Follett ITS1350SG60, ITS700SG31, ITS500NS31, ITS2250SG60, ITS3250SG90 User Manual

...

Ice Storage and Transport Systems

®

with SmartGATE

Ice Shield

Order parts online

www.follettice.com

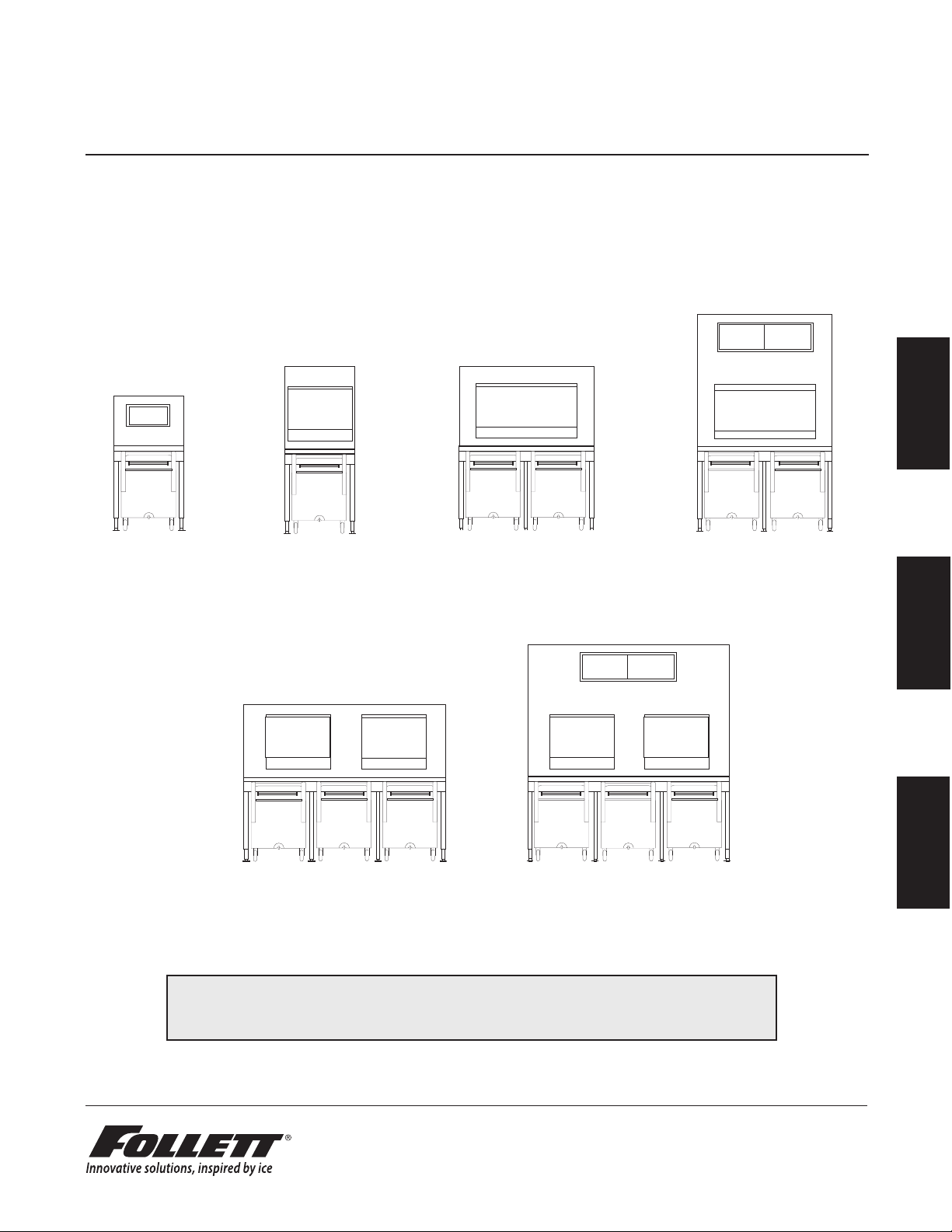

ITS500-31

ITS700-31

Installation, Operation and Parts Manual

After Service Number A36000

ITS1350-60

ITS2250-60

English

Español Française

ITS1700-90

Following installation, please forward this manual to the

appropriate operations person.

801 Church Lane • Easton, PA 18040, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

ITS3250-90

208992R07

Contents

Welcome to Follett ..................................................................................................................... 3

Installation ................................................................................................................................. 4

Operation ................................................................................................................................... 6

Cleaning .................................................................................................................................... 9

2

Welcome to Follett

!

Follett Ice Storage and Transport Systems enjoy a well-deserved reputation for excellent performance and longterm reliability. To ensure that your equipment delivers this same degree of service, please read this manual

carefully before installing or operating the system. If you have questions during installation or operation of this

system, please call our technical service group at (877) 612-5086 or +1 (610) 252-7301.

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If

damage is found, notify your shipper immediately and contact Follett Corporation for help in ling a claim, if

necessary.

Important cautions and operating rules

Read this manual completely before assembling or operating Ice Transport System

and follow cautions and instructions listed below.

To avoid damage to Ice Transport System and injury during operation:

• Anchor anged feet to oor as instructed on page 4

• Only use paddle provided to assist ice ow

• Only use cart to transport ice and reinstall carefully in bin bay when not in use

To avoid injury during operation of unit:

• Keep head and face away from paddle handle when breaking up ice

• Lock caster before scooping or shoveling ice from cart and when parked in bay

• Keep oor around Ice Transport System free of ice and water

• Always operate cart at a slow, reasonable speed

For best operation and to ensure delivery of clean, sanitary ice:

• Position cart in bay before opening hopper door

• Install charcoal water lter on inlet water for icemaker

• Hang paddle implement in supplied bracket after each use

• Keep paddle clean and in good repair to avoid ice contamination

• Cover ice with cart lid when transporting

• Follow instructions in this manual for bin and cart cleaning and maintenance

• Drain melt water from cart when positioned in bay by opening drain valve

• Keep glass, dirt and other foreign objects out of bin and cart at all times

• Do not move Ice Transport System once icemaker has been installed

• Keep entire body clear of bin when breaking up ice

• Be sure bin system is level in both directions to provide proper drainage

English

3

Installation

!

!

Uncrating cart

1. Remove paddle from skid by cutting plastic straps.

2. Cut strap holding front axle to skid.

3. Remove wheel chocks from skid at handle end of cart.

4. Roll cart(s) out of base section.

5. Remove tape holding lid to cart.

6. Remove lid storage bracket(s) from inside cart. (Brackets may be installed on left or right side of bin.

See Installing Bin section.)

