Follett 110CT400A-W-L Service Manual

110 Series

Ice and Water Dispensers

Order parts online

www.follettice.com

Installation, Operation and Service Manual

110CT400A/W-L

110CR400A/W-L

Following installation, please forward this manual

to the appropriate operations person.

801 Church Lane • Easton, PA 18044, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

110FB400A/W-L

208597R09

2 110 Series Ice and Water Dispensers

Table of contents

Before you begin ................................................................................................................................................................ 4

Speci cations ..................................................................................................................................................................... 5

Field wiring .......................................................................................................................................................................... 6

Installation ........................................................................................................................................................................... 8

Installing freestanding dispensers ............................................................................................................................... 8

Installing wall mount dispensers ................................................................................................................................10

Installing RIDE

Installing top mount ice machines ............................................................................................................................. 12

User information ............................................................................................................................................................... 14

Cleaning and sanitizing procedures .......................................................................................................................... 14

Service Information .......................................................................................................................................................... 17

Wiring diagram – lever models .................................................................................................................................. 17

Wiring diagram – SensorSAFE™ models ..................................................................................................................18

Dispenser troubleshooting ......................................................................................................................................... 19

Troubleshooting SensorSAFE board and sensors .....................................................................................................20

Disassembly and replacement instructions ............................................................................................................... 21

Thermostat locations ................................................................................................................................................. 24

Parts ................................................................................................................................................................................... 25

Dispenser exterior ..................................................................................................................................................... 25

Dispense chute and splash panel areas (lever models) — Serial Number E08194 and above ................................26

Dispense chute and splash panel areas (lever models) — Serial Numbers below E08193 ...................................... 27

Electrical box – lever models ..................................................................................................................................... 27

Electrical box – level ll .............................................................................................................................................28

Dispense chute and splash panel areas (SensorSAFE) — Serial Number E08194 and above ................................ 29

Dispense chute and splash panel areas (SensorSAFE) — Serial Numbers below E08193 ..................................... 30

Electrical box – SensorSAFE models ........................................................................................................................31

Wheel motor and drive system ..................................................................................................................................31

Hopper components .................................................................................................................................................. 32

Chilled water components ......................................................................................................................................... 33

Solenoid dispense assembly ..................................................................................................................................... 34

Water treatment accessories for Symphony ice and water dispensers ..................................................................... 35

®

ice machines ................................................................................................................................... 12

110 Series Ice and Water Dispensers 3

Welcome to Follett

!

Follett equipment enjoys a well-deserved reputation for excellent performance, long-term reliability and outstanding

after-the-sale support. To ensure that this equipment delivers that same degree of service, we ask that you review the

installation portion of this manual before beginning to install the unit. Our installation instructions are designed to help

you achieve a trouble-free installation. Should you have any questions or require technical help at any time, please call our

technical service group toll free at (877) 612-5086 or (610) 252-7301.

Note: To expedite assistance, all correspondence or communication MUST include the model number, serial number and

complete and detailed explanation of the problem

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If damage is

found, notify your shipper immediately and contact Follett Corporation for help in ling a claim, if necessary.

Check your paperwork to determine which model you have. Follett model numbers are designed to provide information

about the type and capacity of Follett equipment. Following is an explanation of model numbers:

110CT400A-L

L = Lever dispensing, S = SensorSAFE infrared dispensing

Condenser type – A = air-cooled, W = water-cooled

Ice machine capacity and refrigerant – 400 = 400 lbs (181kg)/day, R404A refrigerant

Ice machine location – R = RIDE ice machine, T = integral ice machine in top of cabinet,

B = ice machine in base of freestanding units

Dispenser con guration – C = countertop, F = freestanding

Approximate storage capacity in lbs

Important cautions

• Do not tilt any unit further than 30° off vertical during uncrating or installation.

• Dispenser bin area contains mechanical, moving parts. Keep hands and arms clear of this area

at all times. If access to this area is required, power to unit must be disconnected rst.

• Follett recommends a Follett water lter system be installed in the ice machine inlet water line

(standard capacity #00130299, high capacity #00978957, carbonless high capacity #01050442).

• Prior to operation clean and sanitize the dispenser in accordance with instructions found in this

manual.

• Ice is slippery. Be sure counters and oors around dispenser are clean, dry and free of ice.

4 110 Series Ice and Water Dispensers

Speci cations

Electrical

1. Models with RIDE ice machines (110CR400A/W)

Ice machine and dispenser require their own separate, dedicated circuit.

Ice machine Max. fuse Dispenser Max. fuse

Basic electrical: 115V/60Hz/1 phase 11.0A 20A 4.0A 20A

2. Freestanding models and models with integral ice machines (110FB400A/W, 110CT400A/W)

Require a dedicated circuit.

