Page 1

T.O. 33A6-4-30-1

RPM3/HPMS A30000/A 6000-AF

Operation and Maintenance

Manual

NSN 6685-01-470-8667

(2 of 2)

1 August 2000

©2000 DH Instruments, Inc.

Page 2

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

High pressure liquids and ga ses a re po tentially haza rdous. Energy stored in these liquids and gas es can

be released unexpectedly and with extreme force. High pressure systems should be assembled and

operated only by p ers o nnel who have b een instructed in prop er s a fety pra ctices.

© 2000 DH Instruments, Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this document may be repr oduced or

transmitted in any form or by any means, electronic or mechanical, for any purpose, without the express written

permission of DH Instruments, I nc. 4765 East Beaut iful Lane Phoenix AZ 85044-5318 USA.

DH Instruments makes sincere efforts to ensure accuracy and quality of its published materials; however, no

warranty, expressed or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or

indirect damages resulting from t he use of the information in this manual or product s descr ibed in it. M ent ion of any

product does not constitute an endorsement by DH Instruments of that product. This manual was originally

composed in English and was subsequently translated into other languages. The fidelity of the t ranslation cannot

be guaranteed. In case of conflict between the English version and other language versions, t he English version

predominates.

DH Instruments, DH, DHI, AutoZ, CalTool, HGC, HPMS, OPG1, PPC, PPC2+, RPM3, SDS (Self Defense System)

are trademarks, r egister ed and ot herwise.

LabVIEW is a registered trademar k of Nat ional Inst r um ent s Corpor at ion.

Document No. 550115

000124

Printed in the USA.

©2000 DH Instruments, Inc.

Page 3

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

T

AABBLLEE O

T

TABLE OF CONTENTS ................................................................................i

TABLES.................................................................................................... v

FIGURES ................................................................................................. vi

ABOUT THIS MANUAL ............................................................................. vii

1. INTRODUCTION .................................................................................... 1

1.1 PRODUCT OVERVIEW .......................................................................................................................1

1.2 SPECIFICATIONS...............................................................................................................................2

1.2.1 GENERAL SPECIFICATIONS............................................................................................................................... 2

1.2.2 PRESSURE MEASUREMENT SPECIFICATIONS...............................................................................................2

1.2.2.1 RPT MEASUREMENT SPECIFICATIONS (% FS OF ACTIVE RANGE)............................................3

1.2.2.2 ON-BOARD BAROMETER ...................................................................................................................4

2. INSTALLATION.....................................................................................5

2.1 UNPACKING AND INSPECTION .........................................................................................................5

2.1.1 REM OVING FROM PACKAGING.........................................................................................................................5

2.1.2 INSPECTING CONTENTS.....................................................................................................................................5

2.2 SITE REQUIREMENTS........................................................................................................................6

2.3 INITIAL SETUP ...................................................................................................................................6

2.3.1 PREPARING F OR OPERATION...........................................................................................................................6

2.3.2 RPM3/HPMS FRONT AND REAR PANEL S.........................................................................................................7

2.3.2.1 FRONT PANEL......................................................................................................................................7

2.3.2.2 REAR PANEL........................................................................................................................................8

2.3.3 RPM3 FRONT AND REAR PANELS....................................................................................................................9

2.3.4 POWER CONNECTION.......................................................................................................................................10

2.3.5 FOOT SW ITCH CONNECTION........................................................................................................................... 11

2.3.6 TEST PORT CONNE CTION................................................................................................................................11

2.3.7 SETTING UP FILE SEQUENCES .......................................................................................................................12

2.4 POWER UP AND VERIFICATION .....................................................................................................12

2.4.1 APPLY POWER ...................................................................................................................................................12

2.4.2 CHECK PROPER PRESS URE MEASUREMENT OPERATION.......................................................................12

2.5 SHORT TERM STORAGE.................................................................................................................13

2.6 LONG TERM STORAGE AND SHIPPING .........................................................................................13

2.3.2.3 SIDE VIEW ............................................................................................................................................8

2.3.3.1 FRONT PANEL......................................................................................................................................9

2.3.3.2 REAR PANEL......................................................................................................................................10

2.3.6.1 THE RPM3 ATM PORT.......................................................................................................................11

2.4.2.1 CHECKING A B S OLUTE MODE PRESSURE MEASUREMENT.......................................................12

2.4.2. 2 CHECKIN G GA UGE MODE PRESSURE MEA S UREMENT.............................................................13

OFF

C

C

O

O

NTTEE

N

NTTSS

N

3. OPERATION ....................................................................................... 15

3.1 GENERAL/MANUAL OPERATION....................................................................................................15

3.1.1 KEYPAD LAY OUT AND PROTOCOL................................................................................................................15

3.1.2 MAIN RUN SCREE N............................................................................................................................................16

3.1.3 SOUNDS...............................................................................................................................................................17

3.1.4 SOFT [ON/OFF] KEY...........................................................................................................................................17

3.1.5 PRESSURE READY <*>/NOT READY (<↑

↑> OR <↓↓↓↓>) INDICATION................................................................18

↑↑

Page i ©2000 DH Instruments, Inc.

Page 4

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

3.1.6 MULT IPLE PRESSURE RANGES......................................................................................................................18

3.1.7 AUTOMATE D TEST/CALIBRATION SE QUE NCE S.......................................................................................... 19

3.1.8 HPMS (HIGH PRESSURE MOUNTING SYSTEM)............................................................................................. 20

3.2 DIRECT FUNCTIO N KEYS ................................................................................................................22

3.2.1 DIRECT FUNCTION KEYS SUMMARY.............................................................................................................. 22

3.2.2 [RANGE]...............................................................................................................................................................24

3.2.3 [UNIT] ...................................................................................................................................................................26

3.2.4 [MODE].................................................................................................................................................................27

3.2.5 [UL] (UPPER LIMIT) ............................................................................................................................................ 28

3.2.6 [RES] (RESOLUTION).........................................................................................................................................31

3.2.7 [DISPLAY]............................................................................................................................................................ 33

3.2.8 [HEAD].................................................................................................................................................................41

3.2.9 [SDS] (SELF DEFENSE SYSTEM).....................................................................................................................44

3.2.10 [AUTOZ] ............................................................................................................................................................... 44

3.2.11 [ENTER] RUN TEST SEQUENCE......................................................................................................................49

3.3 [SETUP] MENU KEY.........................................................................................................................54

3.3.1 HEAD....................................................................................................................................................................54

3.3.2 PRESU..................................................................................................................................................................55

3.3.3 READRT (READ RATE)...................................................................................................................................... 56

3.3.4 STAB (STABILI TY)..............................................................................................................................................57

3.3.5 LEAK (LEAK CHECK).........................................................................................................................................59

3.3.6 SEQ....................................................................................................................................................................... 60

3.4 [SPECIAL] MENU KEY......................................................................................................................65

3.4.1 AUTOZ..................................................................................................................................................................66

3.4.2 SDS.......................................................................................................................................................................70

3.4.3 ATM ......................................................................................................................................................................70

3.4.4 REMOTE...............................................................................................................................................................71

3.4.5 RESET..................................................................................................................................................................72

3.4.6 CAL.......................................................................................................................................................................75

3.4.7 INTERN.................................................................................................................................................................75

3.4.8 LEVEL...................................................................................................................................................................78

3.4.9 LOG ......................................................................................................................................................................81

3.1.6.1 RANGES AND IDENTIFICATION....................................................................................................... 19

3.2.5.1 OVER-PRESSURE FUNCT I ON (<PMAX!>)......................................................................................30

3.2.5.2 LO RPT PROTECTION (<!!LO RPT ACTIVE!!> )................................................................................31

3.2.7.1 AVG (AVERAGE) ................................................................................................................................34

3.2.7.2 RATE....................................................................................................................................................36

3.2.7.3 DEV (DEVIATION)...............................................................................................................................36

3.2.7.4 RPT......................................................................................................................................................37

3.2.7.5 HI/LO.................................................................................................................................................... 39

3.2.7.6 FREEZE...............................................................................................................................................39

3.2.7.7 CLEAN.................................................................................................................................................40

3.2.10.1 RUNNING AUTOZ IN GAUGE MEASUREMENT MODE..................................................................44

3.2.10.2 RUNNING AUTOZ IN ABSOLUTE MEASUREMENT MODE............................................................45

3.2.11.1 TEST INITIALIZATION (QUICK SEQUENCE) ...................................................................................51

3.2.11 .2 TEST EXECUTION (QUICK SEQUENCE AND FIL E S E QUENCE )..................................................52

3.3.6.1 SEQUENCE, DA TA.............................................................................................................................61

3.3.6.2 SEQUENCE, FILESEQ .......................................................................................................................62

3.4.1.1 AUTOZ ON/OFF..................................................................................................................................69

3.4.1.2 VIEW AUTOZ.......................................................................................................................................69

3.4.1.3 EDIT AUTOZ........................................................................................................................................70

3.4.5.1 RESET - SETS ....................................................................................................................................73

3.4.5.2 RESET - UNITS...................................................................................................................................74

3.4.5.3 RESET - SEQ......................................................................................................................................74

3.4.5.4 RESET - CAL.......................................................................................................................................74

3.4.5.5 RESET - ALL .......................................................................................................................................75

3.4.7.1 SCRSAV ..............................................................................................................................................76

3.4.7.2 SOUND................................................................................................................................................76

3.4.7.3 TIME.....................................................................................................................................................77

3.4.7.4 ID..........................................................................................................................................................77

4. REMOTE OPE RATION .........................................................................82

4.1 OVERVIEW .......................................................................................................................................82

4.2 INTERFACING ..................................................................................................................................82

4.2.1 RS-232 INTERFACE ............................................................................................................................................82

©2000 DH Instruments, Inc. Page ii

Page 5

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

4.2.1.1 COM1...................................................................................................................................................82

4.2.2 IEEE-488 (GPIB) ..................................................................................................................................................83

4.3 REMOTE COMMAND SYNTAX AND STYLE.....................................................................................83

4.3.1 LOCAL AND REM OTE SETTING.......................................................................................................................83

4.3.2 COMM AND S YNTAX........................................................................................................................................... 84

4.3.3 QUERIES AND REPL IES....................................................................................................................................84

4.3.4 MULT IPLE COMMANDS..................................................................................................................................... 84

4.3.5 COMMAND P ARAMETERS................................................................................................................................85

4.3.6 SUFFIXES ............................................................................................................................................................ 85

4.3.7 PROGRAMMING TIPS........................................................................................................................................ 85

4.4 COMMANDS .....................................................................................................................................89

4.4.1 ERROR MESSAGES ...........................................................................................................................................92

4.4.2 COMMAND DE S CRIPTIONS.............................................................................................................................. 94

4.5 STATUS SYSTEM...........................................................................................................................124

4.5.1 STATUS REPORTING SYSTEM.......................................................................................................................124

4.5.2 STATUS SUBSYSTEM......................................................................................................................................129

4.2.1.2 COM2...................................................................................................................................................83

4.3.7.1 SCPI AND IEEE-488.2 ........................................................................................................................85

4.3.7. 2 PROGRAMMING TECHNIQUE.......................................................................................................... 86

4.4.2.1 IEEE STD. 488.2 COMMON AND STATUS COMMANDS.................................................................94

4.4.2.2 MEASUREMENT SUBSYSTEM.........................................................................................................97

4.4.2.3 CALCULATE SUBSYSTEM.............................................................................................................. 102

4.4.2.4 CALIBRATION SUBSYSTEM ...........................................................................................................103

4.4.2.5 DISPLAY SUBSYSTEM....................................................................................................................105

4.4.2.6 SENSE SUBSYSTEM.......................................................................................................................106

4.4.2.7 STATUS SUBSYSTEM.....................................................................................................................108

4.4.2.8 SYSTEM SUBSYSTEM.....................................................................................................................116

4.4.2.9 UNIT SUBSYSTEM........................................................................................................................... 122

4.5.1.1 SCPI STATUS SUBSYSTEM............................................................................................................ 124

4.5.1.2 ERROR QUEUE................................................................................................................................124

4.5.1.3 STATUS BYTE REGISTER...............................................................................................................125

4.5.1. 4 STANDARD EVENT REGISTER...................................................................................................... 127