Uncrating and installing base section

1. Remove screws holding anged feet and tie-down straps to skid and remove skid.

2. Remove packing material from inside of legs and around shutter door.

3. Position base in intended position and adjust feet to level unit in both directions.

4. Mark position of each anged foot anchoring hole.

5. Move base out of way and install anchors for 1/4" bolts in oor (supplied by others).

6. Reposition unit in intended position and anchor base unit to oor through anged feet.

When leveling, do not extend any leg more than 1" (26mm) for total leg height no greater than

2.125" (54mm).

Legs must be secured to oor through feet to avoid possible movement and resulting injury.

Installing bin

1. Remove 4 bolts fastening skid to underside of bin.

2. Remove all protective wrap from exterior.

3. Run 1/8" bead of supplied silastic in center of each gasket

band on base.

4. Install bin section on base section, taking care that locating

pins in base engage holes in bin.

5. Use fasteners provided to install paddle support bracket on

right or left side of bin in holes provided.

6. Remove paper from back of cart lid storage bracket(s) and position

brackets on side of bin.

7. Remove all tape and temporary fastenings from door assemblies

and outside of bin.

8. Mount icemaker(s) on top of bin in accordance with icemaker

manufacturer's instructions.

9. Install tie-down straps.

Installing tie-down straps

Tie-down straps to secure bin to base are provided on each side of unit. Straps MUST be

installed to avoid possible injury should unit move. Bolt unit to wall for increased stability, and

bolt to oor to prevent side-to-side movement.

