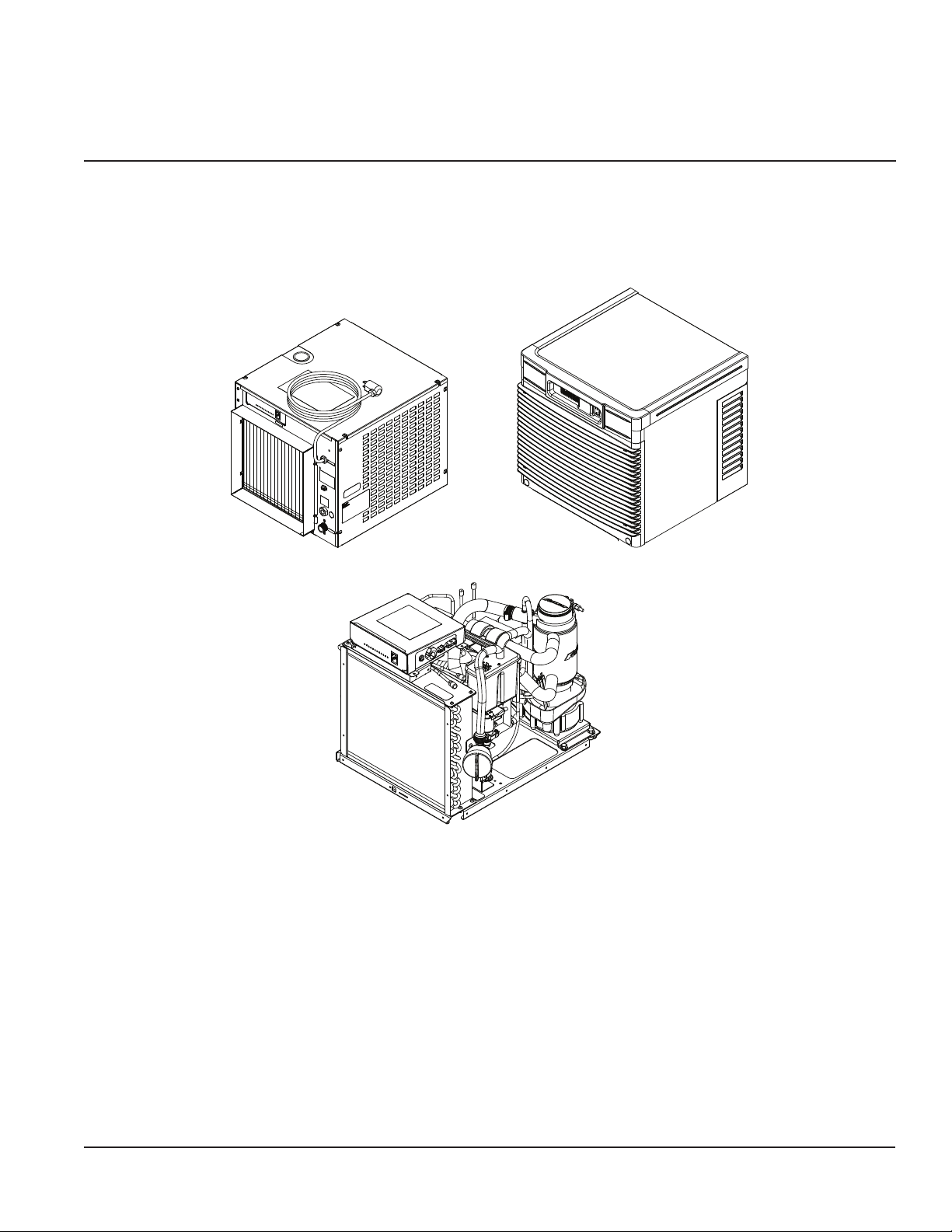

Follett MFD425WBT, MCD425WBT, MCD425WHT Installation Manual

MCD425A/W, R425A/W, MFD425A/W, P425A/W

Ice Machines

Installation, Operation and Service Manual

After serial number K39863

Please visit https://www.follettice.com/technicaldocuments

for the Operation and Service manual for your unit.

MCD425A/W_S

R425A/W

P425A/W

MCD425A/W_T

MFD425A/W_T

Welcome to Follett

Follett equipment enjoys a well-deserved reputation for excellent performance, long-term reliability and outstanding

after-the-sale support. To ensure that this equipment delivers that same degree of service, review this guide carefully

before you begin your installation.

Should you have need technical help, please call our Technical Service group at (877) 612-5086 or (610) 252-7301.

Please have your model number, serial number and complete and detailed explanation of the problem when

contacting Technical Service.

Getting Started

After uncrating and removing all packing material. Inspect the equipment for concealed shipping damage. All freight

is to be inspected upon delivery. If visible signs of damage exist, please refuse delivery or sign your delivery receipt

"damaged." Follett Customer Service must be notied within 48 hours. Wherever possible, please include detailed

photos of the damage with the original packaging so that we may start the freight claim process.

801 Church Lane • Easton, PA 18040, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

Installation and Service Videos:

www.follettice.com/servicevideolibrary

01234590R01

Contents

Welcome to Follett. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Getting Started ........................................................................... 1

Specications .............................................................................. 4

Electrical ................................................................................ 4

Plumbing ................................................................................ 4

Ambient ................................................................................. 4

Water usage (water-cooled condenser only) ....................................................4

Shipping weight .......................................................................... 4

Refrigeration pressure data ................................................................. 5

Compressor data ......................................................................... 5

Dimensions and clearances ................................................................. 6

Cleaning ................................................................................... 7

Weekly ................................................................................. 7

Monthly ................................................................................. 7

Semi-Annually (more often if conditions dictate) .................................................7

Service .................................................................................... 9

Ice machine Operation (all models) ........................................................... 9

Water system ........................................................................... 10

Electrical system ..........................................................................11

Electrical control system schematic .......................................................... 13

Electrical control system operation ........................................................... 13

Refrigeration system (all models) ............................................................ 24

Replacement parts ......................................................................... 28

Air-cooled skins assembly (MCD425A_S, R425A) .............................................. 28

Water-cooled skins assembly (MCD425W_S, R425W) ........................................... 29

Louvered docking station (MCD425A/W_T) .................................................... 30

Electrical components ....................................................................31

Evaporator ............................................................................. 32

Air-cooled ice machines ................................................................... 34

Air-cooled ice machines ................................................................... 35

Water-cooled ice machines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Water-cooled ice machines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Replacement ice machine ordering matrix ..................................................... 38

