Page 1

TECHNICAL DATA

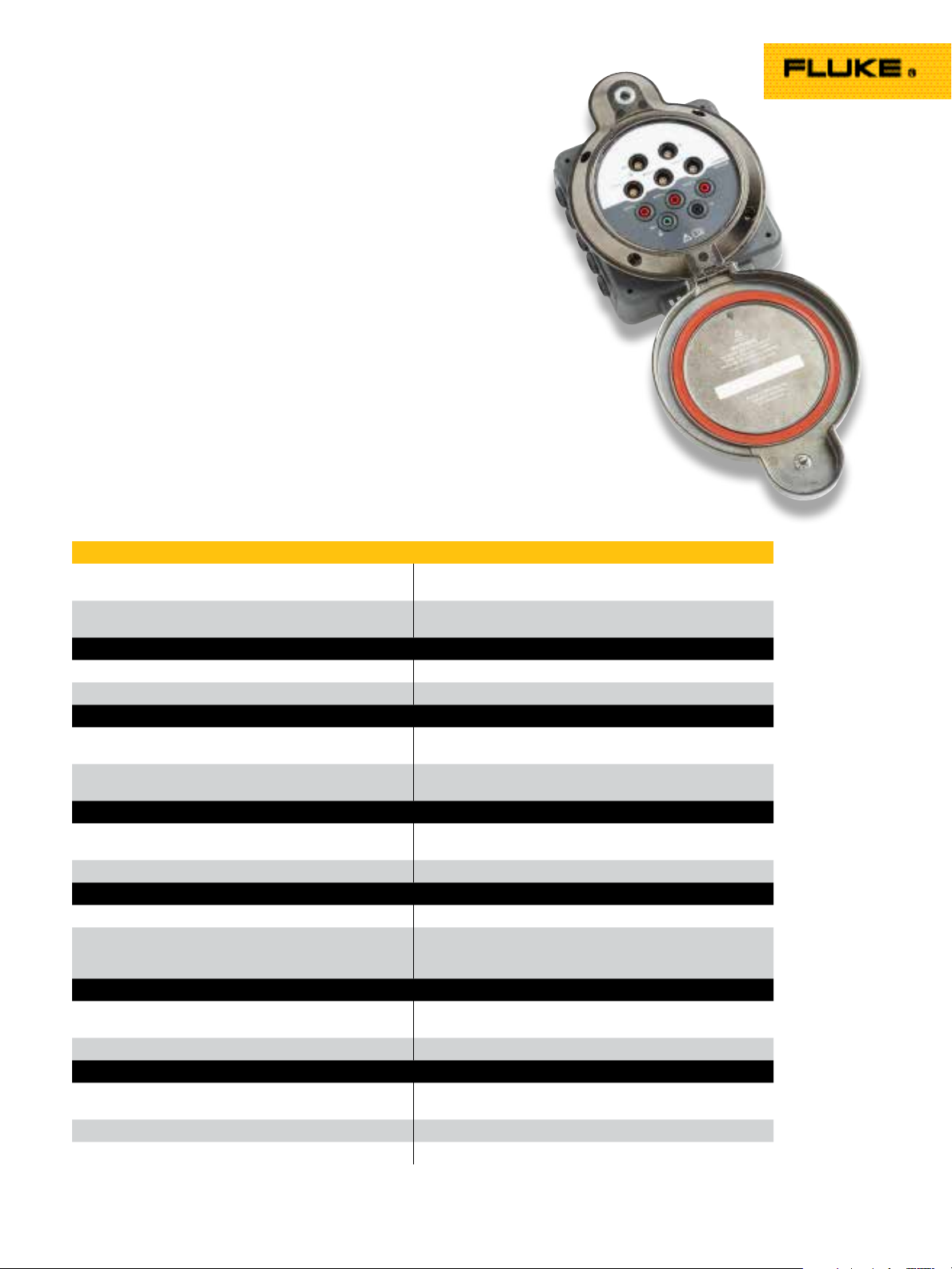

Fluke PQ400 Electrical

Measurement Window

The Fluke PQ400 Electrical Measurement Window enables the

connection of three phase measurement equipment to energized

panels, without the need to open the panel door, or wear

supplemental personal protective equipment (PPE)

Compliance without compromise. Safety without

sacrifice.

