Fluke 88 Service Manual

88

Automotive Meter

Service Manual

For IEC 61010 CAT II Meters Only

PN 666856

November 1998 Rev.1, 11/99

© 1998, 1999 Fluke Corporation. All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

LIMITED WARRANTY & LIMITATION OF LIABILITY

Fluke Corporation (Fluke) warrants this product to be free from defects in material and workmanship under normal use and service for the life

of the product. This warranty extends only to the original buyer or end-user customer of a Fluke authorized reseller, and does not apply to

fuses, batteries or to any product which, in Fluke’s opinion, has been misused, altered, neglected or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate on appropriate Fluke instruments substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media. Fluke does not warrant that

software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers only but have no authority to

extend a greater or different warranty on behalf of Fluke.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price, or free of charge repair or replacement of a defective

product which is returned to an authorized Fluke Service Center within the warranty period.

To obtain warranty service, contact your nearest Fluke Service Center or send the product, with a description of the difficulty, postage and

insurance prepaid (FCA Destination), to the nearest Fluke Service Center. Fluke assumes no risk for damage in transit. Following warranty

repair, the product will be returned to Buyer, transportation prepaid (FCA Destination). If Fluke determines that the failure was caused by

misuse, alteration, accident or abnormal condition of operation or handling, Fluke will provide an estimate of repair costs and obtain

authorization before commencing the work. Following repair, the product will be returned to the Buyer transportation prepaid and the Buyer

will be billed for the repair and return transportation charges (FCA Shipping Point).

Warranty service is available outside the United States only if product was purchased through a Fluke Authorized Sales Outlet in the country

of use or the applicable Fluke international price was paid. Product transported from the United States for which the applicable Fluke

international price was not paid must be returned to the U.S. to receive warranty service, at the shipment expense and risk of Buyer. Fluke

reserves the right to invoice Buyer for importation costs of repair/replacement parts when product purchased in one country is submitted for

repair in another country.

THIS WARRANTY IS PURCHASER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIM ITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR

LOSSES, INCLUDING LOSS OF DATA, WHETHER ARI SI NG FROM BREACH OF WARRANTY OR BASED ON CONTRACT, TORT,

RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or

consequential damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty is held

invalid or unenforceable by a court of competent jurisdiction, such holding will not affect the validity or enforceability of any other provision of

this warranty.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett WA 5602 B.D. Eindhoven

98206-9090 The Netherlands

Safety Information

This meter complies with EN 61010-1:1993, ANSI/ISA S82.01-1994 and CAN/CSA

C22.2 No. 1010.1-92 Overvoltage Category II. Use the meter only as specified in the

Users Manual, otherwise the protection provided by the meter may be impaired.

A Warning identifies conditions and actions that pose hazards to the user; a Caution

identifies conditions and actions that might damage the meter. International electrical

symbols used on the meter are shown below.

W Warning

To avoid possible electric shock or personal inj ury:

• Do not use the meter if it is damaged. Bef ore use, inspect the

case for cracks or missing plastic. Pay particular att ent ion to the

insulation surrounding the connectors.

• Always turn off power to the circui t before cutting, unsoldering,

or breaking the circuit. Small amounts of current can be

dangerous.

• Inspect the test leads for damaged insulat ion or exposed metal.

Check test lead continuity. Replace damaged leads.

• To avoid damage or injury, never use the meter on unprotected

circuits that exceed 4800 volt-amps.

• Do not use the meter if it operates abnormally. Prot ect i on may be

impaired. When in doubt, have the meter serviced.

• Do not operate the meter around explosive gas, vapor or dust.

• Do not apply more than 300 V dc or ac rms (sine) between

terminals or between any terminal and earth ground.

• Before each use, verify the meter’s operation by measuring a

known voltage.

• When servicing the meter, use only specified replacement part s.

• Use caution when working above 30 V ac rms, 42 V ac peak, or 60

V dc. Such voltages pose a shock hazard.

• Keep your fingers behind the finger guards on the probe when

making measurements.

• Connect the common test lead before connecting the l i ve test

lead. Disconnect the live test lead first.

• Remove test leads from the meter before opening the case.

• Use only a single 9 V battery, properly installed in the meter case,

to power the meter.

