Page 1

PPC2 AF™

Operation and Maintenance Manual

Page 2

© 1998,2002 DH Instruments, Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the express written permission of DH Instruments, Inc.

4765 East Beautiful Lane, Phoenix AZ 85044-5318, USA.

DH Instruments makes sincere efforts to ensure accuracy and quality of its’ published materials; however, no warranty, expressed

or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or indirect damages resulting from the

use of the information in this manual or products described in it. Mention of any product or brand does not constitute an

endorsement by DH Instruments of that product or brand. This manual was originally composed in English and was subsequently

translated into other languages. The fidelity of the translation cannot be guaranteed. In case of conflict between the English

version and other language versions, the English version predominates.

DH Instruments, DH, DHI, PPC, PPC2 and PPC2 AF are trademarks, registered and otherwise, of DH Instruments, Inc.

Document No. 550090C-01

980812, 021025

Printed in the USA.

© 1998 DH Instruments, Inc.

Page 3

TABLE OF CONTENTS

T

AABBLLEE

T

O

O

FF

C

OONNTTEENNTTS

C

S

TABLE OF CONTENTS ............................................................. I

1. INTRODUCTION .................................................................1

1.1 PRODUCT OVERVIEW ...........................................................................................................................1

1.2 SUBASSEMBLY DESCRIPTION AND LOCATION ................................................................................1

1.2.1 FRONT PANEL ASSEMBLY ..................................................................................................................... 1

1.2.2 REAR PANEL ASSEMBLY ....................................................................................................................... 2

1.2.3 POWER SUPPLIES................................................................................................................................... 3

1.2.4 MICRO CARD............................................................................................................................................ 3

1.2.5 DRIVER BOARD ....................................................................................................................................... 4

1.2.6 BAROMETER BOARD .............................................................................................................................. 4

1.2.7 PNEUMATIC MODULE ............................................................................................................................. 5

1.2.8 TRANSDUCER SELECTION MODULE.....................................................................................................6

1.2.9 REFERENCE PRESSURE TRANSDUCERS............................................................................................. 6

1.2.9.1 HIGH (PRIMARY) PRESSURE REFERENCE TRANSDUCER.............................................................. 7

1.2.9.2 LOW (SECONDARY) PRESSURE REFERENCE TRANSDUCER ........................................................ 7

1.2.10 SOURCE PRESSURE RELIEF VALVE..................................................................................................... 7

1.2.11 SELF PURGING LIQUID TRAP (SPLT) .................................................................................................... 8

1.3 SPECIFICATIONS ...................................................................................................................................9

1.3.1 GENERAL SPECIFICATIONS................................................................................................................... 9

1.3.2 PRESSURE MEASUREMENT SPECIFICATIONS.................................................................................... 9

1.3.2.1 HIGH PRESSURE REFERENCE TRANSDUCER (HI REF) .................................................................. 9

1.3.2.2 LOW PRESSURE REFERENCE TRANSDUCER (LO REF).................................................................. 9

1.3.2.3 BAROMETER ...................................................................................................................................... 10

1.3.3 PRESSURE CONTROL SPECIFICATIONS ............................................................................................ 10

1.3.3.1 STATIC PRESSURE CONTROL .........................................................................................................10

1.3.3.2 DYNAMIC PRESSURE CONTROL...................................................................................................... 10

2. INSTALLATION AND SHORT TERM STORAGE ..................... 11

2.1 UNPACKING AND INSPECTION ..........................................................................................................11

2.1.1 REMOVING FROM PACKAGING............................................................................................................ 11

2.1.2 INSPECTING CONTENTS....................................................................................................................... 11

2.2 SITE REQUIREMENTS..........................................................................................................................11

2.3 INITIAL SETUP...................................................................................................................................... 12

2.3.1 PREPARING FOR OPERATION.............................................................................................................. 12

2.3.2 POWER CONNECTION .......................................................................................................................... 12

2.3.3 CONNECTING TO A PRESSURE SUPPLY (SUPPLY PORT)................................................................ 12

2.3.4 CONNECTING A VACUUM PUMP (EXHAUST PORT) ........................................................................... 12

2.3.5 CONNECTING TO THE DEVICE UNDER TEST (TEST PORT)................................................ 13

2.3.5.1 INSTALLING THE SPLT...................................................................................................................... 13

2.3.6 THE VENT CONNECTION (VENT PORT)............................................................................................... 14

2.3.7 THE AUTOZERO CONNECTION (AUTOZERO PORT)........................................................................... 14

2.4 POWER UP AND VERIFICATION.........................................................................................................14

2.4.1 SWITCH POWER ON.............................................................................................................................. 14

2.4.2 SET THE USER LEVEL (INITIAL START UP ONLY).............................................................................. 15

2.4.3 CHECK PROPER PRESSURE MEASUREMENT OPERATION ............................................................. 15

2.4.3.1 CHECKING ABSOLUTE PRESSURE MEASUREMENT ..................................................................... 15

2.4.3.2 CHECKING GAUGE PRESSURE MEASUREMENT ........................................................................... 15

2.4.4 LEAK CHECK.......................................................................................................................................... 15

2.4.5 PURGE.................................................................................................................................................... 15

2.4.6 CHECK PROPER PRESSURE CONTROL OPERATION........................................................................ 16

2.5 SHORT TERM STORAGE.....................................................................................................................16

Page I © 1998 DH Instruments, Inc.

Page 4

PPC2 AF OPERATION AND MAINTENANCE MANUAL

3. OPERATION .................................................................... 17

3.1 GENERAL/MANUAL OPERATION .......................................................................................................17

3.1.1 THE MAIN RUN SCREEN ....................................................................................................................... 17

3.1.2 GENERAL OPERATING PRINCIPLES ................................................................................................... 18

3.1.2.1 MAIN KEYPAD LAYOUT AND PROTOCOL........................................................................................ 18

3.1.2.2 DIRECT PRESSURE CONTROL KEYS .............................................................................................. 18

3.1.2.3 AUTOMATED PRESSURE CONTROL................................................................................................ 19

3.1.2.4 PRESSURE READY/NOT READY INDICATION................................................................................. 21

3.1.2.5 MULTIPLE PRESSURE RANGES....................................................................................................... 22

3.2 DIRECT FUNCTION KEYS....................................................................................................................23

3.2.1 RANGE .................................................................................................................................................... 23

3.2.2 UNIT ........................................................................................................................................................ 24

3.2.3 CONTROL............................................................................................................................................... 25

3.2.3.1 EXECUTING AUTOMATED PRESSURE CONTROL COMMANDS..................................................... 26

3.2.4 UPPER LIMIT .......................................................................................................................................... 28

3.2.5 SEQ ......................................................................................................................................................... 29

3.2.5.1 SETTING UP/EDITING A QUICK SEQUENCE.................................................................................... 29

3.2.5.2 SETTING UP/EDITING A FILE SEQUENCE ....................................................................................... 31

3.2.5.3 RUNNING A SEQUENCE.................................................................................................................... 31

3.2.6 CUSTOM CONTROL............................................................................................................................... 33

3.2.6.1 TURNING-OFF CUSTOM CONTROL PARAMETERS......................................................................... 34

3.2.7 HEAD....................................................................................................................................................... 34

3.2.8 LEAK CHECK/PURGE............................................................................................................................ 36

3.2.8.1 LEAK CHECK/PURGE MENU AND FUNCTIONS FLOW CHART................................................ 37

3.2.8.2 LEAK CHECK SCREEN FUNCTION ................................................................................................... 37

3.2.8.3 PURGE FUNCTION............................................................................................................................. 38

3.2.8.4 SETTING PRESSURES FOR LEAK CHECK/PURGE FUNCTION............................................... 39

3.2.8.5 TYPICAL USE OF THE LEAK CHECK/PURGE FUNCTION................................................................ 39

3.2.9 ANALOG.................................................................................................................................................. 40

3.3 SETUP MENU KEY ...............................................................................................................................40

3.3.1 CONTROLREF........................................................................................................................................ 41

3.3.2 RESLTN .................................................................................................................................................. 41

3.3.3 SEQUENCE............................................................................................................................................. 42

3.3.4 DRIVERS................................................................................................................................................. 45

3.4 SPECIAL MENU KEY............................................................................................................................45

3.4.1 PRESU .................................................................................................................................................... 46

3.4.2 HEAD....................................................................................................................................................... 47

3.4.3 CONFIG................................................................................................................................................... 47

3.4.4 INTERNAL............................................................................................................................................... 47

3.4.4.1 AUTOZ................................................................................................................................................. 47

3.4.4.2 CAL...................................................................................................................................................... 48

3.4.4.3 REMOTE ............................................................................................................................................. 48

3.4.4.4 DATE ................................................................................................................................................... 48

3.4.4.5 RESET................................................................................................................................................. 49

3.4.4.6 LEVEL.................................................................................................................................................. 50

3.4.4.7 ATM ..................................................................................................................................................... 52

3.4.4.8 MAINT.................................................................................................................................................. 53

3.4.5 DIAG........................................................................................................................................................ 53

4. REMOTE OPERATION....................................................... 55

4.1 OVERVIEW ............................................................................................................................................55

4.2 INTERFACING.......................................................................................................................................55

4.2.1 RS232 INTERFACE................................................................................................................................. 55

4.2.1.1 COM1 .................................................................................................................................................. 55

4.2.1.2 COM2 .................................................................................................................................................. 56

4.3 COMMANDS.......................................................................................................................................... 57