The Fluke PQ400 gives you access to the critical power quality and

energy data you need, all while decreasing testing time and help-

ing you to maintain safety.

• Reduce the risk of arc-flash and electrocution, while increasing

the safety of your personnel

• Decrease maintenance costs and reduce downtime by making

critical power quality and energy measurements without

opening the panel door, enabling logging and monitoring at any

time—without disrupting operations

• Reduce work permit requirements and processes by reducing

the hazards associated with taking measurements on open

panels, saving time and effort

• Increase measurement efficiency and reduce the need for arc-

flash PPE, saving time, increasing efficiency and increasing

operator comfort

REDUCED RISK

Permanently installed voltage and

current connections can be accessed

without opening the panel door

INCREASED EFFICIENCY

Quickly connect your logger

or analyzer and begin taking

measurements faster than ever

EASY I N S TA LLATION

A standard step drill bit and

electro-hydraulic hole punch

provide the simple means to quickly

mount the window in the panel

Features

• Permanently connected voltage and current sensors located

inside the electrical panel allow you to make power quality and

energy measurements using the external access points without

opening the panel door, reducing operator risk

• Voltage and current connections for three-phase voltages,

neutral and ground cover most measurement scenarios

• Automatic probe detection for Fluke 1740 and 1730 series power

quality and energy loggers and compatible clamps, eliminates

the need to open cabinet to check the clamp model

• Full 360 degree rotation allows the PQ400 window to be

oriented in any direction

• Simple installation using a step drill bit and electro-hydraulic

hole punch (114.3 mm, 4.5 inch diameter)

• CAT IV, 600V and CATIII 1,000V rating according to

IEC61010 -2-30

• Compatibility with standard 4mm shrouded safety-socket

voltage test leads makes it easier to make voltage connections,

increases safety by reducing the risk of accidently touching live

electrical components, and reduces the need for purchasing

specialized voltage leads

Comply with local and national safety codes. Use personal protective equipment

(approved rubber gloves, face protection, and flame-resistant clothes) to prevent shock

and arc blast injury wh0ere hazardous live conductors are exposed.

Page 2

How it works

The Fluke PQ400 Electrical Measurement Window is a

permanently installed interface that provides technicians with

near instant access to electrical panels for making critical power

quality and energy measurements. The PQ400 installs using a

standard step drill bit and electro-hydraulic hole punch (114.3

mm, 4.5-inch hole diameter), and allows users to make threephase voltage, current and ground connects covering most

measurement configurations. Once installed users can simply

unlock the window cover, lift the lid, and connect the voltage

leads of the logger or analyzer. Then, connect the leads for the

current sensors and start making critical measurements. Once

complete, simply remove the voltage and current connections from

the front panel interface and lock the window lid, leaving the

internal connections in place for future use.

Specifications

General specifications

Maximum voltage between any voltage terminal and

earth ground

Maximum voltage between any current terminal and

earth ground

Safety

General IEC 61010-1: pollution degree 2

Measurement IEC 61010-2-030: CAT IV 600 V / CAT III 1000 V

Dimensions

Outside 148 mm x 187 mm x 23 mm (W x H x D) (148 mm x 370 mm

Inside 140 mm x 158 mm x Di (W x H x D)

Supported electrical enclosures

Enclosure UL 50/NEMA environmental type 1 (Type 12 when PQ400

Panel thickness Max. 3.5 mm (10 gauge)

Environment

Operating/storage temperature -25 °C to 60 °C (-13 °F to 140 °F)

Humidity 10 % to 90 % in dependency of temperature according to

Altitude

Operating 2,000 m (up to 4000 m derate to CAT II 1000 V, CAT III 600

Storage 12 000 m

Ingress protection

Rating IEC 60529: IP67 with cover closed, IP50 with cover opened

Vibration IEC 60068-2-6 , MIL-PRF28800F: Random vibration class 2

Weight 2.1 kg (4.6 lb)

1000 V

30 V

x 19 mm with cover opened)

Di = 58 – thickness of panel door in mm

cover is closed)