locating pin

bead of

silastic

gasket

bin

section

bead of

silastic

gasket

base

section

1. Remove screws from rivnuts on each side of bin section.

2. Reposition tie-down strap up until slot matches rivnut opening.

3. Reinstall screws in rivnuts and tighten.

4

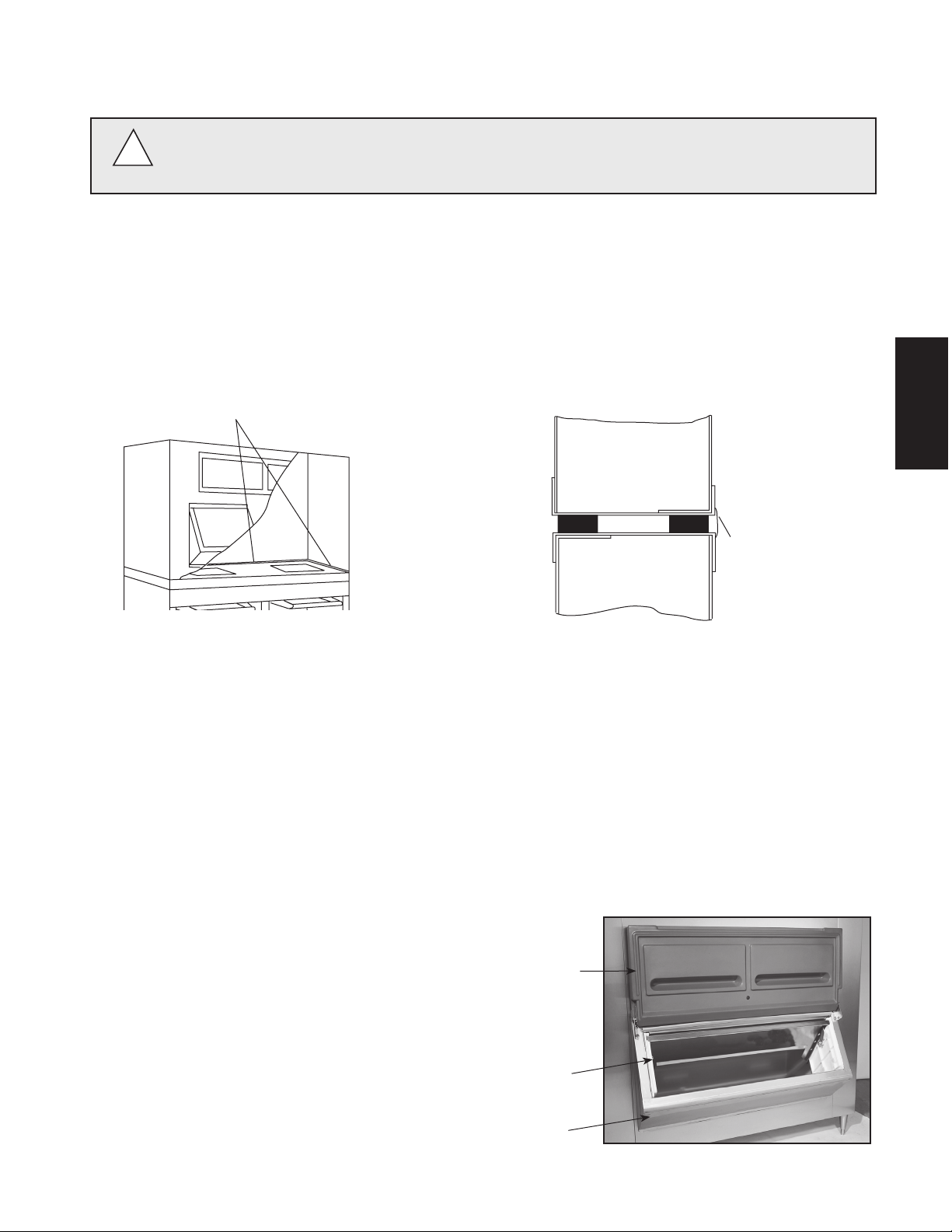

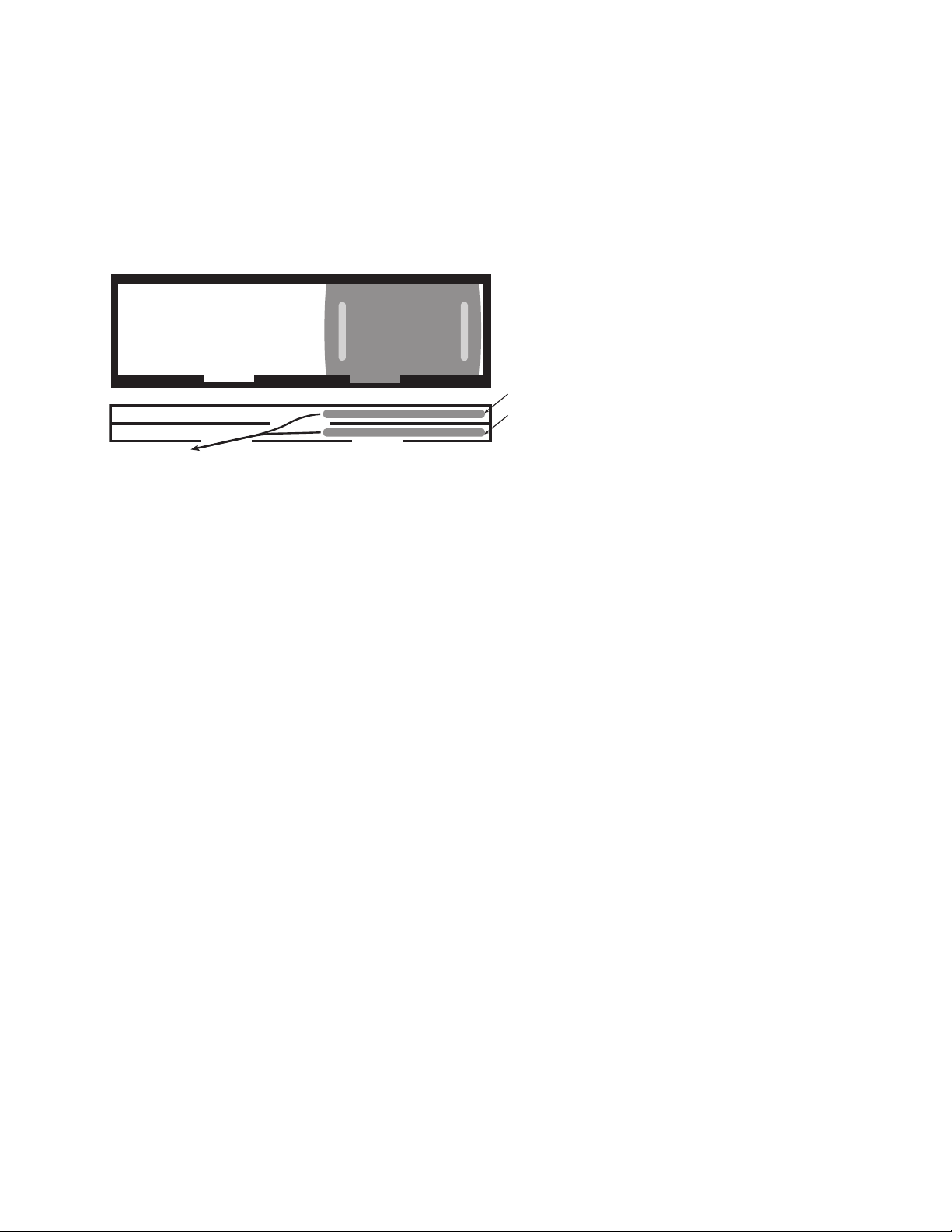

Sealing bin interior

!

The joint between base and bin sections must be sealed with silastic to prevent leakage and/

or ice contamination and potential voiding of warranty. One or more shutter doors may need

to be removed to seal bin.

1. Support shutter door(s) with one hand and remove thumbscrews from side of shutter door(s) at underside

of base.

2. Pivot door(s) downward to remove.

3. Gain access through this opening and seal entire perimeter of seam between bin and base with provided

sealant or equivalent.

4. After sealant has set but before shutter door(s) have been reinstalled, clean inside of bin following instructions in

this manual.

5. Reinstall shutter door(s) .

English

Use sealant provided to seal entire

perimeter of seam where base and

bin section join.

Cross section of ITS sections joined

bin

exterior

section

base

interior

completely

seal gasket

section

Plumbing connections

Note: It is recommended that a full width grated oor drain be installed in front of bin.

1. Units are shipped for a right side exiting drain. To drain to left, switch positions of screws in trough brackets

from lower hole to upper hole on left bracket and upper hole to lower hole on right bracket.

2. Remove plug from left side of drain trough and insert in right side.

3. Connect drain line to 1 1/4" PVC slip t drain tting.

4. Make nal connections to icemaker.

Affixing operating labels

Operating labels taped to base front educate staff to shutter door operation. If desired, these labels can be affixed

permanently by peeling off back paper and affixing in locations desired.

Note: Adhesive backing is extremely strong and labels cannot be easily removed once installed.

Removing lower door assembly

(only if required for access through narrow doors)

1. With lower access door closed remove Phillips

head screw and washer from hinge area on each

side of lower access door.

access

door

2. Insert screwdriver between door and hinge bracket

on one side of door and gently push against bracket

to provide room for door stud to clear bracket.

3. Remove access door.

4. Pull up on SmartGATE to remove.

SmartGATE

5. Remove three or four (3 or 4) screws along top of

door assembly.

6. Pull forward on assembly and remove.

lower door

assembly

5

Reinstalling door assembly

PUSH TO CLOSE

1. Reinstall lower door assembly in bin opening.

2. Reinstall three or four (3 or 4) screws in hood at top of door assembly.

3. Reinstall SmartGATE in side panel tracks and push down to seat.

4. With door closed insert one door stud through hinge bracket.

Note: For proper operation the access door must be reinstalled in the closed position.

5. On other side, insert screwdriver between door and hinge bracket and gently push against bracket to provide

room for door stud to clear bracket.