4.3.1 COMMAND LIST..................................................................................................................................... 57

4.3.2 ERROR MESSAGES............................................................................................................................... 58

4.3.3 COMMAND SUMMARY........................................................................................................................... 59

© 1998 DH Instruments, Inc. Page II

Page 5

TABLE OF CONTENTS

5. MAINTENANCE, ADJUSTMENTS AND CALIBRATION ............ 75

5.1 MAINTENANCE.....................................................................................................................................75

5.1.1 PNEUMATIC CONTROL MODULE CONFIGURATION........................................................................... 75

5.1.2 REPAIRS................................................................................................................................................. 76

5.1.2.1 FUSE REMOVAL AND REPLACEMENT............................................................................................. 76

5.1.2.2 FRONT PANEL REMOVAL AND REPLACEMENT.............................................................................. 77

5.1.2.3 DISPLAY REMOVAL AND REPLACEMENT........................................................................................ 77

5.1.2.4 REAR FITTING REMOVAL AND REPLACEMENT .............................................................................. 78

5.1.2.5 POWER SUPPLY REMOVAL.............................................................................................................. 78

5.1.2.6 BAROMETER BOARD REPLACEMENT ............................................................................................. 79

5.1.2.7 COOLING FAN REMOVAL AND REPLACEMENT .............................................................................. 79

5.1.2.8 SUPPLY PRESSURE RELIEF VALVE REMOVAL AND REPLACEMENT .......................................... 80

5.1.2.9 RELOADING EMBEDDED SOFTWARE INTO FLASH MEMORY ....................................................... 80

5.1.3 OVERHAUL............................................................................................................................................. 80

5.1.4 SELF PURGING LIQUID TRAP (SPLT) .................................................................................................. 81

5.1.4.1 MAINTENANCE................................................................................................................................... 81

5.1.4.2 REPAIR ............................................................................................................................................... 81

5.1.4.3 OVERHAUL ......................................................................................................................................... 81

5.1.5 ILLUSTRATED PARTS BREAKDOWN................................................................................................... 82

5.1.5.1 PARTS LISTS...................................................................................................................................... 82

5.1.5.2 FIGURES............................................................................................................................................. 87

5.2 AUTOZERO OF REFERENCE TRANSDUCERS..................................................................................99

5.2.1 HI REF (BY COMP AT ATM) ..................................................................................................................100

5.2.2 LO REF (BY VACUUM)..........................................................................................................................102

5.2.3 VIEWING AND EDITING AUTOZERO VALUES.....................................................................................105

5.3 ADJUSTMENT OF BAROMETER....................................................................................................... 106

5.4 CALIBRATION OF REFERENCE TRANSDUCERS............................................................................107

5.4.1 PRINCIPLE.............................................................................................................................................107

5.4.2 EQUIPMENT REQUIRED.......................................................................................................................109

5.4.3 SET-UP AND PREPARATION................................................................................................................109

5.4.4 ON-BOARD REFERENCE TRANSDUCER CALIBRATION FUNCTION ................................................110

5.4.4.1 OVERVIEW ........................................................................................................................................110

5.4.4.2 SELECTION OF REFERENCE TRANSDUCER (HI, LO) TO CALIBRATE .........................................111

5.4.4.3 SELECTION OF RANGE TO CALIBRATE AND ASSIGNMENT OF PA/PM.......................................111

5.4.4.4 RUNNING THE CALIBRATION OF A RANGE....................................................................................112

5.4.4.5 SETTING PA(Z)TARE.........................................................................................................................114

5.4.4.6 PREVIEWING CALIBRATION DATA..................................................................................................114

5.4.4.7 ACTIVATING CALIBRATION RESULTS.............................................................................................115

5.4.5 THE REFERENCE PRESSURE TRANSDUCERS CAN BE CALIBRATED WITHOUT USING THE ON-

BOARD CALIBRATION FUNCTION. THIS REQUIRES: .......................................................................115

5.4.6 VIEWING REFERENCE TRANSDUCER CALIBRATION INFORMATION .............................................116

5.5 DIAGNOSTIC FUNCTION ...................................................................................................................117

5.5.1 MODE.....................................................................................................................................................117

5.5.2 CALIB.....................................................................................................................................................119

5.5.2.1 DUCER...............................................................................................................................................119

5.5.2.2 TBASE................................................................................................................................................119

5.5.2.3 TEMP..................................................................................................................................................119

5.5.3 DISP .......................................................................................................................................................119

5.5.4 RELAY....................................................................................................................................................120

5.5.4.1 AMBIENT............................................................................................................................................120

5.5.4.2 ANALOGOPT......................................................................................................................................120

5.5.5 VALVE....................................................................................................................................................120

5.5.6 TEST.......................................................................................................................................................120

5.5.7 LOG........................................................................................................................................................120

6. TROUBLESHOOTING ...................................................... 121

7. PREPARTION FOR SHIPMENT OR LONG TERM STORAGE

Page III © 1998 DH Instruments, Inc.

. 125

Page 6

PPC2 AF OPERATION AND MAINTENANCE MANUAL

8. MENU TREE .................................................................. 127

8.1 FUNCTION KEYS ................................................................................................................................127

8.2 SETUP MENU......................................................................................................................................128

8.3 VIEW/EDIT SEQUENCE MENU ..........................................................................................................129

8.4 EDIT SEQUENCE MENU.....................................................................................................................130

8.5 SPECIAL MENU ..................................................................................................................................131

8.6 AUTOZERO MENU..............................................................................................................................132

8.7 INTERNAL MENU................................................................................................................................133

8.8 CALIBRATION MENU .........................................................................................................................134

8.9 RUN CALIBRATION MENU.................................................................................................................135

8.10 RUN PA(Z) TARE MENU..................................................................................................................... 136

8.11 DIAGNOSTICS MENU.........................................................................................................................137

9. APPENDIX .................................................................... 139

9.1 DRIVERS .............................................................................................................................................139

9.2 SPLT CABLE AND CONNECTIONS................................................................................................... 140

9.3 UNIT CONVERSION............................................................................................................................141

9.3.1 PRESSURE............................................................................................................................................141

9.4 WARRANTY STATEMENT (FOR DELIVERIES UNDER F33660-96-C7004).....................................142

© 1998 DH Instruments, Inc. Page IV

Page 7

1. INTRODUCTION

11..

I

NNTTRROODDUUCCTTIIOON

I

N

1.1 PRODUCT OVERVIEW

PPC2 AF is a high precision pressure controller/calibrator intended to apply and measure accurate values

of gas pressure for the calibration and testing of pressure measuring instruments.

PPC2 AF measures and controls pressures in the range of 0 to 1 000 psi (0 to 7 MPa) in both gauge and

absolute mode. Six pressure measuring ranges are available using two high accuracy reference

transducers and an on-board barometer. Internal valving chooses the appropriate transducer for the

desired range and protects the lower pressure transducer when working at high pressures. Pressures are

controlled by a pneumatic module consisting of fast and slow inlet and exhaust solenoid valves and

differential pressure regulators.

PPC2 AF can be controlled locally by the operator using a front panel display, keypad and special function

keys or remotely by a computer using ASCII character command strings over an RS232 interface.

A Self Purging Liquid Trap (SPLT) can be used to protect PPC2 AF from liquid contaminants in the device

or system being tested.

1.2 SUBASSEMBLY DESCRIPTION AND LOCATION

1.2.1 FRONT PANEL ASSEMBLY

1. Display

2. Multi-Function Keypad

The front panel assembly provides a 2 X 20 vacuum fluorescent display of PPC2 AF

operating status and a membrane keypad for local user control.

3. Direct Pressure Control Keys

4. Remote Indicator

Front Panel

Page 1 © 1998 DH Instruments, Inc.