• Follow all equipment safety procedures.

• Before measuring current, check the meter’s fuses (see “How to

Test the Fuse”).

Safety-1

• Never touch the probe to a voltage source when the test l eads are

plugged into the 10 A input jack.

• Always use clamp-on probes (dc current clamps) when

measuring current exceeding 10 A.

• DO NOT connect thermocouple to voltages exceeding 30 V.

• Always use a high voltage probe to measure voltage if peak

voltage might exceed 300 V.

• To avoid false readings, which could l ead t o possi ble electric

shock or personal injury, replace the meter’s battery as soon as

the low battery indicator (N) appears.

• To avoid fire hazard, only use a fuse identical in type, voltage

rating, and current rating to that speci f ied on the fuse rating label

located on the case bottom.

• Do not operate the meter if it is di sassembled. Always operate the

meter with the case top and bottom properly assembled.

Disassembly procedures and warnings are in the 78 Automotive

Service Manual. Service procedures are for qualified personnel

only.

Caution

To avoid possible damage to the meter or to equipment under

test:

• Disconnect the power to the circuit under t est and discharge all

high voltage capacitors before testing resi stance, continuity or

diodes.

• Use the proper function and range for your measurement

applications.

• When measuring current, turn off circuit power before connect i ng

the meter in the circuit. Remember to place the met er i n seri es

with the current.

Symbols

Symbol Meaning

Important information. See manual.

Ground

Fuse

Double insulation (Protection Class II)

Conforms to European Union directives

Safety-2

Table of Contents

Chapter Title Page

1 Introduction and Specifications........................................................ 1-1

1-1. Introduction.......................................................................................... 1-3

1-2. Organization of the Service Manual..................................................... 1-3

1-3. Conventions.......................................................................................... 1-4

1-4. Specifications....................................................................................... 1-4

2 Theory of Operation........................................................................... 2-1

2-1. Introduction.......................................................................................... 2-3

2-2. Functional Block Description............................................................... 2-3

2-3. Detailed Circuit Description ................................................................ 2-5

2-4. Input Overload Protection................................................................ 2-5

2-5. Rotary Switch................................................................................... 2-5

2-6. Input Signal Conditioning Circuits.................................................. 2-5

2-7. Volts............................................................................................. 2-6

2-8. Ohms............................................................................................ 2-6

2-9. Analog Section of Integrated Meter IC (U4) ................................... 2-6

2-10. Microcomputer Control ................................................................... 2-8

2-11. Peripherals to U4.............................................................................. 2-9

2-12. AC Buffer .................................................................................... 2-10

2-13. AC Converter............................................................................... 2-10

2-14. Active Filter................................................................................. 2-10

2-15. A/D Converter ............................................................................. 2-10

2-16. Beeper.......................................................................................... 2-10

2-17. Reference Voltage ....................................................................... 2-10

2-18. Power Supply............................................................................... 2-10

2-19. Display............................................................................................. 2-11

2-20. Rotary Knob Switch and Potentiometer .......................................... 2-11

3 Maintenance....................................................................................... 3-1

3-1. Introduction.......................................................................................... 3-3

3-2. Required Tools and Equipment............................................................ 3-3

3-3. Operator Maintenance.......................................................................... 3-4

3-4. Disassembing the Case..................................................................... 3-5

3-5. Removing and Reinstalling the Circuit Assembly........................... 3-5

i

88

Service Manual

3-6. Reassembling the Case..................................................................... 3-6

3-7. Replacing the Battery....................................................................... 3-7

3-8. Testing Fuses ................................................................................... 3-7

3-9. Replacing Fuses ............................................................................... 3-7

3-10. Cleaning........................................................................................... 3-8

3-11. Input Terminals............................................................................ 3-8

3-12. Function Encoding Potentiometer............................................... 3-8

3-13. Performance Test.................................................................................. 3-9

3-14. Testing the Display.......................................................................... 3-9

3-15. Testing Function Selection (Rotary Switch).................................... 3-10

3-16. Testing the AC Voltage Function.................................................... 3-10

3-17. Testing the Frequency Counter Function......................................... 3-11

3-18. Testing Frequency Sensitivity and Trigger Level............................ 3-12