4.5.1.5 RPT READY STATUS REGISTER...................................................................................................128

4.5.2.1 OPERAT ION REGISTER STRUCTURE..........................................................................................129

4.5.2.2 QUESTIONABLE REGISTER ST RUCTURE...................................................................................132

5. MAINTENANCE, CALIBRATIO N AND REPAIR ...................................... 136

5.1 INTRODUCTION .............................................................................................................................136

5.2 RPM3 MAINTE NANCE....................................................................................................................137

5.2.1 AUTOZER O OF RPTS.......................................................................................................................................137

5.2.1.1 GAUGE MODE OPERATION ...........................................................................................................137

5.2.2 ADJUSTMENT OF ON-BOARD BAROMETE R...............................................................................................138

5.2.3 RPM3 OVERHAUL.............................................................................................................................................138

5.3 RPM3 RPT CALIBRATION..............................................................................................................139

5.3.1 PRINCIPLE.........................................................................................................................................................139

5.3.2 EQUIPMENT REQUIRED ..................................................................................................................................141

5.3.3 SET-UP AND PREPARAT ION.......................................................................................................................... 142

5.3.4 RPT CALI BRATION USING RPM3 CALTOOL SOFTWARE..........................................................................142

5.3.5 EDITING AND V IEWING RPT CALIBRATION INFORMATION...................................................................... 143

5.3.6 SETTING ZNATERR.......................................................................................................................................... 144

5.3.7 RPT CALIBRATION/ADJUSTMENT WITHOUT RPM3 CALTOOL SOFTWARE...........................................145

5.4 RPM3 REPAIR ................................................................................................................................146

5.4.1 REMOVING AND REINSTALLING RP M3 IN THE HPMS................................................................................146

5.4.2 OPENING AND CLOS ING THE RPM3 CASE..................................................................................................147

5.4.3 RELOADING RPM3 EMBEDDED SOFTWARE INTO FLASH MEMORY.......................................................148

5.4.4 RPM3 INTERNAL VIEW.................................................................................................................................... 148

5.2.1.2 ABSOLUTE MODE OPERATION .....................................................................................................137

5.3.1.1 PA/PM COEFFICIENTS.................................................................................................................... 140

5.3.1.2 SETTING ZNATERR......................................................................................................................... 140

5.3.1. 3 ORDER OF OPE R A TIONS...............................................................................................................141

5.3.1.4 AS RECEIVED/AS LEFT DATA........................................................................................................141

5.4.4.1 SDS MODULE ...................................................................................................................................149

5.4.4.2 RPTS..................................................................................................................................................149

5.4.4.3 POWER SUPPLY..............................................................................................................................149

Page iii ©2000 DH Instruments, Inc.

Page 6

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

5.4.4.4 COOLING FAN..................................................................................................................................149

5.4.4.5 MICRO BOARD.................................................................................................................................149

5.4.4.6 MAIN BOARD....................................................................................................................................149

5.4.4.7 ON-BOARD BAROMETER ...............................................................................................................149

5.4.4.8 DISPLAY............................................................................................................................................149

5.5 HPMS MAINTENANCE....................................................................................................................150

5.5.1 HPMS OV E RHAUL............................................................................................................................................ 150

6. TROUBLESHOOTING......................................................................... 152

6.1 OVERVIEW .....................................................................................................................................152

7. APPENDIX ........................................................................................ 157

7.1 PRESSURE UNIT CONVERSIONS..................................................................................................157

7.2 WARRANTY STATEMENT..............................................................................................................158

8. GLOSSARY....................................................................................... 161

©2000 DH Instruments, Inc. Page iv

Page 7

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

T

AABBLLEES

T

Table 1. RPM3/HPMS A 30000/A6000-AF Supplied Items...................................................................5

Table 2. RPM3 Range Identific ation Summary..................................................................................19

Table 3. Summary of RPM 3 Dir ect Function Key Operation..............................................................23

Table 4. PresU - Available Units .......................................................................................................56

Table 5. READRT - Display Updat e Rates........................................................................................56

Table 6. Functions - S ec ur ity Levels .................................................................................................79

Table 7. RPM3 COM1 DB-9F P in Designations ................................................................................82

Table 8. IBM PC/XT DB-9F, DB- 9M Connec tions .............................................................................82

Table 9. RPM3 COM2 DB-9M P in Des ignations................................................................................83

Table 10. Quick Programm ing Tips.....................................................................................................88

Table 11. Command Summary ...........................................................................................................89

Table 12. “SYSTEM:ERROR?” QUERY REPLY.................................................................................93

Table 13. 8 Bit Status Byte Register .................................................................................................125

Table 14. Standard Event Regis ter...................................................................................................127

Table 15. 8 Bit RPT Ready Status Register ......................................................................................128

Table 16. Troubleshooting Sym ptom/Probable Cause/S olution List...................................................152

Table 17. Pressure Unit of M eas ur e Conv er s ions .............................................................................157

Table 18. DH Instrument s, Inc. Authorized Service Prov ider s .........................................................159

S

Page v ©2000 DH Instruments, Inc.

Page 8

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

F

Figure 1. RPM3/HPMS Front P anel .....................................................................................................7

Figure 2. RPM3/HPMS Rear Panel......................................................................................................8

Figure 3. RPM3/HPMS Side View........................................................................................................8

Figure 4. RPM3 Front Panel ................................................................................................................ 9

Figure 5. RPM3 Rear Panel...............................................................................................................10

Figure 6. RPM3 Keypad.....................................................................................................................15

Figure 7. RPM3/HPMS Front P anel ...................................................................................................21

Figure 8. RPM3/HPMS Internal S c hem atic.........................................................................................22

Figure 9. Status Byte Regist er .........................................................................................................125

Figure 10. Illustration of t his S tructure Duplicat ed for Each of the OPERation, INS Trument, and

Figure 11. Relationship of the OPERation Register and It s S uppor t Registers....................................131

Figure 12. Illustration of t his S tructure Duplicat ed for Each of the OPERation, INS Trument, and

Figure 13. Relationship of the QUEStionable Register and It s S uppor t Registers...............................134

Figure 14. RPM3/HPMS Side View....................................................................................................147

Figure 15. RPM3 Internal View..........................................................................................................148

G

IIG

F

ISUMmary Registers.........................................................................................................130

ISUMmary Registers.........................................................................................................133

URREESS

U

©2000 DH Instruments, Inc. Page vi

Page 9

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

A

A

This manual provides the user with the basic information necessary to operate an RPM3/HPMS

A30000/A6000-AF Reference Pressure Monitor with High Pressure Mounting System. It also

includes a great deal of addit ional information provided to help you opt imize use of t he instrument

and take full advantage of its many features and functions.

Before using this manual, take a moment to f amiliarize yours elf with the T able of Content s struc ture.

All first time users should read Chapter 2. Chapter 3 provides a comprehensive description of

general RPM3/HPMS operating principles. Section 3.1.7 describes the automated Sequence

function used to run calibrations and verifications of typical ins truments under test . This is the way

the instrument is typically used. Chapter 4 is for remote operation from an external computer.

Chapter 5 provides maintenance and calibration information. Chapter 6 is a quick troubleshooting

guide. Use it to troubleshoot unexpected RPM3/HPMS behavior based on the symptoms of that

behavior. Certain words and expr essions hav e specif ic meaning as t hey pert ain to t his produc t. The

Glossary is usef ul as a quick ref erence f or exact definit ion of specif ic words and expr essions as t hey

are used in this manual.

RPM3/HPMS A30000/A6000-AF is usually delivered as part of an HGC-30000-AF system which

includes an OPG1 hydraulic pressure generator/controller. The OPG1 has its own Operation and

Maintenance M a nual.

O

BBO

UTT

U

T

HIISS

H

T

M

M

N

AAN

UAALL

U

FOR THOSE OF YOU W HO “DO N’T RE AD M ANUAL S”, GO DIRE CTL Y T O SEC TION 2 .3 TO SE T UP YOUR

RPM3/HPMS AND THEN 2.4 FOR POWER UP AND VERIFICATION. THIS WILL GET YOU RUNNING

QUICKLY WITH MINIMAL RISK OF CAUSING D AMAGE TO YOURSE LF OR YOUR NE W RPM3. THE N…

WHEN YOU HAVE QUESTIONS OR START TO WONDER ABOUT ALL THE GREAT FEATURES YOU

MIGHT BE MISSING, GET IN TO THE M ANUAL!

Manual Conventions

(CAUTION) is us ed throughout the m a nua l to identify user w a rnings a nd cautions.

(NOTE) is used throughout the manual to identify operating and applications advice and

additional explanations.

[ ] indicates direct function keys (for example [RANGE]).

< > indicates RPM3 scr een dis play s ( for example <1yes>).

Page vii ©2000 DH Instruments, Inc.

Page 10

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

N

N

OOTTEES

S

©2000 DH Instruments, Inc. Page viii

Page 11

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

1. INTRODUCTION

1.1 PRODUCT OVERVIEW

RPM3/HPMS A30000/A6000-AF is the combination of an RPM3 A5000/A6000-AF reference

pressure monitor and an HPMS High Pressure Mounting System. The combination of an

RPM3/HPMS A30000/A6000-AF and an OPG1-AF oil pressure generator make up the

HGC-30000-AF hydraulic gauge calibrator. The OPG1-AF has it s own Operation and Maintenance

manual.

RPM3 A30000/A6000-AF is a stand-alone, microprocessor driven, reference pressure monitor

intended to accurat ely measure oil pressure in a variety of pressure calibr ation, measurement and

testing applications . It has been designed t o provide very high perfor mance and extensiv e features

combined with maximum v er s atility and ease of use. RPM3 A30000/A6000-AF is a special version of

the standard DHI RPM3 product configured specifically for the USAF HGC-30000-AF hydraulic

gauge calibrator.

The HPMS mounts the RPM3 at a conv enient viewing angle and c ontains t he hardware t o isolat e the

RPM3’s low pressure tr ans ducer (A6000) when the high press ure transducer (A30000) is in use.

RPM3 A30000/A6000-AF uses tw o high accurac y ref erence pres sure t ransduc ers (RP Ts) and an onboard barometer t o m eas ur e pr es s ur e.

RPM3 A30000/A6000-AF is controlled locally by the operator using its front panel display, keypad

and foot pedal or remot ely by a computer using ASCI I character command strings over its RS-232

and IEEE-488 interfaces.

RPM3 A30000/A6000-AF has s ix pressure m easurement r anges from 0 t o 2 000 psi (7 MPa) t o 0 to

30 000 psi (200 MPa) in gauge and absolut e m eas ur em ent modes.

RPM3/HPMS A30000/A6000-AF is usually delivered as part of an HGC-30000-AF system which

includes an OPG1 hydraulic pressure generator/controller. The OPG1 has its own Operation and

Maintenance M a nual.

Page 1 ©2000 DH Instruments, Inc.

Page 12

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

1.2 SPECIFICATIONS

1.2.1 GENERAL SPECIFICATIONS

Power Requirements: 85 to 264 VAC, 47 to 440 Hz , 18 VA max consumption

Operating Temperature Range: 15 to 45 °C

Storage Temper ature Range: -20 to 70 °C

Weight: RPM3: 3.5 kg ( 7.7 lb)

Dimensions: 21.5 cm H x 29 cm W x 38 cm D

Microprocessor: Motorola 68302, 16 MHz

Communication Port s : RS-232 (COM1), RS-232 (COM2), I EEE-488

Pressure Ranges: 2 000 psi (14 MPa), 4 000 ps i ( 28 M P a) , 6 000 psi

Operating Medium: Oil (Di-ethyl hexy l s ebac ate)

Pressure Connections:

Test port (RPT > 10 000 psi): DH500 (gland and c ollar type for coned and left hand

Pressure Limits:

Maximum working pressure:

Maximum pressur e w/o damage:

HPMS: 5.8 kg (12.8 lb)

RPM3/HPMS: 9.3 kg (20.5 lb)

(8.5 in. x 11.5 in. x 15.0 in.) approx .

(42 MPa), 10 000 psi ( 70 M P a) , 18 000 psi (126 MPa),

30 000 psi (200 MPa) gauge and absolut e.

threaded tube, equivalent to AE F250C, HIP HF4, etc.)

