Page 1

303-01C-1 303-01C-1Engine — Cobra 4.6L (4V)

DESCRIPTION AND OPERATION

Engine

WARNING: Do not operate the engine

with the hood open until the fan blade has been

first examined for possible cracks and separation.

The 4.6L (4V) (281 CID) Cobra engine is a V-8

with the following features:

• intercooled supercharger

• dual overhead camshafts

• four valves per cylinder

• sequential multiport fuel injection (SFI)

• an aluminum intake manifold

• aluminum cylinder heads

• a cast aluminum, 90-degree V- cylinder block

• individually chain-driven camshafts with a

hydraulic timing chain tensioner on each timing

chain

• the electronic ignition system with eight ignition

coils

Induction System

The sequential multiport fuel injection (SFI)

provides the fuel/air mixture needed for combustion

in the cylinders. The eight solenoid-operated fuel

injectors:

• are mounted in the lower intake manifold.

• meter fuel into the air intake stream in accordance

with engine demand.

• are positioned so that their tips direct fuel just

ahead of the engine intake valves.

• are connected in series with the fuel pressure

sensor.

• supply fuel from the fuel tank with a fuel pump

mounted in the fuel tank.

A constant fuel pressure drop is maintained across

the fuel injectors by the fuel pressure sensor. The

fuel pressure sensor:

• is positioned upstream from the fuel injectors on

the fuel injection supply manifold.

Identification

Always refer to these labels when replacement parts

are necessary or when checking engine calibrations.

The engine parts often differ within a CID family.

Valve Train

The valve train operates as follows:

• ball-tip hydraulic lash adjusters provide automatic

lash adjustment.

Verification of the identification codes will ensure

that the correct parts are obtained. These codes

contain all the pertinent information relating to the

dates, optional equipment and revisions. The Ford

Master Parts Catalog contains a complete listing of

• roller followers ride on the camshaft lobes,

transferring the up-and-down motion of the

camshafts to the valves in the cylinder heads.

Positive Crankcase Ventilation System

the codes and their application.

All engines are equipped with a closed-type positive

Code Information crankcase ventilation system recycling the crankcase

The engine code information label, located on the

side of the valve cover and the front side of the

vapors to the upper intake manifold.

Lubrication System

valve cover, contains the following:

The engine lubrication system operates as follows:

• engine build date

• oil is drawn into the oil pump through the oil

• engine plant code

• engine code

Exhaust Emission Control System

pump screen cover and tube in the sump of the

oil pan.

• oil is pumped through the oil bypass filter on the

left front side of the cylinder block.

Operation and necessary maintenance of the exhaust

emission control devices used on this engine is

covered in the Powertrain Control/Emissions

Diagnosis (PC/ED) manual.

• oil enters the main oil gallery where it is

distributed to the crankshaft main journals and to

both cylinder heads.

Copyright 2002, Ford Motor Company

Last updated: 6/14/2002

2003 Mustang, 8/2002

Page 2

303-01C-2 303-01C-2Engine — Cobra 4.6L (4V)

DESCRIPTION AND OPERATION (Continued)

• From the main journals, the oil is routed through • Oil pump displacement has been selected to

cross-drilled passages in the crankshaft to provide adequate volume to ensure correct oil

lubricate the connecting rod bearings. Controlled pressure both at hot idle and maximum speed.

leakage through the crankshaft main bearings and

connecting rod bearings is slung radially outward

to cool and lubricate the cylinder walls as well as

the entire connecting rod, piston and piston rings

assembly.

• The left cylinder head is fed from a drilling into

the supply passage feeding the main gallery at the

front of the cylinder block. The right cylinder Cooling System

head is fed from a drilling into the rear of the

main gallery. Main gallery pressure is reduced as

it enters the cylinder head galleries through fixed

serviceable orifices located at the upper part of

the feed passages. It is this reduced pressure in

the cylinder head galleries which feeds the

camshaft journals, the hydraulic lash adjusters

and the primary and secondary timing chain

tensioners.

