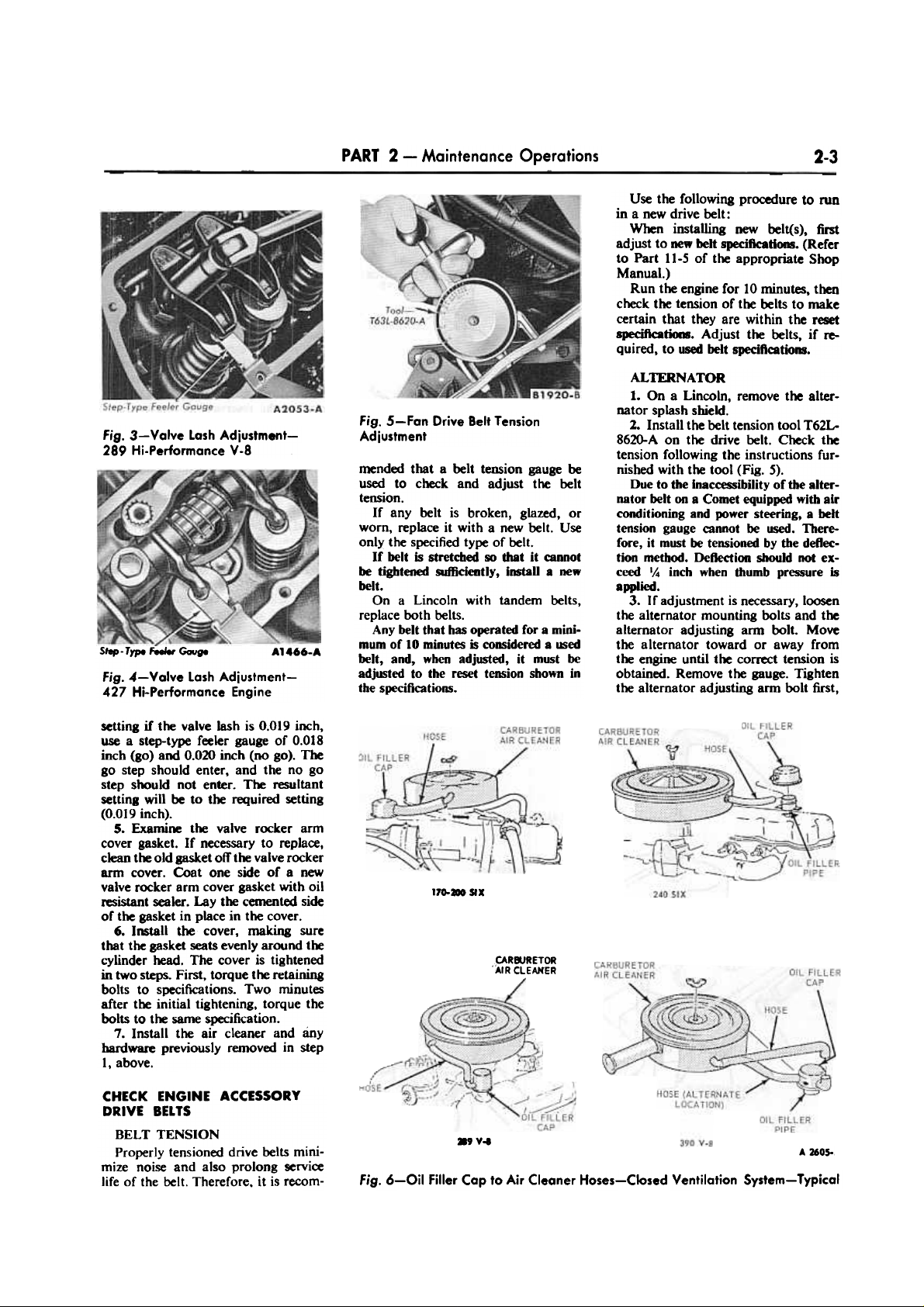

Use the following procedure to run

in a new drive belt:

When installing new belt(s), first

adjust to new belt SpeclficatiOlW. (Refer

to Part 11-5 of the appropriate Shop

Manual.)

Run the engine for 10 minutes, then

check the tension of tbe belts to make

certain that they are within the reset

spedftca~. Adjust the belts, if required, to used belt spedfications.

Fig. 5-Fan Drive Belt Tension

Adjustment

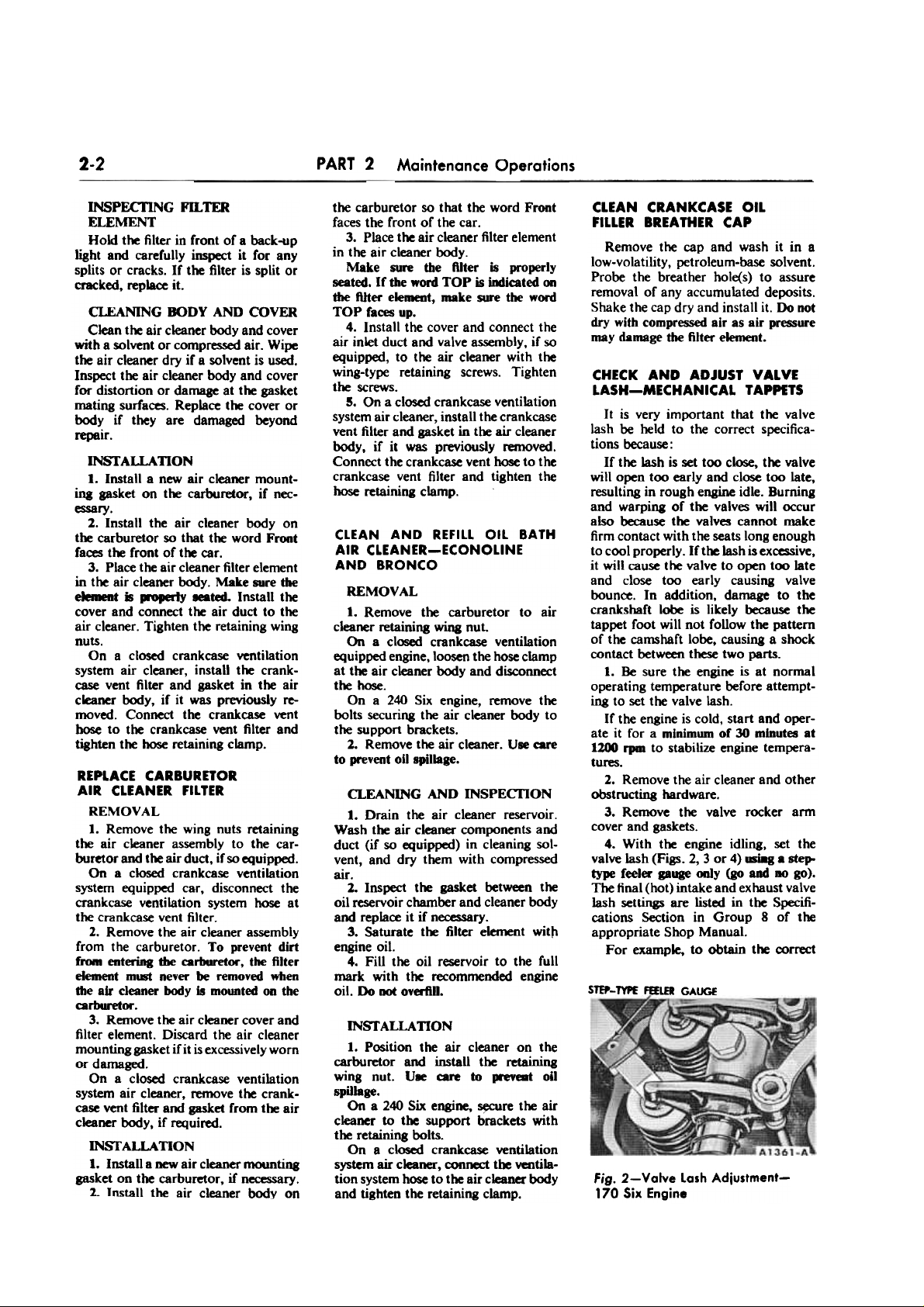

Fig. 3-Valve lash Adjustment289 Hi-Performance V-8

ALTERNATOR

1. On a Lincoln, remove the alter-

nator splash shield.

2. Install the belt tension tool T62L8620-A on the drive belt. Check the

tension following the instructions furnished with the tool (Fig. 5).

Due to the inaccessibility of the alternator belt on a Comet equipped with air

conditioning and power steering, a belt

tension gauge cannot be used. Therefore, it must be tensioned by the dellection method. DeOedion should not exceed 14 inch when thumb pressure is

applied.

3. If adjustment is necessary, loosen

the alternator mounting bolts and the

alternator adjusting arm bolt. Move

the alternator toward or away from

the engine until the correct tension is

obtained. Remove the gauge. Tighten

the alternator adjusting arm bolt first,

mended that a belt tension gauge be

used to check and adjust the belt

tension.

If any belt is broken, glazed, or

worn, replace it with a new belt. Use

only the specified type of belt.

If belt is stretched so that it cannot

be tightened sufficiently, install a new

belt.

On a Lincoln with tandem belts,

replace both belts.

Any belt that has operated for a minimum of 10 minutes is considered a ~ed

belt, and, when adjusted, it must be

adjusted to the reset tension sbown in

the specifications.

S/ep- Type Feeler ~ge A1466-A

Fig. 4-Valve lash Adjustment427 Hi-Performance Engine

setting if the valve lash is 0.019 inch,

use a step-type feeler gauge of 0.018

inch (go) and 0.020 inch (no go). The

go step should enter, and the no go

step should not enter. The resultant

setting will be to the rtXIuired setting

(0.019 inch).

5. Examine the valve rocker arm

cover gasket. If necessary to replace,

clean the old gasket off the valve rocker

arm cover. Coat one side of a new

valve rocker arm cover gasket with oil

resistant sealer. Lay the cemented side

of the gasket in place in the cover.

6. Imtall the cover, making sure

that the gasket seats evenly around the

cylinder head. The cover is tightened

in two Steps. First, torque the retaining

bolts to specifications. Two minutes

after the initial tightening, torque the

bolts to the same specification.

7. Install the air cleaner and any

hardware previously removed in step

1, above.

170.- SIX

CARaJRETOR

'AIR CLEANER

»9 V..

CHECK ENGINE ACCESSORY

DRIVE BELTS

BELT TENSION

Properly tensioned drive belts minimize noise and also prolong ~rvice

life of the belt. Therefore, it is recom-

A 2605-

Fig. 6-0il Filler Cap to Air Cleaner Hoses-Closed Ventilation System-Typical

Page 9

\ \

PART 2 - Maintenance Operations

INTAKE MANIFOl.D

C~HECTI<»I

...

1700310 SIX

VIEW.

,HOSE

/

i

rCLAMP

' VEN'

.ATOR VALVE

I

~E

and then the mounting bolts. Install

the tension gauge and check the belt

tension.

4. On a Lincoln, install the alter-

nator splash shield.

POWER STEERING

I. Loosen the mounting bolts incorporated on the front face of the

pump cover plate (hub side) and the

one nut at the rear.

1. Fix a 9/I6-inch open end wrench

on the projecting l/2-inch boss and pry

upward to correct tension. Do DOt pry

against the resenoir to obtain proper

belt load as it can be deformed and

cause a leak.

3. Recheck the belt tension. When

the tension has been correctly adjusted,

tighten the bolts to specifications.

AIR CONDmONING

Adjust the belt by repositioning the

idler pulley if so equipped. Otherwise,

follow this procedure:

I. Loosen the bolts securing the

compressor to the compressor mounting bracket. On a Lincoln. first remove

the bolts securing the compressor to

the support bracket that is attached to

the cylinder head.

1. Install the tension gauge on the

compressor clutch drive belt. Move

the compressor toward or away from

the engine until the specified belt tension is obtained. Remove the gauge.

Tighten the compressor to support

bracket bolts. Install the tension gauge

and check the belt tension.

THERMACTOR AIR PUMP

I. Loosen the air supply pump ad-

justIng arm nut and bolt.

1. Loosen the air supply pump

mounting bracket nut and bolt.

3. Move the air pump toward or

away from the engine until the correct

tension is obtained. UE a suitable bar

and IWY agalDSt the JKIInp rear cover to

hold belt tension while tightening the

mounting bolts. Do not IWY agaiDSt the

pump boI8ing. Remove the gauge.

Tighten the air pump adjusting arm

and mounting bolts. Install the tension

gauge and check the belt tension.

