Ford 2n series, 8n series, 9n series Shop Manual

I&T Shop Service

Ford Shop Manual

Series 2N 8N 9N

Manual NO. FO-4

copyright 1953 - EXPIRED

This book free to print, share, distribute with anyone!

Remastered Version 1.2

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

PREFACE

This book was transcribed, reformatted to this PDF version by me, John

Chapman.

I'd be delighted for you to connect with me at any or all of:

Email: j cchapster@gmail.com

Twitter: http://twitter.com/jcchapster

Linked-In: https://www.linkedin.com/in/jcchapster

Facebook: https://www.facebook.com/thejcchapster

TRACTOR MANUAL ARCHIVE

I'm building a Tractor Manual Archive. The Tractor Manual Archive is a

repository of Tractor Manuals that are typically out of Copyright, and

are now in Public Domain. Additionally, manuals that have Copyright

holder permission to be included will be archived as well.

Do you have an old manual? It might be a manual others are looking for.

Contact the Tractor Manual Archive about how to share your manual with

others, and be a part of preserving useful history.

Do you have a PDF of an old manual? Even if purchased, if it is out of

copyright it can be shared.–

Email me to learn more, to participate, to download manuals as they

become available.

ERRORS and OMMISSIONS If you discover an error with this manual, –

please email: jcchapster@gmail.com and I will correct and release an

updated version.

- John Chapman / Tractor Manual Archive administrator

Connect/Report Errors – jcchapster@gmail.com

Change log

5-23-2015 Corrected some images placements and typos. Moved to –

version 1.1.

5-24-2015 Corrected some other minor issues. Moved to version –

1.2.

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

SHOP MANUAL

FORD

Models:

8N - 8NAN

2N - 2NAN - 9N - 9NAN (Ford - Ferguson)

Serial number is stamped on left side of engine block.

Beginning Tractor Serial Numbers

Models 9N - 9NAN Models 2N - 2NAN Models 8N - 8NAN

1942 99047 1947 1

1943 105412 1948 37908

1939 1 1944 126575 1949 141370

1940 10276 1945 170018 1950 245637

1941 46018 1946 198767 1951 343593

1942 88934 1947 258540 1952 442035

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

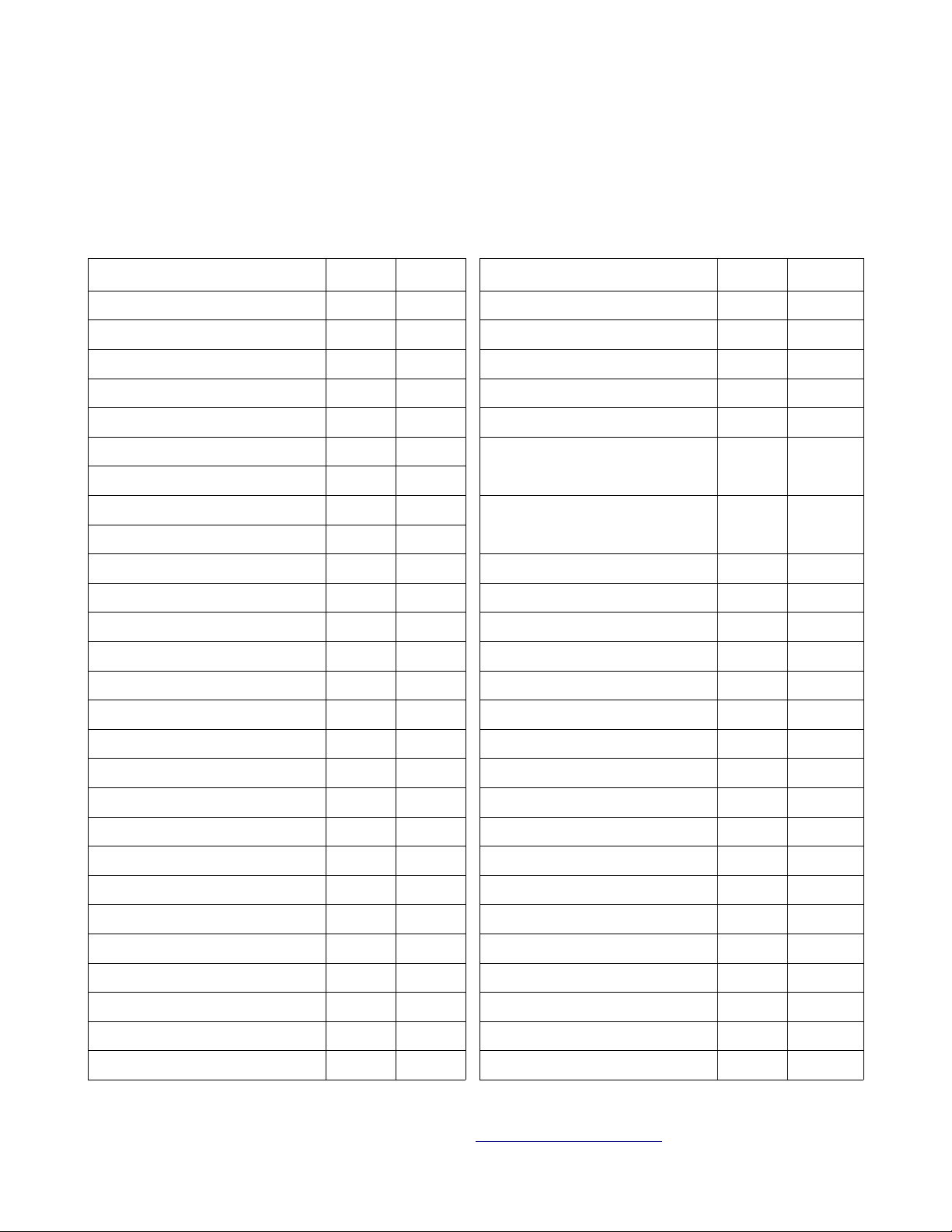

INDEX

(By Starting Paragraph)

