Page 1

Measuring air velocity with

the Fluke 975 AirMeter:

Using the velocity probe

Air velocity is a key parameter in evaluating airflow system performance. As part of basic testing, adjusting

and balancing of HVAC air distribution systems, most

HVAC technicians now use an anemometer to measure air velocity at grilles-registers-diffusers, within a

duct, or in open spaces.

Anemometers are typically very accurate tools,

especially at low velocities, but they must compensate

for air temperature, absolute pressure, and ambient

absolute pressure. The Fluke 975 AirMeter tool has an

accessory velocity probe that uses a thermal anemometer to measure air velocity. A temperature sensor in

the probe tip compensates for air temperature, a sensor in the meter reads absolute pressure, and ambient

absolute pressure is determined upon meter initialization. For users who prefer to calculate their own compensation factors, the meter will also display air velocity

or volume at standard conditions.

This application note describes how to take accurate

air volume measurements within a duct, air measurements at grilles-registers-diffusers, and other locations.

Application Note

Air volumes within a duct

The ultimate goal of any duct

system is to move the required

air volume, while keeping all

other factors within acceptable

limits, and to deliver it in quantities and patterns that serve the

intended purpose: heating, cooling, ventilating, exhausting, mixing, humidifying, dehumidifying,

or otherwise conditioning the air

within a space. Velocity within

a duct is determined not only

by application, but also by how

the duct is designed. Key design

factors include: The level of

available static pressure that can

be overcome by the fan due to

friction losses and pressure drops

of devices within the air stream;

the cost of duct work; the space

available for duct work; and

acceptable noise levels.

F r o m t h e F l u k e D i g i t a l L i b r a r y @ w w w . f l u k e . c o m / l i b r a r y

To determine the air volume

delivered to all downstream terminal devices, technicians use a

duct traverse. Duct traverses can

determine air volume in any duct

by multiplying average velocity

readings by the inside area of

the duct. Traverses in main ducts

measure total system air volume,

which is critical to HVAC system

performance, efficiency, and even

life expectancy. The difference

in air volumes between the main

supply duct traverse and the

main return duct traverse results

in outdoor air volume. A traverse

in run-outs is the most accurate

way to determine the air volume

delivered by the terminal device

(grille-register-diffuser). A traverse in exhaust ducts reveals

exhaust air volume.

Measuring air velocity in a duct.