Roc:KER ~

COVER

~~~~~~~(/'

~ OIL FILLER

" CAP

. ~~https://manualmachine.com/

I

"

~,:¥:

--~~

.:\i.

"-

r-t'J}

[ ~ ""~

~

~~ . ..

- --

~ , '. ~.-i1

~"""~'

~:" ~.- ' ~~

j~"\.. ' L'

Ii'-"-~'-"""

~ "rr~ .' --- ='- '.

r;(o'

J {"'- v

')~~;~~ INTAKE MANIFOL~ ,~~" ~" /"

~~', J

NIPPLE '~'" "-/ ( I tJJ--;.P

,:~=... I l

CLEAN POSITIVE CRANKCASE

VENTILATION SYSTEM

COMPONENTS-ALL VEHICLES

EXCEPT LINCOLN

Current production vehicles which

are equipped with positive crankcase

vehtilation systems have the components located at different points on

each type of engine. The following

procedure is a general procedure. Specific procedures will be found in Group

240 SIX

A~A

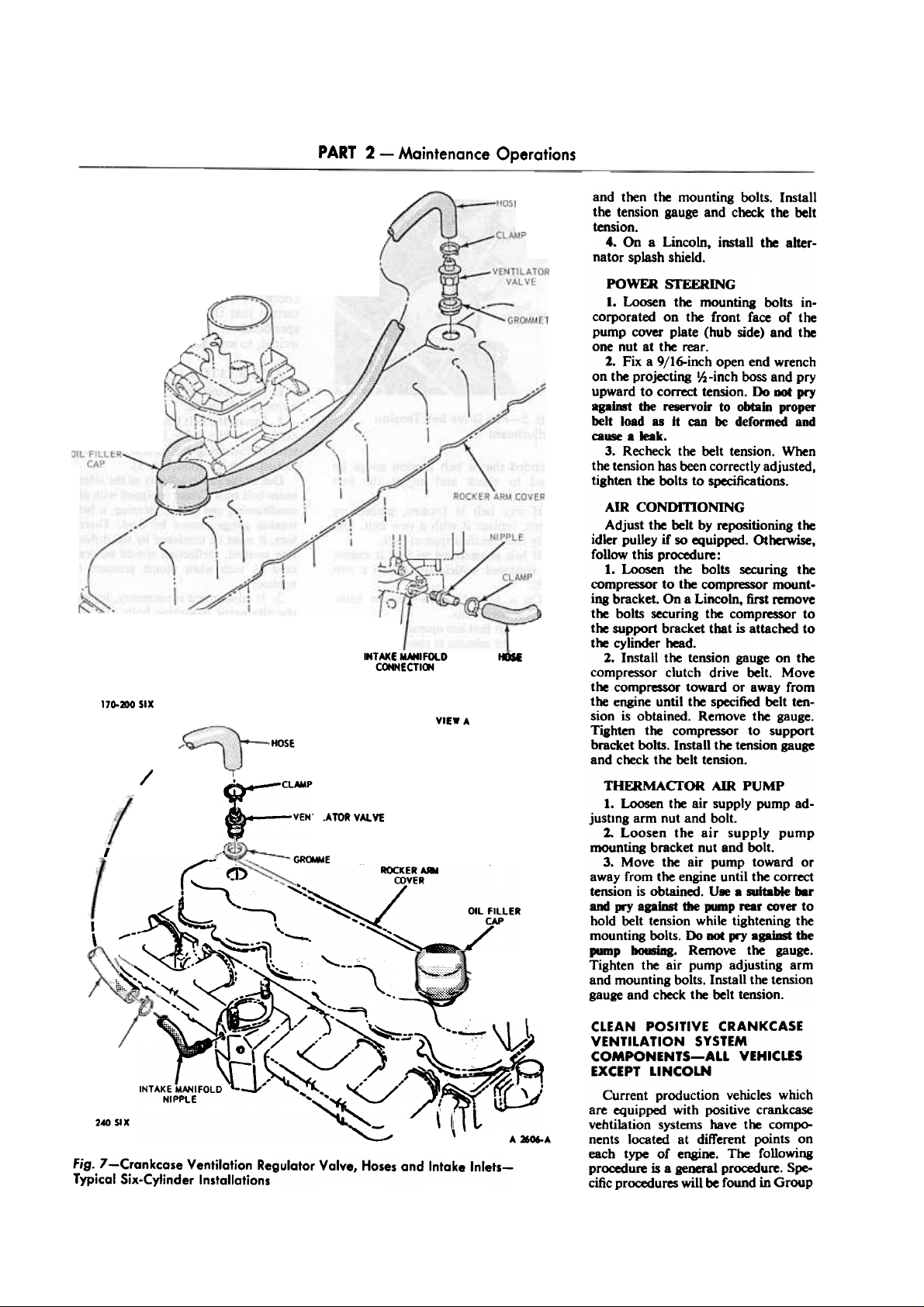

Fig. 7-Crankcase Ventilation Regulator Valve, Hoses and Intake InletsTypical Six-Cylinder Installations

Page 10

2-5PART 2

Maintenance Operations

8 of the Shop Manual for the vehicle

being serviced .

REMOVAL OF COMPONENfS

Closed Ventilation System

Remove the following components

from the crankcase ventilation system.

Figs. 6 through 9 show typical components which should be removed.

Refer to Group 8 of the appropriate

Shop Manual for specific removal

procedures.

1. Remove the oil filler cap and its

connecting hose to the air cleaner.

1.. Remove the air cleaner (and ducts,

if so equipped). Refer to Group 10 of

the appropriate Shop Manual for specific removal procedures.

3. Remove the hose (Figs. 7 or 8) oj'

hose assembly (Fig. 9) from the venti.

lator valve in the rocker arm cover.

Remove the other end of this hose (or

hose assembly) from the intake manifold connection, or carburetor spacer

connection, if so connected.

If a hose aSlembly was removed,

disassemble the hoses from the tee or

hot idle compensator, if so equipped.

4. Pull the ventilator valve from

grommet in the rocker arm cover.

Discard the ventilator valve 8S8eI8JIy.

Open Ventllotlon System

Remove the following components

from the crankcase ventilation system.

Figs. 6 through 9 show typical components which should be removed.

Refer to Group 8 of the appropriate

Shop Manual for specific removal

procedures.

1. Remove the hose (Fias. 7 or 8)

or hose assembly (Fig. 9) from the

ventilator valve in the rocker arm

cover. Remove the other end of this

hose (or hose assembly) from the intake manifold connection, or carburetor spacer connection if so connected.

If a hose assembly was removed,

disassemble the hoses from the tee or

hot idle compensator. if so equipped.

1.. Pull the ventilator valve from the

grommet in the rocker arm cover.

DiIC8rd die ventilator valve 88emb1y.

CLEANING

Closed Ventilation System

1. Wash the crankcase filler cap in

a low-volatility, petroleum-base solvent. Shake the cap dry. Do not dry

with ~pressed air. since air ~

may damage the filter element.

2. Remove the crankcase ventilation

air filter (screen type) from the carburetor air cleaner body and clean it,

using the ~ procedure as in step 1,

and re-install it into the air cleaner

body.

A »O7-A

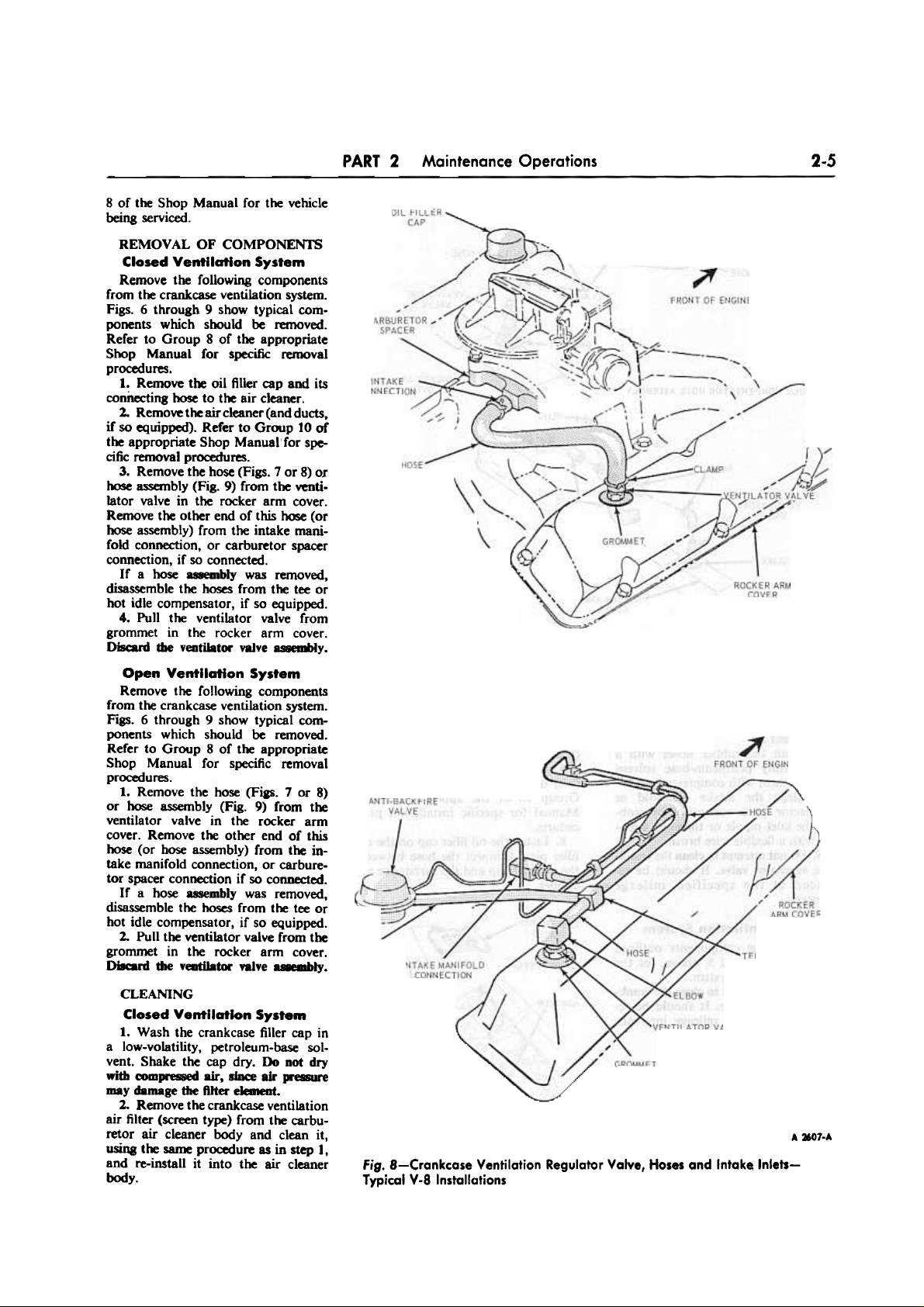

Fig. 8-Crankcase Ventilation Regulator Valve, Hoses and Intake Inlets-

Typical V-8 Installations

Page 11

PART 2 - Maintenance Operations

2-6

HO11DLE C~PENSATOR

CARBURETOR

SPACER

CONNECTING

NIPPLE

Open Ventilation System

Follow the same procedure outlined

in steps 1 thru 4 for the Closed Ventilation System, above.

HOSE

HOSE ~.

-VENTltAJ-9R

'~ - VALVE"

/,-,

:LAMPS

~

', /;;

v

A ROCKER ARM

COVER

HOT IDLE COMPEHSATOR HOSE ASSEMBLY

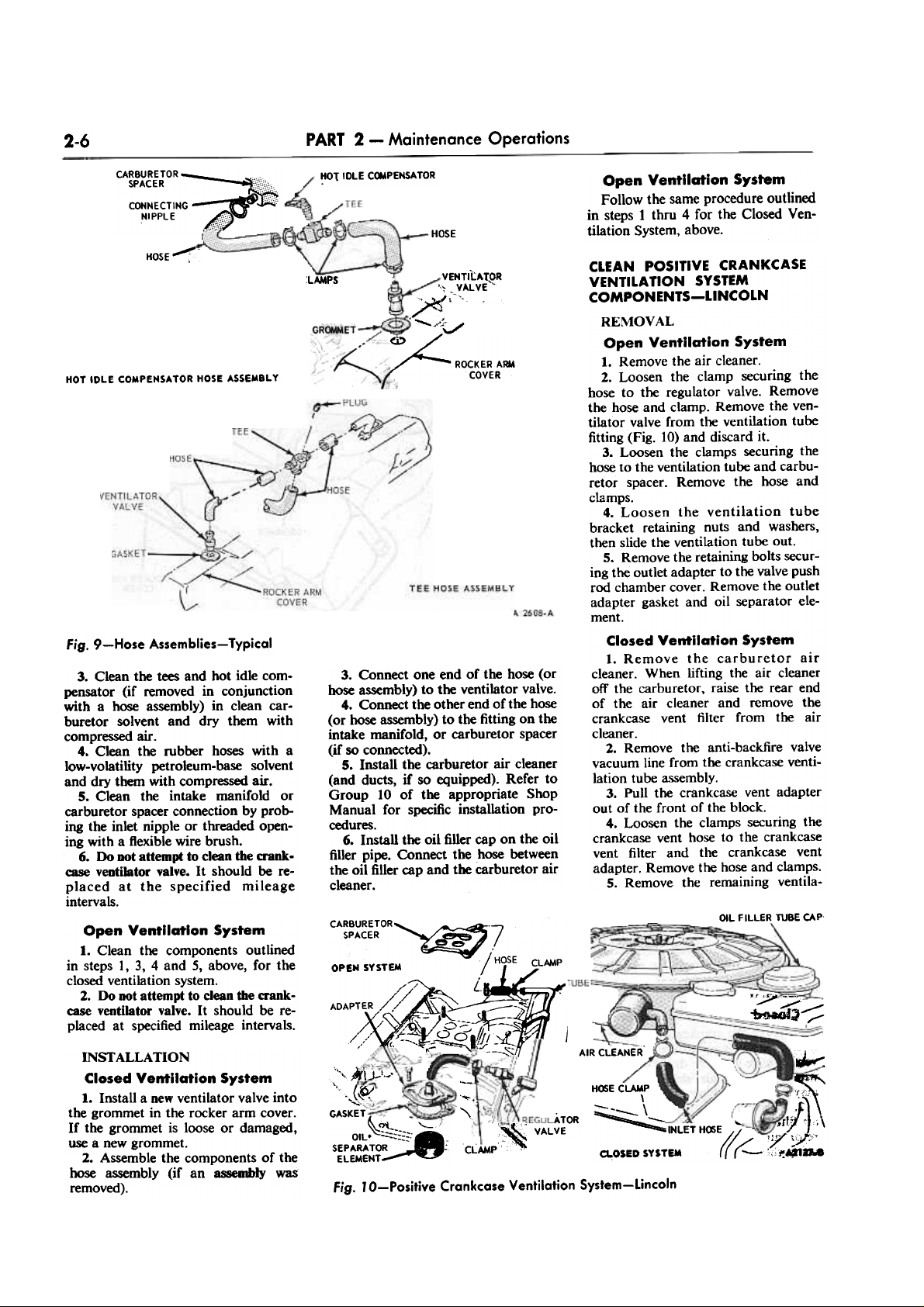

Fig. 9-Hose Assemblies-Typical

CLEAN POSITIVE CRANKCASE

VENTILATION SYSTEM

COMPONENTS-LINCOLN

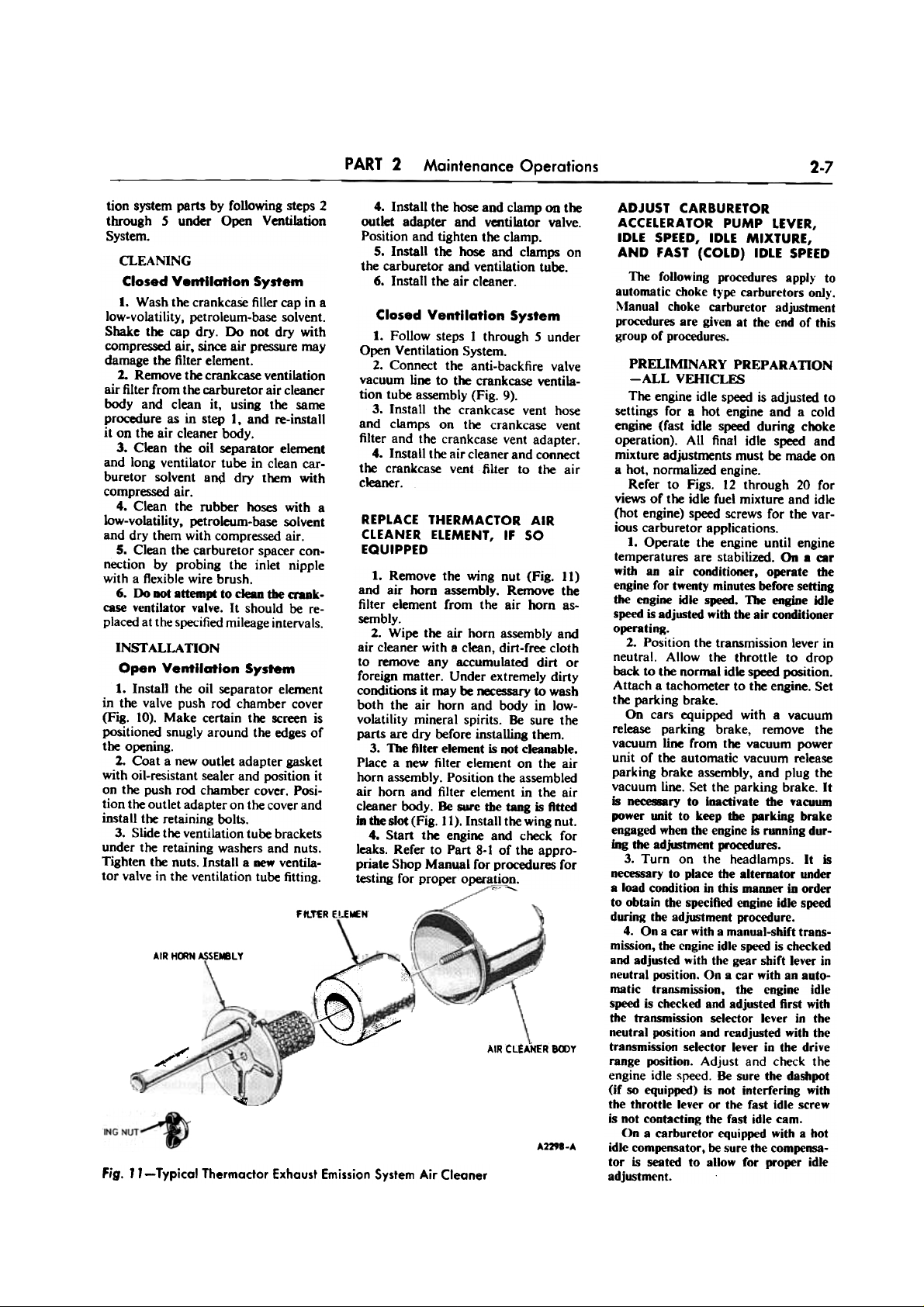

REMOVAL

Open Ventilation System

1. Remove the air cleaner.

2. Loosen the clamp securing the

hose to the regulator valve. Remove

the hose and clamp. Remove the ventilator valve from the ventilation tube

fitting (Fig. 10) and discard it.

3. Loosen the clamps securing the

hose to the ventilation tube and carburetor spacer. Remove the hose and

clamps.

4. Loosen the ventilation tube

bracket retaining nuts and washers,

then slide the ventilation tube out.

5. Remove the retaining bolts securing the outlet adapter to the valve push

rod chamber cover. Remove the outlet

adapter gasket and oil separator element.

Closed Ventilation System

1. Remove the carburetor air

cleaner. When lifting the air cleaner

off the carburetor, raise the rear end

of the air cleaner and remove the

crankcase vent filter from the air

cleaner.

2. Remove the anti-backfire valve

vacuum line from the crankcase ventilation tube assembly.

3. Pull the crankcase vent adapter

out of the front of the block.

4. Loosen the clamps securing the

crankcase vent hose to the crankcase

vent filter and the crankcase vent

adapter. Remove the hose and clamps.

5. Remove the remaining venti la-

3. Connect one end of the hose (or

hose assembly) to the ventilator valve.

4. Connect the other end of the hose

(or hose assembly) to the fitting on the

intake manifold, or carburetor spacer

(if so connected).

5. Install the carburetor air cleaner

(and ducts, if so equipped). Refer to

Group 10 of the appropriate Shop

Manual for specific installation pro-

cedures.

6. Install the oil filler cap on the oil

filler pipe. Connect the hose between

the oil filler cap and the carburetor air

cleaner.

3. Clean the tees and hot idle compensator (if removed in conjunction

with a hose assembly) in clean carburetor solvent and dry them with

compressed air.

4. Clean the rubber hoses with a

low-volatility petroleum-base solvent

and dry them with compressed air.

5. Clean the intake manifold or

carburetor spacer connection by probing the inlet nipple or threaded opening with a flexible wire brush.

6. Do DOt attempt to clean the crank-

case ventilator valve. It should be replaced at the specified mileage

intervals.

OIL FILLER TU8E CAP

CAR8URETOR,,/~ ~

SPACER ~~7' ,7

OPEN SYSTEM I'HOSE CLAMP

~/ L.

AOAPTER /,~ -It :

/ ,(i\-)O-;;:-~-

/,//' {,~~~I&~ '" !

Open Ventilation System

1. Clean the components outlined

in steps 1, 3, 4 and 5, above, for the

closed ventilation system.

2. Do not attempt to clean the crankcase ventilator valve. It should be re-

placed at specified mileage intervals.

":? ? '/

~~,

AIR CLEANER'

'~

,~

..~J};\

;7t~,;"

:;;~~

~,

""'.

""

ATOR

VALVE

H~EC~

\

'"'-.

\~ -.~~

- '"'

INLET H~E 1/

a,OSED SYSTEM (( r-::::-

'.. ...

" 161:\.)-1_,

\

c.

('tII

~,

'.:.

GASKET

-<-.i"- ,--.

OIL~:-'-:

~~f':::: -

SEPARATOR :;

ELEMENT

~ ~' ,~

CC',

.CLAMP

INSTALLAllON

Closed Ventilation System

1. Install a new ventilator valve into

the grommet in the rocker arm cover.

If the grommet is loose or damaged,

use a new grommet.

2. Assemble the components of the

hose assembly (if an assembly was

removed).

Fig. la-Positive Crankcase Ventilation System-Lincoln

Page 12

PART 2

Maintenance Operations

2-7

tion system parts by following steps 2

through 5 under Open Ventilation

System.

4. Install the hose and clamp on the

outlet adapter and ventilator valve.

Position and tighten the clamp.

5. Install the hose and clamps on

the carburetor and ventilation tube.

6. Install the air cleaner.

ADJUST CARBURETOR

ACCELERATOR PUMP LEVER,

IDLE SPEED, IDLE MIXTURE,

AND FAST (COLD) IDLE SPEED

The following procedures apply to

automatic choke type carburetors only.

Manual choke carburetor adjustment

procedures are given at the end of this

group of procedures.

Closed Ventilation System

1. Follow steps 1 through 5 under

Open Ventilation System.

2. Connect the anti-backfire valve