3-19. Testing the DC Voltage Function.................................................... 3-12

3-20. Testing the DC mV Function........................................................... 3-13

3-21. Testing the Ohms Function.............................................................. 3-13

3-22. Testing the Diode Test Function...................................................... 3-13

3-23. Testing the mA Functions................................................................ 3-13

3-24. Testing the Amp Functions.............................................................. 3-14

3-25. Testing the Inductive Pickup............................................................ 3-14

3-26. Calibration............................................................................................ 3-18

3-27. Troubleshooting the Power Supply...................................................... 3-19

3-28. Common (Shunt) Regulator Troubleshooting.................................. 3-21

3-29. VDD (Series) Regulator Troubleshooting....................................... 3-23

3-30. Troubleshooting a Function Selection Malfunction............................. 3-23

3-31. Meter Does Not Turn Off (Problem 1)............................................ 3-24

3-32. Meter Enters Wrong Function (Problem 2)..................................... 3-24

4 List of Replaceable Parts .................................................................. 4-1

4-1. Introduction.......................................................................................... 4-3

4-2. How to Obtain Parts............................................................................. 4-3

4-3. Manual Status Information................................................................... 4-3

4-4. Newer Instruments................................................................................ 4-4

4-5. Service Centers..................................................................................... 4-4

4-6. Parts Lists............................................................................................. 4-4

5 Schematic Diagrams.......................................................................... 5-1

ii

List of Tables

Table Title Page

1-1. Summary of Accuracy Specifications.................................................................... 1-5

2-1. Typical Voltage Levels and Tolerance.................................................................. 2-11

3-1. Required Equipment.............................................................................................. 3-3

3-2. Function Selection Test......................................................................................... 3-10

3-3. AC Voltage Test.................................................................................................... 3-11

3-4. Frequency Test....................................................................................................... 3-11

3-5. Frequency Counter Sensitivity and Trigger Level Tests....................................... 3-12

3-6. DC Voltage Test.................................................................................................... 3-12

3-7. Ohms Test.............................................................................................................. 3-13

3-8. Milliamp Tests....................................................................................................... 3-14

3-9. Amp Tests.............................................................................................................. 3-14

3-10. Functional Description of Power Supply Components......................................... 3-20

3-11. Voltage Levels....................................................................................................... 3-20

4-1. Fluke 88 Final Assembly....................................................................................... 4-5

4-2. A1 Main PCA........................................................................................................ 4-7

iii

88

Service Manual

iv

List of Figures

Figure Title Page

2-1. Overall Functional Block Diagram........................................................................ 2-4

2-2. A/D Conversion..................................................................................................... 2-8

2-3. Function-Encoding Switch .................................................................................... 2-12

3-1. Battery and Fuse Replacement .............................................................................. 3-4

3-2. Assembly Details................................................................................................... 3-6

3-3. Display Test........................................................................................................... 3-9

3-4. Setup for Inductive Pickup Test ............................................................................ 3-16

3-5. Waveform for Inductive Pickup Test..................................................................... 3-17

3-6. Calibration Adjustment Points............................................................................... 3-19

3-7. Simplified Power Supply Schematic..................................................................... 3-22

4-1. Fluke 88 Final Assembly....................................................................................... 4-6

4-2. A1 Main PCA........................................................................................................ 4-9

5-1. A1 Main PCA........................................................................................................ 5-3