30 000 psi (214 MPa)

37 000 psi (255 MPa)

1.2.2 PRESSURE MEASUREMENT SPECI FICATIONS

RPM3 A30000/A6000-AF is configured with two reference pressure transducers (RPT).

Each transducer has three ranges. The RPTs are of the absolute pressure type with an

evacuated, permanently sealed reference. Absolute RPTs measure both absolute and

gauge pressure. Gauge pressures are defined by offsetting atmospheric pressure

dynamically with compensation for atmos pher ic c hanges us ing an on board barometer.

©2000 DH Instruments, Inc. Page 2

Page 13

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

1.2.2.1 RPT MEASUREMENT SPECIFICATIONS (% FS OF ACTIVE RANGE)

Transducer Type: Oscillating quart z resonator

Warm Up Time: 30 minutes for operation within s pec ifications

Resolution: To 1 ppm, user settable by individual range

Overpressur e Lim its:

Without effect on calibration:

Without perm anent damage:

Temperature E ffect: ± 0.008 % max imum temper ature eff ect in normal

Acceleration Affect: ± 0.008 % /g maximum, worst axis

Precision

Stability

1

: Range: H3: 0.0150 %

2

:

Gauge Mode (w/Autozero):

Absolute Mode (w/ A utozero):

Measurement Uncer tainty

3

:

Gauge Mode (w/Autozero):

Absolute Mode (w/ A utozero):

115 % of Range 3

125 % of Range 3

ambient operating range of 15 to 45 °C

Ranges H1, H2: 0.0125 %

Ranges L1, L2, L3: 0. 010 %

All Ranges

0.008 %

0.008 %

H3 H2, H1

0.017 % 0.015 % 0.013 %

0.017 % 0.015 % 0.013 %

L1, L2, L3

1 Precision: Combined linearity, hysteresis, r epeatability of measurement s made by the

reference pressure transducer. When using an absolute RPT for gauge mode

measurement add

account the resolution and short term stability of the on-board barometer used for

dynamic atmospheric pressure compensation.

2 Stability: Maximum change in zero and span over 180 days for t ypical tr ansducer us ed

under typical conditions. As stability can only be predicted and varies from transducer to

transducer, stability for a specif ic RPT should be established from exper ience.

3 Measurement Uncertainty: Combined precision, st ability, temperature effect.

± 2.5 Pa (0.00035 psi) to the precision specification to take into

Page 3 ©2000 DH Instruments, Inc.

Page 14

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

1.2.2.2 ON-BOARD BAROMETER

Sensor Technology: Micro-machined silicon

Warm Up Time: None required

Resolution: 1.25 Pa (0.00018 psi)

The on-board barom eter is NOT used as a so urce of absolute accuracy. It is used

only to measure changes in atmospheric pressure for dynamic compensation of the

atmospheric pressure offset when using an absolute reference pressure transducer

to make gauge pressure measurements (see Section 3.4.1, Gauge Mode with an

Absolute RPT, Dynamic Compensation for Atmospheric Pressure).

©2000 DH Instruments, Inc. Page 4

Page 15

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

2. INSTALLATION

2.1 UNPACKING AND INSPECTION

RPM3/HPMS A30000/A6000-AF is usually delivered as part of an HGC-30000-AF system which

includes an OPG1 hydraulic pressure generator/controller. The OPG1-3000-AF is shipped in a

separate corrugated conta ine r a nd ha s its O p er a tio n a nd Maintenance Manual.

2.1.1 REMOVING FROM PACKAGING

RPM3/HPMS A30000/A6000-AF is delivered, along with its accessories, in a reusable

molded plastic, shipping c ontainer with polyurethane ins er ts to hold it in place.

Remove the RPM3/H P M S A 30000/A6000-AF and its ac c es s ories from the shipping container

and remove each element from its protec tive plastic bag.

Retain the shipping conta iner for repacking the RPM3/HPMS A3 0000/A6000-AF when it is

shipped for recalib ration of repair.

2.1.2 INSPECTING CONTENTS

Check that all item s are present and have NO vis ible dam age.

A standard RPM3/ HP M S A 30000/A6000-AF includes all items listed in Table 1.