6. Reinstall washers and screws in lift door and tighten.

7. Check door to ensure proper operation.

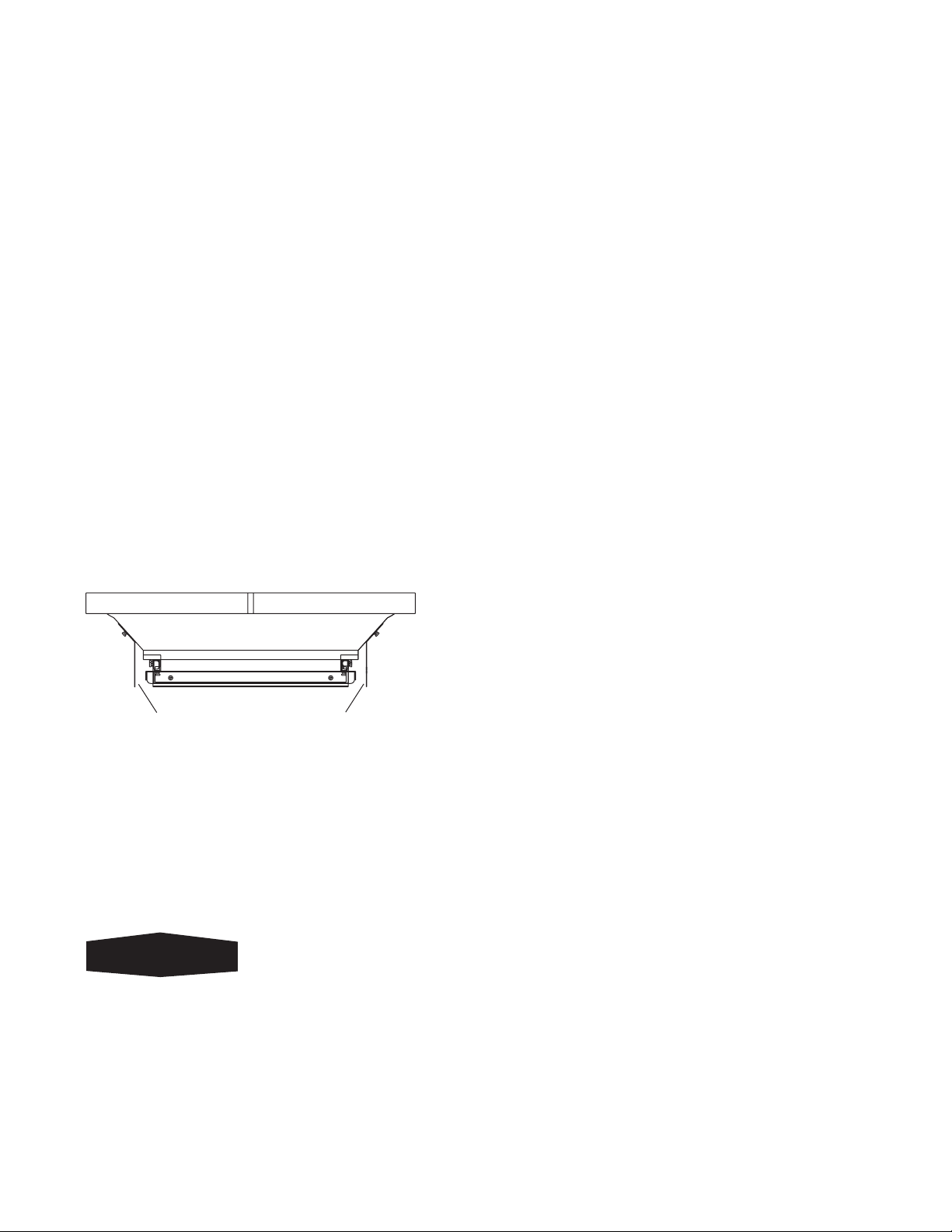

Ice guide adjustment

Some ice types are very “slippery” and may ow over sides of cart when exiting hopper. Ice guides hang down below

hopper and help contain owing ice inside cart.

Guides are installed in highest position at factory, providing 3/4" clearance to top of cart when legs are in full

down position. If legs are adjusted up during leveling of Ice Transport System, ice guides should be lowered to

maintain 3/4" (19mm) clearance. Access to sides of Ice Transport System is required to perform operation.

To reposition ice guides after legs have been adjusted:

1. Position cart (with totes, if so equipped) in bay below shutter door opening.

2. Determine amount guides must be lowered to maintain 3/4" (19mm) clearance.

3. Remove thumbscrews holding guides.

4. Select hole to reposition guide at proper level and resecure with thumbscrew.

5. Repeat process for each bay in system.

brackets on underside of hopper to which

ice guides are secured

Operation

Cart drain operation

1. Position cart all the way in bay.

2. Lock caster to prevent cart movement.

3. To open drain, pull knob out.

4. To close, push knob in.

Cart lids

1. Hang cart lids on brackets on bin side when carts positioned in bay.

2. Remove from bracket and place lid on cart when transporting ice.

3. To avoid placing lid on oor, position lid horizontally on cart lip, resting lid against cart handle when unloading ice

from cart.

