Page 1

Information and Instructions

This individual Shop

ies on agricultural wheel type tractors

Manual is one unit of a ser-

.

Contained

in it are the necessary specifications and the brief

but terse procedural data needed by a mechanic

when repairing a tractor on which he has had no

previous actual experience.

The material is arranged in a systematic order

beginning with an index which is followed immediately by a Table of Condensed Service Specifications. These specifications include dimen-

sions, fits

in order of arrangement is the procedures section.

In the procedures

tion starts with the front

and proceeds

clearances and timing instructions. Next

,

section, the order of presenta-

axle system and steering

toward the rear axle

. The last por-

tion of the procedures section is devoted to the

power take-off and

power

lift systems.

Interspersed

where needed in this section are additional tabu-

lar specifications pertaining to wear limits, torqu-

ing, etc.

HOW TO USE THE INDEX

Suppose you want to know the procedure for R&R

(remove and

first step is to look in the index under the main

heading of ENGINE until you find the entry "Camshaft" Now read to the right where under the

column covering the tractor you are repairing, you

will find a number

paragraph pertaining to the camshaft

wanted paragraph in the manual

until the running index appearing

side corner of each page contains

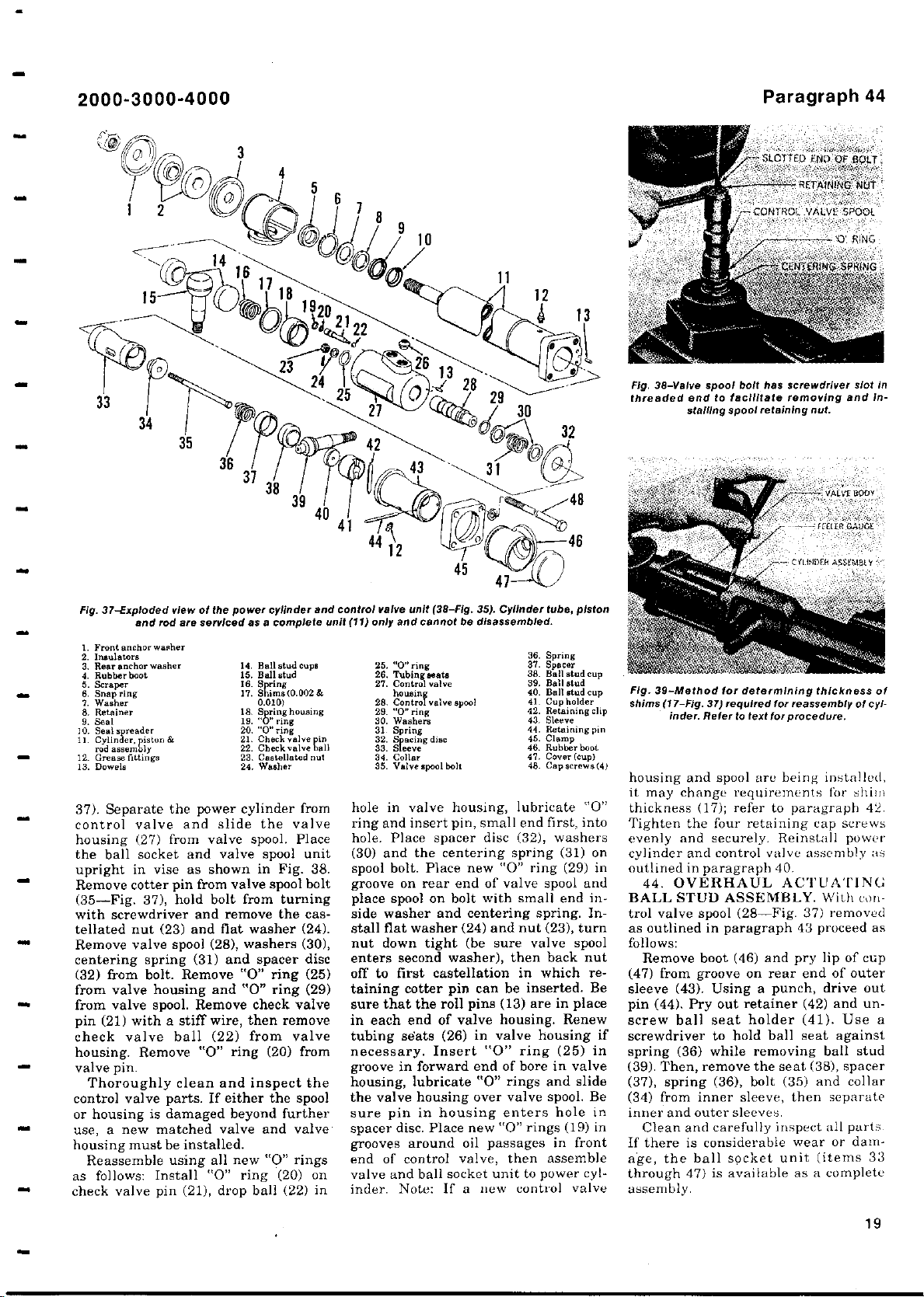

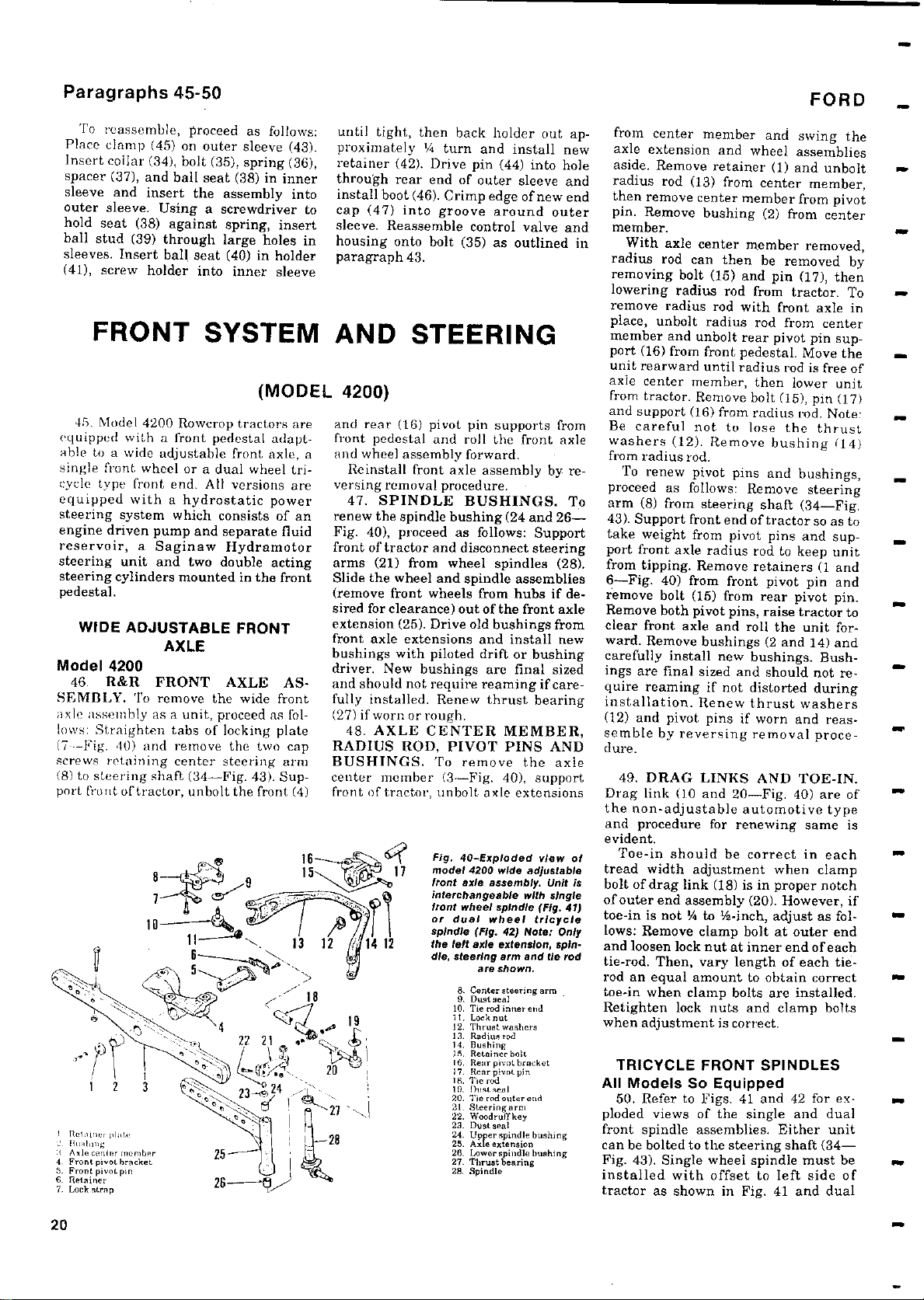

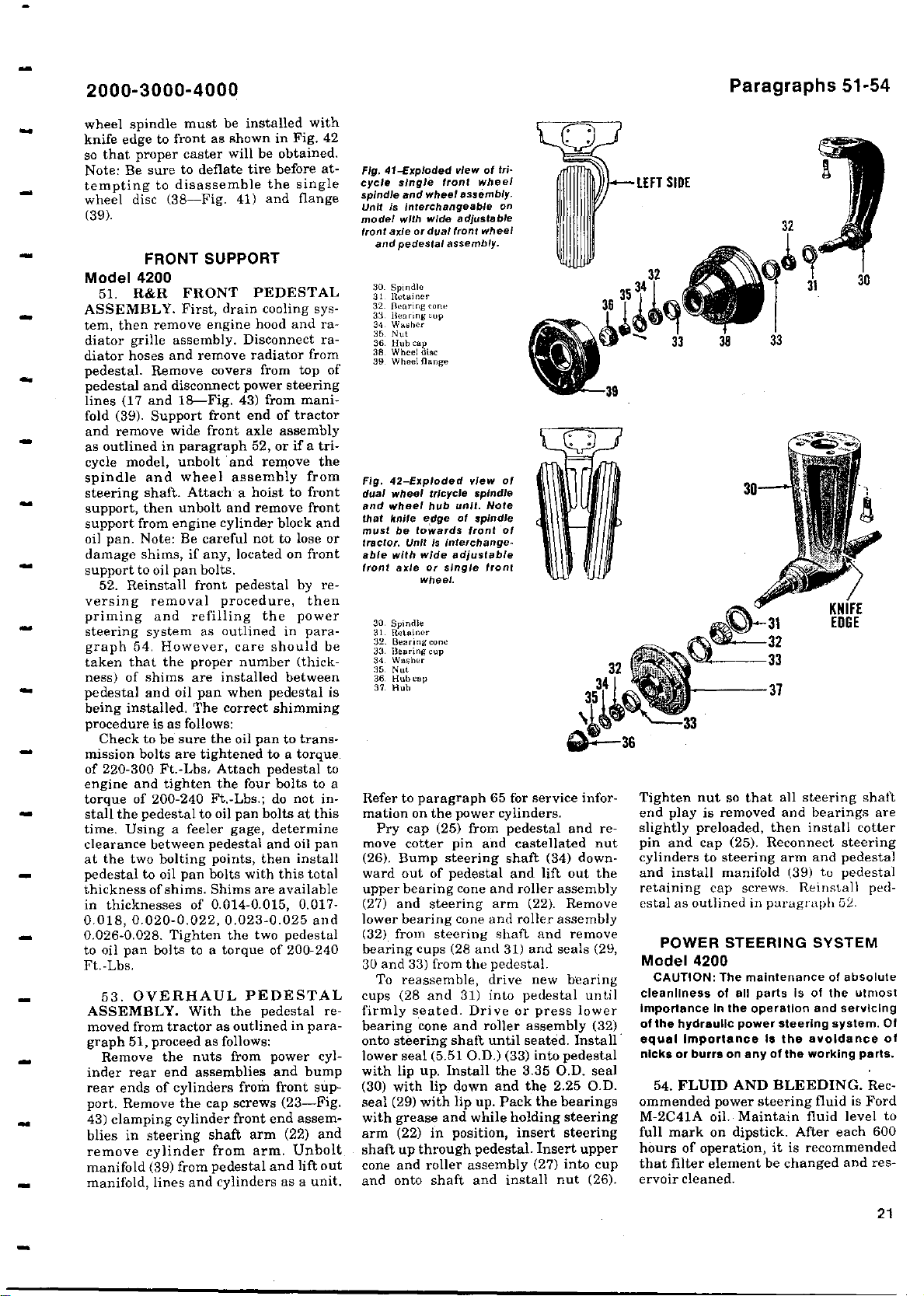

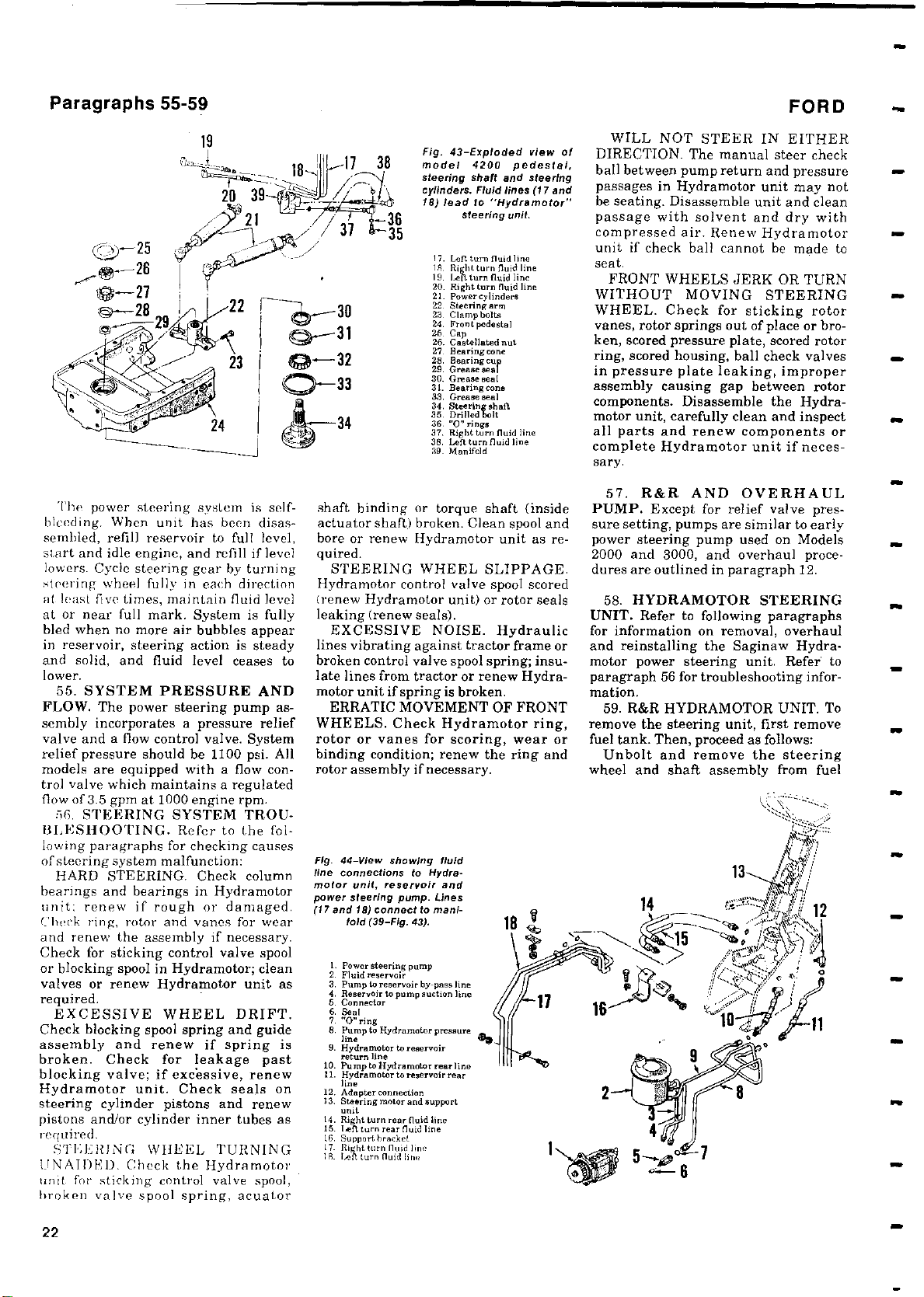

are seeking.In this paragraph

formation concerning the removal

reinstall)of the engine

which indicates

camshaft. Your

the beginning

. To locate this

, turn the pages

on the top out-

the number you

you will find the in-

of the camshaft.