2 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

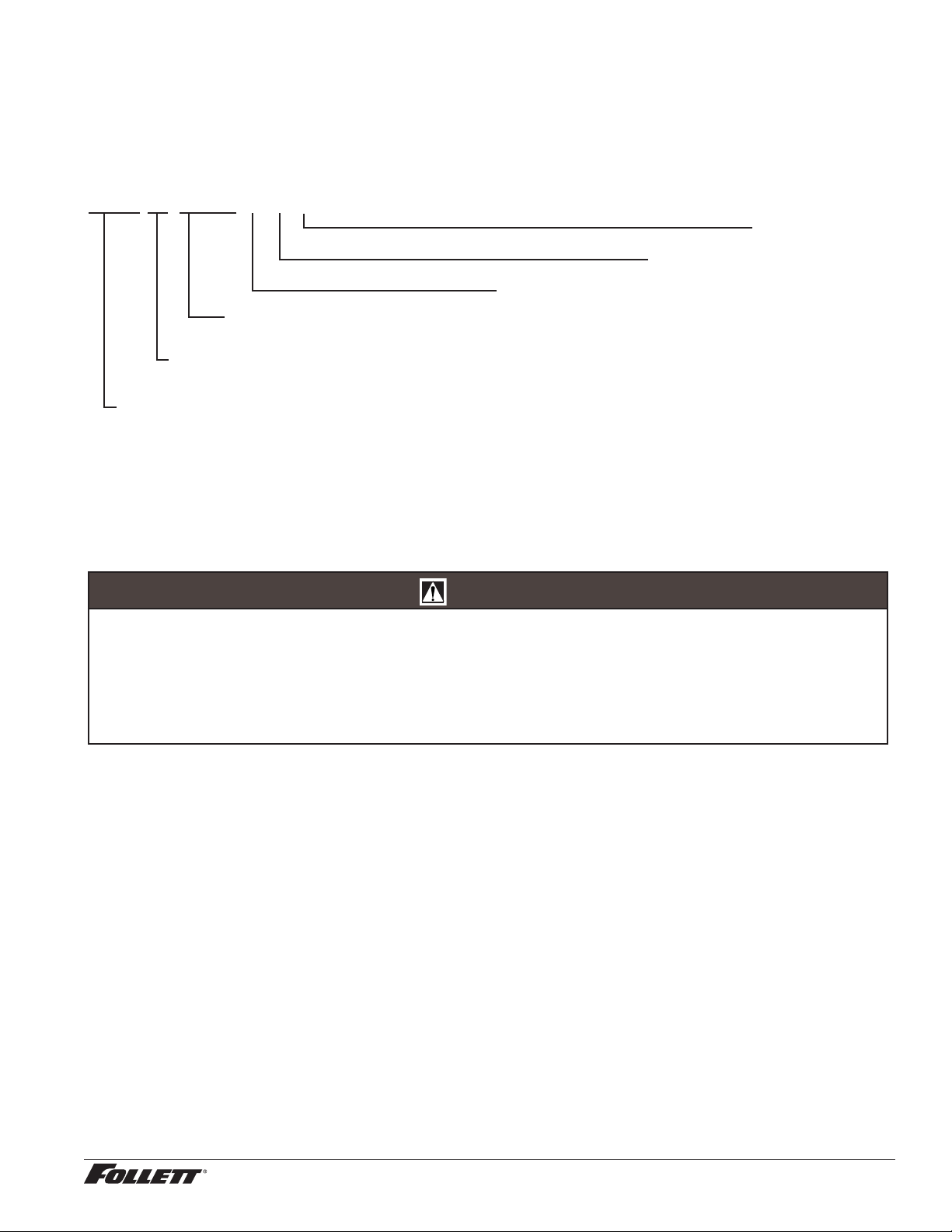

Check your paperwork to determine which model you have. Follett model numbers are designed to provide

MCD425ABT

Application

V – Vision

B – Bin

H – Harmony

Configuration

S – RIDE

®

T – top-mount

Ice machine capacity and refrigerant

400 – 425 lbs (193 kg)/day, R404A

Ice machine series

Nugget ice machine

Voltage

D – 115V 60Hz

Condenser type

A – air-cooled

W – water-cooled

MCD – RIDE model installation, Vision

™

ice and beverage dispensers and top installation, Follett ice storage bins

R – Remote installation, Symphony

™

ice and water dispensers

P – Replacement icemaker, Symphony ice and water dispensers

Flake ice machine

MFD – Top installation, Follett ice storage bins

information about the type and capacity of Follett equipment. Following is an explanation of the different model

numbers in the 425 series.

§ Moving parts. Do not operate with front cover removed.

§ Hot parts. Do not operate with cover removed.

§ To reduce risk of shock disconnect power before servicing.

§ Most ice machine cleaners contain citric or phosphoric acid, which can cause skin irritation. Read caution label

on product and follow instructions carefully.

§ Ice is slippery. Be sure counters and oors around dispenser are clean, dry and free of ice.

§ Ice is food. Follow recommended cleaning instructions to maintain cleanliness of delivered ice.

CAUTION!

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 3

Specications

Electrical

§ Each ice machine and dispenser requires a separate circuit with electrical disconnect within 10 ft (6 m).

§ Equipment ground required.

§ Standard electrical – 115 V, 60 Hz, 1 phase.

§ Connect to a dedicated 15A circuit.

§ Maximum ice machine amperage – 11A each.

§ Cord and plug provided on ice machine.

Plumbing

§ 3/8" FPT water inlet

§ 3/4" MPT drain

§ 3/8" FPT condenser inlet (water-cooled condenser only)

§ 3/8" FPT condenser drain (water-cooled condenser only)

Notes:

§ Slope to drain of 1/4" per foot (20 mm per 1 m run) with a 1/2" min. is recommended.

§ Water shut-off recommended within 10 feet (3 m), drain to be hard piped and insulated.

§ Separate drains for ice machine and condenser. To prevent back ow, do NOT connect drains.

§ Follett recommends a Follett water lter system be installed in the ice machine inlet water line (standard capacity

#00130229, high capacity #00978957, carbonless high capacity #01050442).

Ambient

Air temperature* 100 F/38 C max. 50 F/10 C min. (best performance below 80 F/27 C)

†

Water temperature

90 F/32 C max. 45 F/10 C min. (best performance below 70 F/21 C)

Water pressure 70 psi max. (482 kPA) 10 psi min. (68 kPA)

Condenser water

90 F/32.2 C max. 45 F/7.2 C min

temperature

Condenser water

125 psi (862 kPA) max. 10 psi (68 kPA) min.

pressure

*

Ambient air temperature is measured at the air-cooled condenser coil inlet.

