Page 1

123

Industrial ScopeMeter

Service Manual

4822 872 05375

August 1997, Rev. 3, 01/00

© 1997 Fluke Corporation. All rights reserved. Printed in the Netherlands

All product names are trademarks of their respective companies.

Page 2

SERVICE CENTERS

To locate an authorized service center, visit us on the World Wide Web:

http://www.fluke.com

or call Fluke using any of the phone numbers listed below:

+1-888-993-5853 in U.S.A. and Canada

+31-402-678-200 in Europe

+1-425-356-5500 from other countries

Page 3

Table of Contents

Chapter Title Page

1 Safety Instructions ............................................................................. 1-1

1.1 Introduction................................................................................................. 1-3

1.2 Safety Precautions....................................................................................... 1-3

1.3 Caution and Warning Statements................................................................ 1-3

1.4 Symbols....................................................................................................... 1-3

1.5 Impaired Safety........................................................................................... 1-4

1.6 General Safety Information......................................................................... 1-4

2 Characteristics ................................................................................... 2-1

2.1 Introduction................................................................................................. 2-3

2.2 Dual Input Oscilloscope.............................................................................. 2-3

2.2.1 Vertical ................................................................................................ 2-3

2.2.2 Horizontal ............................................................................................ 2-4

2.2.3 Trigger ................................................................................................. 2-4

2.2.4 Advanced Scope Functions.................................................................. 2-5

2.3 Dual Input Meter......................................................................................... 2-5

2.3.1 Input A and Input B ............................................................................. 2-5

2.3.2 Input A ................................................................................................. 2-8

2.3.3 Advanced Meter Functions.................................................................. 2-8

2.4 Miscellaneous ............................................................................................. 2-9

2.5 Environmental............................................................................................. 2-10

2.6 Service and Maintenance ............................................................................ 2-11

2.7 Safety .......................................................................................................... 2-11

2.8 EMC Immunity ........................................................................................... 2-12

3 Circuit Descriptions ........................................................................... 3-1

3.1 Introduction................................................................................................. 3-3

3.2 Block Diagram ............................................................................................ 3-3

3.2.1 Channel A, Channel B Measurement Circuits..................................... 3-4

3.2.2 Trigger Circuit ..................................................................................... 3-4

3.2.3 Digital Circuit ...................................................................................... 3-5

3.2.4 Power Circuit....................................................................................... 3-6

3.2.5 Start-up Sequence, Operating Modes .................................................. 3-7

Page 4

123

Service Manual

3.3 Detailed Circuit Descriptions...................................................................... 3-9

3.3.1 Power Circuit....................................................................................... 3-9

3.3.2 Channel A - Channel B Measurement Circuits ................................... 3-15

3.3.3 Trigger Circuit ..................................................................................... 3-20

3.3.4 Digital Circuit ...................................................................................... 3-25

4 Performance Verification ................................................................... 4-1

4.1 Introduction................................................................................................. 4-3

4.2 Equipment Required For Verification ........................................................ 4-3

4.3 How To Verify ............................................................................................ 4-3

4.4 Display and Backlight Test......................................................................... 4-4

4.5 Input A and Input B Tests ........................................................................... 4-5

4.5.1 Input A and B Base Line Jump Test.................................................... 4-6

4.5.2 Input A Trigger Sensitivity Test.......................................................... 4-7

4.5.3 Input A Frequency Response Upper Transition Point Test................. 4-8

4.5.4 Input A Frequency Measurement Accuracy Test ................................ 4-8

4.5.5 Input B Frequency Measurement Accuracy Test ................................ 4-9

4.5.6 Input B Frequency Response Upper Transition Point Test ................. 4-10

4.5.7 Input B Trigger Sensitivity Test .......................................................... 4-10

4.5.8 Input A and B Trigger Level and Trigger Slope Test.......................... 4-11

4.5.9 Input A and B DC Voltage Accuracy Test .......................................... 4-14

4.5.10 Input A and B AC Voltage Accuracy Test ........................................ 4-15

4.5.11 Input A and B AC Input Coupling Test............................................. 4-16

4.5.12 Input A and B Volts Peak Measurements Test.................................. 4-17

4.5.13 Input A and B Phase Measurements Test.......................................... 4-18

4.5.14 Input A and B High Voltage AC/DC Accuracy Test......................... 4-19

4.5.15 Resistance Measurements Test.......................................................... 4-20

4.5.16 Continuity Function Test ................................................................... 4-21

4.5.17 Diode Test Function Test .................................................................. 4-22

4.5.18 Capacitance Measurements Test ....................................................... 4-22

4.5.19 Video Trigger Test............................................................................. 4-23

5 Calibration Adjustment ...................................................................... 5-1

5.1 General ........................................................................................................ 5-3

5.1.1 Introduction.......................................................................................... 5-3

5.1.2 Calibration number and date................................................................ 5-3

5.1.3 General Instructions............................................................................. 5-3

5.2 Equipment Required For Calibration.......................................................... 5-4

5.3 Starting Calibration Adjustment ................................................................. 5-4

5.4 Contrast Calibration Adjustment ................................................................ 5-6

5.5 Warming Up & Pre-Calibration.................................................................. 5-7

5.6 Final Calibration ......................................................................................... 5-7

5.6.1 HF Gain Input A&B ............................................................................ 5-7

5.6.2 Delta T Gain, Trigger Delay Time & Pulse Adjust Input A................ 5-9

5.6.3 Pulse Adjust Input A (firmware V01.00 only) .................................... 5-10

5.6.4 Pulse Adjust Input B............................................................................ 5-11

5.6.5 Gain DMM (Gain Volt)....................................................................... 5-11

5.6.6 Volt Zero.............................................................................................. 5-13

5.6.7 Zero Ohm (firmware V01.00 only)...................................................... 5-13

5.6.8 Gain Ohm............................................................................................. 5-14

5.6.9 Capacitance Gain Low and High......................................................... 5-15

5.6.10 Capacitance Clamp & Zero................................................................ 5-15

5.6.11 Capacitance Gain............................................................................... 5-16

5.7 Save Calibration Data and Exit................................................................... 5-16

Page 5

Contents (continued)

6 Disassembling the Test Tool............................................................. 6-1

6.1. Introduction................................................................................................ 6-3

6.2. Disassembling Procedures ......................................................................... 6-3

6.1.1 Required Tools .................................................................................... 6-3

6.2.2 Removing the Battery Pack ................................................................. 6-3

6.2.3 Removing the Bail ............................................................................... 6-3

6.2.4 Opening the Test Tool ......................................................................... 6-3

6.2.5 Removing the Main PCA Unit............................................................. 6-5

6.2.6 Removing the Display Assembly......................................................... 6-6

6.2.7 Removing the Keypad and Keypad Foil.............................................. 6-6

6.3 Disassembling the Main PCA Unit............................................................. 6-6

6.4 Reassembling the Main PCA Unit.............................................................. 6-8

6.5 Reassembling the Test Tool........................................................................ 6-8

7 Corrective Maintenance..................................................................... 7-1

7.1 Introduction................................................................................................. 7-3

7.2 Starting Fault Finding. ................................................................................ 7-4

7.3 Charger Circuit............................................................................................ 7-4

7.4 Starting with a Dead Test Tool ................................................................... 7-6

7.4.1 Test Tool Completely Dead................................................................. 7-6

7.4.2 Test Tool Software Does not Run. ...................................................... 7-7

7.4.3 Software Runs, Test Tool not Operative ............................................. 7-7

7.5 Miscellaneous Functions............................................................................. 7-8

7.5.1 Display and Back Light ....................................................................... 7-8

7.5.2 Fly Back Converter.............................................................................. 7-9

7.5.3 Slow ADC............................................................................................ 7-10

7.5.4 Keyboard.............................................................................................. 7-11

7.5.5 Optical Port (Serial RS232 Interface).................................................. 7-11

7.5.6 Channel A, Channel B Voltage Measurements ................................... 7-12

7.5.7 Channel A Ohms and Capacitance Measurements.............................. 7-13

7.5.8 Trigger Functions................................................................................. 7-14

7.5.9 Reference Voltages.............................................................................. 7-15

7.5.10 Buzzer Circuit.................................................................................... 7-15

7.5.11 Reset ROM Circuit (PCB version <8 only)....................................... 7-16

7.5.12 RAM Test .......................................................................................... 7-16

7.5.13 Power ON/OFF.................................................................................. 7-16

7.5.14 PWM Circuit...................................................................................... 7-17

7.5.15 Randomize Circuit............................................................................. 7-17

7.6 Loading Software........................................................................................ 7-17

8 List of Replaceable Parts................................................................... 8-1

8.1 Introduction................................................................................................. 8-3

8.2 How to Obtain Parts.................................................................................... 8-3

8.3 Final Assembly Parts .................................................................................. 8-4

8.4 Main PCA Unit Parts .................................................................................. 8-6

8.5 Main PCA Parts .......................................................................................... 8-7

8.6 Accessory Replacement Parts ..................................................................... 8-24

8.7 Service Tools............................................................................................... 8-24

9 Circuit Diagrams................................................................................. 9-1

9.1 Introduction................................................................................................. 9-3

9.2 Schematic Diagrams.................................................................................... 9-4

Page 6

123

Service Manual

10 Modifications ...................................................................................... 10-1

10.1 Software modifications ............................................................................. 10-1

10.2 Hardware modifications............................................................................ 10-1

Page 7

List of Tables

Table Title Page

2-1. No Visible Trace Disturbance ............................................................................... 2-12

