Page 1

®

8845A/8846A

Digital Multimeter

Users Manual

July 2006

© 2006 Fluke Corporation. All rights reserved.

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is one year and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

To register your product online, visit register.fluke.com

Page 3

Table of Contents

Chapter Title Page

1 Introduction and Specifications......................................................... 1-1

Introduction........................................................................................................ 1-3

Manual Set ......................................................................................................... 1-3

About this Manual ............................................................................................. 1-4

Safety Information ............................................................................................. 1-4

General Safety Summary............................................................................... 1-4

Symbols ......................................................................................................... 1-6

Instrument Security Procedures ......................................................................... 1-6

Volatile Memory ........................................................................................... 1-6

Non Volatile Memory.................................................................................... 1-6

Media Memory (8846A Only)....................................................................... 1-7

Accessories ........................................................................................................ 1-7

General Specifications ....................................................................................... 1-9

Power............................................................................................................. 1-9

Dimensions.................................................................................................... 1-9

Display........................................................................................................... 1-9

Environment .................................................................................................. 1-9

Safety............................................................................................................. 1-9

EMC .............................................................................................................. 1-9

Triggering...................................................................................................... 1-9

Memory ......................................................................................................... 1-10

Math Functions.............................................................................................. 1-10

Electrical........................................................................................................ 1-10

Remote Interfaces.......................................................................................... 1-10

Warranty........................................................................................................ 1-10

Electrical Specifications .................................................................................... 1-10

DC Voltage Specifications ............................................................................ 1-10

AC Voltage Specifications ............................................................................ 1-11

Resistance...................................................................................................... 1-13

DC Current .................................................................................................... 1-15

AC Current .................................................................................................... 1-16

Frequency ...................................................................................................... 1-18

Capacitance (8846A Only) ............................................................................ 1-19

Temperature (8846A only) ............................................................................ 1-19

Continuity...................................................................................................... 1-19

i

Page 4

8845A/8846A

Users Manual

Diode Test ..................................................................................................... 1-20

Measurement Rates ....................................................................................... 1-20

2 Preparing the Meter for Operation..................................................... 2-1

Introduction........................................................................................................ 2-3

Unpacking and Inspecting the Meter ................................................................. 2-3

Contacting Fluke................................................................................................ 2-3

Storing and Shipping the Meter ......................................................................... 2-3

Power Considerations ........................................................................................ 2-3

Selecting the Line Voltage ............................................................................ 2-4

Replacing the Fuses....................................................................................... 2-4

Connecting to Line Power ................................................................................. 2-7

Turning Power-On ............................................................................................. 2-8

Adjusting the Bail .............................................................................................. 2-8

Installing the Meter in an Equipment Rack ....................................................... 2-8

Cleaning the Meter............................................................................................. 2-9

3 Front-Panel Operation ........................................................................ 3-1

Introduction........................................................................................................ 3-3

Controls and Indicators...................................................................................... 3-3

Front-Panel Feature Descriptions .................................................................. 3-3

Display Panel................................................................................................. 3-4

Rear-Panel Connectors .................................................................................. 3-6

Adjusting the Meter’s Range......................................................................... 3-7

Navigating the Front-Panel Menu...................................................................... 3-7

Configuring the Meter for a Measurement ........................................................ 3-7

Setting the Display Resolution ...................................................................... 3-7

Setting the AC Signal Filter .......................................................................... 3-8

Setting Continuity Resistance Threshold and Diode Test Parameters .......... 3-8

Setting the Default Temperature Scale (8846A Only) .................................. 3-9

Enabling Automatic Input Impedance........................................................... 3-9

Using the Analyze Functions ............................................................................. 3-9

Collecting Statistics on Measurements.......................................................... 3-10

Testing Using Limits ..................................................................................... 3-11

Setting an Offset Value ................................................................................. 3-12

Using MX+B ................................................................................................. 3-12

Using TrendPlot............................................................................................. 3-13

Using the Histogram Function....................................................................... 3-14

Controlling Trigger Functions ........................................................................... 3-15

Choosing a Trigger Source............................................................................ 3-15

Setting the Trigger Delay .............................................................................. 3-16

Setting the Number of Samples..................................................................... 3-16

Understanding the Measurement Complete Signal ....................................... 3-17

Accessing and Controlling Memory.............................................................. 3-17

Storing Readings in Memory......................................................................... 3-17

Recalling Readings from Memory ................................................................ 3-18

Storing Meter Configuration Information ..................................................... 3-18

Recalling a Meter Configuration ................................................................... 3-19

Managing Memory ........................................................................................ 3-20

Controlling System-Related Operations ............................................................ 3-21

Identifying Meter Errors................................................................................ 3-21

Querying the Firmware for Revision Level................................................... 3-21

Adjusting Display Brightness........................................................................ 3-21

Setting the Meter’s Date and Time................................................................ 3-21

ii

Page 5

Contents (continued)

Configuring the Remote Interface ..................................................................... 3-22

Checking the Meter’s Calibration Date ............................................................. 3-22

Resetting the Meter’s Default Settings .............................................................. 3-22

4 Making Measurements........................................................................ 4-1

Introduction........................................................................................................ 4-3

Selecting Function Modifiers............................................................................. 4-3

Activating the Secondary Display ..................................................................... 4-3

Measuring Voltage............................................................................................. 4-4

Measuring DC Voltage.................................................................................. 4-4

Measuring AC Voltage.................................................................................. 4-5

Measuring Frequency and Period ...................................................................... 4-6

Measuring Resistance ........................................................................................ 4-7

Making a Two-Wire Resistance Measurement ............................................. 4-7

Making a Four-Wire Resistance Measurement ............................................. 4-8

Measuring Current ............................................................................................. 4-9

Measuring DC Current .................................................................................. 4-10

Measuring AC Current .................................................................................. 4-11

Measuring Capacitance (8846A only) ............................................................... 4-12

Measuring RTD Temperature (8846A only) ..................................................... 4-13

Testing Continuity ............................................................................................. 4-14

Checking Diodes................................................................................................ 4-14

Making a Triggered Measurement..................................................................... 4-15

Setting the Trigger Mode............................................................................... 4-16

Setting a Trigger Delay ................................................................................. 4-16

Setting Number of Samples per Trigger........................................................ 4-16

Connecting an External Trigger .................................................................... 4-17

Monitoring the Measurement-Complete Signal................................................. 4-17

Appendices

A 2X4 Test Leads............................................................................................ A-1

B Errors........................................................................................................... B-1

C RS-232 Port Connections ............................................................................ C-1

Index

iii

Page 6

8845A/8846A

Users Manual

iv

Page 7

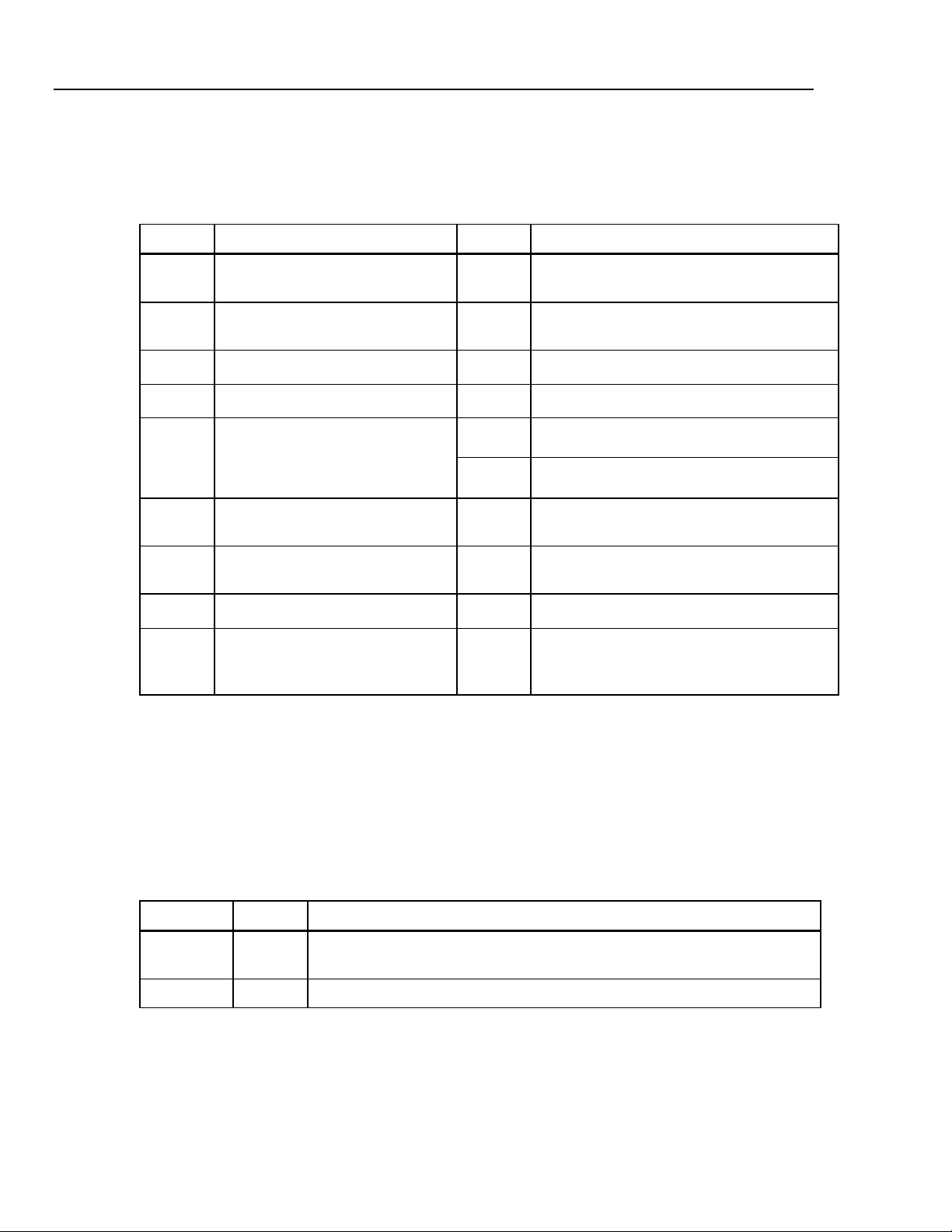

List of Tables

Table Title Page

1-1. Safety Information ................................................................................................. 1-5

1-2. Safety and Electrical Symbols................................................................................ 1-6

1-3. Volatile Memory Space.......................................................................................... 1-6

1-4. Non-volatile Memory Space .................................................................................. 1-7

1-3. Accessories............................................................................................................. 1-7

2-1. Line Voltage to Fuse Rating................................................................................... 2-5

2-2. Line Power Cord Types Available from Fluke ...................................................... 2-7

3-1. Front-Panel Controls and Connectors .................................................................... 3-3

3-2. Display Elements ................................................................................................... 3-5

3-3. Rear-Panel Conncetors........................................................................................... 3-6

C-1. RS-232 Pin to Signal List....................................................................................... C-1

v

Page 8

8845A/8846A

Users Manual

vi

Page 9

List of Figures

Figure Title Page

2-1. Replacing the Line Fuse......................................................................................... 2-5

2-2. Replacing the Current Input Fuses ......................................................................... 2-6

2-3. Line Power Cords Types Available from Fluke..................................................... 2-7

2-4. Bail Adjustment and Removal ............................................................................... 2-8

3-1. TrendPlot Display .................................................................................................. 3-14

3-2. Histogram Display ................................................................................................. 3-14

4-1. Input Connections for Voltage, Resistance, and Frequency Measurements .......... 4-4

4-2. Input Connections for 4-Wire Resistance Measurements ...................................... 4-8

4-3. Input Connections for 4-wire ohms using 2x4 wire leads...................................... 4-9

4-4. Input Connections for Current Measurements Below 120 mA.............................. 4-10

4-5. Input Connections for Current Measurements Above 120 mA.............................. 4-10

4-6. Measuring Capacitance .......................................................................................... 4-12

4-7. Temperature Measurements ................................................................................... 4-13

4-8. Diode Testing Connections .................................................................................... 4-15

4-9. TRIG I/O Pin-out Description................................................................................ 4-17

vii

Page 10

8845A/8846A

Users Manual

viii

Page 11

Chapter 1

Introduction and Specifications

Title Page

Introduction........................................................................................................1-3

Manual Set .........................................................................................................1-3

About this Manual .............................................................................................1-4

Safety Information .............................................................................................1-4

General Safety Summary...............................................................................1-4

Symbols .........................................................................................................1-6

Instrument Security Procedures .........................................................................1-6

Volatile Memory ...........................................................................................1-6

Non Volatile Memory....................................................................................1-7

Media Memory (8846A Only).......................................................................1-7

Accessories ........................................................................................................1-7

General Specifications .......................................................................................1-9

Power.............................................................................................................1-9

Dimensions....................................................................................................1-9

Display...........................................................................................................1-9

Environment ..................................................................................................1-9

Safety.............................................................................................................1-9

EMC ..............................................................................................................1-9

Triggering......................................................................................................1-9

Memory .........................................................................................................1-10

Math Functions..............................................................................................1-10

Electrical........................................................................................................1-10

Remote Interfaces..........................................................................................1-10

Warranty........................................................................................................1-10

Electrical Specifications ....................................................................................1-10

DC Voltage Specifications ............................................................................1-10

AC Voltage Specifications ............................................................................1-11

Resistance......................................................................................................1-13

DC Current ....................................................................................................1-15

AC Current ....................................................................................................1-16

Frequency ......................................................................................................1-18

Capacitance (8846A Only) ............................................................................1-19

Temperature (8846A only) ............................................................................1-19

Continuity......................................................................................................1-19

1-1

Page 12

8845A/8846A

Users Manual

Diode Test .....................................................................................................1-20

Measurement Rates .......................................................................................1-20

1-2

Page 13

Introduction and Specifications

Introduction 1

Introduction

The 8845A and 8846A are 6-1/2 digit, dual-display multimeters designed for bench-top,

field service, and system applications. Their full complement of measurement functions

plus its RS-232, IEEE 488, and Ethernet Remote Interfaces makes these multimeters

ideal candidates for precision manual measurements and use in automated systems. For

portability, these multimeters include a carrying handle that also serves as a bail for

bench top operation.