MODELS 2N-9N 8N

BELT PULLEY 97,97A 97,97A FINAL DRIVE

Bevel Gears 86,87 86,87

BRAKES Differential Overhaul 85 85

Adjustment 91 92 Differential R&R 84 84

R&R and Overhaul 93 94

CARBURETOR 42 42

CLUTCH Wheel Axle Shaft R&R 89 90

Overhaul 64A 66

Pedal Adjustment 63 63 FRONT SYSTEM

Remove & Reinstall 64,64A 65,66 Axle Main Member 1 1

COOLING SYSTEM Steering Gear Adjust 6 7,12

Pump R&R 46 46 Steering Gear Overhaul 6B 11,14

Pump Overhaul 47 48 Steering Gear R&R 6A 11

Thermostat 49 49 Steering Spindles 2 2

DIFFERENTIAL GOVERNOR

Overhaul 85 85 Adjustment 44 44

Wheel Axle Shaft

Bearings Adjust 88,88A 88,88A

Wheel Axle Shaft

Bearings Renew 89 90

Axle Pivot Pin & Bushing 3 3

Remove & Reinstall 84 84 Overhaul 45 45

ELECTRICAL HYDRAULIC SYSTEM

Ignition 54-61 54-58 Adjustment 99 101

Generator 50 50 Lift Cover 105 109

Generator Regulator 51,52 51,52 Pump Overhaul 124 116

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

MODELS 2N-9N 8N

Starting Motor & Switch 53 53 Pump R&R 115 115

Pump Test 114 114

ENGINE Trouble Shooting 112 112

Assembly R&R 20 20 Work Cylinder 106 106

Cam Followers 26 26

Camshaft 29 29 IGNITION SYSTEM

Connecting Rods & Brgs 36 36 Battery Ignition 54-57 54-60

Crankshaft & Bearings 37 37 Magneto Ignition 61-62A - - -

Crankshaft Oil Seals 38 38

Cylinder Head 21 21 POWER TAKE-OFF 95,96 95,96

Cylinder Sleeves 32-33 32-33

Flywheel R&R 39 39 REAR AXLE

Flywheel Timing Marks 39A 39A Bearing, Renewal 89 90

Front Oil Seal 38 38 Seals, Renewal 89 90

Ignition Timing 55-62 55-59 Shaft, R&R 89 90

Main Bearings 37 37

Oil Pan 40 40 STEERING GEAR

Oil Pump 41 41 Adjustment 6 ,12

Pistons 32 32 Overhaul 6B 11,14

Piston Pins 35 35 Remove & Reinstall 6A 11

Piston & Rod Removal 30 30 TRANSMISSION

Piston Rings 31 32 Assembly R&R 70,70A 70,70A

Rear Oil Seal 38 38 Bevel Pinion 86 86

Tappets 26 26 Clutch Shaft 74 79

Timing Gear Cover 28 28 Countershaft 75 80

Timing Gears 28A 28A Main Drive Gear & Shaft 74 79

Valves 22,22A 22,22A Mainshaft 72 78

Valve Guides 25 25 Reverse Gear 76 81

Valve Push Rods 26 26 Shifter Rails and Forks 71 77

Valve Rotators 23,27 26,27

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

MODELS 2N-9N 8N

Valve Seats 24 24

Valve Springs 25 25

Valve Timing 28A 28A

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

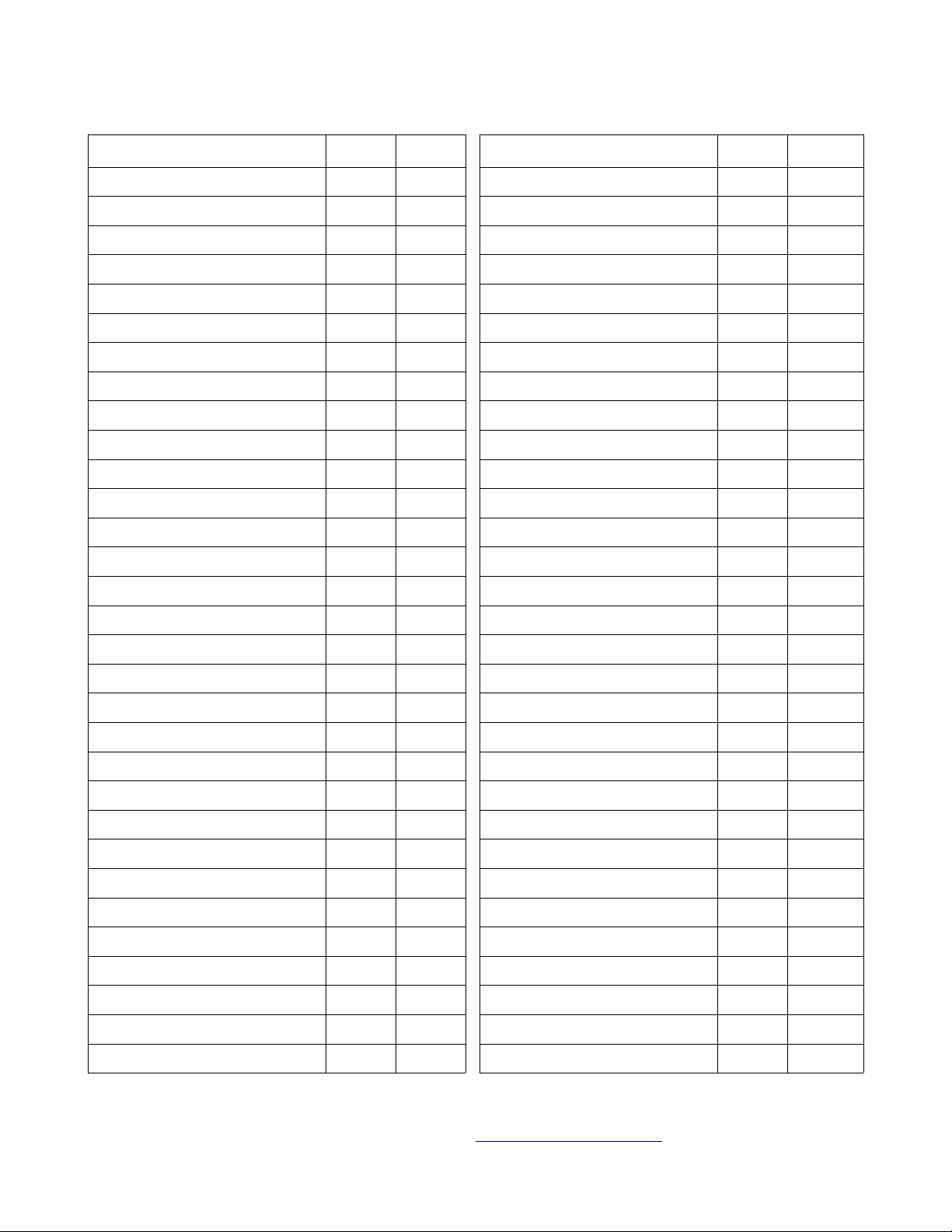

CONDENSED SERVICE DATA

Tractor Models 2N, 8N, 9N

GENERAL

Engine Make Own

Engine Type L Head

Cylinders 4

Bore-Inches 3-3/16

Stroke-Inches 3-3/4

Displacement-Cubic Inches 119.7

Compression Ratio-Kerosene 4.75

Compression Ratio-Gasoline:

2N-9N-Early 8N 6.1

Later 8N 6.7

Pistons Removed From: Above

Main Bearings, Number of 3

Main Bearings, Adjustable? No

Rod Bearings, Adjustable? No

Cylinder Sleeves, Dry, Wet Dry

Production Cylinder Sleeves-Material (8N Prior 433578 2N - 8N)– Steel

Production Cylinder Sleeves-Material (8N After 433577) Iron

Service Cylinder Sleeves-Material Iron

Forward Speeds (2N-9N) 3

Forward Speeds (8N) 4

Generator-Make Own

Starter-Make Own

TUNE-UP

Firing Order 1-2-4-3

Valve Tappet Gap-Inlet 10-12C

Valve Tappet Gap-Exhaust 14-16C

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

Exhaust Tappet Gap-Fitted With Rotators 14-16C

Valve Face Angle-Degrees 45

Valve Seat Angle-Degrees 45

Ignition Distributor Make Own

Distributor Model (8N Prior 263844 - 2N - 9N) 9N12100

Distributor Model (8N After 263843) 8N12127

Breaker Gap (Angle Mounted Distributor 8N12127) 0.025

Retarded Timing (8N Prior 263844 - 2N - 9N) TC

Retarded Timing (8N After 263843) 4°B

Advanced Timing (8N Prior 263844 - 2N - 9N) 25°B

Advanced Timing (8N After 263843) 17°B

Flywheel Timing Mark Indicating:

Retarded Timing (8N Prior 263844 - 2N - 9N) None

Retarded Timing (8N After 263843) 4° line

Advanced Timing (8N Prior 263844 - 2N - 9N) None

Advanced Timing (8N After 263843) 17° line

Distributor Governor Advance Curve Para: 54, 58

Spark Plug Make Champion

Spark Plug Model for Gasoline H10

Carburetor Make, Marvel-Schebler yes

Carburetor Model Paragraph: 42

Carburetor Float Setting-Inches 9/32

Engine Low Idle RPM 400

Engine High Idle RPM 2200

Belt Pulley RPM @ 2000 Engine RPM 1358

PTO RPM @ 1500 Engine RPM 545

SIZES-CAPACITIES-CLEARANCES

(Clearances in Thousandths)