2-2. Trace Disturbance < 10%...................................................................................... 2-12

2-3. Multimeter Disturbance < 1%............................................................................... 2-12

3-1. Fluke 123 Main Blocks ......................................................................................... 3-3

3-2. Fluke 123 Operating Modes.................................................................................. 3-9

3-3. Voltage Ranges And Trace Sensitivity ................................................................. 3-18

3-4. Ohms Ranges, Trace Sensitivity, and Current ...................................................... 3-18

3-5. Capacitance Ranges, Current, and Pulse Width.................................................... 3-20

3-6. D-ASIC PWM Signals........................................................................................... 3-29

4-1. Input A,B Frequency Measurement Accuracy Test .............................................. 4-9

4-2. Volts DC Measurement Verification Points ......................................................... 4-15

4-3. Volts AC Measurement Verification Points ......................................................... 4-16

4-4. Input A and B AC Input Coupling Verification Points......................................... 4-17

4-5. Volts Peak Measurement Verification Points ....................................................... 4-18

4-6. Phase Measurement Verification Points ............................................................... 4-18

4-7. V DC and V AC High Voltage Verification Tests................................................ 4-20

4-8. Resistance Measurement Verification Points........................................................ 4-21

4-9. Capacitance Measurement Verification Points ..................................................... 4-23

5-1. HF Gain Calibration Points Fast ........................................................................... 5-8

5-2. HF Gain Calibration Points Slow.......................................................................... 5-9

5-3. Volt Gain Calibration Points <300V..................................................................... 5-12

5-4. Ohm Gain Calibration Points ................................................................................ 5-14

7-1. Starting Fault Finding............................................................................................ 7-4

8-1. Final Assembly Parts............................................................................................. 8-4

8-2. Main PCA Unit...................................................................................................... 8-6

8-3. Main PCA.............................................................................................................. 8-7

9-1. Parts Location Main PCA Side 1 .......................................................................... 9-4

9-2. Parts Location Main PCA Side 2 .......................................................................... 9-5

Page 8

Page 9

List of Figures

Figure Title Page

3-1. Fluke 123 Block Diagram...................................................................................... 3-2

3-2. Fluke 123 Start-up Sequence, Operating Modes................................................... 3-8

3-3. Power Supply Block Diagram............................................................................... 3-9

3-4. CHAGATE Control Voltage ................................................................................. 3-12

3-5. Fly-Back Converter Current and Control Voltage ................................................ 3-12

3-6. Fly-Back Converter Block Diagram...................................................................... 3-13

3-7. Back Light Converter Voltages............................................................................. 3-15

3-8. C-ASIC Block Diagram......................................................................................... 3-15

3-9. Capacitance Measurement..................................................................................... 3-19

3-10. T-ASIC Trigger Section Block Diagram............................................................... 3-21

3-11. Random Repetitive Sampling Mode ..................................................................... 3-22

3-12. Reference Voltage Section .................................................................................... 3-24

3-13. LCD Control .......................................................................................................... 3-28

4-1. Display Pixel Test Pattern ..................................................................................... 4-4

4-2. Menu item selection .............................................................................................. 4-6

4-3. Test Tool Input A to 5500A Scope Output 50Ω ................................................... 4-7

4-4. Test Tool Input B to 5500A Scope Output 50Ω ................................................... 4-9

4-5. Test Tool Input A-B to 5500A Normal Output..................................................... 4-11

4-6. Test Tool Input A-B to 5500A Normal Output for >300V ................................... 4-19

4-7. Test Tool Input A to 5500A Normal Output 4-Wire............................................. 4-20

4-8. Test Tool Input A to TV Signal Generator ........................................................... 4-23

4-9. Test Tool Screen for PAL/SECAM line 622 ........................................................ 4-24

4-10. Test Tool Screen for NTSC line 525..................................................................... 4-24

4-11. Test Tool Screen for PAL/SECAM line 310 ........................................................ 4-25

4-12. Test Tool Screen for NTSC line 262..................................................................... 4-25

4-13. Test Tool Input A to TV Signal Generator Inverted ............................................. 4-25

4-14. Test Tool Screen for PAL/SECAM line 310 Negative Video .............................. 4-26

4-15. Test Tool Screen for NTSC line 262 Negative Video .......................................... 4-26

5-1. Version & Calibration Screen ............................................................................... 5-3

5-2. Display Test Pattern .............................................................................................. 5-6

5-3. HF Gain Calibration Input Connections................................................................ 5-7

5-4. 5500A Scope Output to Input A............................................................................ 5-9

5-5. 5500A Scope Output to Input B ............................................................................ 5-11

5-6. Volt Gain Calibration Input Connections <300V ................................................. 5-12

5-7. Volt Gain Calibration Input Connections 500V.................................................... 5-13

Page 10

123

Service Manual

5-8. Four-wire Ohms calibration connections .............................................................. 5-14

5-9. Capacitance Gain Calibration Input Connections ................................................. 5-15

5-10. 20 V Supply Cable for Calibration........................................................................ 5-16

6-1. Fluke 123 Main Assembly..................................................................................... 6-4

6-2. Flex Cable Connectors .......................................................................................... 6-5

6-3. Main PCA Unit Assembly..................................................................................... 6-7

6-4. Mounting the display shielding bracket ................................................................ 6-9

6-5. Battery pack installation........................................................................................ 6-9

7-1. Operative Test Tool without Case......................................................................... 7-3

7-2. 20V Supply Cable for Loading Software.............................................................. 7-17

8-1. Fluke 123 Final Assembly..................................................................................... 8-5

8-2. Main PCA Unit...................................................................................................... 8-6

9-1. Circuit Diagram 1, Channel A Circuit................................................................... 9-7

9-2. Circuit Diagram 2, Channel B Circuit................................................................... 9-8

9-3. Circuit Diagram 3, Trigger Circuit........................................................................ 9-9

9-4. Circuit Diagram 4, Digital Circuit......................................................................... 9-10

9-5. Circuit Diagram 4 (cont), Digital Circuit Keyboard ............................................. 9-11

9-6. Circuit Diagram 5, Power Circuit.......................................................................... 9-12

9-7. Main PCA side 1 ................................................................................................... 9-13

9-8. Main PCA side 2 ................................................................................................... 9-14

9-9. Main PCA side 1, PCB version 8 .......................................................................... 9-15

9-10. Main PCA side 2, PCB version 8 .......................................................................... 9-16

Page 11

Chapter 1

Safety Instructions

Title Page

1.1 Introduction................................................................................................. 1-3

1.2 Safety Precautions....................................................................................... 1-3

1.3 Caution and Warning Statements................................................................ 1-3

1.4 Symbols....................................................................................................... 1-3

1.5 Impaired Safety........................................................................................... 1-4

1.6 General Safety Information......................................................................... 1-4

1-1

Page 12

Page 13

1.1 Introduction

Read these pages carefully before beginning to install and use the instrument.

The following paragraphs contain information, cautions and warnings which must be

followed to ensure safe operation and to keep the instrument in a safe condition.

Servicing described in this manual is to be done only by

qualified service personnel. To avoid electrical shock, do not

service the instrument unless you are qualified to do so.

1.2 Safety Precautions

For the correct and safe use of this instrument it is essential that both operating and

service personnel follow generally accepted safety procedures in addition to the safety

precautions specified in this manual. Specific warning and caution statements, where

they apply, will be found throughout the manual. Where necessary, the warning and

caution statements and/or symbols are marked on the instrument.

Warning

Safety Instructions

1.1 Introduction

1

1.3 Caution and Warning Statements

Caution

Used to indicate correct operating or maintenance procedures

to prevent damage to or destruction of the equipment or other

property.

Warning

Calls attention to a potential danger that requires correct

procedures or practices to prevent personal injury.

1.4 Symbols

Read the safety information in the Users

Manual

Equal potential inputs, connected

internally

Live voltage Recycling information

Earth Disposal information

DOUBLE INSULATION (Protection Class)

Static sensitive components

(black/yellow).

Conformité Européenne

1-3

Page 14

123

Service Manual

1.5 Impaired Safety

1.6 General Safety Information

Whenever it is likely that safety has been impaired, the instrument must be turned off

and disconnected from line power. The matter should then be referred to qualified

technicians. Safety is likely to be impaired if, for example, the instrument fails to

perform the intended measurements or shows visible damage.

Warning

Removing the instrument covers or removing parts, except

those to which access can be gained by hand, is likely to

expose live parts and accessible terminals which can be

dangerous to life.

The instrument shall be disconnected from all voltage sources before it is opened.

Capacitors inside the instrument can hold their charge even if the instrument has been

separated from all voltage sources.

Components which are important for the safety of the instrument may only be replaced

by components obtained through your local FLUKE organization. These parts are

indicated with an asterisk (*) in the List of Replaceable Parts, Chapter 8.

1-4

Page 15

Chapter 2

Characteristics

Title Page

2.1 Introduction................................................................................................. 2-3

2.2 Dual Input Oscilloscope.............................................................................. 2-3

2.2.1 Vertical ................................................................................................ 2-3

2.2.2 Horizontal ............................................................................................ 2-4

2.2.3 Trigger ................................................................................................. 2-4

2.2.4 Advanced Scope Functions.................................................................. 2-5

2.3 Dual Input Meter......................................................................................... 2-5

2.3.1 Input A and Input B ............................................................................. 2-5

2.3.2 Input A ................................................................................................. 2-8

2.3.3 Advanced Meter Functions.................................................................. 2-8

2.4 Miscellaneous ............................................................................................. 2-9

2.5 Environmental............................................................................................. 2-10

2.6 Service and Maintenance ............................................................................ 2-11

2.7 Safety .......................................................................................................... 2-11

2.8 EMC Immunity ........................................................................................... 2-12

2-1

Page 16

Page 17

2.1 Introduction

Performance Characteristics

FLUKE guarantees the properties expressed in numerical values with the stated

tolerance. Specified non-tolerance numerical values indicate those that could be

nominally expected from the mean of a range of identical ScopeMeter test tools.