There are a few feature differences between these two multimeters, and some

specifications are tighter for the 8846A. Features that exist in only one multimeter will be

identified with the addition of “8846A Only” by each feature that is found only in that

model. Separate specification tables are also used to clarify the differences between these

two models.

The following is a list of some of the features and functions:

• Bright, large-digit, wide-viewing-angle display

• Dual display for displaying two properties of an input signal (e.g., ac voltage in one

display and frequency in the other).

• Remote operation via IEEE 488, RS-232, and Ethernet interface.

• Trigger in and measurement-complete out

• Front panel USB port for optional memory (8846A Only)

• 6-1/2 digit resolution

• Half-rack width

• True rms ac

• 2 and 4-wire resistance measurements

• Extended 10 Ω and 1 GΩ ranges (8846A Only)

• Frequency measurements to 300 kHz (8846A to 1 MHz)

• Capacitance measurements (8846A Only)

• Temperature measurement (8846A Only)

• 10 A current capability

• Decibels (dB and dBm) with variable reference impedance and audio power

measurement capability

• Input terminals on both front and rear panels of the meter

• Closed-case calibration (no internal calibration adjustments)

Manual Set

The manual set for these multimeters consists of a Users Manual and Programmers

Manual on a CD ROM. The Users Manual contains information on specifications, setup,

and operating from the front panel. The Programmers Manual covers operating the Meter

from a PC or controller.

1-3

Page 14

8845A/8846A

Users Manual

About this Manual

Safety Information

This is the Users Manual for the 8845A and 8846A Digital Multimeters (hereafter

referred to as the Meter). It contains all of the information a new user will need to operate

the Meter effectively. The manual is divided into the following chapters:

Chapter 1 “Introduction and Specifications” provides information on how to safely

use the Meter, standard and optional accessories, and specifications.

Chapter 2 “Preparing for Operation” provides information on setting the Meter’s line

voltage, connecting it to a power source, and turning the Meter on.

Chapter 3 “Front Panel Operation” introduces the controls and connections on the

front and rear panels of the Meter.

Chapter 4 “Making Measurements” provides detailed information on using the Meter

to make electrical measurements.

Appendices

This section addresses safety considerations and describes symbols that may appear on

the Meter or in the manual.

A X Warning statement identifies conditions or practices that could result in injury or

death.

A W Caution statement identifies conditions or practices that could result in damage to

the Meter or equipment to which it is connected.

To avoid electric shock, personal injury, or death, carefully read

the information under “Safety Information” before attempting to

install, use, or service the Meter.

General Safety Summary

This instrument has been designed and tested in accordance with the European standard

publication EN 61010-1:2001 and U.S. / Canadian standard publications UL 61010-1A1

and CAN/CSA-C22.2 No.61010.1. The Meter has been supplied in a safe condition.

This manual contains information and warnings that must be observed to keep the

instrument in a safe condition and ensure safe operation.

To use the Meter correctly and safely, read and follow the precautions in Table 1-1, and

follow all the safety instructions or warnings given throughout this manual that relate to

specific measurement functions. In addition, follow all generally accepted safety

practices and procedures required when working with and around electricity.

XW Warning

1-4

Page 15

Introduction and Specifications

Table 1-1. Safety Information

Safety Information 1

XW Warning

To avoid possible electric shock, personal injury, or death, read the following before using

the Meter:

• Use the Meter only as specified in this manual, or the protection provided by the Meter

might be impaired.

• Do not use the Meter in wet environments.

• Inspect the Meter before using it. Do not use the Meter if it appears damaged.

• Inspect the test leads before use. Do not use them if insulation is damaged or metal is

exposed. Check the test leads for continuity. Replace damaged test leads before using

the Meter.

• Verify the Meter's operation by measuring a known voltage before and after using it. Do

not use the Meter if it operates abnormally. Protection may be impaired. If in doubt, have

the Meter serviced.

• Whenever it is likely that safety protection has been impaired, make the Meter inoperative

and secure it against any unintended operation.

• Have the Meter serviced only by qualified service personnel.

• Do not apply more than the rated voltage, as marked on the Meter, between the terminals

or between any terminal and earth ground.

• Always use the power cord and connector appropriate for the voltage and outlet of the

country or location in which you are working.

• Remove test leads from the Meter before opening the case.

• Never remove the cover or open the case of the Meter without first removing it from the

main power source.

• Never operate the Meter with the cover removed or the case open.

• Use caution when working with voltages above 30 V ac rms, 42 V ac peak, or 42 V dc.

These voltages pose a shock hazard.

• Use only the replacement fuse(s) specified by the manual.

• Use the proper terminals, function, and range for your measurements.

• Do not operate the Meter around explosive gas, vapor, or dust.

• When using probes, keep your fingers behind the finger guards.

• When making electrical connections, connect the common test lead before connecting

the live test lead; when disconnecting, disconnect the live test lead before disconnecting

the common test lead.

• Disconnect circuit power and discharge all high-voltage capacitors before testing

resistance, continuity, diodes, or capacitance.

• Before measuring current, check the Meter's fuses and turn OFF power to the circuit

before connecting the Meter to the circuit.

• When servicing the Meter, use only specified replacement parts.

1-5

Page 16

8845A/8846A

Users Manual

Symbols

Table 1-2 is a list of safety and electrical symbols that appear on the Meter or in this

manual.

Table 1-2. Safety and Electrical Symbols

Symbol Description Symbol Description

W

X

B

F

D

or

C

R

Y

T

h

Risk of danger. Important

information. See manual

Hazardous voltage. Voltage > 30 V

dc or ac peak might be present

AC (Alternating Current)

DC (Direct Current)

AC or DC (Alternating or Direct

Current)

Continuity test or continuity beeper

tone

Potentially hazardous voltage

Double insulated

Static awareness. Static discharge

can damage part(s)

O

J

E

G

I

Y

U

CAT II

<

~

Display ON / OFF

Earth ground

Capacitance

Diode

Fuse

Digital signal

Maintenance or Service

IEC 61010 Overvoltage (installation or

measurement) Category 2.

Recycle

Do not dispose of this product as unsorted

municipal waste. Contact Fluke or a qualified

recycler for disposal

1-6

Instrument Security Procedures

This section describes the Meter’s memory elements and the procedures for clearing

them.

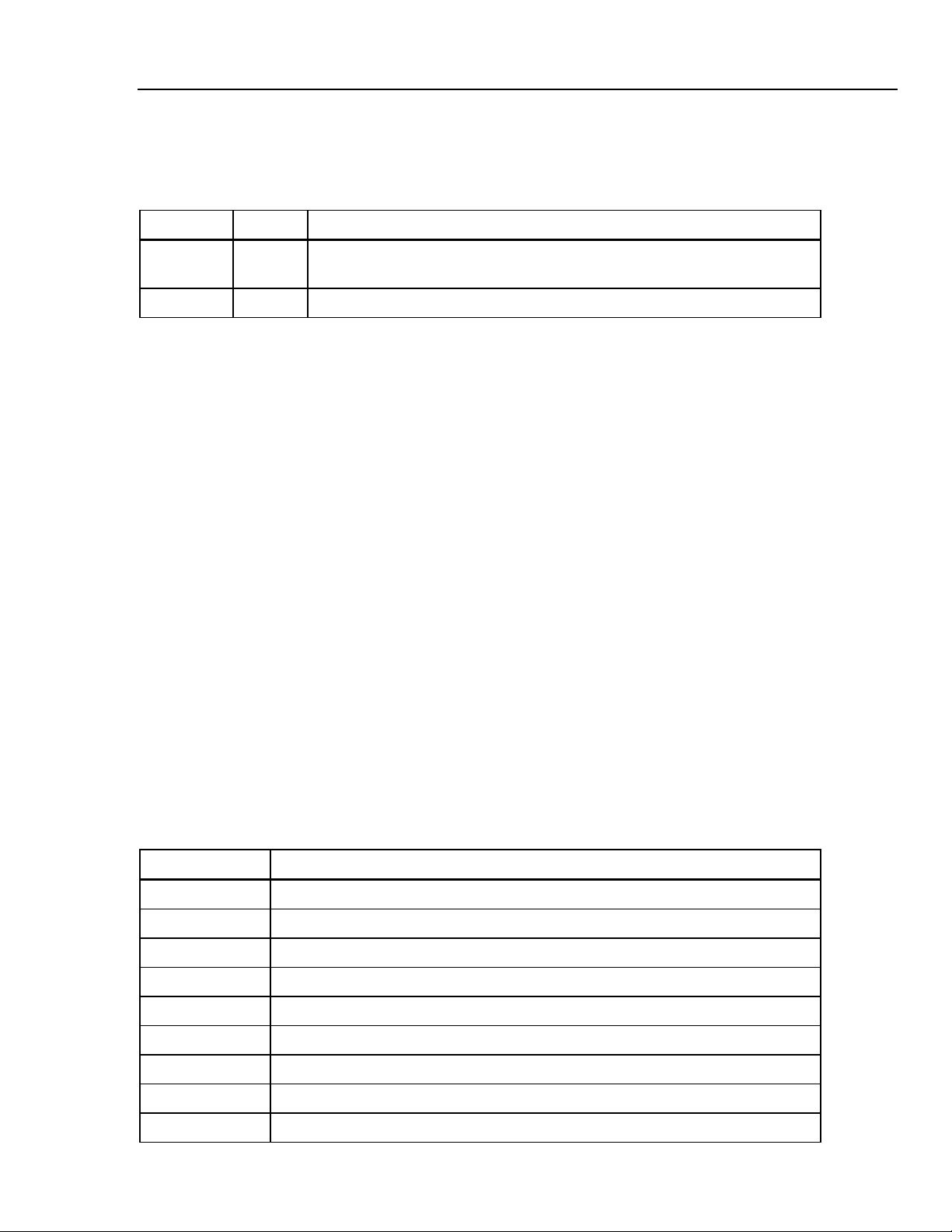

Volatile Memory

Table 1-3 lists the Meter’s volatile memory elements.

Table 1-3. Volatile Memory Space

Type Size Function

SDRAM 128 MB Out-guard measurement data, user strings, temporary configuration information,

and Ethernet Host name.

SRAM 4 MB In-guard Measurement data and configuration information.

To clear both volatile memory elements listed in Table 1-3:

1. Press M.

2. Select the MANAGE MEMORY soft key.

3. Select the ERASE MEMORY soft key.

Page 17

Introduction and Specifications

Accessories 1

Non Volatile Memory

Table 1-4 lists the Meter’s non-volatile memory elements.

Table 1-4. Non-volatile Memory Space

Type Size Function

Flash 128 MB Application program storage, user string, user data, user remote interface

settings.

Flash 4 MB FPGA hardware setup, application program storage, calibration constants.

To clear the 128 MB of non-volatile flash memory listed in Table 1-4:

1. Press M.

2. Select the MANAGE MEMORY soft key.

3. Select the ERASE MEMORY soft key.

This process clears only the user accessible portion of memory.

Note

The 4 MB non-volatile memory element is not usable and cannot be cleared

by the user.

Media Memory (8846A Only)

The 8846A has a front-panel USB port for connecting flash memory modules up to 2

Gigabytes to store Meter configuration and measurement data. To clear a memory

module while connected to the 8846A:

1. Press M.

2. Select the MANAGE MEMORY soft key.

3. Select the ERASE USB MEMORY soft key.

Accessories

Table 1-3 lists the available accessories for the 8845A and 8846A.

Table 1-5. Accessories

Model/Fluke PN Description

TL71 Premium Test Lead Set

6303 Kelvin Probes

6730 Kelvin Lead Set with Alligator Clips

5940 Kelvin clip set

5143 SMD Test Tweezer Leads

6275 Precision Electronic Probe Set

6344 Basic Electronic DMM Test Set

884X-Short 4-Wire Short

884X-Case Black plastic case

1-7

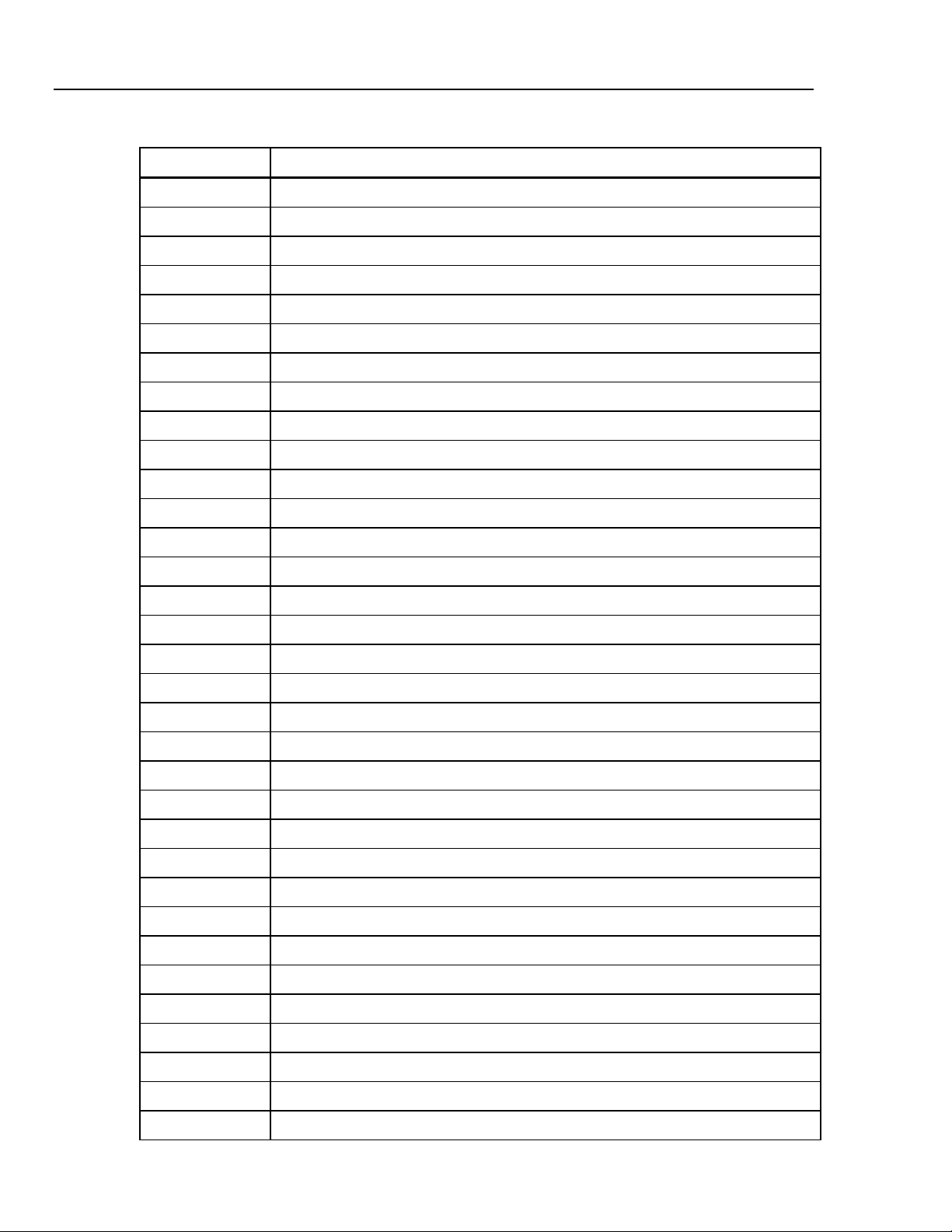

Page 18

8845A/8846A

Users Manual

Table 1-3. Accessories (cont)