Page 8

PPC2 AF OPERATION AND MAINTENANCE MANUAL

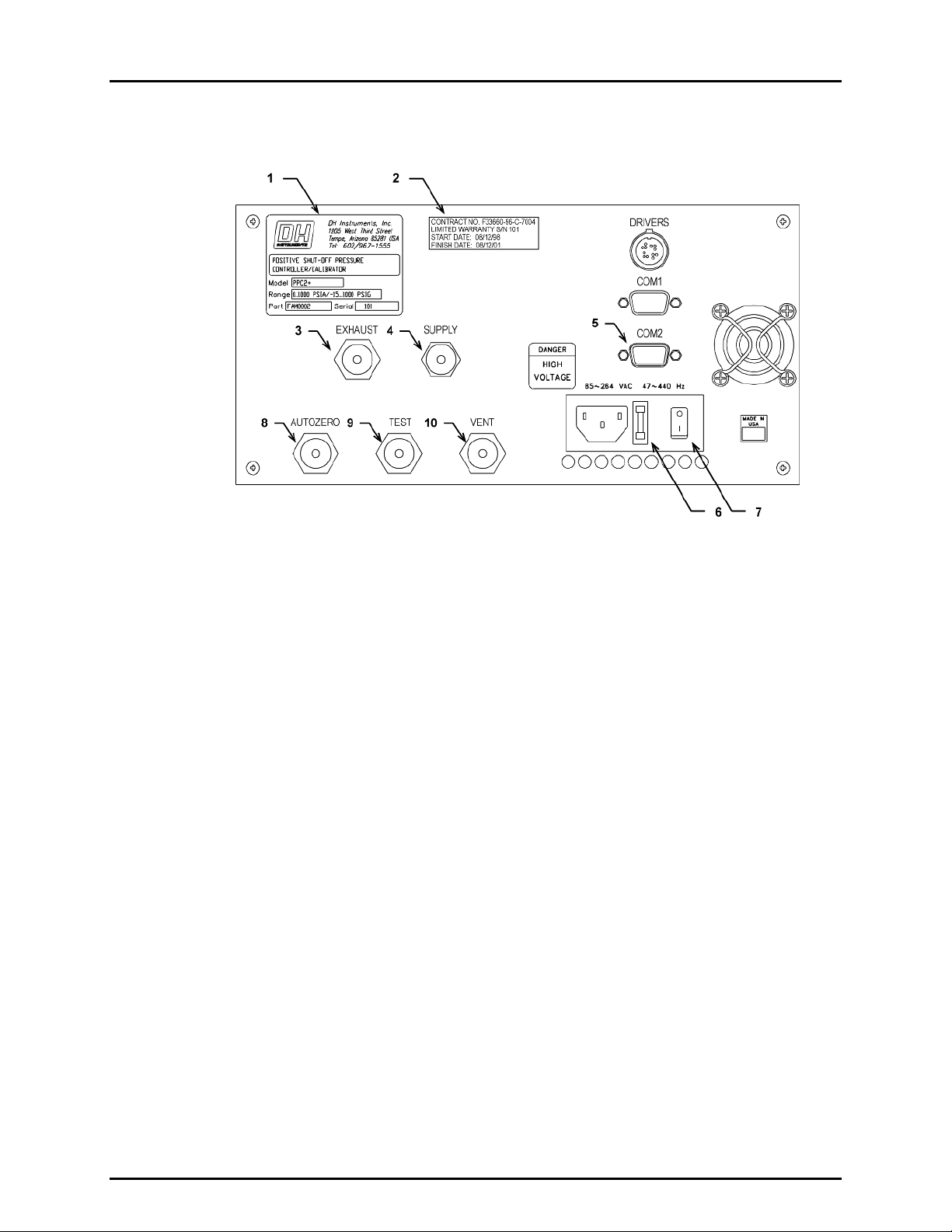

1.2.2 REAR PANEL ASSEMBLY

1. Label, Product

2. Label, Warranty

3. Pressure Connection, EXHAUST

4. Pressure Connection, SUPPLY

5. COM1 Port

6. Fuse

7. Power Switch

8. Fitting, AUTOZERO

9. Fitting, TEST

10. Fitting, VENT

Rear Panel

The rear panel assembly provides pressure connections, the host communications interface

and the power on/off module, and product and warranty labeling. Pressure fittings are

internally secured to prevent loosening when making and breaking connections.

© 1998 DH Instruments, Inc. Page 2

Page 9

1. INTRODUCTION

1.2.3 POWER SUPPLIES

Internal Layout

PPC2 AF has two independent power supplies.

1. + 12 V DC (± 2 %) @ 3.3 Amps: for internal and external valve execution.

2. + 5 V DC (± 2 %) @ 3.0 Amps; + 15 V DC (± 10 % / - 3 %) @ 2.0 Amps; - 15 V DC

(± 5 %) @ 0.35 Amps: for the supply of the micro board and driver board electronics.

1.2.4 MICRO CARD

Internal Layout

The micro card supports a Motorola 68302 microcontroller; EPROM, EEPROM, NVRAM and

flash memories; RS-232 communications; the front panel keypad and display control; and a

two channel frequency counter for reading reference pressure transducers. An I/O port

controls other boards and devices in PPC2 AF.

Page 3 © 1998 DH Instruments, Inc.

Page 10

PPC2 AF OPERATION AND MAINTENANCE MANUAL

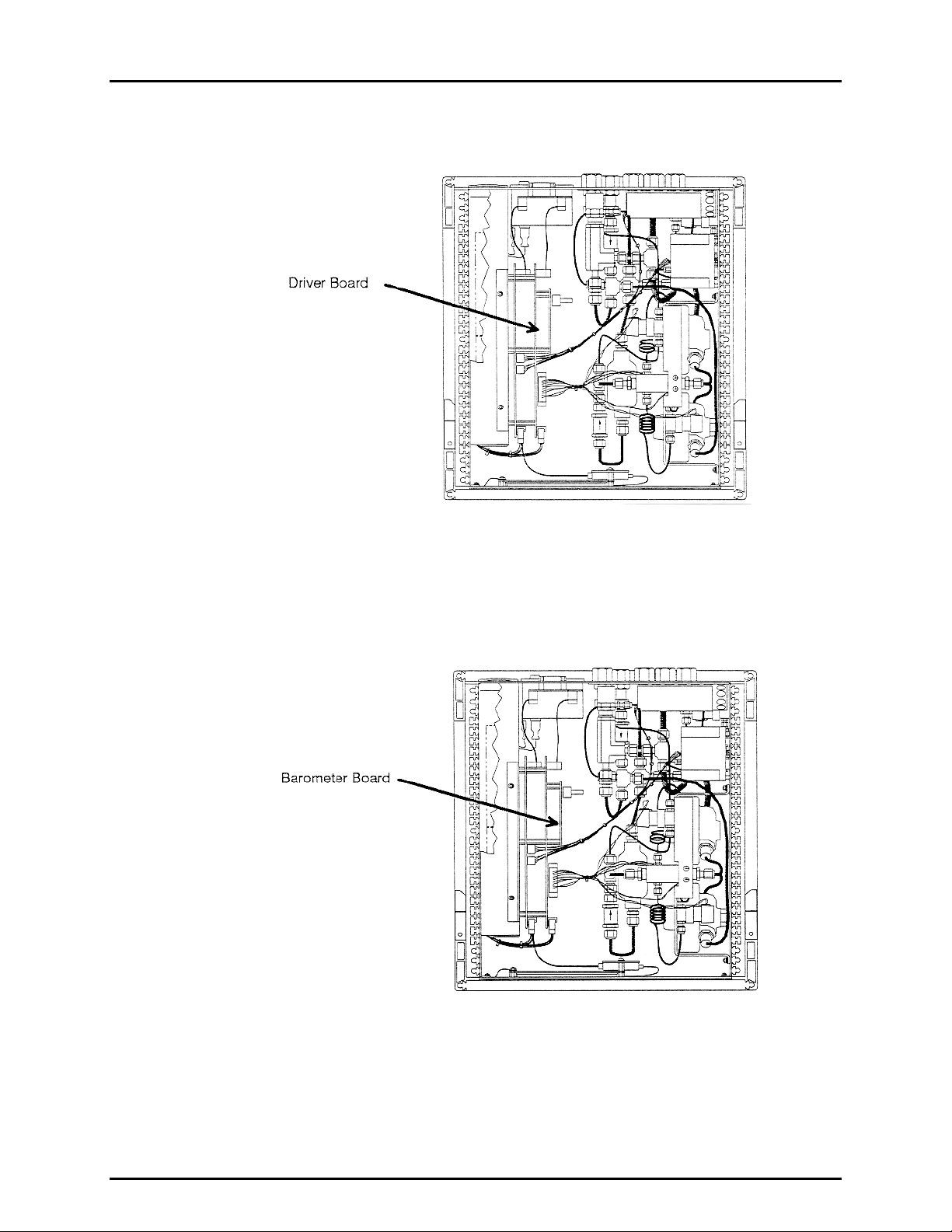

1.2.5 DRIVER BOARD

Internal Layout

The driver board is controlled by the micro card (see Section 1.2.4). It supports the

12 V drivers for the internal and external solenoid valve actuation and the barometer board

(see Section 1.2.6). It also supplies power to the cooling fan.

1.2.6 BAROMETER BOARD

Internal Layout

The barometer board supports a board mounted, barometric range, micromachined silicon

sensor and an ambient temperature sensor. The barometer readings are used for dynamic

atmospheric pressure compensation when measuring gauge pressure with an absolute

reference transducer.