• The camshaft lobe and roller followers are

lubricated by splash created through valve train

operation.

Oil Pump • heater water hoses

The lubrication system of the 4.6L (4V) engine is

designed to provide optimum oil flow to critical

components of the engine through its entire

operating range. The heart of the system is a

positive displacement internal gear oil pump using

top seal rotors. Generically this design is known as

a gerotor pump, which operates as follows.

• The oil pump is mounted on the front face of the

cylinder block. • The serpentine drive belt is routed over each

• The inner rotor is piloted on the crankshaft post

and is driven through flats on the crankshaft.

• System pressure is limited by an integral,

internally-vented relief valve which directs the

bypassed oil back to the inlet side of the oil

pump.

• The relief valve calibration protects the system

from excessive pressure during high viscosity

conditions.

• The relief valve is designed to provide adequate

connecting rod bearing lubrication under

high-temperature and high-speed conditions.

The engine cooling system includes the following:

• radiator

• water pump

• the electric cooling fan motor and fan blade,

activated by the variable control module

• the degas bottle, which aids in maintaining the

correct volume of engine coolant

• water thermostat

• upper radiator hose

• lower radiator hose

Drive Belt System

The 4.6L (4V) DOHC engine is equipped with a

serpentine drive belt. To ensure maximum life, a

replacement drive belt should be of the same type

as originally installed.

• The accessories mounted on the front of the

engine are belt-driven by the crankshaft.

accessory pulley, driven by the crankshaft pulley

bolted to the crankshaft.

For service procedures, including tensioning, refer to

Section 303-05.

2003 Mustang, 8/2002

Page 3

303-01C-3 303-01C-3Engine — Cobra 4.6L (4V)

DESCRIPTION AND OPERATION (Continued)