†

Ambient water temperature is measured in the ice machine reservoir.

Water usage (water-cooled condenser only)

§ 0.25 gpm @ 50 F (10 C)

§ 0.5 gpm @ 70 F (21 C)

§ 1.25 gpm @ 90 F (32 C)

Shipping weight

§ 160 lb (73 kg)

4 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

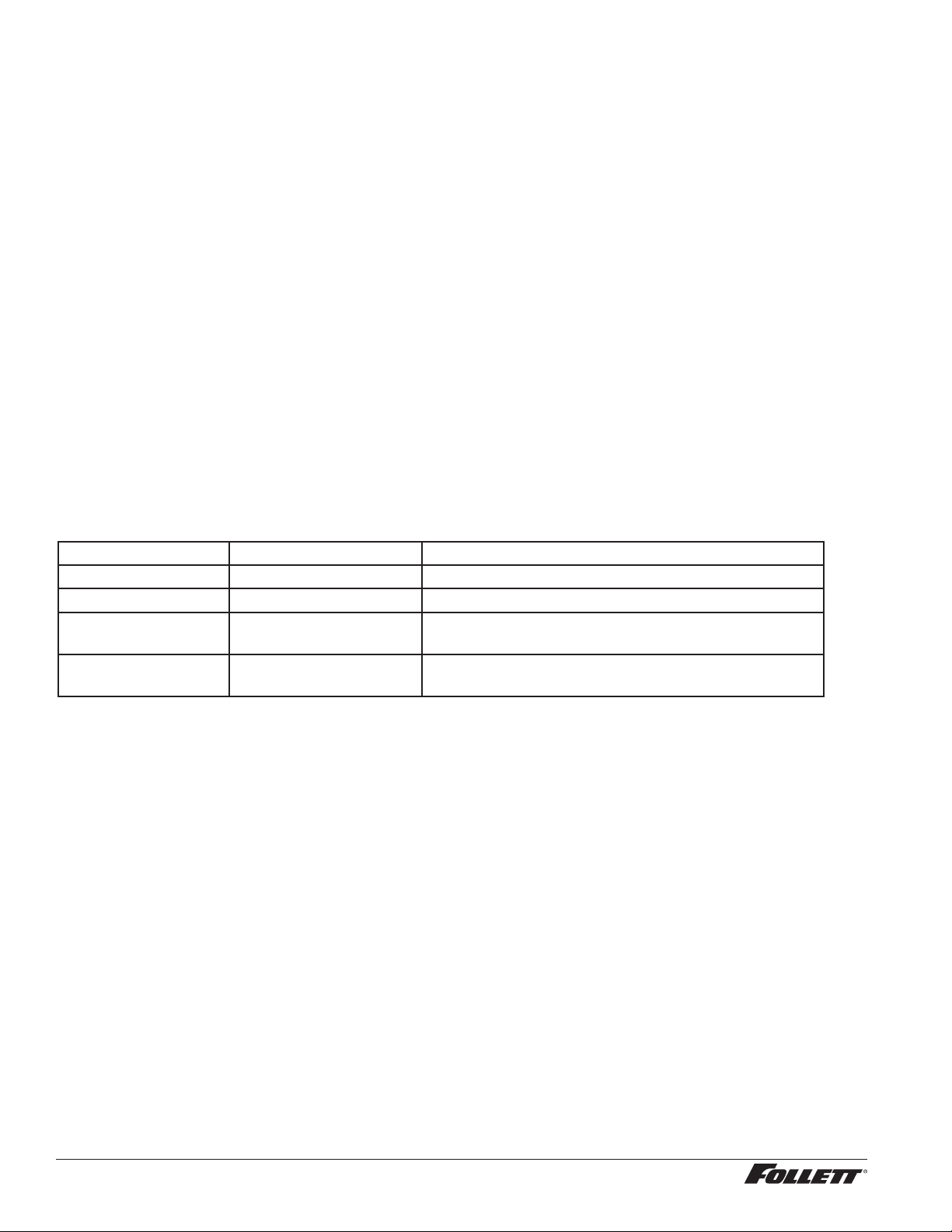

Refrigeration pressure data

Ice machine inlet

mperatur

§ Water regulating valve is factory set at 300 (±10) PSIG head pressure.

§ Readings within 10% of table values should be considered normal.

Compressor data

Locked rotor amps 58.8A

Compressor current draw

Air-cooled

Ambient air temperature 60 F/15.6 C 70 F/21.1 C 80 F/26.7 C 90 F/32.2 C 100 F/37.8 C

Amperage 6.3A 6.5A 6.7A 6.9A 7.1A

High-side pressure (psi) 190 220 250 290 330

Low-side pressure (psi) 27 29 31 33 36

Water-cooled

Water temperature at oat 50 F/10 C 60 F/15.6 C 70 F/21.1 C 80 F/26.7 C 90 F/32.2 C

5.6A 5.6A 5.7A 5.8A 5.8A

Water-cooled Ice Machine Refrigeration Pressure

Discharge Pressure/Suction Pressure

Condenser inlet water temperature ˚F/˚C

water

˚F/˚C

50/10

e ˚F/˚C

70/21

90/32

te

50/10

280/27

280/27

280/27

70/21

285/29

285/29

285/29

90/32

290/31

290/31

290/31

psi

psi

psi

Gearmotor data Split-Phase PSC (permanent split capacitor)

Gearmotor current 1.8A–1.9A (nominal) 0.8A–0.9A (nominal)

Locked rotor amps 14A 7A–14A (temperature dependent)