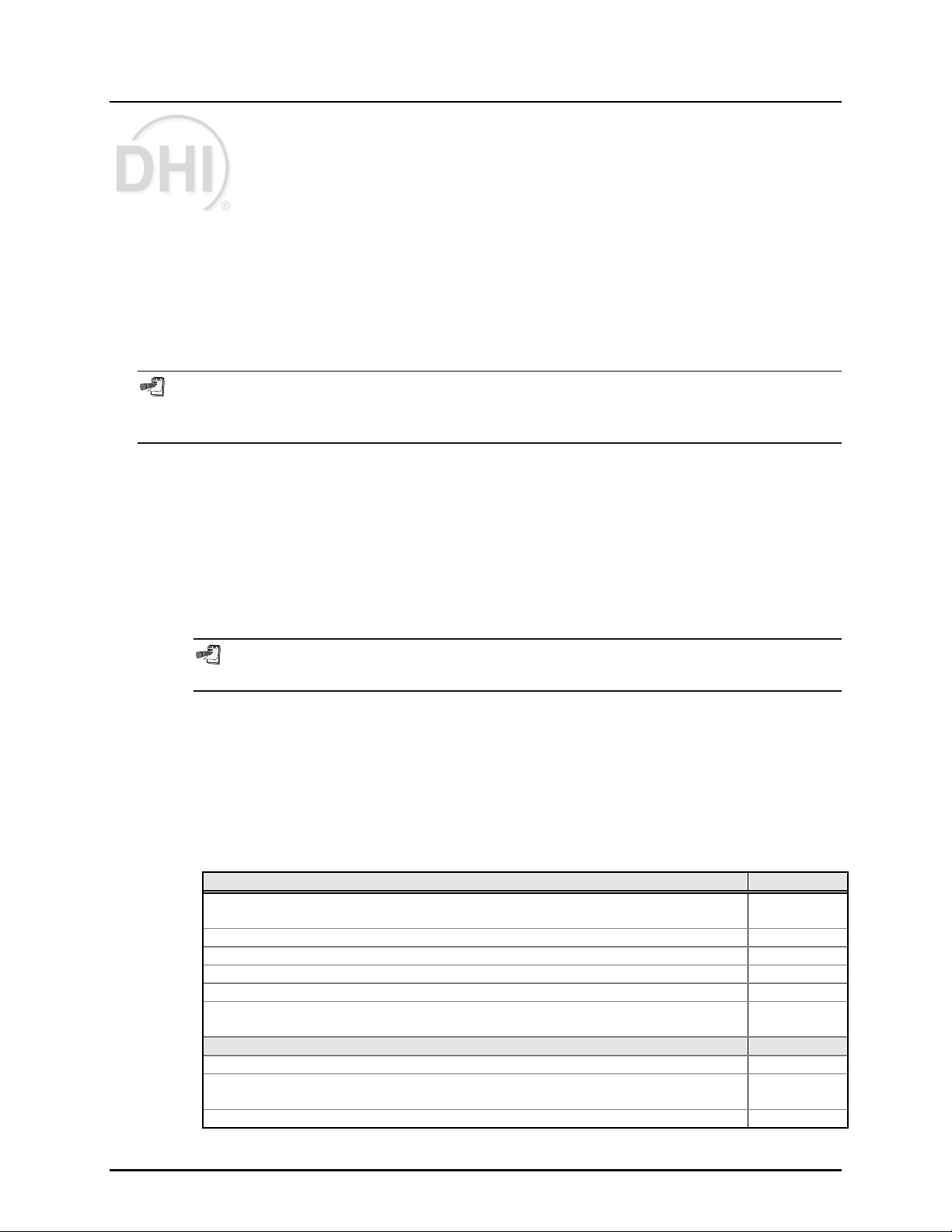

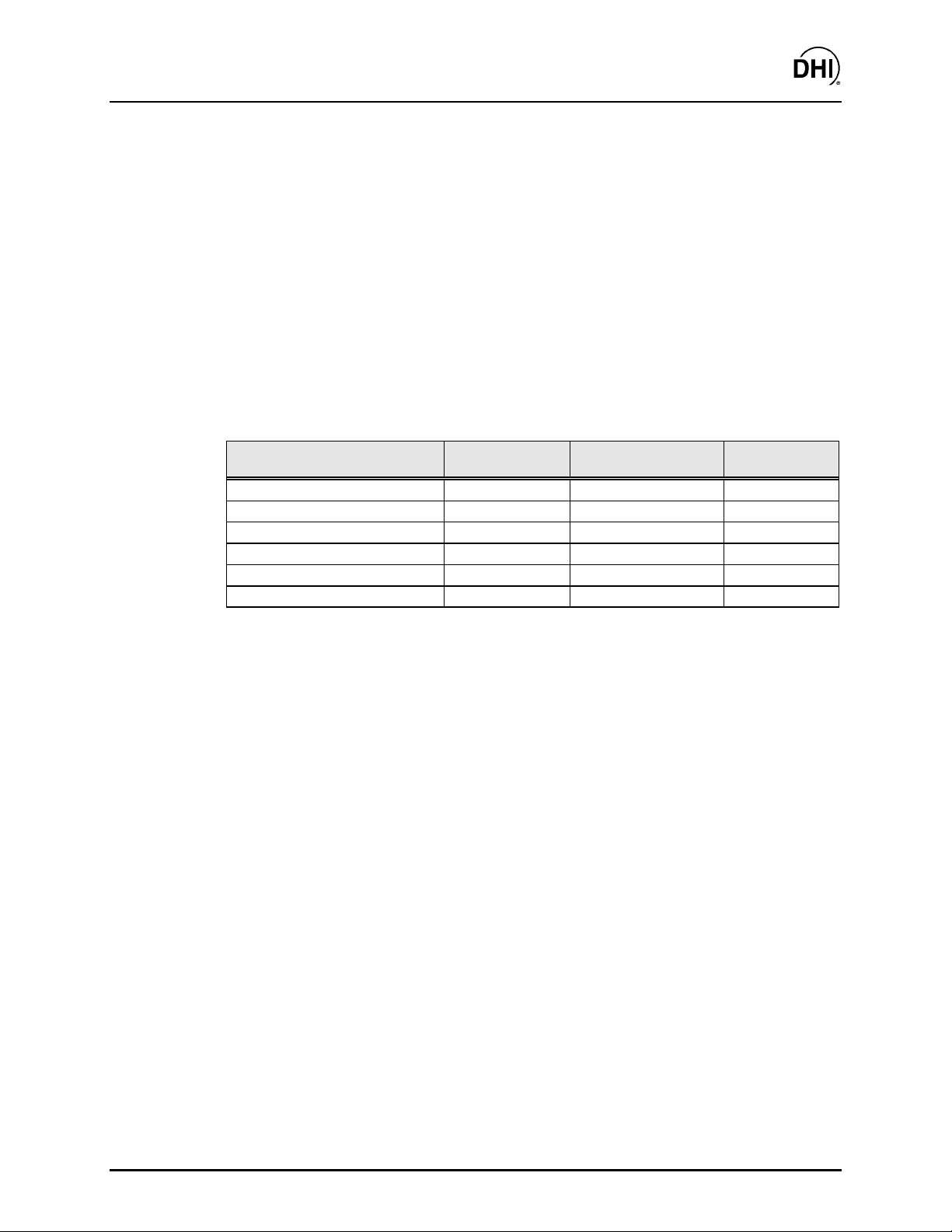

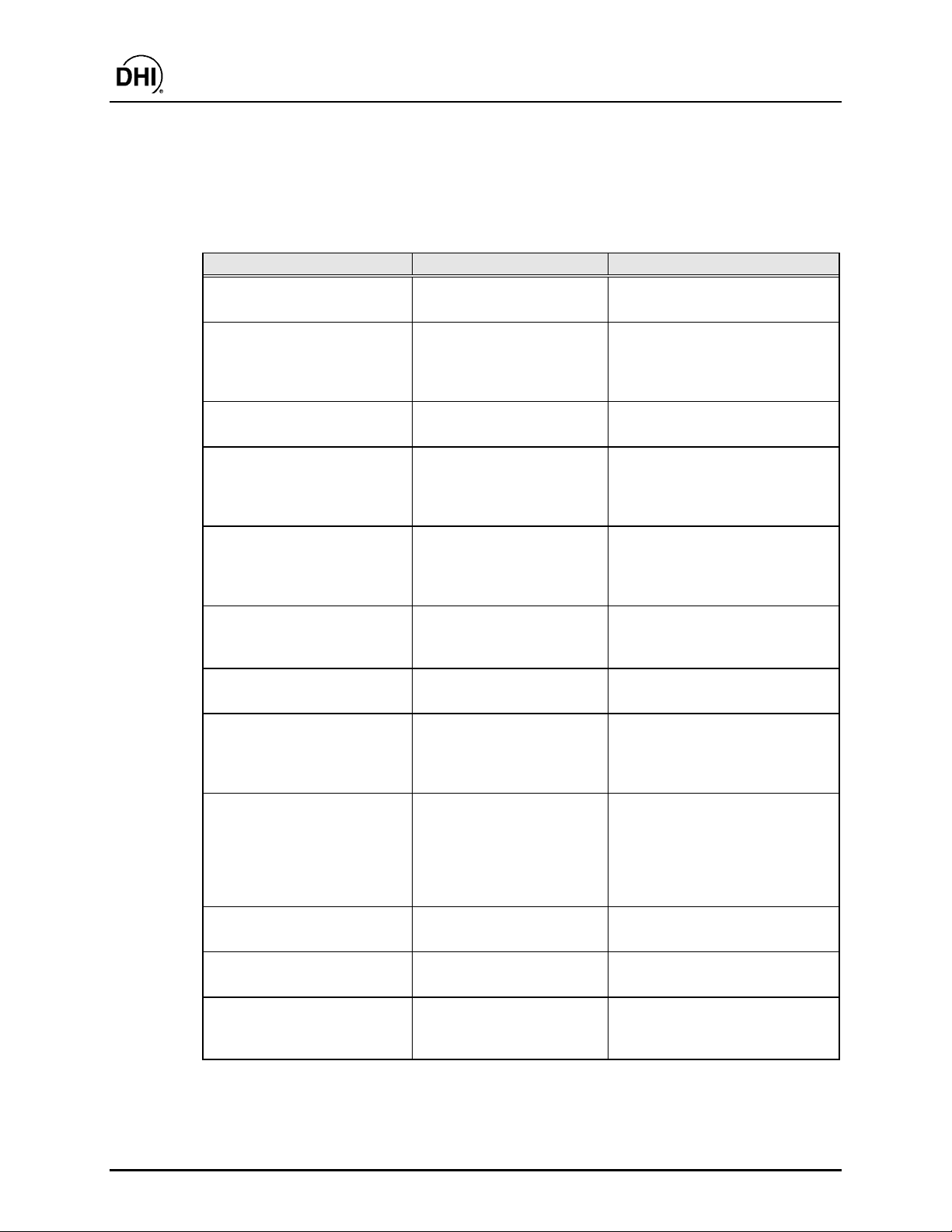

Table 1. RPM3/HPMS A30000/A6000-AF Supplied Items

DESCRIPTION PART NO.

RPM3/HPMS A30000/A6000-AF Reference Pressure Monitor/ High Pressure

Mounting System

Transport case (with inserts) ( used f or or iginal shipment) 123122

Foot Switch Assembly 401613

Operation and Maintenance Manual, RPM3/HPMS A30000/A6000 550115

Calibration Certificate 550100

Test Report, HGC-30000-AF ( if RPM3/ HPMS delivered as par t of HG C-30000- AF

system)

Accessories: 401605

Power Cord (7.5 ft.) 100770

General Accessories Disk (Important: I ncludes syst em suppor t sof t war e and

documentation)

RPM3 CalTool Manual 550106

401604

550116

102987

Page 5 ©2000 DH Instruments, Inc.

Page 16

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

2.2 SITE REQUIREMENTS

The RPM3/HPMS A30000/A6000-AF is typically delivered as part of an HGC-30000-AF hydraulic

gauge calibrator that includes an OPG1-30000-AF that has its own Operation and

Maintenance Manual. See the OPG1-30000- AF Operation and Maint enance Manual for infor mation

on site requirement s for the HGC-30000-AF.

Install RPM3/HPM S A30000/A6000-AF on any stable surface at a convenient height. Consider t he

placement of the FOOT SWITCH which may need to be accessed frequently while

running calibrations.

Support facilities required f or RPM3/HPMS A30000/A6000- AF include an electrical power sour ce of

85 to 264 VAC, 47 to 440 Hz .

2.3 INITIAL SETUP

2.3.1 PREPARING FOR OPERATION

To prepare RPM3/ HP M S A 30000/A6000-AF for c hec k out and operation:

• Remove the plastic plug from the RPM3/HPMS A30000/A6000-AF rear panel

TEST connection.

• Remove the protective plastic sheet from the RPM3 f r ont panel display.

• Familiarize yourself briefly with the RPM3 and HPMS f ront and rear panels ( see Sect ions

2.3.2, 2.3.3).