Total system Max. fuse

Basic electrical: 115V/60Hz/1 phase 14.0A 20A

3. Dispensers and RIDE ice machines are supplied with 7-foot power cord with NEMA 5-20 hospital grade plug.

Connect to 20A circuit fuse or breaker.

Note: It is preferred that circuit be protected by a GFCI.

Ambient

Air temp 100 F/38 C max. 50 F/10 C min. (best performance below 80 F/27 C)

Water temp 90 F/32 C max. 40 F/4 C min. (best performance below 70 F/21 C)

Water pressure 70 P.S.I. max. 10 P.S.I. min.

Plumbing

110CR with 110CT with 110FB with

RIDE ice machine integral ice machine ice machine in base

Dispenser drain 3/4" FPT 3/4" FPT 3/4" FPT

Ice machine drain 3/4" MPT 3/4" MPT 3/4" MPT

Dispenser water inlet 3/8" FPT 3/8" FPT 3/8" FPT

Ice machine water inlet – 3/8" FPT –

RIDE IM water inlet 3/8" OD push-in – –

Cond. inlet – w/c only 3/8" FPT 3/8" FPT 3/8" FPT

Cond. drain – w/c only 3/8" FPT 3/8" FPT 3/8" FPT

Note: Water shut-off recommended within 10 feet (3m) of dispenser. Drain to be hard piped and insulated, and maintain

slope of at least 1/4" per foot (6mm per 305mm run) of slope. All plumbing connections must be made in accordance with

local building codes.

Ventilation clearances

Countertop models with RIDE ice machine (110CR400A/W) — none. 12" (775mm) at top advised for service.

Countertop models with integral ice machine (110CT400A/W) — 6" (153mm) at top. 6" (153mm) each side advised for

service.

Freestanding models (110FB400A/W) — 4" (102mm) at rear. 12" (305mm) at top advised for service.