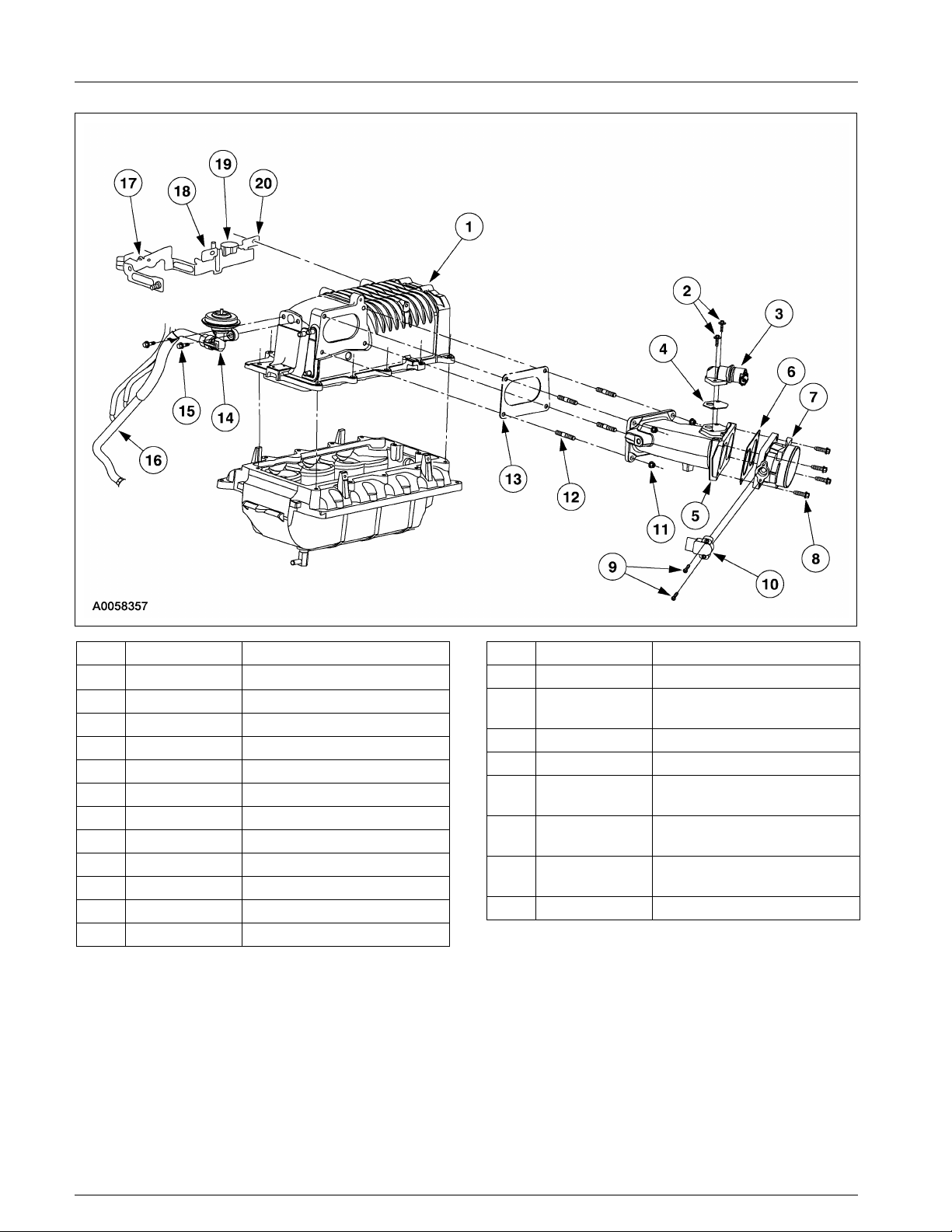

Item Part Number Description Item Part Number Description

1 6F066 Supercharger assembly

2 N806154 Screws (2 req’d)

3 9F715 Idle air control valve

4 — Idle air control valve gasket

5 9P697 Spacer assembly

6 9E936 Throttle body gasket

7 9E926 Throttle body

8 — Bolts (4 req’d)

9 — Bolts (2 req’d)

10 9E926 Throttle position sensor

11 N804178 Nuts (4 req’d)

12 — Studs (4 req’d)

(Continued)

13 — Spacer assembly gasket

14 9D475 Exhaust gas recirculation

valve

15 — Stud

16 9D477 Exhaust gas recirculation tube

17 — Manifold absolute pressure

sensor

18 9J460 Differential pressure feedback

EGR system

19 9J459 Exhaust gas recirculation

vacuum regulator

20 9J472 Vacuum accessory bracket

2003 Mustang, 8/2002

Page 4

303-01C-4 303-01C-4Engine — Cobra 4.6L (4V)

DESCRIPTION AND OPERATION (Continued)

2003 Mustang, 8/2002

Page 5

303-01C-5 303-01C-5Engine — Cobra 4.6L (4V)

DESCRIPTION AND OPERATION (Continued)