© 1998 DH Instruments, Inc. Page 4

Page 11

1. INTRODUCTION

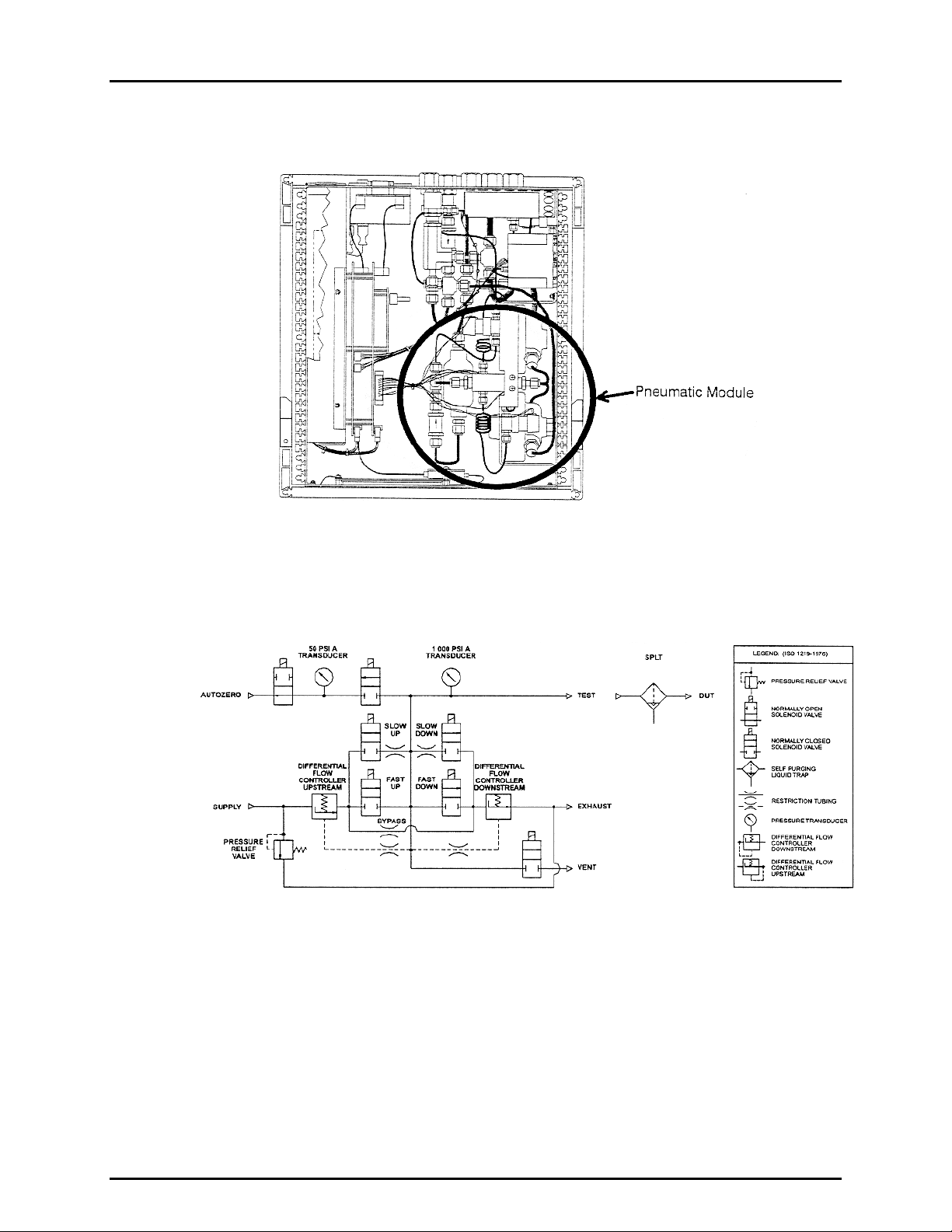

1.2.7 PNEUMATIC MODULE

Internal Layout

The pneumatic module is an integrated assembly that includes two inlet (fast and slow) and

two exhaust control valves and differential pressure regulators. The differential pressure

regulators use pressure feedback to maintain a constant differential pressure across the

control valves. The control valves are solenoid type actuated by 12 V.

Pneumatic Module

Page 5 © 1998 DH Instruments, Inc.

Page 12

PPC2 AF OPERATION AND MAINTENANCE MANUAL

1.2.8 TRANSDUCER SELECTION MODULE

Internal Layout

The transducer selection module includes solenoid valves to connect and disconnect the low

pressure (secondary) reference transducer from the test system and to independently vent

the low pressure reference transducer.

1.2.9 REFERENCE PRESSURE TRANSDUCERS

Internal Layout

There are two reference pressure transducers. Their basic sensing principle is the

measurement of the change in the natural oscillating frequency of a quartz tuning fork with

temperature and with mechanical stress resulting from the change in pressure applied to a

connecting bellows or bourdon tube. Two independent quartz elements are used: one subjected

to pressure related stress; the other is used only to monitor temperature.

© 1998 DH Instruments, Inc. Page 6

Page 13

1. INTRODUCTION

1.2.9.1 HIGH (PRIMARY) PRESSURE REFERENCE TRANSDUCER

The high pressure reference transducer has a full scale range of 1 000 psi

(7 MPa) in gauge and absolute mode.

1.2.9.2 LOW (SECONDARY) PRESSURE REFERENCE TRANSDUCER

The low pressure reference transducer has a full scale range of 35 psi (220 kPa)

in gauge mode and 50 psi (330 kPa) in absolute mode.

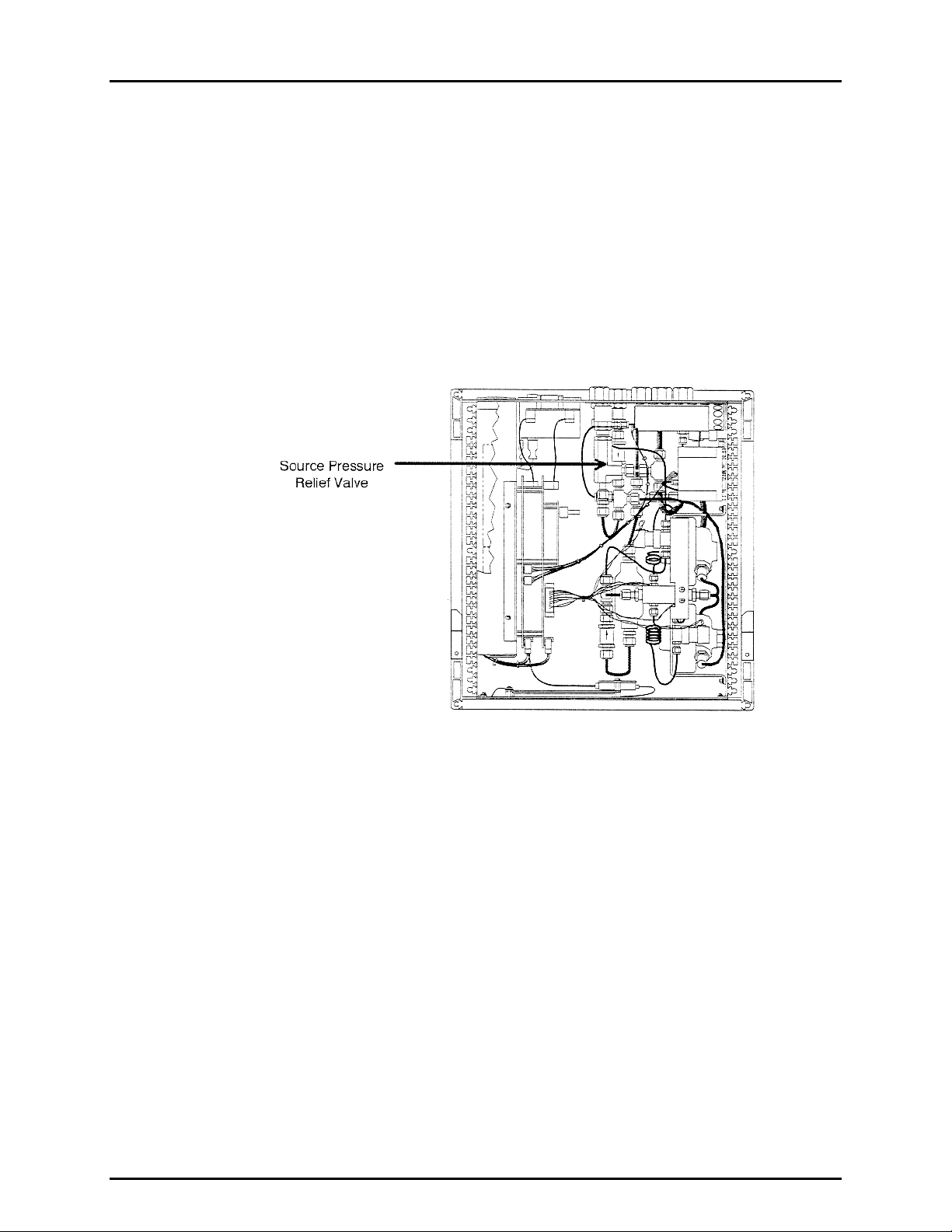

1.2.10 SOURCE PRESSURE RELIEF VALVE

Internal Layout

The source pressure relief valve is a factory set, adjustable, spring loaded pressure relief

valve with a brass body, Viton O-ring seal and stainless steel internal parts. The valve is set

to relieve at 1 200 psi (8.3 MPa).

Page 7 © 1998 DH Instruments, Inc.

Page 14

PPC2 AF OPERATION AND MAINTENANCE MANUAL

1.2.11 SELF PURGING LIQUID TRAP (SPLT)

SPLT (Overall View)

1. Purge Tube

2. Exhaust

Valve

3. Pressure

Connections

4. Electrical

Connection

The SPLT is a free standing accessory designed to protect the PPC2 AF from liquid

contamination returning form the system or device under test. It is made up of a stainless

steel body with an internal X-Type coalescing filter and a bottom drain port fitting with an

electrically actuated purge valve. The filter valve assembly is installed in a mounting stand.

© 1998 DH Instruments, Inc. Page 8

Page 15

1. INTRODUCTION

1.3 SPECIFICATIONS

1.3.1 GENERAL SPECIFICATIONS

Power Requirements

Operating Temperature Range

Storage Temperature Range

Vibration

Weight

Dimensions

Microprocessor

Communication Port

Pressure Ranges

Operating Medium

Pressure Connections

85 to 264 VAC, 47 to 440 Hz, 30 VA max consumption.

15 to 35 °C

- 20 to 70 °C

Meets MIL-T-28800D

12.8 kg (28.2 lb)

7.1" H X 12.6" W X 15.8" D (18 cm X 32 cm X 40 cm)

Motorola 68302, 16 MHz

RS232 (COM1)

-15 to 1 000 psi (7 MPa) gauge/0 to 1 000 psi absolute in six ranges using two

reference pressure transducers and a barometer

Clean, dry, non-corrosive gas

Supply: 1/8 in. NPT F

Test: 1/4 in. NPT F

Vent: 1/4 in. NPT F

Exhaust: 1/4 in. NPT F

AutoZero: 1/4 in. NPT F

1.3.2 PRESSURE MEASUREMENT SPECIFICATIONS

PPC2 AF measures pressures in gauge and absolute mode in six ranges using two reference

pressure transducers and a barometer.