110 Series Ice and Water Dispensers 5

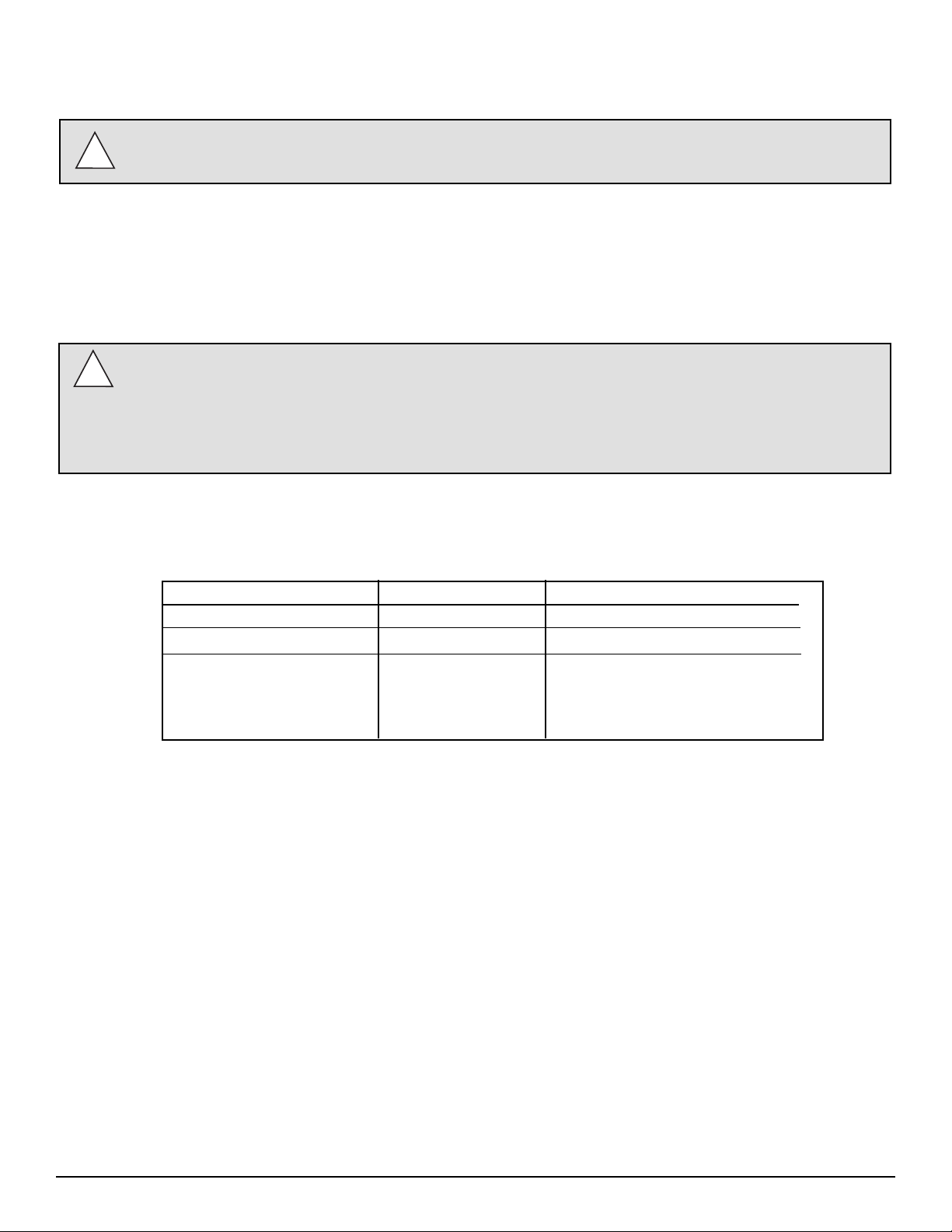

Field wiring for countertop and wall mount dispensers with RIDE ice machines

!

!

All eld wiring must be installed in accordance with NEC and local electrical codes. Field wiring

diagram is intended only to aid electrician or technician in understanding how equipment works.

Field wiring for countertop and wall mount dispensers with RIDE ice machines

Attention – Should local codes require a hard-wired connection and/or shielded wiring, eliminate the

cord and plug(s) and follow the appropriate eld wiring diagram on the following page.

See Ice machine Installation and Operation manual for recommended junction box preparation of

hard-wired RIDE ice machines.