v

88

Service Manual

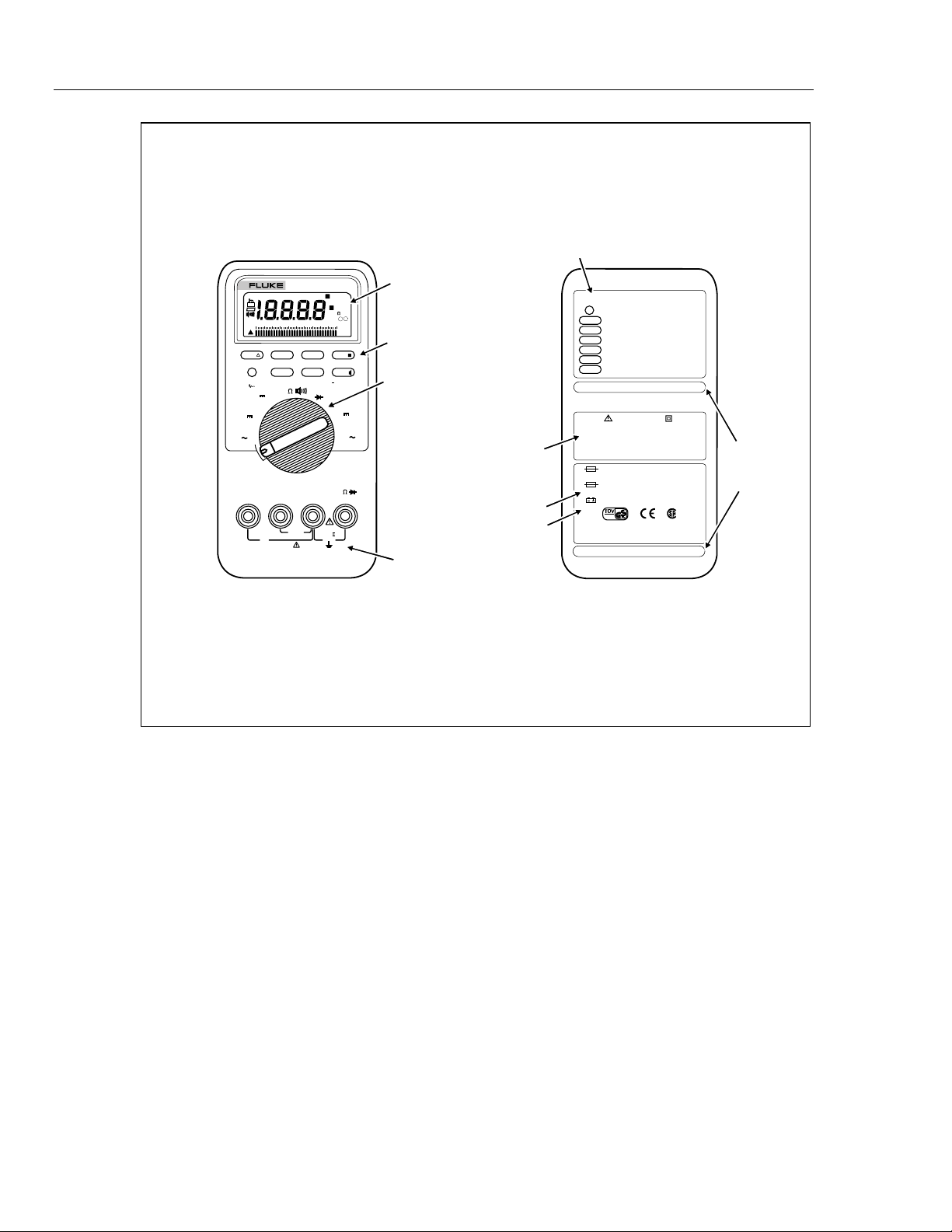

AUTO

RECORD MAX

RANGE

_

+

TRIG

20 2

4 6 3108 2 4 6 8 420

_

+

ZERO

MIN MAX RANGE HOLD

RPM

SMOOTH

mV

V

RPM

V

OFF

A

mA

10A

FUSED

88

Hz

400mA

FUSED

AUTOMOTIVE METER

MIN

AVG

AVG

H

M k

RPM

%DUTY

ms-PULSE

COM RPM

CAT

300V

m s %

T

AC

+

mA

A

II

DC

m V A

1

4000

mV

ALERT

TRIGGER

mA

A

V

POWER-UP OPTIONS

DISPLAY

+

Hz

2

PUSHBUTTONS

H

POWER-UP OPTIONS

PRESS 2 SEC. WHILE TURNING METER ON

LOW, OHMS/HIGH RESOLUTION

DISABLE AUTOMATIC POWER-OFF

ZERO

HI ACCURACY, 1 SEC. RESPONSE

MIN MAX

AUTORANGE VDC, VAC

RANGE

HI IMPENDANCE mV DC INPUT

HOLD

TURN OFF BEEPER

ALERT

TEST ROTARY SWITCH

RPM

ROTARY SWITCH

WARNING

TO AVOID ELECTRICAL SHOCK REMOVE

TEST LEADS BEFORE OPENING CASE

TO PREVENT DAMAGE OF INJURY

ELECTRICAL SHOCK

AND FUSE WARNINGS

FUSE RATINGS

BATTER Y TYPE

INSTALL QUICK ACTING FUSES WITH

AMP/VOLT RATINGS SHOWN.