The reference pressure transducers are of the absolute pressure type using an evacuated,

permanently sealed reference. They are used to measure gauge pressures by atmospheric

offset determined by direct measurement when the reference transducer is vented. The

atmospheric offset is dynamically compensated while operating in gauge mode using

measurements of the changes in atmosphere provided by a separate barometer.

1.3.2.1 HIGH PRESSURE REFERENCE TRANSDUCER (HI REF)

Ranges

Measurement Precision

(Combined Linearity, Hysteresis

and Repeatability)

Stability (6 Month with Use of

AutoZero Function)

Resolution

High (3): 0 to 1 000 psi (7 MPa) gauge/absolute

Mid (2): 0 to 600 psi (4 MPa) gauge/absolute

Low (1): 0 to 300 psi (2 MPa) gauge/absolute

± 0.01% F.S. of each range

± 0.005% F.S. of maximum range

1 ppm of maximum range

1.3.2.2 LOW PRESSURE REFERENCE TRANSDUCER (LO REF)

Ranges

Measurement Precision

(Combined Linearity, Hysteresis

and Repeatability)

Stability (6 Month with Use of

AutoZero Function)

Resolution

High (3): - 15 to 35 psi (250 kPa) gauge

0 to 50 psi (350 kPa) absolute

Mid (2): - 15 to 15 psi (100 kPa) gauge

0 to 30 psi (200 kPa) absolute

Low (1): - 15 to 0 psi gauge

0 to 15 psi (100 kPa) absolute

± 0.01 % F.S. of each range

± 0.005 % F.S. of maximum range

1 ppm of maximum range

Page 9 © 1998 DH Instruments, Inc.

Page 16

PPC2 AF OPERATION AND MAINTENANCE MANUAL

1.3.2.3 BAROMETER

The barometric sensor is not used to provide absolute accuracy, it is used only to

measure the changes in atmospheric pressure to provide dynamic compensation

of the reference pressure transducer atmospheric pressure offset measurements

when using a reference pressure transducer to make gauge pressure

measurements.

Range

Accuracy (Nominal)

Resolution

1.3.3 PRESSURE CONTROL SPECIFICATIONS

11 to 16 psia (70 to 110 kPa)

± 0.5 % of reading

0.001 psi (7 Pa)

Control Modes Available

Control Volume

Control Limits

Static and dynamic

0 to 30 in

System defaults provided for each pressure measurement

range but can be customized by the user using the CUSTOM

CONTROL function.

3

(500 cc), ideal 7 to 15 in3 (125 to 250 cc)

1.3.3.1 STATIC PRESSURE CONTROL

Default Hold Limit

Default Stability Limit

± 1 % of F.S. of the active pressure measurement range

± 0.005 % of F.S./sec of the active pressure

measurement range

1.3.3.2 DYNAMIC PRESSURE CONTROL

Default Hold Limit

Default Stability Limit

± 0.05 psi (138 Pa) for Hi Ref ranges (1 to 3)

± 0.0025 psi (7 Pa) for Lo Ref ranges (1 to 3)

± 0.05 psi (350 Pa)/sec for Hi Ref ranges (1 to 3)

± 0.0025 psi (18 Pa)/sec for Lo Ref ranges (1 to 3)

© 1998 DH Instruments, Inc. Page 10

Page 17

2. INSTALLATION AND SHORT TERM STORAGE

22..

I

NNSSTTAALLLLAATTIIOONN AANNDD

I

T

EERRMM

T

S

TTOORRAAGGE

S

E

S

HHOORRTT

S

2.1 UNPACKING AND INSPECTION

2.1.1 REMOVING FROM PACKAGING

PPC2 AF is delivered in a molded medium density polyethylene shipping case with a custom

foam insert for holding the PPC2 AF, SPLT if included, documentation and accessories.

Remove all PPC2 AF elements from the shipping case and remove each element from its

protective plastic bag.

2.1.2 INSPECTING CONTENTS

Check that all items are present and have no visible damage.

PPC2 AF includes:

DESCRIPTION PART NO.

PPC2 AF Pressure Controller/Calibrator 401270

Calibration Certificate 550200

Test Report 550102

ACCESSORIES: 401273

User’s Manual 550090

Power Cord (7.5 ft.) 100770

(4) Rubber Feet Caps 400202

1/4 in. NPT Male X KF 16 SS Vacuum Adaptor 102519

Male Electrical Connector for Drivers 102478

SPLT on Stand (with filter) * 401271

(1) Spare SPLT Filter Element * 102502

Shipping Case with Inserts 401272

* If supplied.

2.2 SITE REQUIREMENTS

The PPC2 AF can be installed on any flat, stable surface at a convenient height. The front feet can be

extended so that the unit can be inclined slightly for easier viewing. The PPC2 AF can also be mounted in

a standard 19" rack mount using the optional rack mount kit.

Minimizing the length of tubing between the PPC2 AF to the device or system to be tested will

enhance control performance and reduce pressure setting times.

Ready access to the PPC2 AF rear panel should be considered to facilitate making and breaking

pressure connections.

The SPLT, if used, needs to be mounted vertically at the low point of the pneumatic system.

Page 11 © 1998 DH Instruments, Inc.

Page 18

PPC2 AF OPERATION AND MAINTENANCE MANUAL

Support facilities required include:

• An electrical power source of 85 to 264 VAC, 47 to 440 Hz.

• A continuous regulated source pressure of 1 100 psi (8 MPa) clean, dry, non-corrosive gas

to connect to the pressure supply. Lower gas pressure sources can be used but should

exceed the maximum desired test output pressure by 10 to 20%.

• A vacuum source of less than 1 psia (7 kPa) and at least 3 cfm (90 lm) is needed to control

under 2 psi (14 kPa) gauge.

When supply pressure is applied to the PPC2 AF supply port, there is a constant gas exhaust through

the EXHAUST port of PPC2 AF to which the vacuum source will be connected. Therefore, the vacuum

source should either be continuously "on" or should bypass to atmosphere when the vacuum source is

"off" to avoid building up pressure on the EXHAUST port and/or the vacuum pump. To conserve gas,

vent the test volume and shut off the pressure supply when PPC2 AF is not in use.

2.3 INITIAL SETUP

2.3.1 PREPARING FOR OPERATION

To prepare PPC2 AF for check out and operation:

• Remove the plastic caps from the five (5) PPC2 AF rear panel pressure connections.

• Remove the protective plastic sheet from the front panel display.

• Install the rubber feet caps onto the bottom case feet, if desired.

2.3.2 POWER CONNECTION

• Check that the PPC2 AF power switch is off.

• Connect the supplied power cable to the rear panel power module.

• Connect the other end of the power cable to an electrical supply of 85 to 264 VAC, 47 to 440 Hz.

2.3.3 CONNECTING TO A PRESSURE SUPPLY (SUPPLY PORT)

Using a pressure connecting hose of appropriate pressure rating, connect the pressure supply

to the SUPPLY connection on the rear panel of PPC2 AF. The PPC2 AF SUPPLY connection

is 1/8 in. NPT female.

Never connect a pressure supply greater than 1 200 psi (8 MPa) to PPC2 AF.

2.3.4 CONNECTING A VACUUM PUMP (EXHAUST PORT)

For PPC2 AF to set pressures under atmosphere and/or to reliably set pressure under 2 psi (914 kPa)

gauge other than zero gauge, a vacuum pump must be connected to the exhaust port.

Never connect a pressure supply to or plug the PPC2 AF EXHAUST port.

When changing the pressure applied to the EXHAUST port from vacuum to atmosphere, be

sure to change the control reference setting (see Section 3.3.1).

© 1998 DH Instruments, Inc. Page 12

Page 19

2. INSTALLATION AND SHORT TERM STORAGE

2.3.5 CONNECTING TO THE DEVICE UNDER TEST (TEST PORT)

See Section 2.3.5.1 before proceeding to connect the device under test.

Using a pressure connecting hose of appropriate pressure rating, connect the device or system to

be tested to the TEST port of the PPC2 AF. The PPC2 AF TEST connection is ¼ in. NPT female.

Minimizing the length of the test connection hose will enhance control performance and

reduce pressure setting time. For normal operation, the total volume of the device of

3

system under test including connecting tubing should be less than 30 in

(500 cc).

PPC2 AF pressure control will not operate properly if there are excessive leaks in the test

system (see Section 3.2.8).

PPC2 AF pressure may be adversely affected if the test connection hose is too restrictive.

For optimum results, the inner diameter of the connecting hose should be > 0.07” (1.75 mm).

NEVER apply pressure to the TEST port without having a pressure supply equal to or great than

the applied pressure connected to the SUPPLY port. When controlling pressure externally, or

measuring external pressure through the SUPPLY port, NEVER

cause the pressure to change at

a very rapid rate. For example, do not vent suddenly by opening an external valve. Internal

PPC2 AF damage may result.

2.3.5.1 INSTALLING THE SPLT

The SPLT (if provided) is intended to collect and exhaust liquid contaminants that may be

present in the device or system under test so that they do not return to the PPC2 AF.

The SPLT is installed in the test connection line at a low point between PPC2 AF and

the device or system under test. The SPLT pressure connections are 1/4 in. NPT female.