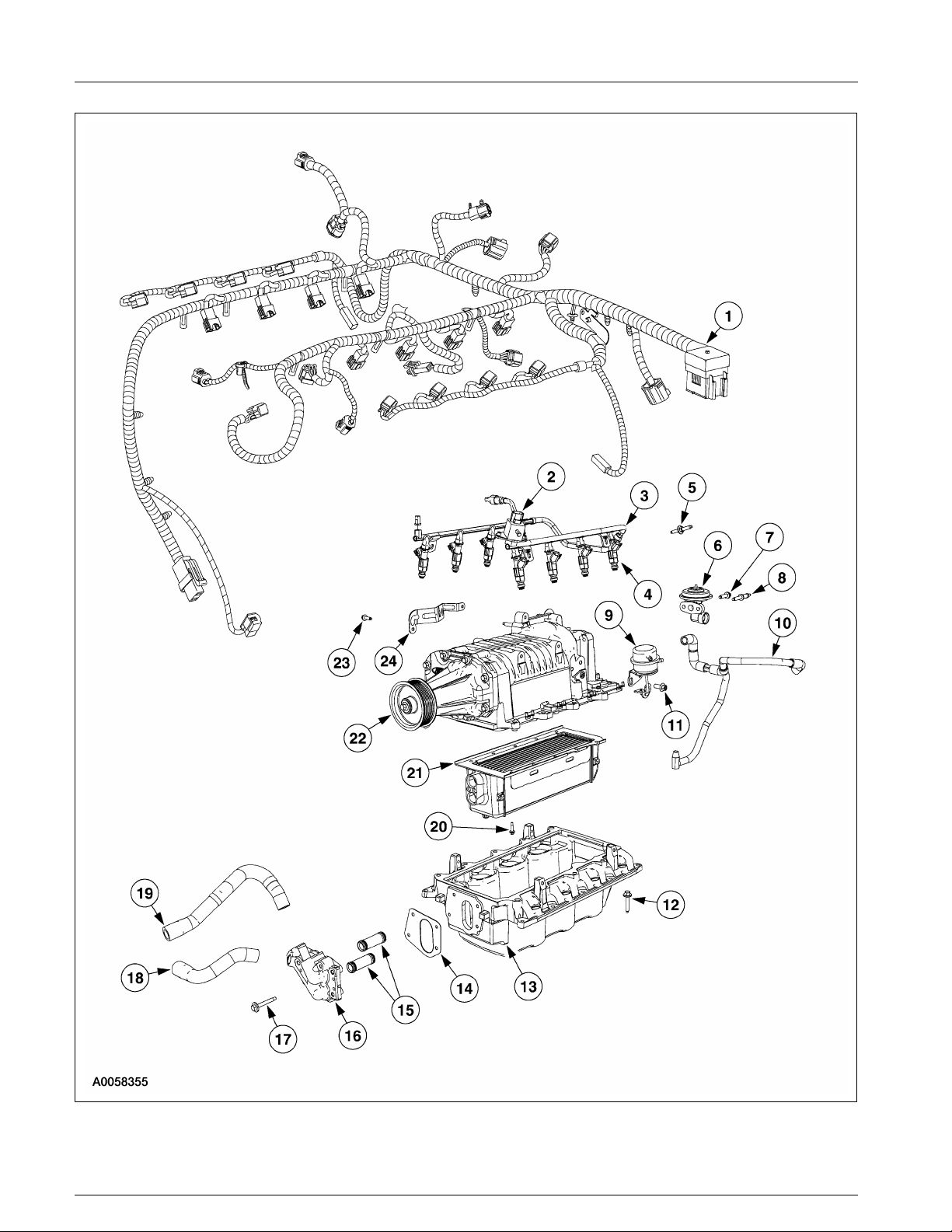

Item Part Number Description Item Part Number Description

1 12B637 Wiring harness

2 9C986 Fuel pulse damper

3 9F792 Fuel injection supply

manifold

4 9F593 Fuel injector

5 — Stud

6 9D475 Exhaust gas recirculation

valve

7 W701232 Bolt

8 N806979 Stud

9 — EGR vacuum hoses

10 6F089 Vacuum actuator valve

11 N605892 Bolts (2 req’d)

12 — Bolts (10 req’d)

(Continued)

13 9J447 Lower intake manifold

14 9L438 Coolant intake manifold

gasket

15 — Coolant tubes

16 9N491 Coolant intake manifold

17 W701592 Bolt

18 NL443 Inter cooler hose

19 NL443 Inter cooler hose

20 W506404 Bolts (10 req’d)

21 6K755 Charge air cooler

22 6F066 Supercharger assembly

23 N605892 Bolt

24 9726 Accelerator cable bracket

2003 Mustang, 8/2002

Page 6

303-01C-6 303-01C-6Engine — Cobra 4.6L (4V)

DESCRIPTION AND OPERATION (Continued)

2003 Mustang, 8/2002

Page 7

303-01C-7 303-01C-7Engine — Cobra 4.6L (4V)

DESCRIPTION AND OPERATION (Continued)