Page 2

SHOP MANUAL

FORD

SERIES 2000-3000-4000

(COVERS MODELS

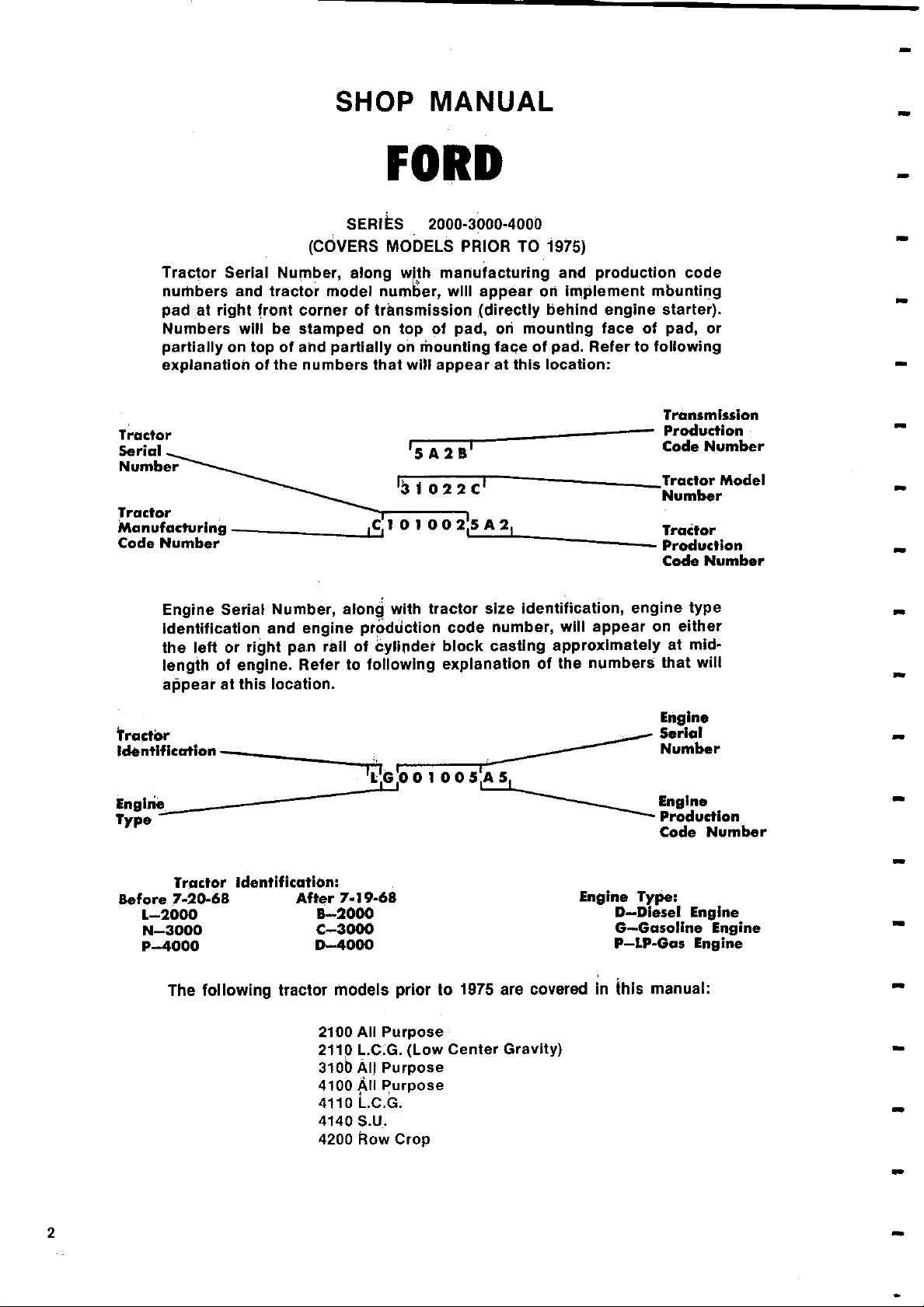

Tractor Serial Number

numbers and tractor model number

pad at right front corner of transmission

Numbers will be stamped on top of pad

partially on top of and partially on mounting face of pad

explanation of the numbers that will appear at this location:

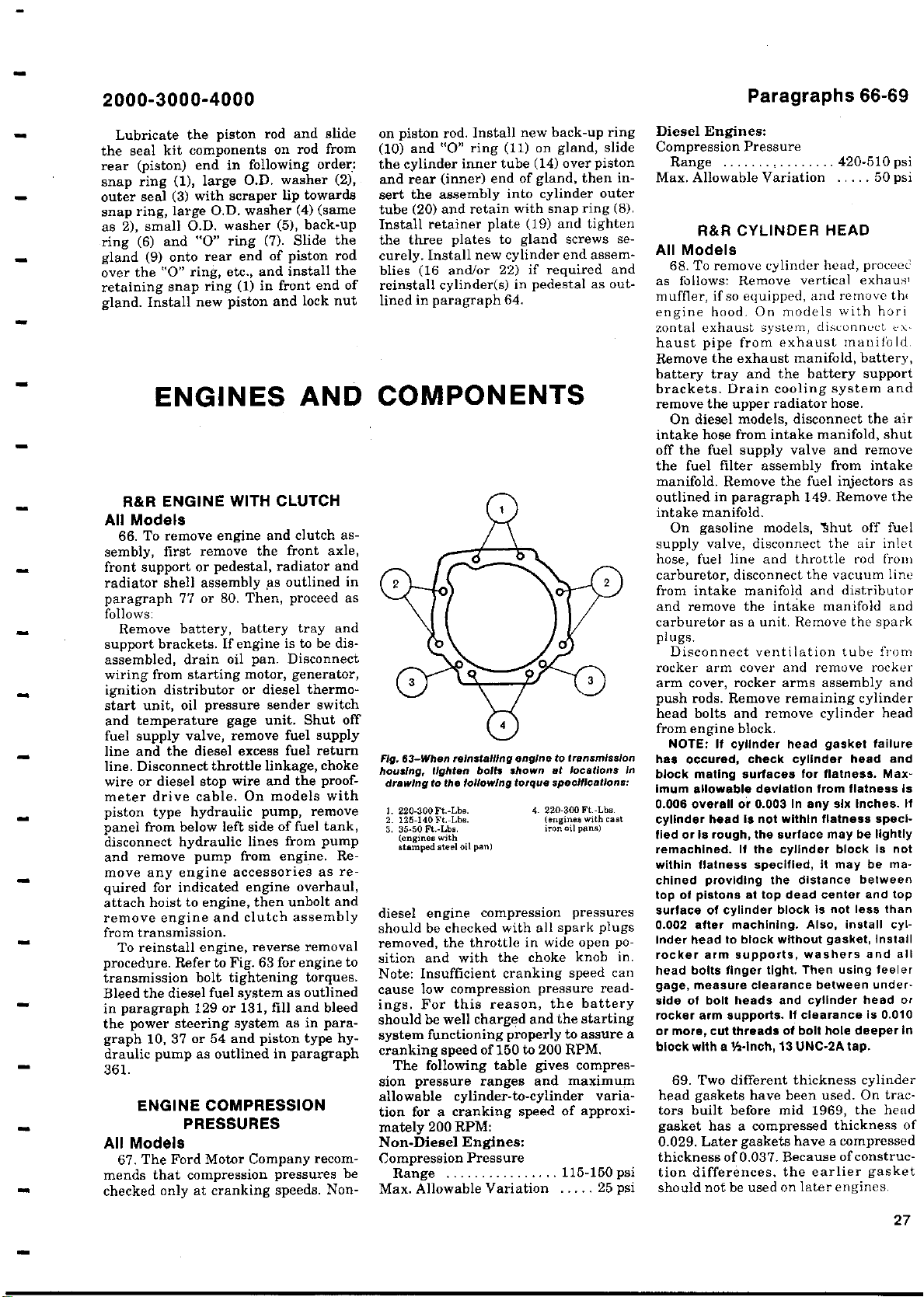

,

along with manufacturing and production code

5A25

PRIOR

will appear on implement mbunting

,

TO 1975)

directly behind engine starter).

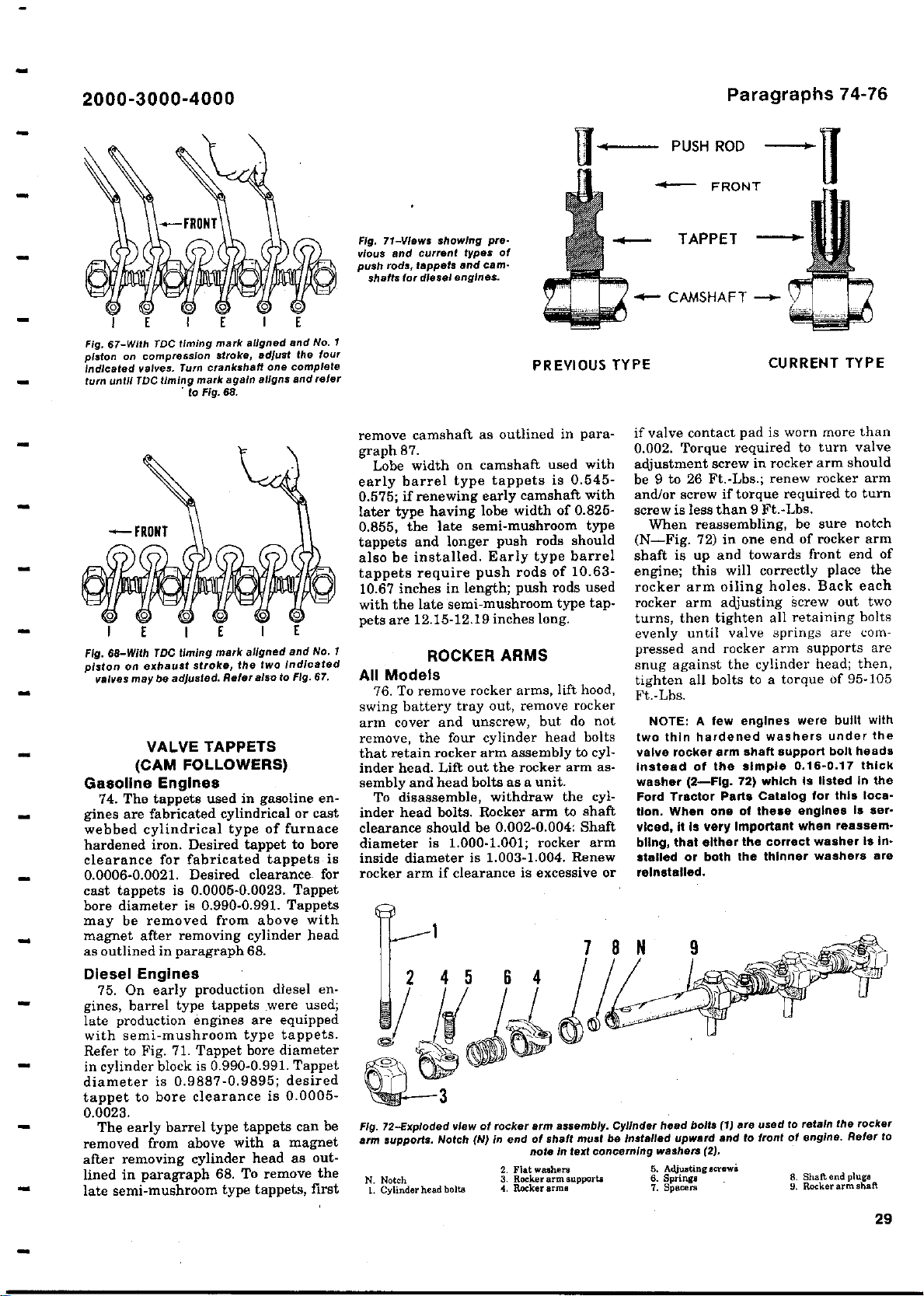

(

on mounting face of pad, or

,

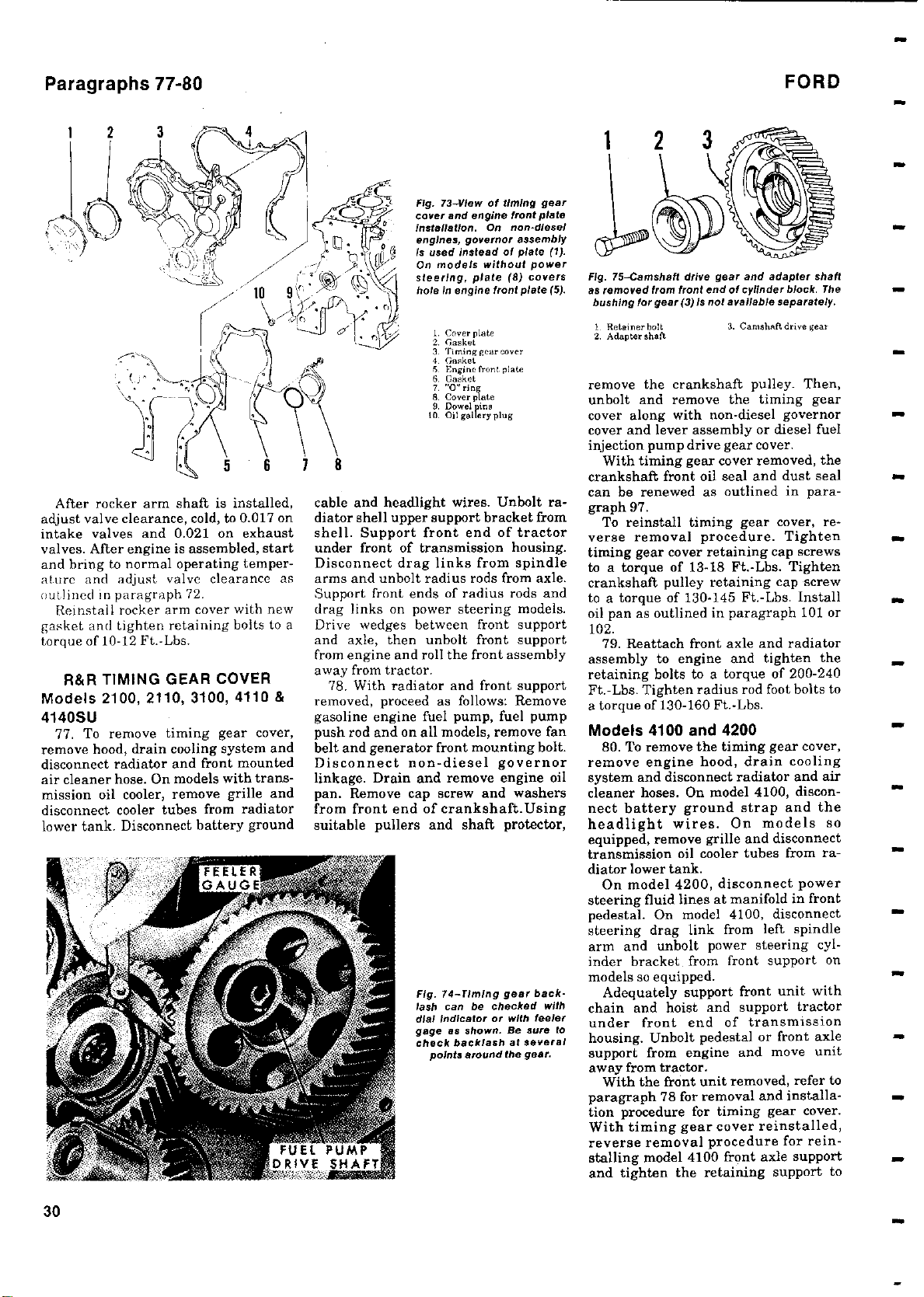

.

Refer to following

Transmission

Production

Code Number

31022C

Tractor

Manufacturing

Code Number

Engine Serial Number

Identification and engine production code number

C0 025A2

along with tractor size identification

,

will appear on either

,

the left or right pan rail of cylinder block casting approximately at mid-

Refer to following explanation of the numbers that will

length of engine

.

appear at this location.

Tractor

Identification

L:G:o 0 1 0 0 S:A 5

Engine

Type -

Tractor Identification:

Before 7-20-68

L-2000

N-3000

P-4000

After 7-19-68

B-2000

C-3000

D-4000

Engine Type:

Tractor Model

Number

Tractor

Production

Code Number

engine type

,

Engine

Serial

Number

Engine

Production

Code Number

D-Diesel Engine

G-Gasoline Engine

P-LP-Gas Engine

The following tractor models prior to 1975 are covered in this manual:

2100 All Purpose

2110 L

3106

4100 All

4110 L.C.G.

4140 S.U.

4200 Row Crop

2

C:G. (Low Center Gravity)

.

All Purpose

Purpose

Page 3

By Starting Paragraph)

INDEX

(

BELT PULLEY ................................ 337

BRAKES ......................................308

CARBURETOR, GASOLINE ................... 106

CARBURETOR, LP-GAS ....................... 117

CLUTCH, SINGLE DISC ....................... 184

CLUTCH, DUAL DISC ......................... 185

CLUTCH, POWER TAKE-OFF ................. 332

COOLING SYSTEM:

Radiator .................................... 169

Thermostat ..................................168

Water Pump ................................. 170

DIESEL FUEL SYSTEM:

Bleeding ............................... 129,131

Filters ......................................128

Injection Pump ......................... 151,155

Injector Nozzles ..............................132

Troubleshooting .............................120

DIFFERENTIAL ......................... 284, 300

DIFFERENTIAL LOCK ................... 290,304

ELECTRICAL SYSTEM:

Generator & Regulator ....................... 171

Ignition Distributor .......................... 175

Starting Motor .......................... 172,173

ENGINE:

Assembly, R&R ............................... 66

Camshaft .................................... 87

Connecting Rod Bearings ...................... 95

Crankshaft & Bearings ........................ 96

Crankshaft Oil Seals .......................... 97

Cylinder Head ................................ 68

Cylinders ....................................91

Flywheel, R&R ..............................100

Oil Pan .....................................101

Oil Pump .................................... 103

Pistons & Rings ............................... 89

Piston & Rod Removal ......................... 88

Piston Pins ................................... 94

Rocker Arms ................................. 76

ENGINE

: (

cent)

Timing Gear Cover ............................ 77

Timing Gears ................................. 81

Valve Adjustment

Valves & Seats

Valve Guides

.............................

...............................

Springs ....................... 71

&

72

70

FINAL DRIVE GEARS ......................... 307

FRONT AXLE .............

non-Diesel

GOVERNOR

HYDRAULIC

Adjustments

Lift Cover Assembly

Lift Cylinder

Pump

Pump

Remote Control

Selector Valve ............................... 368

Troubleshooting

IGNITION SYSTEM

LP-GAS SYSTEM

(

LIFT SYSTEM:

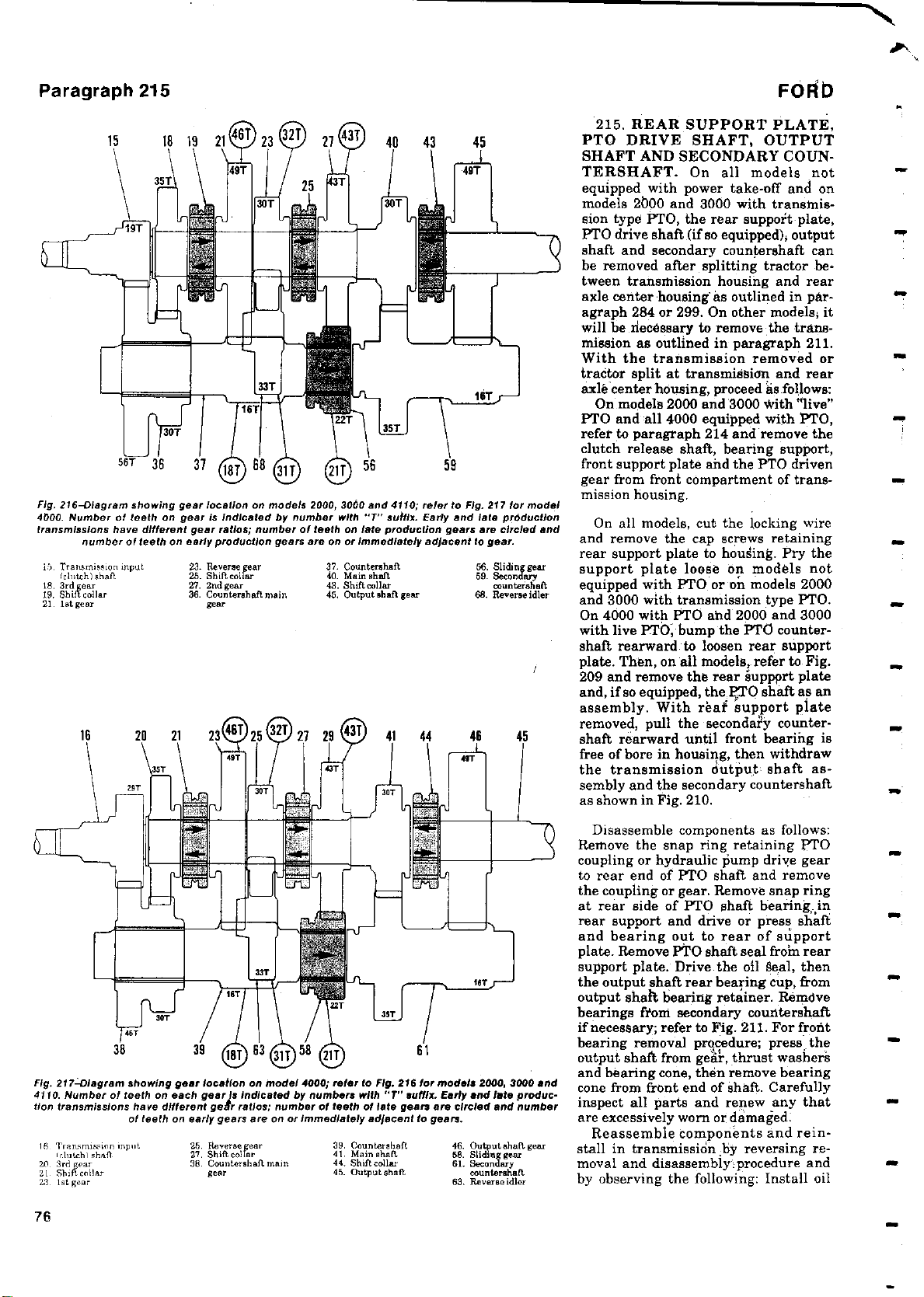

.................................344

Overhaul .......................349

,

Piston Type

(

Gear Type

(

Valves .......................370

,

) ..........................