Environmental Data

The environmental data mentioned in this manual are based on the results of the

manufacturer’s verification procedures.

Safety Characteristics

The test tool has been designed and tested in accordance with Standards ANSI/ISA

S82.01-1994, EN 61010-1 (1993) (IEC 1010-1), CAN/CSA-C22.2 No.1010.1-92

(including approval), UL3111-1 (including approval) Safety Requirements for Electrical

Equipment for Measurement, Control, and Laboratory Use. Use of this equipment in a

manner not specified by the manufacturer may impair protection provided by the

equipment.

Characteristics

2.1 Introduction

2

2.2 Dual Input Oscilloscope

2.2.1 Vertical

Frequency Response

DC Coupled:

excluding probes and test leads: DC to 20 MHz (-3 dB)

with STL120 1:1 shielded test leads: DC to 12.5 MHz (-3 dB)

with PM8918 10:1 probe: DC to 20 MHz (-3 dB)

(optional accessory)

AC Coupled (LF roll off):

excluding probes and test leads <10 Hz (-3 dB)

with STL120 <10 Hz (-3dB)

with PM8918 <1 Hz (-3 dB)

Rise Time

excluding probes and test leads <17.5 ns

Input Impedance

excluding probes and test leads 1 MΩ//12 pF

with BB120 1 MΩ//20 pF

with STL120 1 MΩ//225 pF

with PM8918 10 MΩ//15 pF

DC to 20 MHz (-6 dB)

Sensitivity 5 mV to 500 V/div

Display Modes A, -A, B, -B

2-3

Page 18

123

Service Manual

2.2.2 Horizontal

Max. Input Voltage A and B

direct or with test leads 600 Vrms

with BB120 300 Vrms

(For detailed specifications see “2.7 Safety”)

Max. Floating Voltage

from any terminal to ground 600 Vrms, up to 400Hz

Resolution 8 bit

Vertical Accuracy ±(1% + 0.05 range/div)

Max. Vertical Move ±4 divisions

Max. Base Line Jump After changing time base or sensitivity

Normal & Single mode ±0.04 divisions (= ±1 pixel)

Scope Modes Normal, Single, Roll

Ranges

Normal:

equivalent sampling 20 ns to 500 ns/div

real time sampling 1 µs to 5 s/div

Single (real time) 1 µs to 5 s/div

Roll (real time) 1s to 60 s/div

Sampling Rate (for both channels simultaneously)

Equivalent sampling (repetitive signals) up to 1.25 GS/s

Real time sampling:

1 µs to 5 ms/div 25 MS/s

10 ms to 5 s/div 5 MS/s

Time Base Accuracy

Equivalent sampling ±(0.4% +0.04 time/div)

Real time sampling ±(0.1% +0.04 time/div)

Glitch Detection ≥40 ns @ 20 ns to 5 ms/div

≥200 ns @ 10 ms to 60 s/div

Glitch detection is always active.

Horizontal Move 10 divisions

Trigger point can be positioned anywhere

across the screen.

2-4

2.2.3 Trigger

Screen Update Free Run, On Trigger

Source A, B, EXT

EXTernal via optically isolated trigger

probe ITP120 (optional accessory)

Page 19

Sensitivity A and B

@ DC to 5 MHz 0.5 divisions or 5 mV

@ 25 MHz 1.5 divisions

@ 40 MHz 4 divisions

Voltage level error ±0.5 div. max.

Slope Positive, Negative

Video on A Interlaced video signals only

Modes Lines, Line Select

Standards PAL , NTSC, PAL+, SECAM

Polarity Positive, Negative

Sensitivity 0.6 divisions sync.

2.2.4 Advanced Scope Functions

Display Modes

Normal Captures up to 40 ns glitches and displays analog-like persistence

waveform.

Smooth Suppresses noise from a waveform.

Envelope Records and displays the minimum and maximum of waveforms

over time.

Characteristics

2.3 Dual Input Meter

2

Auto Set

Continuous fully automatic adjustment of amplitude, time base, trigger levels, trigger

gap, and hold-off. Manual override by user adjustment of amplitude, time base, or

trigger level.

2.3 Dual Input Meter

The accuracy of all measurements is within ± (% of reading + number of counts) from

18 °C to 28 °C.

Add 0.1x (specific accuracy) for each °C below 18 °C or above 28 °C. For voltage

measurements with 10:1 probe, add probe uncertainty +1%.

More than one waveform period must be visible on the screen.

2.3.1 Input A and Input B

DC Voltage (VDC)

Ranges 500 mV, 5V, 50V, 500V, 1250V

Accuracy ±(0.5% +5 counts)

Turnover ±12 counts

Normal Mode Rejection (SMR) >60 dB @ 50 or 60 Hz ±1%

Common Mode Rejection (CMRR) >100 dB @ DC

>60 dB @ 50, 60, or 400 Hz

Full Scale Reading 5000 counts

Move influence ±6 counts max.

2-5

Page 20

123

Service Manual

True RMS Voltages (VAC and VAC+DC)

Ranges 500 mV, 5V, 50V, 500V, 1250V

Accuracy for 5 to 100% of range

DC coupled:

DC to 60 Hz (VAC+DC) ±(1% +10 counts)

1 Hz to 60 Hz (VAC) ±(1% +10 counts)

AC or DC coupled:

60 Hz to 20 kHz ± (2.5% +15 counts)

20 kHz to 1 MHz ±(5% +20 counts)

1 MHz to 5 MHz ±(10% +25 counts)

5 MHz to 12.5 MHz ±(30% +25 counts)

5 MHz to 20 MHz ±(30% +25 counts), excluding test leads or

probes

AC coupled with 1:1 (shielded) test leads:

60 Hz (6 Hz with 10:1 probe) -1.5%

50 Hz (5 Hz with 10:1 probe) -2%

33 Hz (3.3 Hz with 10:1 probe) -5%

10 Hz (1 Hz with 10:1 probe) -30%

DC Rejection (only VAC) >50 dB

Common Mode Rejection (CMRR) >100 dB @ DC

>60 dB @ 50, 60, or 400 Hz

Full Scale Reading 5000 counts

The reading is independent of any signal

crest factor.

Move influence ±6 counts max.

Peak

Modes Max peak, Min peak, or pk-to-pk

Ranges 500 mV, 5V, 50V, 500V, 1250V

Accuracy:

Max peak or Min peak 5% of full scale

Peak-to-Peak 10% of full scale

Full Scale Reading 500 counts

Frequency (Hz)

Ranges 1Hz, 10Hz, 100Hz, 1 kHz, 10 kHz,

100 kHz,1 MHz, 10 MHz, 40 MHz

Frequency Range for Continuous Autoset 15Hz (1Hz) to 30 MHz

2-6

Accuracy:

@1Hz to 1 MHz ±(0.5% +2 counts)

@1 MHz to 10 MHz ±(1.0% +2 counts)

@10 MHz to 40 MHz ±(2.5% +2 counts)

Full Scale Reading 10 000 counts

Page 21

Duty Cycle (DUTY)

Range 2% to 98%

Frequency Range for Continuous Autoset 15Hz (1Hz) to 30 MHz

Accuracy:

@1Hz to 1 MHz ±(0.5% +2 counts)

@1 MHz to 10 MHz ±(1.0% +2 counts)

@10 MHz to 40 MHz ±(2.5% +2 counts)

Resolution 0.1%

Pulse Width (PULSE)

Frequency Range for Continuous Autoset 15Hz (1Hz) to 30 MHz

Accuracy:

@1Hz to 1 MHz ±(0.5% +2 counts)

@1 MHz to 10 MHz ±(1.0% +2 counts)

@10 MHz to 40 MHz ±(2.5% +2 counts)

Full Scale reading 1000 counts

Characteristics

2.3 Dual Input Meter

2

Amperes (AMP) with optional current probe

Ranges same as VDC, VAC, VAC+DC, or PEAK

Scale Factor 1 mV/A, 10 mV/A, 100 mV/A, and 1 V/A

Accuracy same as VDC, VAC, VAC+DC, or PEAK

(add current probe uncertainty)

Temperature (TEMP) with optional temperature probe

Range 200 °C/div (200 °F/div)

Scale Factor 1 mV/°C and 1 mV/°F

Accuracy as VDC (add temperature probe

uncertainty)

Decibel (dB)

0 dBV 1V

0 dBm (600Ω /50Ω) 1 mW, referenced to 600Ω or 50Ω

dB on VDC, VAC, or VAC+DC

Full Scale Reading 1000 counts

Crest Factor (CREST)

Range 1 to 10

Accuracy ±(5% +1 count)

Full Scale Reading 100 counts

Phase

Modes A to B, B to A

Range 0 to 359 degrees

Accuracy ±(1 degree +1 count)

Resolution 1 degree

2-7

Page 22

123

Service Manual

2.3.2 Input A

Ohm (ΩΩΩΩ)

Ranges 500Ω, 5 kΩ, 50 kΩ, 500 kΩ, 5 MΩ,

30 MΩ

Accuracy ±(0.6% +5 counts)

Full Scale Reading

500Ω to 5 MΩ 5000 counts

30 MΩ 3000 counts

Measurement Current 0.5 mA to 50 nA

decreases with increasing ranges

Open Circuit Voltage <4V

Continuity (CONT)

Beep 30Ω ± 5Ω in 50Ω range

Measurement Current 0.5 mA

Detection of shorts of ≥1 ms

Diode

Maximum Voltage:

@0.5 mA >2.8V

@open circuit <4V

Accuracy ±(2% +5 counts)

Measurement Current 0.5 mA

Polarity + on input A, - on COM

Capacitance (CAP)

Ranges 50 nF, 500 nF, 5 µF, 50 µF, 500 µF

Accuracy ±(2% +10 counts)

Full Scale Reading 5000 counts

Measurement Current 5 µA to 0.5 mA, increases with increasing

Measurement principle Dual slope integrating measurement with

2.3.3 Advanced Meter Functions

ranges

parasitic serial and parallel resistance

cancellation.