Model/Fluke PN Description

TL910 Precision Electronic Probe Set

TL80A Basic Electronic DMM Test Set

TL2X4W-PT 2X4 Wire Ohms Test Lead

TL2X4W-TWZ 2X4 Wire Ohms SMD Test Tweezer

6262-02 Test Probe Tip Adapter, Extended Fine Point

6263-02 Test Probe Tip Adapter, IC Probe Tip

803293 Fuse, 11 A, 1000 V, Fast, 406INX1.5IN, Buik

943121 Fuse, 440 mA, 1000 V, Fast, 406X1.375, Buik

884X-RTD 100 Ohm RTD Temperature Probe

Y8846 Rackmount Kit. Allows meter to be mounted in a standard 19-inch rack.

Y8021 Shielded IEEE 488 one-meter (39.4 inches) cable, with plug and jack at each end.

Y8022 Shielded IEEE 488 two-meter (78.8 inches) cable, with plug and jack at each end.

884X-USB USB to RS-232 Cable Adapter

RS43 Shielded RS-232 Cable (2 Meters)

884X-ETH Ethernet Cable

884X-512M 512 Mbyte memory (8846A only)

884X-1G 1 Gbyte memory (8846A only)

FVF-SC5 FlukeView Forms, Basic Software

FVF-UG FlukeView Forms, Software Upgrade – No Cable

FVF-SC4 Extended FlukeView Forms with USB Cable

2132558 Calibration, traceable with data

1259800 Calibration, traceable without data

1256480 Calibration, Z540 traceable with data

1258910 Calibration, Z540 traceable, without data

1256990 Calibration, accredited

1024830 Agreement, Extended Warranty

2426684 Agreement, Calibration, Traceable, with data

1-8

1028820 Agreement, Calibration, Traceable, without data

1259170 Agreement, Calibration, Z540 Traceable, with data

1258730 Agreement, Calibration, Z540 Traceable, without data

1259340 Agreement, Calibration, Accredited

2441827 Agreement, Calibration, primary standards lab

1540600 Agreement, Calibration, artifact

Page 19

Introduction and Specifications

General Specifications 1

General Specifications

Power

Voltage

100 V Setting ...................................................... 90 V to 110 V

120 V Setting ...................................................... 108 V to 132 V

220 V Setting ...................................................... 198 V to 242 V

240 V Setting ...................................................... 216 V to 264 V

Frequency ............................................................... 47 Hz to 440 Hz. Automatically sensed at power-on.

Power Consumption................................................ 28 VA peak (12 Watt average)

Dimensions

Height...................................................................... 88 mm (3.46 in.)

Width....................................................................... 217 mm (8.56 in.)

Depth ...................................................................... 297 mm (11.7 in.)

Weight..................................................................... 3.6 kg (8.0 Ibs.)

Shipping Weight...................................................... 5.0 kg (11.0 lbs)

Display

Vacuum Fluorescent Display, dot matrix

Environment

Temperature

Operating ............................................................ 0 °C to 55 °C

Storage ............................................................... -40 °C to 70 °C

Warm Up............................................................. 1 hour to full uncertainty specifications

Relative Humidity (non-condensing)

Operating ............................................................ 0 °C to 28 °C <90 %

Storage ............................................................... -40 °C to 70 °C <95 %

Altitude

Operating ............................................................ 2,000 Meters

Storage ............................................................... 12,000 Meters

Vibration and Shock................................................ Complies with Mil-T-28800E Type III, Class 5 (Sine Only)

28 °C to 40 °C <80 %

40 °C to 55 °C <50 %

Safety

Designed to comply with IEC 61010-1:2000-1, UL 61010-1A1, CAN/CSA-C22.2 No. 61010.1, CAT I 1000V/CAT II 600V

EMC

Designed to comply with IEC 61326-1:2000-11 (EMC) when used with shielded communications cables. This Meter has

shown susceptibity to radiated frequencies greater than 1 V/m from 250 to 450 MHz while in the 100 µA range.

Triggering

Samples per Trigger ...........................................1 to 50,000

Trigger Delay ...................................................... 0 S to 3600 S; in 10 µS increments

External Trigger Delay ........................................ <1 mS

External Trigger Jitter ......................................... <500 µS

Trigger Input ....................................................... TTL Levels

Trigger Output..................................................... 5 V maximum. (Open collector)

1-9

Page 20

8845A/8846A

Users Manual

Memory

Math Functions

Zero, dBm, dB, MX+B, Trend-plot, Histogram, Statistics (min/max/average/standard deviation), and Limit Test

Electrical

Input Protection .................................................... 1000 V all ranges

Overrange .............................................................. 20 % on all ranges except 1000 V dc, 1000 V ac (8846A),

Remote Interfaces

Warranty

8845A ................................................................. 10,000 measurements, Internal only

8846A ................................................................. 10,000 measurements, Internal and up to 2 Gigabyte capacity with

USB memory module (available separately. see “Accessories”) through

front-panel USB port

750 V ac (8845A), Diode, and 10 A ranges

RS-232 (RS-232 to USB cable available to connect the Meter to a PC USB port. See accessories)

IEEE 488.2

LAN

One year

Electrical Specifications

Accuracy specifications are valid for 6½ digit mode after at least a 1-hour warm-up with Auto Zero is enabled.

24-hour specifications are relative to calibration standards and assume a controlled electromagnetic environment per