) .......... 366

.............................

...........................

................ . .............

............... L 24,46

) ...................... 164

R&R .................... 347

360

342

174

107

POWER STEERING:

Bleed System

Control Valve ............................. 13,40

Pump ........................................ 12

Steering Gear

System Pressure

POWER TAKE

..........................

......................

...........................

OFF .................. 316, 324, 326

-

10,37,54

13,28,34,58

11,38

REAR AXLE:

Axle Housings

Bearing Adjustment

Remove & Reinstall

Shaft

STEERING

TRANSMISSION (By Type):

,

Auxiliary

Four-Speed

Six-Speed

Eight-Speed

Select-O-Speed

..........................

Manual

(

...................................

...................................201

) .........................

..................................193

.................................210

..............................219

..................... 294, 307

...............

298,307

295, 306

5,28

186

CONDENSED

General

Engine Make ........................

No. of Cylinders .....................

Bore-Inches, Non-Diesel .............

Diesel .............................

Stroke-Inches, Non-Diesel ...........

Diesel .............................

Displacement-Cubic Inches,

Non-Diesel ........................

Diesel .............................

Compression Ratio, Non-Diesel .......

Diesel .............................

TRACTOR SERIES

(Before 7/

2000

Own

3

4.2

4.2

3.8

3.8

158

158

8.0:1

16.5:1

SERVICE DATA

20/68)

3000

Own

3

4.2

4.2

3.8

4.2

158

175

8.0:1

16.5:1

4000

Own

3

4.4

4.4

4.2 3.8

4.4

192

201

8.01:1

16.5:1

TRACTOR SERIES

(After 7/

2000

Own

3

4.2

4.2

3.8

158

158

7.8:1

16.5:1

3000

Own

3

4.2

4.2

3.8

4.2

158

175

7.8:1

16.5:1

19/68)

4000

Own

3

4.4

4.4

4.4

4.4

201

201

7.8:1

16.5:1

3

Page 4

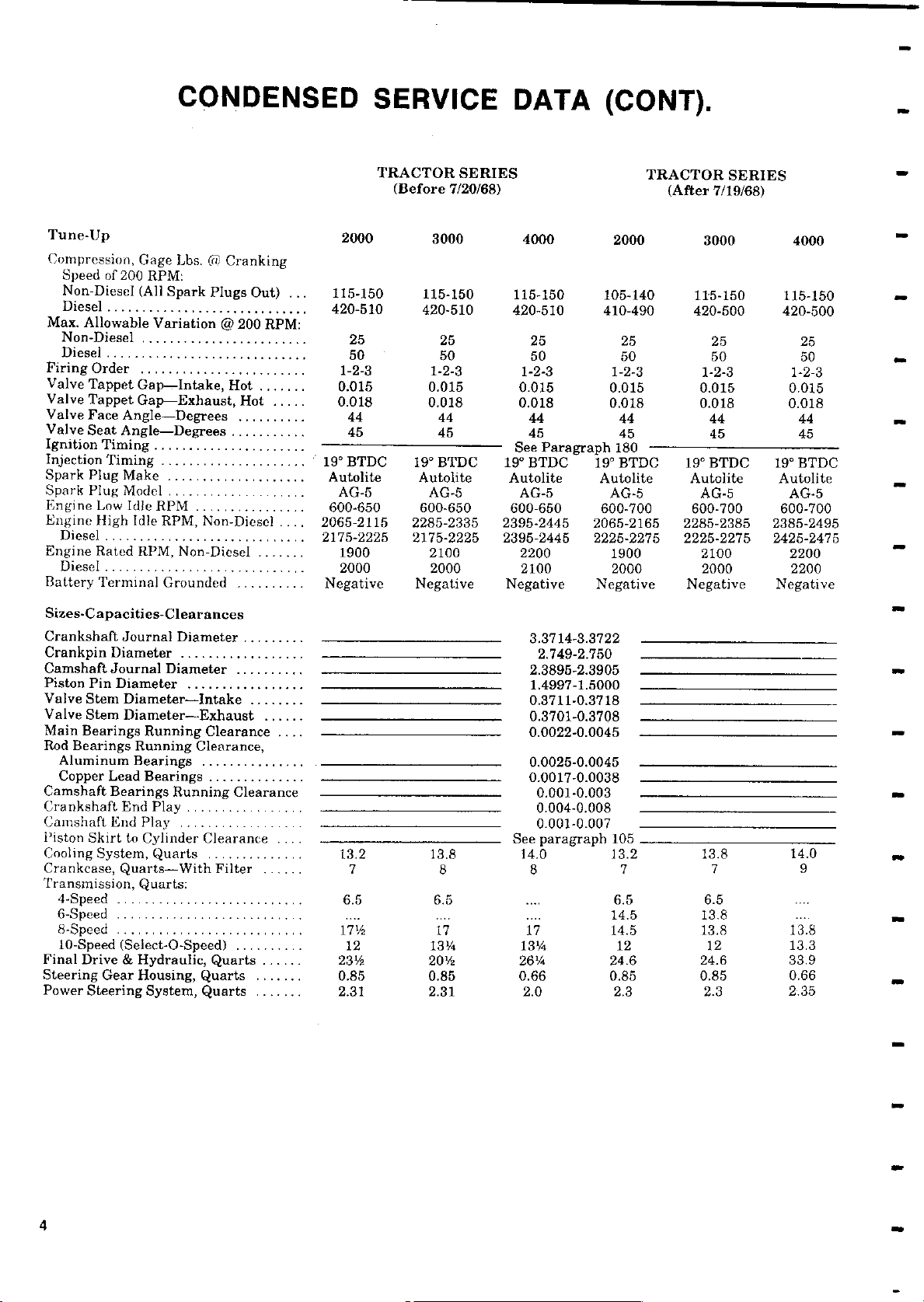

CONDENSED SERVICE

TRACTOR SERIES TRACTOR SERIES

(

Before 7/20/68

DATA (CONT).

) (After 7/

19/68)

Tune-Up

Compression

,

Gage

Lbs. C(

, Cranking

2000 3000 4000 2000 3000 4000

Speed of 200 RPM:

Non-Diesel (All Spark Plugs Out) ...

Diesel .............................

115-150 115-150 115-150 105-140 115-150 115-150

420-510 420-510 420-510 410-490 420-500 420-500

Max. Allowable Variation @ 200 RPM:

Non-Diesel ........................ 25

Diesel ............................. 50

Firing Order ........................ 1-2-3

Valve Tappet Gap-Intake, Hot ....... 0.015

Valve Tappet Gap-Exhaust, Hot ..... 0.018

Valve Face Angle-Degrees .......... 44

Valve Seat Angle-Degrees ........... 45

Ignition Timing ......................

Injection Timing ..................... . 19° BTDC

Spark Plug Make .................... Autolite

Spark Plug Model .................... AG-5

Engine Low Idle RPM ................ 600-650

Engine High Idle RPM, Non-Diesel .... 2065-2115

Diesel ............................. 2175-2225

Engine Rated RPM, Non-Diesel ....... 1900

Diesel ............................. 2000

Battery Terminal Grounded .......... Negative

Sizes-Capacities

Crankshaft

Crankpin Diameter

Camshaft

Piston Pin Diameter

Valve

Valve

Main Bearings Running Clearance ....

Rod Bearings Running

Aluminum Bearings

Copper Lead

Camshaft

Crankshaft End Play .................

Camshaft End Play ..................

Piston Skirt to Cylinder Clearance ....

Cooling System, Quarts ..............

Crankcase, Quarts-With Filter ......

Transmission, Quarts:

4-Speed ........................... 6.5

6-Speed ...........................

8-Speed ........................... 171/2

10-Speed(Select-O-Speed

Final Drive

Steering Gear Housing

Power Steering System, Quarts ....... 2.31

Journal Diameter

Stem Diameter

Stem Diameter

Bearings Running Clearance

-

Clearances

Journal Diameter

..................

.................

-

Intake ........

-

Exhaust ......

Clearance,

Bearings

&

Hydraulic

...............

,

,

Quarts ....... 0.85

.........

..........

..............

13.2 13.8 14.0 13.2 13.8 14.0

7 8 8 7 7 9

) .......... 12

Quarts ...... 231

25 25 25 25 25

50 50 50 50 50

1-2-3 1-2-3 1-2-3 1-2-3 1-2-3

0.015 0.015 0.015 0.015 0.015

0.018 0.018 0.018 0.018 0.018

44 44 44 44 44

45 45 45 45 45

19°BTDC 19° BTDC 19°BTDC 19° BTDC 19°BTDC

Autolite Autolite Autolite Autolite Autolite

AG-5 AG-5 AG-5 AG-5 AG-5

600-650 600-650 600-700 600-700 600-700

2285-2335 2395-2445 2065-2165 2285-2385 2385-2495

2175-2225 2395-2445 2225-2275 2225-2275 2425-2475

2100 2200 1900 2100 2200

2000 2100 2000 2000 2200

Negative Negative Negative Negative Negative

See Paragraph 180

3.3714-3.3722

2.749-2.750

2.3895-2.3905

1.4997-1.5000

0.3711-0.3718

0.3701-0.3708

0.0022-0.0045

0.0025-0.0045

0.0017

0.0038

-

0.001-0.003

0.004-0.008

0.001-0.007

See paragraph 105

6.5

17

131/4

20V2

0.85

2.31

.... 6.5 6.5 ...

.... 14.5 13.8 ....

17 14.5 13.8 13.8

13V4 12 12 13.3

26'4 24

0.66 0.85 0.85 0.66

2.0 2.3 2.3 2.35

.6 24.6 33.9

4

Page 5

2000

3000-4000

-

FRONT SYSTEM AND STEERING

4110 & 4140 S.U.)

(MODELS 2100

2110

,

,

3100

,

Paragraphs 1-6

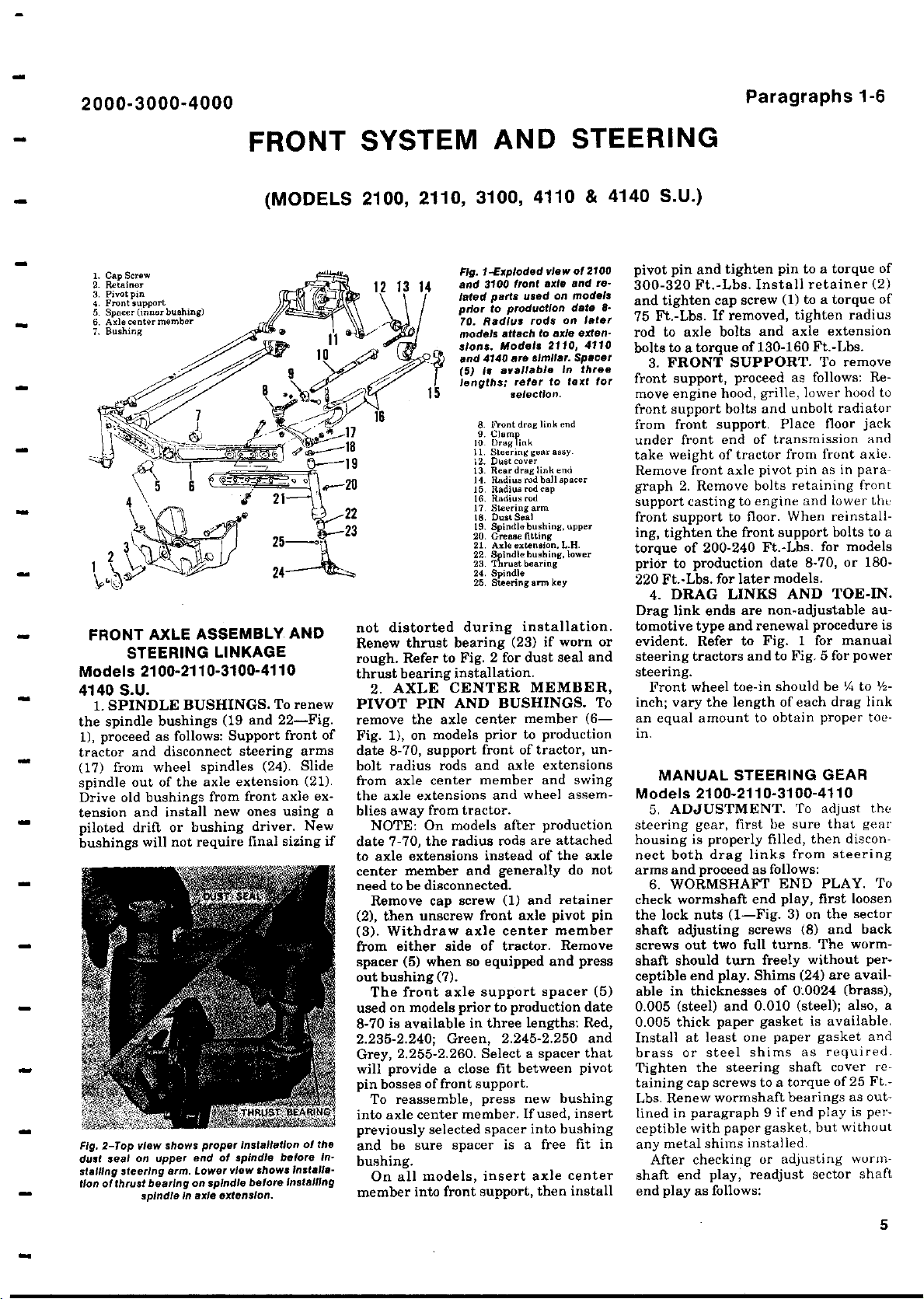

1. Cap Screw

2. Retainer

3. Pivotpin

4. Front support

(

5. Spacer

6. Axle center member

7. Bushing

inner bushing)

FRONT AXLE ASSEMBLY AND

STEERING LINKAGE

3100-4110

2110

Models 2100

-

-

4140 S.U.

1. SPINDLE BUSHINGS. To renew

the spindle bushings (19 and 22-Fig.

1), proceed as follows: Support front of

tractor and disconnect steering arms

(17) from wheel spindles (24). Slide

spindle out of the axle extension (21).

Drive old bushings from front axle extension and install new ones using a

piloted drift or bushing driver. New

bushings will not require final sizing if

Lower

extension.

installation of the

view show,

Fig. 2-Top view shows proper

dust seal on

stalling steering

tion of thrust bearing on spindle before

upper end of spindle before in-

arm.

spindle In axle

installa-

installing

pivot pin and tighten pin to a torque of

300-320 Ft.-Lbs. Install retainer (2)

and tighten cap screw (1) to a torque of

75 Ft.-Lbs. If removed, tighten radius

rod to axle bolts and axle extension

bolts to a torque of 130-160 Ft.-Lbs.

front support, proceed as follows: Re-

move engine hood, grille, lower hood to

rods

similar

to text for

and remodels

on

on later

.

of 2100

Spacer

Exploded view

-

Fig. 1

and

3100 front axle

lated parts

prior to production date 8-

70. Radius

models attach to axle exten-

sions

and

(5) is available in three

lengths;

used

Models 2110, 4110

.

4140 are

refer

selection.

front support bolts and unbolt radiator

8. l' ont drag link end

9. Clamp

10. [)rag link

11. Steering

12. Dust c.var

lI Rear dreg link and

14. Radius

15. Radius rod cap

16. Radius red

12 Steering arm

18. Dust Seal

19. Spindle bushing, upper

20. Grease fitting

21. Axle extension, L.H.

22. S indle bushing, lower

23. Thrust bearing

24. Spindle

25. Steering arm key

gear easy.

red ball spacer

from front support. Place floor jack

under front end of transmission and

take weight of tractor from front axle.

Remove front axle pivot pin as in paragraph 2. Remove bolts retaining front

support casting to engine and tower the

front support to floor. When reinstalling, tighten the front support bolts to a

torque of 200-240 Ft.-Lbs. for models

prior to production date 8-70, or 180220 Ft.-Lbs. for later models.

Drag link ends are non-adjustable au-

not distorted during installation.

Renew thrust bearing (23) if worn or

rough. Refer to Fig. 2 for dust seal and

thrust bearing installation.

2. AXLE CENTER

MEMBER,

PIVOT PIN AND BUSHINGS. To

remove the axle center member (6Fig. 1), on models prior to production

tomotive type and renewal procedure is

evident. Refer to Fig. 1 for manual

steering tractors and to Fig. 5 for power

steering.

inch; vary the length of each drag link

an equal amount to obtain proper toe-

in.

date 8-70, support front of tractor, unbolt radius rods and axle extensions

from axle center member and swing

the axle extensions and wheel assem-

Models 2100-2110

blies away from tractor.

NOTE: On models after production

date 7-70, the radius rods are attached

to axle extensions instead of the axle

center member and generally do not

steering gear, first be sure that gear

housing is properly filled, then disconnect both drag links from steering

arms and proceed as follows:

need to be disconnected.

Remove cap screw (1) and retainer

(2), then unscrew front axle pivot pin

(3). Withdraw axle center member

from either side of tractor. Remove

5) when so equipped and press

spacer

(

out bushing (7).

The front axle support spacer (5)

used on models prior to production date

8-70 is available in three lengths: Red,

2.235-2.240; Green, 2.245-2.250 and

Grey, 2.255-2.260. Select a spacer that

will provide a close fit between pivot

pin bosses of front support.

To reassemble, press new bushing

into axle center member. If used, insert

previously selected spacer into bushing

and be sure spacer is a free fit in

check wormshaft end play, first loosen

the lock nuts (1-Fig. 3) on the sector

shaft adjusting screws

screws out two full turns. The wormshaft should turn freely without perceptible end play. Shims (24) are avail-

able in thicknesses of 0.0024 (brass),

0.005 (steel) and 0.010 (steel); also, a

0.005 thick paper gasket is available.

Install at least one paper gasket and

brass or steel shims as required.

Tighten the steering shaft cover retaining cap screws to a torque of 25 Ft.-

Lbs. Renew wormshaft bearings as outlined in paragraph 9 if end play is perceptible with paper gasket, but without

any metal shims installed.

bushing.