2-8

Zero Set Set actual value to reference

Fast/Normal/Smooth

Meter settling time Fast 1s @ 1µs to 10 ms/div

Meter settling time Normal 2s @ 1µs to 10 ms/div

Meter settling time Smooth 10s @ 1µs to 10 ms/div

Page 23

Touch Hold (on A) Captures and freezes a stable measurement

TrendPlot Graphs meter readings of the Min and

Fixed Decimal Point Possible by using attenuation keys.

2.4 Miscellaneous

Display

Size 72 x 72 mm (2.83 x 2.83 in)

Characteristics

2.4 Miscellaneous

result. Beeps when stable. Touch Hold

works on the main meter reading , with

threshholds of 1 Vpp for AC signals and

100mV for DC signals.

Max values from 15 s/div (120 seconds) to

2 days/div (16 days) with time and date

stamp. Automatic vertical scaling and time

compression.

Displays the actual and Minimum,

Maximum, or average (AVG) reading.

2

Resolution 240 x 240 pixels

Waveform display:

Vertical 8 divisions of 20 pixels

Horizontal 9.6 divisions of 25 pixels

Backlight Cold Cathode Fluorescent (CCFL)

Power

External: via Power Adapter PM8907

Input Voltage 10 to 21V DC

Power 5W typical

Input Connector 5 mm jack

Internal:

Battery Power Rechargeable Ni-Cd 4.8V

Operating Time 4 hours with bright backlight

5 hours with dimmed backlight

Charging Time 4 hours with test tool off

12 hours with test tool on

12 hours with refresh cycle

Allowable ambient temperature

during charging 0 to 45 °C (32 to 113 °F)

Memory

Number of Screens 2

Number of User Setups 10

Mechanical

Size 232 x 115 x 50 mm (9.1 x 4.5 x 2 in)

Weight 1.1 kg (2.5 lbs), including battery pack.

2-9

Page 24

123

Service Manual

2.5 Environmental

Interface RS-232, optically isolated

To Printer supports Epson FX, LQ, and HP Deskjet

Laserjet

, and Postscript

Serial via PM9080 (optically isolated

RS232 adapter/cable, optional).

Parallel via PAC91 (optically isolated

print adapter cable, optional).

To PC Dump and load settings and data.

Serial via PM9080 (optically isolated

RS232 adapter/cable, optional), using

SW90W (FlukeView software for

Windows).

Environmental MIL 28800E, Type 3, Class III, Style B

Temperature

Operating 0 to 50 °C (32 to 122 °F)

Storage -20 to 60 °C (-4 to 140 °F)

,

Humidity

Operating:

@0 to 10 °C (32 to 50 °F) noncondensing

@10 to 30 °C (50 to 86 °F) 95%

@30 to 40 °C (86 to 104 °F) 75%

@40 to 50 °C (104 to 122 °F) 45%

Storage:

@-20 to 60 °C (-4 to 140 °F) noncondensing

Altitude

Operating 4.5 km (15 000 feet)

Max. Input and Floating Voltage 600

Vrms up to 2 km, linearly derating to 400

Vrms @ 4.5 km

Storage 12 km (40 000 feet)

Vibration max. 3g

Shock max. 30g

Fungus Resistance MIL28800E, Class 3, 3.7.7 & 4.5.6.1

Salt Exposure MIL28800E, Class 3, 3.7.8.2 & 4.5.6.2.2.

Structural parts meet 48 hours 5% salt

solution test.

Electromagnetic Compatibility (EMC)

2-10

Emission EN 50081-1 (1992): EN55022 and

EN60555-2

Immunity EN 50082-2(1992): IEC1000-4-2, -3, -4, -5

(see also Section 2.8, Tables 2-1 to 2-3)

Enclosure Protection IP51, ref: IEC529

Page 25

2.6 Service and Maintenance

Calibration Interval 1 Year

2.7 Safety

Designed for measurements on 600 Vrms Category III Installations, Pollution Degree 2,

per:

• ANSI/ISA S82.01-1994

• EN61010-1 (1993) (IEC1010-1)

• CAN/CSA-C22.2 No.1010.1-92 (including approval)

• UL3111-1 (including approval)

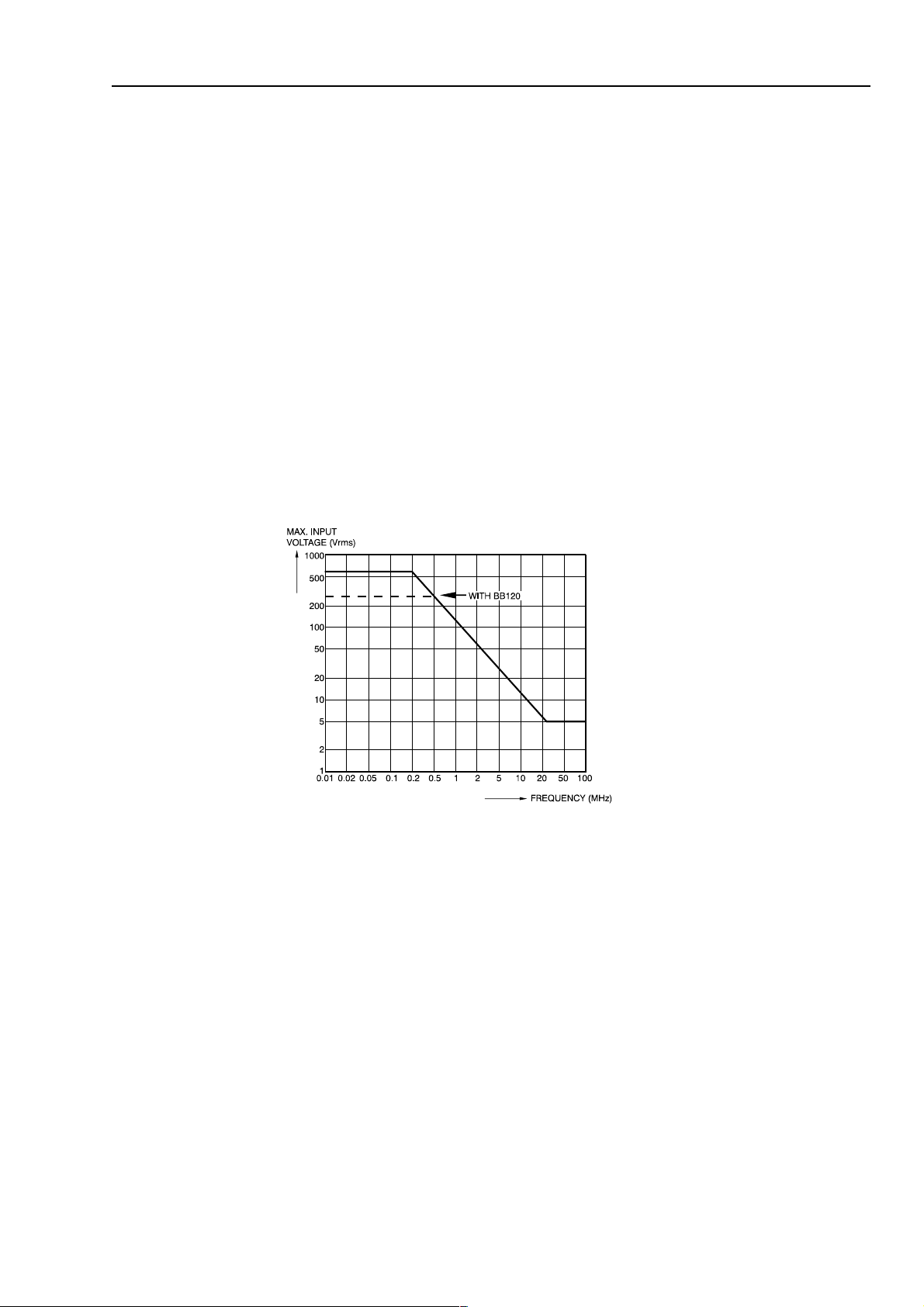

Max. Input Voltage Input A and B

Direct on input or with leads 600 Vrms. For derating see Figure 2-1.

With Banana-to-BNC Adapter BB120 300V rms. For derating see Figure 2-1.

Max. Floating Voltage

from any terminal to ground 600 Vrms up to 400Hz

Characteristics

2.6 Service and Maintenance

2

Figure 2-1. Maximum Input Voltage vs Frequency

ST8112.CGM

2-11

Page 26

123

Service Manual

2.8 EMC Immunity

No visible disturbance E= 3 V/m E= 10 V/m

The Fluke 123, including standard accessories, conforms with the EEC directive 89/336

for EMC immunity, as defined by IEC1000-4-3, with the addition of tables 2-1 to 2-3.