Teflon tape or another sealing material should be used to assure leak free

connection of adapters installed in the SPLT pressure connections.

Proper SPLT operation is dependent on the gas flowing through it in the correct

direction. Be sure to connect the SPLT to the device or system under test and

the PPC2 AF following the connector port labels on the SPLT.

Connect the SPLT electrically to the PPC2 AF rear panel DRIVER connection and to the

SPLT terminal blocs. See Appendix 9.2 for information on preparing the SPLT

electrical cable and connection to the SPLT terminal blocs.

The SPLT must be mounted vertically with the purge valve at the bottom to

perform properly. It must be at a lower point in the system than the PPC2 AF

and/or the device under test. In operation, liquid contaminants collected from the

device or system under test will be exhausted through the SPLT purge valve.

Liquid contaminants will be forcibly ejected from the SPLT purge tube. Provision

for collecting the purged liquids should be considered when installing the SPLT.

Excessively dirty or wet filter elements can adversely affect pressure control.

Page 13 © 1998 DH Instruments, Inc.

Page 20

PPC2 AF OPERATION AND MAINTENANCE MANUAL

PPC2 AF with SPLT and DUT

2.3.6 THE VENT CONNECTION (VENT PORT)

The PPC2 AF VENT connection is the system vent to atmosphere point used to set zero

gauge pressure and obtain reference pressure transducer measurements of atmospheric

pressure. Though a pressure hose can be connected to the VENT connection to direct the

vented gas flow, a completely unobstructed connection to atmosphere must be obtained for

PPC2 AF reference pressure measurements to operate normally.

The PPC2 AF VENT connection is 1/4 in. NPT female.

Never plug, obstruct or connect a supply pressure to the PPC2 AF vent connection.

2.3.7 THE AUTOZERO CONNECTION (AUTOZERO PORT)

The PPC2 AF AUTOZERO connection is used for the AutoZero by Vacuum function and is

not needed at start up. It should be left open to atmosphere.

2.4 POWER UP AND VERIFICATION

2.4.1 SWITCH POWER ON

Actuate the power switch on the PPC2 AF rear panel. Observe the front panel display as

PPC2 AF initializes, error checks and goes to the main run screen (see Section 3.1.1).

PPC2 AF operating condition at power up is VENT valve closed, Hi reference pressure

transducer active.

If the PPC2 AF fails to reach the main run screen, service is required. Record the sequences

of operation and displays observed.

If the active range on power down was a Hi reference transducer range, the same range will

be active on the next power up. If the active power down range was a Lo reference

transducer range, range H3 will be active on power up. This is to protect the Lo reference

transducer from accidental overpressure (see Section 3.1.2.5).

© 1998 DH Instruments, Inc. Page 14

Page 21

2. INSTALLATION AND SHORT TERM STORAGE

2.4.2 SET THE USER LEVEL (INITIAL START UP ONLY)

PPC2 AF's front panel interface provides the means to access all PPC2 AF data and

functions including functions which, if used inadvertently or incorrectly, could change critical

metrological and/or operational parameters. The USER LEVEL function (see Section 3.4.4.6)

allows these areas to be password protected. The "low" security level protects only the most

critical internal calibration data. It is recommended that this level be set on all PPC2 AF's

even if no special security precautions are desired.

2.4.3 CHECK PROPER PRESSURE MEASUREMENT OPERATION

2.4.3.1 CHECKING ABSOLUTE PRESSURE MEASUREMENT

If the PPC2 AF is not vented, press the VENT direct pressure control key to vent

it (see Section 3.1.2.2).

Press the UNIT function key (see Section 3.2.2). Select psi and then select

absolute mode.

Using the RANGE function key to change ranges (see Section 3.2.1), observe the

current value of atmospheric pressure displayed by each range. Check that

these values agree within ± 0.2 psi (1.4 kPa). If they do not agree, PPC2 AF may

need calibration or repair.

2.4.3.2 CHECKING GAUGE PRESSURE MEASUREMENT

If the PPC2 AF is not vented, press the VENT direct pressure control key to vent

it (see Section 3.1.2.2).

Press the UNIT function key. Select psi and then select gauge mode.

Using the RANGE function key to change ranges, observe that zero psi, ± 0.01 psi

is indicated for each range within 10 seconds. If it is not, PPC2 AF may need repair.

2.4.4 LEAK CHECK

If desired, perform a leak check of the test system (see Section 3.2.8).

2.4.5 PURGE

If the SPLT is included and installed in the test line, perform a purge of the system if it may be

liquid contaminated and descending pressures will be controlled (see Section 3.2.8).

Operating the PPC2 AF connected to a system with liquid contaminants without taking

proper precautions to purge the system and test line may cause contamination of the

PPC2 AF that will require non-warranty service.

Page 15 © 1998 DH Instruments, Inc.

Page 22

PPC2 AF OPERATION AND MAINTENANCE MANUAL

2.4.6 CHECK PROPER PRESSURE CONTROL OPERATION

Select a pressure range using the RANGE function (see Section 3.2.1).

Press the CONTROL function key and select "dynamic" (see Section 3.2.3).

Select1Vac under 1ControlRef of the SETUP menu if a vacuum supply is connected to the

PPC2 AF EXHAUST port, otherwise, set 2Atm (see Sections 3.3.1).

Press ENTER, specify a target pressure within the current range to be set and press ENTER

again (see Section 3.2.3).

PPC2 AF should set the target pressure and indicate "ready" (see Section 3.1.2.4)

continuously in 30 to 60 seconds. If it does not, see Section 6.

2.5 SHORT TERM STORAGE

The following is recommended for short term storage of PPC2 AF:

• Vent the PPC2 AF test pressure.

• Turn the power "off" using the rear panel power switch.

• Shut-off or disconnect the pressure supply.

• Shut-off or disconnect the vacuum supply.

© 1998 DH Instruments, Inc. Page 16

Page 23

3. OPERATION

33..

O

PPEERRAATTIIOON

O

N

3.1 GENERAL/MANUAL OPERATION

PPC2 AF is designed to offer a balance between simple, straight forward operation and the

availability of a wide variety of functions with a high level of operator discretion if desired. The local

operator interface is through a 2 X 20 display, a 4 X 4 keypad and 4 direct pressure control keys.

3.1.1 THE MAIN RUN SCREEN

The PPC2 AF main run screen is its home display that is reached on power up and from

which other functions and menus are accessed. It is the very top level of all menu structures.

The main run screen is where the operator works with PPC2 AF to set and read pressures.

It provides complete information on the system's current configuration and operating status.

1. * Ready/Not Ready indication (See Section 3.1.2.4).

* when Ready,

if Not Ready.

2. PRESSURE1: Numerical value and sign of pressure

currently measured by currently active transducer and range.

3. UNIT: Current unit of measure of pressure indication

(see Section 3.2.2).

4. M: Pressure measurement mode: g for gauge, a for

absolute (see Section 3.2.2).

5. H: Indicates if a head correction is applied. H if applied,

blank if not (see Section 3.2.7).

6. SR: Indicates active reference transducer (H for high, L for low) and range (1 = low, 2 = mid, 3 = hi)

(see Section 3.2.1).

7. T: Indicates whether number following is target pressure (T), rate of change of pressure (R) or deviation

from target value (D) (see Section 3.2.3).

• Target pressure (T) will be indicated when:

- Dynamic control is active and pressure is NOT READY.

- Static control is active and valves are operating.

• Deviation (D) will be indicated when:

- Dynamic control is active and pressure is READY.

• Rate of change (R) will be indicated when:

- No control is active, i.e. control is suspended or

system is vented.

- Static control is active, and no valves are active.

8. PRESSURE2: Numerical sign and value of either target pressure, rate of change of pressure or deviation

from target. Target value and deviation in the same pressure unit as the current unit in 3. above. Rate of

change of pressure is in current unit per second (see Section 3.2.3).

9. CC: Pressure control mode (S for static, D for dynamic) with a (C) appended if custom control settings are

in use. These characters flash when the system is controlling. In static mode, if control is active they flash

even if no valve is operating, for example while inside the hold limit and waiting for stability. Characters flash

while controlling pressure down to vent but not when vent valve is open (see Sections 3.2.3 and 3.2.6).

10. NN/NN: Used only when running a sequence. Indicates number of increment currently being worked on

over total number of increments in the sequence or enter when “ready”. Changes to a countdown time during

count down when next increment of sequence is on timed delay rather than enter.

or indication direction of pressure evolution

*PRESSURE1 UNITMH SR

TPRESSURE2 CC NN/NN

PPC2 AF has a screen saver function which causes the display to dim if no key is pressed

for 10 minutes. Pressing a key restores full power to the display.

Page 17 © 1998 DH Instruments, Inc.

Page 24

PPC2 AF OPERATION AND MAINTENANCE MANUAL

3.1.2 GENERAL OPERATING PRINCIPLES

3.1.2.1 MAIN KEYPAD LAYOUT AND PROTOCOL

The PPC2 AF has a 4 X 4 keypad for local operator access to direct functions,

function menus and for data entry.

3. The Editing and Execution keys are for causing execution, suspending execution, backing up

in menus and editing entries.

1. The Function/Data keys allow very

commonly used functions to be

accessed directly by a single

keystroke when pressed from the

main run screen. The name of the

function is on the bottom half of the

key (see Section 3.2). These keys

enter numerical values when editing.