Model Electrical connection Circuits required

110FB400A/W cord & plug provided 115/60/1, 20A max. fuse size

110CT400A/W cord & plug provided 115/60/1, 20A max. fuse size

110CR400A/W cord & plug provided 115/60/1

dispenser: 20A max. fuse size

ice machine: 20A max. fuse size

6 110 Series Ice and Water Dispensers

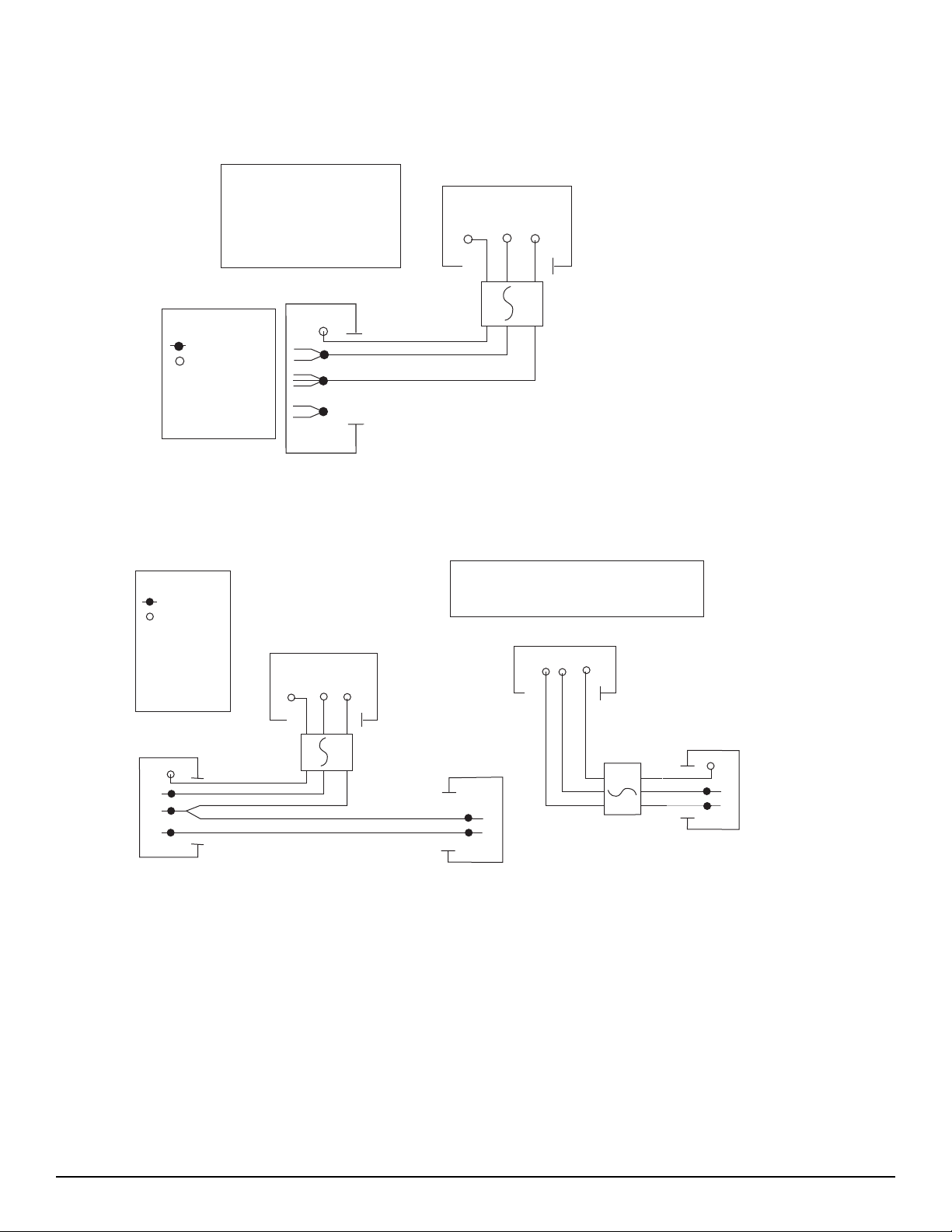

Field wiring diagrams

Freestanding dispensers and countertop dispensers with integral ice machines

LEGEND

WIRENUT

EQUIPMENT

X

GROUND

B - BLACK

W - WHITE

R - RED

IMPORTANT

FIELD WIRING DIAGRAM IS

INTENDED TO AID ELECTRICIAN

OR TECHNICIAN IN UNDERSTANDING

HOW EQUIPMENT WORKS. ALL FIELD

WIRING MUST BE INSTALLED IN

ACCORDANCE WITH NEC AND LOCAL

ELECTRICAL CODES.

DISPENSER

JUNCTION BOX

GRN

GND

X

B

W

R

Electric Power Source

GND

GRN

GRN - GREEN

Countertop dispensers with RIDE ice machines

LEGEND

WIRENUT

X

EQUIPMENT

GROUND

B - BLACK

W - WHITE

R - RED

GRN - GREEN

DISPENSER

JUNCTION BOX

GRN

GND

X

B

W

R

Standard electric - 115V, 60 Hz, 1 Ph,

Max. fuse size per circuit - 20 amps

Electric Power Source

BW

GND

X

GRN

FUSED

DISCONNECT

FIELD WIRING DIAGRAM IS INTENDED TO AID ELECTRICIAN

OR TECHNICIAN IN UNDERSTANDING HOW EQUIPMENT WORKS.

ALL FIELD WIRING MUST BE INSTALLED IN ACCORDANCE WITH

NEC AND LOCAL ELECTRICAL CODES.

LOWER ICEMAKER

JUNCTION BOX

(BIN SIGNAL)

X

BW

Electric Power Source

W

B

Standard electrical - 115V, 1 Ph, 60 Hz,

max. fuse size 20 amps

FUSED

DISCONNECT

IMPORTANT

GND

W

B

X

GRN

UPPER ICEMAKER

JUNCTION BOX

FUSED

DISCONNECT

(POWER)

GND

GRN

X

W

B

110 Series Ice and Water Dispensers 7

Installation procedures

!

Before you begin

• All dispensers must be installed level in both directions to ensure proper operation

• Required ventilation and recommended service clearances:

• Countertop models with RIDE ice machine (110CR400A/W) — none. 12" (305mm) at top recommended for service.

• Countertop models with integral ice machine (110CT400A/W) — 6" (153mm) at top. 6"(153mm) each side recommended

for service.

• Freestanding models (110FB400A/W) — 4" (102mm) at rear. 12" (305mm) at top recommended for service.

• All countertop dispensers provide the option of taking utilities out the bottom or back of the dispenser. See counter

cutout on page 10 (Fig. 2) for bottom exiting utilities on units with and without drain pans. For installations where utilities will exit

through back of dispenser, refer to back view drawings.

• SensorSAFE dispensers are shipped with a plastic, protective lm on sensor lenses. For proper operation, plastic lm

must be removed after installation.