4. Reinstall lid in bracket on side of bin before placing cart in bay.

6

2

1

3

1

2

2

1

3

1

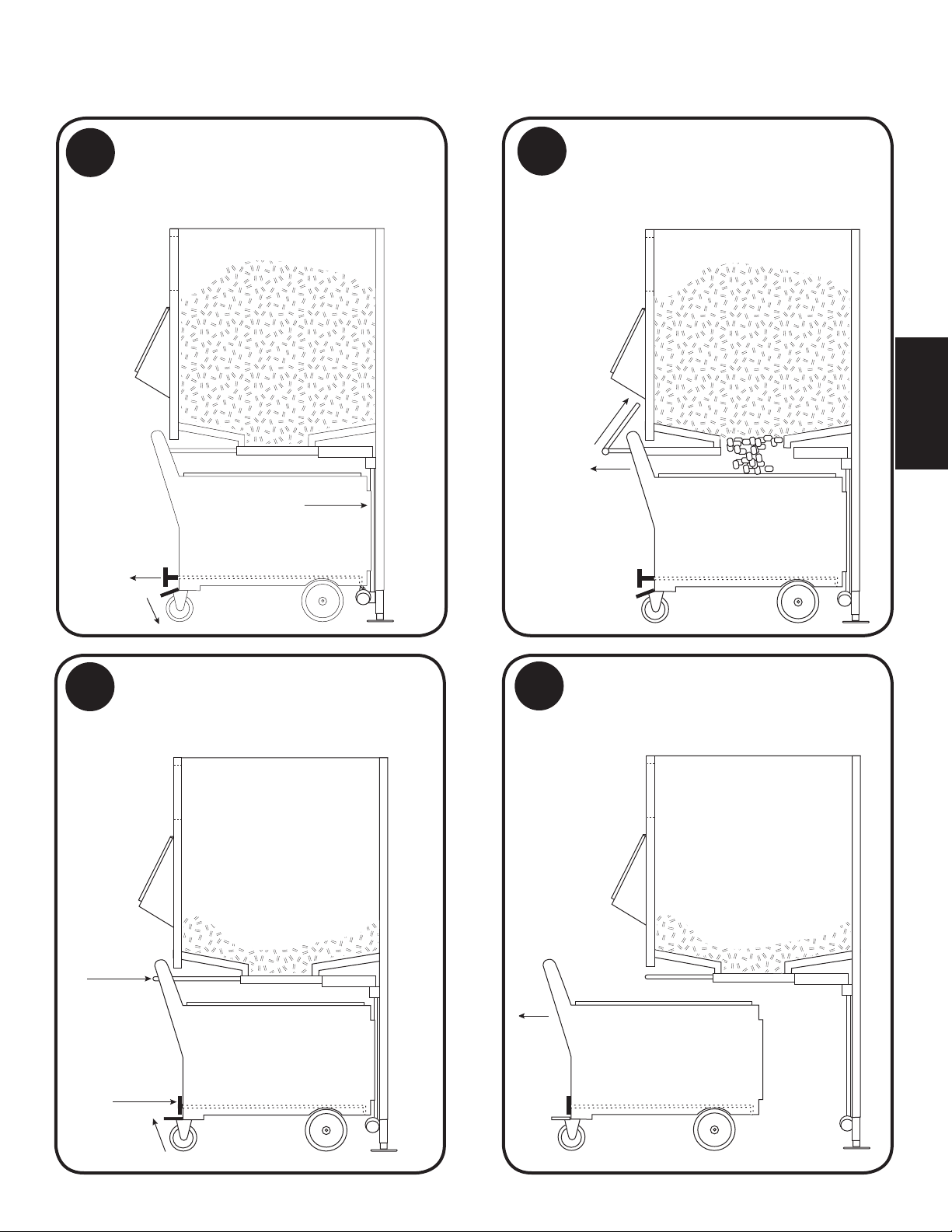

Ice Transport System operation

A

Pushing cart into bay

1. PUSH cart all the way to back.

2. PULL cart drain open.

3. Lock brake on caster DOWN.

Loading ice

B

1. PULL shutter handle open.

2. Store handle up against bin.

English

Pulling cart out

C

1. PUSH shutter handle closed.

2. PUSH cart drain closed.

3. Release brake on caster.

D

Transporting ice

1. PULL cart from base.

2. Place lid on cart.

7

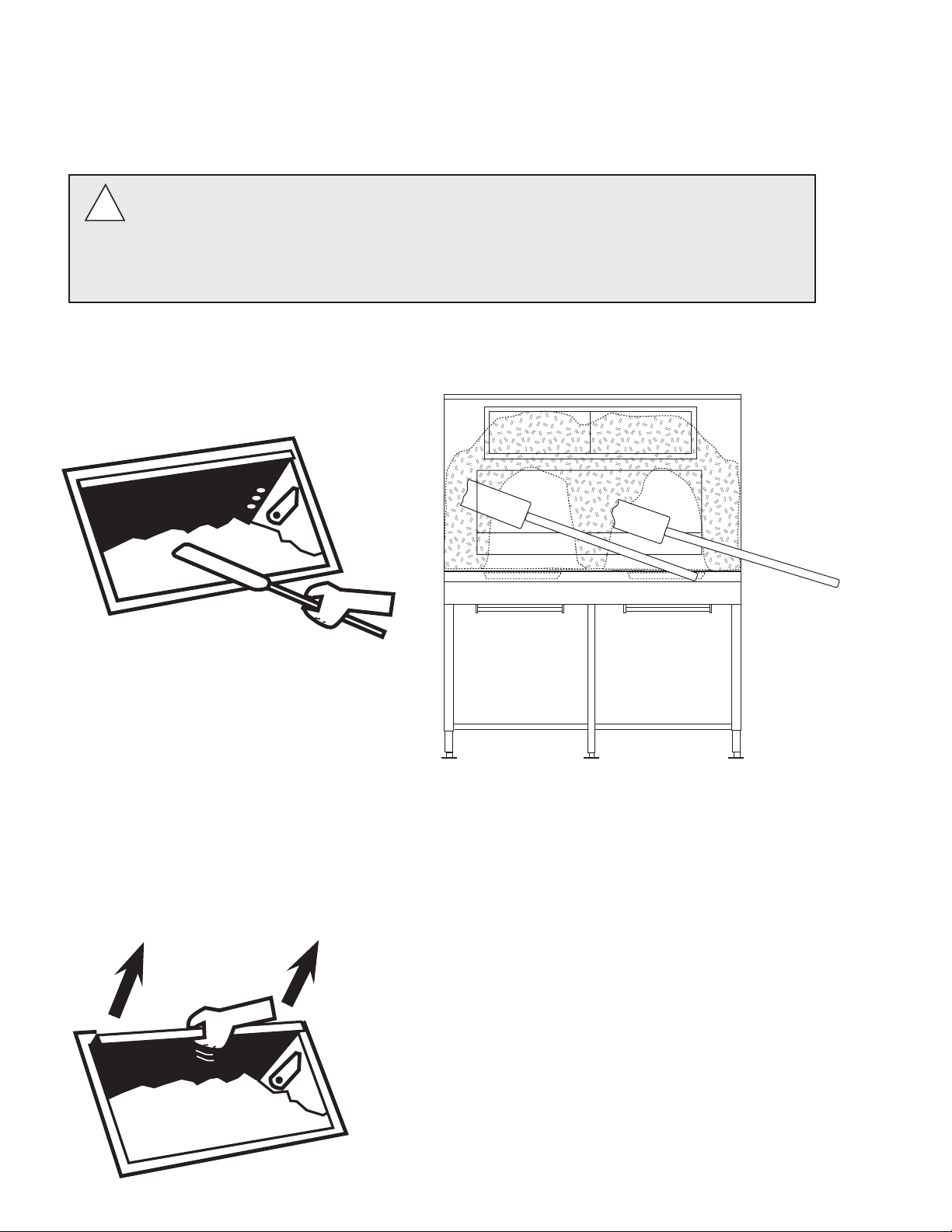

Breaking ice bridges

!

It may be necessary to use the paddle to break up ice bridges that occur along the sides and in the middle of the bin.

This often happens if ice has been held in storage for a period of time without use. Use supplied paddle accessory to

break up bridges.

Do NOT dig up at ice. Instead, break away “legs” that are holding bridges. Ice above will

then fall.

To avoid injury, do not attempt to break up bridged ice through upper windows or hopper

shutter door. A falling ice bridge can cause paddle to lift. Keep head and face away from

paddle handle to avoid injury.

1. Completely knock down all ice from sides and back of bin.

2. Knock down any bridge that has occurred in middle.

3. Agitate paddle back and forth to break up congealed ice mass.

SmartGATE operation

SmartGATE can be adjusted and locked at one of several levels to accommodate ow characteristics of different

types of ice.

Bin is shipped with SmartGATE in full down position. SmartGATE can be raised and locked in higher position for

better ow or when more access is needed.

8

Cleaning

!

Clean and sanitize bin and cart(s) interiors prior to use and on regular schedule as

needed. Use non-chlorine based cleaner and sanitizer suitable for use in a food zone. Do

NOT use chlorine-based cleaners, which can cause staining and pitting of stainless steel

components. Do not run Totes through a dishwasher. Turn off icemaker(s) and remove ice

from bin before beginning.

Bin drain system cleaning

1. Remove upper tray(s) and wash with cleaning solution, rinse and reposition in brackets.

2. Saturate a cloth with cleaning solution and insert through a loop in end of a piece of wire.

3. Feed wire through vertical drain tube, and pull wire and cloth through tube.

4. Pour 1 gallon (4L) hot water into lower drain trough.

Drain tray cleaning

1. Remove two thumbscrews on side of drain tray and pull drain tray forward to remove.

2. Wash with an approved cleaner.

Shutter doors and rails

1. Support hopper shutter door with one hand and remove thumbscrews from side of hopper shutter door at under

side of base section.

2. Pivot door down to remove.

3. Wash door, rinse thoroughly and sanitize.

4. Remove thumbscrews holding front and rear of shutter tracks.

5. Wash tracks, rinse thoroughly and sanitize.

Cart and cart drain system

1. Wash cart liner with an approved cleaner.

2. Rinse and sanitize.

Cleaning bin before use and ongoing bin maintenance

Interior of bin must be cleaned and sanitized prior to use and should be cleaned on routine basis during use

(see next page).

English

9

Interior bin care

rear window

front window

Follett ice storage bins with SmartGAT E are equipped with polyethylene liner walls which should be cleaned and

sanitized periodically with Ecolab Mikro-chlor Cleaner or any product suitable for use in a food zone.