vacuum line to tre crankcase ventilation tube assembly (Fig. 9).

3. Install the crankcase vent hose

and clamps on the crankcase vent

filter and the crankcase vent adapter.

4. InstaU the air cleaner and connect

the crankcase vent filter to the air

cleaner.

REPLACE THERMACTOR AIR

CLEANER ELEMENT, IF SO

EQUIPPED

1. Remove the wing nut (Fig. 11)

and air horn assembly. Remove the

filter element from the air horn as-

sembly.

2. Wipe the air horn assembly and

air cleaner with a clean, dirt-free cloth

to remove any accumulated dirt or

foreign matter. Under extremely dirty

conditions it may be ~ to wash

both the air horn and body in lowvolatility mineral spirits. Be sure the

parts are dry before installing them.

3. The filter element ~ not cleanable.

Place a new filter element on the air

horn assembly. Position the assembled

air horn and filter element in the air

cleaner body. Be sure the tang ~ fitted

in the sI~ (Fig. 11). Install the wing nut.

4. Start the engine and check for

leaks. Refer to Part 8-1 of the appropriate Shop Manual for procedures for

testing for proper operation.

",c

CLEANING

Closed Ventilation System

1. Wash the crankcase filler cap in a

low-volatility, petroleum-base solvent.

Shake the cap dry. Do not dry with

compressed air. since air pressure may

damage the filter element.

2. Remove the crankcase ventilation

air filter from the carburetor air cleaner

body and clean it, using the same

procedure as in step I, and re-install

it on the air cleaner body.

3. Clean the oil separator element

and long ventilator tube in clean carburetor solvent a~ dry them with

compressed air.

4. Clean the rubber hoses with a

low-volatility, petroleum-base solvent

and dry them with compressed air.

5. Clean the carburetor spacer con-

nection by probing the inlet nipple

with a flexible wire brush.

6. Do DOt attempt to clean tile cruk-

case ventilator valve. It should be replaced at the specified mileage intervals.

INSTALLAllON

Open Ventilation System

1. Install the oil separator element

in the valve push rod chamber cover

(Fig. 10). Make certain the screen is

positioned snugly around the edges of

the opening.

2. Coat a new outlet adapter gasket

with oil-resistant sealer and position it

on the push rod chamber cover. Position the outlet adapter on the cover and

install the retaining bolts.

3. Slide the ventilation tube brackets

under the retaining washers and nuts.

Tighten the nuts. Install a new ventilator valve in the ventilation tube fitting.

F/t.T£R fl-E~N

AIR HMN ~SE~LY

~'.

'.

'.

i "

\~r

~

;/

~

AIRCLEAN£R BOOY

~

...

A"

~

PRELIMINARY PREPARATION

-ALL VEHICLES

The engine idle speed is adjusted to

settings for a hot engine and a cold

engine (fast idle speed during choke

operation). All final idle speed and

mixture adjustments must be made on

a hot, norma~ engine.

Refer to Figs. 12 through 20 for

views of the idle fuel mixture and idle

(hot engine) speed screws for the various carburetor applications.

I, Operate the engine until engine

temperatures are stabilized. On . car

with an air conditioner, operate the

engine for twenty minutes before setting

the engine idle speed. The engine idle

speed is adjusted with the air conditioner

operating.

2. Position the transmission lever in

neutral. Allow the throttle to drop

back to the normal idle speed position.

Attach a tachometer to the engine. Set

the parking brake.

On cars equipped with a vacuum

release parking brake, remove the

vacuum line from the vacuum power

unit of the automatic vacuum release

parking brake assembly, and plug the

vacuum line. Set the parking brake. It

is necegary to Inactivate the 'facuum

power unit to keep the parking brake

engaged when the engine is running during the adj4fitment procedures.

3. Turn on the head lamps. It is

necessary to place the alternator under

a load condition in this manner in order

to obtain the specified engine idle speed

during the ad~ment procedure.

4. On a car with a manual-shift transmission, the engine idle speed is checked

and adjusted with the gear shift lever in

neutral position. On a car with an automatic transmission, the engine idle

speed is checked and adjusted first with

the transmission selector lever in the

neutral position and readjusted with the

transmission selector lever in the drive

range position. Adjust and check the

engine idle speed. Be sure the dash pot

(if so equipped) is not interfering with

the throttle lever or the fast idle screw

is not contacting the fast idle eam.

On a carburetor equipped with a hot

idle compensator, be sure the compensator is seated to ailow for proper idle

adjustment.

'-2298-A

Fig. " -Typical Thermador Exhaust Emission System Air Cleaner

Page 13

2-8

PART 2 - Maintenance Operations

When checking or adjusting idle (hot

engine) speed on any Thecmactor

equipped engine with a thermal sensing

valve in the distributor vacuum line,

die valve m..t be bypassed. Disconnect

the distributor vacuum' hose at the

sensing valve. Plug or pinch~ff the

manifold vacuum hose; t~n cbeckor

adjust the idle speed in the normal

manner. Do not unplug and reconnect

the hose until after the fast idle (cold

engine) speed adjustments havt been

completed.

FORD t-V CARBURETOR

Refer to Preliminary PreparatioD-

All Vehicles, above.

Adiust Accelerator Pump

Lever

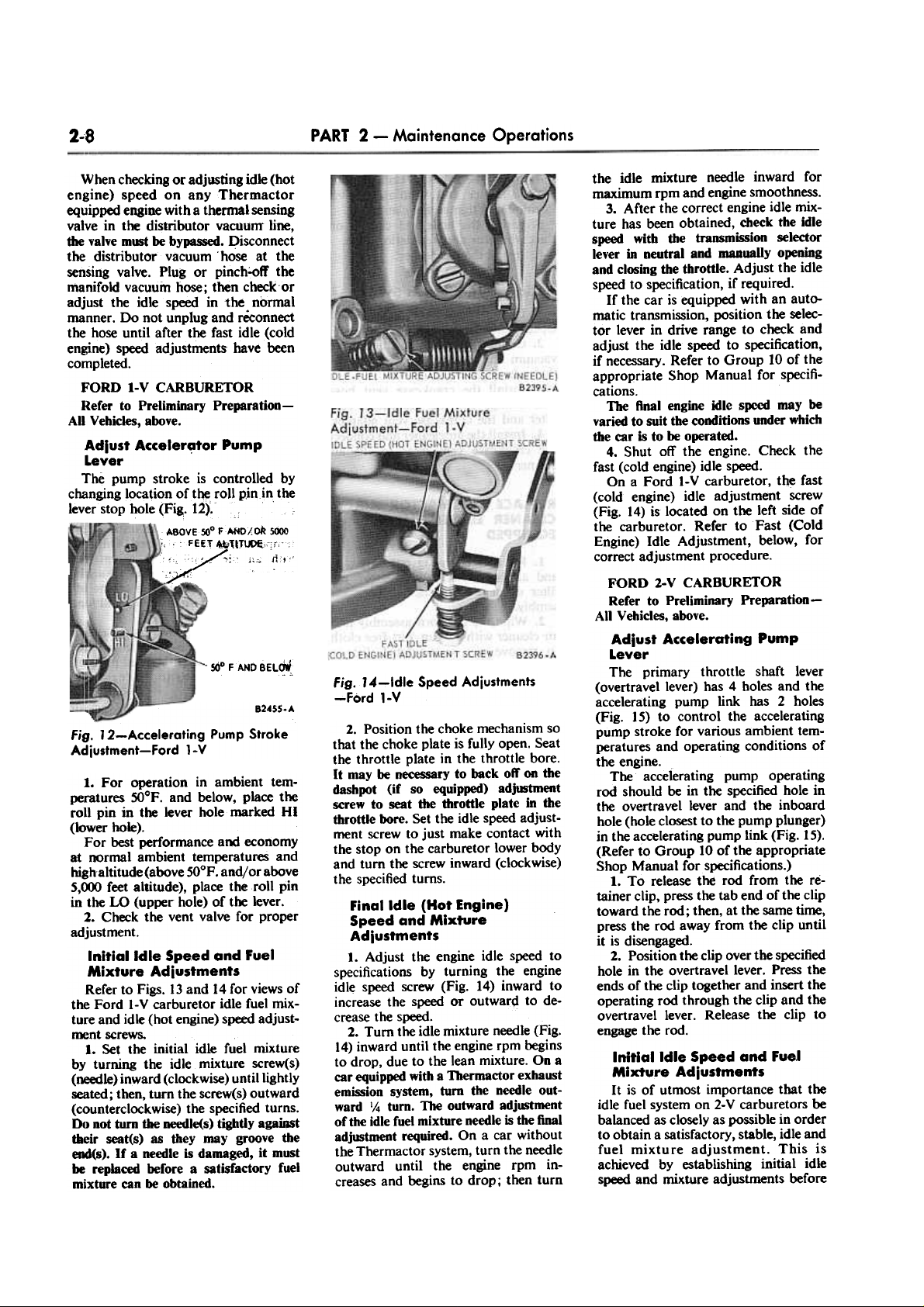

The pump stroke is controlled by

changing location oft~ roll p,inin the

lever stop hole (Fig,. 12).

A80VESOO FAHDAoR 5000

" : FEE.'\" ~11~"~r'

:,:~:c i~C;_~!

/

560 FAND BEL~

Fig. J 4-ldle Speed Adjustments

-Ford 1-V

B24SS.A

Fig. 12-Accelerating Pump Stroke

Adjustment-Ford 1-V

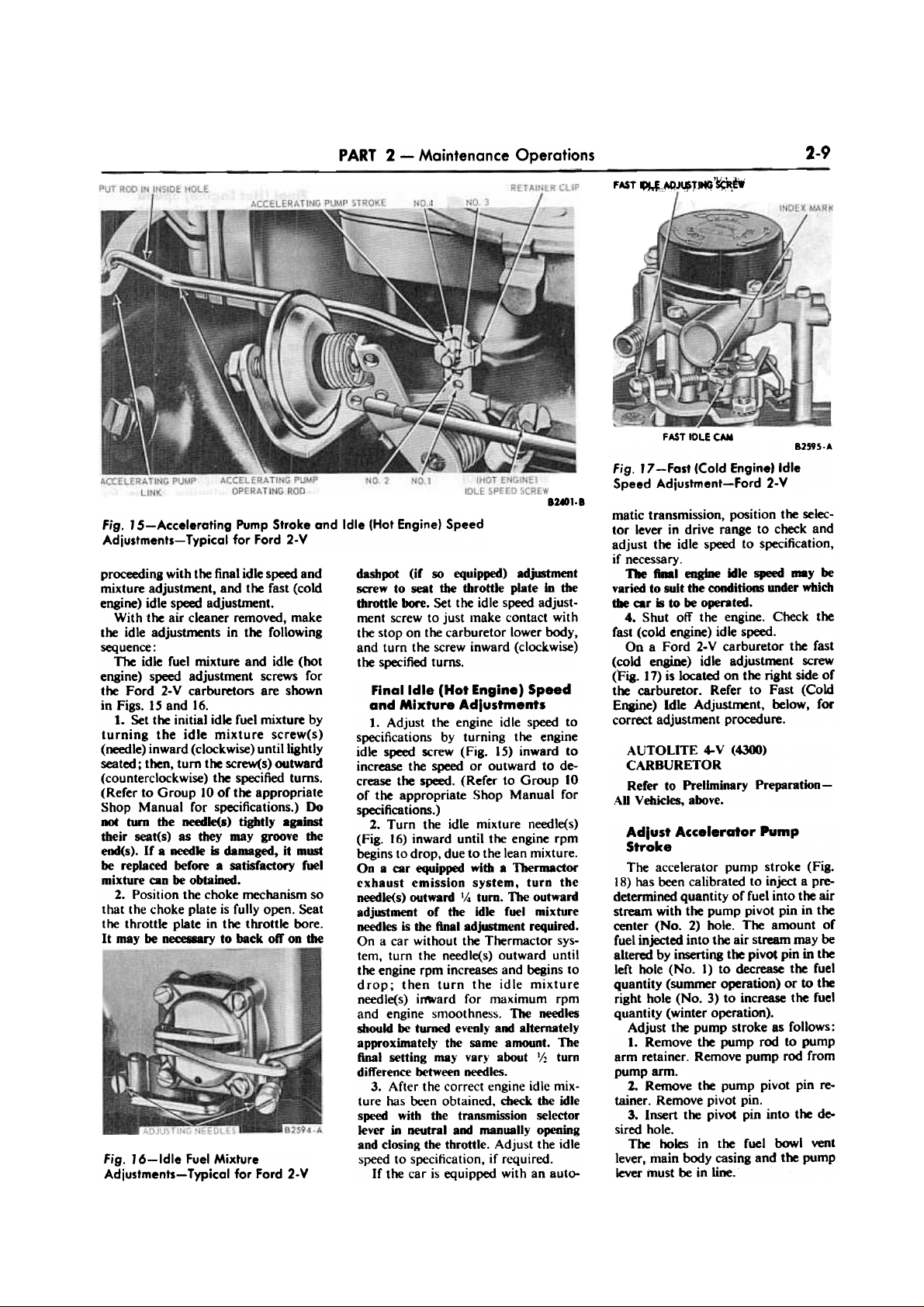

2. Position the choke mechanism so

that the choke plate is fully open. Seat

the throttle plate in the throttle bore.

It may be necessary to back oft' on the

dasbpot (if so equipped) adjIWtment

screw to seat the throttle plate in the

throttle bore. Set the idle speed adjustment screw to just make contact with

the stop on the carburetor lower body

and turn the screw inward (clockwise)

the specified turns.

Final Idle (Hot Engine)

Speed and Mixture

Adiustments

1. Adjust the engine idle speed to

specifications by turning the engine

idle speed screw (Fig. 14) inward to

increase the speed or outwar(i to de-

crease the speed.

2. Turn the idle mixture needle (Fig.

14) inward until the engine rpm begins

to drop, due to the lean mixture. On a

car equipped with a Thermactor exhaust

emission system, turn the needle out-

ward 1/4 turn. The outward adj~nt

of the idle fuel mixture needle is the final

adjIWtment required. On a car without

the Thermactor system, turn the needle

outward until the engine rpm increases and begins to drop; then turn

1. For operation in ambient temperatures SOoF. and below, place the

roll pin in the lever hole marked HI

(lower hole).

For best performance and economy

at normal ambient temperatures and

high altitude (above 50oP. and/or above

5,()X) feet altitude), place the roll pin

in the W (upper hole) of the lever.

2. Check the vent valve for proper

adjustment.

Initial Idle Speed and Fuel

Mixture Adiustments

Refer to Figs. 13 and 14 for views of

the Ford I-V carburetor idle fuel mixture and idle (hot engine) speed adjustment screws.

1. Set the initial idle fuel mixture

by turning the idle mixture screw(s)

(needle) inward (clockwise) until lightly

seated; then, turn the screw(s) outward

(counterclockwise) the specified turns.

Do not turn die needle(s) tightly aga~t

their seat(s) as they may groove the

eIMI(s). If a needle is damaged, it must

be replaced before a satisfactory fuel