2. The Menu/Data keys provide access

to function menus when pressed

from the main run screen. The menu

name is on the bottom half of the

key. The SETUP menu is for more

frequently used functions (see

Section 3.3). The SPECIAL menu is

for functions that are not generally

used as a part of normal operation

(see Section 3.4). These keys enter

numerical values when editing.

Keypad

The ENTER key generally causes execution or forward movement in the menu tree.

ENTER from the main run screen allows an automated pressure control

command to be given.

The ESCAPE key moves back in the menu tree and/or causes execution to

cease or suspend. Pressing ESCAPE repeatedly always eventually brings you

back to the main run screen and from there will allow a momentary viewing of the

PPC2 AF introduction screen.

The

key changes a numerical sign when editing. It also toggles through

multiple screens when available.

The

and keys allow reverse and forward cursor movement when editing

data entry.

Some screens go beyond the two lines provided by the display. This is

indicated by a flashing arrow in the second line of the display. Use the ←

→ arrow keys to move the cursor to access the lines that are not

and

visible or directly enter the number of the desired menu choice if you know it.

3.1.2.2 DIRECT PRESSURE CONTROL KEYS

Direct Pressure Control Keys

The direct pressure control keys provide direct manual control of pressure

increase, decrease and vent. They can be useful in adjusting pressure when

automated pressure control to a target value is not needed.

© 1998 DH Instruments, Inc. Page 18

Page 25

3. OPERATION

The direct pressure control keys interrupt and override automated pressure control.

The VENT key causes the system to control pressure to near atmospheric

pressure and then open the system vent valve (see Section 1.2.7). Vent valve

open is indicated by lighting a red LED just above the VENT key. The vent valve

will remain open until the VENT key is pressed again or pressure is changed by a

direct pressure control key or an automated pressure control command. The VENT

key also causes the purge function to execute when the PPC2 AF LEAK

CHECK/PURGE function is active (see Section 3.2.8).

and keys cause pressure to increase or decrease at the slow slew rate.

The

Pressing the FAST key while pressing an

increase or decrease speed to change from slow to fast.

or key will cause the pressure

3.1.2.3 AUTOMATED PRESSURE CONTROL

PPC2 AF automated pressure control provides automated adjustment and control

of pressure to a user designated target value. This feature allows pressure

values to be set simply and precisely by simple numerical entry. Pressing

ENTER from the main run screen allows a pressure control target value to be

entered and executed. Pressing ESCAPE or a direct pressure control key will

cause pressure control to be interrupted.

PPC2 AF supports two pressure control modes, static and dynamic, to meet

different pressure setting and controlling requirements. Pressure control

parameters for each control mode are automatically adjusted to optimal values

for each PPC2 AF range when the control mode is selected in that range (see

Section 3.2.3). If desired, control parameters can be customized by the user

using the CUSTOM CONTROL function (see Section 3.2.6).

Control parameters:

Target Value: The pressure setpoint specified by the operator.

Hold Limit: A symmetrical positive and negative limit around the target value.

Stability Limit: A rate of change of pressure limit in units of pressure/second.

See Sections 3.1.2.3.1 and 3.1.2.3.2 for a detailed explanation of each control mode

and its advantages, the default control parameters and the Custom Control options.

3.1.2.3.1 Static Control

Static control mode is designed to set the pressure near the target value and then

stop controlling to allow pressure to stabilize naturally. The advantage of this

control mode is that pressure can be measured without interference from a

pressure control system. In a system without excessive leaks, the pressure

stability achieved, especially at low pressures, may be greater than the stability

with which the pressure control system can actively control pressure. Using static

control to control pressures near the desired set point and then measuring back

the stabilized pressure without interference of the control function, can allow

control errors to be eliminated. However, the final pressure achieved will be

different from the target value.

Page 19 © 1998 DH Instruments, Inc.

Page 26

PPC2 AF OPERATION AND MAINTENANCE MANUAL

During static pressure control, the hold limit is active. If the pressure goes

outside of the hold limit, a "not ready" condition will occur (see Section 3.1.2.4)

and pressure will be readjusted to the target value (see Section 3.2.3 for default hold

and stability limit values and Section 3.2.6 for setting the hold and stability limits).

Static Pressure Control Operation

3.1.2.3.2 Dynamic Control

Dynamic control mode is designed to set the pressure to the target value and

control continuously to keep pressure within the hold limit and as close to the

target value as possible. The advantage of this control mode is that the final

pressure achieved will be the same as the target value. However, unlike static

control, in dynamic control, a control error will be included in the pressure

achieved. The maximum value of the control error is equal to the hold limit. The

average value of the control error is generally well inside the hold limit.

During dynamic pressure control, the hold limit is active. If the pressure goes outside

of the hold limit, a "not ready" condition will occur (see Section 3.1.3.4; see

Section 3.2.3 for default hold limit values and Section 3.2.6 for setting the hold limit).

Dynamic Pressure Control Operation

© 1998 DH Instruments, Inc. Page 20

Page 27

3. OPERATION

3.1.2.4 PRESSURE READY/NOT READY INDICATION

The far left character of the display provides a pressure "Ready/Not Ready" indication.

This indication is intended to provide the user with a clear and objective criterion

for determining when a valid pressure measurement can be made.

Ready/Not Ready indications are:

* : Pressure "ready".

: Pressure "not ready" and decreasing.

: Pressure "not ready" and increasing.

When pressure control is not active, a "ready" condition will occur any time no

control valve is operating and the pressure rate of change is inside the stability

limit. The stability limit is defined in terms of rate of change of pressure in current

pressure units per second.

The determination of the "ready/not ready" condition is different for static and

dynamic pressure control. Pressure Ready/Not Ready parameters are set by

default when a control mode is selected and can be customized (see Sections

3.2.3 and 3.2.6).

3.1.2.4.1 Static Control Ready/Not Ready

When static pressure control mode is active a "ready" condition will occur when:

1. No control valve is operating.

2. The current measured pressure is inside the hold limit.

3. The rate of change of pressure is less than the current stability limit.

Ready/Not Ready Static Control Mode

Page 21 © 1998 DH Instruments, Inc.

Page 28

PPC2 AF OPERATION AND MAINTENANCE MANUAL

3.1.2.4.2 Dynamic Control Ready/Not Ready

When dynamic pressure control mode is active a "ready" condition will occur when:

1. The current measured pressure is inside the hold limit.

Ready/Not Ready in Dynamic Pressure Control Mode

3.1.2.4.3 Ready/Not Ready When Automated Pressure Control is Not Active

When no automated pressure control is active, "ready" is indicated whenever the

rate of change of pressure is less than the current stability limit.

3.1.2.5 MULTIPLE PRESSURE RANGES

PPC2 AF has two reference pressure transducers each of which has three

ranges for a total of six pressure ranges. This multiranging feature allows

accuracy to be optimized for the range of pressure in which you are working.

Generally, the best range to select (see Section 3.2.1) is that whose full scale is

closest to, but not less than, the maximum pressure at which you need to work.

PPC2 AF handles all of the data and internal valving operations needed to make

range changes occur transparently to the operator when the RANGE function is

used to select a range. Ranges available can be viewed at any time but changing

ranges can only occur when PPC2 AF is vented.

When ranges are changed, the upper limit is automatically changed to the default

for that range or to the last upper limit that was set for that range (see Section 3.2.4).

In addition, most other functions are range specific (see Section 3.2.1 below).

PPC2 AF has six ranges on two transducers. In general, user settings and

operational adjustments are specific to the range currently in use, as if you

had six instruments rather than one.

The PPC2 AF internal valving for handling of the two reference transducers is:

Valving – Hi and Lo Reference Transducers

© 1998 DH Instruments, Inc. Page 22

Page 29

3. OPERATION

RANGES AND IDENTIFICATION

The currently active reference transducer and range is continuously displayed in

the upper right hand corner of the main run screen. Ranges available and main

run screen indication are as follows:

REFERENCE TRANSDUCER

AND RANGE NUMBER

Lo, 1 (Lo) 0/15 L1

Lo, 2 (Mid) 15/30 L2

Lo, 3 (Hi) 35/50 L3

Hi, 1 (Lo) 300/300 H1

Hi, 2 (Mid) 600/600 H2

Hi, 3 (Hi) 1 000/1 000 H3

RANGE (PSI)

GAUGE/ABSOLUTE

MAIN RUN SCREEN

INDICATION

All ranges start at zero in absolute mode and in gauge mode go negative by the

current value of atmospheric pressure.

3.2 DIRECT FUNCTION KEYS

3.2.1 RANGE

PURPOSE

To change the currently active pressure measurement range.

PRINCIPLE

PPC2 AF uses a 1 000 psi (7 MPa) absolute transducer and a 50 psi (350 kPa) absolute

transducer to measure reference pressures. In addition, each one of these transducers is

triple ranged providing a total of six pressure ranges over the 1 000 psi pressure range of the

PPC2 AF (see Section 3.1.2.5).

The RANGE function keys allows ranges to be selected including automated switching of

transducers when necessary with built-in logic to prevent accidental overpressure of the low

pressure transducer.

PPC2 AF functions and settings such as pressure unit of measure (UNIT) and control mode

(CONTROL) are range specific. Only the HEAD function is not range specific (see Section 3.4.2).

Changes made while in one range apply to that range only and will not affect the other ranges.

OPERATION

Pressing the RANGE function key activates the range viewing and selecting function.

Pressing the +/- key or the RANGE key again while in the RANGE functions steps through

displays of available ranges, Lo to Hi. Pressing ENTER while in the RANGE function when

PPC2 AF is vented makes the currently displayed range the active range. Pressing ESCAPE

while in the range function returns to the main run screen with no range change having been made.