Trace Disturbance with STL120 See Table 2-1 and Table 2-2.

Table 2-1. No Visible Trace Disturbance

Frequency range 10 kHz to 27 MHz

Frequency range 27 MHz to 1 GHz

Table 2-2. Trace Disturbance < 10%

Disturbance less than 10% of full scale E= 3 V/m E= 10 V/m

Frequency range 10 kHz to 27 MHz

Frequency range 2 MHz to 1 GHz

(-): no visible disturbance

Test tool ranges not specified in Table 2-1 and Table 2-2 may have a disturbance of more than 10% of full

scale.

50 mV/div to 500 V/div

50 mV/div to 500 V/div

10 mV/div to 20 mV/div

5 mV/div to 20 mV/div

500 mV/div to 500 V/div

50 mV/div to 500 V/div

50 mV/div to 200 mV/div

-

Multimeter disturbance See Table 2-3.

• VDC, VAC, and VAC+DC with STL 120 and short ground lead

• OHM, CONT, DIODE, and CAP with STL120 and black test lead to COM

Table 2-3. Multimeter Disturbance < 1%

Disturbance less than 1% of full scale E= 3 V/m E= 10 V/m

2-12

Frequency range 10 kHz to 27 MHz

VDC, VAC, VAC+DC

OHM, CONT, DIODE

CAP

Frequency range 27 MHz to 1 GHz

VDC, VAC, VAC+DC

OHM, CONT, DIODE

CAP

Test tool ranges not specified in Table 2-3 may have a disturbance of more than 10% of full scale.

500 mV to 1250V

500Ω to 30 MΩ

50 nF to 500 µF

500 mV to 1250V

500Ω to 30 MΩ

50 nF to 500 µF

500 mV to 1250V

500Ω to 30 MΩ

50 nF to 500 µF

500 mV to 1250V

500Ω to 30 MΩ

50 nF to 500 µF

Page 27

Chapter 3

Circuit Descriptions

Title Page

3.1 Introduction................................................................................................. 3-3

3.2 Block Diagram ............................................................................................ 3-3

3.2.1 Channel A, Channel B Measurement Circuits..................................... 3-4

3.2.2 Trigger Circuit ..................................................................................... 3-4

3.2.3 Digital Circuit ...................................................................................... 3-5

3.2.4 Power Circuit....................................................................................... 3-6

3.2.5 Start-up Sequence, Operating Modes .................................................. 3-7

3.3 Detailed Circuit Descriptions...................................................................... 3-9

3.3.1 Power Circuit....................................................................................... 3-9

3.3.2 Channel A - Channel B Measurement Circuits ................................... 3-15

3.3.3 Trigger Circuit ..................................................................................... 3-20

3.3.4 Digital Circuit ...................................................................................... 3-25

3-1

Page 28

123

Service Manual

3-2

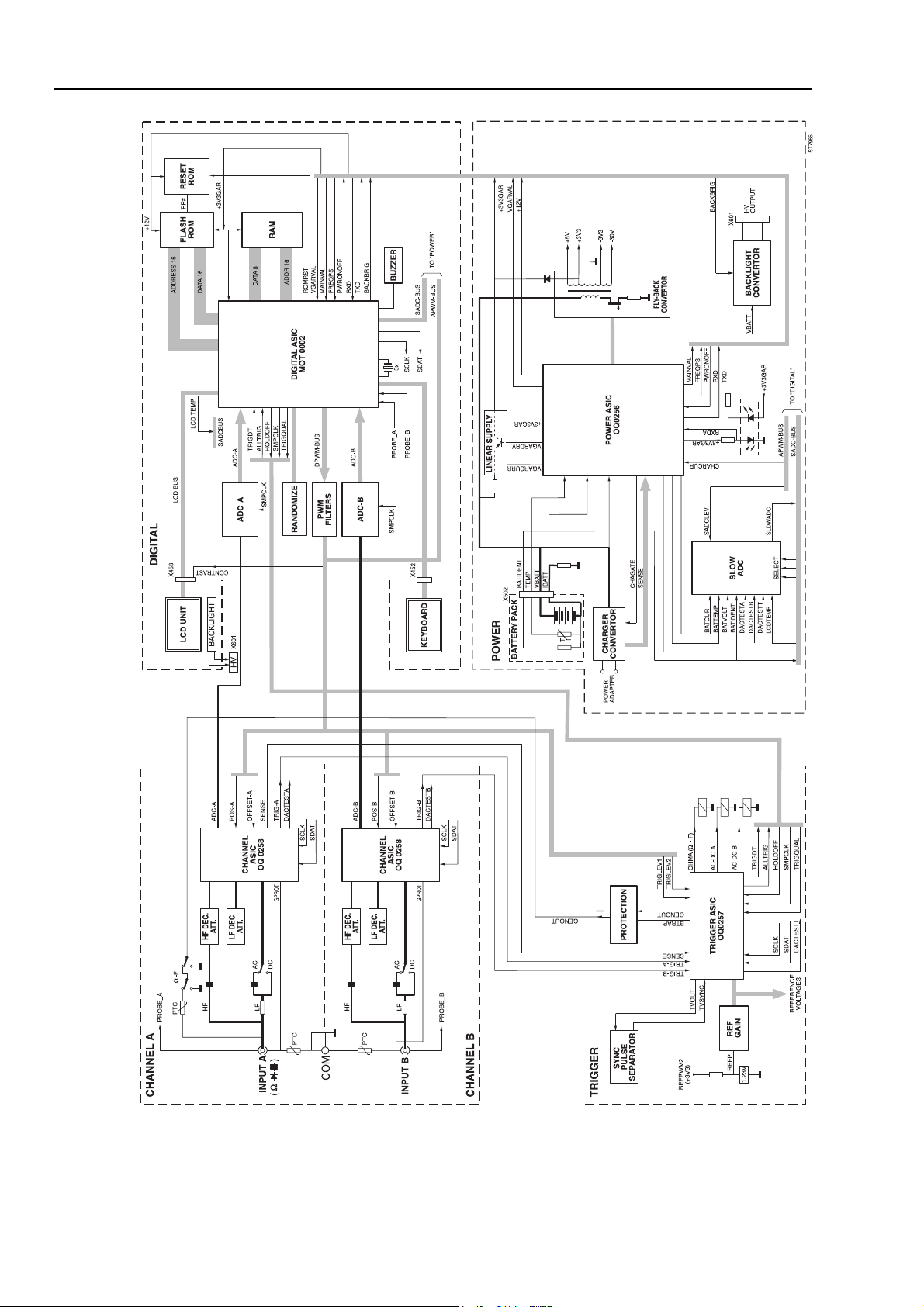

Figure 3-1. Fluke 123 Block Diagram

ST7965.EPS

Page 29

3.1 Introduction

Section 3.2 describes the functional block diagram shown in Figure 3-1. It provides a

quick way to get familiar with the test tool basic build-up.

Section 3.3 describes the principle of operation of the test tool functions in detail, on the

basis of the circuit diagrams shown in Figures 9-1 to 9-5.

For all measurements, input signals are applied to the shielded input banana jackets.

Traces and readings are derived from the same input signal samples. So readings are

related to the displayed readings.

3.2 Block Diagram

In the overall block diagram Figure 3-1, the test tool is divided in five main blocks. Each

block represents a functional part, build up around an Application Specific Integrated

Circuit (ASIC). A detailed circuit diagram of each block is shown in Section 9.

See Table 3-1. for an overview of the blocks in which the test tool is broken down, the

main block function, the ASIC name, and the applicable circuit diagram.

Circuit Descriptions

3.1 Introduction

3

Table 3-1. Fluke 123 Main Blocks

Block Main Functions ASIC Circuit

Diagram

CHANNEL A Input A signal (V-Ω-F) conditioning C(hannel)-ASIC OQ0258 Figure 9-1

CHANNEL B Input B signal (V) conditioning C(hannel)-ASIC OQ0258 Figure 9-2

TRIGGER Trigger selection and conditioning

Current source for resistance, capacitance,

continuity, and diode measurements

AC/DC input coupling and Ω/F relay control

Voltage reference source

DIGITAL Analog to Digital Conversion

Acquisition of ADC samples

Micro controller (µP-ROM-RAM)

Keyboard- and LCD control

POWER Power supply, battery charger

LCD back light voltage converter

Optical interface input

T(rigger)-ASIC OQ0257 Figure 9-3

D(igital)-ASIC MOT0002 Figure 9-4

P(ower)-ASIC OQ0256 Figure 9-5

All circuits, except the LCD unit and the KEYBOARD, are located on one Printed

Circuit Board (PCB), called the MAIN PCB.

The ASIC’s are referred to as C-ASIC (Channel ASIC), T-ASIC (Trigger ASIC), P-ASIC

(Power ASIC), and D-ASIC (Digital ASIC).

3-3

Page 30

123

Service Manual

3.2.1 Channel A, Channel B Measurement Circuits

The Channel A and Channel B circuit are similar. The only difference is that Channel A

can do all measurements, whereas Channel B does not provide resistance, diode, and

capacitance measurements.

Volts, and derived measurements (e.g. current with optional probe)

The input voltage is supplied to the C-ASIC, via the LF and HF path. The C-ASIC

converts (attenuates, amplifies) the input signal to a normalized output voltage ADCA/ADC-B, which is supplied to the Analog to Digital Converters (ADC-A and ADC-B)

on the DIGITAL part. The D-ASIC acquires the digital samples to build the trace, and to

calculate readings. For the HF and LF attenuation section of the C-ASIC some external

components are required: the HF DECade ATTenuator and LF DECade ATTenuator

section.