mixture can be obtained.

the idle mixture needle inward for

maximum rpm and engine smoothness.

3. After the correct engine idle mixture has been obtained, check the idle

speed with the transmission selector

lever in neutral and manually opening

and closing the throttle. Adjust the idle

speed to specification, if required.

If the car is equipped with an automatic transmission, position the selector lever in drive range to check and

adjust the idle speed to specification,

if necessary. Refer to Group 10 of the

appropriate Shop Manual for specifications.

The final engine idle s~ may be

varied to suit the conditions under which

the car is to be operated.

4. Shut off the engine. Check the

fast (cold engine) idle speed.

On a Ford I-V carburetor, the fast

(cold engine) idle adjustment screw

(Fig. 14) is located on the left side of

the carburetor. Refer to Fast (Cold

Engine) Idle Adjustment, below, for

correct adjustment procedure.

FORD 2-V CARBURETOR

Refer to Preliminary Preparation-

All Vehicles, above.

Adiust Accelerating Pump

Lever

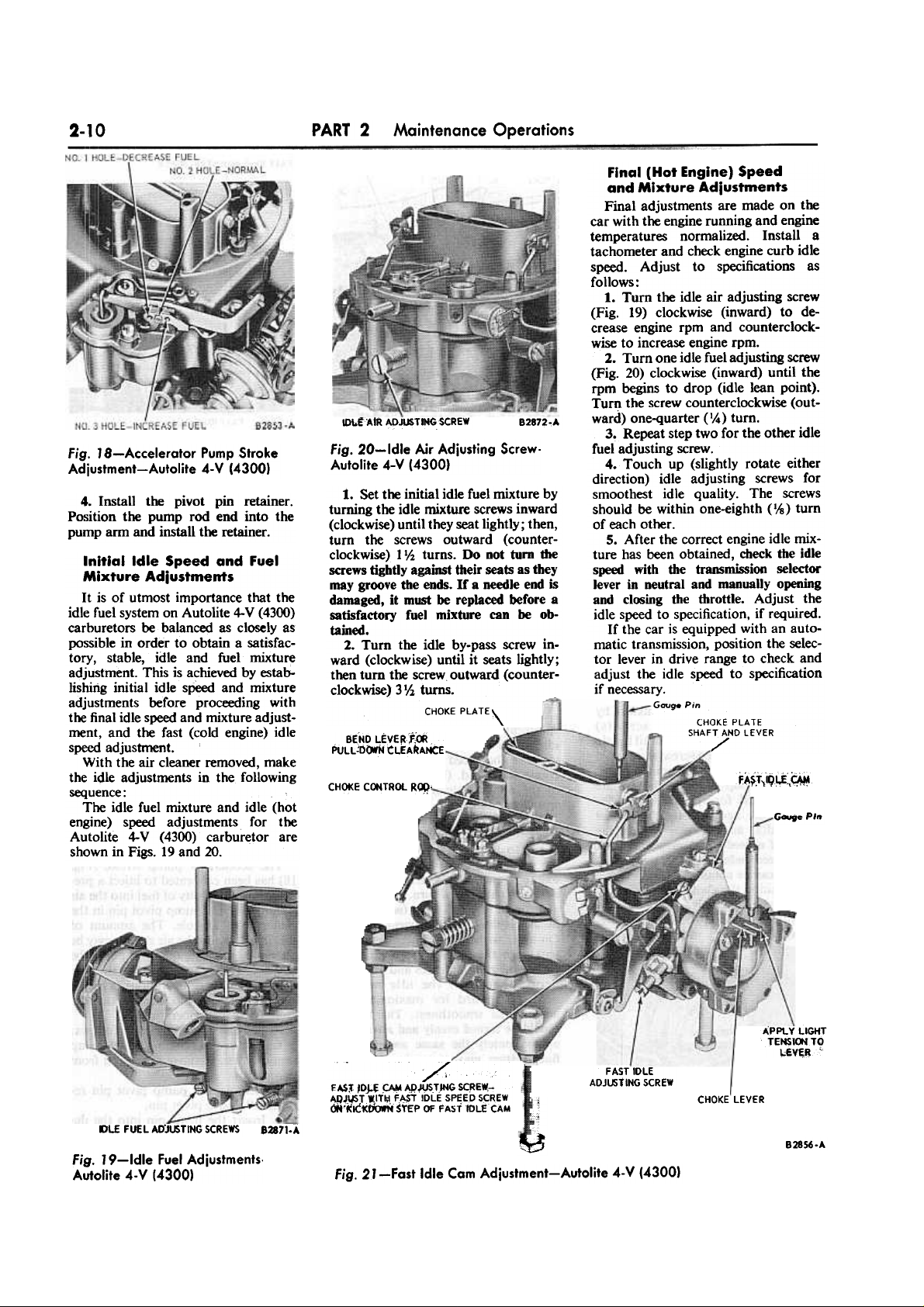

The primary throttle shaft lever

(overtravellever) has 4 holes and the

accelerating pump link has 2 holes

(Fig. 15) to control the accelerating

pump stroke for various ambient temperatures and operating conditions of

the engine.

The accelerating pump operating

rod should be in the specified hole in

the overt ravel lever and the inboard

hole (hole closest to the pump plunger)

in the accelerating pump link (Fig. 15).

(Refer to Group 10 of the appropriate

Shop Manual for specifications.)

1. To release the rod from the re-

tainer clip, press the tab end of the clip

toward the rod; then, at the same time,

press the rod away from the clip until

it is disengaged.

2. Position the clip over the specified

hole in the overtravel lever. Press the

ends of the clip together and insert the

operating rod through the clip and the

overtravel lever. Release the clip to

engage the rod.

Initial Idle Speed and Fuel

Mixture Adiustments

It is of utmost importance that the

idle fuel system on 2-V carburetors be

balanced as closely as possible in order

to obtain a satisfactory, stable, idle and

fuel mixture adjustment. This is

achieved by establishing initial idle

speed and mixture adjustments before

Page 14

2-9

PART 2 - Maintenance Operations

FAST ~o~~"I~ '~E'I

FAST I1)LE tAM

82595..

Fig. '7 -Fast (Cold Engine) Idle

Speed Adjustment-Ford 2-V

8~1.8

Fig. 15-Accelerating Pump Stroke and Idle (Hot Engine) Speed

Adjustments-Typical for Ford 2-V

dashpot (if so equipped) adjustment

screw to seat the throttle plate in tile

throttle bore. Set the idle speed adjustment screw to just make contact with

the stop on the carburetor lower body,

and turn the screw inward (clocKwise)

the specified turns.

matic transmission, position the selector lever in drive range to check and

adjust the idle speed to specification,

if necessary.

The hi engine idle speed a.y be

varied to suit the conditions under which

tile car is to be operated.

4. Shut off the engine. Check the

fast (cold engine) idle speed.

On a Ford 2-V carburetor the fast

(cold engine) idle adjustment screw

(Fig. 17) is located on the right side or

t~ carburetor. Refer to Fast (Cold

Enaine) Idle Adjustment, below, for

correct adjustment procedure.

AUTOLITE 4-V (4300)

CARBURETOR

Refer to Preliminary Preparation-

AU Vehicles, above.

proceeding with the final idle speed and

mixture adjustment. and the fast (cold

engine) idle speed adjustment.

With the air cleaner removed, make

the idle adjustments in the following

sequence:

The idle fuel mixture and idle (hot

engine) speed adjustment screws for

the Ford 2-V carburetors are shown

in Figs. IS and 16.

1. Set the initial idle fuel mixture by

turning the idle mixture screw(s)

(needle) inward (clockwise) until lightly

seated; then, turn the screw(s) outward

(counterclockwise) the specified turns.

(Refer to Group 10 of the appropriate

Shop Manual for specifications.) Do

not turn the needle(s) tightly apjmt

tbeir seat(s) as tbey may groove the

end(s). If a needle is damaged, it must

be replaced before a satisfactory fuel

mixture can be obtained.

2. Position the choke mechanism so

that the choke plate is fully open. Seat

the throttle plate in the throttle bore.

It may be necessary to back oft' on the

Adlust Accelerator Pump

Stroke

The accelerator pump stroke (Fig.

18) has been calibrated to inject a predetermined quantity of fuel into the air

stream with the pump pivot pin in the

center (No.2) hole. The amount of

fuel injected into the air stream may be

altered by inserting the pivot pin in the

left hole (No. J) to decrease the fuel

quantity (sum~r operation) or to the

right hole (No.3) to increase the fuel

quantity (winter operation).

Adjust the pump stroke as follows:

1. Remove the pump rod to pump

arm retainer. Remove pump rod from

pump arm.

z. Remove the pump pivot pin re-

tainer. Remove pivot pin.

3. Insert the pivot pin into the de-

sired hole.

The holes in the fuel bowl vent

lever. main body casing and the pump

lever must be in line.

Fig. J 6-ldle Fuel Mixture

Adjustments-Typical for Ford 2-V

Final Idle (Hat Engine) Speed

and Mixture Adlustments

1. Adjust the engine idle speed to

specifications by turning the engine

idle speed screw (Fig. 15) inward to

increase the speed or outward to decrease the speed. (Refer to Group 10

of the appropriate Shop Manual for

specifications.)

2. Turn the idle mixture needle(s)

(Fig. 16) inward until the engine rpm

begins to drop, due to the lean mixture.

On a car equipped with a Thermactor

exhaust emission system, turn the

needle(s) outward 14 turn. The outward

adjustment of the idle fuel mixture

needles is the final adjustment required.

On a car without the Therrnactor sys-

tem, turn the needle(s) outward until

the engine rpm increases and begins to

drop; then turn the idle mixture

needle(s) i~ard for maximum rpm

and engine smoothness. The needles

should be turned evenly and alternately

approximately the same amount. The

final setting may vary about 1/2 turn

difference between needles.

3. After the correct engine idle mixture has been obtained, check the idle

speed with the transmission selector

lever in neutral and manually opening

and closing the throttle. Adjust the idle

speed to specification, if required.

If the car is equipped with an auto-

Page 15

2-10

PART 2 Maintenance Operations

IDt.tAIR ADJUSTING SCREW

82872.,A

Fig. 20-ldle Air Adjusting Screw-

Autolite 4-V (4300)

Fig. J 8-Accelerator Pump Stroke

Adjustment-Autolite 4-V (4300)

4. Install the pivot pin retainer.

Position the pump rod end into the

pump arm and install the retainer.

1. Set the initial idle fuel mixture by

turning the idle mixture screws inward

(clockwise) until they seat lightly; then,

turn the screws outward (counter-

clockwise) llh turns. Do not turn die

screws tightly against their seats as they

may groove the ends. If a needle end is

damaged, it must be replaced before a

satisfactory fuel mixture can be obtained.

2. Turn the idle by-pass screw inward (clockwise) until it seats lightly;

then turn the screw outward (counter-

clockwise) 3lh turns.

CHOKE PLATE\

Final (Hat Engine) Speed

and Mixture Adjustments

Final adjustments are made on the

car with the engine running and engine

temperatures normalized. Install a

tachometer and check engine curb idle

speed. Adjust to specifications as

follows :

1. Turn the idle air adjusting screw

(Fig. 19) clockwise (inward) to decrease engine rpm and counterclockwise to increase engine rpm.

