Fluke OIL INTENSIFIER SYSTEM INSTALLATION

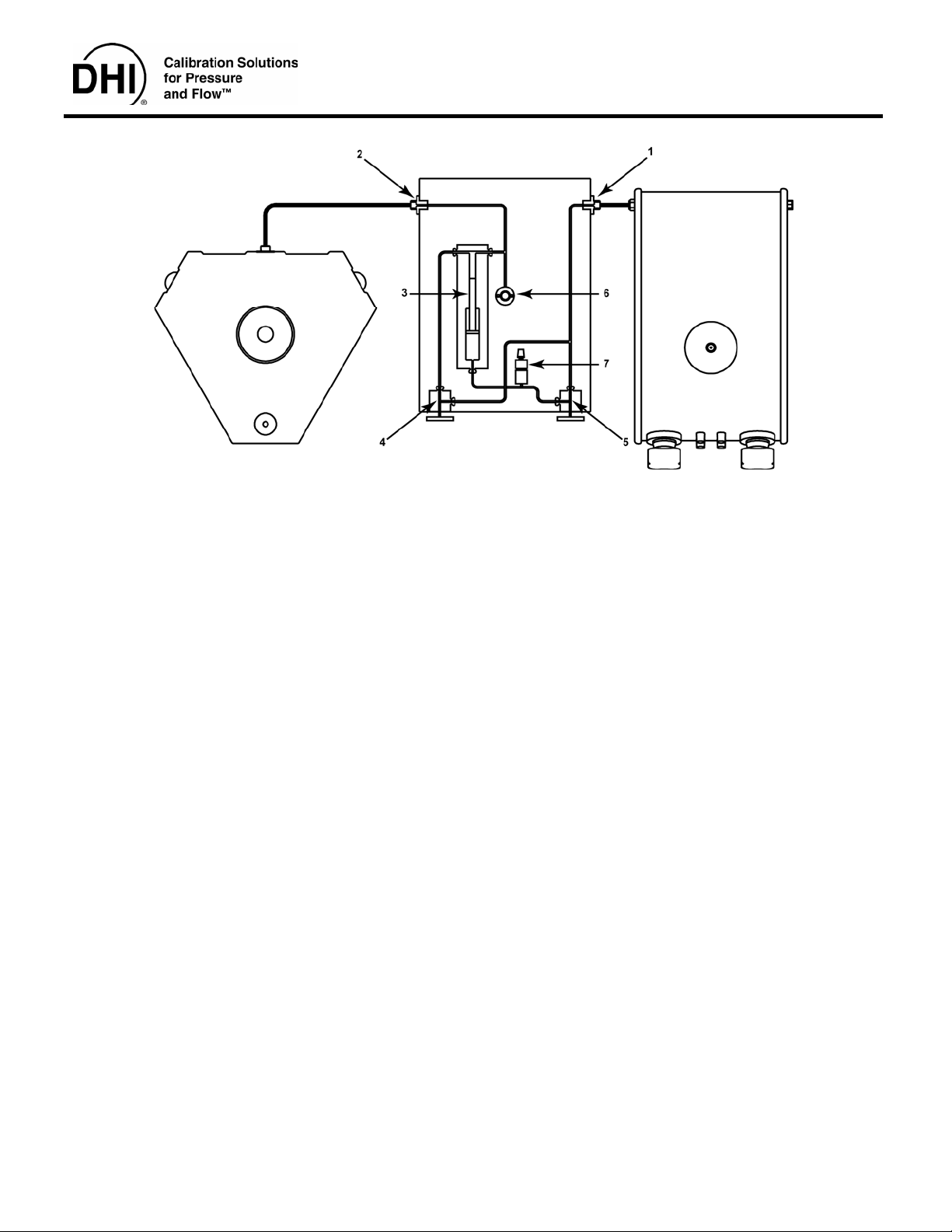

1. SUPPLY connection to OPG1 or MPG1 TEST Port (DH500) 5. INTENSIFIER SHUTOFF valve

2. TEST connection to PG7302 (DH500) 6. TEST connection to Device Under Test (DUT)

3. Intensifier

4. LOW PRESSURE SHUTOFF valve

DESCRIPTION

The Oil Intensifier System (OIS) is intended to generate

pressure up to 500 MPa (75 000 psi) using an OPG1 or

MP G1 (whose maximum pressure is 200 MPa (30 000 psi)).