EN 61326-1:2000-11

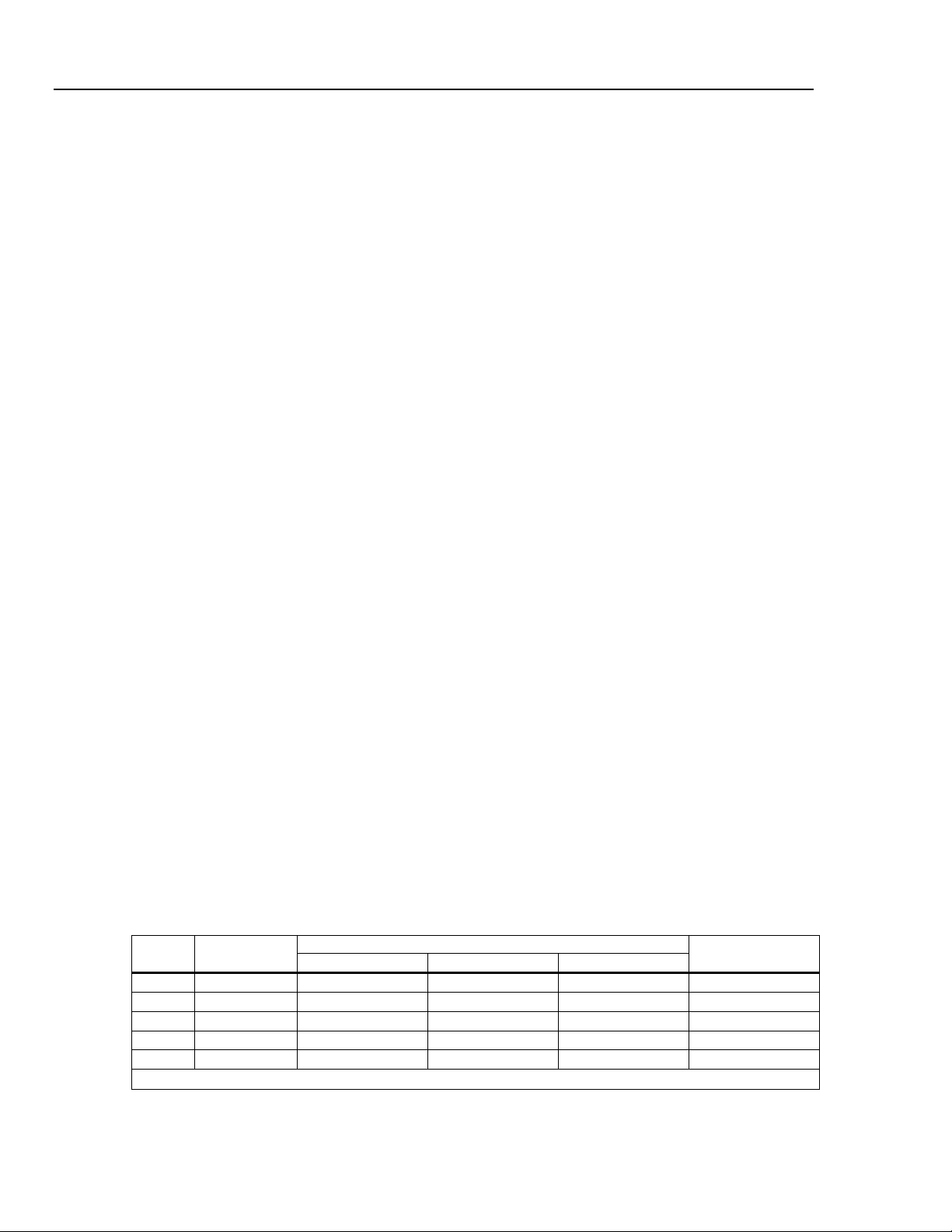

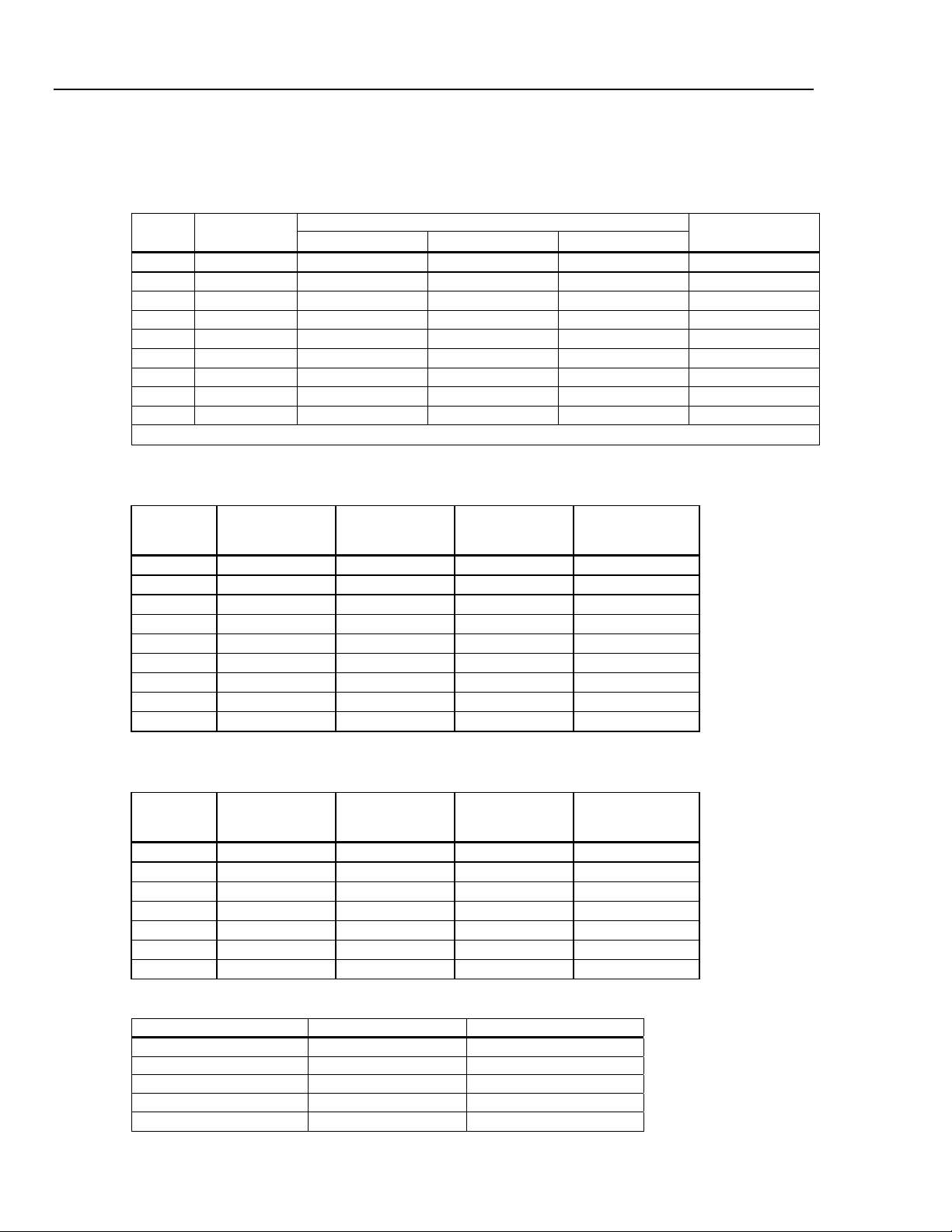

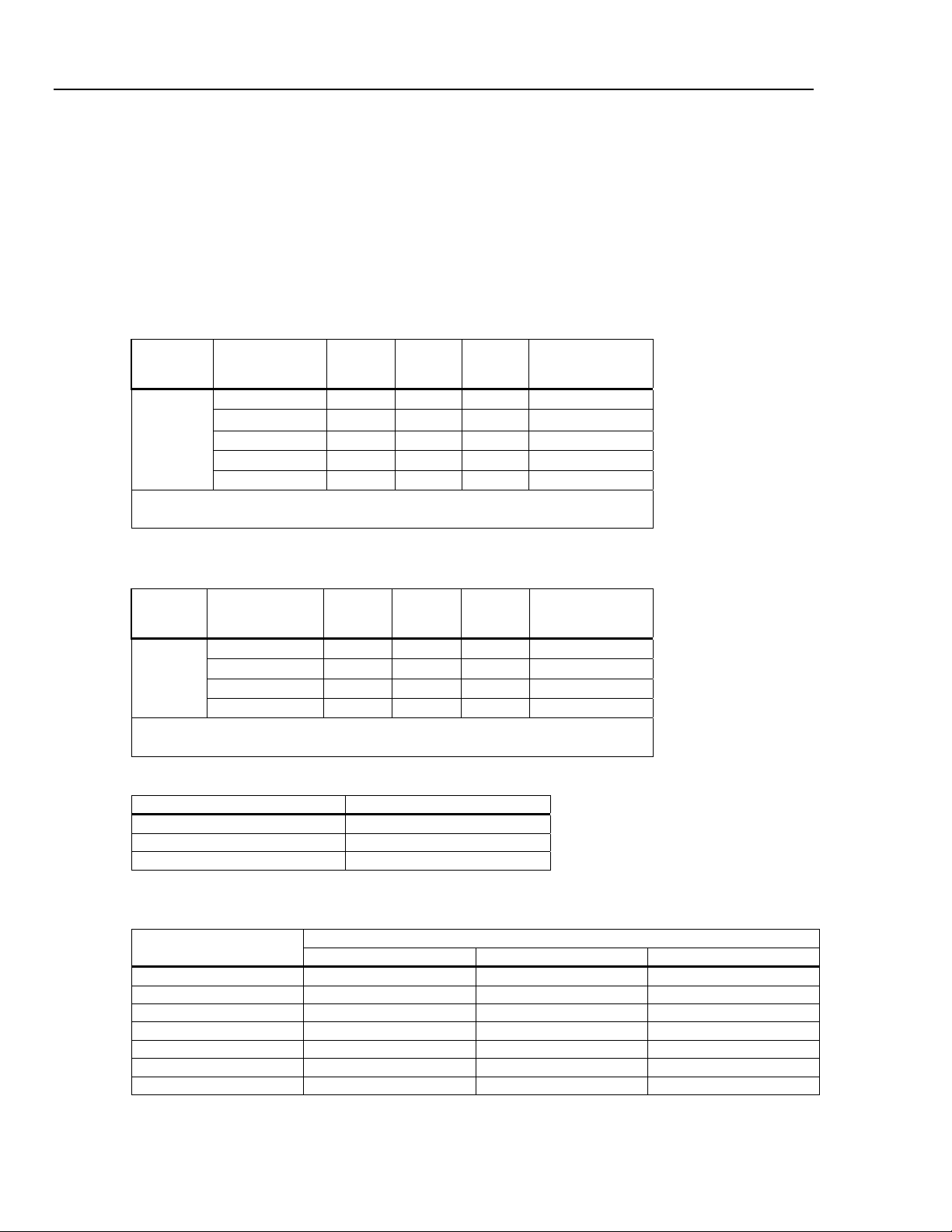

DC Voltage Specifications

Maximum Input...................................................... 1000 V on any range

Common Mode Rejection..................................... 140 dB at 50 or 60 Hz ± 0.1 % (1 kΩ unbalance)

Normal Mode Rejection ........................................ 60 dB for NPLC of 1 or greater with dc filter off and power line

Measurement Method ........................................... Multi-ramp A/D

A/D Linearity.......................................................... 0.0002 % of measurement + 0.0001 % of range

Input Bias Current................................................. <30 pA at 25 °C

Autozero Off Operation ........................................ Following instrument warm-up at calibration temperature ±1 °C and

Settling Considerations........................................ Measurement settling times are affected by source impedance, cable

Input Characteristics

Range

100 mV 100.0000 mV 10 µV 1 µV 100 nV

1 V 1.000000 V 100 µV 10 µV 1 µV

10 V 10.00000 V 1 mV 100 µV 10 µV

100 V 100.0000 V 10 mV 1 mV 100 µV

1000 V 1,000.000 V 100 mV 10 mV 1 mV

[1] Inputs beyond ±14 V are clamped through 200 kΩ typical. 10 MΩ is default input impedance.

Full Scale

(6½ Digits)

4½ Digits 5½ Digits 6½ Digits

frequency ±0.1 %

100 dB for NPLC of 1 or greater with dc filter on and power line

frequency ±0.1 %

less than 10 minutes, add error: 0.0002 % range additional error + 5

µV.

dielectric characteristics, and input signal changes.

Resolution

Input Impedance

10 MΩ or >10 GΩ

10 MΩ or >10 GΩ

10 MΩ or >10 GΩ

10 MΩ ±1%

10 MΩ ±1%

[1]

[1]

[1]

1-10

Page 21

Introduction and Specifications

Electrical Specifications 1

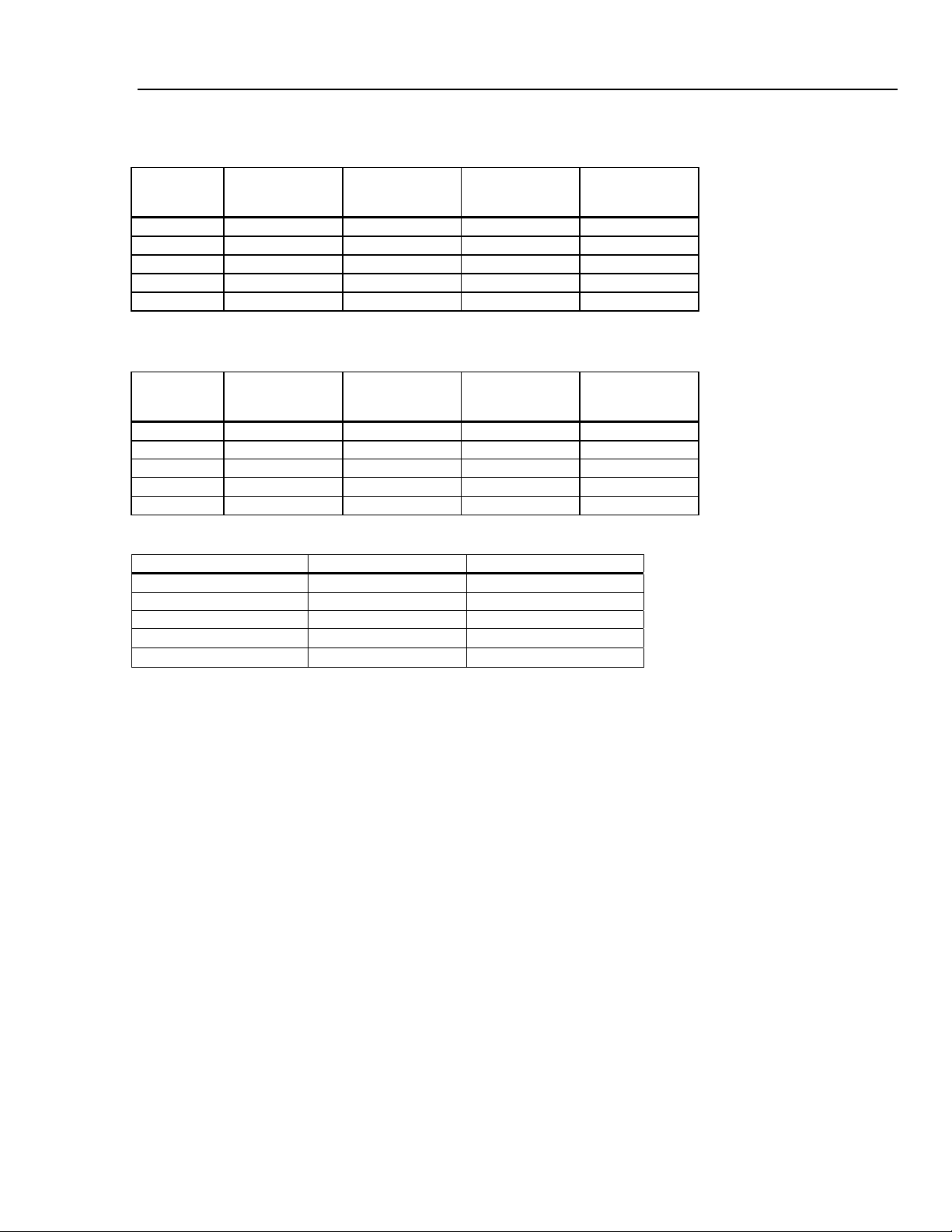

8846A Accuracy

Accuracy is given as ± (% measurement + % of range)

Range

100 mV 0.0025 + 0.003 0.0025 + 0.0035 0.0037 + 0.0035 0.0005 + 0.0005

1 V 0.0018 + 0.0006 0.0018 + 0.0007 0.0025 + 0.0007 0.0005 + 0.0001

10 V 0.0013 + 0.0004 0.0018 + 0.0005 0.0024 + 0.0005 0.0005 + 0.0001

100 V 0.0018 + 0.0006 0.0027 + 0.0006 0.0038 + 0.0006 0.0005 + 0.0001

1000 V 0.0018 + 0.0006 0.0031 + 0.001 0.0041 + 0.001 0.0005 + 0.0001

24 Hour

(23 ± 1 °C)

90 Days

(23 ± 5 °C)

1 Year

(23 ± 5 °C)

Temperature

Coefficient/ °C

Outside 18 to 28 °C

8845A Accuracy

Accuracy is given as ± (% measurement + % of range)

Range

100 mV 0.003 + 0.003 0.004 + 0.0035 0.005 + 0.0035 0.0005 + 0.0005

1 V 0.002 + 0.0006 0.003 + 0.0007 0.004 + 0.0007 0.0005 + 0.0001

10 V 0.0015 + 0.0004 0.002 + 0.0005 0.0035 + 0.0005 0.0005 + 0.0001

100 V 0.002 + 0.0006 0.0035 + 0.0006 0.0045 + 0.0006 0.0005 + 0.0001

1000 V 0.002 + 0.0006 0.0035 + 0.0010 0.0045 + 0.0010 0.0005 + 0.0001

24 Hour

(23 ± 1 °C)

90 Days

(23 ± 5 °C)

1 Year

(23 ± 5 °C)

Temperature

Coefficient/ °C

Outside 18 to 28 °C

Additional Errors

Digits NPLC Additional Noise Error

6½ 100 0 % of range

6½ 10 0 % of range

5½ 1 0.001 % of range

5½ .2

4½ 0.02

0.001 % of range + 20 µV

0.01 % of range + 20 µV

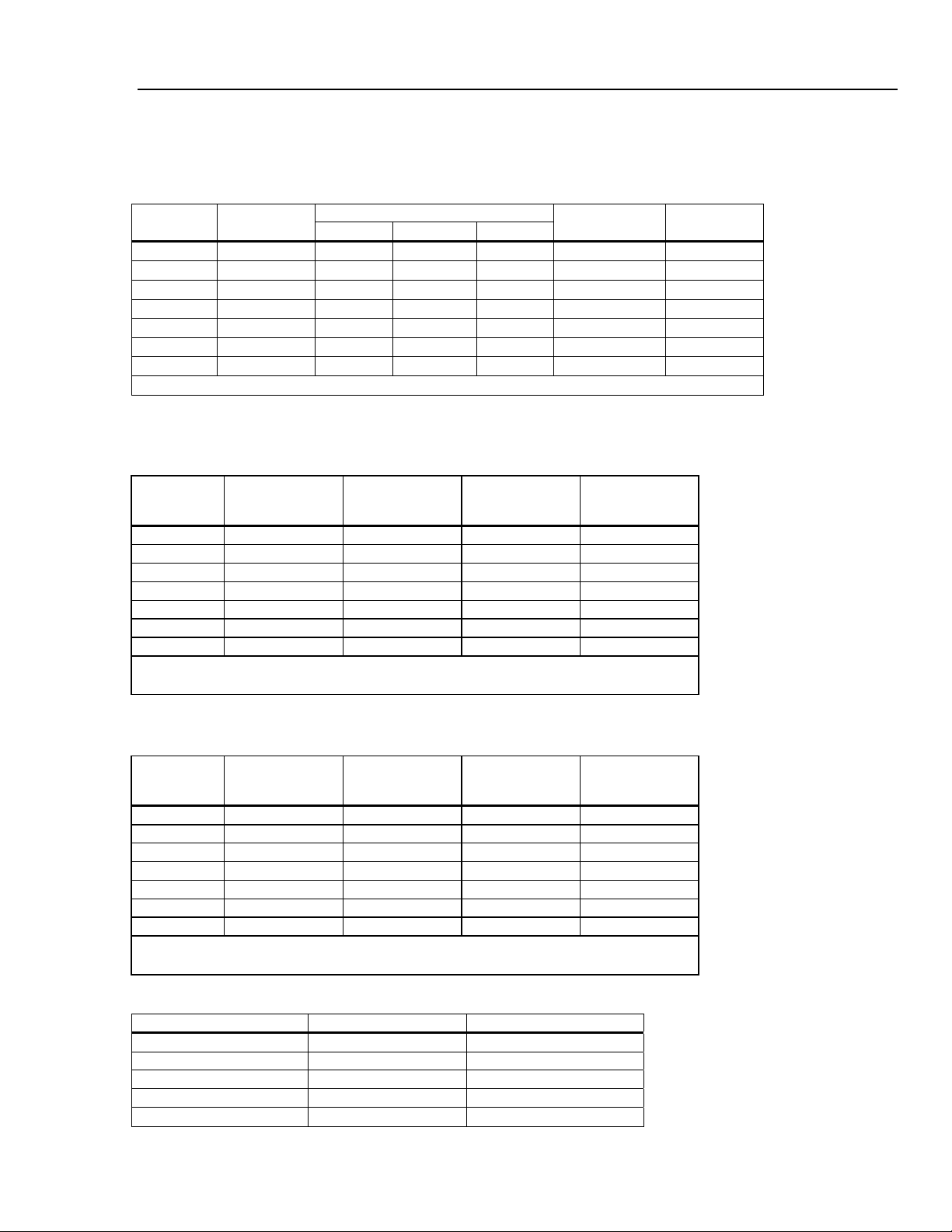

AC Voltage Specifications

AC Voltage specifications are for ac sinewave signals >5 % of range. For inputs from 1 % to 5 % of range and <50 kHz,

add an additional error of 0.1 % of range, and for 50 to 100 kHz, add 0.13 % of range.