2. Turn one idle fuel adjusting screw

(Fig. 20) clockwise (inward) until the

rpm begins to drop (idle lean point).

Turn the screw counterclockwise (outward) one-quarter (II.) turn.

3. Repeat step two for the other idle

fuel adjusting screw.

4. Touch up (slightly rotate either

direction) idle adjusting screws for

smoothest idle quality. The screws

should be within one-eighth (lis) turn

of each other.

5. After the correct engine idle mix-

ture has been obtained, check the idle

speed with the trammission selector

lever in neutral and manually opening

and closing the throttle. Adjust the

idle speed to specification, if required.

If the car is equipped with an automatic transmission, position the selector lever in drive range to check and

adjust the idle speed to specification

if necessary.

Gau~ Pin

CHOKE PLATE

SHAFT AND LEVER

../'

BEND LEVE~f:OO

PuLL-UCJfN tLEARAI-K:E

fA~.i)i9~~~

CHOKE CONTROL R~.

Initial Idle Speed and Fuel

Mixture Adjustments

It is of utmost importance that the

idle fuel system on Autolite 4-V (4300)

carburetors be balanced as closely as

possible in order to obtain a satisfactory, stable, idle and fuel miXture

adjustment. This is achieved by establishing initial idle speed and miXture

adjustments before proceeding with

the final idle speed and miXture adjustment, and the fast (cold engine) idle

speed adjustment.

With the air cleaner removed, make

the idle adjustments in the following

sequence:

The idle fuel mixture and idle (hot

engine) speed adjustments for the

Autolite 4-V (4300) carburetor are

shown in Figs. 19 and 20.

G""fe PIn

APPLY LIGHT

TENSIOOTO

L~VER'

~

/

EA,$~ IDJ;.f' ~ APWSTJNGSC.RE~-

AQ~\JST WITI;\ F~ IDLE SPEED SCREW

cJt'"«tC1<tJowN $YEP OF FAST IDLE CAM

FAST IDLE

ADJ~TING SCREW

CHOKE LEVER

j

;}

~

DLEFfJEL AD"JUSTING SCREWS

82871:-'

82856.A

Fig. 19-1dle Fuel Adjustments.

Autolite 4- V (4300)

Fig. 21 -Fast Idle Cam Adjustment-Autolite 4-V (43001

Page 16

PART 2 2

Maintenance Operations

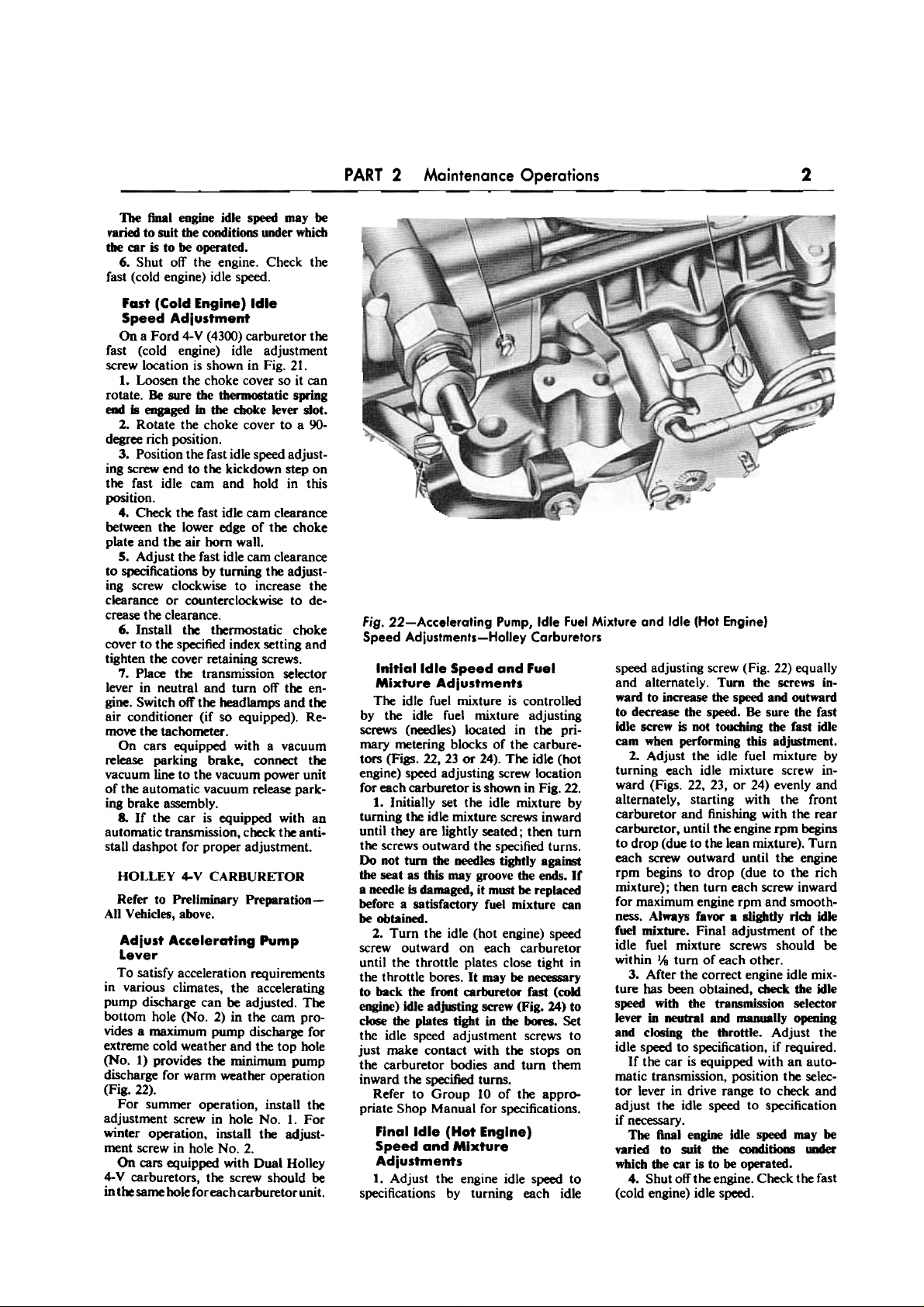

Fig. 22-Accelerating Pump, Idle Fuel Mixture and Idle (Hot Engine)

Speed Adjustments-Holley Carburetors

The final engine idle speed may be

varied to suit the conditions under whim

tbe car is to be operated.

6. Shut off the engine. Check the

fast (cold engine) idle speed.

Fast (Cold Engine) Idle

Speed Adlustment

On a Ford 4-V (4300) carburetor the

fast (cold engine) idle adjustment

screw location is shown in Fig. 21.

I. Loosen the choke cover so it can

rotate. Be sure the thermostatic spring

elM! Is engaged in tbe choke lever slot.

2. Rotate the choke cover to a 90-

degree rich position.

3. Position the fast idle speed adjust-

ing screw end to the kickdown step on

the fast idle cam and hold in this

position.

4. Check the fast idle cam clearance

between the lower edge of the choke

plate and the air horn wall.

S. Adjust the fast idle cam clearance

to specifications by turning the adjusting screw clockwise to increase the

clearance or counterclockwise to decrease the clearance.

6. Install the thermostatic choke

cover to the specified index setting and

tighten the cover retaining screws.

7. Place the transmission selector

lever in neutral and turn off the en-

gine. Switch off the headlarnps and the

air conditioner (if so equipped). Re-

move the tachometer.

On cars equipped with a vacuum

release parking brake, connect the

vacuum line to the vacuum power unit

of the automatic vacuum release parking brake assembly.

8. If the car is equipped with an

automatic transmission, check the antistall dashpot for proper adjustment.

speed adjusting screw (Fig. 22) equally

and alternately. Turn the screws inward to increase the speed and outward

to decrease the speed. Be sure the fast

idle screw is not toudling the fast idle

cam when performing this adj~tment.

2. Adjust the idle fuel mixture by

turning each idle miJcture screw inward (Figs. 22, 23, or 24) evenly and

alternately, starting with the front

carburetor and finishing with the rear

carburetor, until the engine rpm begins

to drop (due to the lean mixture). Turn

each screw outward until t~ engine

rpm begins to drop (due to the rich

mixture); t~n turn each screw inward

for maximum engine rpm and smoothness. Always favor. slightly rid! idle

fuel mixture. Final adjustment of the

idle fuel mixture screws should be

within lis turn of each other.

3. After the correct engine idle mixture has been obtained, dleck the idle

speed with the transmission selector

lever in neutral and manually opening

and cl~ing the throttle. Adjust the

idle speed to specification, if required.

If the car is equipped with an auto-

matic transmission, position the selec-

tor lever in drive range to check and

adjust the idle speed to specification

if necessary.

The final engine idle speed may be

varied to suit the cooditions UIMler

which the car is to be operated.

4. Shut off the engine. Check the fast

(cold engine) idle speed.

HOLLEY ~V CARBURETOR

Refer to Preliminary PrelNlrBtion-

All Vehicles, above.

Adjust Accelerating Pump

Lever

To satisfy acceleration requirements

in various climates, the accelerating

pump discharge can be adjusted. The

bottom hole (No.2) in the cam pro-

vides a maximum pump discharge for

extreme cold weather and the top hole

(No.1) provides the minimum pump

discharge for warm weather operation

(Fig. 22).

For summer operation, install the

adjustment screw in hole No. I. For

winter operation, install the adjust-

ment screw in hole No.2.

On cars equipped with Dual Holley

~ V carburetors, the screw should be

int~same hole for each carburetor unit.

Initial Idle Speed and Fuel

Mixture Adlustments

The idle fuel mixture is controlled

by the idle fuel mixture adjusting

screws (needles) located in the primary metering blocks of the carburetors (Figs. 22, 23 or 24). The idle (hot

engine) speed adjusting screw location

for each carburetor is shown in Fig. 22.

1. Initially set the idle mixture by

turning the idle mixture screws inward

until they are lightly seated; then turn

the screws outward the specified turns.

Do not turn the needles tightly against

the seat as this may groove the ends. If

a needle is damaged, it mmt be replaced

before a satisfactory fuel mixture can

be obtained.

2. Turn the idle (hot engine) speed

screw outward on each carburetor

until the throttle plates close tight in

the throttle bores. It may be necessary

to back the front carburetor fast (cold

engine) idle adjusting screw (Fig. 24) to

close the plates tight in the bores. Set

the idle speed adjustment screws to

just make contact with the stops on

the carburetor bodies and turn them

inward the specified turns.

Refer to Group 10 of the appro-

priate Shop Manual for specifications.

Final Idle (Hot Engine)

Speed and Mixture

Adjustments

1. Adjust the engine idle speed to

specifications by turning each idle

Page 17

2-12

PART 2 - Maintenance Operations

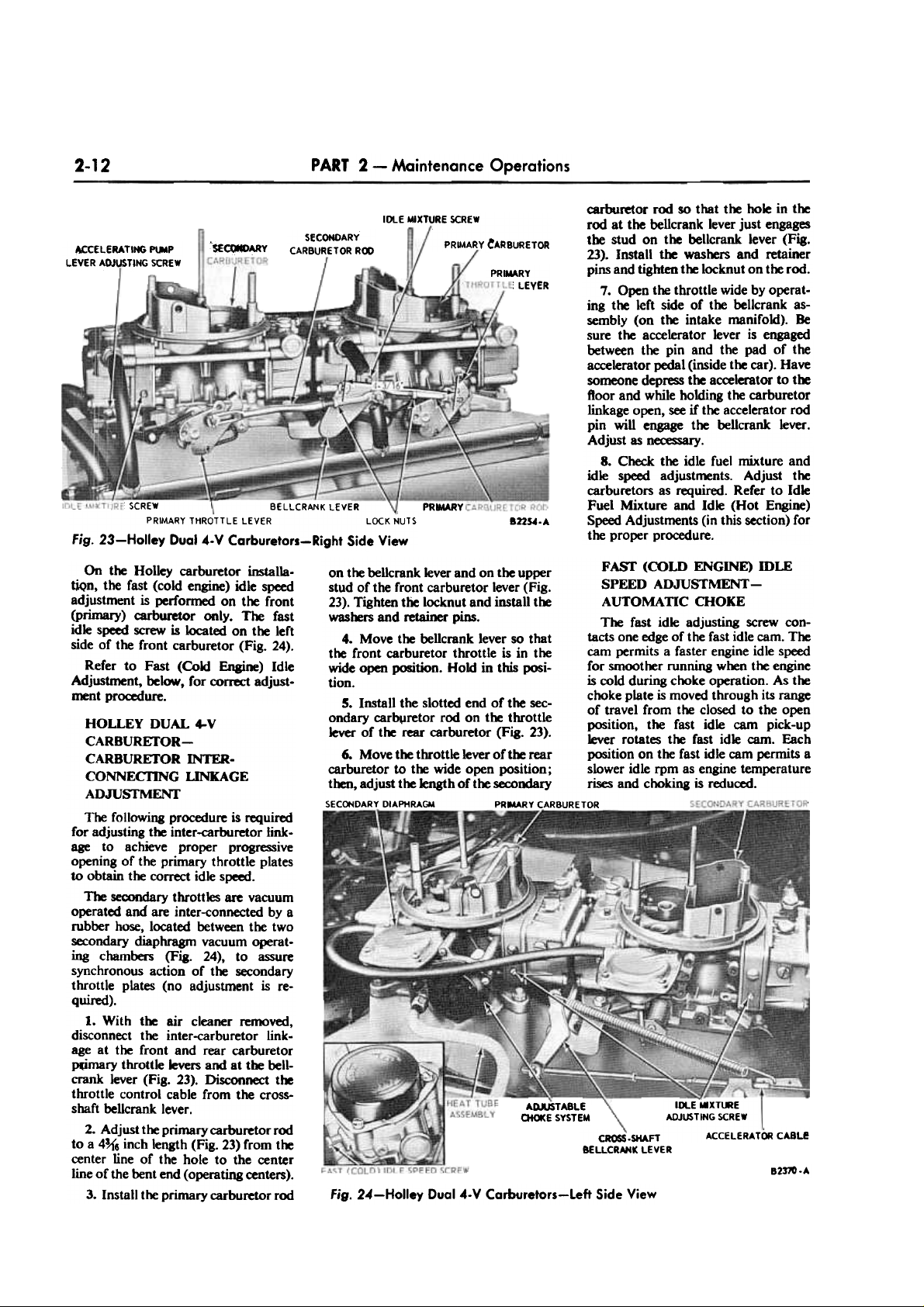

SeCONDARY

CARBURETOR ROO

IDLE MIXTURE SCREW

PRIMARY eARBURETOR

ACCELERATIIK; PlMP

LEVER ADJUSTING SCREW

'SEC(WC)ARY

PRIMARY

: LEVER

carburetor rod so that the hole in the

rod at the bellcrank lever just engages

the stud on the bellcrank lever (Fig.

23). Install the washers and retainer

pins and tighten the locknut on the rod.

7. Open the throttle wide by operating the left side of the bellcrank assembly (on the intake manifold). Be

sure the accelerator lever is engaged

between the pin and the pad of the

accelerator pedal (inside the car). Have

someone depress the accelerator to the

Roor and while holding the carburetor

linkage open, see if the accelerator rod