©2000 DH Instruments, Inc. Page 6

Page 17

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

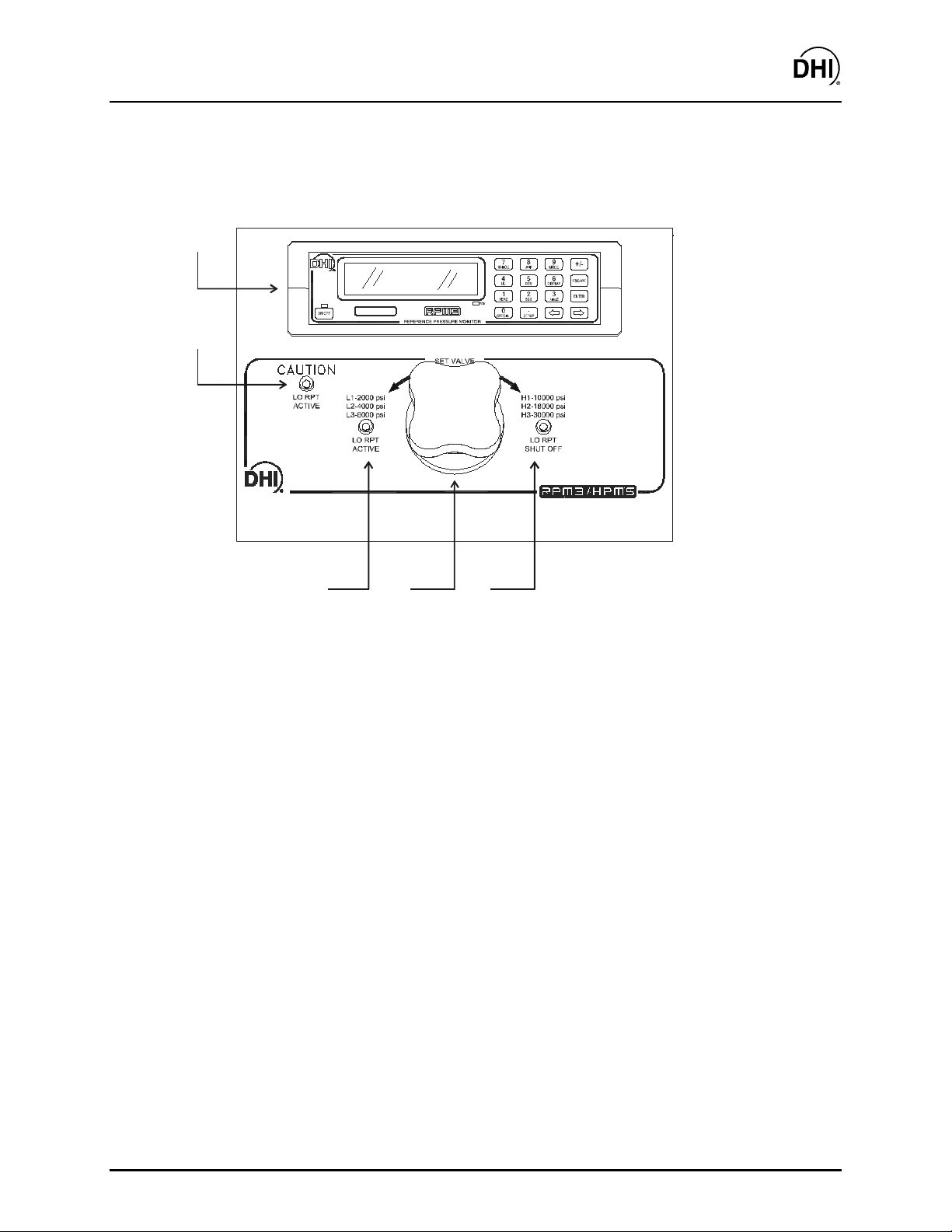

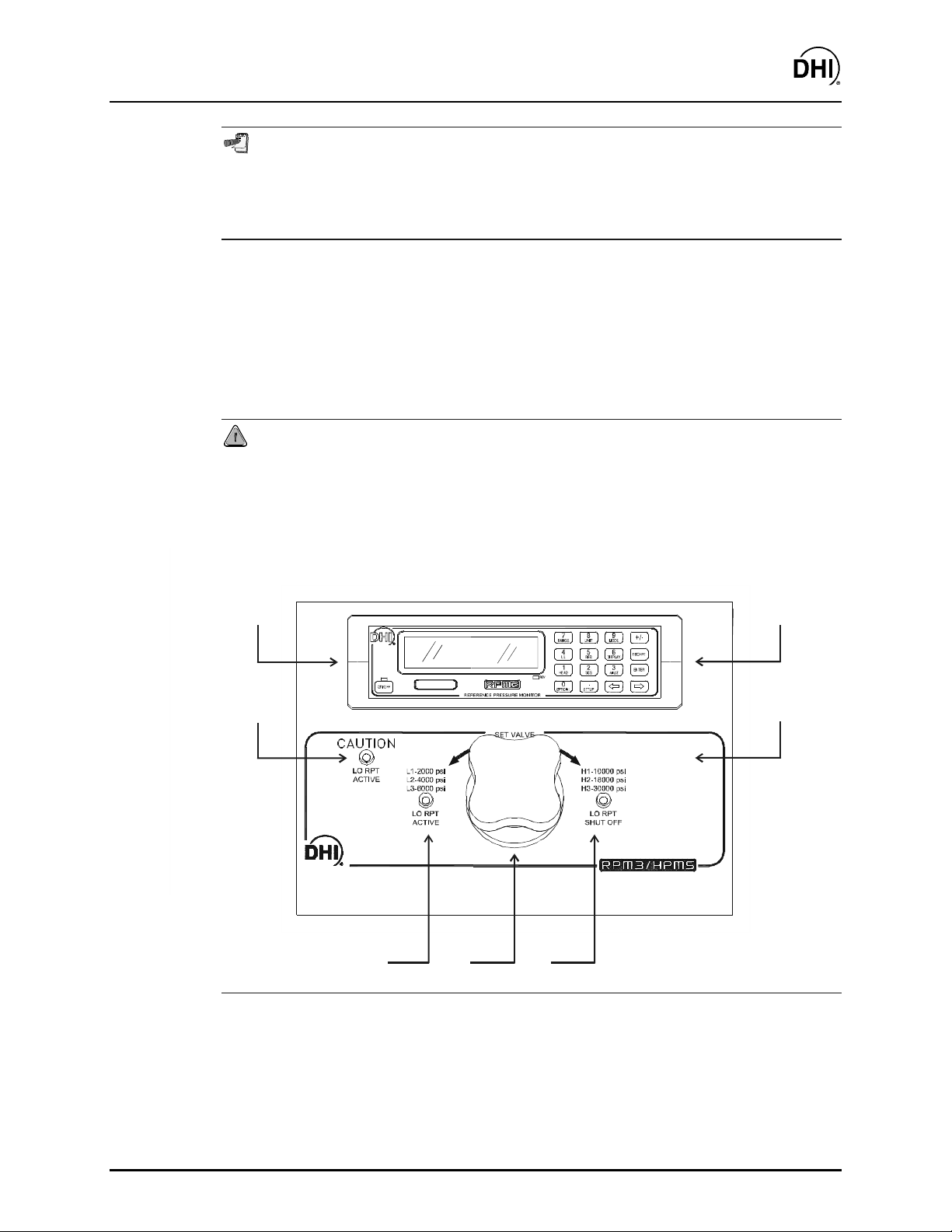

2.3.2 RPM3/HPMS FRONT AND REAR PANELS

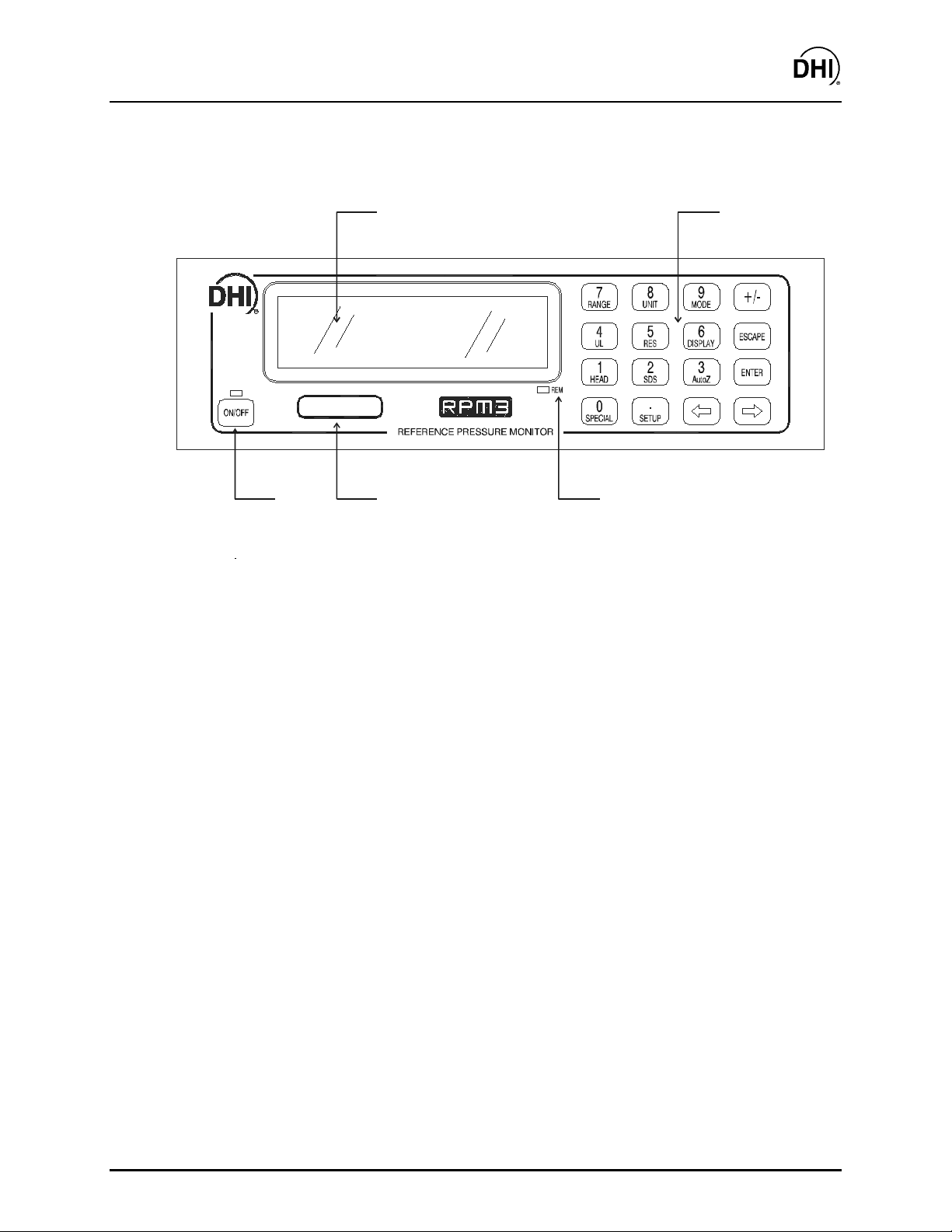

2.3.2.1 FRONT PANEL

5

4

3

1. Lo RPT Shut Off Valve Position LED

2. Lo RPT Shut Off Valve Knob

3. Lo RPT Active Valve Position LED

4. Caution Lo RPT Active LED

5. RPM3 A30000/A6000-AF Reference Pressure Monitor

2

1

Figure 1. RPM3/HPMS Front Panel

Page 7 ©2000 DH Instruments, Inc.

Page 18

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

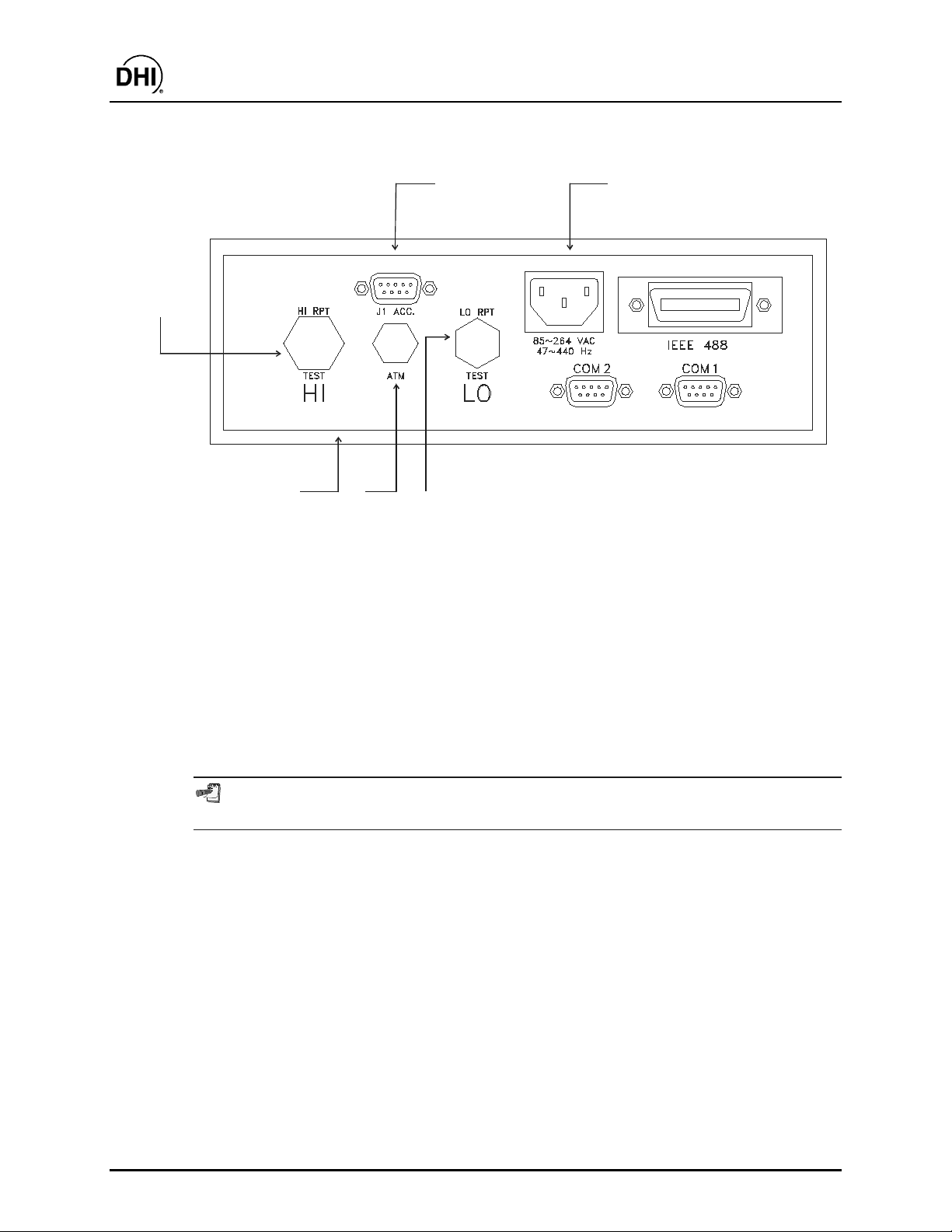

2.3.2.2 REAR PANEL

DH Instrume nts, Inc.

4765 East Beautiful Lane

Phoenix AZ 85044- 5318

USA

Tel 602.431.9100

Fax 602.431.9559

dhi@dhinstruments.com

www.dhinstruments.com

Made in USA

!

1. Foot switch (Remote [ENTER]) cable connection

2. TEST port (DH500 F)

Figure 2. RPM3/HPMS Rear Panel

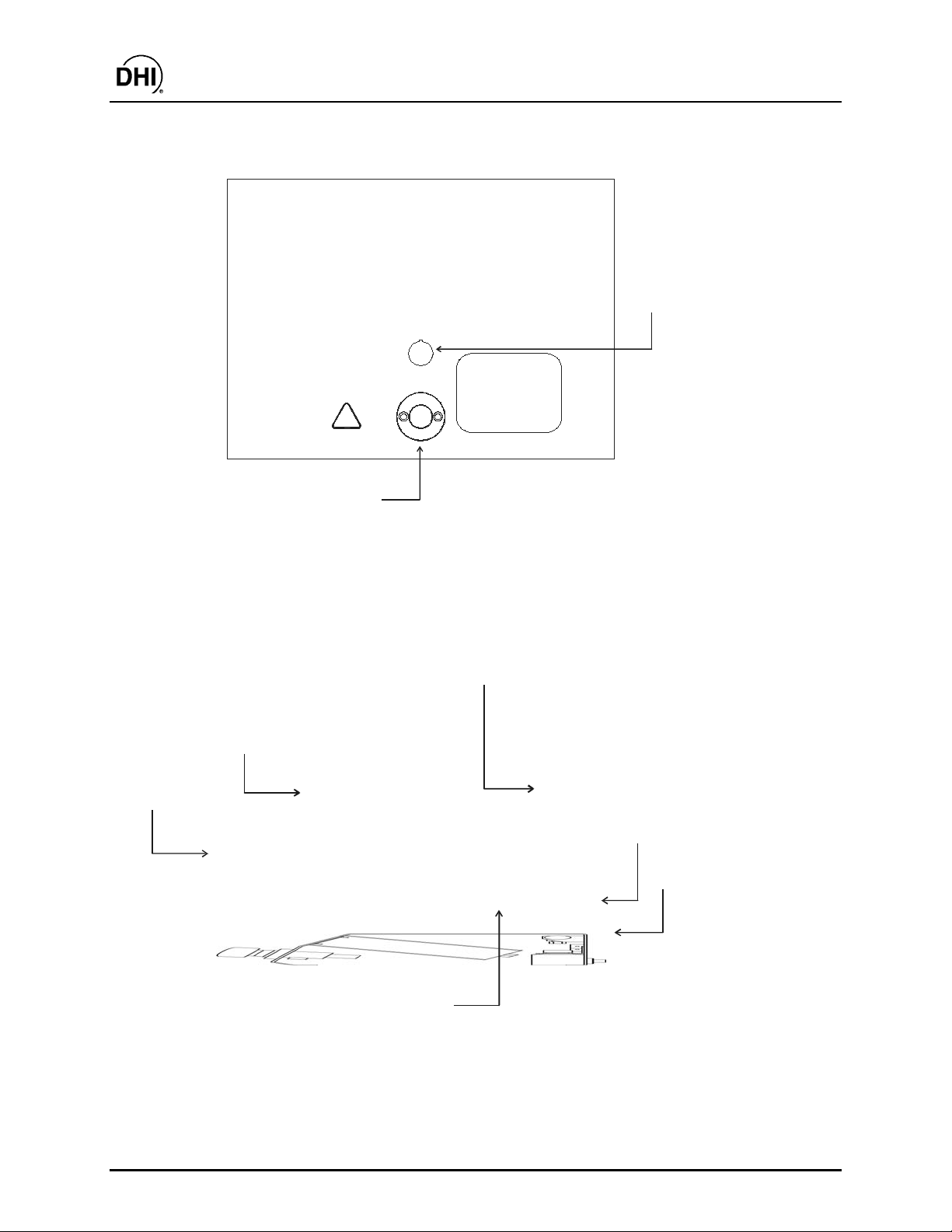

2.3.2.3 SIDE VIEW

2

DO NOT

EXCEED

30000 psi

(200 MPa)

2

FOOT

SWITCH

TEST

1

3

1

6, 7

1. Lo RPT Isolation Valve Control Knob 5. TEST port (DH500 F)

2. RPM3 A30000/A6000-AF Reference Pressure Monitor 6. Electrical Power Connector (IEC320-C13)

3. Lo RPT Pressure Relief Valve 7. Foot switch (remote [ENTER]) connector

4. Oil Collection Cup (from Relief Valve)

Figure 3. RPM3/HPMS Side View

©2000 DH Instruments, Inc. Page 8

4

5

Page 19

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

2.3.3 RPM3 FRONT AND REAR PANELS

2.3.3.1 FRONT PANEL

1

2

345

1. Display 4. RPT designator label

2. Multi-Function Keypad 5. Soft ON/OFF key and indicator

3. Remote Indicator

Figure 4. RPM3 Front Panel

Page 9 ©2000 DH Instruments, Inc.