On all models, insert axle center

member into front support, then install

shaft end play, readjust sector shaft

end play as follows:

3. FRONT SUPPORT. To remove

4. DRAG LINKS AND TOE-IN.

Front wheel toe-in should be Y4 to 'A-

MANUAL STEERING GEAR

3100-4110

5. ADJUSTMENT. To adjust the

6. WORMSHAFT END PLAY. To

After checking or adjusting worn-

-

(8) and back

5

Page 6

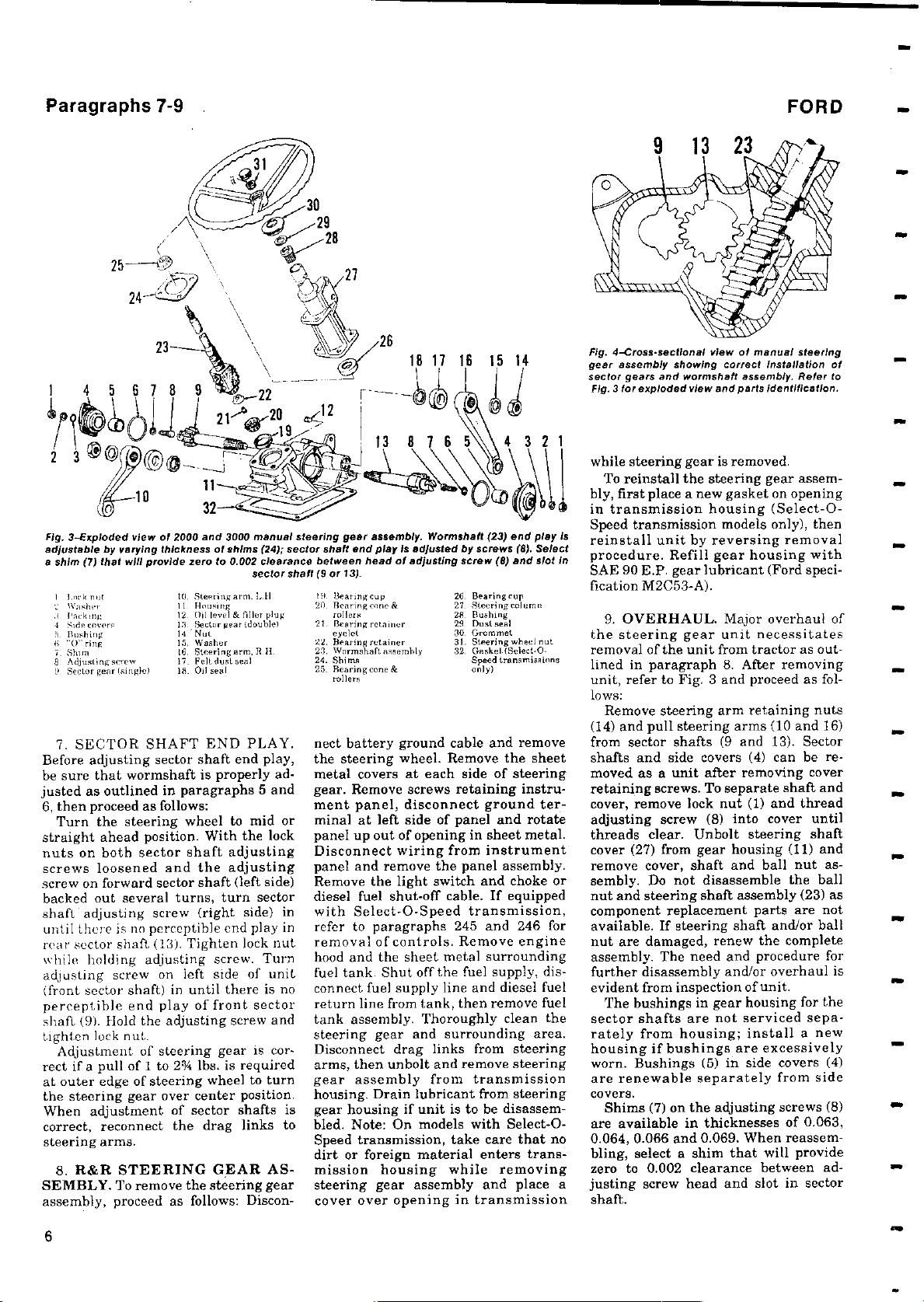

Paragraphs 7-9

Fig. 3-Exploded

adjustable

a shim(7) that

I ,rknut

d parkin,

4 Sidecovere

5. Hushing

6 "0` ring

.. Shun

8. Adjust, ngsrrew

9. Sector gear I urn e)

7. SECTOR SHAFT END PLAY.

Before adjusting sector shaft end play,

be sure that wormshaft is properly ad-

justed as outlined in paragraphs 5 and

6, then proceed as follows:

Turn the steering wheel to mid or

straight ahead position. With the lock

nuts on both sector shaft adjusting

screws loosened and the adjusting

screw on forward sector shaft (left side)

backed out several turns, turn sector

shaft adjusting screw (right side) in

until there is no perceptible end play in

rear sector shaft (13). Tighten lock nut

while holding adjusting screw. Turn

adjusting screw on left side of unit

(front sector shaft) in until there is no

perceptible end play of front sector

shaft (9). Hold the adjusting screw and

tighten lock nut.

Adjustment of steering gear is cor-

rect if a pull of 1 to 2%4 lbs. is required

at outer edge of steering wheel to turn

the steering gear over center position.

When adjustment of sector shafts is

correct, reconnect the drag links to

steering arms.

8. R&R STEERING GEAR ASSEMBLY. To remove the steering gear

assembly, proceed as follows: Discon-

view of 2000 and 3000 manual steering

by varying

thicknessof shims (24);

will provide

zero to 0

10

.

11. HnusIFg

1 2 Oiilevel & filler plug

18. Bettor pear (doublet21Hearing retainer

14, Nut

1.5, Washer

16.Steeringarm,Rll-

17. Felt dust seal

IS. Oil seal

Steering arm

.

002

clearance

sector

.

1,11

gear

shaft end play Is adjusted

sector

betweenhead of adjusting screw(8) and slot In

9 or 13).

shaft

(

14.

20

22.

23.

24.

25.

assembly

Ilearingeup

Bearingrvne&

rnl lers

t

Hearing retainer

Wormshaft nseembly

Shims

Rearing cure &

rollers

Wormshaft(23) end play is

.

by screws(8). Select

Bearing cup

26

.

27. Steeringeolumn

28

Bushing

Dustseal

29

Grommet

30

31. Steering wheel nut

Geekel (select-

32.

0-

Speed transmissions

only)

nect battery ground cable and remove

the steering wheel. Remove the sheet

metal covers at each side of steering

gear. Remove screws retaining instrument panel, disconnect ground terminal at left side of panel and rotate

panel up out of opening in sheet metal.

Disconnect wiring from instrument

panel and remove the panel assembly.

Remove the light switch and choke or

diesel fuel shut-off cable. If equipped

with Select-O-Speed transmission,

refer to paragraphs 245 and 246 for

removal of controls. Remove engine

hood and the sheet metal surrounding

fuel tank. Shut off the fuel supply, disconnect fuel supply line and diesel fuel

return line from tank, then remove fuel

tank assembly. Thoroughly clean the

steering gear and surrounding area.

Disconnect drag links from steering

arms, then unbolt and remove steering

gear assembly from transmission

housing. Drain lubricant from steering

gear housing if unit is to be disassembled. Note: On models with Select-OSpeed transmission, take care that no

dirt or foreign material enters transmission housing while removing

steering gear assembly and place a

cover over opening in transmission

Fig.

4-Cross-

gear assembly

sector

Fig. 3 for exploded

sectional view

gears and wormshaft assembly

showing

view and parts Identification.

of manual steering

correct

Installation of

while steering gear is removed.

To reinstall the steering gear assembly, first place a new gasket on opening

in transmission housing (Select-OSpeed transmission models only), then

reinstall unit by reversing removal

procedure. Refill gear housing with

SAE 90 E.P. gear lubricant (Ford specification M2C53-A).

9. OVERHAUL. Major overhaul of

the steering gear unit necessitates

removal of the unit from tractor as outlined in paragraph 8. After removing

unit, refer to Fig. 3 and proceed as follows:

Remove steering arm retaining nuts

(14) and pull steering arms (10 and 16)

from sector shafts (9 and 13). Sector

shafts and side covers (4) can be removed as a unit after removing cover

retaining screws. To separate shaft and

cover, remove lock nut (1) and thread

adjusting screw (8) into cover until

threads clear. Unbolt steering shaft

cover (27) from gear housing (11) and

remove cover, shaft and ball nut assembly. Do not disassemble the ball

nut and steering shaft assembly (23) as

component replacement parts are not

available. If steering shaft and/or ball

nut are damaged, renew the complete

assembly. The need and procedure for

further disassembly and/or overhaul is

evident from inspection of unit.

The bushings in gear housing for the

sector shafts are not serviced separately from housing; install a new

housing if bushings are excessively

worn. Bushings (5) in side covers (4)

are renewable separately from side

covers.

Shims (7) on the adjusting screws (8)

are available in thicknesses of 0.063,

0.064, 0.066 and 0.069. When reassembling, select a shim that will provide

zero to 0.002 clearance between ad-

justing screw head and slot in sector

shaft.

FORD

.

Refer to

6

Page 7

2000

3000-4000

-

Paragraphs 10-11

M

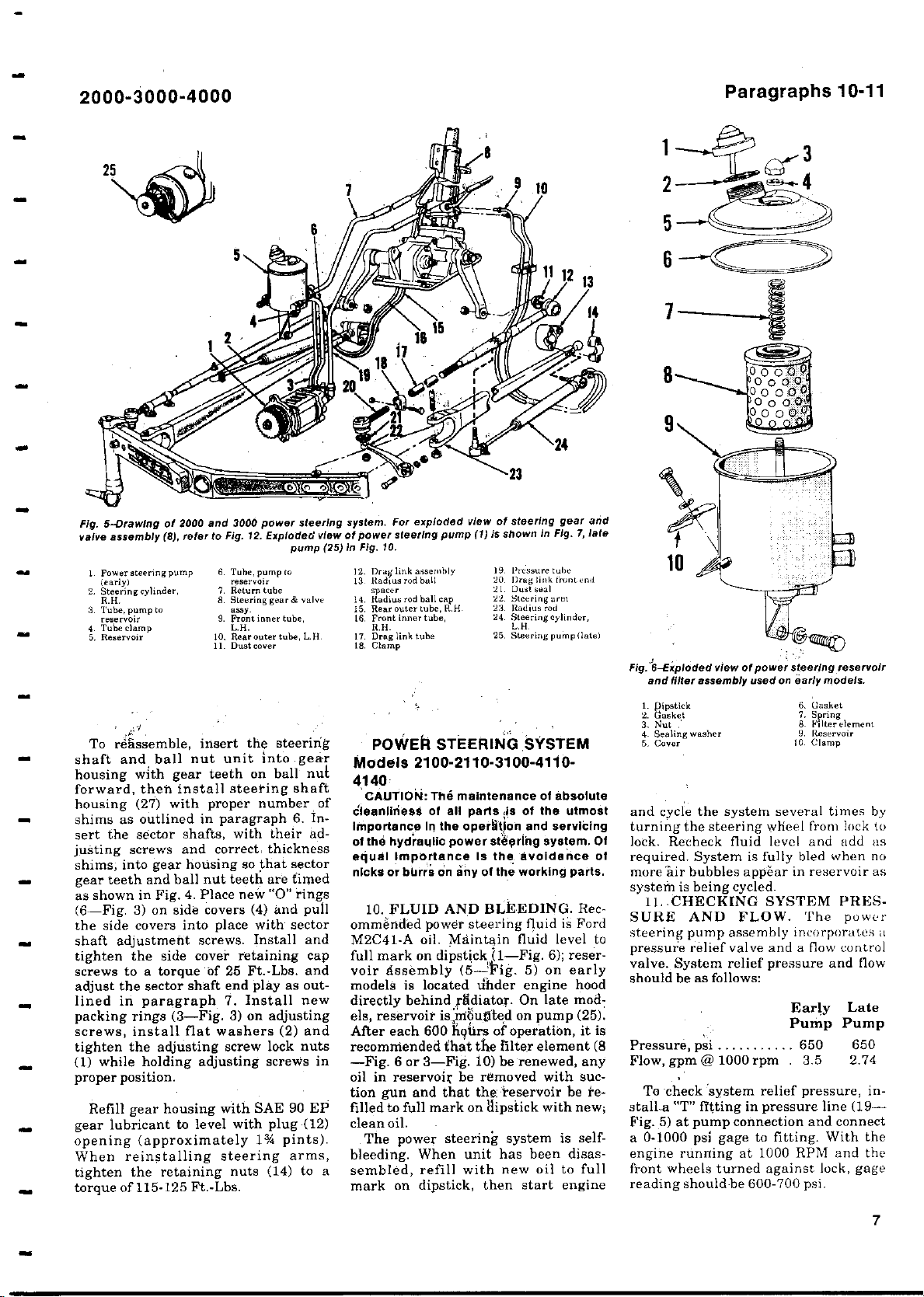

Fig. 5-Drawing

valve

assembly

I Power steering pump

(early)

2. Steering cylinder,

R

H

.

.

3. Tube, pump to

reservoir

Tube clamp

4

.

5. Reservoir

of 2000

(

8),

refer to Fig.

3000

and

12.Exploded

6. Tune, pump to

reservoir

7. Return tube

8. Steering

tossy

9. Front inner tube,

L.H.

10. Rose mar tube, L. H.

ll. Dust cover

To rehssemble, insert the steering

shaft and ball nut unit into gear

housing with gear teeth on ball nut

forward, then install steering shaft

housing (27) with proper number of

shims as outlined in paragraph 6. Insert the sector shafts, with their ad-

justing screws and correct, thickness

shims, into gear housing so that sector

gear teeth and ball nut teeth are timed

as shown in Fig. 4. Place new "0" rings

(6-Fig. 3) on side covers (4) and pull

the side covers into place with sector

shaft adjustment screws. Install and

tighten the side cover retaining cap

screws to a torque of 25 Ft.-Lbs. and

adjust the sector shaft end play as outlined in paragraph 7. Install new

packing rings (3-Fig. 3) on adjusting

screws, install flat washers (2) and

tighten the adjusting screw lock nuts

(1) while holding adjusting screws in

proper position.

Refill gear housing with SAE 90 EP

gear lubricant to level with plug (12)

opening (approximately 1%4 pints).

When reinstalling steering arms,

tighten the retaining nuts (14) to a

torque of 115-125 Ft.-Lbs.

power steering

pump

our & valve

For exploded view of steering

system

view of power steering pump

25) in Fig. 10.

(

.

12. Drag link asscmhly

13 Radius tad ball

14. Radius rod ball cap

15. Rear outer tube, R.H.

t6. Front inner tube,

R.H.

17. Drag link tube

18. Clamp

(

1) is shown

POWER STEERING SYSTEM

Models 2100

-2110-3100-4110-

4140

CAUTION:

dleanliness of all parts

Importance In the operilitlon and servicing

of the hydraylic power steering system. Of

equal Importance Is the avoidance of

nicks or burrs on any of the working parts.

10. FLUID AND BLEEDING. Recommended power steering fluid is Ford

M2C41-A oil. Maintain fluid level to

full mark on dipstick ,it-Fig. 6); reservoir assembly (5-Fig. 5) on early

models is located tinder engine hood

directly behind,ptidiator. On late models, reservoir is nlburlted on pump (25).

After each 600 hgiirs of operation, it is

recommended that the filter element (8

-Fig. 6 or 3-Fig. 10) be renewed, any

oil in reservoir be removed with suction gun and that the, reservoir be refilled to full mark on 'dipstick with new;

clean oil.

The power steering system is selfbleeding. When unit has been disassembled, refill with new oil to full

mark on dipstick, then start engine

The maintenance of absolute

gear and

In Fig. 7, late

19.

Ore'vsure tube

Drag link fruit tend

20.

21. Duatseal

22 .

Steering arm

23. Radius ad

24. Steering cylinder,

L.H.

25. Steering pump (late)

s of the utmost

J

Fig.-6-Exploded

and filter assembly usedonearly models.

1. (lipstick

2. Gasket

3. Nut

4. Sealing washer

5. Cover

view of power steering

reservoir

6. Gasket

7. Spring

8. Filter element

9. Reservoir

10 Clamp

and cycle the system several times by

turning the steering wheel from lock to

lock. Recheck fluid level and add as

required. System is fully bled when no

more 'air bubbles appear in reservoir as

systerh is being cycled.

11.. CHECKING SYSTEM PRES-

SURE AND FLOW. The power

steering pump assembly incorporates a

pressure relief valve and a flow control

valve. System relief pressure and flow

should be as follows:

Early Late

Pump Pump

Pressure, psi ........... 650 650

Flow, gpm @ 1000 rpm . 3.5 2.74

To check 'system relief pressure,in-

stall..a "T" fitting in pressure line (19Fig. 5) at pump connection and connect

a 0-1000 psi gage to fitting. With the

engine running at 1000 RPM and the

front wheels turned against lock, gage

reading should be 600-700 psi.

7

Page 8

Paragraph 12

36

FORD

'0' RINGS

r

23

35 34 I

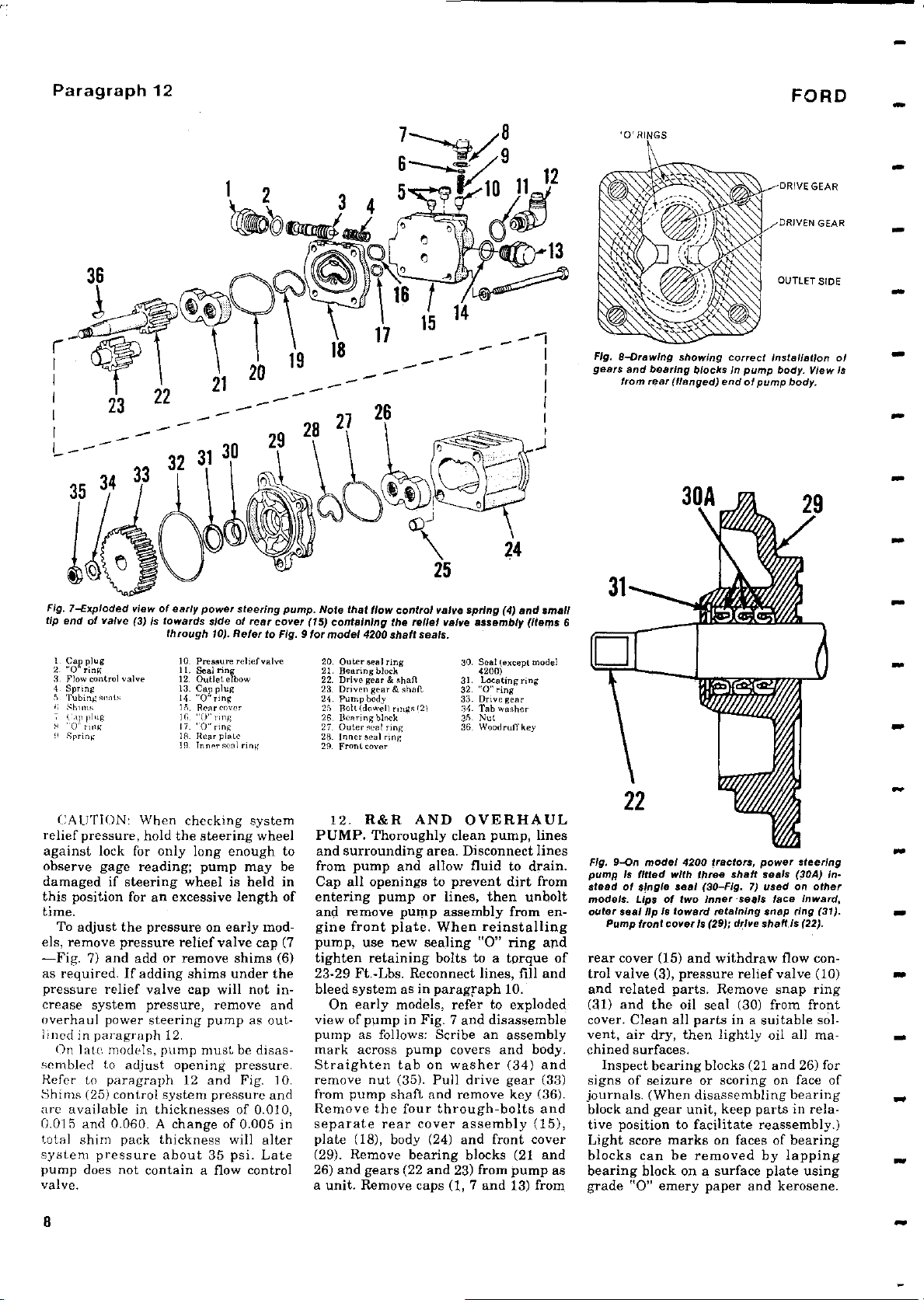

Fig. 7-Exploded

tip end of valve

I Cap plug

2. "0 ring

3. Flow control valve

4 Spring

5 Tubing .-Tt,

,Shims

Cap ping

0 ring

9 Spring

22

31 3,

29

view of early power steering pump

(

3) Is towards side of rear

through 10). Refer

10. Pressure reliefvalve

11.