Resistance, continuity, and diode measurements (Input A only)

The T-ASIC supplies a current via the Ω/F relays to the unknown resistance Rx,

connected to the Input A and the COM input jacket. The voltage drop across Rx is

measured as for voltage measurements.

Capacitance measurements (Input A only)

The T-ASIC supplies a current via the Ω/F relays to the unknown capacitance Cx,

connected to the Input A and the COM input jacket. Cx is charged and discharged by

this current. The C-ASIC converts the charging time and the discharging time into a

pulse width signal. This signal is supplied to the T-ASIC via the C-ASIC trigger output

TRIG-A. The T-ASIC shapes and levels the signal, and supplies the resulting pulse

width signal ALLTRIG to the D-ASIC. The D-ASIC counts the pulse width and

calculates the capacitance reading.

When the capacitance function is selected no other measurement or wave form display is

possible. There is only a numeric readout of the capacitance value.

Frequency, pulse width, and duty cycle measurements

The input voltage is measured as described above. From the ADC samples to built the

trace, also the frequency, pulse width, and duty cycle of the input signal are calculated.

Miscellaneous

Control of the C-ASIC, e.g. selecting the attenuation factor, is done by the D-ASIC via

the SDAT and SCLK serial communication lines.

An offset compensation voltage and a trace position control voltage are provided by the

D-ASIC via the APWM bus.

The C-ASIC’s also provide conditioned input voltages on the TRIG-A/TRIG-B line.

These voltages can be selected as trigger source by the T-ASIC.

3.2.2 Trigger Circuit

The T ASIC selects one of the possible trigger sources TRIG-A (Input A) or TRIG-B

(Input B). For TV triggering the selected trigger source signal is processed via the

Sync(hronization) Pulse Separator circuit (TVOUT-TVSYNC lines). Two adjustable

trigger levels are supplied by the D-ASIC via the PWM FILTERS (TRIGLEV1 and

TRIGLEV2 line). Depending on the selected trigger conditions (- source, - level, - edge,

- mode), the T-ASIC generates the final trigger signal TRIGDT, which is supplied to the

D-ASIC.

3-4

Page 31

Circuit Descriptions

3.2 Block Diagram

Note

External triggers, supplied via the optical interface RXDA line, are

buffered by the P-ASIC, and then supplied to the D-ASIC (RXD signal).

The TRIG-A input is also used for capacitance measurements, as described in

Section 3.2.1.

The T-ASIC includes a constant current source for resistance and capacitance

measurements. The current is supplied via the GENOUT output and the Ω/F relays to

the unknown resistance Rx or capacitance Cx connected to Input A. The SENSE signal

senses the voltage across Cx and controls a CLAMP circuit in the T-ASIC. This circuit

limits the voltage on Input A at capacitance measurements. The protection circuit

prevents the T-ASIC from being damaged by voltages supplied to the input during

resistance or capacitance measurements.

For probe adjustment, a voltage generator circuit in the T-ASIC can provide a square

wave voltage via the GENOUT output to the Input A connector.

The T-ASIC contains opamps to derive reference voltages from a 1.23V reference

source. The gain factors for these opamps are determined by resistors in the REF GAIN

circuit. The reference voltages are supplied to various circuits.

The T-ASIC also controls the Channel A and B AC/DC input coupling relays, and the

Ω/F relays.

3

Control data for the T-ASIC are provided by the D-ASIC via the SDAT and SCLK serial

communication lines.

3.2.3 Digital Circuit

The D-ASIC includes a micro processor, ADC sample acquisition logic, trigger

processing logic, display and keyboard control logic, I/O ports, and various other logic

circuits.

The instrument software is stored in the FlashROM, the RAM is used for temporary data

storage. The RESET ROM circuit controls the operating mode of the FlashROM (reset,

programmable, operational).

For Voltage and Resistance measurements, the conditioned Input A/ Input B voltages are

supplied to the ADC-A and ADC-B ADC. The voltages are sampled, and digitized by

the ADC’s. The output data of the ADC’s are acquired and processed by the D-ASIC.

For capacitance measurements, the ALLTRIG signal generated by the T-ASIC, is used.

The D-ASIC counts the ALLTRIG signal pulse width, which is proportional to the

unknown capacitance.

The DPWM-BUS (Digital Pulse Width Modulation) supplies square wave signals with a

variable duty cycle to the PWM FILTERS circuit (RC filters). The outgoing APWMBUS (Analog PWM) provides analog signals of which the amplitude is controlled by the

D-ASIC. These voltages are used to control e.g. the trace positions (C-ASIC), the trigger

levels (T-ASIC), and the battery charge current (P-ASIC).

In random sampling mode (time base faster than 1 µs/div.), a trace is built-up from

several acquisition cycles. During each acquisition, a number of trace samples are

placed as pixels in the LCD. The RANDOMIZE circuit takes care that the starting

moment of each acquisition cycle (trigger release signal HOLDOFF goes low) is random.

This prevents that at each next acquisition the trace is sampled at the same time

positions, and that the displayed trace misses samples at some places on the LCD.

The D-ASIC supplies control data and display data to the LCD module. The LCD

module is connected to the main board via connector X453. It consists of the LCD, LCD

3-5

Page 32

123

Service Manual

3.2.4 Power Circuit

drivers, and a fluorescent back light lamp. As the module is not repairable, no detailed

description and diagrams are provided. The back light supply voltage is generated by the

back light converter on the POWER part.

The keys of the keyboard are arranged in a matrix. The D-ASIC drives the rows and

scans the matrix. The contact pads on the keyboard foil are connected to the main board

via connector X452. The ON-OFF key is not included in the matrix, but is sensed by a

logic circuit in the D-ASIC, that is active even when the test tool is turned off.

Via the PROBE-A and PROBE-B lines, connected to the Input A and Input B banana

shielding, the D-ASIC can detect if a probe is connected. This function is not supported

by the Fluke 123 software.

The D-ASIC sends commands to the C-ASICs and T-ASIC via the SCLK and SDAT

serial control lines, e.g. to select the required trigger source.

Various I/O lines are provided, e.g. to control the BUZZER and the Slow-ADC (via the

SADC bus.

The test tool can be powered via the power adapter, or by the battery pack.

If the power adapter is connected, it powers the test tool and charges the battery via the

CHARGER-CONVERTER circuit. The battery charge current is sensed by sense

resistor Rs (signal IBAT). It is controlled by changing the output current of the

CHARGER-CONVERTER (control signal CHAGATE).

If no power adapter is connected, the battery pack supplies the VBAT voltage. The

VBAT voltage powers the P-ASIC, and is also supplied to the FLY BACK

CONVERTER (switched mode power supply).

If the test tool is turned on, the FLY BACK CONVERTER generates supply voltages for

various test tool circuits.

The +3V3GAR supply voltage powers the D-ASIC, RAM and ROM. If the test tool is

turned off, the battery supplies the +3V3GAR voltage via transistor V569. This

transistor is controlled by the P-ASIC. So when the test tool is turned off, the D-ASIC

can still control the battery charging process (CHARCURR signal), the real time clock,

the on/off key, and the serial RS232 interface (to turn the test tool on).

3-6

To monitor and control the battery charging process, the P-ASIC senses and buffers

various battery signals, as e.g. temperature (TEMP), voltage (BATVOLT), current

(IBAT).

Via the SLOW ADC various analog signals can be measured by the D-ASIC. Involved

signals are: battery voltage (BATVOLT), battery type (IDENT), battery temperature

(TEMP), battery current (BATCUR) LCD temperature (LCDTEMP, from LCD unit),

and 3 test output pins of the C-ASIC’s, and the T-ASIC (DACTEST). The signals are

used for control and test purposes.

The BACK LIGHT CONVERTER generates the 400V ! supply voltage for the LCD

fluorescent back light lamp. If the lamp is defective a 1.5 kV voltage can be present for

0.2 second maximum. The brightness is controlled by the BACKBRIG signal supplied

by the D-ASIC.

Serial communication with a PC or printer is possible via the RS232 optically isolated

interface. This interface is also used for external trigger input using the Isolated Trigger

Probe. The P-ASIC buffers the received data line (RXDA) and supplies the buffered

data (RXD) to the D-ASIC. The transmit data line TXD is directly connected to the DASIC.

Page 33

A linear regulator in the P-ASIC derives a +12V voltage from the power adapter voltage.

The +12V is used as programming voltage for the Flash EPROM on the Digital part.

3.2.5 Start-up Sequence, Operating Modes

The test tool sequences through the following steps when power is applied (see also

Figure 3-2):

1. The P-ASIC is directly powered by the battery or power adapter voltage VBAT.

Initially the Fly Back Converter is off, and the D-ASIC is powered by VBAT via

transistor V569 (+3V3GAR).

If the voltage +3V3GAR is below 3.05V, the P-ASIC keeps its output signal

VGARVAL (supplied to the D-ASIC) low, and the D-ASIC will not start up. The

test tool is not working, and is in the Idle mode.

2. If the voltage +3V3GAR is above 3.05V, the P-ASIC makes the line VGARVAL

high, and the D-ASIC will start up. The test tool is operative now. If it is powered

by batteries only, and not turned on, it is in the Off mode. In this mode the D-

ASIC is active: the real time clock runs, and the ON/OFF key is monitored to see if

the test tool will be turned on.