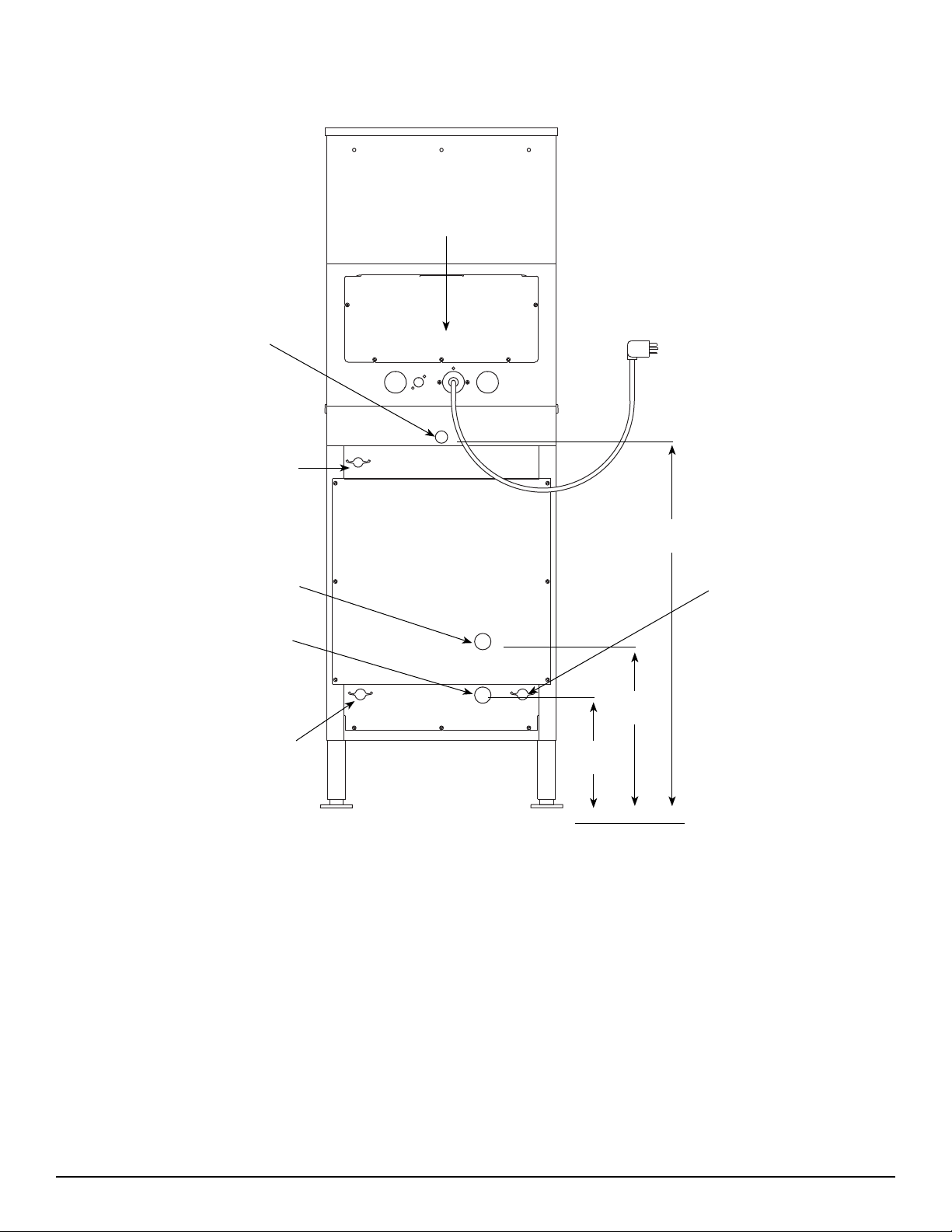

Installing freestanding dispensers

1. Carefully tip dispenser back to expose underside and block up in place.

Do not tilt unit further than 30° off vertical.

2.

Remove legs from shipping box (taped to drain pan of dispenser) and screw into dispenser bottom, taking care to seat

legs securely against underside of dispenser.

3. Position dispenser in desired location and adjust legs to level in both directions.

4. Connect water supply to 3/8" FPT tting on back of dispenser (Fig. 1A).

5. Remove 3/4" dispenser drain line plug from back of unit and discard. Connect separate drain lines to 3/4" FPT

dispenser drain tting and 3/4" MPT ice machine drain tting on back of dispenser (Fig. 1B and 1C.)

6. Run drain lines to wall or oor drain. Provide an air break between the drain lines and drain. If ice machine drain tting

is below an intended wall drain, a condensate pump must be used.

7. If ice machine is water-cooled, connect water-cooled condenser supply line to 3/8" FPT condenser inlet tting on back

of dispenser (Fig. 1D).

Note: Do not run condenser supply water through ice machine water lter system.

8. Connect condenser drain line to 3/8" FPT condenser outlet tting on back of dispenser (Fig. 1E).

Important: Do not connect condenser drain line to any other drain lines.

9. Plug dispenser into 20A rated NEMA 5-20 wall socket.

10. Remove front cover of base section by removing two screws at bottom corners of cover. Allow cover to drop

approximately 3/8" (5mm) and pull forward.