Item Part Number Description Item Part Number Description

1 N605904 Bolt

2 N620480 Nut

3 6A946 Cover

4 17K814 Alternator bracket assembly

5 N811268 Bolts (2 req’d)

6 8620 Accessory drive belt

7 N606543 Bolt (4 req’d)

8 6L266 Timing chain tensioner

9 6268 Timing chain (2 req’d)

10 6M256 Timing chain guide

11 6L266 Timing chain tensioner

12 6L253 Timing chain tensioner arm

13 6268 Timing chain (2 req’d)

14 N804958 Bolt (2 req’d)

15 6B274 Timing chain guide

16 N606527 Bolt

17 19D269 A/C compressor

18 N806184 Bolts (3 req’d)

19 6306 Crankshaft sprocket

20 6L253 Timing chain tensioner arm

21 12A227 Ignition pulse ring

22 6C086 Engine front cover

23 N806177 Bolts (8 req’d)

24 N806300 Studs (5 req’d)

25 6700 Crankshaft front seal

26 6316 Crankshaft pulley

(Continued)

27 N806165 Washer

28 W701512 Stud

29 8A528 Water pump pulley

30 N806282 Bolts (4 req’d)

31 N806177 Bolts (4 req’d)

32 8501 Water pump

33 N808102 Bolt

34 19A216 Belt idler pulley

35 N804178 Nut

36 N806300 Harness support bracket

37 N806300 Stud

38 N806155 Bolt

39 6C315 Crankshaft position sensor

40 N806155 Bolt

41 6B288 Camshaft position sensor

42 N808920 Bolts (3 req’d)

43 6C254 Crankshaft extension support

pulley

44 10153 Lower support bracket

45 N605909 Bolts (2 req’d)

46 8620 Accessory drive belt

47 N811268 Bolt

48 8B603 Belt idler bracket support

49 N808198 Stud

50 9N491 Hose and tube assembly

2003 Mustang, 8/2002

Page 8

303-01C-8 303-01C-8Engine — Cobra 4.6L (4V)

DESCRIPTION AND OPERATION (Continued)

2003 Mustang, 8/2002

Page 9

303-01C-9 303-01C-9Engine — Cobra 4.6L (4V)

DESCRIPTION AND OPERATION (Continued)

Item Part Number Description Item Part Number Description

1 6083 Cylinder head gasket

2 — Bolt (2 req’d)

3 — Washer (2 req’d)

4 6255 Spacer

5 — Secondary timing chain (2

req’d)

6 — Screw and washer

7 6C271 Timing chain vibration

damper

8 6B277 Camshaft bearing cap

9 — Bolt (24 req’d)

10 6A271 Camshaft

11 6529 Roller follower (8 req’d)

12 6C501 Hydraulic lash adjuster

13 6065 Bolt (20 req’d)

14 6A273 Camshaft

(Continued)

15 6B278 Camshaft bearing cap (2

req’d)

16 9448 Exhaust manifold gasket

17 9F485 EGR valve tube to manifold

connector

18 W701706 Nut (8 req’d)

19 9431 Exhaust manifold

20 6C324 PCV tube

21 6A505 Valve cover

22 N808199 Bolt (20 req’d)

23 6766 Oil filler cap

24 12A366 Ignition coils

25 6P068 Ignition coil cover

26 N807309 Bolt (4 req’d)

27 6050 Cylinder head

2003 Mustang, 8/2002

Page 10

303-01C-10 303-01C-10Engine — Cobra 4.6L (4V)

DESCRIPTION AND OPERATION (Continued)

2003 Mustang, 8/2002

Page 11

303-01C-11 303-01C-11Engine — Cobra 4.6L (4V)

DESCRIPTION AND OPERATION (Continued)

Item Part Number Description Item Part Number Description

1 6214 Bolt (2 req’d)

2 6211 Connecting rod bearing (16

req’d)

3 6140 Piston pin retainer (16 req’d)

4 6135 Piston pin (8 req’d)