Circuit Descriptions

3.2 Block Diagram

3

3. If the power adapter is connected (P-ASIC output MAINVAL high), and/or the

test tool is turned on, the embedded D-ASIC program, called mask software, starts

up. The mask software checks if valid instrument software is present in the Flash

ROM’s. If not, the test tool does not start up and the mask software continues

running until the test tool is turned off, or the power is removed. This is called the

Mask active mode. The mask active mode can also be entered by pressing the ^ and

> key when turning on the test tool.

If valid instrument software is present, one of the following modes will become

active:

Charge mode

The Charge mode is entered when the test tool is powered by the power adapter,

and is turned off. The FLY-BACK CONVERTER is off. The CHARGER-

CONVERTER charges the batteries (if installed).

Operational & Charge mode

The Operational & Charge mode is entered when the test tool is powered by the

power adapter, and is turned on. The FLY-BACK CONVERTER is on, the

CHARGER-CONVERTER supplies the primary current. If batteries are installed,

they will be charged. In this mode a battery refresh (see below) can be done.

Operational mode

The Operational mode is entered when the test tool is powered by batteries only,

and is turned on. The FLY-BACK CONVERTER is on, the batteries supply the

primary current. If the battery voltage (VBAT) drops below 4V when starting up the

fly back converter, the Off mode is entered.

3-7

Page 34

123

Service Manual

Battery Refresh

In the following situations the batteries will need a deep discharge-full charge cycle,

called a “refresh”:

• every 50 not-full discharge/charge cycles, or each 6 months. This prevents

battery capacity loss due to the memory effect.

• after the battery has been removed, as the test tool does not know the battery

status then.

The user will be prompted for this action when he turns the test tool on, directly

following the start up screen. A refresh cycle takes 16 hours maximum, depending

on the battery status. It can be started via the keyboard (USER OPTIONS, F1,

activate refresh) if the test tool is on, and the power adapter is connected. During a

refresh, first the battery is completely charged, then it is completely discharged (the

test tool is powered by the battery only, and the power adapter must be connected!),

and then it is completely charged again.

VGARVAL=L

VGARVAL=H

Idle mode

Off mode

TURN ON or

MAINVAL=H

Flash ROM

Mask StartUp

Flash ROM OK

Extern StartUp

NOT OK

OR

& TURN ON&

MAINVAL=L & (TURN OFF or BATTVOLT<4V)

Software

TURN ON & BATTVOLT > 4 & MAINVAL=L TURN OFF&MAINVAL=H

TURN ON & MAINVAL=H

Operational

Mode

MAINVAL=H

Operational &

Charge Mode

MAINVAL=L TURN ON

TURN OFF

Mask Active

mode

Charge Mode

TURN OFF

3-8

BATTVOLT < 4V

or

AutoShutDown

or

TURN OFF

Figure 3-2. Fluke 123 Start-up Sequence, Operating Modes

Battery refresh

Table 3-2 shows an overview of the test tool operating modes.

MAINVAL=L

Page 35

3.3 Detailed Circuit Descriptions

R

E

P

P

P

E

R

P

R

L

T

P

2

7

7

C

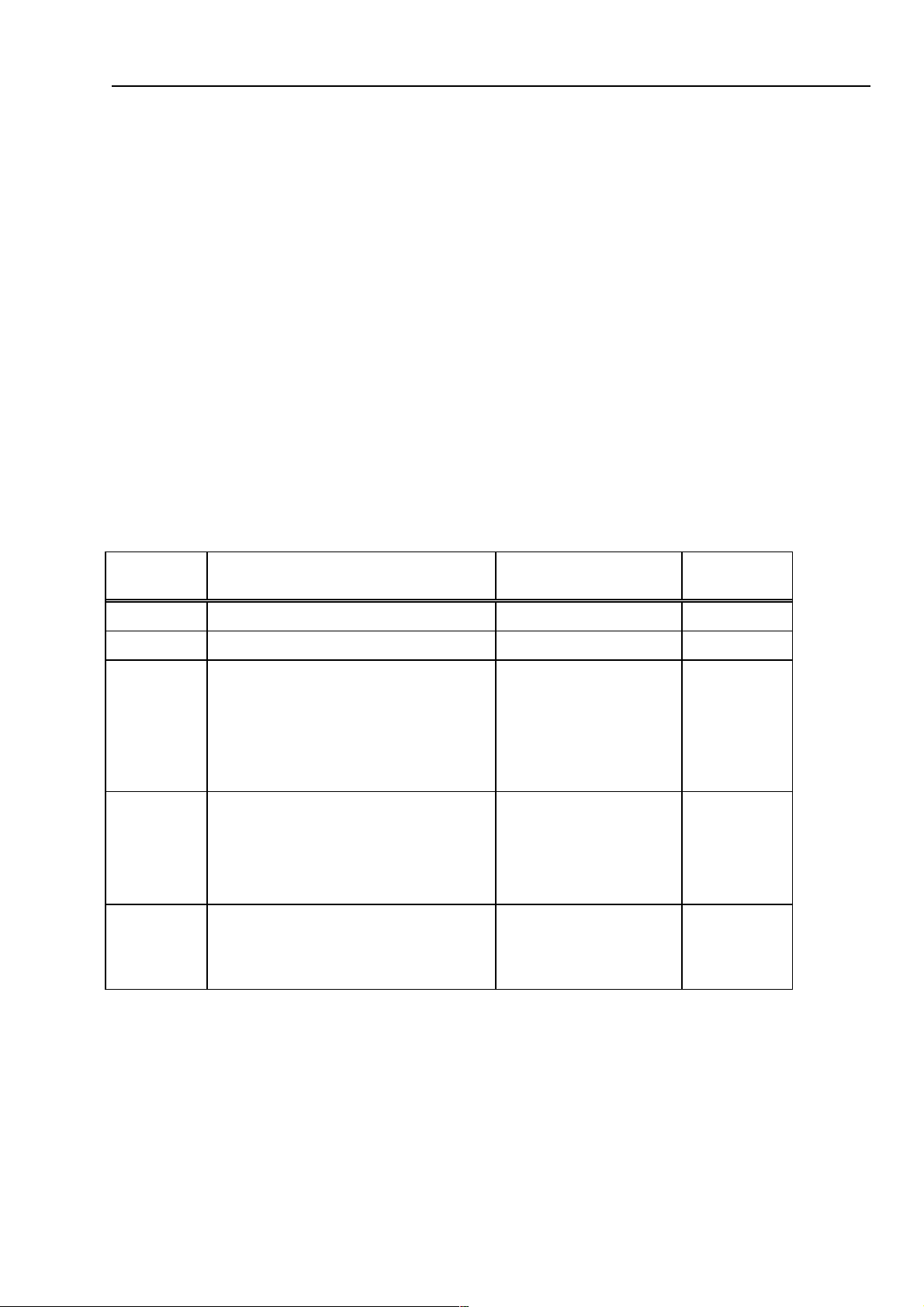

Table 3-2. Fluke 123 Operating Modes

Mode Conditions Remark

Idle mode No power adapter and no battery no activity

Circuit Descriptions

3

Off mode No power adapter connected, battery

installed, test tool off

Mask active mode No valid instrument software, or ^ and > key

P-ASIC & D-ASIC powered

(VBAT & +3V3GAR).

Mask software runs

pressed when turning on

Charge mode Power adapter connected and test tool off Batteries will be charged

Operational &

Charge mode

Operational mode No power adapter connected, battery

Power adapter connected and test tool on Test tool operational, and

batteries will be charged

Test tool operational, powered

installed, and test tool on

by batteries

3.3 Detailed Circuit Descriptions

3.3.1 Power Circuit

The description below refers to circuit diagram Figure 9-5.

Power Sources , Operating Modes

Figure 3-3 shows a simplified diagram of the power supply and battery charger circuit.

FLY BACK

CONVERTER

VBAT

V569

SUPPLY

+3V3GAR

FROM POWER

ADAPTER

R501

R502

C502

CHARGER/CONVERTER

V506

V503

L501

C503

Figure 3-3. Power Supply Block Diagram

R504

R506

R507

R503

R513

R512

R514

R516

VBATSU

VBATHIGH

VBAT

TEM

TEMPHI

IBAT

CHAGAT

CHASENSN

CHASENS

IIMAXCHA

VCHDRI V

VADALOW

VADAPTE

60

69 66

Vref

3

5

4

9

16

CONTROL

14

15

6

19

8

20

linear regulator

linear regulator

linear regulator

POWER ASIC

Amplify

Level shift

100kHz

64

78

79

7

80

1

18

18

22

VGARVA

BATVOLT

BATTEM

BATCU

CHARCUR

43

COS

V565

V566

P7VCHA

+12V

C553

MAI NVAL

C507

3-9

Page 36

123

Service Manual

As described in Section 3.2.5, the test tool operating mode depends on the connected

power source.

The voltage VBAT is supplied either by the power adapter via V506/L501, or by the

battery pack. It powers a part of the P-ASIC via R503 to pin 60 (VBATSUP). If the test

tool is off, the Fly Back Converter is off, and VBAT powers the D-ASIC via transistor

V569 (+3V3GAR). This +3V3GAR voltage is controlled and sensed by the P-ASIC. If it

is NOT OK (<3.05V), the output VGARVAL (pin 64) is low. The VGARVAL line is

connected to the D-ASIC, and if the line is low, the D-ASIC is inactive: the test tool is in

the Idle mode. A low VGARVAL line operates as a reset for the D-ASIC.