Page 2

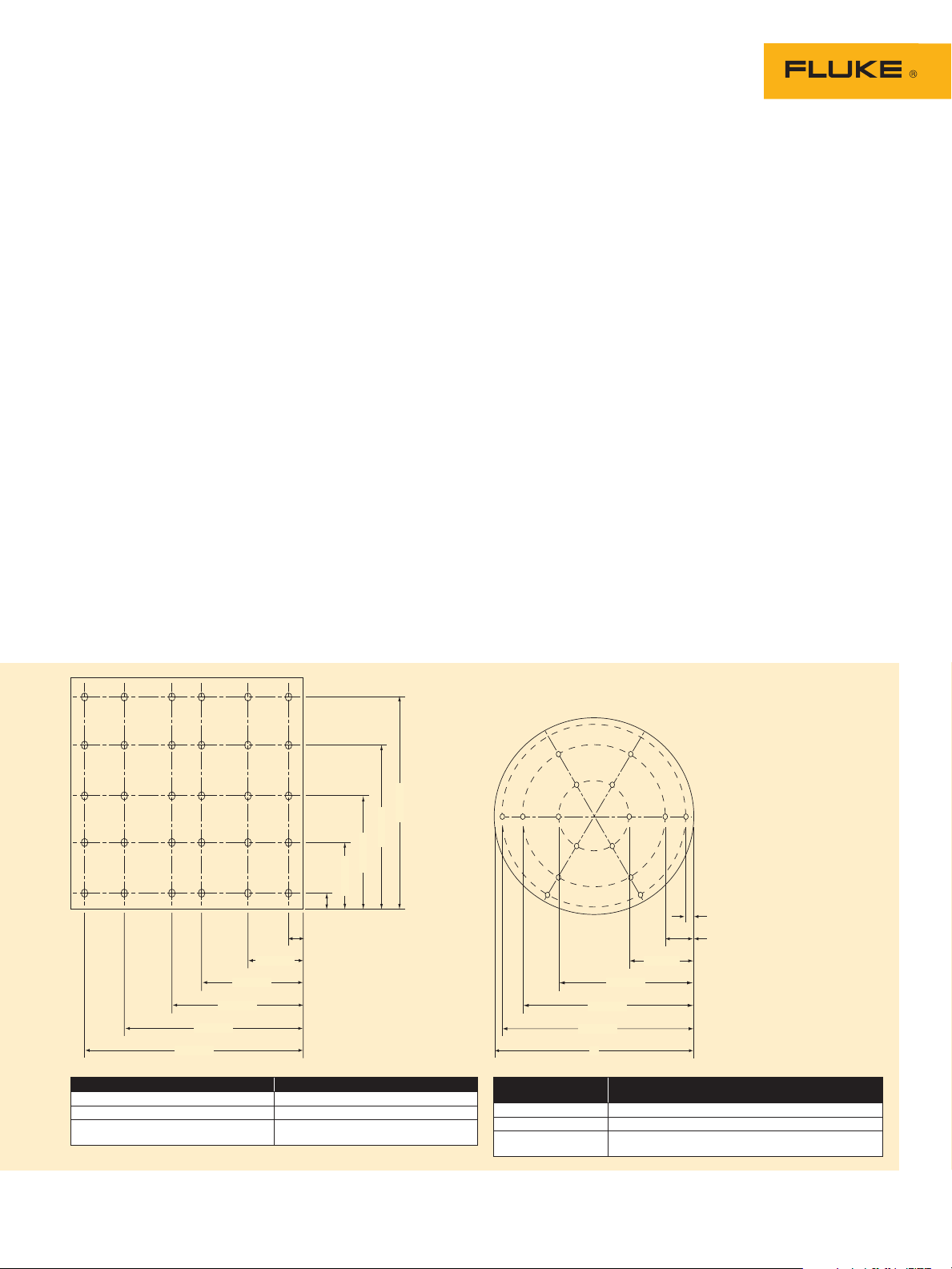

A duct traverse consists of a

0.061 D

0.235 D

0.437 D

0.563 D

0.785 D

0.939 D

0.074 D

0.288 D

0.500 D

0.712 D

0.926 D

0.135 D

0.321 D

0.032 D

0.579 D

0.865 D

0.968 D

D

0.135 D

0.321 D

0.032 D

0.579 D

0.865 D

0.968 D

D

number of regularly spaced air

velocity measurements throughout a cross sectional area of

straight duct. Preferably, the

traverse should be located in a

straight section of duct with ten

straight duct diameters upstream

and three straight duct diameters downstream of the traverse

plane, although a minimum of

five duct diameters upstream and

one duct diameter downstream

can give adequate results.

The number of measurements

taken across the traverse plane

depends on the size and geometry of the duct. Most duct traverses result in at least 18 to 25

velocity readings, with the number of readings increasing with

duct size. The industry accepted

measurement points across the

traverse are determined by the

Log-Tchebycheff rule for rectangular duct, and by the Log-Linear

rule for round duct. Usually, technicians drill five to seven holes

on one side of rectangular ducts,

and two to three holes in round

ducts, in order for the telescoping anemometer probe to access

the traverse points. To ensure

the anemometer is used in the

direction of calibration, align the

mark on the velocity probe tip

with the impact direction. When

extending the probe, align the

wand section with the handle to

help maintain the correct direction inside the duct.

Before taking measurements,

slide the protective sheath

toward the wand handle in

order to expose the sensors in

the probe tip. For volume flow

rate calculations, the Fluke

975 AirMeter™* will prompt for

rectangular or round duct, then

prompt for rectangular side

dimensions or round diameter.

Take the required number of

velocity readings one at a time

by pressing the “capture” key. If

a velocity reading is taken prematurely, the Fluke 975 allows

you to re-take it. When all velocity readings are complete, the

AirMeter™ averages the readings

and multiplies by the duct cross

sectional area to get air volume,

both at standard conditions and

compensated for absolute pressure and temperature.

The velocity readings (FPM)

are averaged and multiplied by

the inside area of the duct (sq ft)

which provides the air volume

(CFM).

Q = V * A

Q = Air volume, CFM (cubic feet per minute)

or M

3

/s (cubic meters per second)

V = Velocity, FPM (feet per minute) or m/sec

(meters per second)

A = Area of duct, inside dimension of duct in

square feet or square meters

*For determining air velocity greater than 600 feet per minute

(FPM) within a duct, an HVAC technician may also use a Pitotstatic tube with an inclined manometer. Anemometers are the

preferred choice below 600 FPM and are quite acceptable at

higher velocities, too. The Fluke 975 AirMeter’s anemometer

measures over a range of 50 to 3000 fpm. In low pressure

duct systems where sound is a concern, such as residences

and health care facilities, velocity usually ranges from 400 to

900 FPM, while in high pressure duct systems, velocities can

approach 3,500 FPM.

No. of points or traverse lines Position relative to inner wall

Patterns of holes drilled in rectangular and round ducts when conducting a duct traversal. Taken from ANSI/ASHRAE Standard 111-1988.

2 Fluke Corporation Measuring air velocity with the Fluke 975 AirMeter: Using the velocity probe

5 0.074, 0.238, 0.500, 0.712, 0.926

6 0.061, 0.235, 0.437, 0.563, 0.765, 0.939

7

0.053, 0.203, 0.366, 0.500, 0.534, 0.797,

0.947

No. of measuring

points per diameter

6 0.032, 0.135, 0.321, 0.679, 0.865, 0.968

8 0.021, 0.117, 0.184, 0.345, 0.655, 0.816, 0.883, 0.981

10 0.019, 0.077, 0.153, 0.217, 0.361, 0.639, 0.783, 0.847, 0.923,

Position relative to inner wall

0.981

Page 3

leading to the GRD. Alternately,

use a traverse with the velocity

probe at the face of a GRD, along

with the GRD manufacturer’s

engineering data, to determine

air volume.