Seal ring

12. Outlet elbow

13. Cap plug

14 "0" ring

15 Rearcover

10. !(.. ring

17 "0" ring

18 _ Rear plate

19. Inner seal ring

29 2

cover

Fig.

to

26

.

Note that

(

15) containing the relief valve

9 for

20. Outer seal ring

21. Bearing block

22. Drive or & shaft

23. Driven gear & shaft

24. Pump body

25 Bolt(dowelt rings 12(

26. Bearing black

27. Outer seal ring

28- Inner seal ring

29 Frontmver

model

flow control

4200 shaft

seals.

24

25

valve

(

spring

4) and small

assembly(Items 6

30. Seal (except model

4200)

31. Locating ring

32 '0" ring

33. Drive gear

84. Tab washer

35. Nut

36. Woodruff key

Fig. 8-Drawing showing

gears and bearing blocks

from rear

(

flanged

correct

Installation of

In pump body. View is

) end of pump body.

CAUTION: When

relief pressure

,

checking system

hold the steering wheel

against lock for only long enough to

observe gage reading; pump may be

damaged if steering wheel is held in

this position for an excessive length of

time.

To adjust the pressure on early mod-

els, remove pressure relief valve cap (7

-Fig. 7

as required

)

and add or remove shims (6)

.

If adding shims under the

pressure relief valve cap will not increase system pressure

,

remove and

overhaul power steering pump as outlined in paragraph 12.

On late models,

sembled to

Refe

r to paragraph 12 and Fig. 10.

Shims (

25) control system pressure and

pump must be disas-

adjust opening pressure.

are available in thicknesses of 0.010,

0.015 and 0.060

.

A change of 0.005 in

total shim pack thickness will alter

system pressure about 35 psi. Late

pump does not contain a flow control

valve.

8

12. R&R AND OVERHAUL

PUMP. Thoroughly clean pump, lines

and surrounding area. Disconnect lines

from pump and allow fluid to drain.

Cap all openings to prevent dirt from

entering pump or lines, then unbolt

and remove pump assembly from engine front plate. When reinstalling

pump, use new sealing "0" ring and

tighten retaining bolts to a torque of

23-29 Ft.-Lbs. Reconnect lines, fill and

bleed system as in paragraph 10.

On early models, refer to exploded

view of pump in Fig. 7 and disassemble

pump as follows: Scribe an assembly

mark across pump covers and body.

Straighten tab on washer (34) and

remove nut (35). Pull drive gear (33)

from pump shaft and remove key (36).

Remove the four through-bolts and

separate rear cover assembly (15),

plate (18), body (24) and front cover

(29). Remove bearing blocks (21 and

26) and gears (22 and 23) from pump as

a unit. Remove caps (1, 7 and 13) from

Fig,

pump Is fitted with

stead

models

outer seal

model 4200

9-On

of single seal (30

Lips of two

.

lip Is toward retaining snap ring (31).

Pump front cover Is

tractors

shaft

three

Fig.

-

Innerseals face

29);

drive shaft is (22).

(

,

power steering

seals

7) used on

rear cover (15) and withdraw flow control valve (3), pressure relief valve (10)

and related parts. Remove snap ring

(31) and the oil seal (30) from front

cover. Clean all parts in a suitable solvent, air dry, then lightly oil all machined surfaces.

Inspect bearing blocks (21 and 26) for

signs of seizure or scoring on face of

journals. (When disassembling bearing

block and gear unit, keep parts in rela-

tive position to facilitate reassembly.)

Light score marks on faces of bearing

blocks can be removed by lapping

bearing block on a surface plate using

grade "0" emery paper and kerosene.

(

30A) in-

other

Inward,

Page 9

2000

3000-4000

-

Paragraphs 13-16

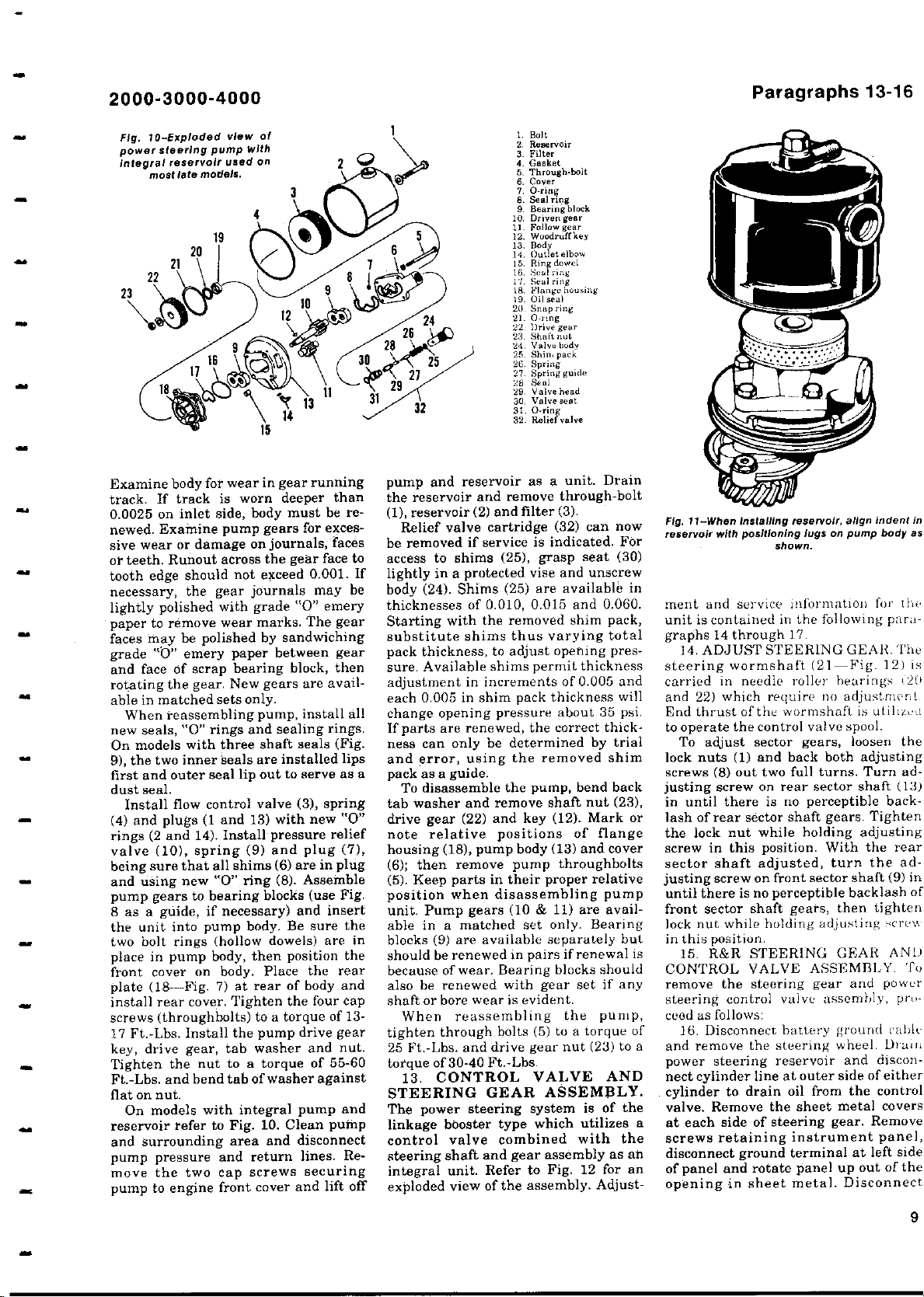

Fig. 10-Exploded

steering

power

integral reservoir used

most

late

view of

pump With

models.

on

Examine body for wear in gear running

track. If track is worn deeper than

0.0025 on inlet side, body must be renewed. Examine pump gears for exces-

sive wear or damage on journals, faces

or teeth. Runout across the gear face to

tooth edge should not exceed 0.001. If

necessary, the gear journals may be

lightly polished with grade "0" emery

paper to remove wear marks. The gear

faces may be polished by sandwiching

grade "0" emery paper between gear

and face of scrap bearing block, then

rotating the gear. New gears are avail-

able in matched sets only.

When reassembling pump, install all

new seals, "0" rings and sealing rings.

On models with three shaft seals (Fig.

are installed lips

9), the two inner

seals

first and outer seal lip out to serve as a

dust seal.

Install flow control valve (3), spring

(4) and plugs (1 and 13) with new "0"

rings (2 and 14). Install pressure relief

valve (10), spring (9) and plug (7),

being sure that all shims (6) are in plug

and using new "0" ring (8). Assemble

pump gears to bearing blocks (use Fig.

8 as a guide, if necessary) and insert

the unit into pump body. Be sure the

two bolt rings (hollow dowels) are in

place in pump body, then position the

front cover on body. Place the rear

plate (18-Fig. 7) at rear of body and

install rear cover. Tighten the four cap

screws (throughbolts) to a torque of 13-

17 Ft.-Lbs. Install the pump drive gear

key, drive gear, tab washer and nut.

Tighten the nut to a torque of 55-60

Ft.-Lbs. and bend tab of washer against

flat on nut.

On models with integral pump and

reservoir refer to Fig. 10. Clean pump

and surrounding area and disconnect

pump pressure and return lines. Remove the two cap screws securing

pump to engine front cover and lift off

1. Bolt

2, Reservoir

3. Filter

4. Gaeket

5. Through-bolt

6. Cover

7. O-ring

8. Seal nng

9. Bearing block

10. Driven gear

1I. Follow gear

12. Woodruffkey

13. Body

14. Outlet elbow

15. Ring dowel

16..Seal ring

17 . Seal ring

16. Flange'casing

10. Oil seal

20. Snap ring

21. O-ring

22 Drive gear

23, Shot, not

24. Valve hody

25. Shin, park

26. Spring

27 . Spring guide

28 Seal

29. Valve head

30. valve seat

31. O-ring

32. Relief valve

pump and reservoir as a unit. Drain

the reservoir and remove through-bolt

(1), reservoir (2) and filter (3).

Relief valve cartridge (32) can now

be removed if service is indicated. For

access to shims (25), grasp seat (30)

lightly in a protected vise and unscrew

body (24). Shims (25) are available in

thicknesses of 0.010, 0.015 and 0.060.

Starting with the removed shim pack,

substitute shims thus varying total

pack thickness, to adjust opening pressure. Available shims permit thickness

adjustment in increments of 0.005 and

each 0.005 in shim pack thickness will

change opening pressure about 35 psi.

If parts are renewed, the correct thickness can only be determined by trial

and error, using the removed shim

pack as a guide.

To disassemble the pump, bend back

tab washer and remove shaft nut (23),

drive gear (22) and key (12). Mark or

note relative positions of flange

housing (18), pump body (13) and cover

(6); then remove pump throughbolts

(5). Keep parts in their proper relative

position when disassembling pump

unit. Pump gears (10 & 11) are available in a matched set only. Bearing

blocks (9) are available separately but

should be renewed in pairs if renewal is

because of wear. Bearing blocks should

also be renewed with gear set if any

shaft or bore wear is evident.

When reassembling the pump,

tighten through bolts (5) to a torque of

25 Ft.-Lbs. and drive gear nut (23) to a

torque of 30-40 Ft.-Lbs.

13, CONTROL VALVE AND

STEERING GEAR ASSEMBLY.

The power steering system is of the

linkage booster type which

control valve combined with the

steering shaft and gear assembly as an

integral unit. Refer to Fig. 12 for an

exploded view of the assembly. Adjust-

utilizes a

align indent in

Fig.

11

reservoir with positioning lugs

-

When

Installing

shown.

reservoir

,

pump body as

on

ment and service information for thr

unit is contained

graphs 14

in the following para-

through 17.

14. ADJUST STEERING GEAR. The

steering

carried in

and 22

End thrust

to operate the control

To adjust sector gears

lock nuts

screws

wormshaft (21-Fig. 12) is

needle roller hearings i20

) which require no adjustment

of the wormshaft is utiliz,,il

valve spool.

loosen the

1) and back both adjusting

(

8) out two full turns. Turn ad-

(

,

justing screw on rear sector shaft (13)

in until there is no perceptible backlash of rear sector shaft gears.

the lock nut while holding adjusting

screw in this position

sector shaft adjusted

. With the rear

,

turn the ad-

justing screw on front sector shaft (9) in

until there is no perceptible backlash of

then tighten

front sector shaft gears

,

lock nut while holding adjusting scre,'

in this position.

15. R&R

STEERING GEAR AND

CONTROL VALVE ASSEMBLY. To

remove the steering

steering

control valve assembly, prt,-

gear and power

ceod as follows:

16. Disconnect

and remove

battery ground cable

the steering wheel. Drai1:

power steering reservoir and disconnect cylinder line at outer side of either

cylinder to drain oil from the control

Remove the sheet metal covers

.

valve

at each side of steering gear

.

screws retaining instrument panel,

disconnect ground terminal at left side

of panel and rotate panel up out of the

opening in sheet metal. Disconnect

Tighten

Remove

9

Page 10

Paragraphs 17-20

FORD

1 3 4

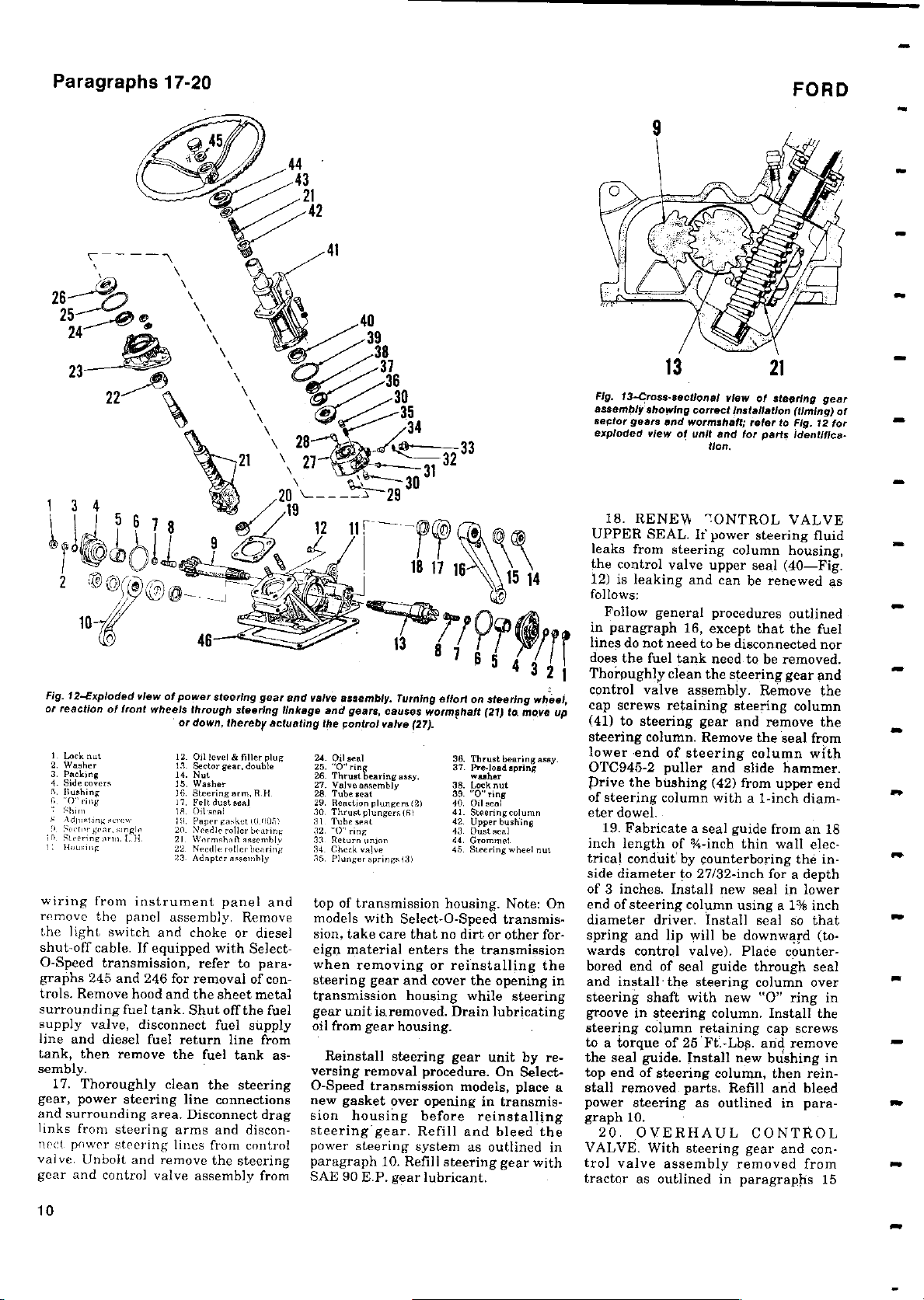

Fig. 12-Exploded view of power steering

or reaction of front wheels through

I buck nut 12

2. Washer 13

3. Packing 14. Nut

4. side covers 15. Washer

5. slushing 36

G. "0 "ring 17.

Shim 13. Ollaeal

S Adma-ring rvcw' IH. Paper "Ilk" 10 1051

9. Seeni'gea g 20. Needlr rollerben ink

Streri gnnnl..H. 21. Warns hallasacmbl

Housing 22 Needle roll crbaaring

wiring from instrument panel and

remove the panel assembly. Remove

the light switch and choke or diesel

shut-off cable. If equipped with SelectO-Speed transmission, refer to para-

graphs 245 and 246 for removal of controls. Remove hood and the sheet metal

surrounding fuel tank. Shut off the fuel

supply valve, disconnect fuel supply

line and diesel fuel return line from

tank, then remove the fuel tank as-

sembly.

17. Thoroughly clean the steering

gear, power steering line connections

and surrounding area. Disconnect drag

links from steering arms and disconnect power steering lines from control

valve. Unbolt and remove the steering

gear and control valve assembly from

or down,

.

Oil level & filler plug

.

Sector gear,double

.

Steering arm, Rit

Felt dust seal

23. Adapter assembly

gear and valve

steering

thereby

linkage and gears

actuating the control valve (27).

24. Oil seal

25. "0" ring

26. Thrust bearing asay,

27. Valve assembly

.