Important: Follett Corporation recommends installing a properly-sized, activated carbon (charcoal) water lter

on water supply to icemaker to remove chlorine.

1. Remove upper inspection windows by sliding windows to one side. Grasp the end of the front window and pull

toward you as the window is slid to the opposite side. Repeat for rear window.

2. Wash bin walls, hopper, access door plate and partition (if any), rinse and sanitize.

Exterior bin care

Exterior stainless steel surfaces can be cleaned with a stainless steel cleaner such as 3M Stainless Steel Cleaner &

Polish or equivalent.

Technical assistance available toll free

Should you have any questions concerning installation or maintenance of Follett ice storage bins, please call our

technical service department at (877) 612-5086 or +1 (610) 252-7301 between 8 a.m. and 5 p.m. Eastern time.

10

Replacement parts

Order parts online

www.follettice.com

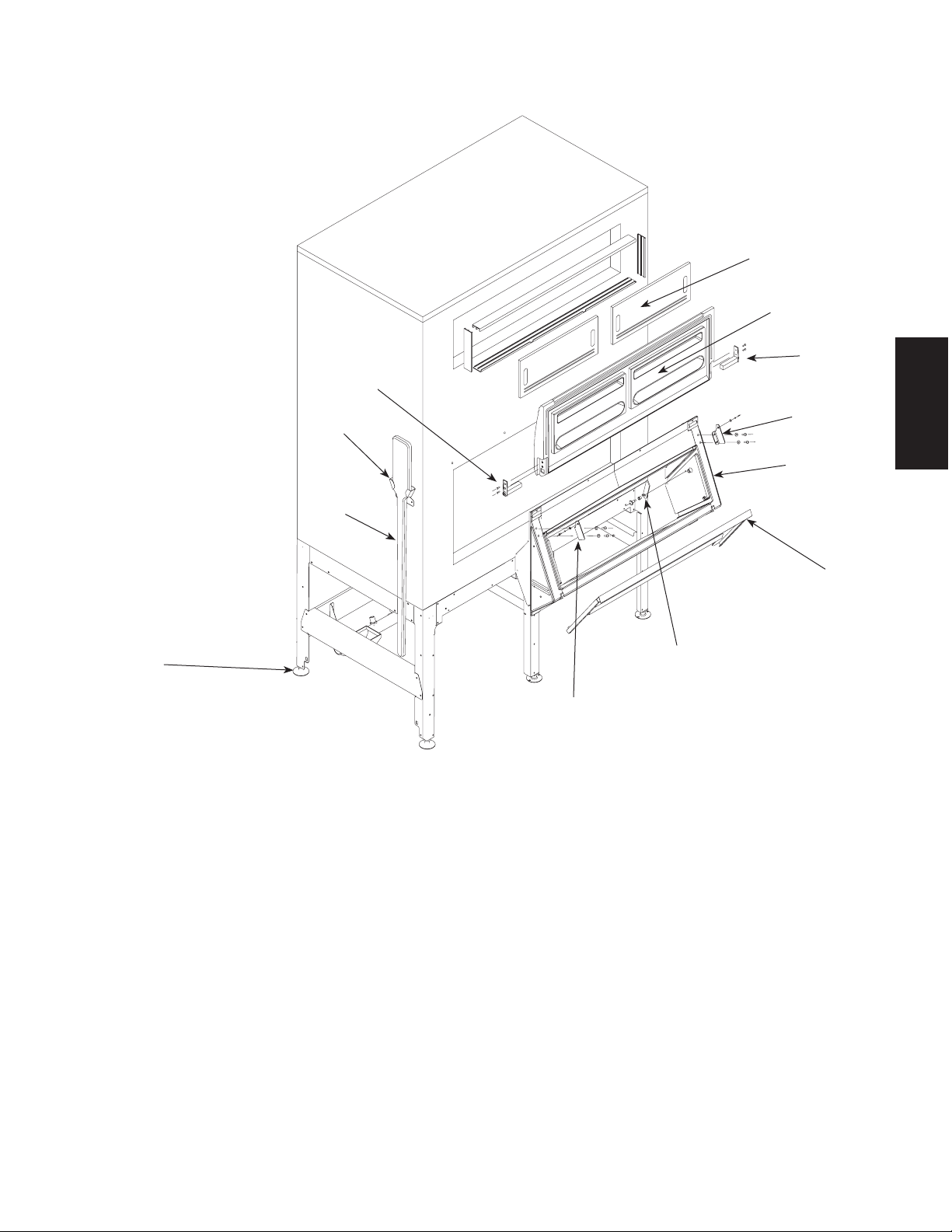

1

3

4

5

10

11

9

8

Reference # Description Part #

1 (2) Inspection window, 21.125"W x 8.625"H (2 used per bin) - 3250/2250 502237

Not shown (2) Inspection window, 12.5"W x 9"H (2 used per bin) - 500 502264

2 Frame assembly, lower door, 45" (includes 502177 & 502182) 502361

Not shown Frame assembly, lower door, 28" (includes 502176 & 502181) 502365

3 Door, outer lift, 45" (includes 502178 & 502179) 502177

3 Door, outer lift, 28" (includes 502178 & 502179) 502176

4 Hinge, RH door mount (includes hardware) 502179

5 Hinge, LH door mount (includes hardware) 502178

6 Ice Gate, 40", w/o holes 502182

6 Ice Gate, 24", w/o holes 502181

7 Catch, Ice Gate 502185