pin will engage the bellcrank lever.

Adjust as necessary.

8. Check the idle fuel mixture and

idle speed adjustments. Adjust the

carburetors as required. Refer to Idle

Fuel Mixture and Idle (Hot Engine)

Speed Adjustments (in this section) for

the proper procedure.

PRNARY

SCREW - BELLCRANK LEVER

PRIMARY THROTTLE LEVER LOCK NUTS

Fig. 23-Holley Dual 4-V Carburetors-Right Side View

82254-A

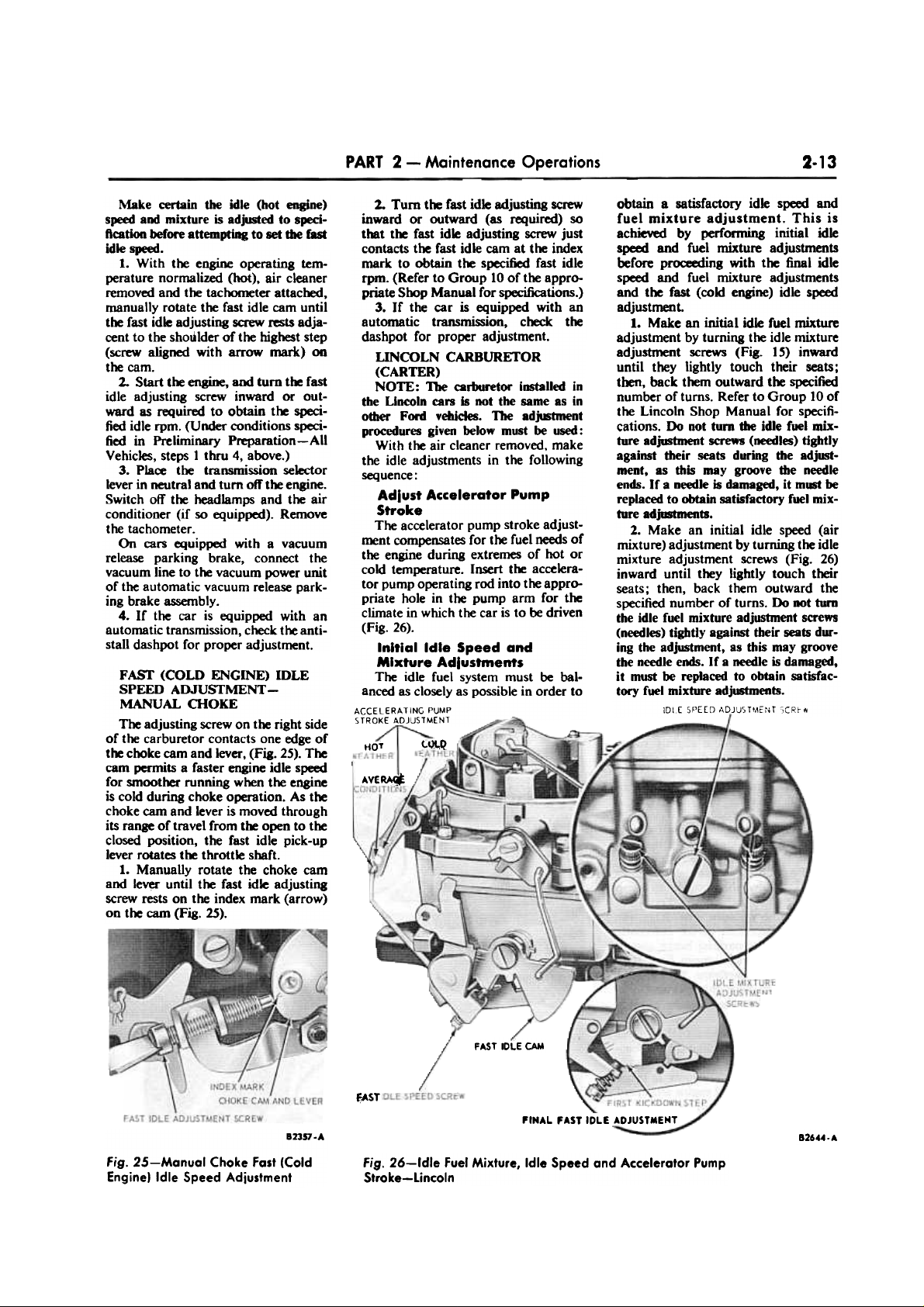

on the bellcrank lever and on the upper FASf (COLD ENGINE) mLE

stud of the front carburetor lever (Fig. SPEED ADJUSTMENT-

23). Tighten the locknut and install t~ AUTOMATIC CHOKE

was~ and retainer pins.

The " .dle d. .

last I a JusUng screw con-

4. Move the bellcrank lever so that tacts one edge of the fast idle cam. The

the front carburetor throttle is in the cam permits a faster engine idle speed

wide open position. Hold in this posi- for smoother running when the engine

tion. is cold during choke operation. As t~

S. Install the slotted end of the sec- choke plate is moved through its range

ondary carb~retor rod on t~ throttle of t.~vel from the c)osed to the. open

lever of the rear carburetor (Fig. 23). posItion, the fast ld~ cam pIck-up

lever rotates t~ fast Idle cam. Each

6. Move the throttle lever of t~ rear position on the fast idle cam permits a

carburetor to t~ wide open position; slower idle rpm as engine temperature

then, adjust the length of t~ secondary rises and choking is reduced.

SECONDARY DIAPHRAGM PR~RY CARBURETOR .

On the Holley carburetor instaUatiQn, the fast (cold engine) idle speed

adjustment is performed on the front

(primary) carburetor only. The fast

idle speed screw is located on the left

side of the front carburetor (Fig. 24).

Refer to Fast (CokJ Engine) Idle

Adjustment, below, for correct adjust-

ment procedure.

ADAJSTABLE

OiOICE SYSTEM

HOLLEY DUAL 4-V

CARBUREfOR-

CARBURETOR INTER-

CONNECI1NG UNKAGE

ADJUSTMENf

~ following procedure is required

for adjusting tre inter-carburetor linkage to achieve proper progressive

opening of the primary throttle plates

to obtain the correct idle speed.

~ secondary throttles are vacuum

operated and are inter-connected by a

rubber hose, located between the two

secondary diaphragm vacuum operating chambers (Fig. 24), to assure

synchronous action of tre secondary

throttle plates (no adjustment is re-

q uired).

1. With tre air cleaner removed,

disconnect the inter-carburetor link-

age at the front and rear carburetor

~ry throttle levers and at tre bell-

crank lever (Fig. 23). Disconnect tre

throttle control cable from the crossshaft beUcrank lever.

2. Adjust the primary carburetor rod

to a 4~6 inch length (Fig. 23) from tre

center line of the hole to the center

line of the bent end (operating centers).

3. Install t~ primary carburetor rod

- -.

IDl..E "X~E

ADJUSTING SCREW

ca.SHAFT ACCELERATOR CABLe

8ELLCRMK LEVER

82m-.

Fig. 24-Holley Dua14-V Corburetors-Left Side View

Page 18

2-13

PART 2 - Maintenance Operations

obtain a satisfactory idle speed and

fuel mixture adjustment. This is

achieved by performing initial idle

speed and fuel mixture adjustments

before proceeding with the final idle

speed and fuel mixture adjustments

and the fast (cold engine) idle speed

adjustment.

1. Make an initial idle fuel mixture

adjustment by turning the idle mixture

adjustment screws (Fig. I S) inward

until they lightly touch their seats;

then, back them outward the specified

number of turns. Refer to Group 10 of

the Lincoln Shop Manual for specifications. Do not turn the idle fuel mixture adjtfitment screws (needles) tightly

against their seats during tbe adjust-

ment, as this may groove the needle

ends. If a needle is damaged, it must be

replaced to obtain satisfactory fuel mix-

ture adjustlnellts.

2. Make an initial idle speed (air

mixture) adjustment by turning the idle

mixture adjustment screws (Fig. 26)

inward until they lightly touch their

seats; then, back them outward the

specified number of turns. Do DOt turn

tbe idle fuel mixture adjustment screws

(needles) tightiy agaiMt their seats during the adjustment, as this may groove

the needle euds. If a needle is damaged,

it must be replaced to obtain satisfactory fuel mixture adjustments.

IDlE 5f'EE[} ADJ'JST'~Er~T "CRI-O

Make certain the idle (hot engine)

speed and mixture is adjusted to speciftcatioo before attempting to set the fast

idle speed.

1. With the engine operating temperature normalized (hot), air cleaner

removed and the tachometer attached,

manually rotate the fast idle cam until

the fast idle adjusting screw rests adjacent to the shoulder of the highest step

(screw aligned with arrow mark) 00

the cam.

2. Start the engine. and turn the fast

idle adjusting screw inward or outward as required to obtain the specified idle rpm. (Under conditions specified in Preliminary Preparation-All

Vehicles, steps 1 thru 4, above.)

3. Place the transnrission selector

lever in neutral and turn off the engine.

Switch off the headlamps and the air

conditioner (if so equipped). Remove

the tachometer.

On cars equipped with a vacuum

release parking brake, connect the

vacuum line to the vacuum power unit

of the automatic vacuum release parking brake assembly.

4. If the car is equipped with an

automatic transmission, check the antistall dashpot for proper adjustment.

2.. Turn tlK: fast idle adjusting screw

inward or outward (as required) so

that tlK: fast idle adjusting screw just

contacts tlK: fast idle cam at the index

mark to obtain tlK: specified fast idle

rpm. (Refer to Group 10 of the appropriate Soop Manual for specifications.)

3. If the car is equipped with an

automatic transmission. check the

dashpot for proper adjustment.

LINCOLN CARBURETOR

(CARTER)

NOTE: The carburetor installed in

the Uncoln cars is not the same as in

other Ford vehides. The adjt8tment

procedures given below must be used:

With the air cleaner removed. make

the idle adjustments in the following

sequence:

Adlust Accelerator Pump

Stroke

The accelerator pump stroke adjustment compe~tes for the fuel needs of

the engine during extremes of hot or

cold temperature. Insert the accelerator pump operating rod into the appropriate hole in the pump arm for the

climate in which the car is to be driven

(Fig. 26).

Initial Idle Speed and

Mixture Adlustments

The idie fuel system must be balanced as closely as possible in order to

ACCELERATING PUMP

STROKE ADJUS1MENT

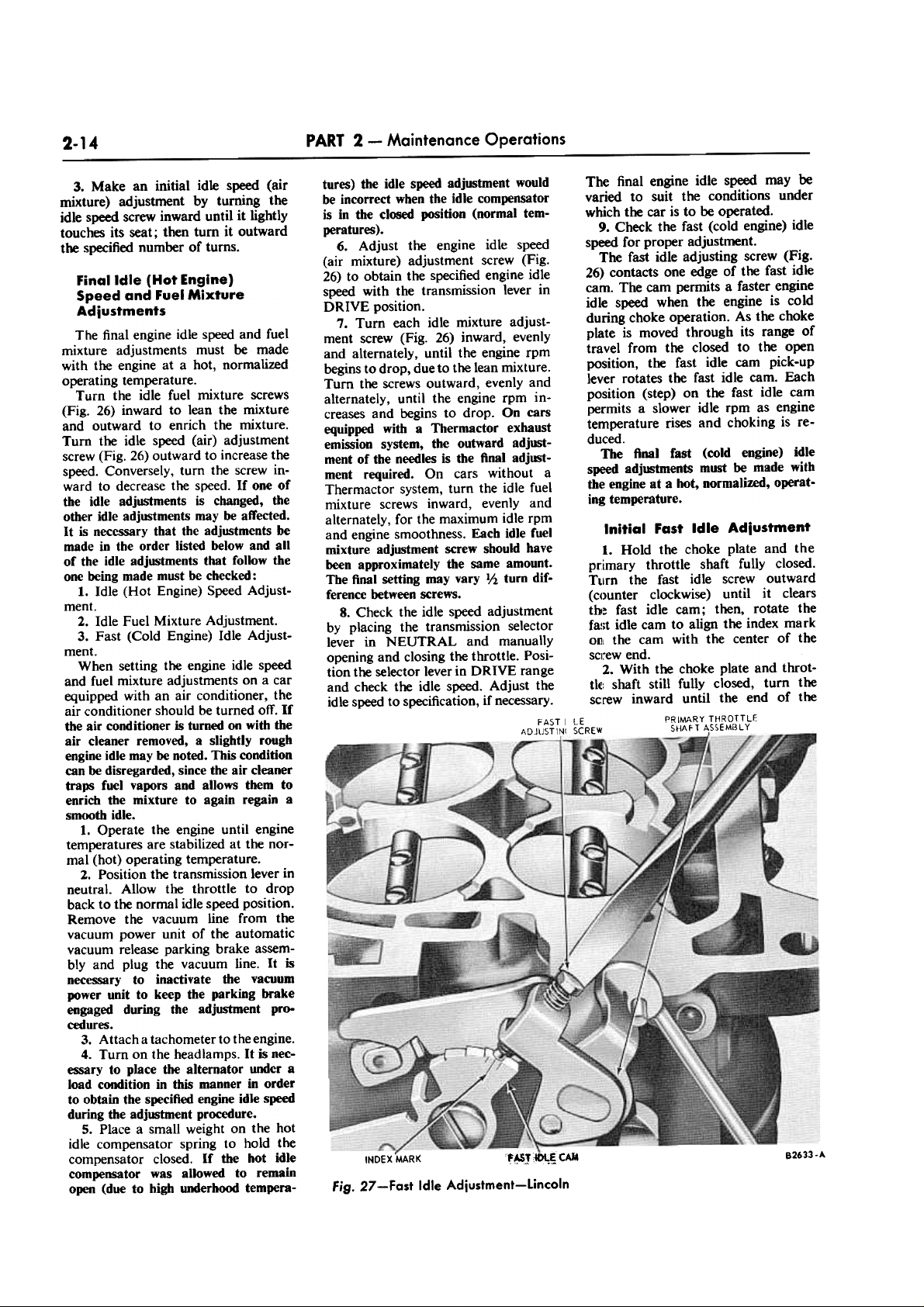

FAST (COLD ENGINE) mLE

SPEED AD.JUSTMENTMANUAL CHOKE

The adjusting screw on the right side

of the carburetor contacts one edge of

the choke cam and lever, (Fig. 25). The

cam permits a faster engine idle speed

for smoother running when the engine

is cold during choke operation. As the

choke cam and lever is moved through

its range of travel from the open to the

closed position, the fast idle pick-up

lever rotates the throttle shaft.

1. Manually rotate the choke cam

and le~ until the fast idle adjusting

screw rests on the index mark (arrow)

on the cam (Fig. 25).

(,;~Q

HoT

~veR4

J

FAST IDLE CAM

~ST

PINAL FAST IDLE ADJUSTMENT

82357 .A

Fig. 25-Manual Choke Fast (Cold

Engine) Idle Speed Adjustment

B2644..

fig. 26-ldle fuel Mixture, Idle Speed and Accelerator Pump

Stroke-Lincoln

Page 19

PART 2 - Maintenance Operations

2-14

3. Make an initial idle speed (air

mixture) adjustment by turning the

idle speed screw inward until it lightly

touches its seat; then turn it outward

the specified number of turns.

tures) the idle speed adjustment would

be incorrect when the idle compensator

is in the closed position (normal tem-

peratures).