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 5

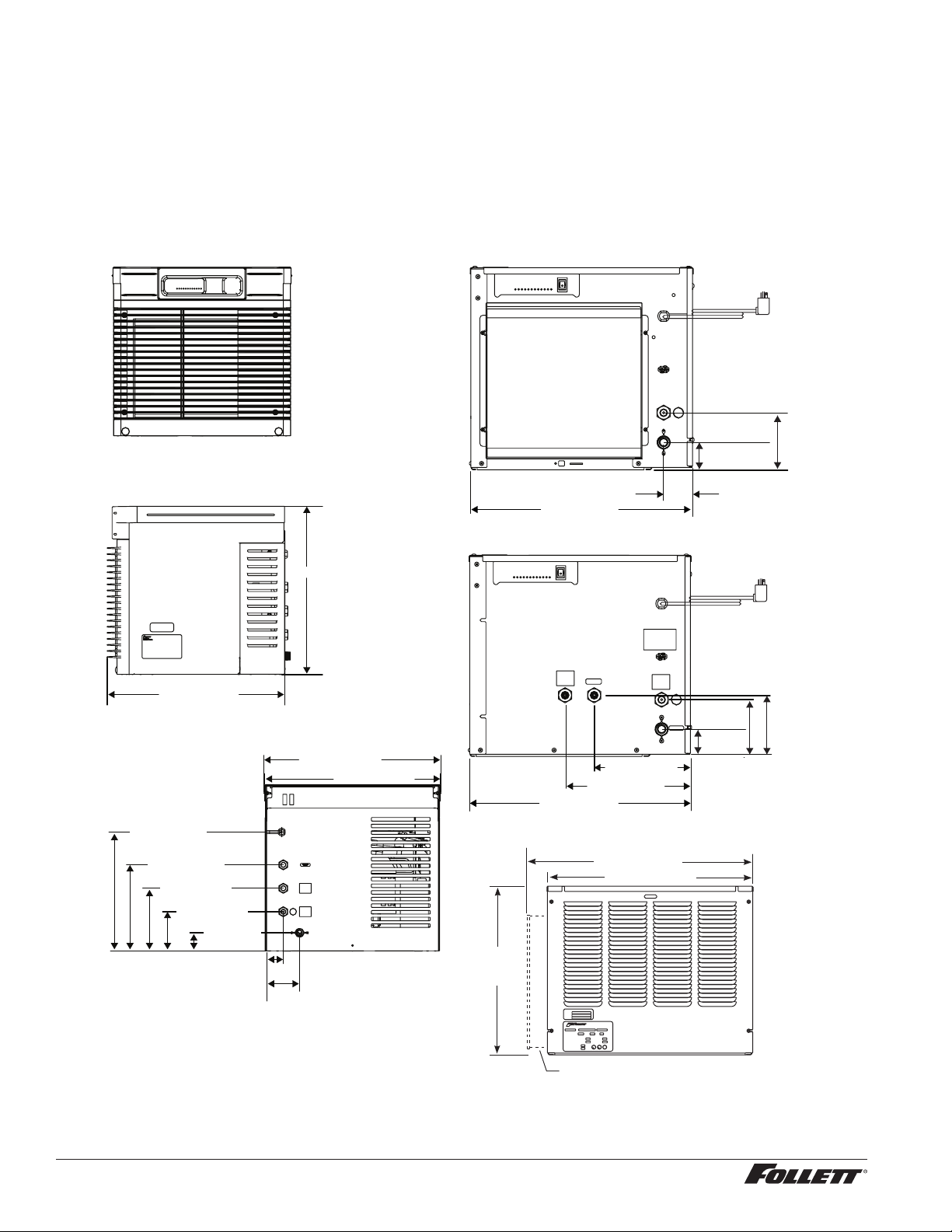

Dimensions and clearances

§ Entire front of ice machine must be clear of obstructions/connections to allow removal.

§ 12" (30.5 cm) clearance above ice machine for service.

§ 6" (15.3 cm) minimum clearance between exhaust side of ice machine and any adjacent equipment.

§ MCD425A & R425A – 18" (45.7 cm) minimum, 10 ft (3 m) maximum clearance between discharge and air

intake grilles.

MCD425A/W_T

MFD425A/W_T

Front view — top mount

Side view — top mount

21.29" (54.1 cm)

MCD425A/W_S

R425A/W

Front view — air-cooled

2.5" (6.4 cm)

18.88" (48 cm)

Front view — water-cooled

C

F

B

4.81"

(12.0 cm)

A

2.31" (5.7 cm)

C

22.49" (57.1 cm)

Back view — top mount

15.22" (38.7 cm)

11.03" (28.0 cm)

8.03" (20.4 cm)

5.03" (12.8 cm)

2.34" (6 cm)

A – 3/4" MPT drain

B – 3/8" FPT water inlet

C – Electrical cord

2.32"

(5.9 cm)

CONDENSER

OUTLET

22.69" (57.6 cm)

22.46" (57.1 cm)

C

E

D

18.88" (48 cm)

Side view — air-cooled and water-cooled

E

8.25" (20.9 cm)

10.62" (27.0 cm)

22.75" (57.8 cm)

20.75" (52.7 cm)

D

B

A

17.00"

4.40" (11.2 cm)

(43.2 cm)

RIDE model air-cooled units only

D – 3/8" FPT condenser inlet

E – 3/8" FPT condenser drain

F – Bin signal connection (DO NOT APPLY VOLTAGE!)

F

B

A

4.81"

(12.0 cm)

2.31"

(5.7 cm)

5.25"

(13.3 cm)

6 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Cleaning

Follett ice machines and dispensers, and their associated cleaning and sanitizing procedures, are designed for

use with potable water sources. The presence, or suspected presence, of infectious agents may call for additional

measures, including the replacement of components and more comprehensive disinfection measures. Follett

recommends that these cleaning and sanitizing procedures be reviewed with the appropriate infectious agent subject

matter experts to assure complete remediation.

Periodic cleaning of Follett’s ice machine system is required to ensure peak performance and delivery of clean,

sanitary ice. The recommended cleaning procedures that follow should be performed at least as frequently as

recommended and more often if environmental conditions dictate.

Cleaning of the condenser can usually be performed by facility personnel. Cleaning of the ice machine system

should be performed by your facility’s trained maintenance staff or a Follett authorized service agent. Regardless of

who performs the cleaning, it is the operator’s responsibility to see that this cleaning is performed according to the

schedule below. Service problems resulting from lack of preventive maintenance will not be covered under the Follett

warranty.

Recommended cleaning intervals*

Maestro Plus Frequency

Drain Line weekly

Drain Pan/Drip Pan weekly

Exterior, Water Station Tube as needed

Condenser monthly (air-cooled only)

Ice Machine semi-annually

Transport Tube semi-annually

* Ice machine must be cleaned prior to start-up.

Weekly

The exterior may be cleaned with a stainless cleaner such as 3M™ Stainless Steel Cleaner & Polish or equivalent.

Monthly

Condenser (air-cooled ice machine only)

1. Use a vacuum cleaner or stiff brush to carefully clean condenser coils of lint and debris to ensure optimal

performance.

2. When reinstalling counter panels in front of RIDE® model ice machines, be sure that ventilation louvers line

up with condenser air duct.

Semi-Annually (more often if conditions dictate)

§ A cleaning procedure should always include both the ice machine and bin/dispenser.