F 44/100A 1000V

MIN INTERRUPT RATING 10 000A

F 11A 1000V

MIN INTERRUPT RATING 17 000A

9V NEDA 1604

PRODUCT

SERVICE

FLUKE CORPORATION

MADE IN USA

PAT. RE. 34,428 DES. 314,715 DES. 312,534 4,217,543

4,556,867 4,532,470 5,073,757 4,940,204 4,951,834

LR44340

SKID

RESISTANT

FEET

INPUT TERMINALS

FRONT

BACK

aad01f.eps

Frontispiece

vi

Chapter 1

Introduction and Specifications

Title Page

1-1. Introduction.......................................................................................... 1-3

1-2. Organization of the Service Manual..................................................... 1-3

1-3. Conventions.......................................................................................... 1-4

1-4. Specifications....................................................................................... 1-4

1-1

88

Service Manual

1-2

1-1. Introduction

This Service Manual provides information necessary to service the Fluke 88 Automotive

Meter. This information includes the following:

• Specifications

• Theory of operation

• Calibration routines

• Performance testing and troubleshooting procedures

• Replacement parts lists

• Schematic diagrams

A meter under warranty will be promptly repaired or replaced (at Fluke’s option) and

returned at no charge. See the registration card for warranty terms. If the warranty has

lapsed, the meter will be repaired and returned for a fixed fee. Contact the nearest

Service Center for information and prices. To contact Fluke, call one of the following

telephone numbers:

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-678-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Introduction and Specifications

Introduction

1

Or, visit Fluke’s Web site at www.fluke.com.

1-2. Organization of the Service Manual

The Service Manual has five chapters.

Chapter 1. Introduction and Specifications

Chapter 1 describes the Service Manual and explains conventions used to describe the

meter’s circuitry. A complete set of specifications appears at the end of this chapter.

Chapter 2. Theory of Operation

Chapter 2 treats the meter’s circuitry as functional blocks, with a description of each

block’s role in overall operation. A detailed circuit description is then given for each

block. These descriptions explore operation to the component level and support the

troubleshooting and repair procedures in Chapter 3.

Chapter 3. Maintenance

Chapter 3 provides complete maintenance information, detailed troubleshooting and

repair procedures to the component level, and performance tests. Troubleshooting and

repair procedures rely on the theory of operation in Chapter 2 and the schematic

diagrams in Chapter 5.

Chapter 4. List of Replaceable Parts

Chapter 4 provides parts lists for all assemblies and information on how to order parts.

1-3

88

Service Manual

1-3. Conventions

Chapter 5. Schematic Diagrams

Chapter 5 provides the schematic diagrams. A list of mnemonic definitions is included to

aid in identifying signal name abbreviations.

The following conventions are used in this manual:

• Instrument Reference

The term "Meter" is used when discussing the Fluke 88 Automotive Meter.

• Printed Circuit Assembly

The term "pca" is used to mean a printed circuit board and its attached parts.

• Signal Logic Polarity

Signal names followed by a minus sign (-) are active (or asserted) low. Signals not

so marked are active high.

• Circuit Nodes

Individual pins or connections on a component are specified by a dash (-) following

the component reference designator. For example, pin 19 of U30 would be U30-19.

• User Notation

Pushbuttons, positions on the rotary switch, input terminals, and the display are

genrally shown in the manual as they appear on the Meter. Mnemonics used in the

text that describe Meter circuitry are the same as those used on the schematic

diagrams in Chapter 5.

1-4. Specifications

Specifications for the Fluke 88 follow.

Accuracy is specified at 18°C to 28°C (64°F to 82°F) with relative humidity up to 90%,

for a period of one year after calibration. AC Conversions are ac-coupled, average

responding, and calibrated to the RMS value of a sine wave input.