28. Tube seat

29. Reaction plungers (2)

30. Thrust plungers(61

31. Tubes,-at

32. "0"ring

33. Return union

34. Check valve

35. Plunger springs (.3)

top of transmission housing. Note: On

models with Select-O-Speed transmission, take care that no dirt or other foreign material enters the transmission

when removing or reinstalling the

steering gear and cover the opening in

transmission housing while steering

gear unit is.removed. Drain lubricating

oil from gear housing.

versing removal procedure. On SelectO-Speed transmission

new gasket over opening in transmission housing before reinstalling

steering gear. Refill and bleed the

power steering system as outlined in

paragraph 10. Refill steering gear with

SAE 90 E.P. gear lubricant.

assembly. Turning

,

causes

effort

on steering

wormshaft

38. Thrust bearing easy.

37. Pre.

.her

38. Lockout

39. "0" ring

40. Oil seal

41. Steeringculumn

42. Upper bushing

43 Dust seal

44. Grommel

45. Steering w heel nut

Reinstall steering gear unit by re-

models,place a

x

4 3 2 1

(21) to move

lad spring

wheel,

up

13

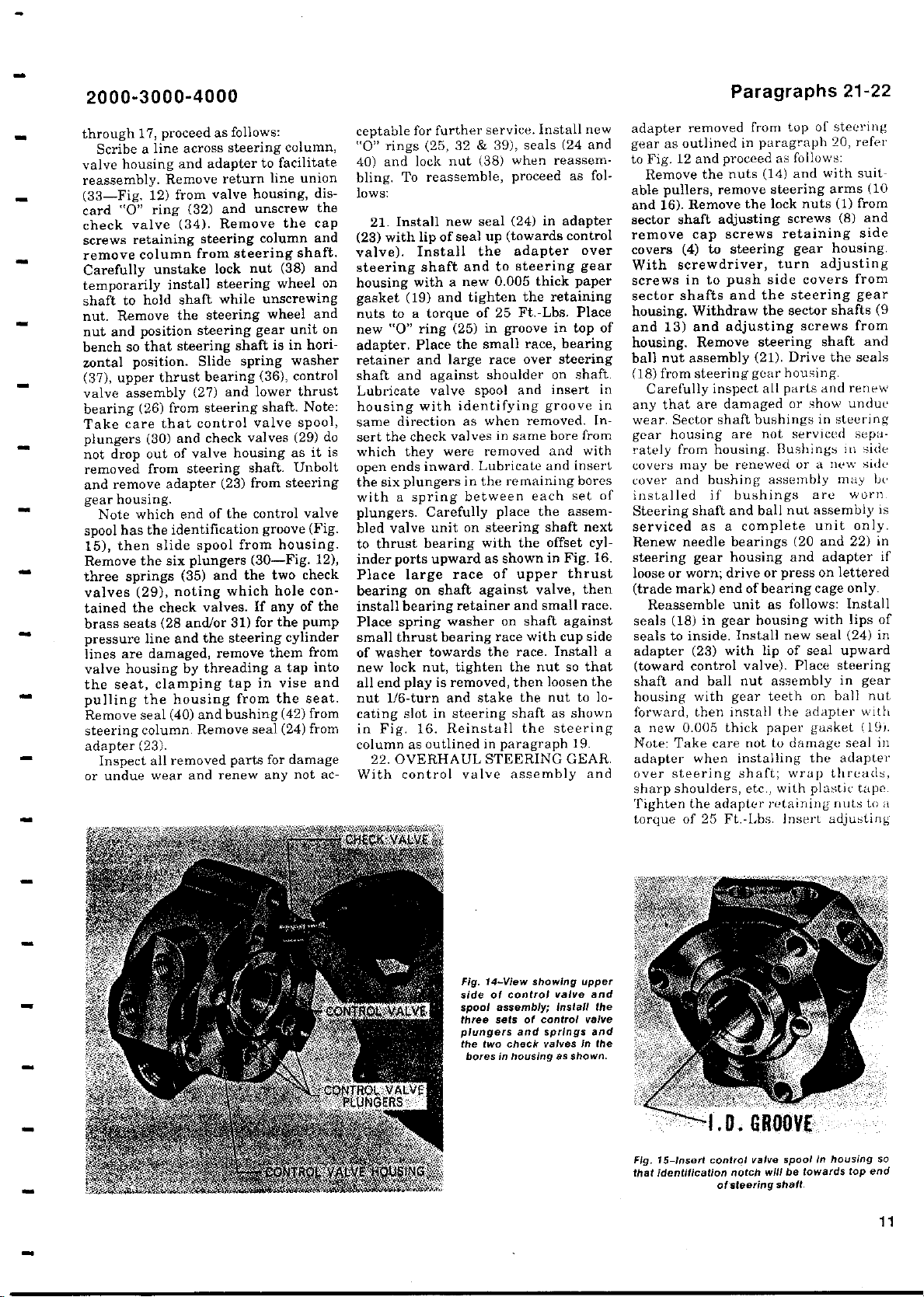

Fig.

13-Cross

-

assembly showing

sector gears

exploded view of unit and for parts Identfllca-

18. RENEFA

UPPER SEAL.

sectional

correct

and wormahaft

tion.

7ONTROL VALVE

If power steering fluid

21

view of steering gear

Installation

;

refer

to

leaks from steering column housing,

the control valve upper seal (40-Fig.

12) is leaking and can be renewed as

follows:

Follow general procedures outlined

in paragraph 16, except that the fuel

lines do not need to be disconnected nor

does the fuel tank need to be removed.

Thoroughly clean the steering gear and

control valve assembly

.

Remove the

cap screws retaining steering column

(41) to steering gear and remove the

steering column

lower

-

end of steering column with

.

Remove the seal from

OTC945-2 puller and slide hammer.

prive

the bushing

(

42) from upper end

of steering column with a 1-inch diameter dowel.

19. Fabricate a seal guide from an 18

inch

length of %-inch

thin

wall electrical conduit by counterboring the inside diameter to 27

of 3 inches

.

/

32-inch for a depth

Install new seal in lower

end of steering column using a 1% inch

diameter driver. Install seal so that

spring and lip will be downward (towards control valve

).

Place counterbored end of seal guide through seal

and install

'

the steering column over

steering shaft with new "0" ring in

groove in steering column

.

Install the

steering column retaining cap screws

to a torque of 25 Ft

.-

Lbs. and remove

the seal guide.Install new bushing in

top end of steering column

,

then reinstall removed parts. Refill and bleed

power steering as outlined in paragraph 10.

20. OVERHAUL CONTROL

VALVE. With

steering gear and con-

trol valve assembly removed from

tractor as outlined in paragraphs 15

(

timing) of

Fig. 12 for

w

•

M

10

Page 11

2000

3000-4000

-

Paragraphs 21-22

through 17, proceed as follows:

Scribe a line across steering column,

valve housing and adapter to facilitate

reassembly. Remove return line union

(33-Fig. 12) from valve housing, dis-

card "0" ring (32) and unscrew the

check valve (34). Remove the cap

screws retaining steering column and

remove column from steering shaft.

Carefully unstake lock nut (38) and

temporarily install steering wheel on

shaft to hold shaft while unscrewing

nut. Remove the steering wheel and

nut and position steering gear unit on

bench so that steering shaft is in hori-

zontal position. Slide spring washer

(37), upper thrust bearing (36), control

valve assembly (27) and lower thrust

bearing (26) from steering shaft. Note:

Take care that control valve spool,

plungers (30) and check valves (29) do

not drop out of valve housing as it is

removed from steering shaft. Unbolt

and remove adapter (23) from steering

gear housing.

Note which end of the control valve

spool has the identification groove (Fig.

15), then slide spool from housing.

Remove the six plungers (30-Fig. 12),

three springs (35) and the two check

valves (29), noting which hole contained the check valves. If any of the

brass seats (28 and/or 31) for the pump

pressure line and the steering cylinder

lines are damaged, remove them from

valve housing by threading a tap into

the seat, clamping tap in vise and

pulling the housing from the seat.

Remove seal (40) and bushing (42) from

steering column. Remove seal (24) from

adapter (23).

Inspect all removed parts for damage

or undue wear and renew any not ac-

ceptable for further service. Install new

"0" rings (25, 32 & 39), seals (24 and

40) and lock nut (38) when reassembling. To reassemble, proceed as follows:

21. Install new seal (24) in adapter

(23) with lip of seal up (towards control

valve). Install the adapter over

steering shaft and to steering gear

housing with a new 0.005 thick paper

gasket (19) and tighten the retaining

nuts to a torque of 25 Ft.-Lbs. Place

new "0" ring (25) in groove in top of

adapter. Place the small race, bearing

retainer and large race over steering

shaft and against shoulder on shaft.

Lubricate valve spool and insert in

housing with identifying groove in

same direction as when removed. Insert the check valves in same bore from

which they were removed and with

open ends inward. Lubricate and insert

the six plungers in the remaining bores

with a spring between each set of

plungers. Carefully place the assembled valve unit on steering shaft next

to thrust bearing with the offset cylinder ports upward as shown in Fig. 16.

Place large race of upper thrust

bearing on shaft against valve, then

install bearing retainer and small race.

Place spring washer on shaft against

small thrust bearing race with cup side

of washer towards the race. Install a

new lock nut, tighten the nut so that

all end play is removed, then loosen the

nut 1/6-turn and stake the nut to locating slot in steering shaft as shown

in Fig. 16. Reinstall the steering

column as outlined in paragraph 19.

22. OVERHAUL STEERING GEAR.

With control valve assembly and

adapter removed from top of steering

gear as outlined in paragraph 20, refer

to Fig. 12 and proceed as follows:

Remove the nuts (14) and with suit-

remove steering

able pullers

and 16). Remove

,

the lock nuts (1) from

sector shaft adjusting screws (8) and

remove cap screws retaining side

covers

With

screws in to

sector shafts and

housing

and 13

housing

ball nut assembly

4) to steering gear housing.

(

screwdriver

push

, turn adjusting

side covers from

the steering gear

. Withdraw

and adjusting screws from

)

Remove steering

.

the sector

(21). Drive the seals

(18) from steering gear housing.

Carefully inspect all parts and renew

any that are damaged or show undue

wear. Sector shaft bushings in steering

gear housing are not serviced separately from housing. Bushings in side

covers may be renewed or a new side

cover and bushing assembly may be

installed if bushings are worn.

Steering shaft and ball nut assembly is

serviced

Renew needle bearings

steering gear housing

loose or worn

(

trade

Reassemble

seals

seals to inside

as a complete unit only.

; drive or press on lettered

end of bearing

mark)

unit as follows:

18) in gear

(

. Install new seal (24) in

(20 and 22) in

and adapter if

housing with lips of

adapter (23) with lip of seal upward

(toward control valve). Place steering

shaft and ball nut assembly in gear

housing with gear teeth on ball nut

forward, then install the adapter with

a new 0.005 thick paper gasket (19).

Note: Take care not to damage seal in

adapter when installing the adapter

over steering shaft; wrap threads,

sharp shoulders, etc., with plastic tape.

Tighten the adapter retaining nuts to a

torque of 25 Ft.-Lbs. Insert adjusting

arms (10

shafts (9

shaft and

cage only.

Install

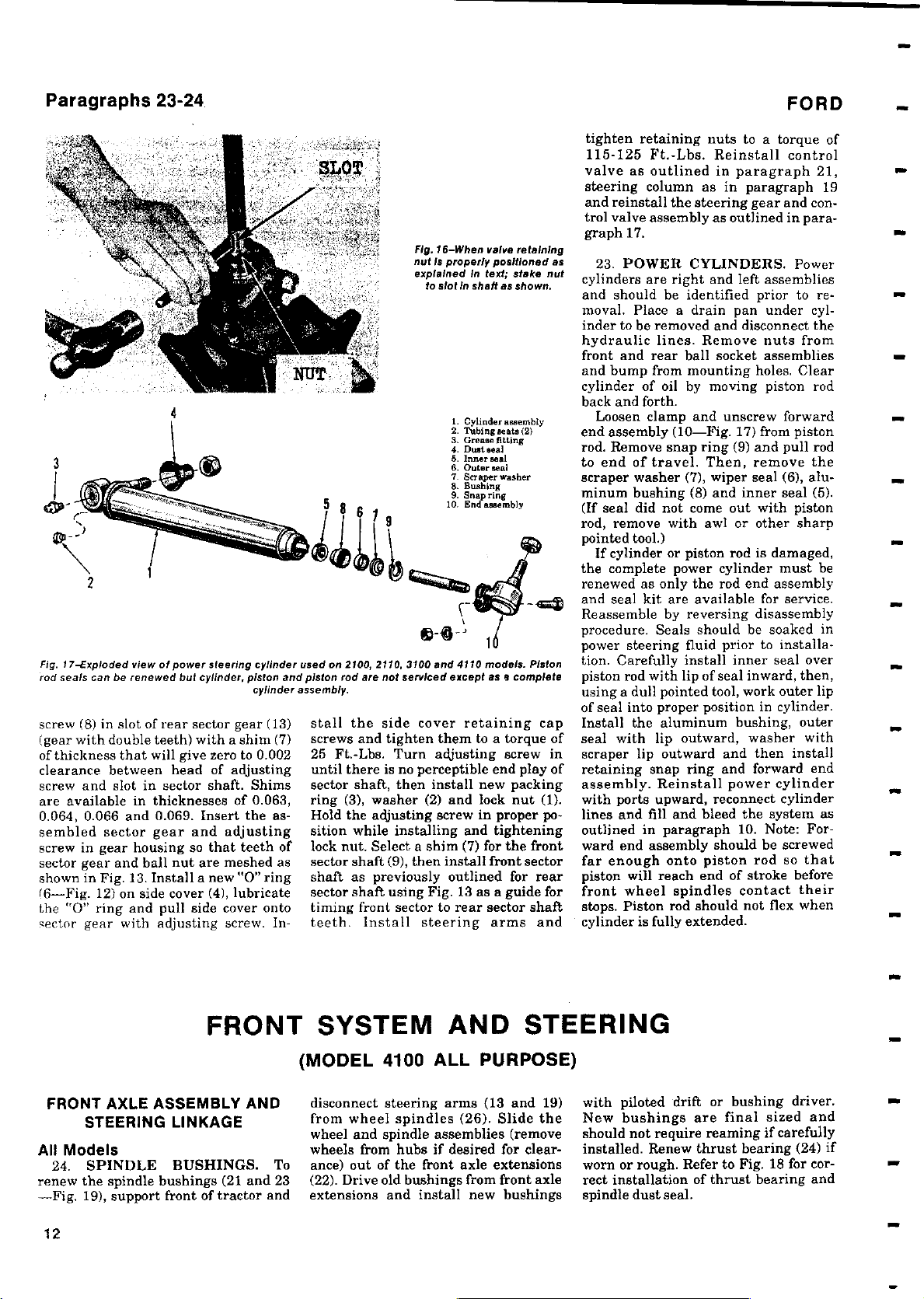

Fig. 14-View

side of control

spool assembly;Install

three sets of control

plungers and springs and

the two check

bores

showing

in housing

valve and

valves in the

as shown.

upper

valve

the

Fig. 15-Insert

that

identification

control

notch

of steering

valve

will be

spool in housing

towards

shaft.

top end

so

11

Page 12

Paragraphs 23-24

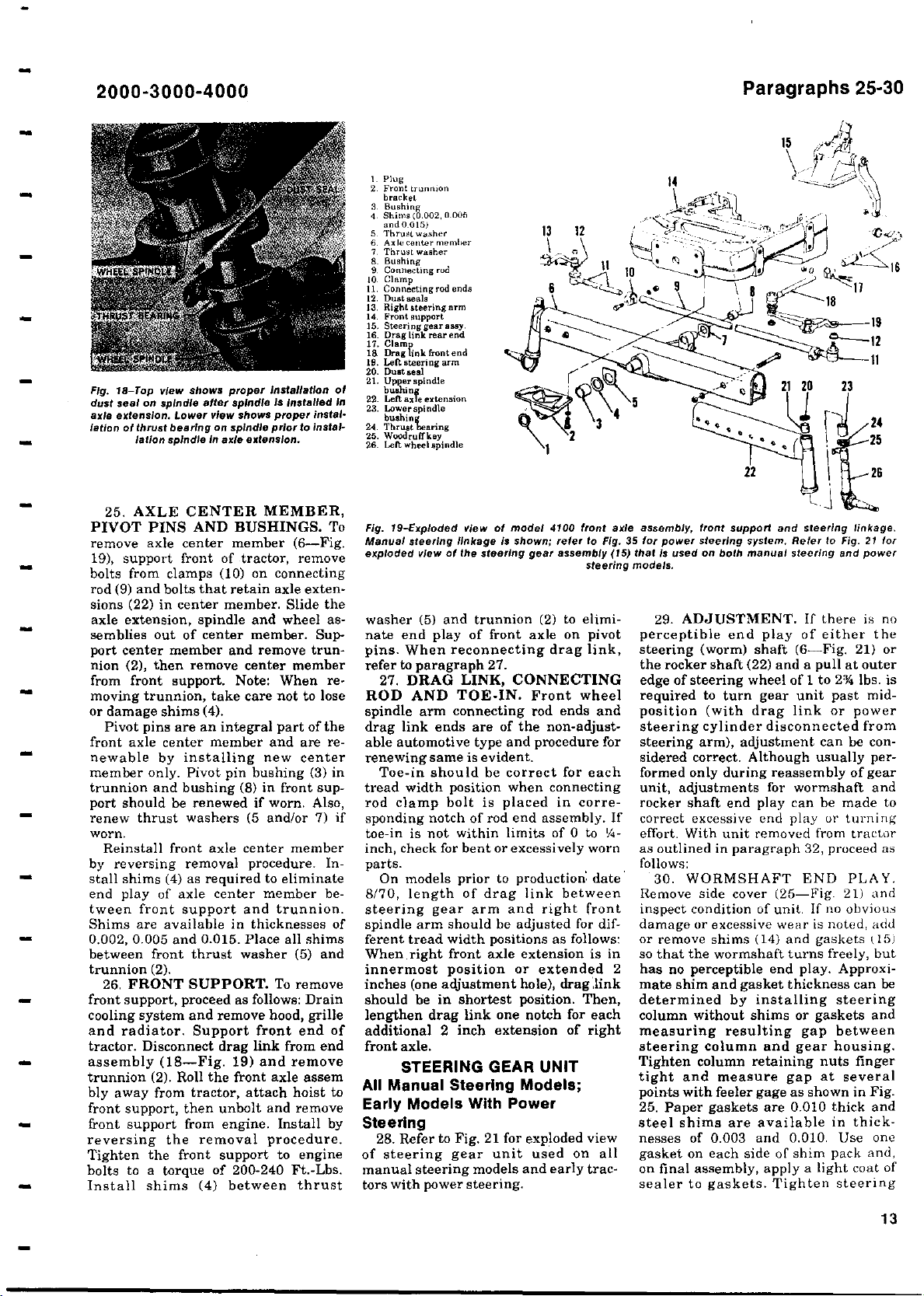

Fig. 17-Exploded view

rod

seals can be

screw (

8) in slot of rear sector gear (13)

(gear with double teeth

of thickness

clearance between head of adjusting

screw and slot in sector shaft. Shims

are available in thicknesses of 0.063,

0.064,0.066 and 0

sembled sector gear and adjusting

screw in gear housing so that teeth of

sector gear and ball nut are meshed as

shown in Fig.13. Install a new

(6-Fig. 12)

the "0"

ring and pull side cover onto

sector gear with adjusting

of power steering cylinder used on 2100

renewed but

will give zero to 0.002

that

on side cover

cylinder,

) with

a shim (7)

.