11. Turn on water supply and check that water level in oat reservoir (when full) is within 1/4" (6mm) of mark on side of

reservoir and that oat moves freely. Check for leaks.

8 110 Series Ice and Water Dispensers

Fig. 1 – Rear connections, freestanding models

(B) 3/4” FPT drain

(A) 3/8" FPT

water inlet (A)

access panel

(D) 3/8" FPT

condenser inlet

location (water-

cooled only)

water inlet

(E) 3/8" FPT

condenser drain

location (water-

cooled only)

(C) 3/4" MPT

ice machine

drain location

(air-cooled only)

(800mm)

10.25"

(260mm)

31.5"

(800mm)

(C) 3/4" MPT

ice machine drain

location (water-

cooled only)

31.5"

12. Verify that water sensor tabs are immersed in water in reservoir.

13. Remove top front cover by removing two screws at bottom corners of cover. Lift cover slightly and pull forward.

14. If dispenser is equipped with SensorSAFE, remove protective plastic coating from dispense sensor labels.

15. Turn on dispenser power and bin signal rocker switches. Check dispenser and ice machine operation.

16. Sanitize ice machine according to instructions in ice machine manual. Discard sanitized ice.

17. Turn off ice machine bin signal switch.

18. Remove dispenser hopper lid; clean and sanitize dispenser according to instructions beginning on page 14.

19. Turn ice machine bin signal switch on and replace front covers, securing with screws.

110 Series Ice and Water Dispensers 9

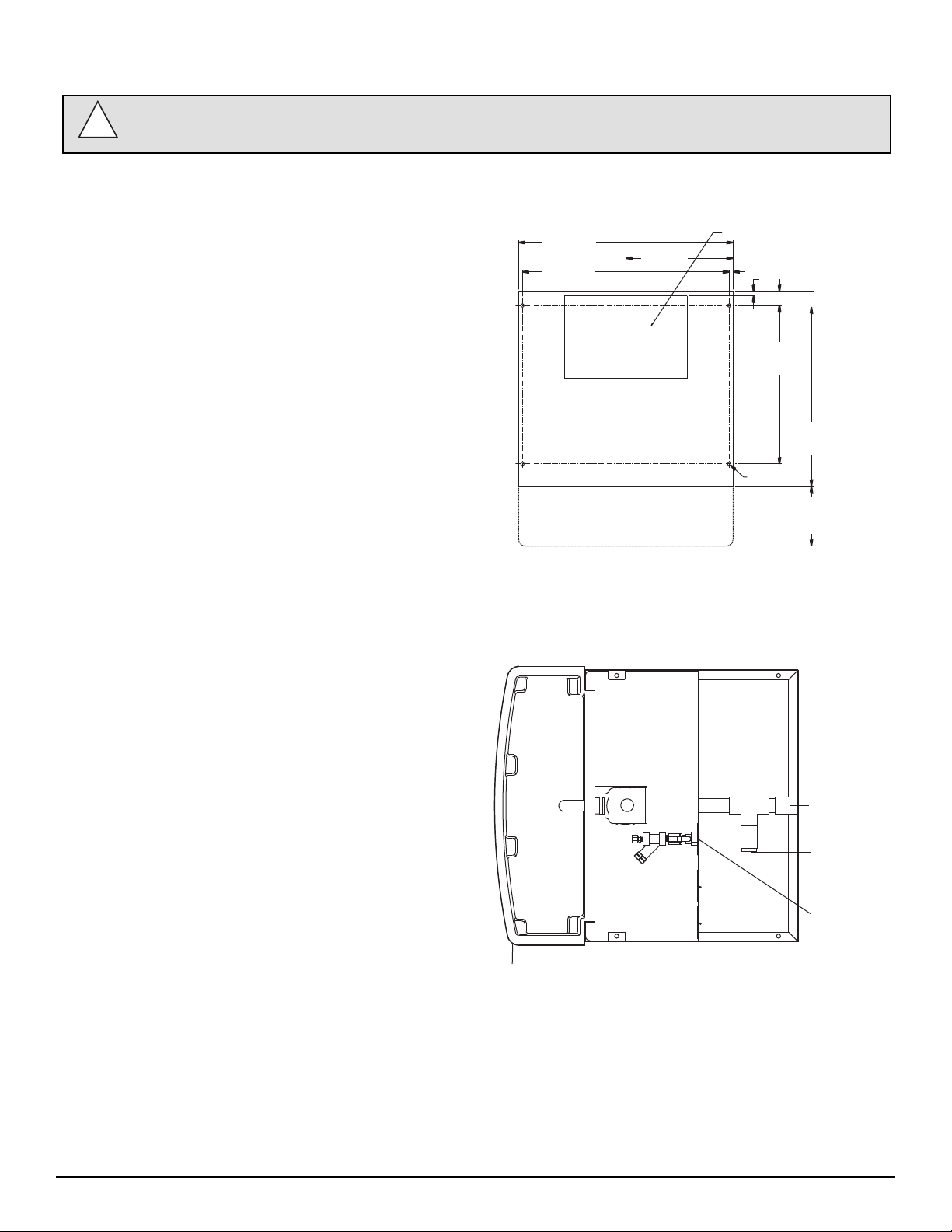

Installing countertop dispensers

24.5"