Maximum Input...................................................... 750 V rms or 1000 V peak (8845A), 1000 V rms or 1414 V peak

(8846A) or 8 x 10

range.

Measurement Method ........................................... AC-coupled true-rms. Measures the ac component of input with up to

1000 V dc bias on any range.

AC Filter Bandwidth:

Slow .................................................................... 3 Hz – 300 kHz

Medium ............................................................... 20 Hz – 300 kHz

Fast..................................................................... 200 Hz – 300 kHz

Common Mode Rejection..................................... 70 dB at 50 Hz or 60 Hz ±0.1 % (1 kΩ unbalance)

Maximum Crest Factor .........................................5:1 at Full Scale

Additional Crest Factor Errors (<100 Hz) ........... Crest Factor 1-2, 0.05 % of full scale

Crest Factor 2-3, 0.2 % of full scale

Crest Factor 3-4, 0.4 % of full scale

Crest Factor 4-5, 0.5 % of full scale

7

Volts-Hertz product (whichever is less) for any

1-11

Page 22

8845A/8846A

Users Manual

Input Characteristics

Range

100 mV 100.0000 mV 10 µV 1 µV 100 nV

1 V 1.000000 V 100 µV 10 µV 1 µV

10 V 10.00000 V 1 mV 100 µV 10 µV

100 V 100.0000 V 10 mV 1 mV 100 µV

1000 V 1,000.000 V 100 mV 10 mV 1 mV

8846A Accuracy

Accuracy is given as ± (% measurement + % of range)

100 mV

1 V

10 V

100 V

1000 V

Full Scale

(6½ Digits)

Range Frequency

3 – 5 Hz 1.0 + 0.03 1.0 + 0.04 1.0 + 0.04 0.1 + 0.004

5 – 10 Hz 0.35 + 0.03 0.35 + 0.04 0.35 + 0.04 0.035 + 0.004

10 Hz – 20 kHz 0.04 + 0.03 0.05 + 0.04 0.06 + 0.04 0.005 + 0.004

20 – 50 kHz 0.1 + 0.05 0.11 + 0.05 0.12 + 0.05 0.011 + 0.005

50 – 100 kHz 0.55 + 0.08 0.6 + 0.08 0.6 + 0.08 0.06 + 0.008

100 – 300 kHz

[1]

4.0 + 0.50 4.0 + 0.50 4.0 + 0.50 0.20 + 0.02

3 – 5 Hz 1.0 + 0.02 1.0 + 0.03 1.0 + 0.03 0.1 + 0.003

5 – 10 Hz 0.35 + 0.02 0.35 + 0.03 0.35 + 0.03 0.035 + 0.003

10 Hz – 20 kHz 0.04 + 0.02 0.05 + 0.03 0.06 + 0.03 0.005 + 0.003

20 – 50 kHz 0.1 + 0.04 0.11 + 0.05 0.12 + 0.05 0.011 + 0.005

50 – 100 kHz 0.55 + 0.08 0.6 + 0.08 0.6 + 0.08 0.06 + 0.008

100 – 300 kHz

[1]

4.0 + 0.50 4.0 + 0.50 4.0 + 0.50 0.2 + 0.02

3 – 5 Hz 1.0 + 0.02 1.0 + 0.03 1.0 + 0.03 0.1 + 0.003

5 – 10 Hz 0.35 + 0.02 0.35 + 0.03 0.35 + 0.03 0.035 + 0.003

10 Hz – 20 kHz 0.04 + 0.02 0.05 + 0.03 0.06 + 0.03 0.005 + 0.003

20 – 50 kHz 0.1 + 0.04 0.11 + 0.05 0.12 + 0.05 0.011 + 0.005

50 – 100 kHz 0.55 + 0.08 0.6 + 0.08 0.6 + 0.08 0.06 + 0.008

100 – 300 kHz

[1]

4.0 + 0.50 4.0 + 0.50 4.0 + 0.50 0.2 + 0.02

3 – 5 Hz 1.0 + 0.02 1.0 + 0.03 1.0 + 0.03 0.1 + 0.003

5 – 10 Hz 0.35 + 0.02 0.35 + 0.03 0.35 + 0.03 0.035 + 0.003

10 Hz – 20 kHz 0.04 + 0.02 0.05 + 0.03 0.06 + 0.03 0.005 + 0.003

20 – 50 kHz 0.1 + 0.04 0.11 + 0.05 0.12 + 0.05 0.011 + 0.005

50 – 100 kHz 0.55 + 0.08 0.6 + 0.08 0.6 + 0.08 0.06 + 0.008

100 –- 300 kHz

[1]

4.0 + 0.50 4.0 + 0.50 4.0 + 0.50 0.2 + 0.02

3 – 5 Hz 1.0 + 0.02 1.0 + 0.03 1.0 + 0.03 0.1 + 0.003

5 – 10 Hz 0.35 + 0.02 0.35 + 0.03 0.35 + 0.03 0.035 + 0.003

10 Hz – 20 kHz 0.04 + 0.02 0.05 + 0.03 0.06 + 0.03 0.005 + 0.003

20 – 50 kHz 0.1 + 0.04 0.11 + 0.05 0.12 + 0.05 0.011 + 0.005

50 – 100 kHz

100 – 300 kHz

[1] Typically 30 % reading error at 1 MHz

[2] 1000 Volt range is limited to 8 X 10

[2]

0.55 + 0.08 0.6 + 0.08 0.6 + 0.08 0.06 + 0.008

[1][2]

4.0 + 0.5 4.0 + 0.50 4.0 + 0.50 0.2 + 0.02

Resolution

4½ Digits 5½ Digits 6½ Digits

24 Hour

(23 ± 1 °C)

7

volt-Hertz

90 Days

(23 ± 5 °C)

1 Year

(23 ± 5 °C)

Temperature

Coefficient/ °C

Outside 18 to 28 °C

Input Impedance

1 MΩ ±2 % shunted

by <100 pf

1-12

Page 23

Introduction and Specifications

Electrical Specifications 1

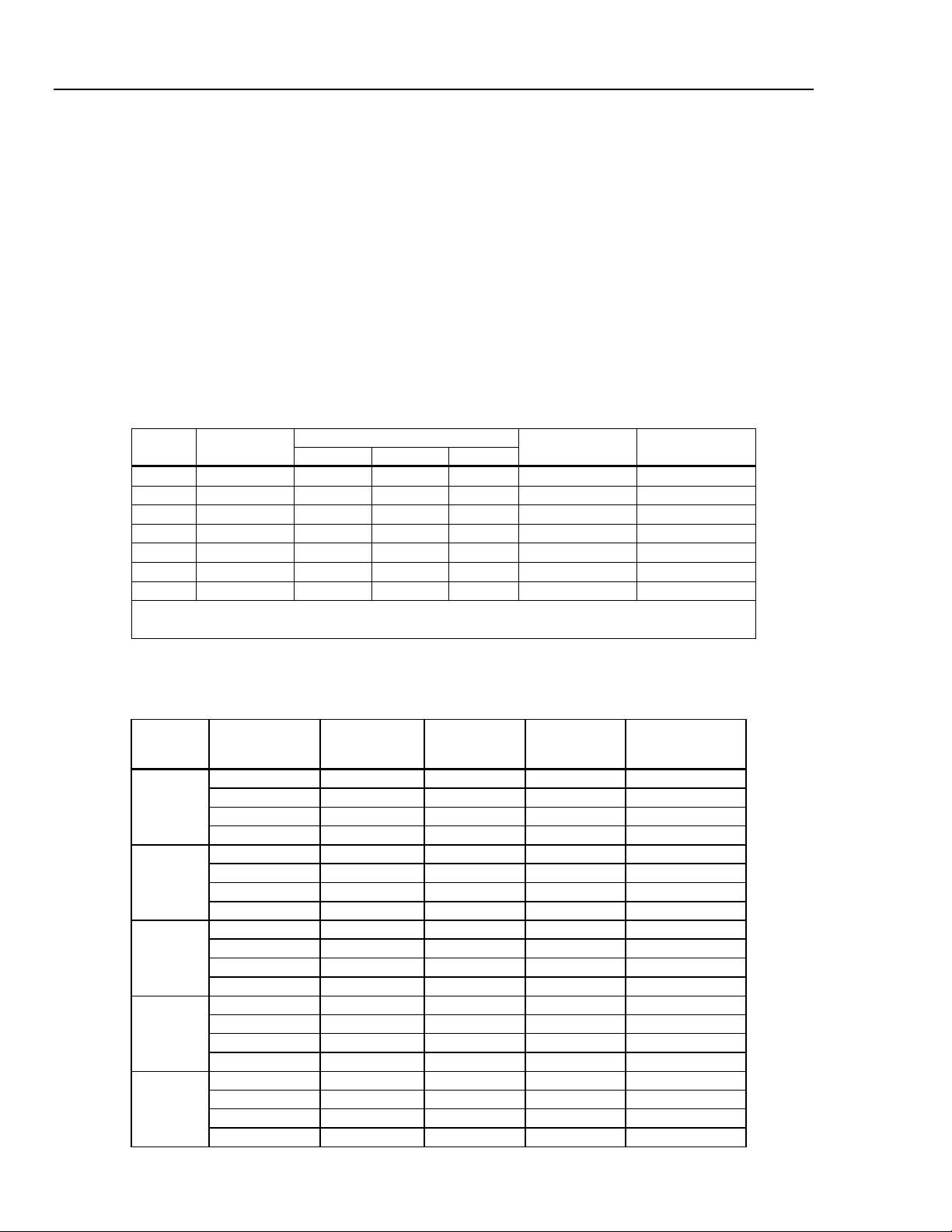

8845A Accuracy

Accuracy is given as ± (% measurement + % of range)

Range

100 mV

Frequency

(Hz)

3 – 5 Hz 1.0 + 0.03 1.0 + 0.04 1.0 + 0.04 0.10 + 0.004

5 – 10 Hz 0.35 + 0.03 0.35 + 0.04 0.35 + 0.04 0.035 + 0.004

10 Hz – 20 kHz 0.04 + 0.03 0.05 + 0.04 0.06 + 0.04 0.005 + 0.004

20 – 50 kHz 0.1 + 0.05 0.11 + 0.05 0.12 + 0.05 0.011 + 0.005

1 V

50 – 100 kHz 0.55 + 0.08 0.6 + 0.08 0.6 + 0.08 0.06 + 0.008

100 – 300 kHz

3 – 5 Hz 1.0 + 0.02 1.0 + 0.03 1.0 + 0.03 0.1 + 0.003

[1]

4.0 + 0.50 4.0 + 0.50 4.0 + 0.50 0.2 + 0.02

5 – 10 Hz 0.35 + 0.02 0.35 + 0.03 0.35 + 0.03 0.035 + 0.003

10 Hz – 20 kHz 0.04 + 0.02 0.05 + 0.03 0.06 + 0.03 0.005 + 0.003

20 – 50 kHz 0.1 + 0.04 0.11 + 0.05 0.12 + 0.05 0.011 + 0.005

10 V

50 – 100 kHz 0.55 + 0.08 0.6 + 0.08 0.6 + 0.08 0.06 + 0.008

100 – 300 kHz

3 – 5 Hz 1.0 + 0.02 1.0 + 0.03 1.0 + 0.03 0.1 + 0.003

[1]

4.0 + 0.50 4.0 + 0.50 4.0 + 0.50 0.2 + 0.02

5 – 10 Hz 0.35 + 0.02 0.35 + 0.03 0.35 + 0.03 0.035 + 0.003

10 Hz – 20 kHz 0.04 + 0.02 0.05 + 0.03 0.06 + 0.03 0.005 + 0.003

20 – 50 kHz 0.1 + 0.04 0.11 + 0.05 0.12 + 0.05 0.011 + 0.005

50 – 100 kHz 0.55 + 0.08 0.6 + 0.08 0.6 + 0.08 0.06 + 0.008

[1]

4.0 + 0.50 4.0 + 0.50 4.0 + 0.50 0.2 + 0.02

100 V

100 – 300 kHz

3 – 5 Hz 1.0 + 0.02 1.0 + 0.03 1.0 + 0.03 0.1 + 0.003

5 – 10 Hz 0.35 + 0.02 0.35 + 0.03 0.35 + 0.03 0.035 + 0.003

10 Hz – 20 kHz 0.04 + 0.02 0.05 + 0.03 0.06 + 0.03 0.005 + 0.003

20 – 50 kHz 0.1 + 0.04 0.11 + 0.05 0.12 + 0.05 0.011 + 0.005

50 – 100 kHz 0.55 + 0.08 0.6 + 0.08 0.6 + 0.08 0.06 + 0.008

[1]

4.0 + 0.50 4.0 + 0.50 4.0 + 0.50 0.2 + 0.02

750 V

100 – 300 kHz

3 –- 5 Hz 1.0 + 0.02 1.0 + 0.03 1.0 + 0.03 0.1 + 0.003

5 – 10 Hz 0.35 + 0.02 0.35 + 0.03 0.35 + 0.03 0.035 + 0.003

10 Hz – 20 kHz 0.04 + 0.02 0.05 + 0.03 0.06 + 0.03 0.005 + 0.003

20 – 50 kHz 0.1 + 0.04 0.11 + 0.05 0.12 + 0.05 0.011 + 0.005

50 – 100 kHz

100 – 300 kHz

[1] Typically 30 % reading error at 1 MHz

[2] 750 Volt range is limited to 8 X 10

[2]

0.55 + 0.08 0.6 + 0.08 0.6 + 0.08 0.06 + 0.008

[1] [2]

4.0 + 0.5 4.0 + 0.5 4.0 + 0.5 0.2 + 0.02

24 Hour

(23 ± 1 °C)

7

volt-Hertz

90 Days

(23 ± 5 °C)

1 Year

(23 ± 5 °C)

Temperature

Coefficient/ °C

Outside 18 to 28 °C

Additional Low Frequency Errors

Error is stated as % of reading.