069. Insert the as-

(

4), lubricate

screw. In-

piston and piston rod

cylinder assembly.

stall the side cover retaining cap

screws and tighten them to a torque of

25 Ft.-Lbs. Turn adjusting

until there is no perceptible end play of

sector shaft, then install new packing

ring

Hold the adjusting screw in proper po-

sition while installing and tightening

lock nut.

sector shaft

0" ring

"

shaft as previously outlined for rear

sector shaft using Fig. 13 as a guide for

timing

teeth.

Fig. 16

nut is properly positioned as

explained In

to slot

,

2110,3100 and

are not serviced

(

3), washer

(

2) and lock nut (1).

Select a shim

9), then install front sector

(

front

sector to rear sector shaft

Install steering arms and

-

When valve retaining

text; stake

In

shaft as

shown.

1. Cylinderaesembly

2. Tubing seats (2)

3. Grease fitting

4. Dust seal

5. Inner seal

6. Outer seal

7. scraper washer

8. Bushing

9. Sn7, ring

10. Enssembly

models.

Piston

4110

except as a complete

screw in

(

7) for the front

tighten retaining nuts to a torque of

115-125 Ft.-Lbs. Reinstall control

valve as outlined in paragraph 21,

steering column as in

and reinstall

the steering

trol valve assembly

graph 17.

nut

23. POWER CYLINDERS. Power

cylinders are right and left assemblies

and should be identified prior to removal. Place a drain pan under cylinder to be removed and disconnect the

hydraulic

lines.

front and rear ball

and bump from mounting holes. Clear

cylinder of oil by moving piston rod

back and forth.

Loosen clamp and unscrew forward

end assembly (10-Fig. 17) from piston

rod. Remove

snap ring

to end of travel. Then, remove the

scraper washer

(7), wiperseal (6), alu-

minum bushing (8) and inner

(If seal did

not come

rod, remove with awl or other sharp

pointed tool.)

If cylinder or piston

the complete power cylinder must be

renewed as only the rod end assembly

and seal kit are available for service.

Reassemble by reversing disassembly

procedure. Seals should be soaked in

power steering fluid prior to installation. Carefully

install inner

piston rod with lip of seal inward, then,

using a dull pointed tool, work outer lip

of seal into proper position in cylinder.

Install the

aluminum

seal with lip outward, washer with

scraper lip outward and then install

retaining

assembly.

snap ring and

Reinstall

with ports upward, reconnect cylinder

lines and fill and bleed the system as

outlined in

paragraph

ward end assembly

far enough

onto piston rod so that

piston will reach end

front wheel spindles contact their

. Piston rod should not flex when

stops

cylinder is fully extended.

FORD

paragraph 19

gear and con-

as outlined in para-

Remove nuts from

socket assemblies

(9) and pull rod

seal (5).

out with piston

rod is damaged,

seal over

bushing, outer

forward end

power cylinder

10. Note: For-

should be screwed

of stroke before

FRONT SYSTEM AND STEERING

FRONT AXLE

STEERING LINKAGE

All Models

24. SPINDLE BUSHINGS. To

renew the spindle bushings (21 and 23

-Fig. 19), support front of tractor and

12

ASSEMBLY AND

(MODEL 4100 ALL PURPOSE)

disconnect steering arms (13 and 19)

from wheel spindles (26). Slide the

wheel and spindle assemblies (remove

wheels from hubs if desired for clearance) out of the front axle

(22). Drive old bushings from front axle

extensions and install new bushings

extensions

with piloted drift or bushing driver.

New bushings are final sized and

should not require reaming

installed

worn or rough

rect installation

. Renew thrust bearing (24) if

. Refer to Fig. 18 for cor-

of thrust bearing and

spindle dust seal.

if carefully

Page 13

-

2000

Fig. 18

dust seal on

axle extension

lation

3000-4000

Top view

-

of thrust

lation spindle In axle

proper installation of

shows

spindle is Installed in

after

spindle

Lower

view

.

bearingonspindle prior

shows

extension.

proper instal-

to instal-

1. Plug

2. Front trunnion

bracket

3. Bushing

4. Shim. (0.002, 0 006

and 0.015)

5. 'throat washer

6. Axle center member

7. Thrust washer

S. Bushing

9. Connecting rod

0. Clamp

1

11. Connecting rod end.

12. Dust ..Is

13. Right steering arm

14. Front support

15, Steering gear assy.

16. Drag link rear end

17. Clamp

1a Drag link front end

19. Left steering arm

20. Dust seal

21. Upper spindle

bushing

22. Left axle extension

23. Lower spindle

bushing

24. Thrust bearing

25. Woodruttkey

26. Left wheel spindle

Paragraphs 25-30

25. AXLE CENTER

MEMBER,

PIVOT PINS AND BUSHINGS. To

remove axle center member (6-Fig.

19), support front of tractor, remove

bolts from clamps (10) on connecting

rod (9) and bolts that retain axle exten-

sions

(22) in center member. Slide the

axle extension

semblies

port center member and

(2), then remove

nion

,

spindle and

out of center member. Sup-

remove trun-

center member

from front support. Note: When removing trunnion, take

care

or damage shims (4).

Pivot pins

are an integral

front axle center member and are renewable by installing new center

member only. Pivot pin bushing (3) in

trunnion and bushing (8) in front support should be renewed if worn, Also,

renew thrust washers (5 and/or 7) if

worn.

Reinstall front axle center member

by reversing removal procedure. Install shims (4) as required to eliminate

end play of axle center member between front support and trunnion.

Shims are available in thicknesses of

0.002, 0.005 and 0.015. Place all shims

between front thrust washer (5) and

trunnion (2).

26, FRONT SUPPORT. To remove

front support, proceed as follows: Drain

cooling system and remove hood,

and radiator. Support front end of

tractor. Disconnect

assembly (18-Fig.

trunnion (2). Roll the front

drag link from end

19) and remove

axle assem

bly away from tractor, attach hoist to

front support, then unbolt and remove

front support from engine. Install by

reversing the removal procedure.

Tighten the front support to engine

bolts to a torque of 200-240 Ft.-Lbs.

Install shims (4) between thrust

wheel as-

not to lose

part of the

grille

Fig. 19-Exploded view of model

Manual steering linkage is

exploded view

of the steering gear

shown

4100

;

refer

washer (5) and trunnion (2) to eliminate end play of front axle on pivot

pins. When reconnecting drag link,

refer to paragraph 27.

27. DRAG LINK, CONNECTING

ROD AND TOE-IN. Front wheel

spindle arm connecting rod ends and

drag link ends are of the non-adjustable automotive type and procedure for

renewing same is evident.

Toe-in should be correct for each

tread width position when connecting

rod clamp bolt is placed in corresponding notch of rod end assembly. If

toe-in is not within limits of 0 to '/4inch, check for bent or excessively worn

parts.

On models prior to production date

8/70, length of drag link between

steering gear arm and right front

spindle arm should be adjusted for different tread width positions as follows:

When right front axle extension is in

innermost position or extended 2

inches (one adjustment hole), drag link

should be in shortest position. Then,

lengthen drag link one notch for each

additional 2 inch extension of right

front axle.

STEERING GEAR UNIT

All Manual Steering Models;

Early Models With Power

Steering

28. Refer to Fig. 21 for exploded view

of steering gear unit used on all

manual steering models and early tractors with power steering.

front axle assembly

to

Fig

assembly

steering

,

35 for

.

15) that is

(

models.

front support and

power

steering

used on both manual steering

system.Refer to Fig. 21 for

29. ADJUSTMENT. If there is no

perceptible end play of either the

steering (worm) shaft (6-Fig. 21) or

the rocker shaft (22) and a pull at outer

edge of steering wheel of 1 to 2% lbs. is

required to turn gear unit past midposition (with drag link or power

steering cylinder disconnected from

steering arm), adjustment can be considered correct. Although usually performed only during reassembly of gear

unit, adjustments for wormshaft and

rocker shaft end play can be made to

correct excessive end play or turning

effort. With unit removed from tractor

as outlined in paragraph 32, proceed as

follows:

30. WORMSHAFT END PLAY.

Remove side cover (25-Fig. 21) and

inspect condition of unit. If no obvious

damage or excessive wear is noted, add

or remove shims (14) and gaskets (15)

so that the wormshaft turns freely, but

has no perceptible end play. Approximate shim and gasket thickness can be

determined by installing steering

column without shims or gaskets and

measuring

resulting gap between

steering column and

Tighten column retaining nuts finger

tight and

measure gap

points with feeler gage as shown in Fig.

25. Paper gaskets are 0.010 thick and

steel shims are available in thicknesses of 0.003 and 0.010. Use one

gasket on each side of shim pack and,

on final assembly, apply a light coat of

sealer to gaskets. Tighten steering

steering linkage.

and power

gear housing.

at several

13

Page 14

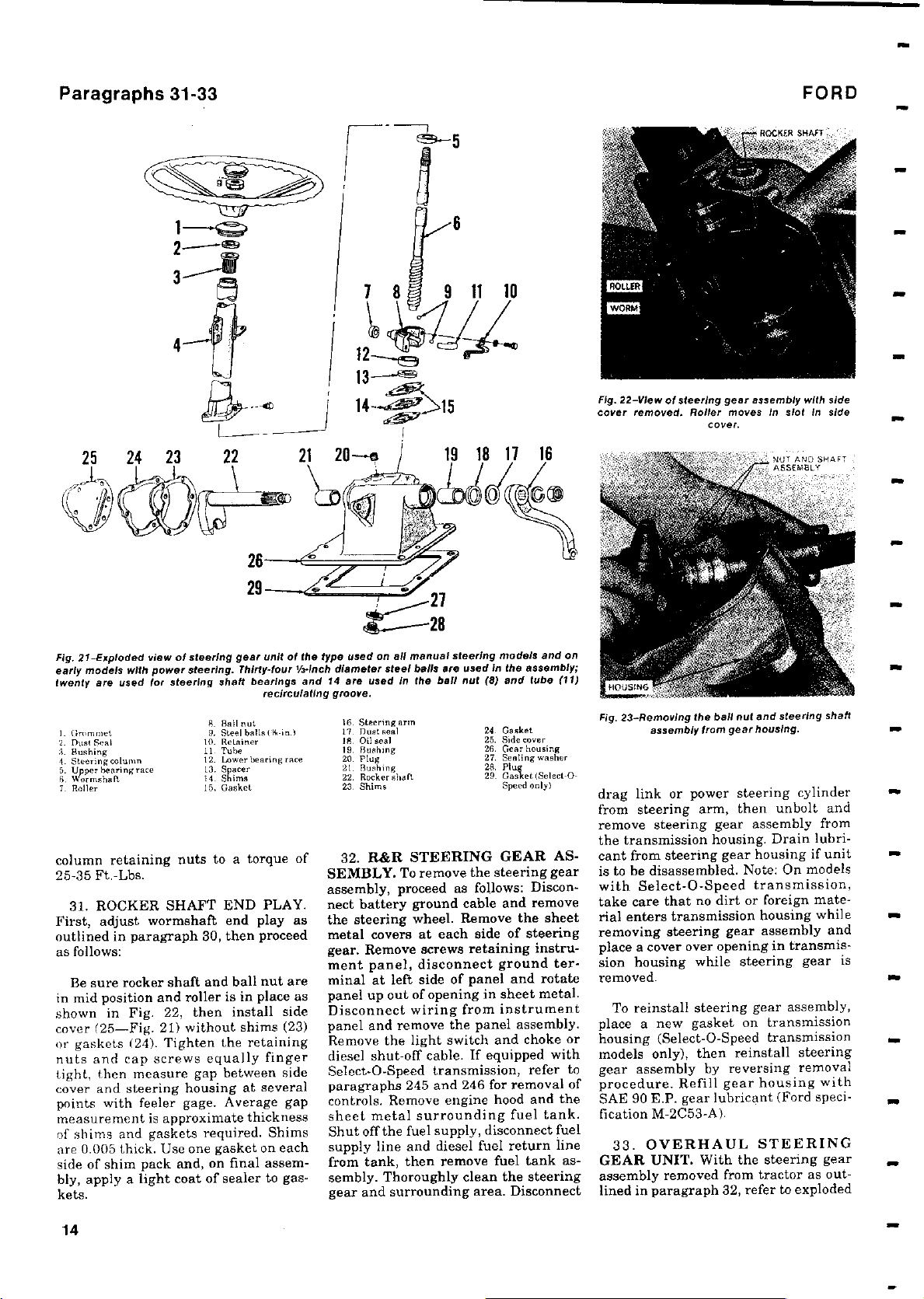

Paragraphs 31-33

3 9

FORD

25 24 23 22

-

Exploded view of steering gear

Fig. 21

early models

twenty

are used

I- Ore mmet

2 Dust Seal

Pushing

3

.

4 Steering column

per hearing race

U

.

p

5

6. RormsheR

7 Roller

column retaining nuts to a torque of

25-35 Ft.-Lbs.

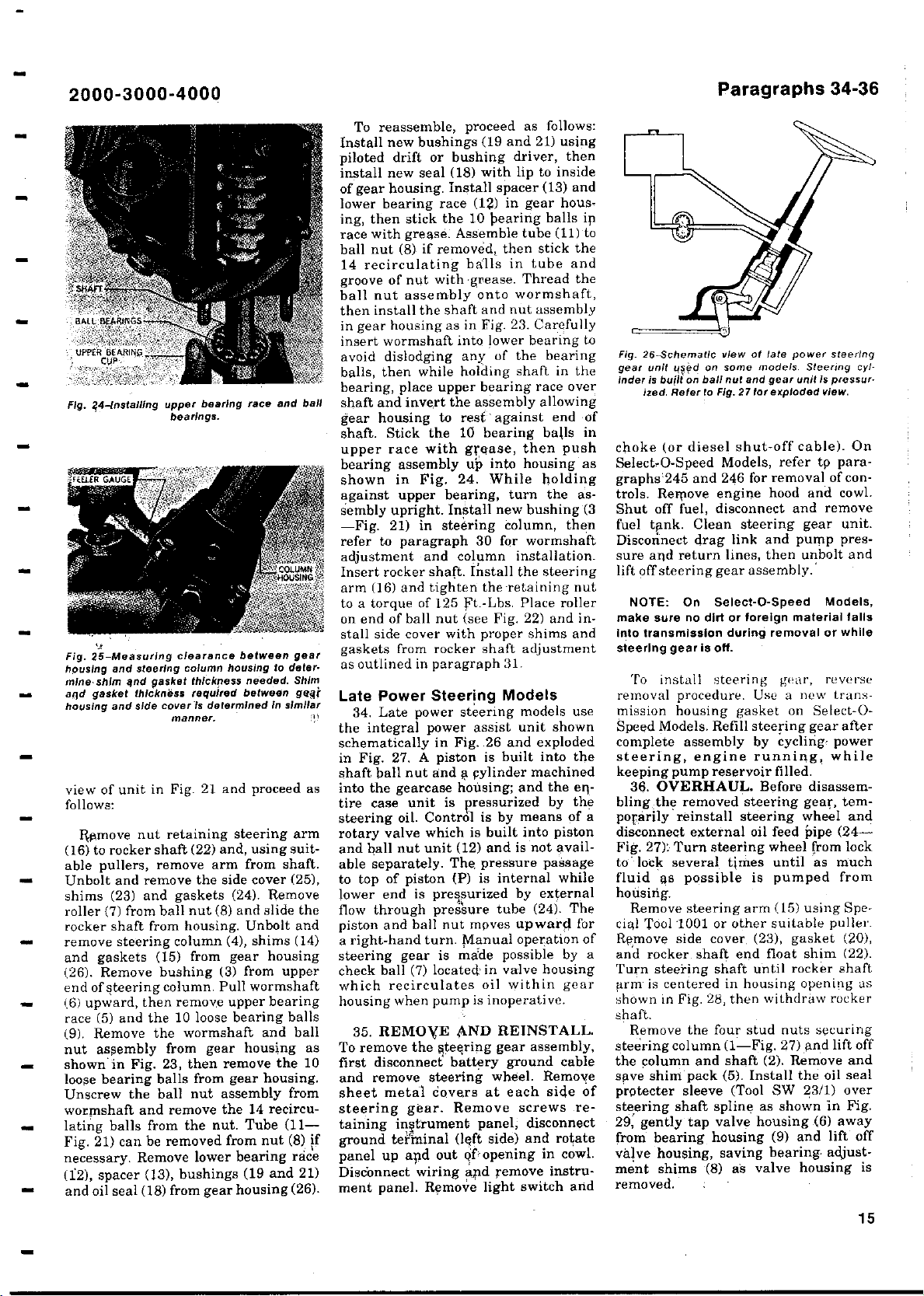

31. ROCKER SHAFT END PLAY.

First, adjust

outlined in paragraph 30, then proceed

as follows:

Be sure rocker shaft and ball nut are

in mid position and roller is in place as

shown in Fig. 22, then install side

cover (25-Fig. 21) without shims (23)

or gaskets (24). Tighten the retaining

nuts and cap screws equally finger

tight, then measure gap between side

cover and steering housing at several

points with feeler gage. Average gap

measurement is approximate thickness

of shims and gaskets required. Shims

are 0.005 thick. Use one gasket on each

side of shim pack and, on final assem-

bly, apply a light coat of sealer to gas-

kets.

power steering

with

for steering shaft bearings and 14

.

Thirty

8 Ball nut

9. Steel balls (*-inl

10

Retainer

.

11. Tube

12. Lower bearing race

13. Spacer

14. Shims

15. Gasket

wormahaft end play as

unit of the

four Vrinch diameter steel balls

-

recirculating groove.

type used on all manual

are used In

IS. Steering arm

Past seal

17.

Is.

Oil Real

19.

Flushing

20.

Plug

21.

Bushing

22.

Rocker shaft

23.

Shims

32. R&R STEERING

SEMBLY. To remove the

assembly, proceed as follows: Disconnect battery ground cable and remove

the steering wheel.

metal covers

Remove screws retaining

.

gear

ment panel

minal at left side of panel and rotate

panel up out of opening in sheet metal.

Disconnect wiring from instrument

panel and remove the panel assembly.

Remove the light switch and choke or

diesel shut-off cable. If equipped with

Select-O-Speed transmission, refer to

paragraphs 245 and 246 for removal of

controls. Remove engine hood and the

sheet metal surrounding fuel tank.

Shut off the fuel supply, disconnect fuel

supply line and diesel fuel return line

from tank, then remove fuel tank assembly. Thoroughly clean the steering

and surrounding

gear

19 18 11 16

steering

are used in

ball nut(8) and tube (11)

the

at each side

, disconnect ground ter-

models and on

24- Gasket

25. Side cover

Gear housing

.

26

27.

Sealing washer

28.