6. Adjust the engine idle speed

(air mixture) adjustment screw (Fig.

26) to obtain the specified engine idle

speed with the transmission lever in

DRIVE position.

7. Turn each idle mixture adjust-

ment screw (Fig. 26) inward, evenly

and alternately, until the engine rpm

begins to drop, due to the lean mixture.

Turn the screws outward, evenly and

alternately, until the engine rpm increases and begins to drop. On cars

equipped with a Thermactor exhaust

emission system, the outward adjustment of the needles is the final adjustment required. On cars without a

Thermactor system, turn the idle fuel

mixture screws inward, evenly and

alternately, for the maximum idle rpm

and engine smoothness. Each idle fuel

mixture adjustment screw should have

been approximately the same amount.

The final setting may vary 1/2 turn dif-

ference between screws.

8. Check the idle speed adjustment

by placing the transmission selector

lever in NEUTRAL and manually

opening and closing the throttle. Position the selector lever in DRIVE range

and check the idle speed. Adjust the

idle speed to specification, if necessary .

FAST I

ADJUSTIN(

Initial Fast Idle Adiustment

1. Hold the choke plate and the

imary throttle shaft fully closed.

1m the fast idle screw outward

)unter clockwise) until it clears

~ fast idle cam; then, rotate the

;t idle cam to align the index mark

l the cam with the center of the

rew end.

2. With the choke plate and throt: shaft still fully closed, turn the

rew inward until the end of the

PRIMARY THROTTLE

SHAfT ASSEMBLY

Final Idle (Hot Engine)

Speed and Fuel Mixture

Adjustments

The final engine idle speed and fuel

mixture adjustments must be made

with the engine at a hot, normalized

operating temperature.

Turn the idle fuel mixture screws

(Fig. 26) inward to lean the mixture

and outward to enrich the mixture.

Turn the idle speed (air) adjustment

screw (Fig. 26) outward to increase the

speed. Conversely, turn the screw inward to decrease the speed. If one of

the idle adjustments is changed, the

other idle adjustments may be affected.

It is necessary that the adjustments be

made in the order listed below and all

of the idle adjustments that follow the

one being made must be checked:

1. Idle (Hot Engine) Speed Adjust-

ment.

2. Idle Fuel Mixture Adjustment.

3. Fast (Cold Engine) Idle Adjust-

ment.

When setting the engine idle speed

and fuel mixture adjustments on a car

equipped with an air conditioner, the

air conditioner should be turned off. If

the air conditioner is turned on with the

air cleaner removed, a slightly rough

engine idle may be noted. This condition

can be disregarded, since the air cleaner

traps fuel vapors and allows them to

enrich the mixture to again regain a

smooth idle.

1. Operate the engine until engine

temperatures are stabilized at the normal (hot) operating temperature.

2. Position the transmission lever in

neutral. Allow the throttle to drop

back to the normal idle speed position.

Remove the vacuum line from the

vacuum power unit of the automatic

vacuum release parking brake assemblyand plug the vacuum line. It is

necessary to inactivate the vacuum

power unit to keep the parking brake

engaged during the adjustment procedures.

3. Attach a tachometer to the engine.

4. Turn on the head lamps. It is necessary to place the alternator under a

load condition in this manner in order

to obtain the specified engine idle speed

during the adjustment procedure.

5. Place a small weight on the hot

idle compensator spring to hold the

compensator closed. If the hot idle

compensator was allowed to remain

open (due to high underhood tempera-

B2633.A

f~J~~ cAJA

INDEX MARK

Fig. 27 -Fast Idle Adjustment-Lincoln

The final engine idle speed may be

varied to suit the conditions under

which the car is to be operated.

9. Check the fast (cold engine) idle

speed for proper adjustment.

The fast idle adjusting screw (Fig.

26) contacts one edge of the fast idle

cam. The cam permits a faster engine

idle speed when the engine is cold

during choke operation. As the choke

plate is moved through its range of

travel from the closed to the open

position, the fast idle cam pick-up

lever rotates the fast idle cam. Each

position (step) on the fast idle cam

permits a slower idle rpm as engine

temperature rises and choking is re-

duced.

The final fast (cold engine) idle

speed adjmtments must be made with

the engine at a hot, normalized, operat-

ing temperature.

pc

Tl

(c(

tho

fa!

011

SCI

tIe

sc

LE

SCREW

Page 20

PART 2 - Maintenance Operations

2-15

CONDITION

CAUSED BY

Any discoloration other than a frosted slate

grey shall be considered as rorned points.

BURNED

Incorrect alignment.

Incorrect voltage regulator setting.

Radio condenser installed to the distributor

side of the coiL

Ignition condenser of improper capacity.

Extended operation of the engine at speeds

other than normaL

EXCESSIVE MnAL

I TRANSFER OR PInING

81443-8

Fig. 28-Breaker Point Inspection

4. Repeat this procedure until speci-

fied dwell is obtained.

If new points are installed, set

the gap to specifications using a

feeler gauge.

~

CONTACT

AR!A

C8'nERED

~-t

CORRECT

ALIGNMENT

81019-A

Fig- 29-Breaker Point Alignment

Guide

Too/-KO.111 or TK.419.A

screw just touches the cam at the

index mark (Fig. 27). Release the

throttle shaft and turn the fast idle

screw inward one full turn.

Final Fast Idle Adiustment

Make certain the idle (hot engine)

speed alMl mixture is adjmted to

specification before attempting to set

the ftD81 fast idle speed.

1. With the engine at a stabilized

normal operating temperature, tachometer installed, headlamps turned

on, idle compensator closed, P8rkinI

brake on and the transmission selector

lever in NEUTRAL; position the fast

idle screw on the first kickdoWD step

(Fig. 26). located next to the highest

(index marked) step on the fast idle

cam. Adjust the fast idle screw to

obtain the specified fast idle rpm.

2. Turn off the engine. Remove

the tachometer. Remove the weight

from the bot idle compensator. Turn

off the headlamps. Connect the vacuum line to the vacuum power unit of

the vacuum release parking brake

assembly.

3. Check the anti-stall dashpot and

accelerating pump for proper adjustment. Install the air cleaner assembly.

LUBRICATE ACCELERATOR

BALL SOCK"S AND

CARBURETOR LEVER KICKDOWN ACTUATING CAM

-ECONOLINE AND BRONCO

Lubricate the accelerator pedal shaft

and kickdown actuating cam on all

engines. When equipped with auto-

matic transmission, lubricate all friction points in the accelerator to

carburetor linkage with specified lubricant.

CHECK DISTRIBUTOR POINTS

AND ADJUST DWELL

Unsnap the distributor cap retain-

ing clips, lift the distributor cap off

the distributor housing, and position

the cap out of the way (if necessary,

remove the air cleaner and/or the

high tension wire to gain access to

the distributor).

Lift the rotor off the cam. Remove

the dust cover (transistorized ignition).

BREAKER POINT INSPEC110N

Breaker points should be inspected,

cleaned and adjusted as necessary.

Breaker points can be cleaned with

chloroform and a stiff bristle brush.

Caution: Make sure there Is te

ventiJatiCMa. Replace the breaker point

assembly if the contacts are badly

burned or excessive metal transfer

between the points is evident (Fig. 28).

BEND STATIONARY BRACKET B2351.A

Fig. 30-Aligning Breaker PointsTypical

Metal transfer is considered excessive

when it equals or exceeds the gap

setting.

BREAKER POINT AUGNMENT

The vented-type breaker points

used in Ford distributors must be

accurately aligned in order to realize