Frequency

3HZ (slow) 20HZ (medium) 200HZ (fast)

AC Filter

10 – 20 Hz 0 0.25 –

20 – 40 Hz 0 0.02 –

40 – 100 Hz 0 0.01 0.55

100 – 200 Hz 0 0 0.2

200 Hz – 1 kHz 0 0 0.02

> 1 kHz 0 0 0

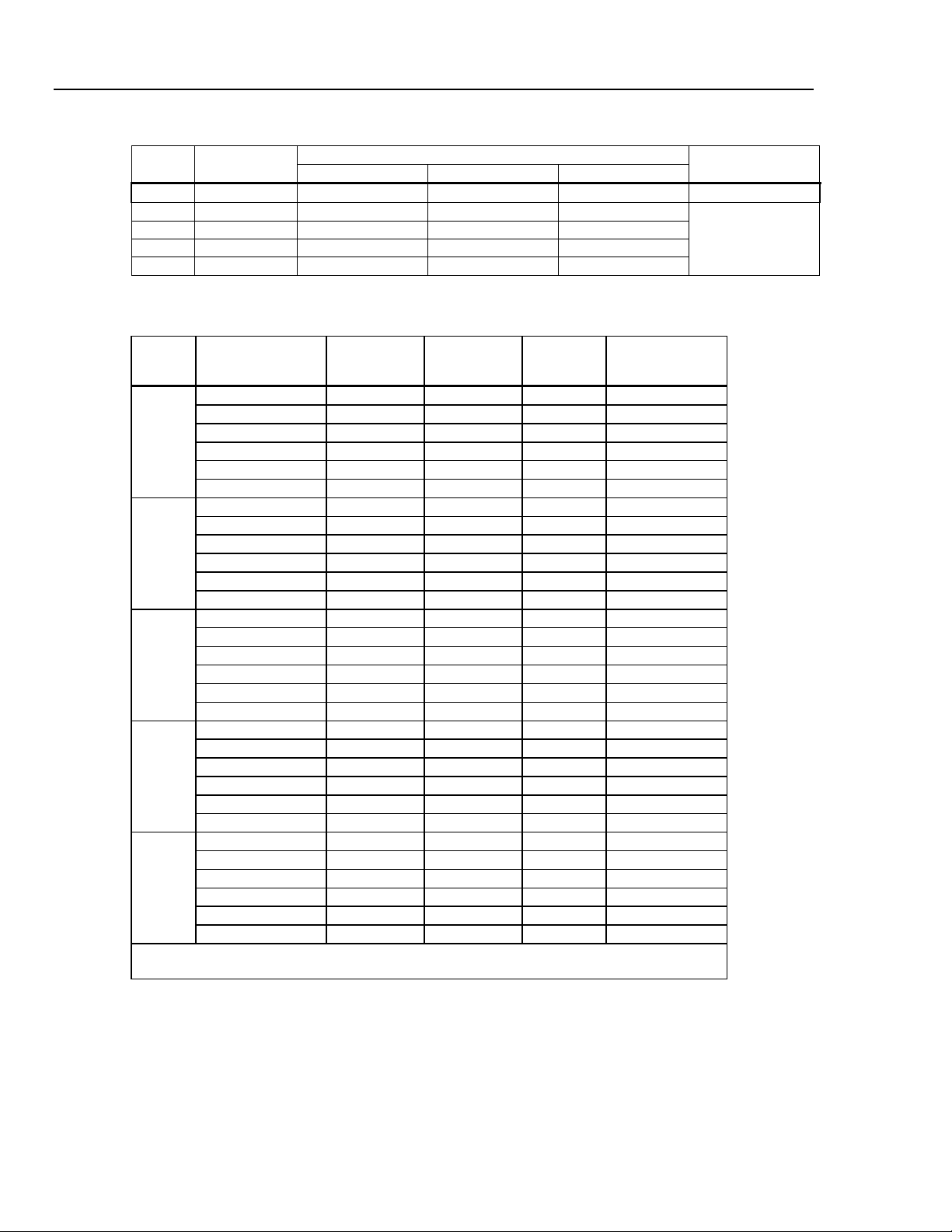

Resistance

Specifications are for 4-wire resistance function, 2 x 4-wire resistance, or 2-wire resistance with zero. If zero is not used,

add 0.2 Ω for 2-wire resistance plus lead resistance, and add 20 mΩ for 2 x 4-wire resistance function.

Measurement Method ........................................... Current source referenced to LO input.

1-13

Page 24

8845A/8846A

Users Manual

Max. Lead Resistance (4-wire ohms) ..................10 % of range per lead for 100 Ω, 1 kΩ ranges. 1 kΩ per lead on all

Input Protection .................................................... 1000 V on all ranges.

other ranges.

Input Characteristics

Range

[1]

10 Ω

100 Ω 100.0000 Ω 10 mΩ 1 mΩ 100 µΩ

1 kΩ 1.000000 kΩ 100 mΩ 10 mΩ 1 mΩ

10 kΩ 10.00000 kΩ 1 Ω 100 mΩ 10 mΩ 100 µA

100 kΩ 100.0000 kΩ 10 Ω 1 Ω 100 mΩ 10 µA

1 MΩ 1.000000 MΩ 100 Ω 10 Ω 1 Ω 10 µA

10 MΩ 10.00000 MΩ 1 kΩ 100 Ω 10 Ω 1 µA

100 MΩ 100.0000 MΩ 10 kΩ 1 kΩ 100 Ω 1 µA || 10 MΩ

1.0 GΩ

[1] 8846A Only

Full Scale

(6½ Digits)

10.00000 Ω 1 mΩ 100 µΩ 10 µΩ

[1]

1.000000 GΩ 100 kΩ 10 kΩ 1 kΩ 1 µA || 10 MΩ

4½ Digits 5½ Digits 6½ Digits

Resolution

Source Current

5 mA

1 mA

1 mA

8846A Accuracy

Accuracy is given as ± (% measurement + % of range)

Range

10 Ω 0.003 + 0.01 0.008 + 0.03 0.01+ 0.03 0.0006 + 0.0005

100 Ω 0.003 + 0.003 0.008 + 0.004 0.01 + 0.004 0.0006 + 0.0005

1 kΩ 0.002 + 0.0005 0.008 + 0.001 0.01 + 0.001 0.0006 + 0.0001

10 kΩ 0.002 + 0.0005 0.008 + 0.001 0.01 + 0.001 0.0006 + 0.0001

100 kΩ 0.002 + 0.0005 0.008 + 0.001 0.01 + 0.001 0.0006 + 0.0001

1 MΩ 0.002 + 0.001 0.008 + 0.001 0.01 + 0.001 0.001 + 0.0002

10 MΩ 0.015 + 0.001 0.02 + 0.001 0.04 + 0.001 0.003 + 0.0004

100 MΩ 0.3 + 0.01 0.8 + 0.01 0.8 + 0.01 0.15 + 0.0002

1 GΩ 1.0 + 0.01 1.5 + 0.01 2.0 + 0.01 0.6 + 0.0002

24 Hour

(23 ± 1 °C)

90 Days

(23 ± 5 °C)

1 Year

(23 ± 5 °C)

Temperature

Coefficient/ °C

Outside 18 to 28 °C

1-14

8845A Accuracy

Accuracy is given as ± (% measurement + % of range)

Range

100 Ω 0.003 + 0.003 0.008 + 0.004 0.01 + 0.004 0.0006 + 0.0005

1 kΩ 0.002 + 0.0005 0.008 + 0.001 0.01 + 0.001 0.0006 + 0.0001

10 kΩ 0.002 + 0.0005 0.008 + 0.001 0.01 + 0.001 0.0006 + 0.0001

100 kΩ 0.002 + 0.0005 0.008 + 0.001 0.01 + 0.001 0.0006 + 0.0001

1 MΩ 0.002 + 0.001 0.008 + 0.001 0.01 + 0.001 0.0010 + 0.0002

10 MΩ 0.015 + 0.001 0.02 + 0.001 0.04 + 0.001 0.0030 + 0.0004

100 MΩ 0.3 + 0.01 0.8 + 0.01 0.8 + 0.01 0.1500 + 0.0002

24 Hour

(23 ± 1 °C)

90 Days

(23 ± 5 °C)

1 Year

(23 ± 5 °C)

Temperature

Coefficient/ °C

Outside 18 to 28 °C

Additional Ohms Errors

Digits NPLC Additional Noise Error

6½ 100 0 % of range

6½ 10 0 % of range

5½ 1 0.001 % of range

5½ 0.2

4½ 0.02

0.001 % of range ± 20 mΩ

0.01 % of range ± 20 mΩ

Page 25

Introduction and Specifications

Electrical Specifications 1

DC Current

Input Protection .................................................... Tool-accessible 11 A/1000 V and 440 mA/1000 V fuses.

Input Characteristics

Range

100 µA 100.0000 µA 10 nA 1 nA 100 pA

1 mA 1.000000 mA 100 nA 10 nA 1 nA

10 mA 10.00000 mA

100 mA 100.0000 mA 10 µA

1 A 1.000000 A 100 µA 10 µA

[1]

3 A

3.00000A 1 mA 100 µA 10 µA

10 A 10.00000 A 1 mA 100 µA 10 µA

[1] Part of 10 A range.

Full Scale

(6½ Digits)

4½ Digits 5½ Digits 6½ Digits

1 µA

Resolution

100 nA 10 nA

1 µA

100 nA

1 µA 0.01 Ω

Shunt Resistance

(Ohms)

100Ω

100Ω

1 Ω

1 Ω

0.01 Ω

0.01 Ω

Burden Voltage

<0.015

<0.15

<0.025 V

<0.25 V

<0.05 V

<0.15 V

<0.5 V

Accuracy (8846A)

Accuracy is given as ± (% measurement + % of range)

Range

100 µA 0.01 + 0.02 0.04 + 0.025 0.05 + 0.025 0.002 + 0.003

1 mA 0.007 + 0.005 0.030 + 0.005 0.05 + 0.005 0.002 + 0.0005

10 mA 0.007 + 0.02 0.03 + 0.02 0.05 + 0.02 0.002 + 0.002

100 mA 0.01 + 0.004 0.03 + 0.005 0.05 + 0.005 0.002 + 0.0005

[2]

1 A

0.03 + 0.02 0.04 + 0.02 0.05 + 0.02 0.005 + 0.001

[1][2]

3 A

0.05 + 0.02 0.08 + 0.02 0.1 + 0.02 0.005 + 0.002

[2]

10 A

0.1 + 0.008 0.12 + 0.008 0.15 + 0.008 0.005 + 0.0008

[1] Part of 10 A range

[2] Available at front panel connectors only

24 Hour

(23 ± 1 °C)

90 Days

(23 ± 5 °C)

1 Year

(23 ± 5 °C)

Temperature

Coefficient/ °C

Outside 18 to 28 °C

Accuracy (8845A)

Accuracy is given as ± (% measurement + % of range)

Range

100 µA 0.01 + 0.02 0.04 + 0.025 0.05 + 0.025 0.002 + 0.003

1 mA 0.007 + 0.005 0.030 + 0.005 0.05 + 0.005 0.002 + 0.0005

10 mA 0.007 + 0.02 0.03 + 0.02 0.05 + 0.02 0.002 + 0.002

100 mA 0.01 + 0.004 0.03 + 0.005 0.05 + 0.005 0.002 + 0.0005

[2]

1 A

0.03 + 0.04 0.08 + 0.02 0.05 + 0.02 0.005 + 0.001

[1][2]

3 A

0.05 + 0.08 0.12 + 0.02 0.1 + 0.02 0.005 + 0.002

[2]

10 A

0.1 + 0.008 0.12 + 0.008 0.15 + 0.02 0.005 + 0.0008

[1] Part of 10 A range

[2] Available at front panel connectors only

24 Hour

(23 ± 1 °C)

90 Days

(23 ± 5 °C)

1 Year

(23 ± 5 °C)

Temperature

Coefficient/ °C

Outside 18 to 28 °C

Additional Current Errors

Digits NPLC Additional Noise Error

6½ 100 0 % of range

6½ 10 0 % of range

5½ 1 0.001 % of range

5½ 0.2

4½ 0.02

1-15

0.001 % of range ± 4 µA

0.01 % of range ± 4 µA

Page 26

8845A/8846A

Users Manual

AC Current

The following ac current specifications are for sinusoidal signals with amplitudes greater than 5 % of range. For inputs

from 1% to 5 % of range, add an additional error of 0.1 % of range.

Input Protection .................................................... Tool accessible 11 A/1000 V and 440 mA/1000 V fuses.