Crankshaft Journal Diameter 2.248-2.249

Crankpin Diameter 2.094

Camshaft Journal Diameter 1.797

Piston Pin Diameter .7501-.7504

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

Valve Stem Diameter (One-Piece Valve Guide) .341-.342

Valve Stem Diameter (Two-Piece Valve Guide) .3105-.3115

Cam Follower (Push Rod) Diameter-Inches .9995

Compression Ring Width-Inches .093

Oil Ring Width-Inches .187

Main Bearings Running Clearance 1-3

Rod Bearings Running Clearance 1-3.5

Piston Skirt Clearance (Steel Pistons) 2.5-4.0

Piston Skirt Clearance (Aluminum Pistons) 1.5-2.5

Camshaft Bearing Clearance 1-2

Cam Follower (Pushrod) Running Clearance .4-1

Crankshaft End Play 2-6

Cooling Systems-Gallons 3

Crankcase Oil-Quarts 6

Transmission, Differential & Hydraulic System-Quarts 20

Belt Pulley Housing-Quarts 1/3

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

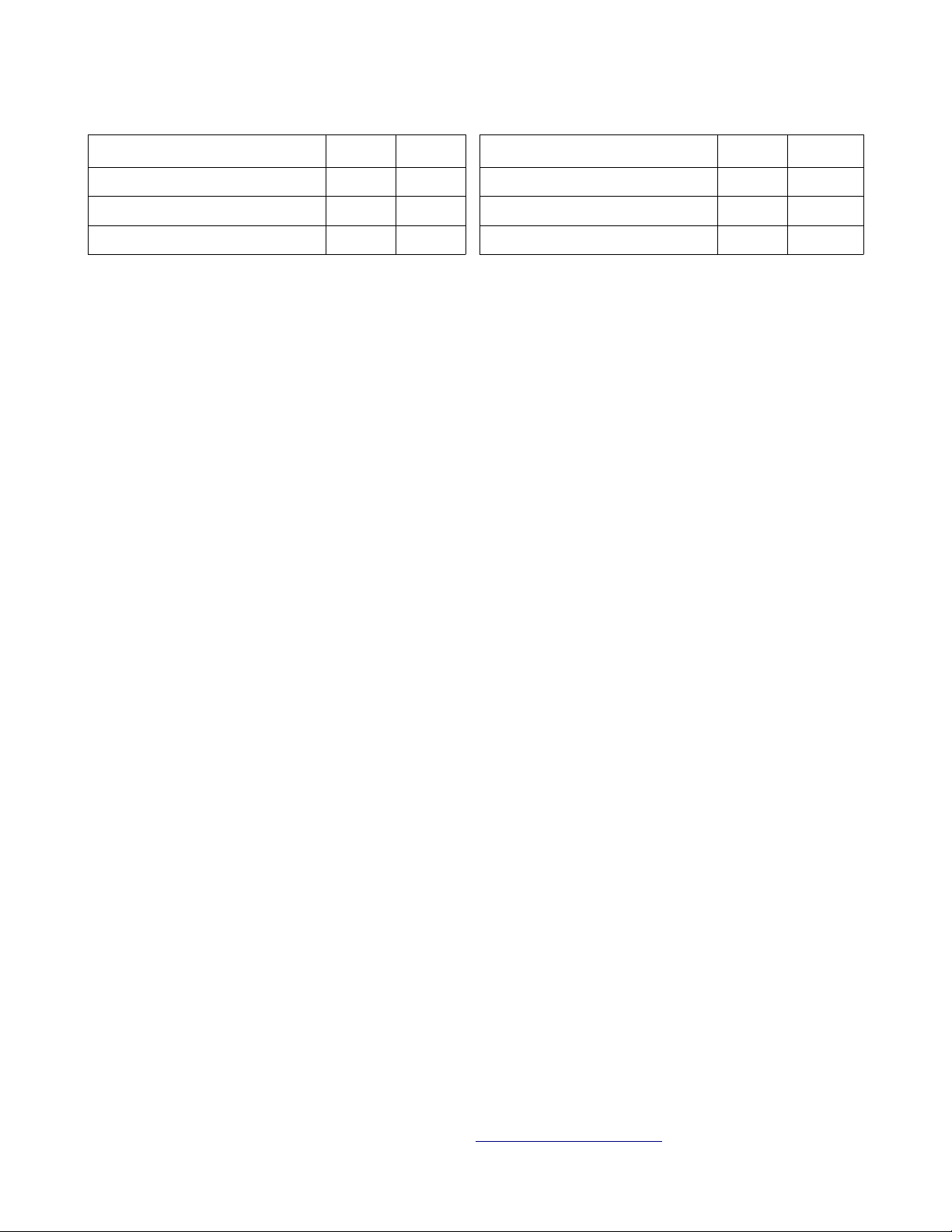

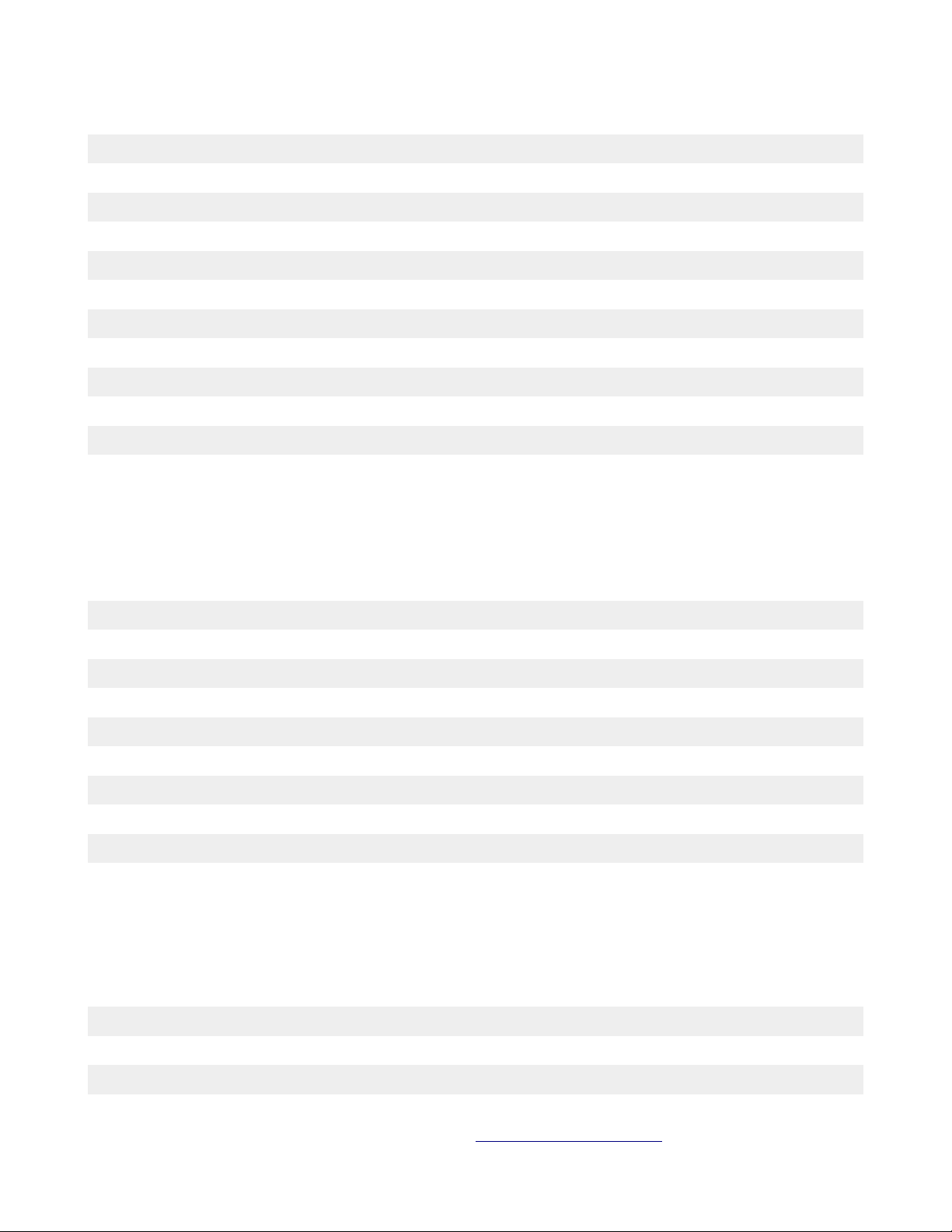

Models 2N and 9N

MODEL 8N

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

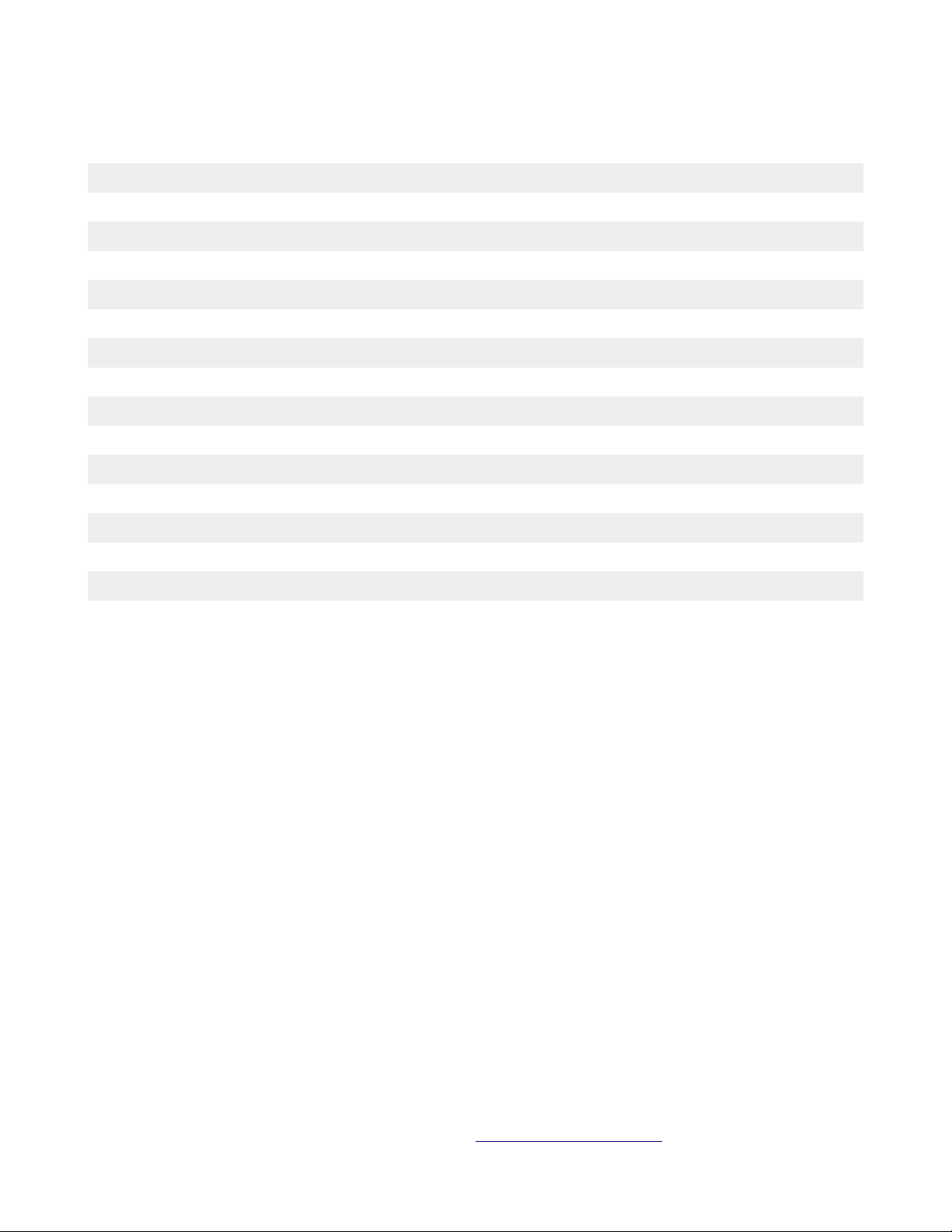

Fig. FO1 - Front axle as used on model 8N.

Note hole spacing of tread adjusting bolts.

Fig. FO2 - Front axle on models 2N and 9N.

reinstallation of axle parts removed. See Fig.

FO3.

FRONT AXLE

1. The front axle is

constructed in three sections

and may be adjusted to vary

tread width. See Figs. FO1 and

FO2. Steering linkage must be

readjusted on model 8N when

tread width is changed. Model

2N - 9N wheel alignment is not

affected by tread width

adjustment.

SPINDLE BUSHINGS

2. To rebush axle spindles,

first block up tractor front

end and remove steering arms.

Slide spindles with wheels

attached, out of axle ends.

Drive old bushings out of axle

and install new bushings, using

a piloted installing tool. New

steel bushings are presized and

are not reamed. Check and

adjust wheel alignment, after

Fig. FO3 - Front axle hub

and spindle on models

2N-8N-9N.

Connect/Report Errors – jcchapster@gmail.com

Fig. FO4 - Method of removing axle center pin.