Page 20

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

2.3.3.2 REAR PANEL

1

6

5

1. Accessories Connection Cable (connects to HPMS 4. ATM Post (On-Board Barometer)

Rear panel FOOT SWITCH and HPMS LEDs) (10-32 UNF)

2. Electrical Power Connector (IEC320-C13) 5. Label, Product (on bottom of case)

3. LO TEST Port (A5000 RPT) (1/8 in. NPT F) 6. HI TEST Port (A30000 RPT) (DH500 F)

4

3

2

Figure 5. RPM3 Rear Panel

2.3.4 POWER CONNECTION

• Connect the power cable t o the RPM3 rear panel electr ic al power connector.

• Do NOT connect the other end of the power c able to a power source yet.

RPM3 is always powered and active when power is supplied through the rear panel

power co nne ctor. The front p a nel O N/OFF key co ntrols a soft O N /O F F (s e e Se ctio n 3.1.4).

©2000 DH Instruments, Inc. Page 10

Page 21

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

2.3.5 FOOT SWITCH CONNECTION

Connect the foot switch supplied in the RPM3/HPMS ac cessories to the HPMS rear panel

electrical connection labeled FOOT SWITCH. Place the foot switch on the floor at a

convenient location. The FOOT SWITCH function is equivalent to the RPM3 front panel

[ENTER] key and may be used fr equently while running tests and c alibr ations.

2.3.6 TEST PORT CONNECTION

A single high pressure TEST port is prov ided on the rear panel of the HPM S .

The test port connection is a DH500 F. DH500 is a gland and collar ty pe fitting f or 1/4 in.

(6 mm) coned and left hand threaded tube. DH500 is equivalent to AE F250C, HIP HF4, etc.

Connecti on to OP G1 if the RPM3/HPMS is Part of an HGC-30000-AF S yst em

If the RPM3/HPMS was delivered as part of an HG C-30000-AF Hydraulic G auge Calibrator,

an OPG1 Oil Pressure Generator/Controller was delivered with it. The OPG1 includes a

fittings kit with the necessary fittings to interconnect the RPM3/HPMS and OPG1 and

instructions on making the connection. S ee the OPG1-30000-A F manual.

USE THE CORRECT PRESSURE CONNECTORS: The RPM3/HPMS TEST port fitting is a

DH500 F (see Section 1.2.1). It is NOT a 1/8 in. NPT F . Never use fittings other than the

correspo nding male fittings in these connec tors. D amage to the connecto rs and d angerous

failure under pressure co uld res ult from using incorrect fittings.

DO NOT AP PLY PRESSURE UN TIL YOU ARE FAM ILIAR WITH OPERATION : The RPM3/HPMS

rear panel test port connects internally to both the RPM3’s 6 000 psi (40 MPa) and

30 000 psi (200 M Pa)RPTs. T he valve on the front o f the HPMS isolate s the low press ure

RPT when the high pressure RPT is in use. Do not app ly pressure to the RPM3/HPMS until

you are familiar with its operation and know how to protect the low pressure RPT from

overpressure (see Section 3.1.8). FAILURE TO PROTECT THE LOW PRESSURE RPT FROM

OVERPRESSURE MAY DESTROY IT. DAMAGE D UE T O RP T OV ERPRESSURE IS NO T COVERE D

BY THE PRODUCT WARRANTY.

2.3.6.1 THE RPM3 AT M PORT

The ATM pass through on the RPM3 rear panel is connected to the RPM3’s onboard barometer. This connection assures that the on-board barometer measures

ambient atmospher ic pressure rather than the press ure inside the RPM3 case that

may vary slightly from ambient pressure. The ATM port should be left open

and unobstructed.

NEVE R plug or obs truct the ATM pas s through as this ma y adverse ly affect gauge

mode operation and autozeroing on an absolute transducer.

Page 11 ©2000 DH Instruments, Inc.

Page 22

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

2.3.7 SETTING UP FILE SEQUENCES

RPM3 supports automated test/calibration sequences. Sequence parameters for testing

specific DUTs can be stored in Sequence Files and recalled when a Sequence is run.

Consider setting up Sequence Files for frequently t ested DUTs as part of t he RPM3 set up

process (see Section 3.3.6).

2.4 POWER UP AND VERIFICATION

2.4.1 APPLY POWER

Connect the RPM3 power cable to an electric supply of 85 to 264 VAC (47 to 440 Hz).

Observe the front panel display as RPM3 initializes, error checks and goes to the main run

screen (see Sect ion 3.1. 2). Check t hat one of the t wo green Valve St atus LEDs on t he front

panel of the HPMS is lit (the red LED should NO T be ON).

RPM3 is always powered and active when power is supplied through the rear panel

power connector. The front panel ON/OFF key controls a soft ON/OFF function (see

Section 3.1. 4).

If the RPM3 fails to reac h the main run sc reen, servic e is required. Recor d the sequence of

operation and displays observed and contact a DHI Authorized Service Center (see

Section 7.2, Table 18).

If neither of the green LEDs on the HPMS front panel lights, check that the 9-pin D-Sub

accessory cable at the rear of the RPM3 itself is properly connected to the ACC. J1

connector.

The active range o n power up is the sam e as the range that was active at the last power

down (see Section 3.1.6).

2.4.2 CHECK PROPER PRESSURE MEASUREMENT OPERATION

2.4.2.1 CHECKING ABSO L UT E MODE PRESSURE MEASUREMENT

Check that the RP M 3 RP Ts operate properly in abs olute mode.

Open the RPM3/HP MS TES T port t o atmosphere. Put the valv e knob in the HPMS

front panel into the Lo RPT Active position. This opens the Lo RPT t o the HPMS

TEST port.

Press [MODE] on the RPM3 and select absolute. Change the pressure unit of

measure using [UNIT] if desired (see Sec tion 3.2.3).

Observe the RPM3 indicated pressure. Check that t he value is equal to at mospheric

pressure

[RANGE] and [ENTER] to change ranges. Check that the values of atmospheric

pressure measured by the different ranges agree with each other within RPM3

measurement tolerances (see Section 1.2.2.1). If they do NOT agree within

©2000 DH Instruments, Inc. Page 12

± 5 psi. Repeat this process for all the ranges on both RPTs using

Page 23

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

tolerances, RPM3 may need calibration or repair.

2.4.2.2 CHECKING GAUGE MODE PRESSURE MEASUREM ENT

Open the RPM3/HP MS TES T port t o atmosphere. Put the valv e knob in the HPMS

front panel into t he Lo RPT Active position. This opens the Lo RPT t o the TEST

port.

Press [MODE] on the RPM3 and select gauge. Change the pressure unit of

measure using [UNIT] if desired (see Sec tion 3.2.3).

The value indicated should be near z ero (

then press [AutoZ]. This runs AutoZ to zero the range (see S ection 3.2.10). Upon

return to the m ain run screen, observe that the indication of m easured pr essure has

zeroed.

Use [RANGE] and [ENTER] to change ranges (see Section 3.2.2) and repeat the

zeroing process for each range (the two minute wait does not need to be repeated

each time).

If a range fails to zero properly, RP M 3 m ay need r epair .

It is normal for RP M3 to indicate a value o ther than zero when vented when gauge

mode is first entered or ra nges are changed, especially if Auto Z is OFF, RPM3 ha s

been OFF for so me time, its location ha s changed or the fluid head to which it is

connected has changed.

± 5 psi, 35 kPa). W ait two minutes and

2.5 SHORT TERM STORAGE

The following is recomm ended for short ter m s torage of RPM3/HPM S :

• Vent the RPM3/ H P M S TEST port.

• Disconnect the power s upply .

When RPM3 will NOT be us ed for some t ime, it m ay be left powered, but use the soft ON/OFF key

to turn OFF the display.

2.6 LONG TERM STORAGE AND SHIPPING

The following is recommended for long term storage and or shipping of RPM3/HPMS:

• Plug the HPMS TE S T port.

• Place the RPM3/HPMS in a plastic bag.

Place the RPM3/HP M S in the custom shipping/ s torage container in which it was deliv er ed.

Page 13 ©2000 DH Instruments, Inc.

Page 24

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

N

N

OOTTEES

S

©2000 DH Instruments, Inc. Page 14

Page 25

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

3. OPERATION

3.1 GENERAL/MANUAL OPERATION

RPM3/HPMS is designed to offer the optimum balance bet ween simple, str aight forward operation

and the availability of a wide v ar iety of funct ions with a high level of operator disc r etion if desired.

The RPM3 provides the local operator interface is through a front panel 2 x 20 character alphanumeric display, a 4 x 4 multi-function k ey pad and an [ENTER] foot switch.

The HPMS mounts the RPM3 at a convenient viewing angle and includes a valve and visual

indicators to isolat e and protect the RP M3’s 6 000 psi RPT (Ranges L1, L2, L3) when using t he 30

000 psi RPT (Ranges H1, H2, H3) (see Section 3.1.6).

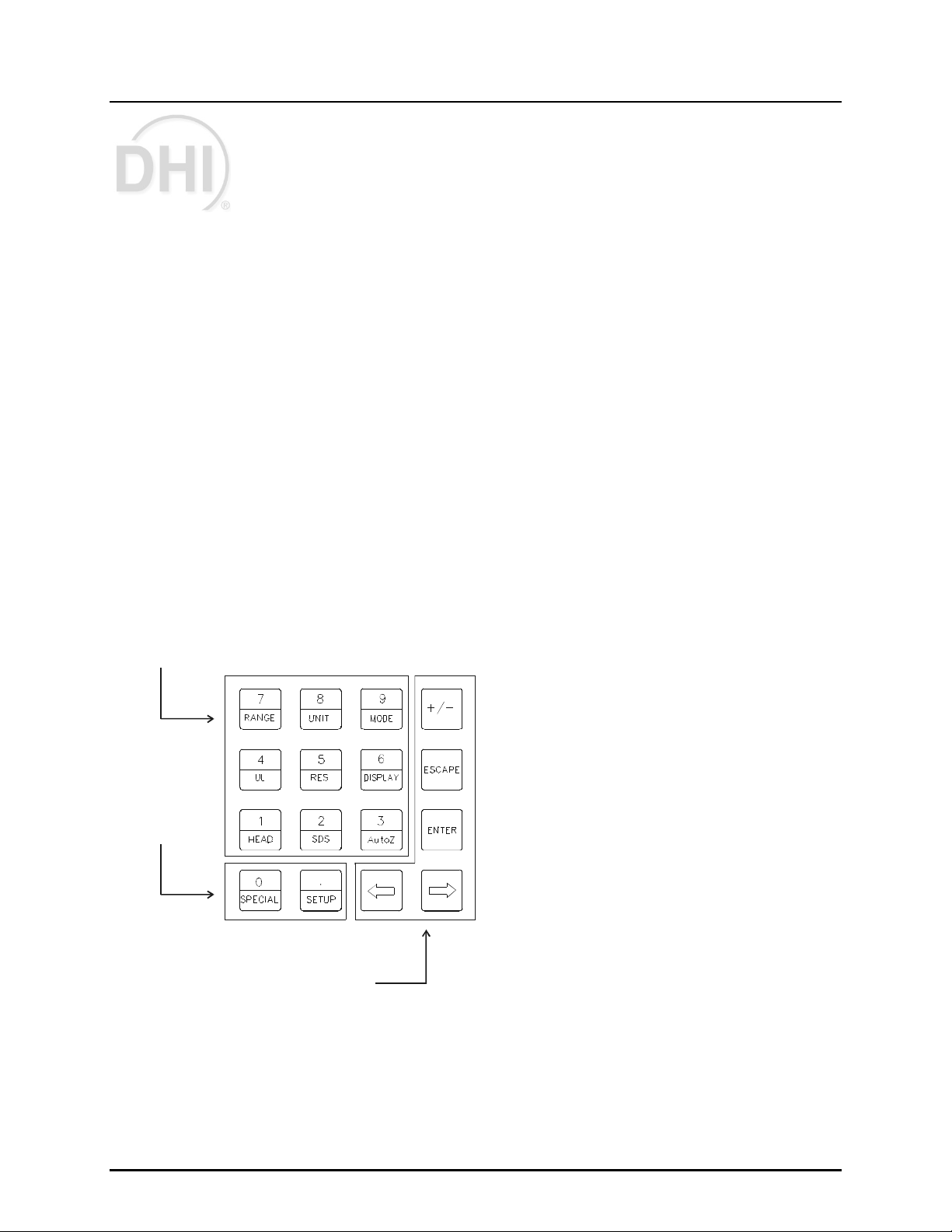

3.1.1 KEYPAD LAYOUT AND PROTOCOL

The RPM3 has a 4 x 4 keypad and an [ENTER] foot switc h for loc al operator access to dir ect

functions, function menus and for data entry.