§ Icemaking system can be cleaned in place.

Cleaning Tool Checklist

§ (1) 1.5 gallon (or larger) plastic bucket

§ (2) clean cloths

§ Sanitary gloves

§ Safety glasses

§ SafeCLEAN™ Plus ice machine cleaner

§ (2) SaniSponge™ (P/N 00131524 - single sponge)

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 7

CAUTION!

§ Wear rubber gloves and safety goggles (or face shield) when handling SafeCLEAN Plus solution.

§ Use only Follett approved cleaners.

§ Do not use solvents, abrasive cleaners, metal scrapers or sharp objects to clean any part of the dispenser.

SafeCLEAN Plus Solution: Follow the directions on the SafeCLEAN Plus packaging to mix 1 gal. (3.8 L) of Follett

SafeCLEAN Plus solution. Use 100 F (38 C) water.

Cleaning Procedure

Note: Check drains and drain cup to ensure they are open and owing freely.

1. If ice machine was running recently, ensure that the evaporator is completely free of ice before proceeding.

If there is ice in the evaporator, complete steps 2-7 using only hot water to remove the ice, then begin

Cleaning Procedure again.

2. Remove front or top cover.

3. Disconnect bin signal cable from ice machine electrical box.

4. Press CLEAN switch. The MAINTENANCE light will turn on and the machine will drain. Wait for the LOW

WATER light to turn on.

5. Remove lid from cleaning cup and ll (about 1 quart) until

reservoir. Place lid back on cup.

6. CLEANER FULL light will turn on and machine will start cleaning cycle then rinse three times; this process

takes approximately 15 minutes.

7. When machine is nished cleaning, the MAINTENANCE light will turn off.

8. Remove top bearing insulation. Loosen Phillips-head screw on nozzle connected to evaporator. Remove

nozzle from evaporator side only, leave other side of nozzle connected to transport tube.

9. Soak one SaniSponge in remaining

10. Insert the sponge soaked in

11. Replace nozzle onto evaporator and tighten screw. Ensure drain is connected to reservoir and vent tubes

are connected to evaporator drain pan. Replace top bearing insulation.

12. Reconnect bin signal cable. Wait for ice to push sponges through transport tube.

13. Collect sponges from ice storage bin.

14. Replace front or top cover.

15. After 10 minutes, dispense all ice and discard.

16. Clean the dispenser/bin.

SafeCLEAN Plus

SafeCLEAN Plus

solution into nozzle then insert a dry sponge into the nozzle.

SafeCLEAN Plus

solution.

solution completely lls the

Exterior Cabinet

Clean stainless steel panels with stainless steel cleaner.

8 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Service

Ice machine Operation (all models)

Follett’s ice machine consists of four distinct functional systems:

§ Harvesting system

§ Water system

§ Electrical control system

§ Refrigeration system

These four systems work together to accomplish the production and harvesting of ice. A problem in any one of these

systems will result in improper operation of the entire ice production cycle. When troubleshooting the ice machine,

it is important to analyze the entire system operation to determine which system is not functioning properly, then

pinpoint the component within that system that is malfunctioning. Determine what corrective action must be taken

before making any adjustments or replacing any components.

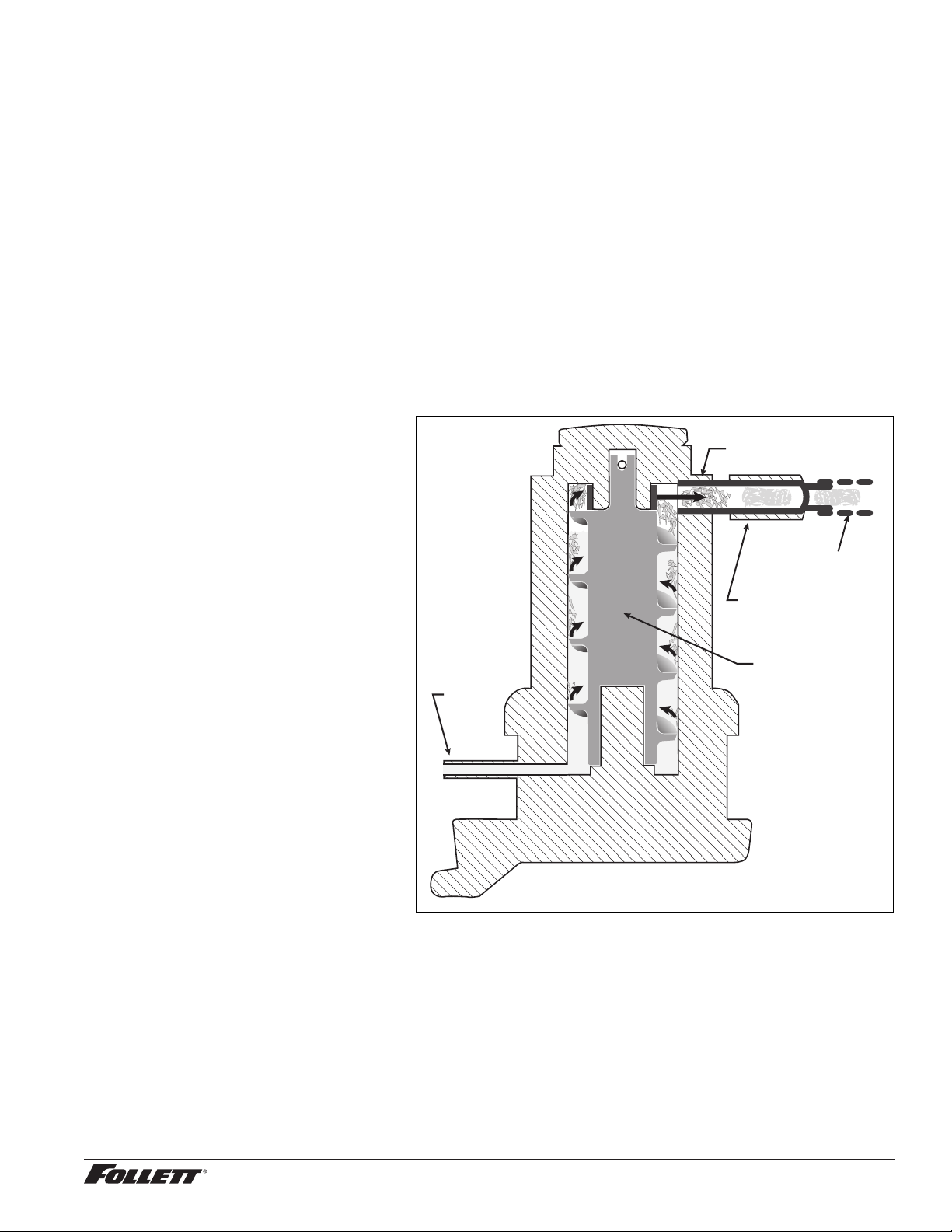

The icemaking process

The Maestro Plus ice machine uses a stainless steel jacketed evaporator and operates on a continuous freezing

cycle. Water is supplied to the evaporator from the water reservoir where the water level is controlled by a oat valve.