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

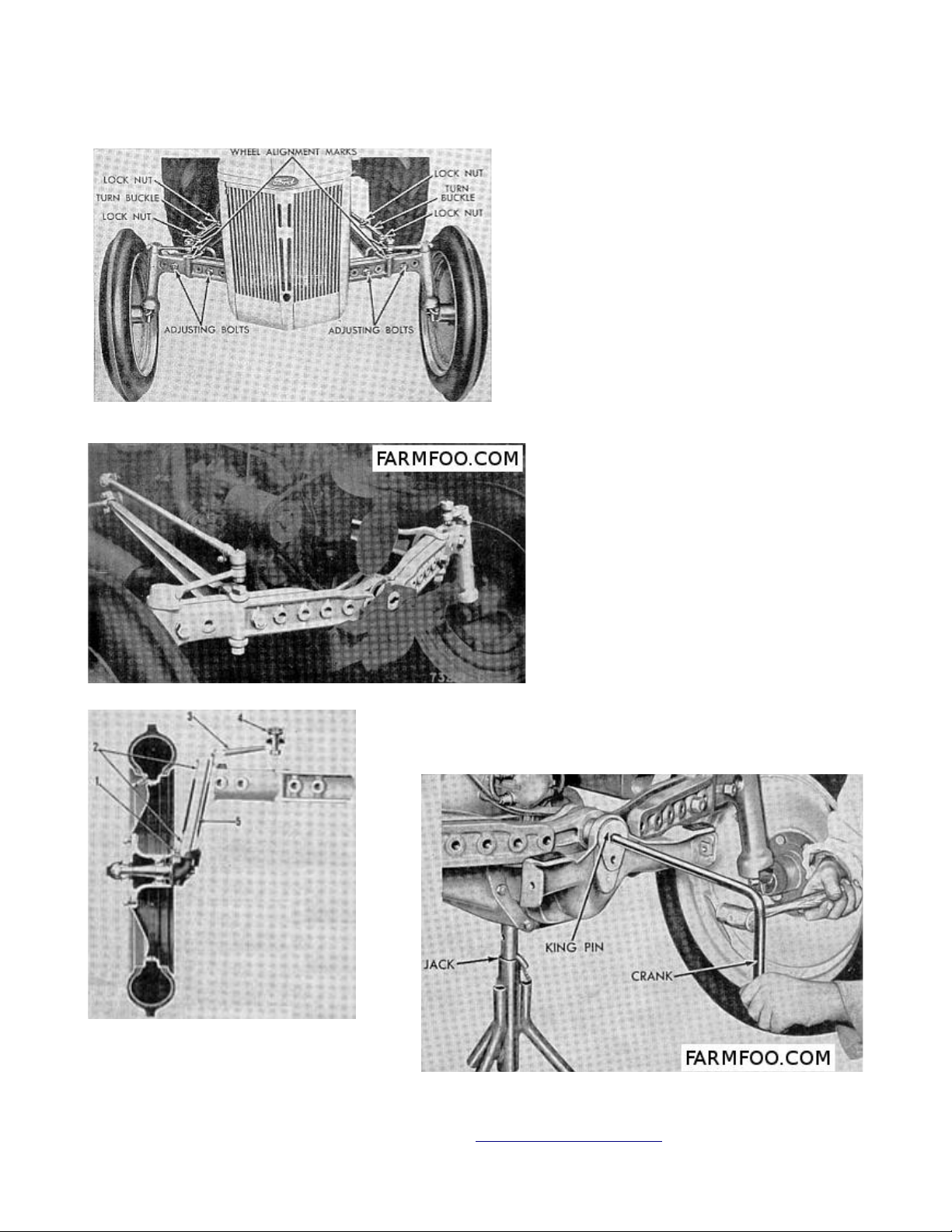

AXLE PIN BUSHINGS

3. Remove front hood bolts at bottom and block up under hood. Hold up front end of

engine with jack under oil pan and unbolt axle support. Remove two bottom radiator

bolts and raise engine and radiator high enough to permit removal of axle center

pin. Remove pin, using hand crank as show in Fig. FO4.

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

STEERING SYSTEM

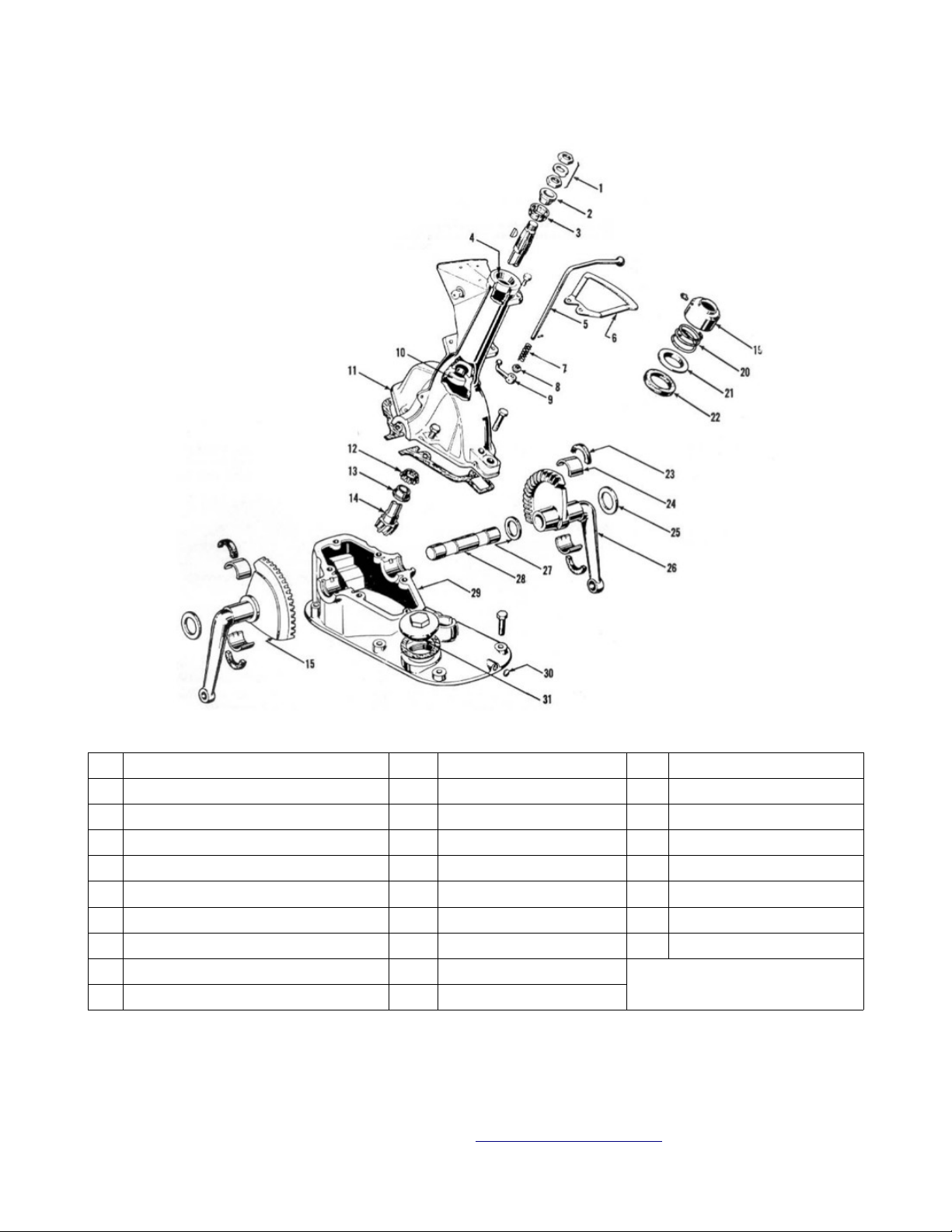

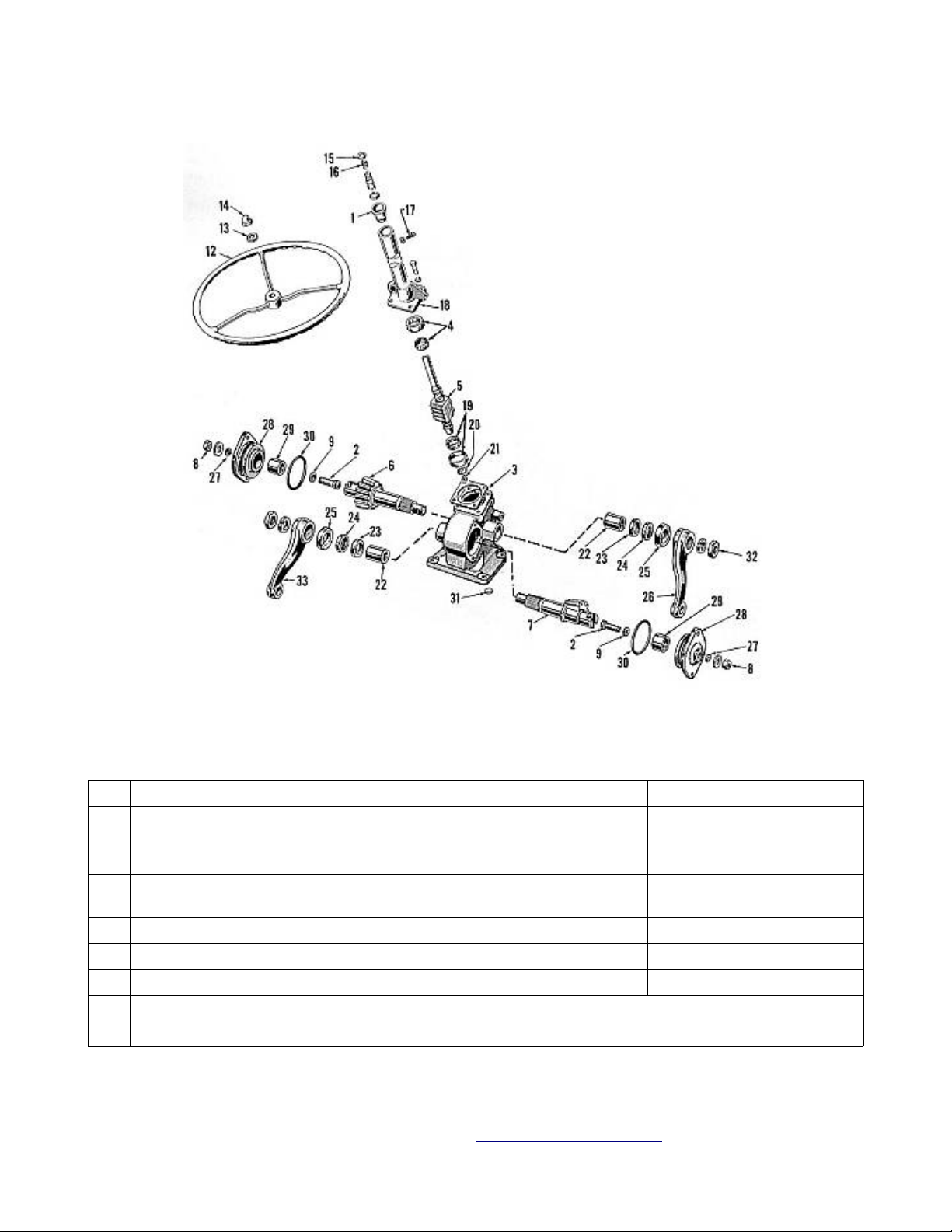

The steering gear on models 2N-9N consists of two sector gears and integral arm

units, both meshed with a steering shaft and pinion assembly. Gear units are

mounted in a housing Fig. FO5, which also serves as a transmission case cover. The

gear housing is constructed in two parts and also supports the instrument panel

Fig. FO6.

The steering gear used on model 8N tractor is a Saginaw screw and recirculating

ball nut type, mounted on top of transmission housing.

ADJUSTMENT & OVERHAUL

Models 2N 9N –

6. ADJUSTMENT. The steering shaft bearing may be adjusted without removing gear

unit from tractor. To adjust steering shaft bearings, remove steering wheel and

shaft bearing dust cover (19 Fig. FO7). Remove locknut–

and lock washer (1). Adjust lower nut until end play is

removed and shaft still turns freely. Install lock washer

and locknut and tighten nut.