Plug

29-

Gasket (Select-O-

Speed only)

GEAR AS-

steering gear

Remove

area.

the assembly;

of steering

Disconnect

the sheet

instru-

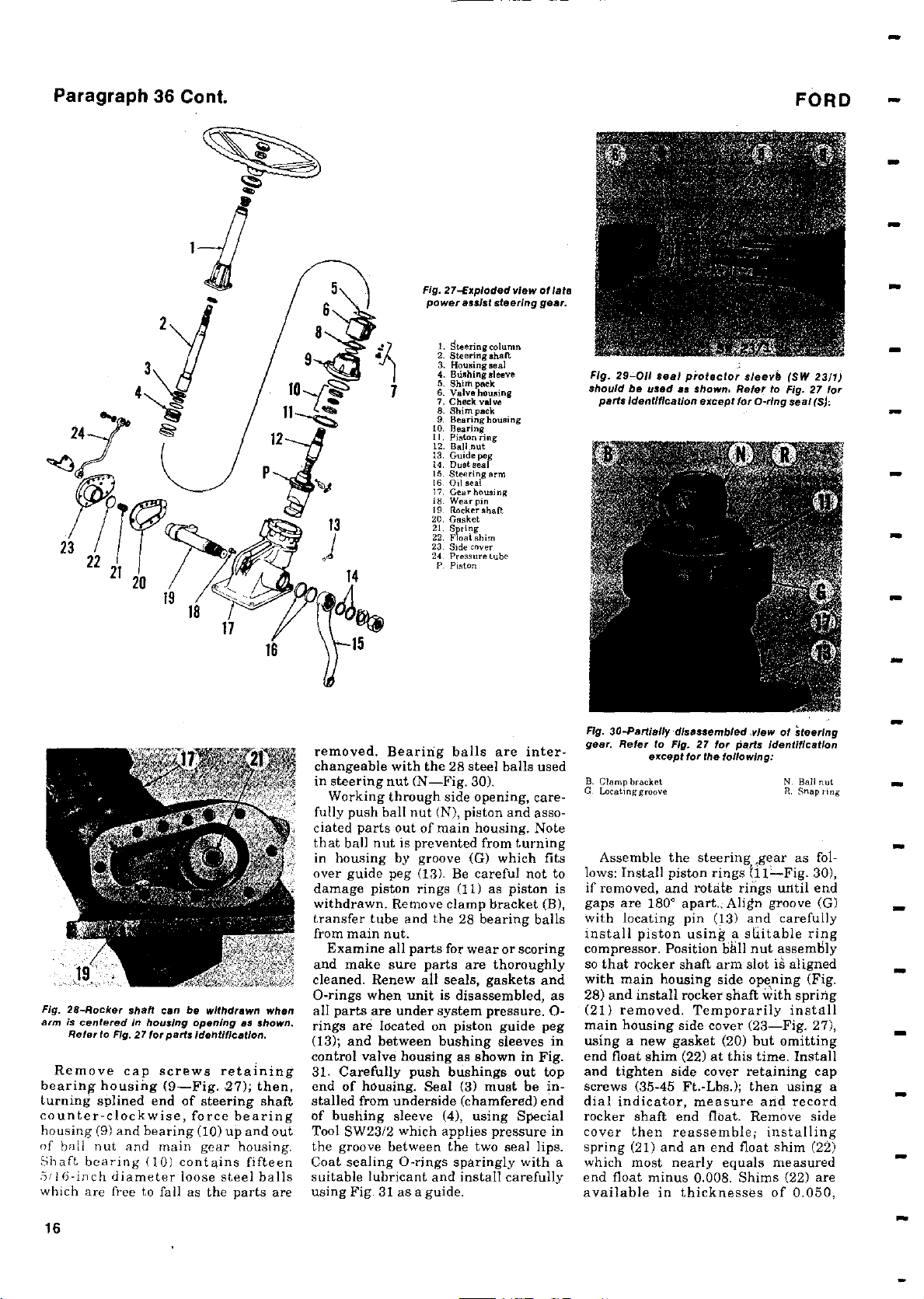

Fig. 22-View

cover removed

Removing

Fig. 23-

assembly from gear housing.

of steering

.

Roller

the ball

gear assembly with

moves in slot In side

cover.

nut and steering

drag link or power steering cylinder

from steering arm, then unbolt and

remove steering gear assembly from

the transmission housing. Drain lubricant from steering gear housing if unit

is to be disassembled. Note: On models

with Select-O-Speed transmission,

take care that no dirt or foreign mate-

rial enters transmission housing while

removing steering gear assembly and

place a cover over opening in transmission housing while steering gear is

removed.

To reinstall steering gear assembly,

place a new gasket on transmission

housing (Select-O-Speed transmission

models only), then reinstall steering

gear assembly by reversing removal

procedure. Refill gear housing with

SAE 90 E.P. gear lubricant (Ford speci-

fication M-2C53-A).

33. OVERHAUL STEERING

GEAR UNIT

. With

the steering gear

assembly removed from tractor as outlined in paragraph 32, refer to exploded

side

shaft

14

Page 15

2000

Fig. ?,4-Installing upper bearing

Fig. 25

housing

mine shim and

aqd gasket thickness

housing

3000-4000

-

bearings.

Measuring

-

and

steering

asket

g

and side cover is

manner.

clearance

column housing

thickness

required

between

determined

race

needed.

between gggj

view of unit in Fig. 21 and proceed as

follows:

Ramove nut retaining steering arm

(16) to rocker shaft (22) and, using suitable pullers, remove arm from shaft.

Unbolt and remove the side cover (25),

shims (23) and gaskets (24). Remove

roller (7) from ball nut (8) and slide the

rocker shaft from housing. Unbolt and

remove steering column (4), shims (14)

and gaskets (15) from gear housing

(26). Remove bushing (3) from upper

end of steering column. Pull wormshaft

(6) upward, then remove upper bearing

race (5) and the 10 loose bearing balls

(9). Remove the wormshaft and ball

nut assembly from gear housing as

shown*in Fig. 23, then remove the 10

loose bearing balls from gear housing.

Unscrew the ball nut assembly from

wormshaft and remove the 14 recirculating balls from the nut. Tube (11Fig. 21) can be removed from nut (8) if

necessary. Remove lower bearing race

(12), spacer (13), bushings (19 and 21)

and oil seal (18) from gear housing (26).

and ball

gear

to deter-

Shim

in

similar

To reassemble, proceed as follows:

Install new bushings (19 and 21) using

piloted drift or bushing driver, then

install new seal (18) with lip to inside

of gear housing. install spacer (13) and

lower bearing race (12) in gear housing, then stick the 10 bearing balls in

race with grease. Assemble tube (11) to

ball nut (8) if removed, then stick the

14 recirculating balls in tube and

groove of nut with grease. Thread the

ball nut assembly onto wormshaft,

then install the shaft and nut assembly

in gear housing as in Fig. 23. Carefully

insert wormshaft into lower bearing to

avoid dislodging any of the bearing

balls, then while holding shaft in the

bearing, place upper bearing race over

shaft and invert the assembly allowing

gear housing to rest against end of

shaft. Stick the 10 bearing balls in

upper race with grease, then push

bearing assembly up into housing as

shown in Fig. 24. While holding

against upper bearing, turn the as-

sembly upright. Install new bushing (3

-Fig. 21) in steering column, then

refer to paragraph 30 for wormshaft

adjustment and column installation.

Insert rocker shaft. Install the steering

arm (a6) and tighten theretaining nut

to a torque of 125 Ft.-Lbs. Place roller

on end of ball nut (see Fig. 22) and in-

stall side cover with proper shims and

gaskets from rocker shaft adjustment

as outlined in paragraph 31.

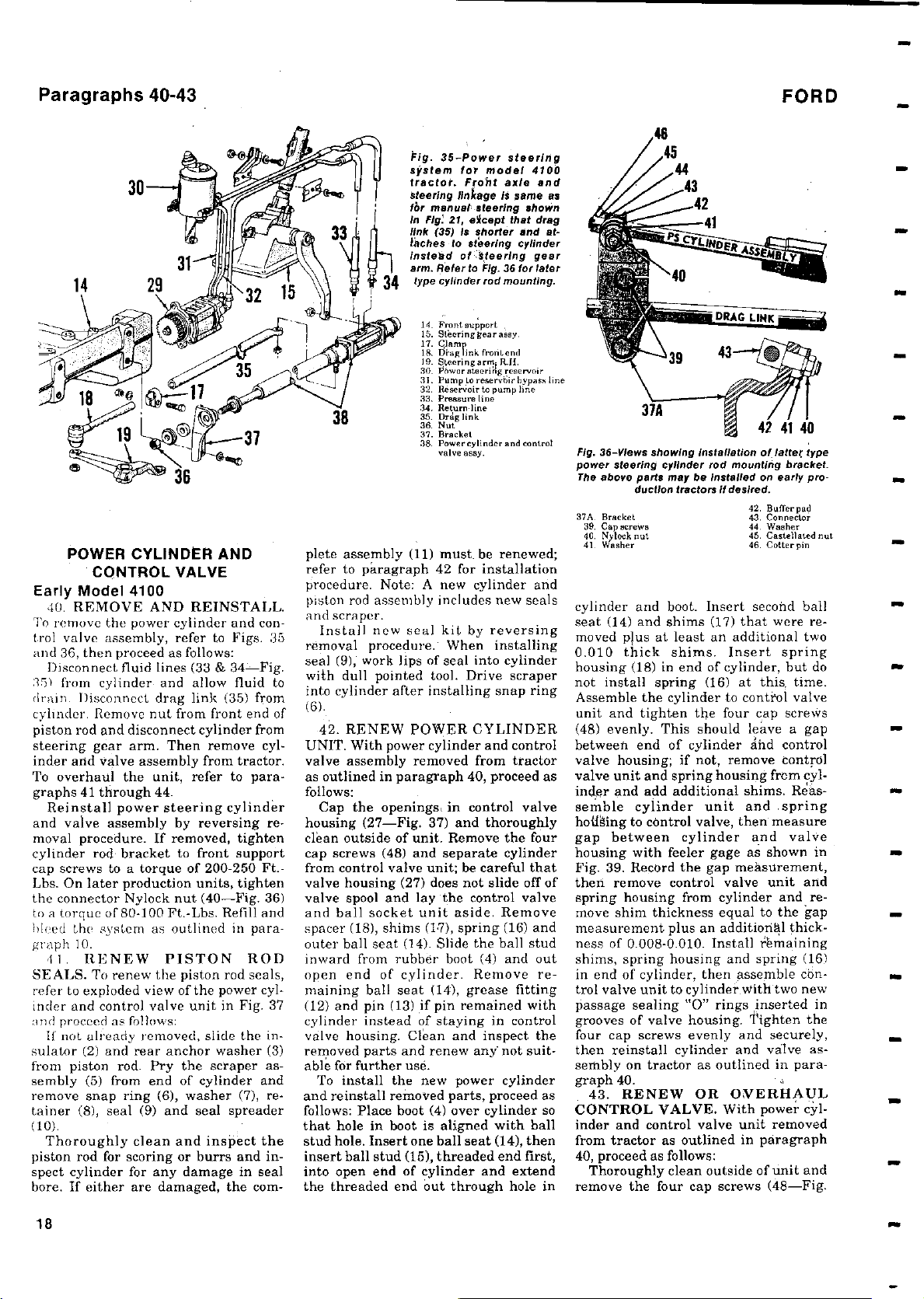

Late Power Steering Models

34. Late power steering models use

the integral power assist unit shown

schematically in Fig. 26 and exploded

in Fig. 27. A piston is built into the

shaft ball nut and a pylinder machined

into the gearcase housing; and the eqtire case unit is pressurized by the

steering oil. Control is by means of a

rotary valve which is built into piston

and ball nut unit (12) and is not available separately. The, pressure passage

to top of piston (P) is internal while

lower end is pressurized by external

flow through pressure tube (24). The

piston and ball nut moves upward for

a right-hand turn. Manual operation of

steering gear is made possible by a

check ball (7) located: in valve housing

which recirculates oil within gear

housing when pump is inoperative.

35. REMOVE AND REINSTALL.

To remove the Steering gear assembly,

first disconnect battery ground cable

and remove steering wheel. Remove

sheet metal covers at each side of

steering gear. Remove screws retaining inf

ground teAninal (left side) and rotate

panel up apd out ofopening in cowl.

Disconnect wiring and remove instru-

ment panel. Remove light switch and

ftrument panel, disconnect

Paragraphs 34-36

Fig.

26-Schematic

gear unit

inder is

used on some

built on

ized.Refer

choke (or diesel shut-off cable). On

Select-O-Speed Models, refer tp paragraphs`245 and 246 for removal of controls. Remove engine hood and cowl.

Shut off fuel, disconnect and remove

fuel tank. Clean steering gear unit.

Disconnect drag link and pump pressure and return lines, then unbolt and

lift off steering gear assembly.

NOTE: On Select-O-Speed Models,

make sure

Into transmission during removal

steering gear is off.

To install steering gear, reverse

removal procedure. Use a new transmission housing gasket on Select-OSpeed Models. Refill steering gear after

complete assembly by cycling- power

steering

keeping pump reservoir filled.

36. OVERHAUL. Before

blingthe removed steering gear, temporarily reinstall steering wheel and

disconnect external oil

Fig. 27): Turn

to _. lock

several

fluid as

housing.

Remove steering arm (15) using Special Tool -1001 or other suitable puller.

Remove side cover. (23), gasket (20),

and rocker shaft end float shim (22).

Turn steering shaft until rocker shaft

arm is centered in housing opening as

shown in Fig. 28, then withdraw rocker

shaft.

Remove the four stud nuts securing

steering column (1-Fig. 27) and lift off

the column and shaft (2). Remove and

save shim pack (5). Install the oil seal

protecter sleeve (Tool SW 23/1) over

steering

shaft spline as shown in Fig.

29, gently tap valve housing (6)

from bearing housing (9) and lift off

valve housing, saving bearing-adjust-

ment shims

removed.

viewoflate power steering

models.

ball nut and

to Fig.27

no dirt or foreign

gear

for exploded view.

, engine running, while

feed pipe (24-

steering

wheel from lock

times until as much

possible is

pumped from

(8) as valve

unit is pressur.

material falls

housing is

Steering

or while

disassem-

away

cyl-

15

Page 16

Paragraph

36 Cont.

FORD

Fig. 28

-

Rocker

arm is centered in housing opening as shown.

Refer

shaft can

to

Fig

.

27 for parts identification.

be withdrawn when

Remove cap screws retaining

bearing housing

(

9-Fig

. 2

7); then,

turning splined end of steering shaft

counter-clockwise

housing(9) and bearing

of ball nut and

Shaft bearing (

5'I6-inch diameter

,

force bearing

(

10) up and out

main gear housing.

10) contains fifteen

loose steel balls

which are free to fall as the parts are

Fig. 27-Exploded

power

assist steering

1. !iteeringcolumn

2. Steering shaft

3. Housing seal

4. Bushing above

5. Shish peck

6. Valve housing

7. Check valve

6. Shim pack

9. Bear., housing

10. Bearing

I I. Piston ring

12. Bali at

13. Guide peg

t4. nustseal

I5. Steering arm

16. Oil seal

17. over housing

Is. Wear pin

19. Backer shaft

20. Gasket

21. Spring

22. Float shim

23. Side cover

24. Pressure tube

P. Piston

removed

changeable

in steering

.

Bearing balls are inter-

with the

28 steel balls used

nut (N-Fig. 30).

Working through side opening, care-

fully push ball nut (N), piston and associated parts out of main housing. Note

that ball nut is prevented from turning

in housing by groove (G) which fits

over guide peg (13). Be careful not to

damage piston rings

(

11) as piston is

withdrawn. Remove clamp bracket (B),

transfer tube and the 28 bearing balls

from

main nut.

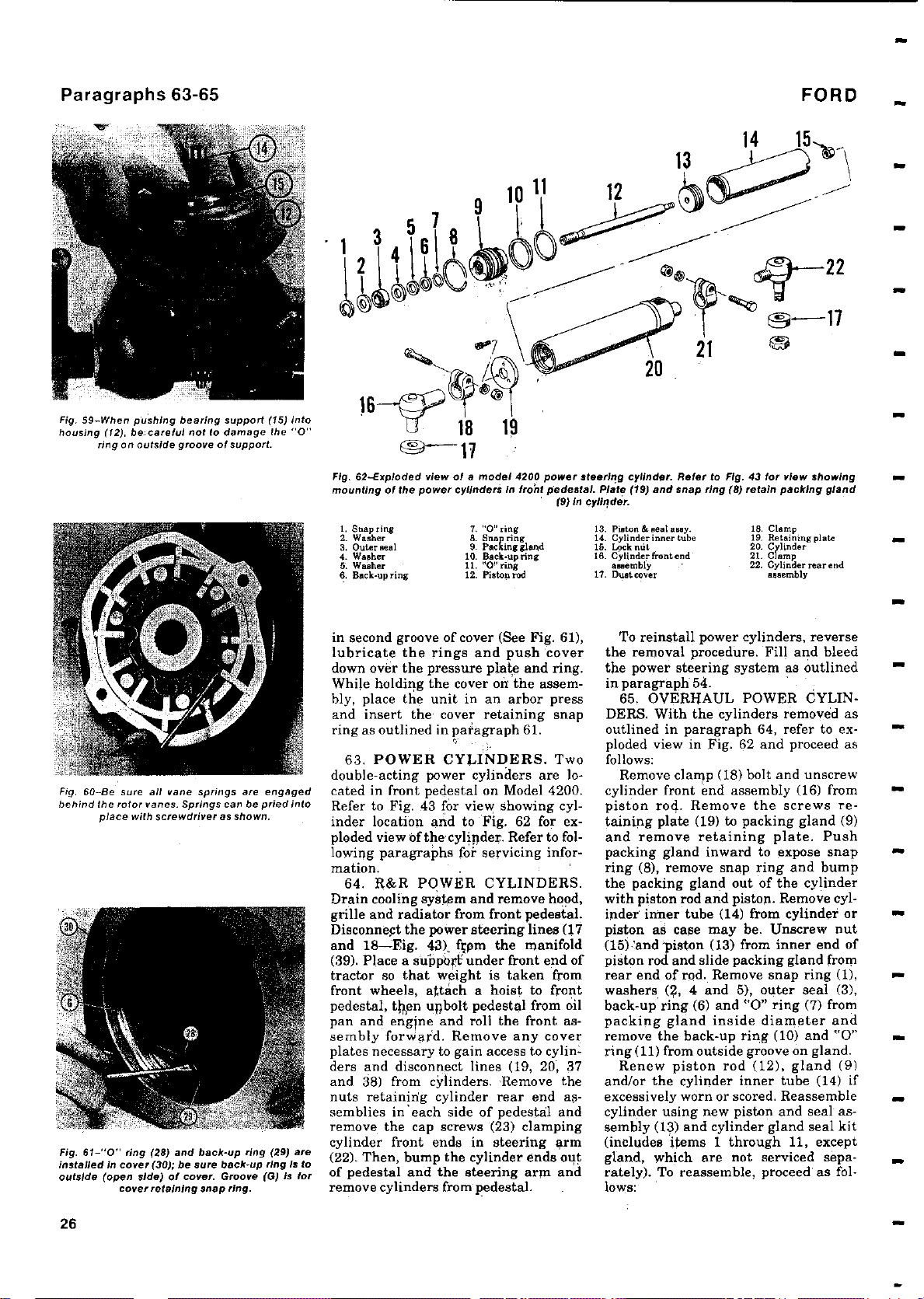

Examine all parts