3

1. The Editing and Execution keys are for

execution, suspending execution, backing up

in menus and editing entries.

The Menu/Data keys provide access to

2.

function menus from the main run screen.

The menu name is on the bottom half of

the key. The SETUP menu is for more

frequently used functions (see Section 3.3).

2

1

The SPECIAL menu is for functions that are

NOT generally used as a part of day to day

operation (see Section 3.4). These keys enter

numerical values when editing.

The Function/Data keys allow very

3.

commonly used functions to be accessed

directly from the main run screen by a single

keystroke. The name of the function is on the

bottom half of the key (see Section 3.2.1).

These keys enter numerical values when

editing.

[ENTER] Foot Switch (not shown) acts in exactly the same manner as t he keypad [ENTER]

4.

key. It serves as a remot e [ENTER] key to be used when the operat or’s hands are occupied or

touching the RPM3 front panel is not convenient.

Figure 6. RPM3 Keypad

Page 15 ©2000 DH Instruments, Inc.

Page 26

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

Key press confirmation is provided by both tactile and audible feedback. A single tone

confirms a valid entry, a descending t wo note t one signals an invalid ent ry. The audible v alid

entry feedback can be suppressed or modified by pressing [SPECIAL] and selecting

<7Intern>, <2sound> (see S ection 3.4.7.2) .

Pressing the [ENTER] key or foot swit ch generally c auses exec ution or f orwar d movement in

the menu tree.

Pressing the [ESCAPE] key moves back in the menu tree and/or causes execution to c ease

or suspend without changes being implemented. Pressing [ESCAPE] repeatedly event ually

returns to the main run screen. From the main run screen, pressing [ESCAPE] allows

momentary viewing of the RPM3 introduction screen.

Pressing the [+/ -] key changes a numerical sign when editing. It also toggles through

multiple screens when available.

Pressing the [

←←←←] and [→→→→] keys allow reverse and forward cursor movement when editing

data entry. These keys are also used to scroll through choic es .

Some screens go beyond the two lines provided by the display. This is ind icated b y a flashing

arrow in the second line of the displa y. Use [←←←←] and [→→→→] to mo ve the cursor to access the

lines that are NOT visible or directly enter the number of the hidden menu choice if yo u know

it.

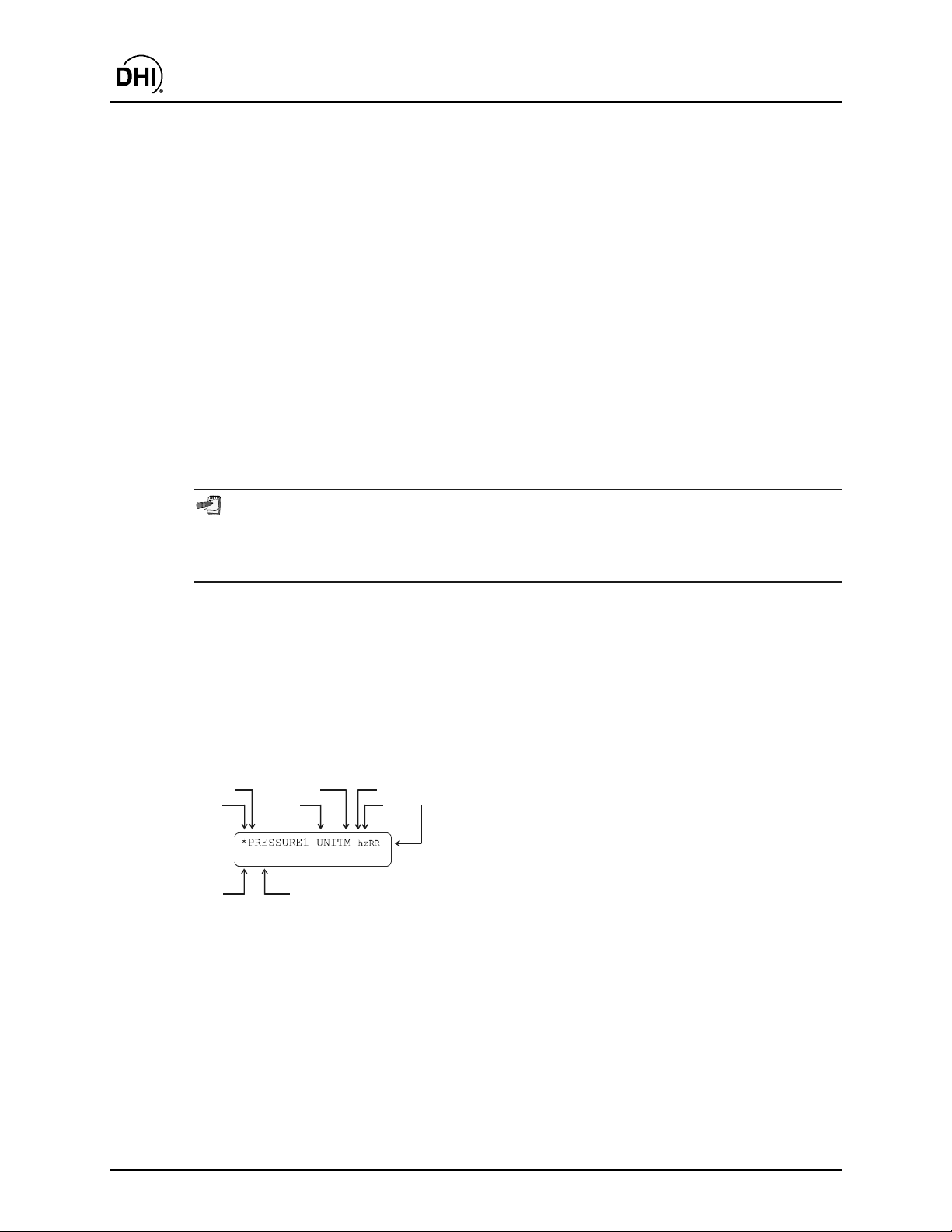

3.1.2 MAIN RUN SCREEN

The RPM3 main run scr een is its home display that is reac hed on power up and from which

other functions and menus are accessed. It is the top level of all menu struct ur es .

The main run screen is where the RPM3 is left in normal operation. It display s the current

measured pressure as well as a v ar iety of additional information if desired.

2

1

D DISPLAY FUNCTION

9

4. <M>: Pressure measurement mode: <g> for gauge, <a> for absolute (see Section 3.2.4).

5. <h>: Indicates whether a head correction is applied. <h> if applied, blank if NOT (see Section 3.2.8).

6. <z>: Indicates whether the autozero function is ON or OFF. <z> if ON; blank if OFF (see Section 3.4.1).

7. <RR>: Indicates active RPT (<H> = high, <L> = low) and range (<1> = low, <2> = mid, <3> = hi) (see

Section 3.2.2).

8. <DISPLAY FUNCTION>: Information displayed depends on current display function.

9. <D>: Indication of w hat is being displayed on the bottom line of the display as set by the DISP LAY func tion (see

Section 3.2.7). Choices include:

• <σσσσ>: Current DISPLAY mode is average (see Section 3.2.7.1).

• <R>: Current DI SPLA Y mode is rate (s ee Sec tion 3. 2.7.2); or if <n avg > is in the bottom r ight hand c or ner of

the display, c urrent DISPLAY mode is average and this is the instantaneous reading average screen (s ee

Section 3.2.7.1).

• <H>: Current DISPLAY mode is hi/lo (see Section 3.2.7.5).

4

3

8

5

7

6

1. <•> Ready/Not Ready indication, <•> when Ready,

↑↑↑↑> or <↓↓↓↓> indicating direction of measur ed pressure

<

evolution when Not Ready (see Section 3.1.5).

2. <PRESSURE1>: Numerical value and sign of

pressure meas ur ed by ac tiv e R PT and r ange. S hows

result of last average in average display

mode (see Section 3.2.7.1).

3. <UNIT>: Current unit of measure (see Section 3.2.3).

©2000 DH Instruments, Inc. Page 16

Page 27

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

• <D>: Current DISPLAY mode is deviation (see Section 3.2.7.3).

• <✳✳✳✳>, <↑↑↑↑> or <↓↓↓↓>: Current DISPLAY mode is RPT (see Section 3.2.7.4).

• <F>: Current DISPLAY mode is freeze (see Section 3.2.7.6).

• Blank, NO character: Current DISPLAY mode is clean (see Section 3.2.7.7).

RPM3 has a screen saver function that causes the display to dim if NO key is pressed for

10 minutes. Pressing a key restores full power to the display. The screen saver activation

time can be changed or screen sa ving can be co m pletely suppressed (see Sectio n 3.4.7.1).

3.1.3 SOUNDS

RPM3 is equipped with a variable frequency tone device to provide audible feedback

and alarms. The beeper is us ed for the following indications :

• Valid key press: Brief beep. Choice between three frequencies or NO sound is

available (see Section 3. 4.7.2).

• Invalid key press or out of tolerance reading when running an automated

test sequence: Descending two tone blurp (see Section 3.2.11.2).

• In tolerance reading when running an automated test sequence: Ascending three

tone fanfare (see Section 3.2.11.2).

• Leak check rout ine compl et ed: Three two sec ond beeps ( s ee S ec tion 3.3.5).

• UL (upper limit) exceeded: Intermittent one s ec ond beeps (see Section 3.2.5).

• Pmax! (overpressure limit) exceeded: Eight second high frequency beep (see

Section 3.2.5.1).

• Lo RPT is active but a Hi RPT range is selected: Intermittent two second high

frequency beep. T he audible alarm is combined wit h flashing of t he red, Lo RPT Active

LED on the HPMS (see Section 3.2.5. 2) .

3.1.4 SOFT [ON/OFF] KEY

RPM3 is equipped with a soft [ON/OFF] key and indicator LED on the bottom left hand

corner of the front panel. The purpose of the soft ON/OFF key is to put RPM3 into a

dormant mode in which the dis play is turned OFF but power is still s upplied and overpres s ur e

functions are still active. When RPM3 is ON, the ON/OFF indicator is ON continuously.

When RPM3 is soft OFF, the ON/OFF indicator blinks ever y five seconds.

The soft [ON/OFF] key can also be used to reset from an overpressure condition (see

Section 3.2.5.1).

When RPM3 is soft OFF, r ec eiv ing a r em ote command turns it ON.

Page 17 ©2000 DH Instruments, Inc.