Detach drag links from sector arms and check backlash at

arms while steering wheel is held stationary. If

excessive sector gear backlash or end play exists, it

will be necessary to remove upper gear housing (11) to

gain access to sectors for adjustment.

6A. To clear upper housing for removal, it will be

necessary to remove hood, battery and instrument panel.

When housing is off, invert same in a vise and place both

sectors (15 & 26) in position, meshed with steering shaft

pinion (14). Check gear mesh and backlash with sectors

held in normal operating position. Thrust washers (25 &

27) which are available in three sizes; thick, medium and

thin, should be installed according to requirements, for minimum sector end play

and backlash. Reinstall assembly after adjustment is complete and synchronize

gears.

Fig. FO5 Models 2N-9N –

steering gear with upper

housing removed.

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

When early model 9N steering gear is

turned to either extreme, severe steering

conditions may cause sectors to jump out

of mesh and result in an uneven turning

radius. To synchronize sectors without

removing steering housing, disconnect both

drag links at steering arms an move left

arm rearward as far as possible, and right

arm in opposite direction to un-mesh

gears. Re-engage both sectors with

steering shaft pinion and check

synchronism by observing whether steering

arms are parallel and point slightly

rearward, when gear is in mid or straight

ahead position. Reconnect drag links and

adjust same if necessary.

6B. OVERHAUL. To completely overhaul the

steering gear it is necessary to first

remove the unit as per paragraph 6A. Renew

worn parts and install new oil seals.

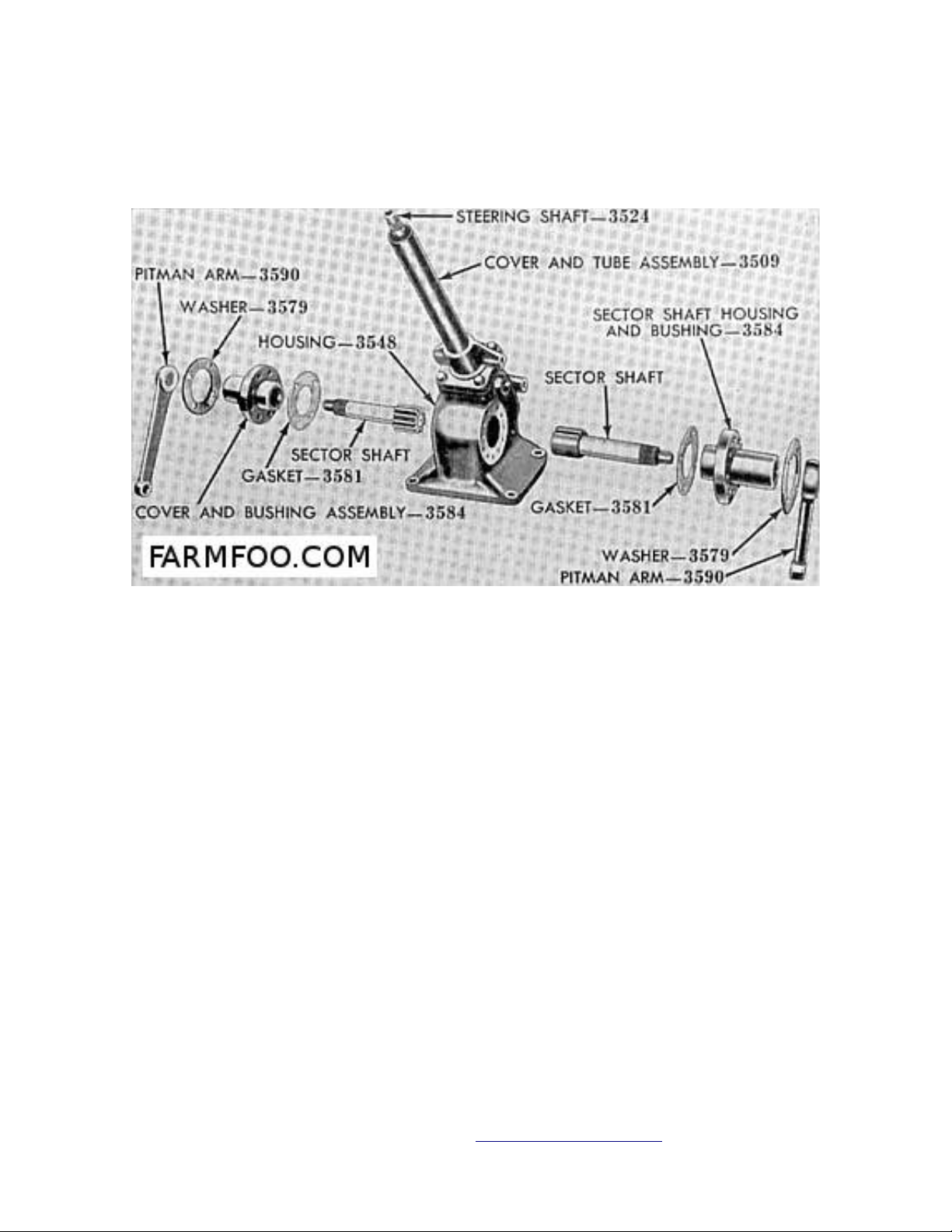

Model 8N Prior to 216989

Fig. FO6 Models 2N-9N steering gear–

unit with attached instrument panel.

nut. Refer to Fig. FO8. The right sector meshes with the left sector and rotates in

the opposite direction. On tractors after serial 216988 the arrangement is reversed

as shown in Fig. FO12A, the right sector being meshed with the ball nut, and

because the sector teeth are of the bevel type a different method of backlash

adjustment is employed.

On tractors prior to serial 216989 the

sector teeth are straight cut and the left

sector (viewed from rear of tractor)

meshes with the rack teeth on the ball

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

Fig. FO7 - Steering gear on models 2N-9N.

1. Steering post nuts and lock 11. Upper gear housing 24. Sector bearing

2. Bearing cone 12. Lower post bearing 25. Outer thrust washer

3. Upper post bearing 13. Bearing cone 26. Right sector

4. Bearing cup 14. Shaft and pinion 27. Inner thrust washer

5. Throttle control rod 15. Left sector 28. Sector shaft

6. Quadrant 19. Cap 29. Lower gear housing

7. Spring 20. Spring 30. Expansion plug

8. Spring seat 21. Seal retainer 31. Filler plug

9. Control rod arm 22. Dust seal

10. Bearing cup 23. Packing

7. ADJUSTMENT. Before making any adjustments, disconnect both drag links at

sector shaft arms. Turn steering wheel until sector arms are parallel, and both

point slightly rearward. Grasp left sector arm and check gear backlash while

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

steering wheel is held steady to prevent movement of worm. If any backlash is felt,

proceed as follows:

Fig. FO8 - Disassembled sector shafts of ball nut gear used on model 8N

tractors prior to serial 216989. Later type is shown in Fig. FO12.

8. SECTOR MESH ADJUSTMENT. Remove four cap screws from left (viewed from rear of

tractor) sector shaft cover Fig. FO8. Rotate cover and metal gasket counterclockwise (viewed from left side of tractor) as far as possible by hand and

reinstall cap screws in four matching holes. Recheck backlash and if none is

present, proceed to adjust right sector in a similar manner, rotating right sector

shaft cover clockwise to remove backlash instead of counter-clockwise. IF BOTH

SECTOR ARMS NOW HAVE ZERO BACKLASH, STEERING GEAR UNIT IS COMPLETELY ADJUSTED AND

WORM SHAFT END PLAY ADJUSTMENT OUTLINED IN PARAGRAPH 9 WILL NOT BE REQUIRED.

Adjustment is correct when pull required to rotate steering wheel through mid or

straight forward position is not less than 2-1/2 or more than 6 pounds with drag

links disconnected. Measure pull with a spring scale hooked to rim of steering

wheel and read scale when wheel is in motion. With adjustment of right sector

loosened, correct scale reading for worm shaft and left sector after adjustment is

2 to 3 pounds. When all of the backlash of LEFT sector can not be corrected by

foregoing adjustment, any remaining free motion is probably due to excessive worm

shaft bearing clearance. If that condition exists, rotate both sector housings

opposite the directions given for backlash adjustment, to relieve load on worm

shaft, and adjust worm shaft bearing clearance as outlined in next paragraph.

WORM SHAFT BEARING ADJUSTMENT. With both drag links disconnected from sector shaft

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

arms, and with both sector adjustments loosened, check worm shaft bearing

adjustment by pulling up and pushing down on steering wheel. If looseness is

present, adjust bearings to a slight pre-load by removing a shim or shims from top

face of gear housing, after first removing steering gear cover and tube assembly

Fig. FO10. To clear gear assembly for removal, it will be necessary to remove hood,

battery and instrument panel.

Bearing adjustment is correct, when pull

required to rotate steering wheel through

center or straight forward position is 1-1/2

pounds with drag links disconnected and sector

mesh adjustments loosened. Measure pull with a

spring scale hooked to rim of wheel and take

the reading while wheel is in motion.

After completing worm shaft bearing adjustment,

readjust backlash of both sectors as outlined

in paragraphs 7 and 8.

11. OVERHAUL. Hood, battery and instrument

panel must be removed before steering gear unit

can be removed. After unit is cleared for

removal, disconnect both drag links at steering

gear arms, unbolt steering gear unit from

Fig. FO9 It is possible to –

disassemble the screw shaft and

ball nut assembly used in model

8N tractors but such procedure

is not recommended. Refer to

text.

gears and covers from sides of gear case Fig. FO8. To facilitate removal of –

these sub assemblies, turn them clockwise and they are withdrawn. Remove shaft tube

flange cap screws and lift assembly off of gear case. CAUTION: Do not turn worm

shaft if nut is near either end of worm as ball retainers may be damaged.

transmission housing and lift unit off of

tractor.

11A. Pull both steering gear arms off sector

shafts and unscrew cap screws holding sector

shaft housings to gear case. Remove both sector

New sector shaft housing inner bushings are pressed into housing 1/8 inch below

face of hub . Outer bushings are installed flush or slightly below bottom of dust

seal counterbores. Bushings should be align reamed to 1.125 1.126. –

NOTE: Do not disassemble the unit shown in Fig. FO9. Any derangement of excessive

wear in any of the components of this screw shaft and ball nut assembly is

corrected by renewal of the nut and shaft unit Ford part 8N3575 as the individual

parts are not catalogued.