Measurement Method ........................................... ac-coupled true-rms, dc-coupled to the fuse and shunt (no blocking

AC Filter Bandwidth

Maximum Crest Factor .........................................5:1 at full scale

Additional Crest Factor Errors (<100 Hz) ........... Crest Factor 1-2, 0.05 % of full scale

Input Characteristics

100 µA

1 mA

10 mA 10.00000 mA

100 mA 100.0000 mA 10 µA

1 A 1.000000 A 100 µA 10 µA

3 A[2] 3.00000 A 1 mA 100 µA

10 A 10.00000 A 1 mA 100 µA 10 µA

capacitor)

Slow .................................................................... 3 Hz to 10 kHz

Medium ............................................................... 20 Hz to 10 kHz

Fast..................................................................... 200 Hz to 10 kHz

Crest Factor 2-3, 0.2 % of full scale

Crest Factor 3-4, 0.4 % of full scale

Crest Factor 4-5, 0.5 % of full scale

Range

[1] 8846A Only

[2] Part of 10 A range

Full Scale

(6½ Digits)

[1]

100.0000 µA

[1]

1.000000 mA 100 nA 10 nA 1 nA

4½ Digits 5½ Digits 6½ Digits

10 nA 1 nA 100 pA

1 µA

Resolution

100 nA 10 nA

1 µA

100 nA

1 µA 0.01 Ω

10 µA 0.01 Ω

Shunt Resistance

(Ohms)

100Ω

100Ω

1 Ω

1 Ω

0.01 Ω

Burden Voltage

<0.015 V

<0.15 V

<0.025 V

<0.25 V

<0.05 V

<0.05 V

<0.5 V

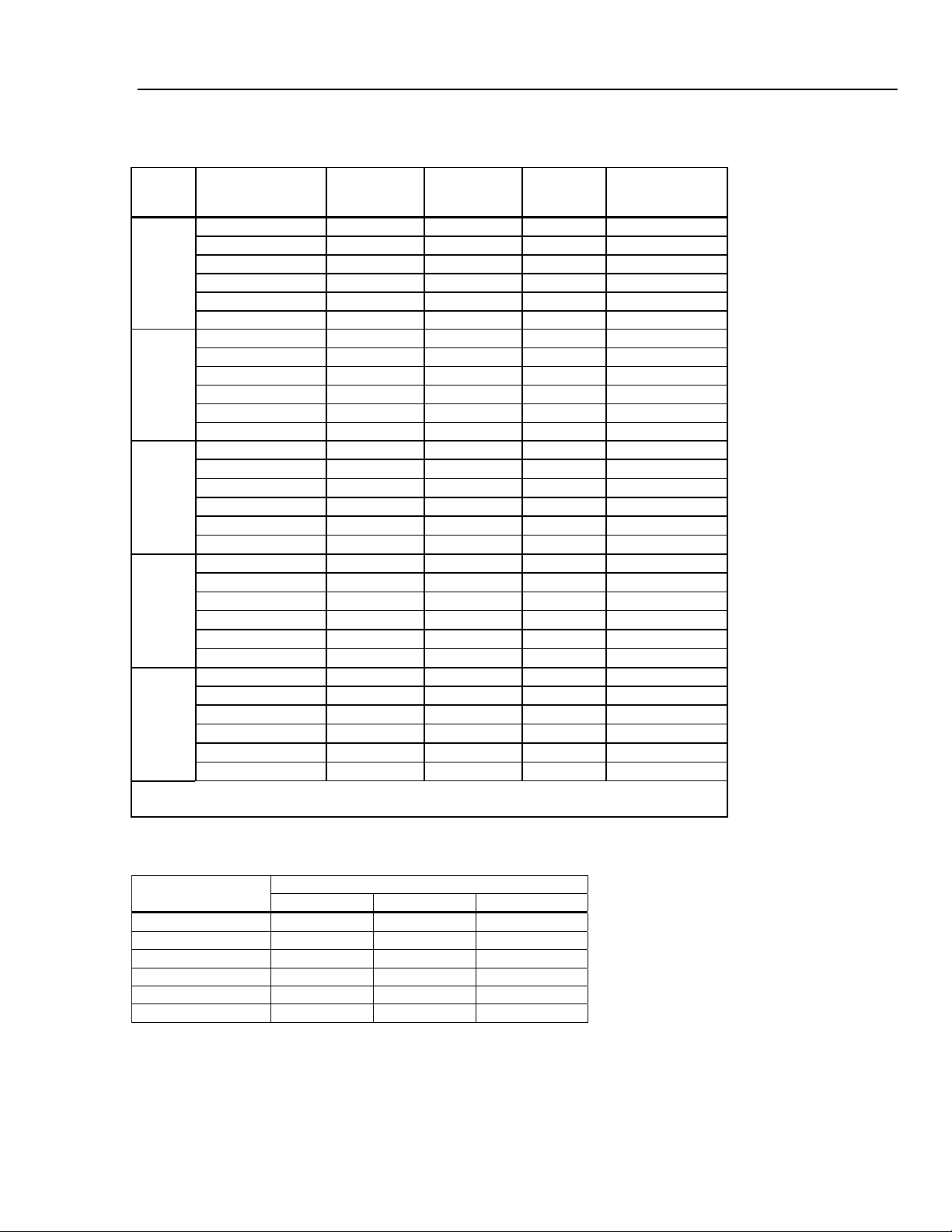

8846A Accuracy

Accuracy is given as ± (% measurement + % of range)

Range

100 µA

1 mA

10 mA

100 mA

[2]

1 A

Frequency

(Hz)

3 – 5 Hz 1.0 + 0.04 1.0 + 0.04 1.0 + 0.04 0.1 + 0.006

5 – 10 Hz 0.3 + 0.04 0.3 + 0.04 0.3 + 0.04 0.035 + 0.006

10 Hz – 5 kHz 0.1 + 0.04 0.1 + 0.04 0.1 + 0.04 0.015 + 0.006

5 – 10 kHz 0.2 + 0.25 0.2 + 0.25 0.2 + 0.25 0.03 + 0.006

3 – 5 Hz 1.0 + 0.04 1.0 + 0.04 1.0 + 0.04 0.1 + 0.006

5 – 10 Hz 0.3 + 0.04 0.3 + 0.04 0.3 + 0.04 0.035 + 0.006

10 Hz – 5 kHz 0.1 + 0.04 0.1 + 0.04 0.1 + 0.04 0.015 + 0.006

5 – 10 kHz 0.2 + 0.25 0.2 + 0.25 0.2 + 0.25 0.03 + 0.006

3 – 5 Hz 1.0 + 0.04 1.0 + 0.04 1.0 + 0.04 0.1 + 0.006

5 – 10 Hz 0.3 + 0.04 0.3 + 0.04 0.3 + 0.04 0.035 + 0.006

10 Hz – 5 kHz 0.1 + 0.04 0.1 + 0.04 0.1+ 0.04 0.015 + 0.006

5 – 10 kHz 0.2 + 0.25 0.2 + 0.25 0.2 + 0.25 0.03 + 0.006

3 – 5 Hz 1.0 + 0.04 1.0 + 0.04 1.0 + 0.04 0.1 + 0.006

5 – 10 Hz 0.3 + 0.04 0.3 + 0.04 0.3 + 0.04 0.035 + 0.006

10 Hz – 5 kHz 0.1 + 0.04 0.1 + 0.04 0.1 + 0.04 0.015 + 0.006

5 – 10 kHz 0.2 + 0.25 0.2 + 0.25 0.2 + 0.25 0.03 + 0.006

3 – 5 Hz 1.0 + 0.04 1.0 + 0.04 1.0 + 0.04 0.1 + 0.006

5 – 10 Hz 0.3 + 0.04 0.3 + 0.04 0.3 + 0.04 0.035 + 0.006

10 Hz – 5 kHz 0.1 + 0.04 0.1 + 0.04 0.1 + 0.04 0.015 + 0.006

5 – 10 kHz 0.35 + 0.7 0.35 + 0.7 0.35 + 0.7 0.03 + 0.006

24 Hour

(23 ± 1 °C)

90 Days

(23 ± 5 °C)

1 Year

(23 ± 5 °C)

Temperature

Coefficient/ °C

Outside 18 to 28 °C

1-16

Page 27

Introduction and Specifications

Electrical Specifications 1

8846A Accuracy (cont)

[1][2]

3 A

[2]

10 A

[1] Part of 10 A range

[2] Available only on front panel connectors

3 – 5 Hz 1.1 + 0.06 1.1 + 0.06 1.1 + 0.06 0.1 + 0.006

5 – 10 Hz 0.35 + 0.06 0.35 + 0.06 0.35 + 0.06 0.035 + 0.006

10 Hz – 5 kHz 0.5 + 0.7 0.15 + 0.06 0.15 + 0.06 0.015 + 0.006

5 – 10 kHz 0.35 + 0.7 0.35 + 0.7 0.35 + 0.7 0.03 + 0.006

3 – 5 Hz 2.0 + 0.06 2.0 + 0.06 2.0 + 0.06 0.2 + 0.006

5 – 10 Hz 1.1 + 0.06 1.1 + 0.06 1.1 + 0.06 0.1 + 0.006

10 Hz – 5 kHz 0.15 + 0.06 0.15 + 0.06 0.15 + 0.06 0.015 + 0.006

5 – 10 kHz 0.35 + 0.7 0.35 + 0.7 0.35 + 0.7 0.03 + 0.006

8845A Accuracy

Accuracy is given as ± (% measurement + % of range)

Range

10 mA

100 mA

[2]

1 A

[1][2]

3 A

[2]

10 A

[1] Part of the 10 A range

[2] Available only at front panel connectors

Frequency

(Hz)

3 – 5 Hz 1.0 + 0.04 1.0 + 0.04 1.0 + 0.04 0.1 + 0.006

5 – 10 Hz 0.3 + 0.04 0.3 + 0.04 0.3 + 0.04 0.035 + 0.006

10 Hz – 5 kHz 0.1 + 0.04 0.1 + 0.04 0.1+ 0.04 0.015 + 0.006

5 – 10 kHz 0.2 + 0.25 0.2 + 0.25 0.2 + 0.25 0.03 + 0.006

3 – 5 Hz 1.0 + 0.04 1.0 + 0.04 1.0 + 0.04 0.1 + 0.006

5 – 10 Hz 0.3 + 0.04 0.3 + 0.04 0.3 + 0.04 0.035 + 0.006

10 Hz – 5 kHz 0.1 + 0.04 0.1 + 0.04 0.1 + 0.04 0.015 + 0.006

5 – 10 kHz 0.2 + 0.25 0.2 + 0.25 0.2 + 0.25 0.03 + 0.006

3 – 5 Hz 1.0 + 0.04 1.0 + 0.04 1.0 + 0.04 0.1 + 0.006

5 – 10 Hz 0.3 + 0.04 0.3 + 0.04 0.3 + 0.04 0.035 + 0.006

10 Hz – 5 kHz 0.1 + 0.04 0.1 + 0.04 0.1 + 0.04 0.015 + 0.006

5 – 10 kHz 0.35 + 0.7 0.35 + 0.7 0.35 + 0.7 0.03 + 0.006

3 – 5 Hz 1.1 + 0.06 1.1 + 0.06 1.1 + 0.06 0.1 + 0.006

5 – 10 Hz 0.35 + 0.06 0.35 + 0.06 0.35 + 0.06 0.035 + 0.006

10 Hz – 5 kHz 0.15 + 0.06 0.15 + 0.06 0.15 + 0.06 0.015 + 0.006

5 – 10 kHz 0.35 + 0.7 0.35 + 0.7 0.35 + 0.7 0.03 + 0.006

3 – 5 Hz 1.1 + 0.04 1.1 + 0.04 1.1 + 0.04 0.2 + 0.006

5 – 10 Hz 0.35 + 0.04 0.35 + 0.04 0.35 + 0.04 0.1 + 0.006

10 Hz – 5 kHz 0.15 + 0.04 0.15 + 0.04 0.15 + 0.04 0.015 + 0.006

5 – 10 kHz 0.35 + 0.7 0.35 + 0.7 0.35 + 0.7 0.03 + 0.006

24 Hour

(23 ± 1 °C)

90 Days

(23 ± 5 °C)

1 Year

(23 ± 5 °C)

Temperature

Coefficient/ °C

Outside 18 to 28 °C

Additional Low Frequency Errors

Error is stated as % of reading.

Frequency

10 – 20 Hz 0 0.25 –

20 – 40 Hz 0 0.02 –

40 – 100 Hz 0 0.01 0.55

100 – 200 Hz 0 0 0.2

200 Hz – 1 kHz 0 0 0.02

> 1 kHz 0 0 0

3HZ (slow) 20HZ (medium) 200HZ (fast)

AC Filter

1-17

Page 28

8845A/8846A

Users Manual

Frequency

Gate Times............................................................. Programmable to 1 s, 100 ms, and 10 ms.

Measurement Method ........................................... Flexible counting technique. AC-coupled input using the ac voltage

Settling Considerations........................................ When measuring frequency or period after a dc offset voltage change,

Measurement Considerations.............................. To minimize measurement errors, shield inputs from external noise

8846A Accuracy

Accuracy is given as ± % measurement

100 mV to

1000 V

measurement function.

errors may occur. For the most accurate measurement, wait up to 1

second for the input blocking capacitor to settle.

when measuring low-voltage, low-frequency signals.

Range Frequency

3 – 5 Hz 0.1 0.1 0.1 0.005

[1][2]

5 – 10 Hz 0.05 0.05 0.05 0.005

10 – 40 Hz 0.03 0.03 0.03 0.001

40 Hz – 300 kHz 0.006 0.01 0.01 0.001

300 kHz – 1 MHz 0.006 0.01 0.01 0.001

[1] Input >100 mV. For 10 – 100 mV, multiply percent measurement error by 10.