If VGARVAL is high (+3V3GAR > 3.05V), the D-ASIC becomes active, and the Off

mode is entered. The D-ASIC monitors the P-ASIC output pin 12 MAINVAL, and the

test tool ON/OFF status. By pressing the ON/OFF key, a bit in the D-ASIC, indicating

the test tool ON/OFF status is toggled. If neither a correct power adapter voltage is

supplied (MAINVAL is low), or the test tool is turned on, the Off mode will be

maintained.

If a correct power adapter voltage is supplied (MAINVAL high), or if the test tool is

turned on, the mask software starts up. The mask software checks if valid instrument

software is present. If not, e.g. no instrument firmware is loaded, the mask software will

keep running, and the test tool is not operative: the test tool is in the Mask active state.

For test purposes the mask active mode can also be entered by pressing the ^ and > key

when the test tool is turned on.

If valid software is present, one of the three modes Operational, Operational &

Charge or Charge will become active. The Charger/Converter circuit is active in the

Operational & Charge and in the Charge mode. The Fly back converter is active in the

Operational and in the Operational & Charge mode.

Charger/Converter (See Also Figure 3-3.)

The power adapter powers the Charge Control circuit in the P-ASIC via an internal linear

regulator. The power adapter voltage is applied to R501. The Charger/Converter circuit

controls the battery charge current. If a charged battery pack is installed, VBAT is

approximately +4.8V. If no battery pack is installed, VBAT is approximately +15V.

The voltage VBAT is supplied to the battery pack, to the P-ASIC, to the Fly Back

Converter, and to transistor V569. The FET control signal CHAGATE is a 100 kHz

square wave voltage with a variable duty cycle , supplied by the P-ASIC Control circuit.

The duty cycle determines the amount of energy loaded into L501/C503. By controlling

the voltage VBAT, the battery charge current can be controlled. The various test tool

circuits are supplied by the Fly Back Converter, and/or V569.

Required power adapter voltage

The P-ASIC supplies a current to reference resistor R516 (VADALOW pin 8). It

compares the voltage on R516 to the power adapter voltage VADAPTER on pin 20

(supplied via R502, and attenuated in the P-ASIC). If the power adapter voltage is below

10V, the P-ASIC output pin 12, and the line MAINVAL, are low. This signal on pin 12

is also supplied to the P-ASIC internal control circuit, which then makes the CHAGATE

signal high. As a result FET V506 becomes non-conductive, and the Charger/Converter

is off.

3-10

Battery charge current control

The actual charge current is sensed via resistors R504-R506-507, and filter R509-C509,

on pin 9 of the P-ASIC (IBATP). The sense voltage is supplied to the control circuit.

The required charge current information is supplied by the D-ASIC via the CHARCUR

Page 37

Circuit Descriptions

3.3 Detailed Circuit Descriptions

line and filter R534-C534 to pin 80. A control loop in the control circuit adjusts the

actual charge current to the required value.

The filtered CHARCUR voltage range on pin 80 is 0... 2.7V for a charge current from

0.5A to zero. A voltage of 0V complies to 0.5A (fast charge), 1.5V to 0.2A (top off

charge), 2.3V to 0.06A (trickle charge), and 2.7V to 0A (no charge). If the voltage is > 3

Volt, the charger converter is off (V506 permanently non-conductive).

The D-ASIC derives the required charge current value from the battery voltage VBAT.

The P-ASIC converts this voltage to an appropriate level and supplies it to output pin 78

(BATVOLT). The D-ASIC measures this voltage via the Slow ADC. The momentary

value, and the voltage change as a function of time (-dV/dt), are used as control

parameters.

Charging process

If the battery voltage drops below 5.2V, and the battery temperature is between 10 and

45°C, the charge current is set to 0.5A (fast charge). From the battery voltage change dV/dt the D-ASIC can see when the battery is fully charged, and stop fast charge.

Additionally a timer in the D-ASIC limits the fast charge time to 6 hours. After fast

charge, a 0.2A top off charge current is supplied for 2 hours. Then a 0.06A trickle

charge current is applied for 48 hours maximum. If the battery temperature becomes

higher than 50°C, the charge current is set to zero

3

Battery temperature monitoring

The P-ASIC supplies a current to a NTC resistor in the battery pack (TEMP pin 5). It

conditions the voltage on pin 5 and supplies it to output pin 79 BATTEMP. The D-ASIC

measures this voltage via the slow ADC. It uses the BATTEMP voltage to decide if fast

charge is allowed (10-45°C), or no charge is allowed at all (<10°C, >50°C).

Additionally the temperature is monitored by the P-ASIC. The P-ASIC supplies a

current to reference resistor R512 (TEMPHI pin 4), and compares the resulting TEMPHI

voltage to the voltage on pin 5 (TEMP). If the battery temperature is too high, the PASIC Control circuit will set the charge current to zero, in case the D-ASIC fails to do

this.

If the battery temperature monitoring system fails, a bimetal switch in the battery pack

interrupts the battery current if the temperature becomes higher then 70 °C

Maximum VBAT

The P-ASIC supplies a current to reference resistor R513 (VBATHIGH pin 7). It

compares the voltage on R513 to the battery voltage VBAT on pin 3 (after being

attenuated in the P-ASIC). The P-ASIC limits the voltage VBAT to 7.4V via its internal

Control circuit. This situation arises in case no battery or a defective battery (open) is

present.

Charger/Converter input current

This input current is sensed by R501. The P-ASIC supplies a reference current to R514.

The P-ASIC compares the voltage drop on R501 (CHASENSP-CHASENSN pin 14 and

15) to the voltage on R514 (IMAXCHA pin 6). It limits the input current (e.g. when

loading C503 and C555 just after connecting the power adapter) via its internal Control

circuit.

3-11

Page 38

123

Service Manual

CHAGATE control signal

To make the FET conductive its Vgs (gate-source voltage) must be negative. For that

purpose, the CHAGATE voltage must be negative with respect to VCHDRIVE. The

P-ASIC voltage VCHDRIVE also limits the swing of the CHAGATE signal to 13V.

VCHDRIVE

VCHDRIVE -13V

10 µs

Figure 3-4. CHAGATE Control Voltage

V506 “OFF”

V506 “ON”

+3V3GAR Voltage

When the test tool is not turned on, the Fly Back Converter does not run. In this

situation, the +3V3GAR voltage for the D-ASIC, the FlashROM, and the RAM is

supplied via transistor V569. The voltage is controlled by the VGARDRV signal

supplied by the P-ASIC (pin 69). The current sense voltage across R580 is supplied to

pin 70 (VGARCURR). The voltage +3V3GAR is sensed on pin 66 for regulation. The

internal regulator in the P-ASIC regulates the +3V3GAR voltage, and limits the current.

Fly Back Converter

When the test tool is turned on, the D-ASIC makes the PWRONOFF line (P-ASIC pin

62) high. Then the self oscillating Fly Back Converter becomes active. It is started up

by the internal 100 kHz oscillator that is also used for the Charger/Converter circuit.

First the FLYGATE signal turns FET V554 on (see Figure 3-5), and an increasing

current flows in the primary transformer winding to ground, via sense resistor R551. If

the voltage FLYSENSP across this resistor exceeds a certain value, the P-ASIC turns

FET V554 off. Then a decreasing current flows in the secondary windings to ground. If

the windings are “empty” (all energy transferred), the voltage VCOIL sensed by the PASIC (pin 52) is zero, and the FLYGATE signal will turn FET V554 on again.

3-12

Primary current

Secondary current

V554 “ON”

FLYGATE SIGNAL

Figure 3-5. Fly-Back Converter Current and Control Voltage

V554 “OFF”

The output voltage is regulated by feeding back a part of the +3V3A output voltage via

R552-R553-R554 to pin 54 (VSENS). This voltage is referred to a 1.23V reference

voltage. Any deviation of the +3V3A voltage from the required 3.3V changes the

current level at which current FET V554 will be switched off. If the output voltage

increases, the current level at which V554 is switched off will become lower, and less

energy is transferred to the secondary winding. As a result the output voltage will

become lower.

An internal current source supplies a current to R559. The resulting voltage is a

reference for the maximum allowable primary current (IMAXFLY). The voltage across

Page 39

Circuit Descriptions

3.3 Detailed Circuit Descriptions

the sense resistor (FLYSENSP) is compared to the IMAXFLY voltage. If the current

exceeds the set limit, FET V554 will be turned off.

Another internal current source supplies a current to R558. This resulting voltage is a

reference for the maximum allowable output voltage (VOUTHI). The -3V3A output

voltage (M3V3A) is attenuated and level shifted in the P-ASIC, and then compared to

the VOUTHI voltage. If the -3V3A voltage exceeds the set limit, FET V554 will be

turned off.

The FREQPS control signal is converted to appropriate voltage levels for the FET switch

V554 by the BOOST circuit. The voltage VBAT supplies the BOOST circuit power via

V553 and R561. The FREQPS signal is also supplied to the D-ASIC, in order to detect

if the Fly Back converter is running well.

V551 and C552 limit the voltage on the primary winding of T552 when the FET V554 is

turned of. The signal SNUB increases the FLYGATE high level to decreases ONresistance of V554 (less power dissipation in V554).

+5VA

V553

R561

T552

V561

V562

+3V3A

3

FLYBOOST

C551

C553

SNUB

48 47

BOOST

CONTROL

C552

49

63

55

57

V551

FLYGATE

FREQPS

FLYSENSP

IMAXFLY

-3V3A

VOUTHI

VSENS

PWRONOFF

REFP (1.23V)

V554