Install worm shaft and nut assembly with nut positioned at approximate center of

worm and adjust worm shaft bearing end play as described in paragraph . After

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

bearing adjustment is completed, hold ball nut and rotate worm shaft until nut

center tooth aligns with center of left sector shaft opening. See Fig. FO10.

Assemble left sector shaft (three large and four small teeth) and its housing to

gear housing, with center tooth of three large sector teeth meshed with center

space of teeth on ball nut as shown. The sector housing is installed with locating

notch at bottom. Adjust left sector backlash as described in paragraph 8.

Assemble right sector, meshing

center tooth of same with third

tooth space on left sector

gear, counting from solid

section of gear located on

bottom as shown in Fig. FO10.

Right sector center tooth is

marked on end of tooth and left

sector tooth space is similarly

marked. Adjust backlash as

described in paragraph 8. Fill

gear housing with SAE 90 oil

through filler hole in side of

housing and reinstall assembly.

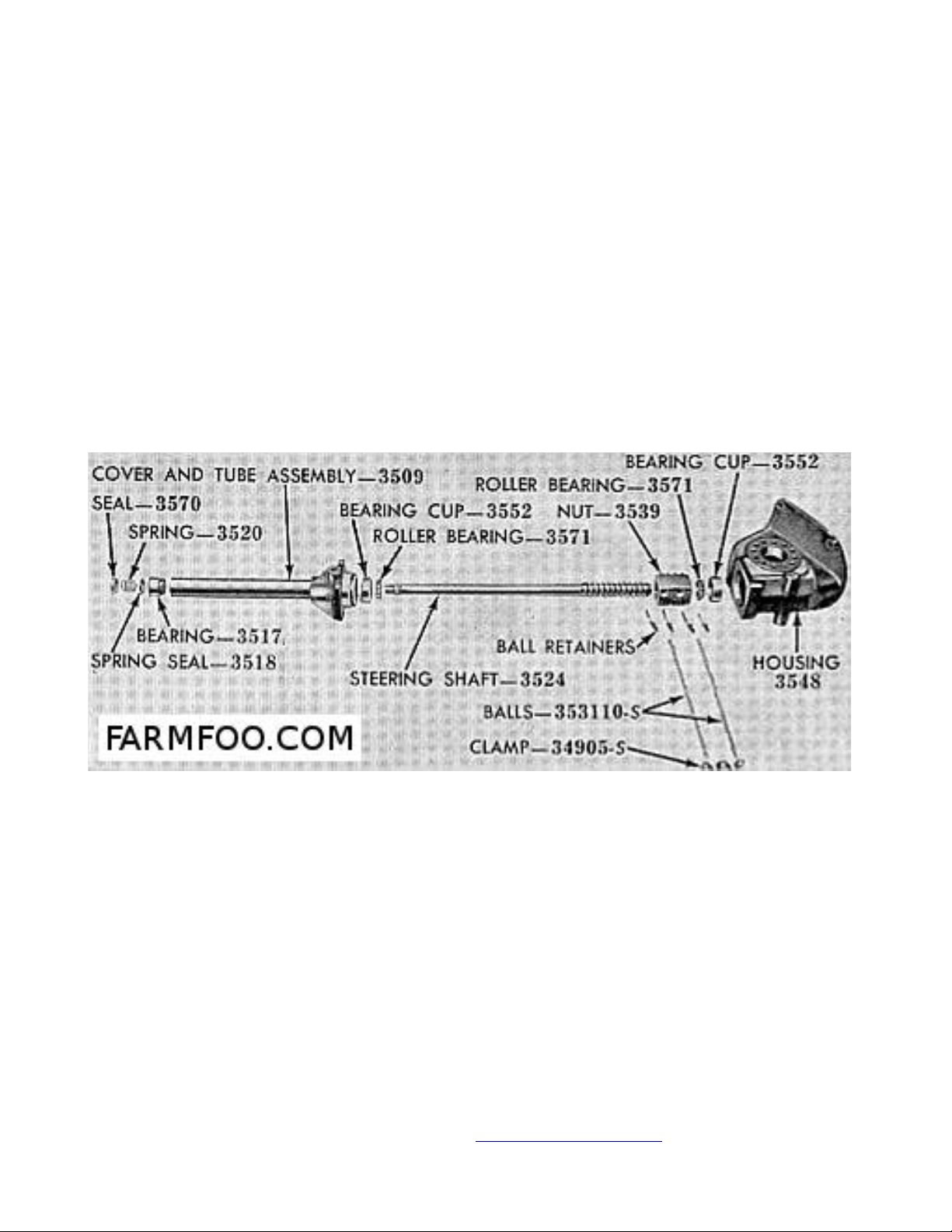

FIG. FO11 Disassembled worm–

shaft for steering gear used on

8N prior to tractor serial

216989. Nut (3539) and steering

shaft (3524) are not sold

separately.

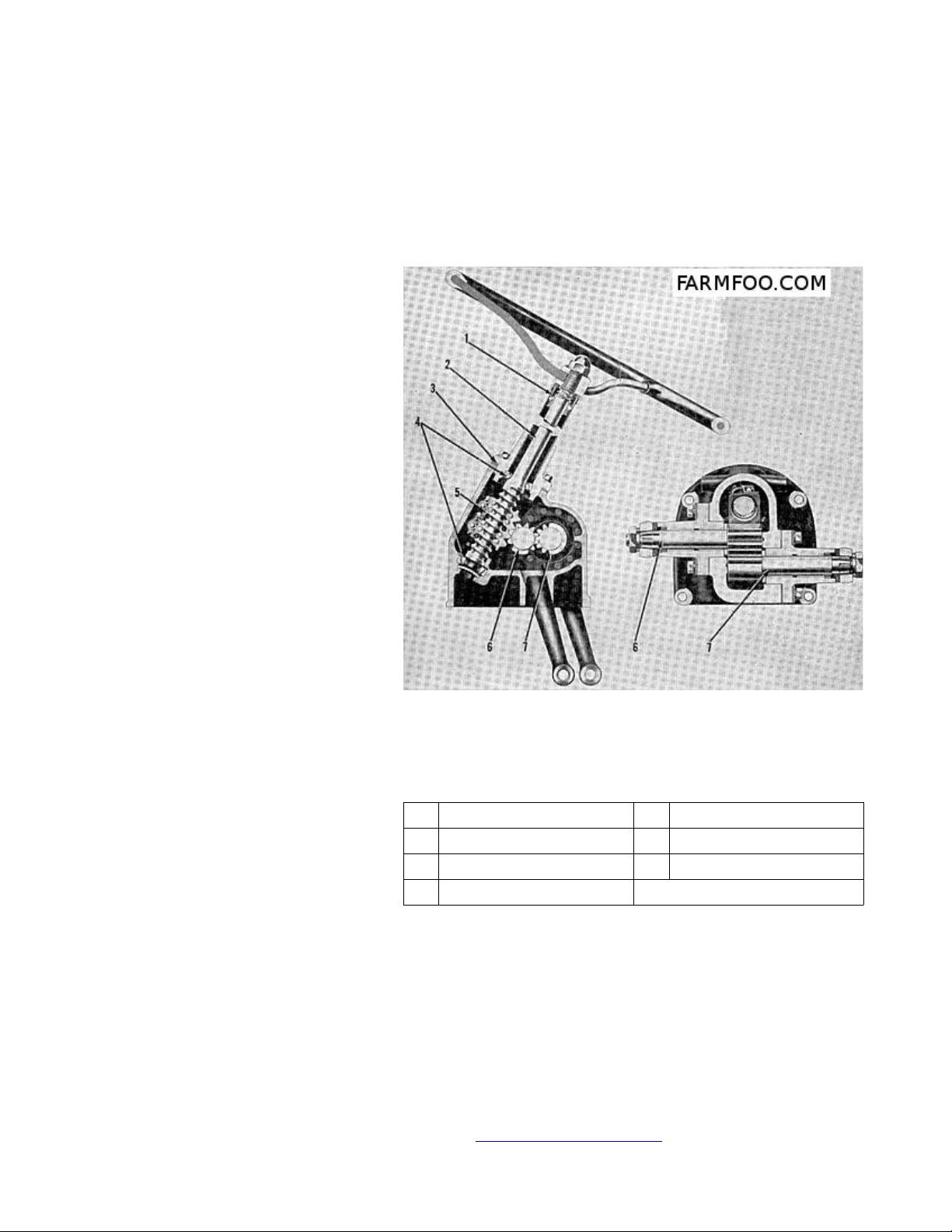

FIG. FO10 Cross section side and top views of –

steering gear unit used on model 8N prior to

tractor serial 216989. Sectors (6&7) have

Model 8N After 216988

12. ADJUSTMENT. Before making

any adjustments, disconnect

both drag links at sector shaft

arms and back off right and

left side sector adjusting

straight teeth and left sector (6) is meshed with

ball nut.

1. Shaft upper bearing 5. Ball nut

2. Shaft and worm 6. Left sector

3. Shims 7. Right sector

4. Worm bearings

screws FIG. FO12A two full

turns after loosening the lock nuts. Check adjustment of wormshaft bearings by

pulling up and pushing down on steering wheel. If any up and down play is present,

adjust to zero end play by varying the shims located at bottom of steering tube and

cover. Adjustment is correct when the pull (measured at outer end of steering wheel

spoke) required to keep the steering wheel in motion after it has crossed the mid

or center point, is 1/2 to 1-1/2 pounds measured with a spring scale. Shims are

available in thicknesses of .002, .005, .010, and .030.