Page 23 © 1998 DH Instruments, Inc.

Page 30

PPC2 AF OPERATION AND MAINTENANCE MANUAL

When the RANGE function key is first pressed, the current reference transducer and range

being used are displayed, for example:

1. Identifies reference transducer in use (Lo or Hi).

2. Identifies range of that reference transducer currently in use

(1, 2 or 3, Lo to Hi).

3. Abbreviated range designation.

4. Units of measure and pressure range for that transducer and

range number when used in gauge (g) or absolute(a) mode.

Pressing the

key or pressing the RANGE key again causes the screen to step through

the other available ranges in sequence Lo to Hi, for example:

Current LO, Rng3 L3

psi 35 g/50 a

1. Identifies reference transducer (Lo or Hi).

2. Identifies range of number on that reference transducer (1, 2 or 3).

3. Abbreviated range designation.

4. Units of measure and pressure range for that transducer and

that range when used in gauge (g) or absolute(a) mode.

Select HI, Rng1 H1

psi 300 g/300 a

Range limits are given in the pressure unit that is currently active for that range.

To protect against overpressure of the Lo pressure reference transducer and avoid

accidentally exceeding range upper limits, the active range can only be changed when the

system is vented. If ENTER is pressed while in the RANGE function when PPC2 AF is not

vented, the display will indicate "Vent system fully to change range". Press ESCAPE or ENTER

to reach the main run screen and vent using the VENT direct pressure control key. Once

the system has fully vented, use the RANGE function to make the desired range change.

RANGE SPECIFIC FUNCTIONS AND SETTINGS

In general, PPC2 AF functions and settings are channel specific. They are set and stored for

each range so that changing them when in one range does not change them in the other

ranges and when you return to a range, you will find the settings you left.

The only functions and settings that are not range specific are:

Functions: HEAD, ANALOG

Setup Menu: 1ControlRef, 4Drivers

3.2.2 UNIT

PURPOSE

To specify the pressure unit in which PPC2 AF displays pressure values.

See also Section 3.4.1.

© 1998 DH Instruments, Inc. Page 24

Page 31

3. OPERATION

OPERATION

To change the pressure unit of measure, press the

UNIT function key. The display is:

1psi 2kPa 3inHg

4inWa 5mmHg 6ft

Select the desired pressure unit. ENTER selects the unit and goes to measurement mode

selection: 1gauge or 2absolute. Making the selection returns to the main run screen with the

selected measurement unit and mode active.

If the pressure unit selected is inWa the reference

temperature for water density must be specified.

When inWa is selected as the unit, the next display is:

Select the desired reference temperature for water density using the

Select inWa ref temp

4ºC 20ºC 60ºF

← or → key to move

the cursor. ENTER returns to the main run screen with the inWa based on water density at

the selected reference temperature as the pressure unit. The current inWa reference

temperature can be viewed by observing the position of the cursor in the reference

temperature screen.

No reference temperature selection is necessary for the unit mmWa as the only reference

temperature commonly used for mmWa is 4º C.

See Section 9.3 for tables of the conversion factors used by PPC2 AF.

The choice of six units available under the UNIT function can be modified from a wider

selection by the user. See Section 3.4.1.

3.2.3 CONTROL

PURPOSE

To set the automated pressure control mode for the currently active range with default control

parameters.

PRINCIPLE

The CONTROL function allows the active control mode for the current range to be set to

either static control or dynamic control (see Section 3.1.2.3). The control mode set is specific

to the current range and will be maintained with that range when ranges are changed.

When the control mode is set using the CONTROL function, CONTROL parameters are set

to system default parameters which have been determined to be those most suitable for the

typical user to operate within PPC2 AF pressure control and measurement specifications

(see SYSTEM DEFAULT CONTROL PARAMETERS below). If desired, control mode

parameters can be customized by the user using the CUSTOM CONTROL function

(see Section 3.2.6).

For a complete description of the operation and purpose of static and dynamic control modes,

see Section 3.1.2.3.

Page 25 © 1998 DH Instruments, Inc.

Page 32

PPC2 AF OPERATION AND MAINTENANCE MANUAL

OPERATION

To select the control mode for the currently active

range and set control parameters to the default control

parameters, press the CONTROL function key from

the main run screen. The display is:

Control mode:

1dynamic 2static

Selecting 1static or 2dynamic causes the selected pressure control mode to be activated with

default control parameters and returns to the main run screen.

Control mode setting is range specific. A change in control mode made while in one

PPC2 AF range does not affect the control mode setting in other ranges (see

Section 3.2.1).

The current control mode is indicated by two characters in the middle of the bottom line

of the main run screen (S for static and D for dynamic with C appended if custom control

settings are in use). (See Section 3.1.1.)

In dynamic control mode, whenever the pressure is "ready" (inside the hold limit), the

display of measured pressure is equal to the target pressure. This is because in dynamic

control mode, when the pressure is "ready", it is assumed that the measured pressure

equals the target pressure. This is not true when setting zero in absolute measure mode

(see Section 3.2.3.1.2).

SYSTEM DEFAULT CONTROL PARAMETERS

LO REFERENCE TRANSDUCER

RANGE 1, 2, 3

HOLD LIMIT STABILITY LIMIT HOLD LIMIT STABILITY LIMIT

Static

Mode

Dynamic

Mode

± 1% of F.S. of the

active pressure

measurement range

± 0.0025 psi

(35 Pa )

± 0.005% of F.S./sec

of the active pressure

measurement range.

± 0.0025 psi

(35 Pa)/sec

HI REFERENCE TRANSDUCER

RANGE 1, 2, 3

± 1% of F.S. of the

active pressure

measurement range

± 0.05 psi (350 Pa ) ± 0.05 psi

± 0.005% of F.S./sec

of the active pressure

measurement range.

(350 Pa )/sec

3.2.3.1 EXECUTING AUTOMATED PRESSURE CONTROL COMMANDS

PURPOSE

To use the automated pressure control functions of PPC2 AF to set target

pressure values.

© 1998 DH Instruments, Inc. Page 26

Page 33

3. OPERATION

OPERATION

To set a pressure press ENTER from the main run screen. The display is:

1. Ready/Not Ready indication, current pressure,

units, measurement mode, range (regular first

line of main run screen).

2. Entry field for target pressure to be set

automatically. Comes up with last entry or

zero if pressure measurement units have

been changed, range has been changed, or

system has been vented.

* 134.56 psi a H3

Target: 135.000 psi

Use the numerical keys and editing keys to enter the target pressure value

desired (see Section 3.2.3.1.2 for information on zero pressure commands).

Press ENTER to start pressure control to the target pressure and return to the

main run screen. The main run screen is:

1. "Ready/Not Ready indication, current

pressure, units, measurement mode, range

(regular first line of main run screen).

2. Target pressure value (T) or pressure rate of

change value (R) if in dynamic control and

pressure is in ready condition.

3. Current control mode flashing to indicate that

control is on.

134.56 psi a H3

T 250.000 DC

A target pressure entry that exceeds the current upper limit (see Section

3.2.4 or that is out of range will not be accepted as the target value when

ENTER is pressed.

Observe the Ready/Not Ready indication for indication of when ready conditions

have been satisfied (see Section 3.1.2.4). PPC2 AF will continue controlling

following static or dynamic control operation protocol (see Section 3.1.2.3) until

automated pressure control is interrupted.

See Section 6 if PPC2 AF is unable to control pressure or appears to control

pressure poorly.

For PPC2 AF to set pressures under atmosphere and/or to reliably set

pressures under 2 psi (14 kPa) gauge other than zero gauge, a vacuum pump

must be connected to the EXHAUST port (see Section 2.3.4) and PPC2 AF

must be set up for control using a vacuum reference (see Section 3.3.1).

Zero gauge pressure can always be set.

3.2.3.1.1 Interrupting Automated Pressure Control

Automated pressure control is interrupted by:

• Pressing ESCAPE.

• Pressing any direct pressure control key (see Section 3.1.2.2).

• Pressing any function key.

To start automated pressure control again, press ENTER and ENTER a target

pressure value.

Page 27 © 1998 DH Instruments, Inc.

Page 34

PPC2 AF OPERATION AND MAINTENANCE MANUAL

3.2.3.1.2 Automated Pressure Commands for Zero Pressure

Zero in gauge mode:

Zero in absolute mode:

A command for automated pressure control of zero when in gauge

pressure measurement mode is interpreted in the same manner as if

the VENT direct pressure control key had been pressed (see Section

3.1.2.2). A "ready" condition will occur when the vent valve has been

opened and the pressure meets the current stability test.

Even with a vacuum pump connected to its reference EXHAUST,

PPC2 AF cannot set absolute zero pressure due to internal

restrictions and the continuous gas flow through its EXHAUST port.

When a command for automated pressure control of zero when in

absolute pressure measurement mode is given, PPC2 AF responds

by reducing the pressure as far as possible using down fast pressure

control. A "ready" condition will be indicated when the stability limit is

reached with the control down fast remaining open.

Due to the manner in which PPC2 AF handles an automated pressure

command for zero in absolute pressure measurement mode, a ready

condition can occur at a pressure well outside of the hold limit. When setting

zero in absolute measurement mode, the "ready" condition should not be

used as an indication that the pressure is zero. "Ready" is an indication that

the PPC2 AF has reduced the pressure as far as possible and that the