This valve also shuts off the water supply when the ice machine is not running.

When the ice machine is running, a layer

of ice forms on the interior surface of the

evaporator. This ice is continuously removed

by a slowly rotating (12RPM) auger. The

auger carries the ice upward into the cavity

formed by the top bearing housing and the

compression loop, where it is compressed to

remove excess water. When the ice reaches

the desired hardness it rotates within the

cavity and is forced through a discharge

port and compression nozzle and into the

ice transport tube. The discharge tube and

compression nozzle are slightly restricted to

further compress the ice and produce the

desired hardness.

A solid state control board located in the

electrical box of the ice machine controls

the normal operation of the ice machine

and monitors gearmotor torque. This control

board will shut down the ice machine should

an over-torque condition occur. It is very

important that you familiarize yourself with

the operational sequences detailed in this

manual before attempting to service the ice

machine.

water

inlet

evaporator

port

ice transport tube

compression nozzle

auger

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 9

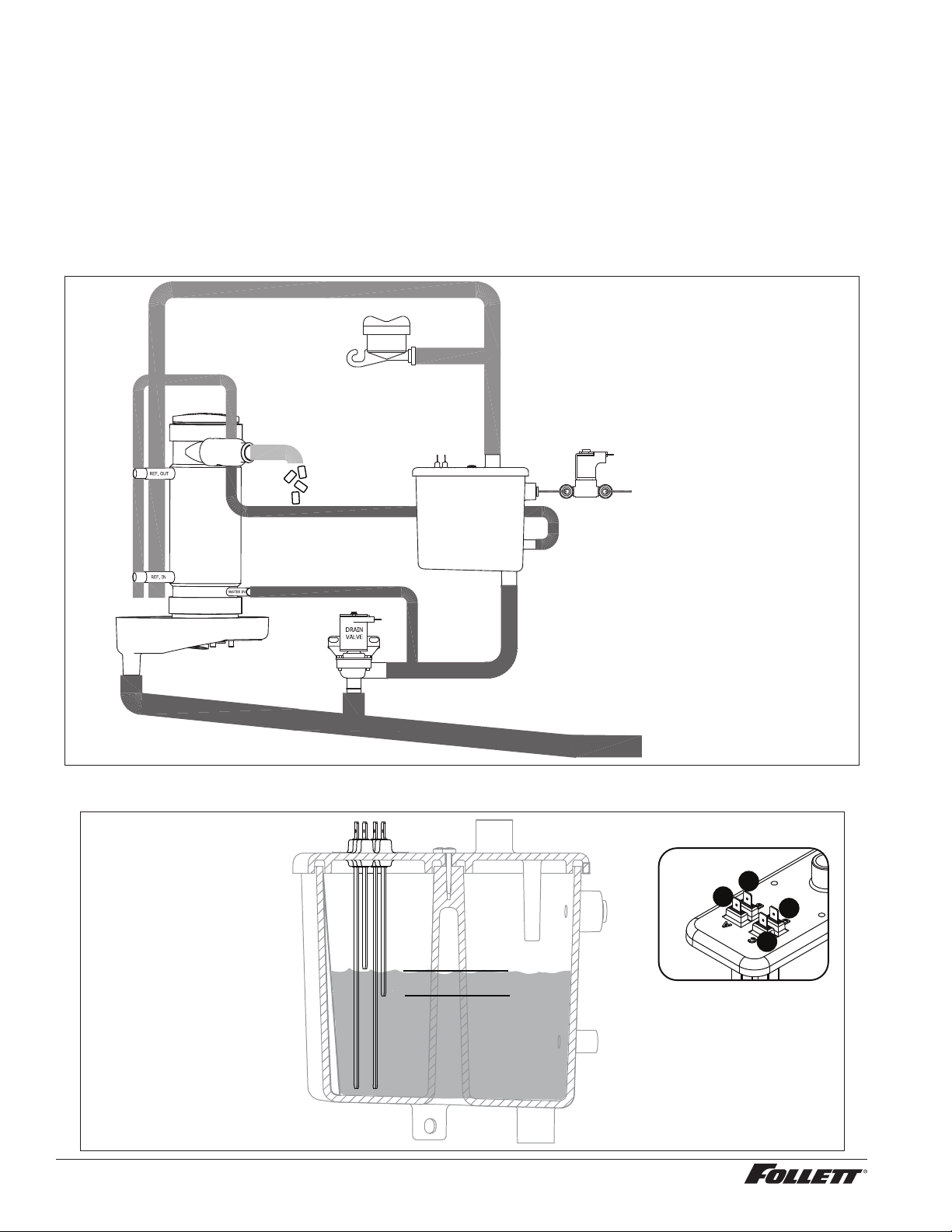

Water system

B

A

C

D

The water level in the evaporator is controlled by a ll solenoid (Fig 1) and level detecting sensors. Water sensing

rods (Fig. 2) extend down into the reservoir at the end of the evaporator assembly. The system works via electrical

conductivity as follows:

One of the longest probes is a common. When water is between any of the other probes and the common, the

PC board will sense the activation. During normal operation, the water level rises and falls between the Normal

High and Normal Low sensors. As water is consumed to make ice, the level will fall until the Normal Low sensor is

exposed, triggering the water feed solenoid on. Water will ll until the Normal High sensor is activated.

Note: The potable water dissolved solids content must be greater than 10 ppm for the water control system to

function properly. If using reverse osmosis water ltration system, ensure T.D.S level is greater than 10 ppm.