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

13. SECTOR ARMS BACKLASH. Before adjusting sector mesh, make sure that wormshaft

bearings are correctly adjusted as outlined in paragraph 12. Make sure that drag

links are disconnected at sector shaft arms and back off right and left side sector

adjusting screws (Fig. FO12A) two full turns. Turn steering wheel to mid or wheelsstraight-ahead position. Now, using a screwdriver rotate the right hand sector

adjusting screw (viewed from rear of tractor) until all backlash is removed from

right sector arm. Correct adjustment is when 2 to 3 pounds of pull is required to

maintain the steering wheel in motion through the straight ahead or mid-position,

drag links disconnected and opposite sector adjustment backed off. After adjusting

the right hand sector as just mentioned, repeat the procedure on the left sector. A

pull of 2-1/2 to 6 pounds (measured at rim end of wheel spoke) should be required

to maintain the steering wheel in motion through the mid or straight-ahead position

after both of the sectors and the steering post bearings have been adjusted and

drag links disconnected.

Fig. FO11 - Disassembled worm shaft for steering gear used on 8N prior to tractor

serial 216989. Nut (3539) and steering shaft (3524) are not sold separately.

14. OVERHAUL. Major overhaul of gear unit necessitates the removal of the unit

from the tractor as per paragraph 11. Procedure for disassembly is self-evident.

Any derangement or wear in any of the components shaft and ball nut assembly (5 –

Fig. FO12) is corrected by renewal of the assembly as the individual parts are not

catalogued.

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

Select and insert shims (9 Fig.–

FO12) between underside of inner head

of lash adjuster screws (2) and slot

in sectors to provide zero to .002

end play of adjuster screws in

sectors. Shims (9) are available in

thicknesses of .063, .065, .067 and

.069.

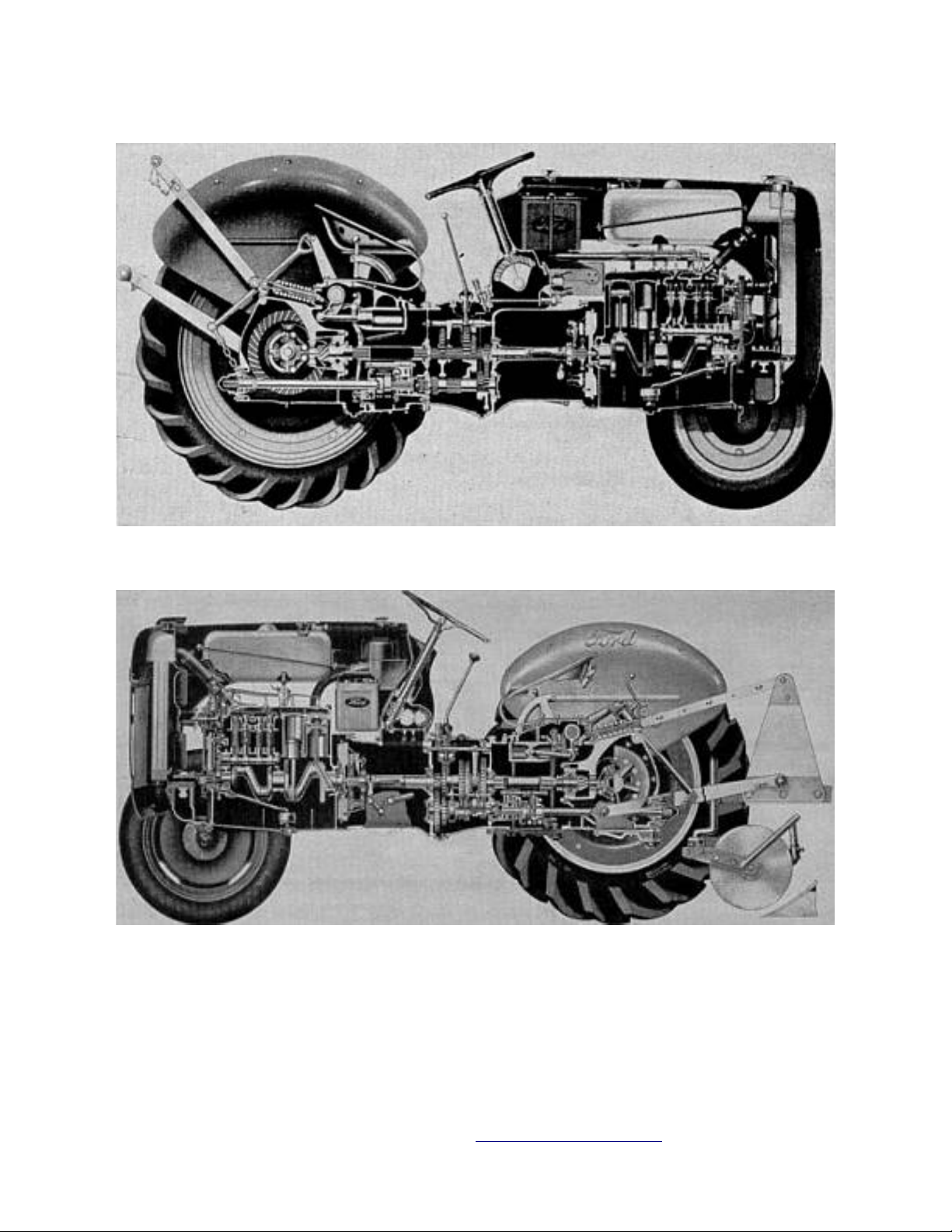

TOE-IN ADJUSTMENT

15. Toe-in is adjusted by varying

the length of the drag links. Models

2N 9N drag link is adjusted by–

disconnecting link front end,

loosening lock clamp and screwing

link end in or out as required. Model

8N drag links are provided with turnbuckle type adjustment and do not

require disconnection. The wheels may

be aligned approximately by adjusting

drag links until spindle arms are

centered over the radius rod to axle

member bolts or the reference marks.

Correct toe-in is 0 to 1/4 inch.

FIG. FO12A Cutaway of latest version of –

ball nut steering gear used on 8N tractors

after serial 216988. The filler plug may

be differently located on some 8N tractors

in this serial range.

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

FIG. FO12 Exploded view of ball nut steering gear used on model 8N –

tractors after serial 216988. Sectors (7) have tapered teeth, and right

sector meshes with ball nut.

1. Shaft upper bearings 15. Seal 25. Seal

2. Sector adjusting screw 16. Spring 26. Steering gear arm (right)

3. Screw shaft adjusting

shims

4. Steering (screw) shaft

bearing

5. Screw shaft & nut assembly 20. Bearing retainer 29. Bushing

6. Left sector 21. Bearing retainer eyelet 30. “O” ring seal

7. Right sector 22. Bushing 33. Steering gear arm (left)

8. Lock nut 23. Packing

9. Shims 24. Retainer

18. Steering tube & cover 27. Lock washer

19. Steering shaft bearing 28. Sector cover

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

ENGINE AND COMPONENTS

R & R ENGINE WITH CLUTCH

20. The engine and clutch assembly may be removed as a unit. Drain cooling system

and oil pan. Remove hood, disconnect battery ground strap and cable at starter.

Disconnect distributor and generator wires and cable at front end and swing wiring

out of way. Block up under transmission and support engine with a chain hoist.

Disconnect radiator hoses, clutch linkage and front axle support. Disconnect front

end of radius rod and mating drag link on either side, then swing axle and front

end assembly away from engine. Remove cap screws holding engine to transmission

housing and separate engine from housing. Reinstall engine in reverse order of

removal. See Fig. FO13.

CYLINDER HEAD R&R

21. Drain cooling system, remove hood and upper radiator hose. Remove ignition

cable harness and cylinder head stud nuts. Remove cylinder head and gasket. When

reinstalling head, tighten center stud nut first and progress alternately to ends

of head, using 50 55 foot pounds torque on nuts, 65 70 on cap screws.– –

FIG. FO13 Method of removing engine on models 2N-8N-9N.–

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

VALVES

Inlet & Plain Exhaust

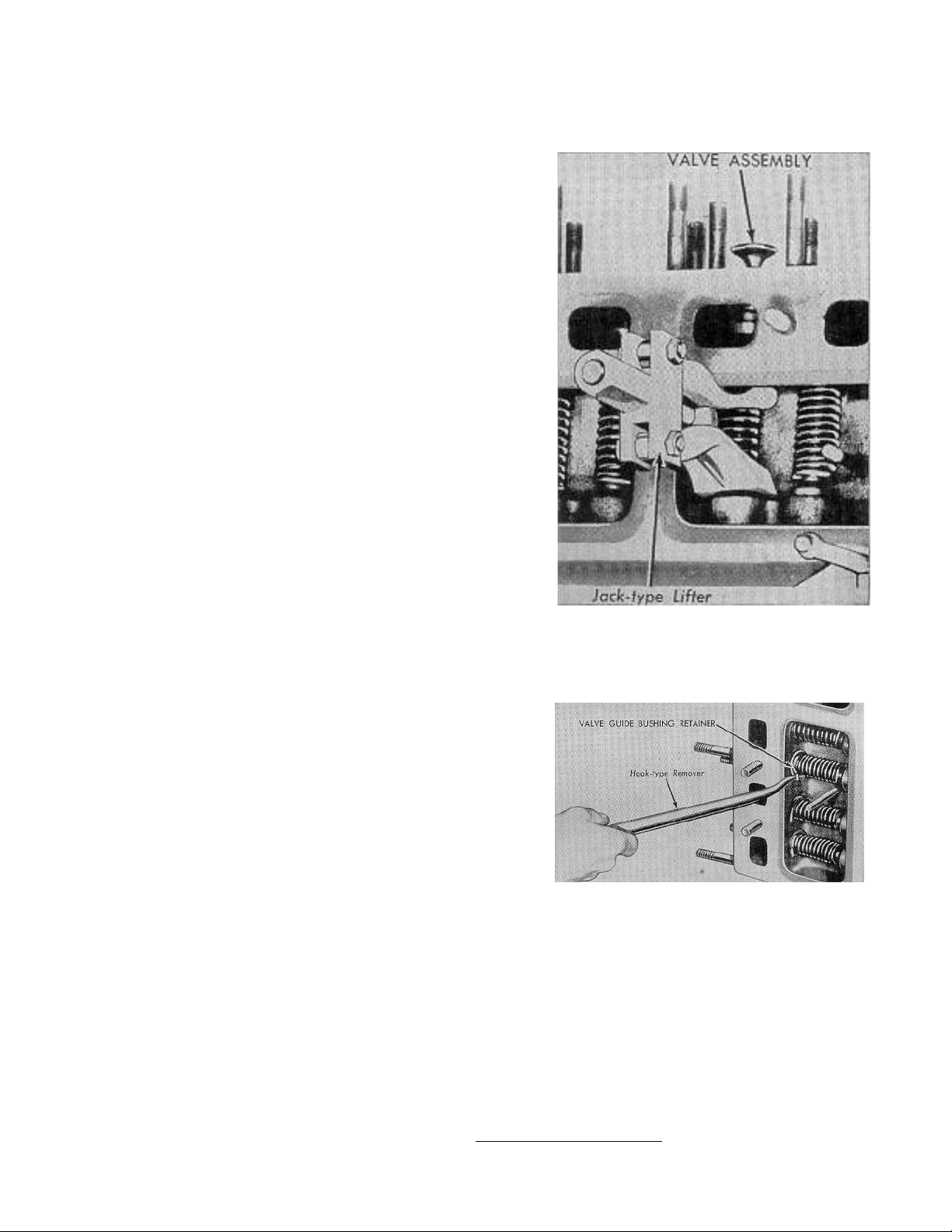

22. Inlet and exhaust valves are not

interchangeable. Valves removed for grinding or

refacing should be reinstalled in their

original location. Valves, guides and springs

are removed from the top after cylinder head

and valve chamber covers are off and valve

guide retainers are out.