Unlike a section of duct, the

Taking measurements at the intake of a

rooftop unit.

Air measurements

at Grilles-RegistersDiffusers (GRDs)

Supply air GRDs are selected and

positioned to deliver specified air

volume in velocities and patterns

that result in acceptable comfort

and ventilation within the occupant zone. The occupant zone is

considered to be one foot from

walls and below head height.

Velocity from a supply GRD normally does not exceed 800 FPM,

and velocity into a return grille

should not exceed 400 FPM in

applications where noise would

be objectionable. Velocity must

be sufficient to mix the supply

air with the room air outside of

the occupant zone, while creating comfortable air patterns and

temperatures within the occupant zone.

Throw is the distance the air

travels from a GRD before reaching terminal velocity. Throw is

normally 75 % to 110 % of the

distance from the GRD to the

next intersecting surface (wall)

or terminal velocity point of

adjacent GRDs. Terminal velocity is simply the velocity at the

point within the throw that is

chosen to stop measuring throw

for engineering design reasons.

Terminal velocity is typically

50 FPM to 75 FPM in residential and office spaces, but may

be specified by the engineer to

be as high as 125 FPM to 150

FPM in commercial applications.

Generally, air velocities in the

occupant zone at 50 FPM are not

objectionable. Stagnant zones are

created when velocities fall to

15 FPM. To determine space air

patterns, use the velocity probe

to “follow” the throw of GRDs .

To determine air volume

delivered by a GRD, it’s best to

perform a duct traverse with the

velocity probe in the duct run-out

area of a GRD cannot be measured in the field due to the fact

that the air changes direction

and accelerates through the vena

contracta (the vena contracta

is an effect that occurs when

air flowing through any opening “sticks” to the edges of the

opening, effectively reducing the

size of the opening). Even careful

field measurements of the free

area of a GRD to determine air

volumes will result in gross miscalculations of air volume. The

GRD manufacturer will publish

an “effective area” (Ak = effective area in square feet) that can

only be determined by laboratory

tests that measure actual air volume and GRD face velocity (V

avg

= average face velocity in feet

per minute). This effective area

can be used in the field for air

volume calculations.

For a given GRD, the manufacturer will normally publish the

effective area along with a range

of face velocities with the resulting volume flow in cubic feet per

minute (CFM) and pressure drop

for each face velocity. These values are determined with straight

duct connected to the GRD carrying non-turbulent air evenly

distributed across the duct.

Calculating air volume from a

GRD requires taking enough face

velocity readings to get an average velocity. Set up a grid of test

points across the face of the GRD

that will result in a good average

when finished. Grid spacing is

typically three to five inches, no

more than six inches, and a minimum of six stable velocity readings per throw direction. Position

the velocity probe sensor flush

with a supply GRD, or one inch

(± .031 in) away from a return

grille, and center the probe in

the opening. Select the Fluke

975 AirMeter volume flow rate,

rectangular duct, and enter 12

inches by 12 inches dimension.

This will result in a CFM calculation that equals the average FPM

3 Fluke Corporation Measuring air velocity with the Fluke 975 AirMeter: Using the velocity probe

calculation. The calculated CFM

is then multiplied by the GRD

manufacturer’s Ak factor for the

actual CFM.

CFM (cubic feet per minute) = Ak x V

avg

Ak = Effective area in square feet

V

= Average face velocity in feet per minute

avg

Miscellaneous velocity

readings

Ventilation air is often supplied

through the outdoor air hood of a

packaged rooftop unit. Within the

hood is a bank of bug screens

that can be traversed in a similar

manner as return grilles. Enter

the volume flow rate function of the Fluke 975 AirMeter,

select rectangular duct, enter

the dimensions of the bank of

bug screens, capture a velocity

reading approximately every six

inches, and let the AirMeter calculate the CFM of ventilation air.

When the balance between

outdoor air intake and exhaust

air is incorrect, a potential for

roof or building damage exists,

and occupants entering a building can be confronted with an

objectionable wind when the

doors are opened. Building pressurization should be limited to

0.02 in to 0.1 in water column

(w.c.) and best if kept below

0.05 inches w.c. The velocity

probe can be used at the building entrance to help evaluate

building pressure. A 1300 FPM

air velocity through an open door

equates to over 0.1 inches w.c.

building pressurization, and a 15

mph wind in the face.

Fluke. Keeping your world

up and running.™

Fluke Corporation

PO Box 9090, Everett, WA USA 98206

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2006 Fluke Corporation. All rights reserved.

Printed in U.S.A. 10/2006 2786472 A-EN-N Rev A

Loading...

Loading...