IEC 60721-3-3 Class 3K6 (modified):-25 °C to 35 °C: 10 %

to 90 %, 50°C: max. 35 %, 60°C: max. 23 %

V, CAT IV 300 V)

and all connectors attached

2 Fluke Corporation Fluke PQ400 Electrical Measurement Window

Page 3

Voltage

Input

Number of inputs 5 (A/L1, B/L2, C/L3, N, and earth/ground)

Wire gauge Solid/flexible: 0.25 mm² to 1.5 mm² (AWG 24 to AWG 16)

Voltage Max. 1000 V

Fuse 2 A 1000 V 1.5 A²s, 10 kA IR (A/L1, B/L2, C/L3, N)

Output

Connectors 5x 4 mm safety terminals, 3x red for A/L1, B/L2, C/L3,

1x black for N, 1x green for earth/ground

Load current Max. 1 A rms

Current

Input/output

Connectors 5x 4-pin circular compatible with Fluke 354x FC, 173x,

and 174x power and energy loggers (these loggers can all

be powered from the measured voltage up to 500V)

Current inputs for installing measurement probes

inside the electrical panel

3 Fluke Corporation Fluke PQ400 Electrical Measurement Window

Page 4

Ordering information

Fluke-PQ400, Power Quality Window*

Fluke-PQ400/B, Power Quality Basic**

I17XX-FLEX2M-M2M4P, male-male cable 2m for con-

nection of Fluke-17xx iFlex

I17XX-FLEX2M-M2M1P male-male cable 2m for con-

nection of Fluke-17xx iFlex

I17XX-B N C - M 2 M , Fluke-17xx 4pin male to BNC male

cable 2m (1pcs)

I17XX-B N C - M 2 F, Fluke-17xx 4pin male to BNC female

cable 0.1m (1pcs)

Fluke-PQ-MARKER, cable marker set 3P+N+PE

* Fluke PQ400 contents: PQ400 enclosure, 4 x male-male cable

2m for connection of Fluke-17xx iFlex

marker set 3P+N+PE, cable ties and instruction sheet.

** Basic version does not include cables, cable ties or markers.

Additional accessories for Fluke 173x and 174x

products

I17XX-FLEX1500 Fluke-17xx iFlex 1500A

I17XX-FLEX1500/3PK Fluke-17xx iFlex 1500A

I17XX-FLEX1500/4PK Fluke-17xx iFlex 1500A

I17XX-FLEX3000 Fluke-17xx iFlex 3000A

I17XX-FLEX3000/3PK Fluke-17xx iFlex 3000A

I17XX-FLEX3000/4PK Fluke-17xx iFlex 3000A

I17XX-FLEX6000 Fluke-17xx iFlex 6000A

I17XX-FLEX6000/3PK Fluke-17xx iFlex 6000A

®

current probes (4pcs).

®

current probes, (1pcs).

®

current probes, cable

12in

12in, 3 pack

12in, 4 pack

24in

24in, 3 pack

24 in, 4 pack

36in

36in, 3 pack

I17XX-FLEX6000/4PK Fluke-17xx iFlex 6000A

36in, 4 pack

I40S-EL3X Fluke-17xx I40S-EL

40A clamp-on current

transformer

I40S-EL3X/3PK Fluke-17xx I40S-EL 40A

clamp-on current

transformer, 3 pack

I400S-EL Fluke-17xx I400S-EL

400A clamp-on current

transformer

I400S-EL/3PK Fluke-I400S-EL 3PK, 17xx

400A clamp-on current

clamp, 3 pack

Additional accessories for Fluke 430 Series II

products

I430-IFLEX-TF-II* 6000A Fluke 430 Thin

iFlex 61cm (24in)

I430-IFLEX-TFII-4P* 6000A Fluke 430 Thin

iFlex 61cm (24in) 4 pack

I430-FLX-TFII-12* 6000A Fluke 430 Thin

iFlex 30cm (12in)

I430-FLX-TFII-48 6000A Fluke 430 Thin

iFlex 122cm (48in)

I400S* Fluke I400S-EL 400A

clamp-on current

transformer

I5S* 5A AC current probe

I5SPQ3* 5A AC current probe 3

pack for 430

* Requires I17XX-BNC-M2F to connect probe to PQ400

4 Fluke Corporation Fluke PQ400 Electrical Measurement Window

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2019 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 2/2019 6012030-en

Modification of this document is not permitted

without written permission from Fluke Corporation.

®

Loading...

Loading...