8 Hinge bracket, bin mount, LH/RH, (pair, includes hardware) 502180

Not shown Strap, hold down 502214

9 Foot, anged (1), bolt base 502196

10 Bracket, ice paddle 502064

11 Paddle, ice 502063

Not shown Shovel, ice 501796

Not shown Bracket, ice shovel 502360

7

8

2

English

6

11

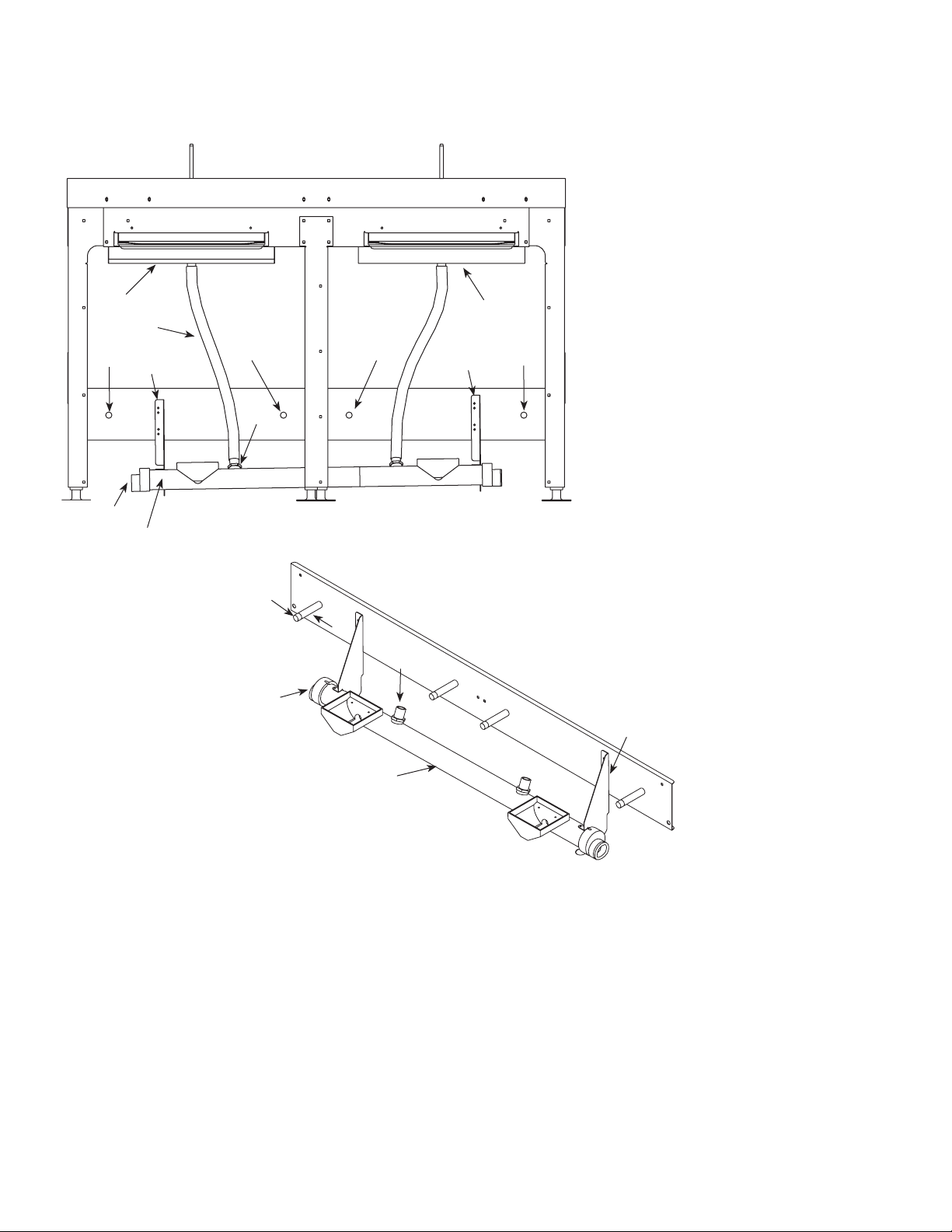

Drain system

Order parts online

www.follettice.com

1

2

3

4

6

7

3

5

8

6

3

3

5

1

4

3

4

7

Reference # Description Part #

1 Drain pan upper – includes (2) 501100 502847

2 Vertical drain tube 502848

3 Bumper, and stud – includes 502865 502849

4 Bracket, lower drain trough 502850

5 Drain tting, vertical drain tube to lower trough 502851

6 End cap, lower drain trough 502852

7 Drain trough – includes (2) 502852 (single bay – ITS500, ITS700) 502853

7 Drain trough – includes (2) 502852 (double bay – ITS1350, ITS2250) 502854

7 Drain trough – includes (2) 502852 (triple bay – ITS1700, ITS3250) 502855

8 Cap, bumper 502865

9 1" MPT x 1" barb 90° tting 00148965

10 Drain assembly 206011

12

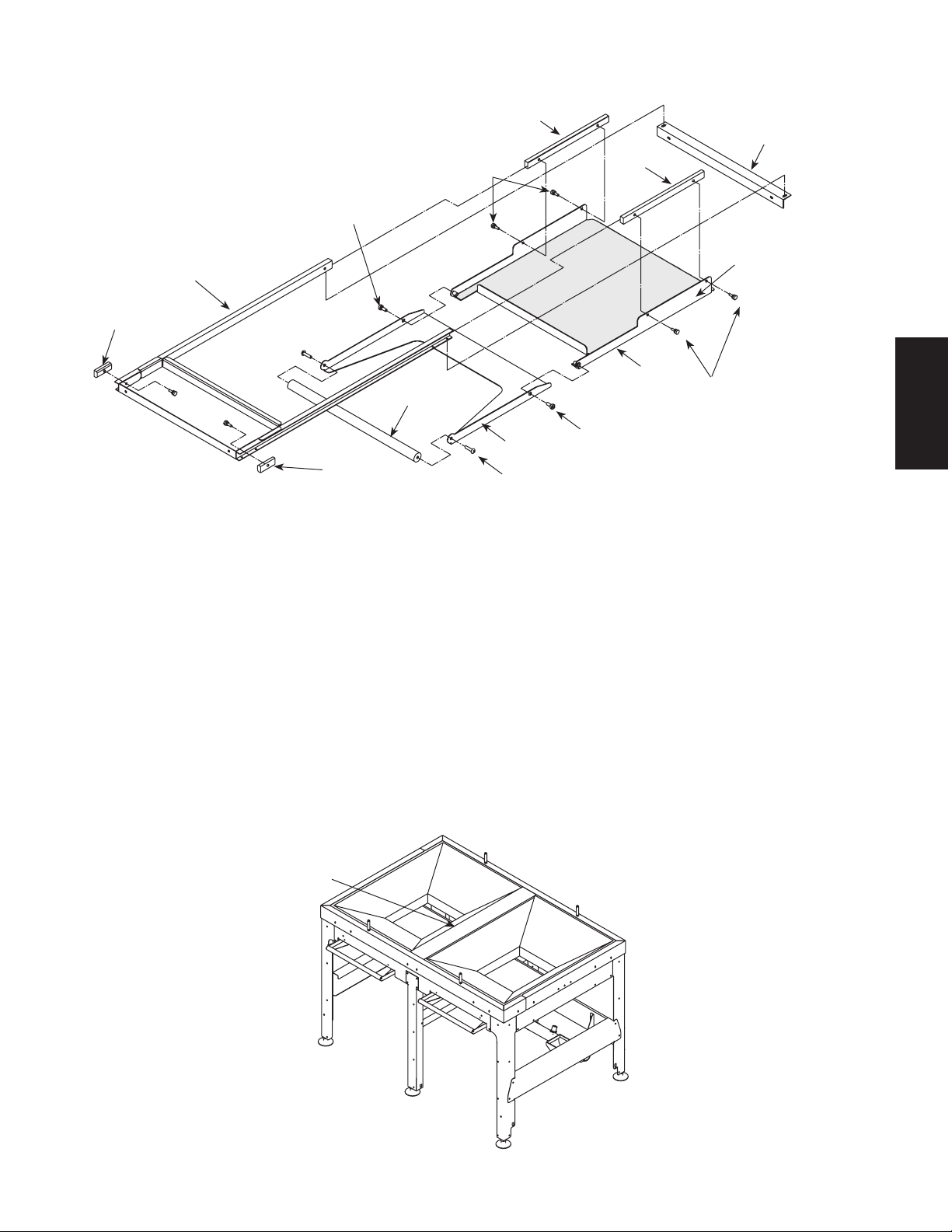

Shutter door assembly

Order parts online

3

www.follettice.com

1

2

9

1

7

6

5

7

8

3

4

4

9

2

Reference # Description Part #

1 Track, shutter door – includes (2) 502272, (8) 501100 502864

2 Thumbscrew, 10-32 X 1/2" 501100

3 Bearings (2), shutter door, nylon 11-7/16" – includes (4) 501100 502269

4 Shutter door – (includes 502857 and (2) 502272) 502856

5 Shutter door, handle assembly – includes 502858 502857

6 Rod handle, shutter door – includes (2)502859 502858

7 Spacer, bearing – includes 501100 502272

8 Screw, shutter handle rod 502859

9 Shoulder screw, handle shutter door 502860