Fig. 1 Water system diagram

VENT

CLEANING CUP

RESERVOIR FILL

ICE

NOZZLE

SOLENOID

EVAPORATOR

DRAIN PAN

DRAIN

Fig. 2 Water level diagram

A ALARM LOW (RED)

B COMMON (BLACK)

C NORMAL HIGH (ORANGE)

D NORMAL LOW (YELLOW)

WATER

RESERVOIR

WATER SUPPLY

3/8" FPT, 45-90 F (7-32 C)

10-70 PSI (69-483 KPA)

WASTE WATER DRAIN

3/4" FPT

C

NORMAL OPERATING RANGE

D

A

B

10 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Electrical system

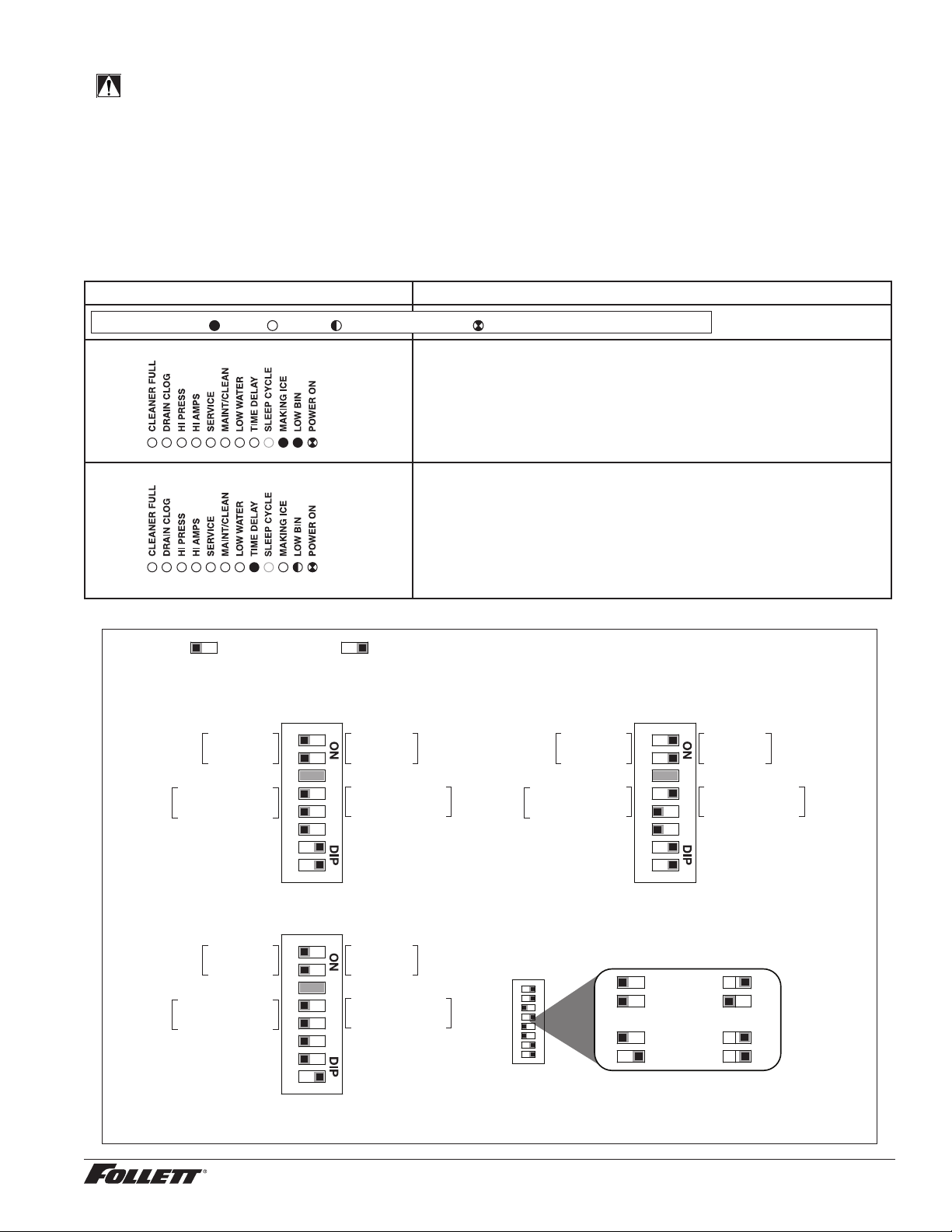

FLASHINGON or OFF

Legend:

OFFON

ATTENTION!

To prevent circuit breaker overload, wait 15 minutes before restarting this unit. This allows the compressor

to equalize and the evaporator to thaw.

Normal control board operation

The PC board indicator lights provide all the information necessary to determine the machine's status. Green

indicator lights generally represent “go” or normal operation; yellow indicators represent normal off conditions; red

indicators generally represent alarm conditions, some of which will lock the machine off.

A ashing green light labeled POWER indicates power to the machine. All other normal operation status indicators

are covered as follows:

Ice machine disposition Operating conditions

1. Ice machine is making ice. 1. Normal running.

2. Ice machine is not making ice.

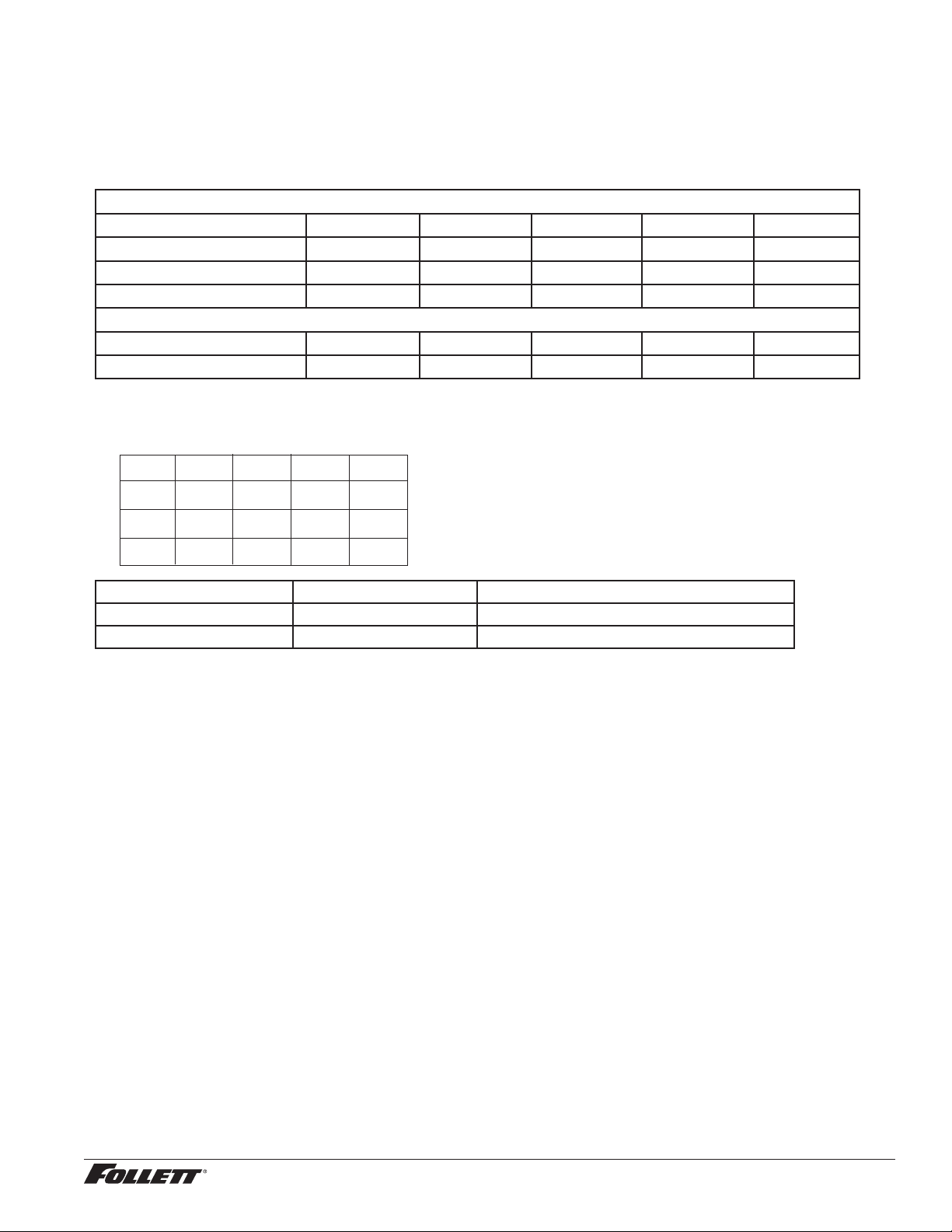

DIP Switch Settings

OFF POSITION ON POSITION

MCD425A/W_T, MCD425A/W_S, R425A/W

OFF ON

Sleep cycle

disabled

Not used

Sleep cycle

dispense duration

20 min. time delay

Flush disabled

Maint. timer ON

Replacement P425A/W installed in Symphony dispenser

Sleep cycle

disabled

Not used

Sleep cycle

dispense duration

20 min. time delay

Flush disabled

Maint. timer ON

1 2 3 4 5 6 7 8

OFF ON

1 2 3 4 5 6 7 8

2. Normal time delay. When the bin lls with ice, the LOW BIN

Sleep cycle

enabled

Not used

Sleep cycle

dispense duration

60 min. time delay

Flush enabled

Maint. timer OFF

Sleep cycle

enabled

Not used

Sleep cycle

dispense duration

60 min. time delay

Flush enabled*

Maint. timer OFF

light goes out momentarily and the refrigeration and auger

drive systems immediately shut down. (Note: The fan motor

will continue to run for 10 minutes to cool condenser) The TIME

DELAY light comes on, initiating the time delay period. When

the time delay expires, the machine will restart provided that the

LOW BIN light is on.

425A/W installed in Symphony Plus

25/50/110 CI, CT, or FB

OFF ON

Sleep cycle

disabled

Not used

Sleep cycle

dispense duration

20 min. time delay

Flush disabled

Maint. timer ON

Sleep cycle dispense duration

OFF ON

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

4 5 4 5

35 s

15 s

Sleep cycle

enabled

Not used

Sleep cycle

dispense duration

60 min. time delay

Flush enabled

Maint. timer OFF

4 5 4 5

5 s

60 s

* Flush can be enabled on Symphony CT and FB models. Flush should be disabled on Symphony CI units due to risk of internal leak if

drain line is blocked. All Symphony Plus models should be set to Flush enabled.

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 11

Relay/triac output indication

Each relay on the board has an indicator light associated with its output. For example, when the relay for the water

feed solenoid is energized, the adjacent indicator light glows green.

Flushing logic

Off cycle: At the completion of off-cycle time delay, the machine checks for a cumulative one (1) hour of ice making

time since the last off-cycle ush. If the cumulative ice making time exceeds one (1) hour, the machine will open

the drain valve for 60 seconds to drain the evaporator in its entirety. It will then rell with water, ush again and rell,

and begin making ice. If the ice making time is less than 1 hour, the machine will start and begin making ice without

draining the evaporator.

Error faults

The Maestro Plus PC board monitors various operating parameters including high pressure, auger gearmotor

amperage limits, clogged drain, and low water alarm conditions. There are two types of errors namely “hard” or “soft”.

A hard error is one that shuts the machine off and will not allow restart until the reset button is pressed. Even cycling

power will not reset a hard error. A soft error can either be automatically reset should the condition rectify, or if power

is cycled. Should an error occur, consult the troubleshooting guide in this manual or a Follett service technician.

Soft errors:

Note: For all soft errors, the ice machine will remain off for 1 hour.

LO WATER: During operation, the water level cycles between the normal low and normal high sensors. Should the

water be shut off to a running machine, a soft error will occur. The error sequence is as follows: During operation,

the water level falls to the normal low sensor, and when it does the water feed solenoid is energized. If water is not

detected at the normal low sensor within 10 seconds, a soft error will occur. The machine will shut down and TIME

DELAY and LOW WATER LEDs will be lit. After time delay, the solenoid will energize and remain energized until the

water level is sufficient for restart.

HI PRESSURE: Should the refrigeration pressure rise above 425 psi, the machine will shut down and the TIME

DELAY and HIGH PRESSURE will be illuminated. After the time delay, and if the pressure has fallen back below the

reset point of 295 psi, the machine will restart and the TIME DELAY and HIGH PRESSURE will clear.

HI AMPS: The PC board monitors the amperage of the auger motor. Should the gear motor experience current draw

above the allowable 3A limit or no current draw (0A), the machine will shut down and the TIME DELAY and HI AMP

will be illuminated. After the time delay the machine will restart and the TIME DELAY and HI AMP will clear.

Hard error:

HI AMPS: If a second hi-amp error occurs within 1 hour of the initial hi-amp error, the ice machine will shut off and

the reset on the board must be pressed to clear the error. If a second hi-amp has occurred, the HI AMP LED only will

be illuminated.

DRAIN CLOG: The drain clog sensor, located in the evaporator drain pan will detect the presence of water just below

the top edge of the pan. If water does not properly ow out of the internal or external drain lines it will backup into the

drain pan (especially during a self-ushing purge cycle). Pressing the reset button will restart the ice machine.

12 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Loading...

Loading...