Page 28

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

3.1.5 PRESSURE READY <*>/NOT READY (<↑↑↑↑> OR <↓↓↓↓>) INDICATION

The character to the left of the measured pressure on the main run screen provides a

pressure Ready <*>/Not Ready (<

provide the user with a clear and objective indication of when a stable pressure has

been achieved. Ready <*> is indicated when the current stability (rate of change) of

pressure is less t han the stability limit. The user can set the stability limit (see Section 3.3.4) .

The Ready indicat ion is often used when c omparing the RPM3 and a t est dev ice to indicate

when a valid reading can be made.

↓↓↓↓> or <↑↑↑↑>) indication. This indication is intended to

Ready <*>/Not Ready (<

• <*>: Pressure Ready (stable).

• <↓↓↓↓>: Pressure Not Ready (unstable) and dec r eas ing.

• <↑↑↑↑>: Pressure Not Ready (unstable) and inc r eas ing.

↓↓↓↓> or <↑↑↑↑>) character indications are:

3.1.6 MULTIPLE PRESSURE RANGES

RPM3 A30000/A6000-AF has t wo ref erence pres sure t ransducer s (RP Ts) eac h of which has

three ranges for a total of six pressure ranges. This multi-ranging feature allows

measurement uncertaint y to be optimized for the range of pressur e in which you ar e working.

Generally, the bes t range to select ( see Section 3.2.2) is that whose full scale is closest t o,

but greater than, the maximum pressure of the device or system under test.

RPM3 handles all of the dat a operat ions needed to mak e r ange c hanges occur t ranspar ently

to the user when the RA NGE f unct ion is used f or range s election. For a range change t o be

executed, the current pressur e applied to the RPT on which the r ange is being select ed must

be lower than the current upper limit (UL) of that range (see Section 3.2.5). The RPM3

Sequence feature automatically selects the most appropriate range based on the range of

the device under test (see Section 3. 2.11).

When the range is changed, the upper limit automatically changes to the default for that

range or to the last upper limit set for that range. In addition, most other functions and

settings are range specific (see Section 3.2.2).

RPM3 A30000/A6 000- AF ha s s ix ranges. In general, s ettings and operationa l adjustments

are specific to the range currently in use, as if you had six instruments rather than one.

The DISP LAY function, HEAD functions and AUTO RE ADRT function are NOT range specific.

In remote mode, m ost settings are RPT specific rather than range specific (see Section 4.3 ).

©2000 DH Instruments, Inc. Page 18

Page 29

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

3.1.6.1 RANGES AND IDENTIFICATION

The active RPT and range is cont inuously indic ated in t he upper right hand cor ner of

the main run screen and m os t other screens.

Hi RPT: The A30000 RPT whose maximum range is 30 000 psi (200 MPa) is

referred to as the Hi RPT.

Lo RPT: The A6000 RPT whose maximum r ange is 6 000 psi (40 MPa) is referred

to as the Lo RPT.

Range 1, 2 or 3: The three ranges of each RPT are r eferred to as 1 = lo range,

2 = mid range, 3 = hi range. The Lo RPT ranges, low to high, are L1, L2, L3.

The high PRT ranges, low to high, are H1, H2, H3.

Table 2. RPM3 Range Identification Summar y

REFERENCE PRESSURE

TRANSDUCER AND RANGE DESIGNATION DISPLAY SYMBOL *

Lo RPT, Lo range Lo, 1 L1 2 000 ( 14)

Lo RPT, Mid range Lo, 2 L2 4 000 (28)

Lo RPT, Hi range Lo, 3 L3 6 000 ( 42)

Hi RPT, Lo range Hi, 1 H1 10 000 (70)

Hi RPT, Mid range Hi, 2 H2 18 000 (125)

Hi RPT, Hi range Hi, 3 H3 30 000 (200)

* The display symbol is included in the upper, right hand corner of most RPM3 menu displays as

a convenient indicator of active range.

RANGE

PSI (MPa)

3.1.7 AUTOMATED TEST/CALIBRATION SEQUENCES

The RPM3 SEQUE NCE function supports “quick” and “file” automated calibrati on sequences.

These automatically set the appropriate RPM3 range, resolution and stability limit based on

the characteristics of the device under test. They also prompt the user through the

increments of the calibration sequence and log calibrat ion data. The SEQUENCE funct ion

should be used for most common calibration tasks, especially calibration of analog pressure

gauges (see Section 3. 2.11).

Page 19 ©2000 DH Instruments, Inc.

Page 30

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

3.1.8 HPMS (HIGH PRESSURE MOUNTING SYSTEM)

The HPMS (high pressure mount ing system) holds the RPM3 at a convenient viewing angle

and includes a valve and visual indicat ors to isolate and prot ect the RPM3’s 6 000 psi RPT

(Ranges L1, L2, L3) when us ing the 30 000 psi RPT (Ranges H1, H2, H3).

m

m OPERATION

mm

Numerical references in this Section ref er to Figure 1.

In normal use, t he operator’s only interaction wit h the HPMS is t o operate the isolation

valve knob to connect and disconnect the Lo RPT from the TEST port. The valve’s

operation is prompt ed by the Valve Posit ion LEDs ( 1, 3).

The Lo RPT isolation valve (2) isolates and protects t he Lo RPT from the TES T port

when it is closed (knob f ully CCW) and opens the Lo RPT to the T EST port when it is

open (knob fully CW).

The Valve Position LEDs (1, 3) indicate the position in which the valve knob s hould be

set based on the current range selection on t he RP M 3. If a range on the Hi RPT (H1, H2

or H3) is selected, the LO RPT SHUT OFF LED (1) is lit indicating that t he valve knob

should be turned fully CW to close t he valve, prot ecting the Lo RPT from high pressur e.

If a range on the Lo RPT (L1, L2 or L3) is selected, t he LO RPT ACTIVE LE D (3) is lit

indicating that the valve knob should be turned fully CCW to open t he valve, connect ing

the Lo RPT to t he test pressure.

The HPMS isolatio n va lve (2) must always b e in the clo s ed position (knob fully CCW) when

operating a t p re ss ure grea te r tha n 6 000 psi (40 MPa ).

The CAUTIO N LO RPT ACTIVE LED (4) is used to indicate t hat the Lo RPT is active

and provide a warning when the Lo RPT is active but a Hi RPT range is selected on

the RPM3.

The CAUTION LO RPT ACTIVE LED (4) is driven by the value of pressure currently

measured by the Lo RPT, it is not driven by the valve posit ion as there is no sensing of

the valve position.

The CAUTION LO RPT ACT IVE LED (4) has three possible conditions:

• LED is OFF: The Lo RPT is NOT act ive. The Lo RP T is considered ac tive when it

measures a pressur e gr eater than 30 psig (200 kPa) .

• LED ON continuously: The Lo RPT IS active and a Lo RPT range is selected on

the RPM3. The LED is lit as a reminder that the Lo RPT is act ive and press ure over

its maximum wor k ing pr es s ur e of 6 600 (46 MPa) should not be applied.

• LED is flashing on accompanied by high frequency beeps and <!!!LO RPT

ACTIVE!!!> disp layed by RPM3: Lo RPT IS ac tive and a Hi RP T range is s elected

on RPM3. The Lo RPT should NOT be active when a Hi RPT range is in use.

Hi RPT ranges will overpres s ur e and dam age the Lo RPT.

©2000 DH Instruments, Inc. Page 20

Page 31

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

If a Hi RPT range is selected w ith the Lo RPT active, RP M3 go es into an alarm condition

to avoid accidental overpressure of the Lo RPT while using a Hi RP T range. The pressure

on the Lo RPT must be reduced to less than 30 psig (200 kPa) so that the CAUTION LO

RPT ACTIVE LE D is O FF b efore shutting the L o RP T is olatio n valve and selecting a Hi RPT

range.

The pressure rel ief valve (6) is set to open at 110 % of the RPM3 range L3 ( 46 Mpa;

6 600 psi). When the pr essure applied to the Lo RPT reaches approximately 6 600 psi

(46 MP a), the pressure relief valve (6) will open reducing pressur e and bleeding oil into

the pressure relief run off cup (7). Prior to opening the pr essure relief valve, the RPM3

will have gone into an overpressure condition (see Sect ion 3.2.5.1). If an overpressure

condition occurs, reduce pressure as soon as possible. The pressure relief valve will

reseat automatically when pressure is reduc ed.

Do NOT overpressure the Lo RPT. The Lo RPT may be da m aged beyond repair by pressure

greater than 6 600 psi (4 6 MPa ). RPT dam age from o verpress ure is lo gged in user and

factory maintenance pages and is not covered by the product warranty. The HPMS

pressure relief valve should only be considered a last resort means of protecting the

Lo RPT. Following proper operating procedures, the Lo RPT should never be

7

6

5

34

overpressured.

1. Lo RPT Pressure Relief Valve (not shown) 5. Lo RPT Active Valve Position LED

2. Lo RPT Relief Oil Run-Off Cup (not shown) 6. Caution Lo RPT Active LED

3. Lo RPT Shut OFF Valve Position LED 7. RPM3 Reference Pressure Monitor

4. Lo RPT Isolation Valve

1

2

Figure 7. RPM3/HPMS Front Panel

Page 21 ©2000 DH Instruments, Inc.

Page 32

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

1

7

6

2

3

4

5

1. HPMS TEST port (DH500 F) 5. Lo RPT Isolation Valve

2. Connection to RPM3 Hi RPT (A30000) 6. RPM3 Reference Pressure Monitor

3. Lo RPT Pressure Relief Valve (6 600 psi) 7. Connection to RPM3 Lo RPT (A6000)

4. Pressure Relief Valve Oil Run Off Cup

Figure 8. RPM3/HPMS Internal Schematic

3.2 DIRECT FUNCTION KEYS

3.2.1 DIRECT FUNCTION KEYS SUMMARY

Local operation of RPM3 is through the 4 x 4 pressure sensitive k eypad and an [ENTER]

foot switch. To minimize the us e of multi-layered menu s tructure, the 4 x 4 keypad numerical

keys also provide direct access to the most commonly used functions. The function

accessed is labeled on the bottom half of the k eys. Direct func tion key s are act ive whenever

RPM3 is in its main run screen. Table 3 summarizes the operation of the direct function

keys.

Table 3 provides a brief summary of direct function key operation. It may be useful to keep a

copy of this summary near the RPM3/HPMS, especially when first becoming acquainted with

its operatio n.

©2000 DH Instruments, Inc. Page 22

Page 33

RPM3/HPMS A30000/ A6000- AF Operation and Mai ntenance Man ual

Table 3. Summary of RPM3

Direct Funct ion K ey Operation

Direct Function Keys are active from the MAIN run screen

See corresponding manual secti ons for fu ll detail .

.

SETUP

0

SPECIAL

1

HEAD

2

SDS

3

AutoZ

4

UL

5

RES

Menu of commonly used setup features including run LEAK CHECK.

Menu of less frequently used internal func tions and settings.

Set fluid head height.

SDS function is not used on RPM3 A30000/A6000- A F.

Runs AutoZ to rezero active range. In gauge mode, should only be used

after assuring the system is vent ed and waiting two minutes.

View/adjust upper pres s ur e lim it alarm.

Adjust display resolution of measured press ur e and other indications and

settings.

6

DISPLAY

7

RANGE

8

UNIT

9

MODE

10

ENTER

Select [DISPLAY] function for sec ond line of RPM3 display. Choices

include <average>, <rate>, <other RP T>, <Hi /Lo>, <Deviation>,

<Freeze>, <Clean>.

View/Select ranges . Shows active range and then toggles through

available ranges. Pressing [ENTER] on a range activates it.

Change pressure measurem ent unit. Choice of unit s c an be c us tomized.

Change pressure measurem ent mode (<gauge>, <absolute>).

ENTER data and/or run automated tes t/calibration sequenc e from MAIN

RUN screen.

Page 23 ©2000 DH Instruments, Inc.

Page 34

3.2.2 [RANGE]

m

m PURPOSE

mm

To view and/or change the active pressure m eas urement range.

m

m PRINCIPLE

mm

RPM3 A30000/A6000 has six ranges (see Section 3. 1.6).

The [RANGE] key allows the range values to be viewed and a range selection to

be made.

Most RPM3 settings such as pressure unit of measure (UNIT) and measur ement mode