10 Cover, joint, two and three bay, blue hopper 00112821

Not shown Ice guide – includes (2) 501100 502861

Not shown Bracket, ice guide – includes (2) 501100 502863

English

Multi-bay joint cover

10

13

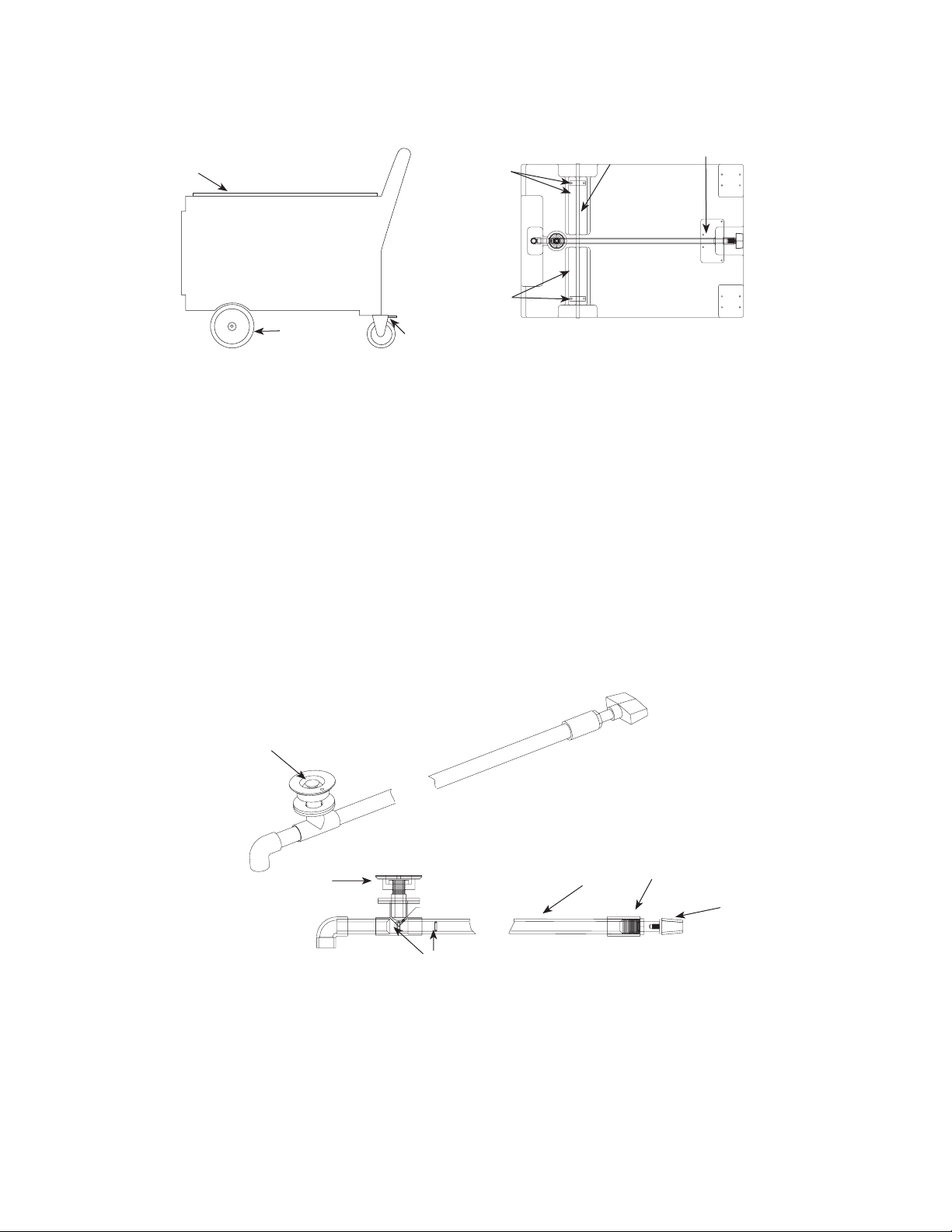

Cart

Order parts online

www.follettice.com

1

3

Side view – cart

Reference # Description Part #

1 Lid 501744

2 Caster, swivel, locking, (includes mounting bolts & lock washers) 502529

Not shown Bushing, 8" wheel, Rhombus 502531

3 Wheel, 8", xed (includes 2 cotter pins & 2 washers) 502530

4 Axle, 24.125" (includes 2 cotter pins & 4 washers) 502332

5 Strap, axle (2 required per axle) 502028

6 Plate, drain support 502061

Not shown Bracket, lid holder 502055

Not shown Ice removal Tote (1) 502263

Not shown Handle, Tote 502097

Not shown Washer, axle 502230

Not shown Cotter pin 502040

2

5

5

4

Bottom view – cart

6

Cart drain

1

6

2

Reference # Description Part #

All Drain assembly (includes entire assembly shown) 502021

1 Vent plug 502106

2 O-ring, drain assembly 502022

3 Rod, drain (includes 502061 plate drain support) 502217

4 Knob, drain 502029

5 Retaining bushing 502289

6 Fitting, drain assembly 501743

3

5

4

14

This page intentionally left blank.

English

15

SmartGATE is a registered trademark of Follett Corporation, registered in the US.

SmartGATE es una marca comercial de Follett Corporation registrada en los EE.UU.

SmartGATE est une marque de commerce déposée de Follett Corporation enregistrée aux États-Unis.

801 Church Lane • Easton, PA 18040, USA/EE.UU/États-Unis

Toll free (877) 612-5086

Phone/ Teléfono / Téléphone: +1 (610) 252-7301

208992R07

4/18

Loading...

Loading...