The OIS includes a 5:1 intensifier. The intensifier is used

only when necessary to generate pressure > 200 MPa

(30 000 psi).

Oil Intensifier System

P/N 401746

Instruction Sheet

7. Safety Head with 120 MPa (17 500 psi)

Rupture Disc and Muffler

Operation: Using Intensifier (Pressure > 200 MPa

(30 000 psi))

OPG1 or MPG1 generates and adjusts pressure up to

200 MPa (30 000 psi). Generally, the OIS intensifier is

used only when running tests that include pressures

greater than 200 MPa (30 000 psi). The OIS may be

switched into and out of use under pressure.

INSTALLATION

n Position the OIS between the OPG1 or MPG1 and

the PG7302 with the PG7302 to the left.

o Using a DH500 coned and threaded tube, connect

the OPG1 or MPG1 TEST port to the OIS SUPPLY

port (1).

p Using a DH500 coned and threaded tube or two

tubes and a tee, connect the PG7302 TEST port to

the OIS lateral TEST port (2).

Operation: Intensifier Not in Use (Pressure

≤ 200 MPa (30 000 psi))

n Open LOW PRESSURE SHUTOFF valve (4) and close

INTENSIFIER SHUTOFF valve (5). In this condition,

OPG1 or MPG1 generates pressure straight through

the Intensifier System, by passing the intensifier.

o Plug TEST port (6) if it is not being used.

n When running tests that include pressures above

200 MPa (30 000 psi), connect the device under test

(DUT) to the upper TEST connection (6) of the OIS.

o Set pressures under 100 MPa (15 000 psi) using the

OPG1 or MPG1, without the intensifier.

p To switch in the intensifier, first close the LOW

PRESSURE SHUTOFF valve (4), then open the

INTENSIFIER SHUTOFF valve (5). In this condition the

OPG1 or MPG1 pressure is shut off from the PG7302

and is applied to the low side of the intensifier.

Increasing pressure on the low side of the intensifier

results in pressure changes five times greater on the

high side (PG7302 side) of the intensifier.

q Use the OPG1 or MPG1 to generate and adjust

pres sure as necessary to set test points and float the

PG7302 piston.

r Before switching out the intensifier, be sure that the

n Load the entire mass set on the PG7302.

PG7302 piston is fully down (LSTOP) as the pressure

may change abruptly during the switching procedure.

If possible, switch out the intensifier at the same

pressure as it was switched in so that its pistons are

o Close the OPG1 or MPG1 EXHAUST valve. Close

the INTENSIFIER SHUTOFF valve (5). Open the

LOW PRESSURE SHUTOFF valve (4).

back to the start position. To switch out the

intensifier, first close the INTENSIFIER SHUTOFF

valve (5) and then open the LOW PRESSURE

p Using the OPG1 or MPG1, generate about 70 MPa

(10 000 psi).

SHUTOFF valve (4).

q Close the LOW PRESSURE SHUTOFF valve (4).

Operation: Returning the Intensifier Pistons

Open the OPG1 or MPG1 EXHAUST valve.

to Start Position

r Open the INTENSIFIER SHUTOFF valve (5).

If the intensifier runs out of stroke towards the high side,

adjusting the pressure on the intensifier's low side no longer

affects the pressure on the high side. This procedure allows

the intensifier pistons to be returned to their start position. It

is only necessary to use this procedure if the intensifier

pistons have become positioned near the end of stroke and

cannot be returned naturally by the high pressure.

The Oil Intensifier System is equipped with a pressure rupture disc on its low pressure circuit. (See schematic

reference 7). The disc ruptures permanently at 120 MPa (17 500 psi). Once ruptured, the disc must be replaced.

If pressure on the high side of the intensifier returns

to zero when the INTENSIFIER SHUTOFF valve is

opened, the intensifier is not at the start position.

Repeat the process until the high side of the

intensifier holds pressure.

OPG1 and PG7302 are trademarks, registered and otherwise, of DH Instruments, Inc.

Document 560035d 070119

DH Instruments, Inc.

4765 East Beautiful Lane

Phoenix AZ 85044-5318

USA

Tel 602.431.9100

Fax 602.431.9559

dhi@dhinstruments.com

www.dhinstruments.com

Loading...

Loading...