5 6110 Piston (8 req’d)

6 6159 Piston ring (8 req’d)

7 6159 Piston ring (8 req’d) (part of

6100)

8 6150 Piston ring (8 req’d) (part of

6100)

9 6152 Piston ring (8 req’d)

10 6758 Crankcase vent tube and

connector

(Continued)

11 6582 Valve cover

12 6051 Cylinder head gasket

13 W701706 Nut (8 req’d)

14 9430 Exhaust manifold

15 9448 Exhaust manifold gasket

16 W701681 Stud (8 req’d)

17 6049 Cylinder head

18 6C527 Spark plug gasket (8 req’d)

19 6200 Connecting rod (8 req’d)

20 6200 Connecting rod (8 req’d)

21 6161 Piston ring (8 req’d)

2003 Mustang, 8/2002

Page 12

303-01C-12 303-01C-12Engine — Cobra 4.6L (4V)

DESCRIPTION AND OPERATION (Continued)

2003 Mustang, 8/2002

Page 13

303-01C-13 303-01C-13Engine — Cobra 4.6L (4V)

DESCRIPTION AND OPERATION (Continued)

Item Part Number Description Item Part Number Description

1 8555 Water bypass tube

2 6750 Oil level indicator

3 6754 Oil level indicator tube

4 N806155 Bolt

5 6C358 Bolt (10 req’d)

6 6714 Oil bypass filter

7 6A642 Oil cooler

(Continued)

8 N806156 Bolt (4 req’d)

9 9278 Oil pressure sender

10 6884 Oil filter adapter

11 6A636 Oil filter adapter gasket

12 N620482 Dowel

13 87836 Plug

Item Part Number Description Item Part Number Description

1 N807198 Dowel pin (2 req’d)

2 N807309 Bolt

3 N807959 Bolt

4 18663 Heater water hose

5 W500110 Bolt (2 req’d)

6 12A699 Knock sensor (2 req’d)

7 N807309 Bolt (2 req’d)

8 18696 Heater water hose

9 7120 Pilot bearing

11 N806155 Bolt (6 req’d)

12 6310 Crankshaft oil slinger

13 6375 Flywheel

14 N808139 Bolt (8 req’d)

15 7550 Clutch disc

16 7563 Clutch pressure plate

17 N808969 Bolt (6 req’d)

18 6701 Crankshaft rear oil seal

19 N806007 Dowel pin (2 req’d)

10 6K318 Crankshaft rear retainer

(Continued)

2003 Mustang, 8/2002

Page 14

303-01C-14 303-01C-14Engine — Cobra 4.6L (4V)

DESCRIPTION AND OPERATION (Continued)

2003 Mustang, 8/2002

Page 15

303-01C-15 303-01C-15Engine — Cobra 4.6L (4V)

DESCRIPTION AND OPERATION (Continued)

Item Part Number Description Item Part Number Description

1 N806177 Bolt (4 req’d)

2 N806459 Dowel (4 req’d)

3 6A341 Thrust washer

4 6303 Crankshaft

5 6A339 Thrust bearing

6 6325 Main bearing cap (5 req’d)

7 6345 Bolt (10 req’d)

8 6K258 Stud (4 req’d)

9 6687 Oil pan baffle

10 N806180 Spacer

11 N605904 Bolt

12 6710 Oil pan gasket

13 6675 Oil pan

14 W701240 Bolt (16 req’d)

(Continued)

15 6622 Oil pump screen pickup and

tube

16 N806155 Bolt (2 req’d)

17 N811280 Spacer (3 req’d)

18 6345 Bolt (6 req’d)

19 6C360 Main bearing cap adjusting

screw (10 req’d)

20 6A338 Crankshaft main bearing (4

req’d)

21 N806201 Woodruff key

22 6621 Oil pump

23 N806183 Bolt (4 req’d)

24 6333 Crankshaft main bearing

25 8501 Water pump

2003 Mustang, 8/2002

Loading...

Loading...