the full advantages provided by this

design, and to assure normal breaker

point life. Any misalignment of the

breaker point surfaces will cause pre-

mature wear, overheating, and pitting.

1. Turn the distributor cam so

that the breaker points are closed and

check the alignment of the points

(Fig. 29).

1. Align the breaker points to make

full face contact by bending the

stationary breaker point bracket (Fig.

30). Do not bend the breaker arm.

3. After the breaker points have

been properly aligned, adjust the

breaker point gap or dwell.

DWELL ANGLE ADJUSTMENT

Use a dwell meter to check the

contact dwell. It is not advisable to

use a feeler gauge to adjust or to

check the gap of used breaker points

because the roughness of the points

makes an accurate gap reading or

setting impossible.

If the I8ed points are serviceable, set

the gap using a dwell meter as follows:

1. Connect the dwell meter following the manufacturer's instructions.

In a car equipped with transistor ignition, make sure that the dwell meter is

connected to the tadlOmeter block

rather than the coil.

1. 0 perate the engine at idle speed

and note the reading on the dwell

meter.

3, Stop the engine and adjust the

gap (decreasing the gap increases the

dwell). Now check the dwell again.

Page 21

2-16

PART 2 - Maintenance Operations

5. Install the dust cover (transis-

torized ignition).

6. Install the ro tor. Install the distributor cap on the distributor housing

and snap the retaining clips in place.

INSPECT, CUAN, ADJUST

AND TEST SPARK PLUGS

REMOVAL

1. Remove the wire from each

spark plug by grasping, twisting and

then pulling the moulded cap of the

wire only. Do not pull on the wire

because the wire connection inside the

cap may become separated or the

weather Ral may be damaged.

1.. Clean the area around each spark

plug port with compressed air, then

remove t~ spark plugs.

CLEANING AND JNSPEcrION

1. Examine t~ firing ends of t~

spark plugs, noting the type of deposits and t~ degree of electrode

erosion. Refer to Fig. 31 for the various types of spark plug fouling and

their causes.

2. Clean t~ plugs on a sand blast

cleaner, following t~ manufacturer's

instructions. Do not prolong the use

of the abrasive blast as it will erode

the iJISuIator. Remove carbon and

other deposits from the threads with

a stiff wire brush. Any deposits will

retard t~ heat flow from the plug

to the cY linder ~ad causing spark

plug overheating and pre-ignition.

3. Oean the electrode surfaces with

a small file (Fig. 32). Dress t~

electrodes to secure flat parallel surfaces on both the center and side

electrode.

4. After cleaning, examine the plug

carefully for cracked or broken insulators. badly pitted electrodes, and

~1.A

Fig. 32-Cleaning Spark Plug

Electrode

Fig. 3 J -Spark Plug Inspection Guide

Page 22

PART 2 - Maintenance Operations

2-17

Fig. 33-Checking Spark Plug Gap

other signs of failure. Replace as

required.

Fig. 36-Typical V-8 Engine Timing

Marks-Except 289

ADJUSTMENT

Set the spark plug gap to specifications by bending the ground electrode.

(Fig. 33). Never bend the center

electrode. (Refer to Group 9 Specifications in the appropriate Shop Manual

for gap settings.)

81474-8

Fig. 34- Typical Six-Cylinder Engine

Timing Marks

TESTING

After the proper gap is obtained,

check the plugs on a testing machine.

Compare the sparking efficiency of

the cleaned and gapped plug with a

new plug. Replace the plug if it fails

to pass the test as outlined in the

tester instruction manual.

Test the plugs for compression

leakage at the insulator seal. Apply

a coating of oil to the shoulder of

the plug where the insulator projects

through the shell, and to the top of

the plug, where the center electrode

and terminal project from the insu-

lator. Place the spark plug under

pressure with the tester's high tension wire removed from the spark

plug. Leakage is indicated by air

bubbling through the oil. If the test

indicates compression leakage, replace the plug. If the plug is satisfactory, wipe it clean.

(BTDC). The crankshaft puUey or

damper has a timing notch.

V -8 Eagines. The crankshaft damper

for the 289 V-8 engine (Fig. 35) has

five timing marks ranging from top

dead center (fDC to 12° before top

dead center (BTDC).

The crankshaft damper for all V-8

engines except the 289 has 15 timing

marks ranging from top dead center

(TDC) to 300 before top dead center

(BTDC) (Fig. 36). Refer to specifications for the correct ignition timing.

INSfALLATlON

1. Install the spark plugs and torque

each plug to 15-20 ft-lbs.

When a new spark plug is installed

in a new replacement cylinder head,

torque the plug to 20-30 ft-lbs.

1. Connect the spark plug wires.

Push all weather seals into position.

CHECK AND ADJUST

IGNlnON TIMING

TL\.fiNG MARK LOCATIONS

Six Cylinder Engines. The timing

pointer (Fig. 34), has five timing

marks ranging from top dead center

(fDC) to 14° before top dead center

Fig. 35-289 V-8 Engine Timing

Marks

DMING PROCEDURE

To check and adjust the timing

with a Rotunda 13-07 power timing

light, proceed as follows:

I. Remove the plug wire from the

number 1 spark plug.

2. Install the spark plug adaptor on

the spark plug.

3. Connect the plug wire to the

spark plug adaptor.

4. Clamp t~ timing light spark

plug lead to the spark plug adaptor.

5. Connect the timing light battery

leads to the battery terminals.

6. Disconnect the distributor vac-

uum line (if so equipped).

7. If necessary, clean and mark the

timing marks.

8. Connect a tachometer to the

engine.

NOTE: When connecting a tachometer to a car equipped with a transistorized ignition, connect the leads

to the tachometer block (positive lead to

red tenninal, negative to black).

9. Start the engine and adjust the

speed to the specified rpm for initial

timing adjustment. Allow the engine

to warm up and point the timing light

at the timing pointer.

10. If the timing is incorrect, loosen

the distributor hold down bolt and

rotate the distributor until the desired

initial advance is obtained.

11. Tighten the distributor hold

down bolt and check the timing again.

12. Turn off the engine.

13. Remove the timing light and

connect the vacuum line.

Page 23

2-18

PART 2 - Maintenance Operations

~.'

~

,...

:nn,

'"

':, ~

i

;:.t

£'.1

'k:i\J:

~

~'

rC;!,;if~", ji ~f --- t 7"f c~ iii ,J ~:-:o:::::::--- ~

"':;~ ~

; !~--~ ~ -"'""F; X

,"CYLINDER ENGINE WITH AUTDMATfC CHOKE

/","

J r II '):::::::J

~~:::; r )~ ,. /

,.,

~::::=J

-::~

/j"'/

-:t:::

"" '

f;' c'

1;:~::.:::::;~~~~:~~:"; -;;.-. ---

/1--

~

~

'Sifj

~/

/

"~

~

~

/

~

~

KI649.A

To drain the radiator, open the

drain cock located at the bottom of

the radiator and remove the cylinder

block drain plug(s). The 6-cylinder

engine block has one drain plug

located at the right rear of the cylinder

block ahead of the starter (Fig. 39).

The V -8 engines have a drain plug on

each side of the cylinder block (Fig.

40).

To fill the cooling system, close the

drain cock. Install the block drain

plug(s). Disconnect the heater outlet

hfJSe at the water pump to bleed or

release trapped air in the system. When

the coolant begins to escape, connect

the heater outlet hose.

DRAIN PLUG

CHECK EXHAUST CONTROL

VALVE FOR FREE OPERATION,

IF SO EQUIPPED

The exhaust control valve, if the

car is so equipped, should be checked

to make certain it is operating properly. A valve that is stuck in the open

position will result in poor engine

performance during initial warm-up,

because the heat passing through the

intake manifold heat riser is insufficient

for proper fuel atomization.