(622mm)

23.75"

(603mm)

6.54"

(167mm)

17.375"

(441mm)

21.375"

(543mm)

3/8"

12.25"

(311mm)

.5" (13mm)

1.625" (41mm)

.5" (13mm)

9" X 14" (227mm x 356mm)

DRAIN PAN

CUT OUT

!

Dispensers with top mount ice machines cannot be mounted on legs. They must be bolted to counter.

Use gloves when lifting ice machine to protect hands from sheet metal edges.

1. Position dispenser in desired location, mark dispenser

outline on counter and remove dispenser.

2. Drill four 3/8" (5mm) holes in counter (Fig. 2) to

anchor dispenser to counter.

Follett countertop dispensers can have any or all

utilities run directly through counter or out rear of

dispenser. For dispensers with any utilities exiting

through counter, make counter cut-out as shown

in Fig. 2.

3. If ice transport tube will exit out rear of dispenser,

remove ice transport tube knock-out (Fig. 5G) from

rear of dispenser.

Note: Utility connections can be accessed through

front of dispenser by removing stainless steel splash

panel on front of dispenser, or by removing access

panel (Figs. 4, 5) on back of dispenser.

4. If any electric utilities or water line will be connected

through rear of dispenser, remove utility knock-out

(Fig. 5H) from rear of dispenser and install supplied

protective grommet.

5. If power is to be supplied through counter cut-out,

complete steps 6-9. If power is to be supplied through

rear of dispenser, proceed to step 10.

6. Temporarily remove rear access panel (Figs. 4, 5)

from rear of dispenser.

7. Loosen junction box mounting screws. Lift junction

box and power cord up until cord and mounting

screws clear notches on rear panel of dispenser.

Remove Phillips head screws from right side of

junction box.

8. Rotate junction box 90 degrees so that screw holes

on right side of junction box align with holes on rear

dispenser panel. Resecure junction box to dispenser

using Phillips head screws.

9. Place power cord inside dispenser and replace

access panel (Figs. 4 and 5) on rear of dispenser.

Note: For dispensers installed with utilities connected

through rear of dispenser, it may be easier to make

preliminary connections before dispenser is set in

place.

Fig. 2 – Counter cut-out, all models

Fig. 3 – Top view, dispenser plumbing connections

countertop and wall mount units with drain pan

(K) 3/4" FPT

dispenser drain

(L) alternate 3/4"

dispenser drain

location

(J) 3/8" FPT

water inlet

drain pan

10 110 Series Ice and Water Dispensers

10. Apply a thick bead, approximately. 1/4" (6mm)

diameter, of NSF listed silicone sealant (DowCorning RTV-732 or equivalent) 1/4" (6mm) inside

marked outline of dispenser.

11. Carefully position dispenser on counter.

12. Remove four screws securing splash panel to front

of dispenser and gently lay splash panel on counter.

(Water line to solenoid valve can be disconnected

from water inlet valve by pushing on ring at end of

inlet tting while pulling on tubing.)

13. Secure dispenser to counter with four 3/8" bolts

(supplied by others).

14. Smooth excess sealant around outside of dispenser.

15. Run water station line from back of dispenser

through utility knock-out (Figs. 4, 5) or up through

counter cut-out. Connect water supply line to 3/8"

FPT, (Fig. 3J) tting on utility ange at bottom of

dispenser.

16. Remove 3/4" drain connection plug from either

tting at rear of dispenser, (Fig. 1K) or internal

tting, (Fig. 3L), as appropriate. Connect and run

a dedicated drain line to wall or oor drain. An air

break should be provided.