[2] Limited to 8 X 10

7

volt-Hertz

24 Hour

(23 ± 1 °C)

90 Days

(23 ± 5 °C)

1 Year

(23 ± 5 °C)

Temperature

Coefficient/ °C

Outside 18 to 28 °C

8845A Accuracy

Accuracy is given as ± % measurement

Range Frequency

100 mV to

750 V

[1] Input >100 mV. For 10 – 100 mV, multiply percent measurement error by 10.

[2] Limited to 8 X 10

3 – 5 Hz 0.1 0.1 0.1 0.005

[1][2]

5 – 10 Hz 0.05 0.05 0.05 0.005

10 – 40 Hz 0.03 0.03 0.03 0.001

40 Hz – 300 kHz 0.006 0.01 0.01 0.001

7

volt-Hertz

24 Hour

(23 ± 1 °C)

90 Days

(23 ± 5 °C)

1 Year

(23 ± 5 °C)

Temperature

Compensation/ °C

Outside 18 to 28 °C

Gate Time vs. Resolution

Gate Time Resolution

0.01 5½

0.1 6½

1.0 6½

Additional Low Frequency Errors

Error stated as percent of measurement for inputs >100 mV. For 10 – 100 mV, multiply percent by 10.

Frequency

3 – 5 Hz 0 0.12 0.12

5 – 10 Hz 0 0.17 0.17

10 – 40 Hz 0 0.2 0.2

40 – 100 Hz 0 0.06 0.21

100 – 300 Hz 0 0.03 0.21

300 Hz – 1 kHz 0 0.01 0.07

> 1 kHz 0 0 0.02

6½ 5½ 4½

Resolution

1-18

Page 29

Introduction and Specifications

Electrical Specifications 1

Capacitance (8846A Only)

Accuracy is stated as ±(% of measurement + % of range)

Range Resolution

1 nF 1 pF

10 nF 10 pF

100 nF 100 pF

1 µF 1 nF

10 µF 10 nF

100 µF 100 nF

1 mF 1 µF

10 mF 10 µF

100 mF 100 µF

[1] Stated accuracy is attained when Zero function is used.

1 Year Accuracy

(23 ± 5 °C)

2% ± 2.5 %

1% ± 0.5 %

1% ± 0.5 %

1% ± 0.5 %

1% ± 0.5 %

1% ± 0.5 %

1% ± 0.5 %

1% ± 0.5 %

4% ± 0.2 %

[1]

Temperature Coefficient/ °C

Outside 18 to 28 °C

0.05 + 0.05

0.05 + 0.01

0.01 + 0.01

0.01 + 0.01

0.01 + 0.01

0.01 + 0.01

0.01 + 0.01

0.01 + 0.01

0.05 + 0.05

Temperature (8846A only)

Test Current........................................................... 1 mA

Accuracy is stated as ± °C and is based on a Platinum RT100 (DIN 43760) RTD with less than 10 ohms lead resistance.

Specifications do not include probe accuracy, which must be added.

Accuracy

Range Resolution

-200 °C 0.001 °C

-100 °C 0.001 °C 0.05 0.08 0.002

0 °C 0.001 °C 0.04 0.06 0.002

100 °C 0.001 °C 0.05 0.08 0.002

300 °C 0.001 °C 0.1 0.12 0.002

600 °C 0.001 °C 0.12 0.14 0.002

90 Days

(23 ± 5 °C)

0.06

1 Year

(23 ± 5 °C)

0.09 0.0025

Temperature

Coefficient/ °C

Outside 18 to 28 °C

Additional Temperature Errors

NPLC Additional Noise Error

100

10

1

0.2

0.02

0 °C

0 °C

0.03 °C

0.1 °C

0.4 °C

Continuity

Continuity Threshold............................................ Selectable between 1 Ω and 1000 Ω

Test Current........................................................... 1 mA

Response Time ..................................................... 300 samples/sec with audible tone

Accuracy is given as ± (% measurements + % of range)

Range

1000.0 Ω 0.002 + 0.01 0.008 + 0.02 0.01 + 0.02

24 Hour

(23 ± 1 °C)

90 Days

(23 ± 5 °C)

1 Year

(23 ± 5 °C)

Outside 18 to 28 °C

0.001 + 0.002

Temperature

Coefficient/ °C

1-19

Page 30

8845A/8846A

Users Manual

Diode Test

Test Current........................................................... 100 µA or 1 mA

Response Time ..................................................... 300 samples/sec with audible tone.

Accuracy is given as ± (% measurements + % of range)

5.0000 V 0.002 + 0.002 0.008 + 0.002 0.01 + 0.002 0.001 + 0.002

10.0000 V 0.002 + 0.001 0.008 + 0.002 0.01 + 0.002 0.001 + 0.002

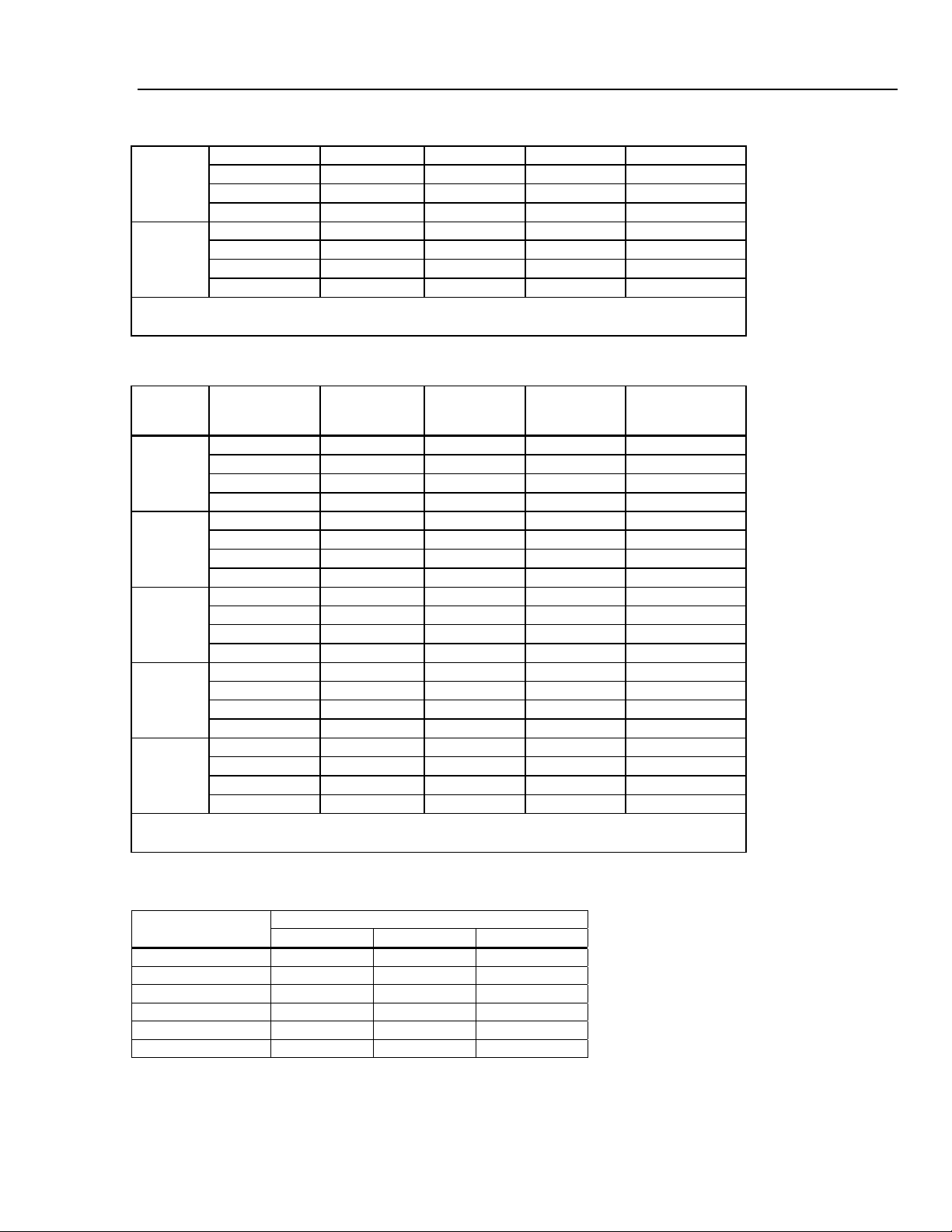

Measurement Rates

DC Volts, DC Current, and

Resistance

AC Voltage and AC Current

Frequency and Period

Range

Function Digits Setting

[1] Typical measurement rates with autozero off.

[2] Maximum measurement rates for 0.01 % of ac step. When dc input varies, additional settling delay is required.

[3] For remote operation or external trigger using default settling delay

[4] Settling delay = 0

24 Hour

(23 ± 1 °C)

[2]

90 Days

(23 ± 5 °C)

6½ 100 NPLC 1.67 (2) s 0.6 (0.5) 0.6 (0.5)

6½ 10 NPLC 167 (200) ms 6 (5) 6 (5)

5½ 10 NPLC 16.7 (20) ms 60 (50) 60 (50)

5½ 0.2 NPLC 3 ms 300 300

6½ 3 Hz 0.14 0.14

6½ 20 Hz 1 1

6½ 200 Hz

6½ 200 Hz

6½ 1 s 1 1

5½ 100 ms 9.8 9.8

4½ 10 ms 80 80

[3]

[4]

1 Year

(23 ± 5 °C)

Integration Time

60 Hz (50 Hz)

1.6 1.6

6 6

Temperature

Coefficient/ °C

Outside 18 to 28 °C

Measurements/Second

8845A 8846A

[1]

1-20

Page 31

Chapter 2

Preparing the Meter for Operation

Title Page

Introduction........................................................................................................ 2-3

Unpacking and Inspecting the Meter ................................................................. 2-3

Contacting Fluke................................................................................................ 2-3

Storing and Shipping the Meter ......................................................................... 2-3

Power Considerations ........................................................................................ 2-3

Selecting the Line Voltage ............................................................................ 2-4

Replacing the Fuses....................................................................................... 2-4

Line-Power Fuse ....................................................................................... 2-4

Current-Input Fuses................................................................................... 2-5

Connecting to Line Power ................................................................................. 2-7

Turning Power-On ............................................................................................. 2-8

Adjusting the Bail .............................................................................................. 2-8

Installing the Meter in an Equipment Rack ....................................................... 2-8

Cleaning the Meter............................................................................................. 2-9

2-1

Page 32

8845A/8846A

Users Manual

2-2

Page 33

Preparing the Meter for Operation

Introduction 2

Introduction

This chapter explains how to prepare the Meter for operation by selecting the proper line

voltage, connecting an appropriate line power cord, and turning on the Meter. Also

included is information on the proper storage and cleaning of the Meter.

Unpacking and Inspecting the Meter

Every care is taken in the choice of packing material to ensure that your equipment will

reach you in perfect condition. If the equipment has been subject to excessive handling in

transit, there may be visible external damage to the shipping carton. In the event of

damage, the shipping container and cushioning material should be kept for the carrier’s

inspection.

Carefully unpack the Meter from its shipping container and inspect the contents for

damaged or missing items. If the Meter appears damaged or something is missing,

contact both the carrier and Fluke immediately. Save the container and the packing

material in case you have to return the Meter.

Contacting Fluke

To order accessories, receive operating assistance, or get the location of the nearest Fluke

distributor or Service Center, call:

USA: 1-888-44-FLUKE (1-888-443-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Service in USA: 1-888-99-FLUKE (1-888-993-5853)

Or, visit Fluke's Web site at www.fluke.com.

To register this product, visit register.fluke.com

Storing and Shipping the Meter

The Meter should be stored under cover. The shipping container provides the most

suitable receptacle for storage, as it provides the necessary shock isolation for normal

handling operations.

Place the Meter inside a sealed bag. Place the bag into the cushioning material inside the

shipping container, and store in a location that complies with the storage environment

specification described in Chapter 1.

If the Meter is shipped, use the original shipping container if possible. It provides shock

isolation for normal handling operations. If the original shipping container is not

available, a box that is 17.5″ x 15.5″ x 8.0″, with cushioning material that fills the space

between the Meter and the sides of the box, should provide similar shock isolation.

.

Power Considerations

The Meter operates on power distribution standards found throughout the world, and

must be set up to operate on the line voltage that will power it. The Meter is packed ready

for use with a line voltage determined at the time of ordering. If the selected line voltage

2-3

Page 34

8845A/8846A

Users Manual

Selecting the Line Voltage

does not match the power the Meter will be plugged into, then the Meter’s line voltage

setting must be changed and the line fuse possibly replaced.

The Meter will operate on any one of four different input line voltages. The set line

voltage is visible through the window in the line fuse holder, found on the Meter’s rear

panel.

To change the line voltage:

1. Remove the power cord from the Meter.

2. Insert a small screwdriver blade in the narrow recess to the left of the fuse holder and

pry to the right until the holder pops out, as shown in Figure 2-1.

3. Remove the voltage selector block from the fuse holder.

4. Rotate the selector block until the preferred voltage rating faces outward.

5. Replace the selector block back into the fuse holder.

Changing the line voltage setting may require a different line-power fuse for proper

operation. Check Table 2-1 for the appropriate fuse for the selected line voltage.

With the voltage set and appropriate fuse installed, replace the fuse holder back into the

Meter and reconnect the power cord.

Replacing the Fuses

The Meter employs fuses to protect both the line-power and current measurement inputs.

Line-Power Fuse

The Meter has a line-power fuse in series with the power supply. Table 2-1 indicates the

proper fuse for each of the four line voltage selections. This fuse is located on the rearpanel.

To replace this fuse:

1. Unplug the power cord from the Meter.

2. Remove the fuse holder by inserting a small screwdriver blade in the narrow recess to

the left of the fuse holder and pry to the right until the holder pops out as shown in

Figure 2-1. The Meter is shipped with a replacement fuse of the same rating as the

fuse installed in the fuse block.

3. Remove the fuse and replace with one rated appropriately for the selected line-power

voltage. See Table 2-1.

4. Replace the selector block back into the fuse holder.

To avoid electric shock or fire, do not use makeshift fuses or

short-circuit the fuse holder. Use only Fluke fuses