Use a hook type puller as shown in Fig. FO15 to

extract retainers from valve guides, then

remove each valve, guide and spring unit from

cylinder block with a jack type lifter as shown

in Fig. FO14. Renew valves having deeply pitted

or warped heads or stems that are bent or

scored or worn. Reface inlet and exhaust valves

to an angle of 45 degrees. Correct valve tappet

clearance cold is .010 to .013 for inlet and

from .014 to .016 for exhaust valves. On

engines with non-adjustable type tappets, grind

valve stem end to correct insufficient

clearance or grind valve head or seat faces to

correct excessive clearance. Use a lever type

tool to reinstall valve guide retainers as shown

in Fig. FO16.

Fig. FO14 Removing valve, valve–

spring and guide as an assembly.

Stem Diameter: Two-piece Guides .3105 - .3115

Stem Diameter: One-piece Guides .341 - .342

Clearance In Guide: Inlet .002 - .004

Clearance In Guide: Exhaust .0025 - .0045

Free Valve Type Exhaust

Fig. FO15 Removing valve guide –

22A. Follow procedure for removing and refacing

valves as outline in paragraph 22. On engines

with free type exhaust valve rotators, a gap or

end clearance of .0002 - .004 must exist between

cap and end of valve stem. Refer to paragraph 31 for checking procedure and method

of correcting the clearance. Correct valve tappet clearance is .010 - .012 cold for

inlet and .014 - .016 cold for exhaust valves.

Connect/Report Errors – jcchapster@gmail.com

retainer preparatory to removal of

valve, spring and guide as an

assembly.

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

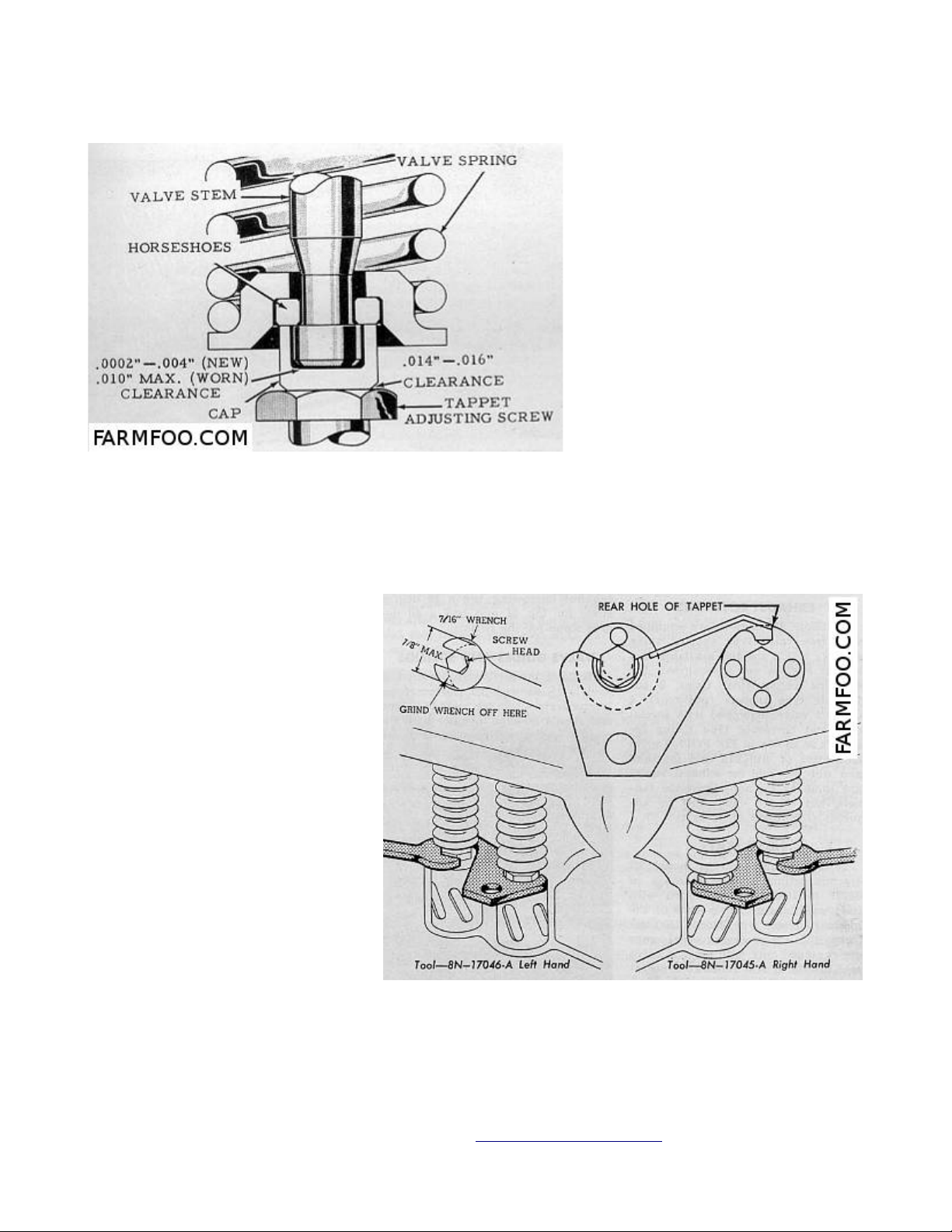

EXHAUST ROTORS

23. Some 8N engines are equipped with free valve type exhaust valve rotators which

are also available as a kit for engines not so equipped. Kit contains among other

items, 8 adjustable type tappets (pushrods), 4 exhaust valves equipped with special

caps and horseshoe type spring retainers as shown in Fig. FO17. Tappet clearances

of .010 - .012 cold for for inlet and .014 - .016 cold for exhaust valves are same

as on non-adjustable tappets, but rotator caps must be adjusted as outlined in

paragraph 27.

VALVE SEATS

24. All tractors except

model 2N tractors within the

serial range of 86271 to

168259 are equipped with

inlet and exhaust valves

seats of the hardened insert

type. Model 2N tractors

within the preceding serial

range are equipped only with

exhaust valve seat inserts.

If seat renewal is necessary

and special equipment for

that purpose is not

available; inserts may be removed as follows: Drill two holes partly through insert

on opposite sites using a drill smaller than insert width, then crack insert at

holes and remove the two halves. Counterbore in block must be .0015 to .003,

smaller than measured diameter of new seat insert. Pack new insert in dry ice for

at least 15 minutes and then drive or press it in place, making certain that it is

bottomed and not cocked. After insert is installed, grind the seat to 45 degrees

angle using a seating stone. If a seat cutter is used, each valve should be lapped

in its seat. Seat width should not exceed .125. If seat requires narrowing, use a

30 degree stone for top of seat and a 60 degree stone for the bottom.

Fig. FO16 Special tool for installing valve –

guide retainers.

VALVE GUIDES AND SPRINGS

25. Early production guides used in models 2N 9N and 8N tractors prior tractor –

serial 42162 are made in halves, and should be kept together with the mating valve,

to maintain stem to guide clearance. Later production guides used in model 8N

tractors after serial 42161 are one-piece type. Valves used with two-piece guides

have a stem diameter of .311; stem diameter of valves used with one-piece guides is

.341. Stem to guide clearance wear limit is .005 for inlet and .006 for exhaust

valves. New guides or guides with least wear should be used with inlet valves.

Connect/Report Errors – jcchapster@gmail.com

FO-4 I&T (Remastered Ver.1.2 ) 05-24-2015

Fig. FO17 - Free valve type exhaust valve rotators

used on later engines and available in kit form

for early engines.

The one-piece valve guides

can be installed in engines

originally equipped with the

two-piece type. If valve

rotators are not included in

the change-over, it will be

necessary to use the same

valve springs as used for the

two-piece type of guide.

Springs in tractors with twopiece valve guides should

test 37-40 pounds @ 2 1/8

inches; for one-piece guides

41-44 pounds @ 1.80 inches.

Renew valve springs if

protective pain coating is

lost or if tension is less

than specified.

VALVE PUSH RODS (TAPPETS)

26. Valve pushrods (tappets)

are of the barrel type. On

tractors built prior to 1951,

the tappets are of the nonadjustable type, later

tractors are equipped with

adjustable tappets.

Adjustable type tappets can

be installed in engines

originally equipped with the

non-adjustable type, and this

change-over is recommended.

Adjustable tappets are also

included in Ford Special

Equipment Kit 8N6546B which

provides special exhaust

valve rotators. This kit can

be installed in 2N, 9N and

early 8N tractors. Tappet

clearances (gaps) of .010 - .

012 inlet, .014 - .016

exhaust, cold, are used on

both types of tappets.

Fig. FO18 Showing special tappet holding wrenches–

needed for adjustment of Ford engines with

adjustable type tappets. A regular tappet end

wrench should be ground off as shown in upper left.

Method of adjusting the adjustable type tappets is shown in Fig. FO18. Required are

Connect/Report Errors – jcchapster@gmail.com

Loading...

Loading...