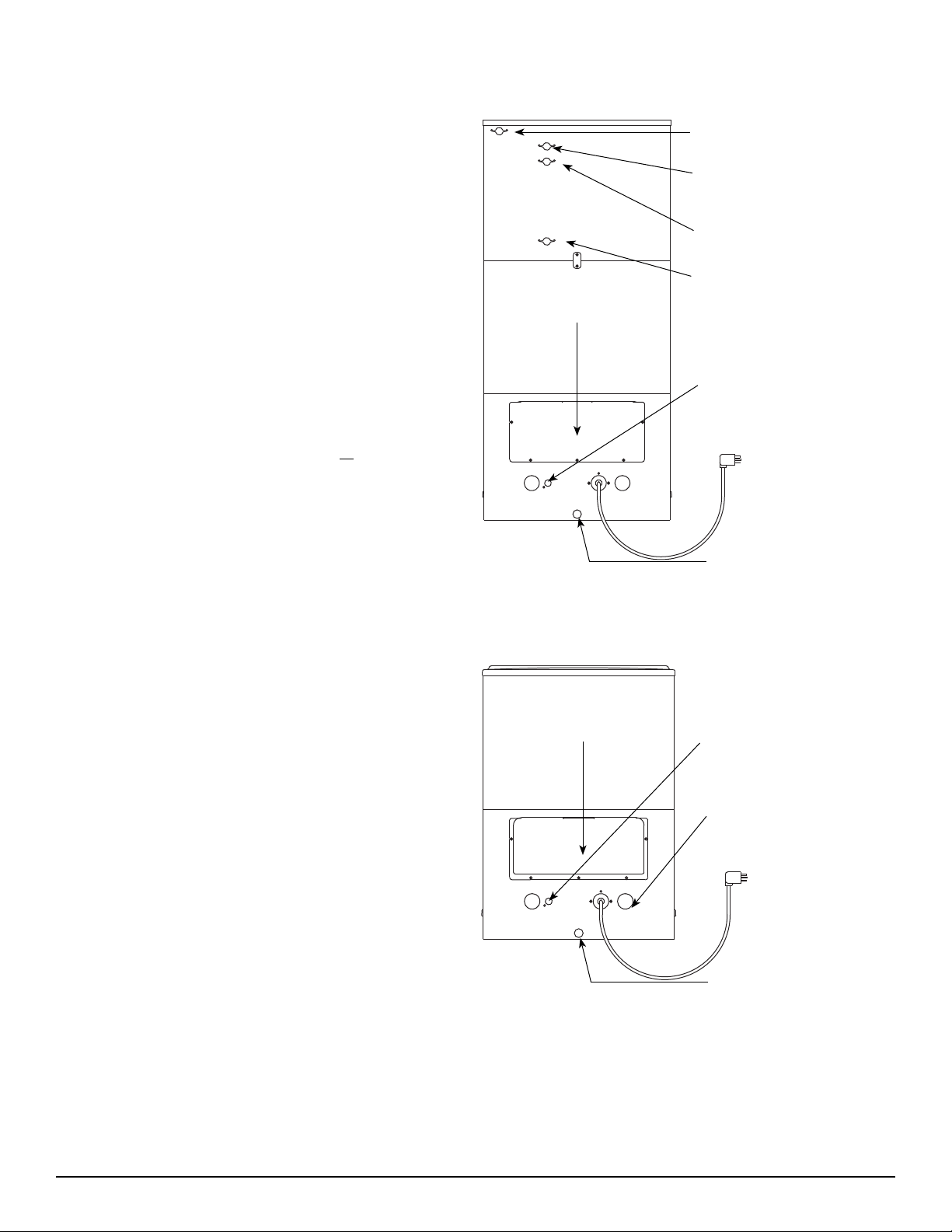

Fig. 4 – Rear connections, countertop models with

integral ice machines

(M) 3/8" FPT

ice machine water inlet

(R) 3/8" FPT condenser inlet

(water-cooled only)

(P) 3/8" FPT

condenser outlet

(water-cooled only)

(N) 3/4" MPT

ice machine drain

access panel

(H) water station knock-out

If dispenser is equipped with a top mount,

water-cooled ice machine complete steps 17

through 20. If equipped with a top mount,

air-cooled ice machine proceed to step 21.

17. Connect ice machine water supply line to 3/8" FPT

water inlet, (Fig. 4M).

18. Connect ice machine drain line to 3/4 MPT drain

connection (Fig, 4N).

19. If ice machine is water-cooled, connect water-cooled

condenser supply line to 3/8" FPT condenser tting

on back of dispenser (Fig. 4R).

Note: Do not run condenser supply water through

ice machine water lter system.

20. Connect condenser drain line to 3/8" FPT tting on

back of dispenser (Fig. 4P).

Important: Do not connect condenser drain line to

any other drain lines.

21. Proceed with either RIDE or top-mounted ice

machine connection instructions, as appropriate.

3/4" FPT dispenser

drain

Fig. 5 – Rear connections, countertop models with RIDE

ice machines

access panel

(H) water station knock-out

(G) ice transport tube knock-out

3/4" FPT dispenser

drain

110 Series Ice and Water Dispensers 11

Loading...

Loading...