The Fluke 88 has a Lo-Ohms/High Resolution power-up option. In the LoOhms/High Resolution mode, the resolution is ten times that in the

following specifications. To enter the Lo-Ohms/High Resolution mode,

press and hold down the SMOOTH button, while turning the rotary switch

to a function setting.

Table 1-1 provides a summary of the accuracy specifications for basic meter functions.

The complete Meter specifications follow Table 1-1. In the complete specifications,

accuracy is given as: ±([% of Reading] + [Number of Least Significant Digits])

Note

1-4

Introduction and Specifications

Specifications

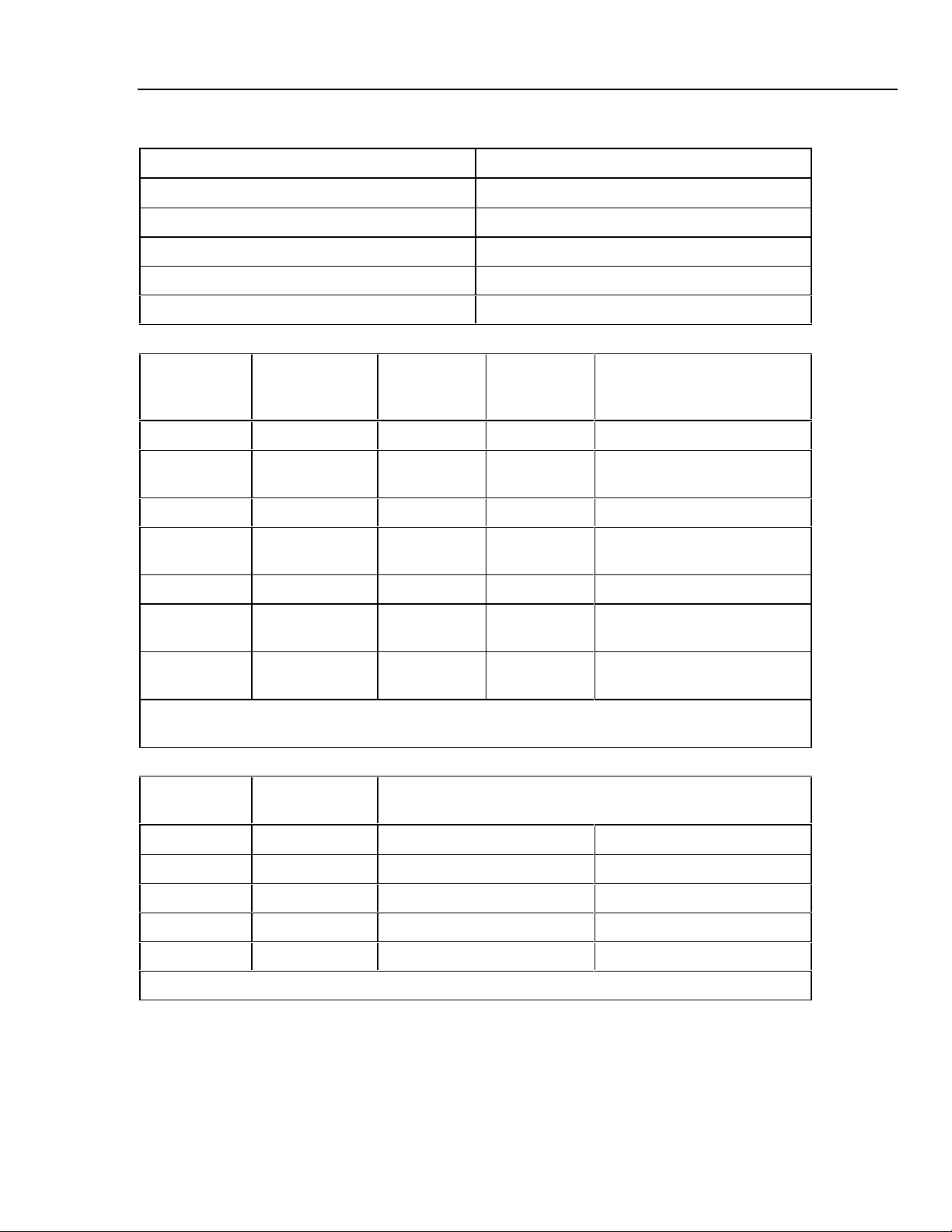

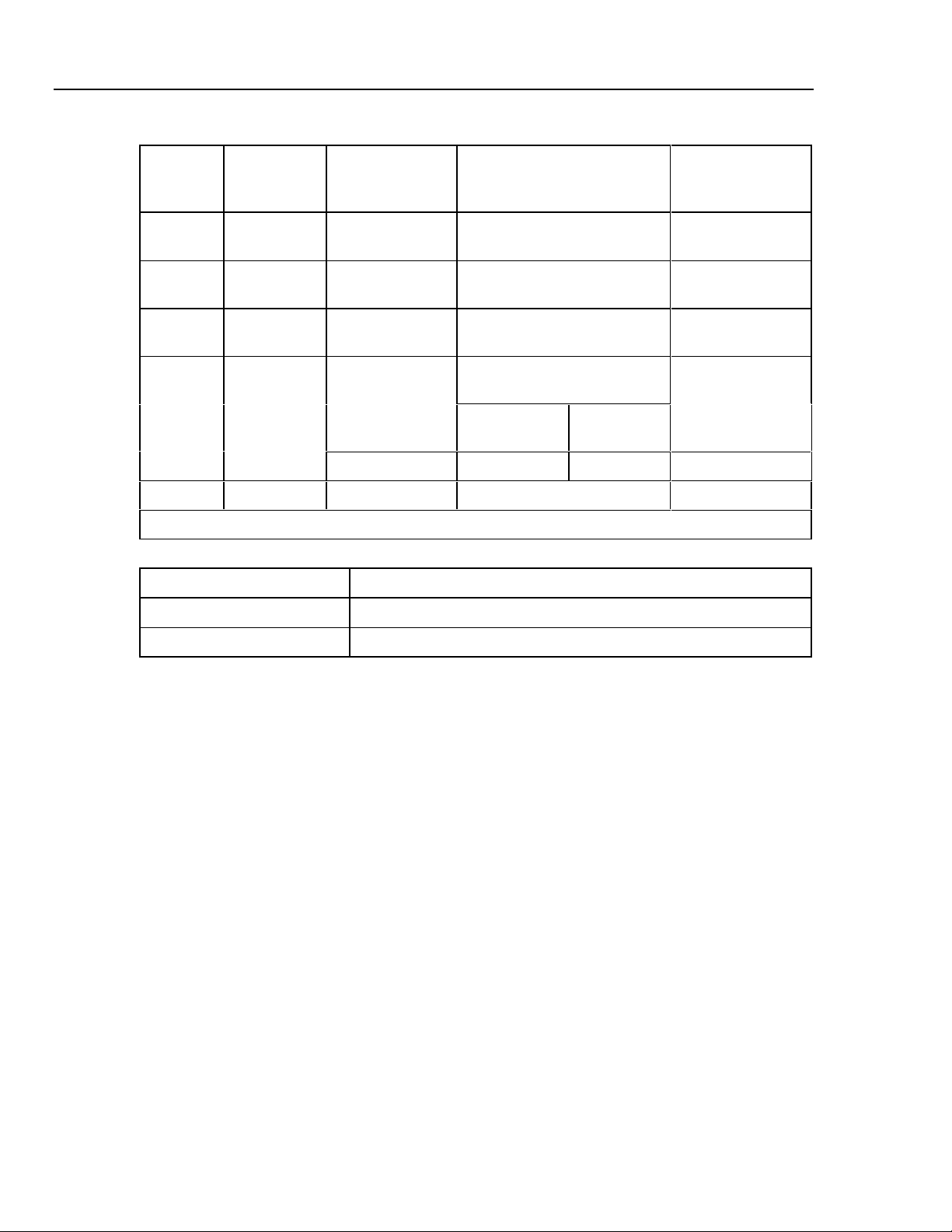

Table 1-1. Summary of Accuracy Specifications

Function Bassic Accuracy (± % of Reading)

Volts AC AV1.5%

Volts DC d V 0.15%

Resistance e 0.2%

Milliamps/Amps DC mA A d 0.8%

Frequency Hz 0.01%

Input Terminal Limits

1

Rotary

Switch

Function

~V V Ω G 0.01 mV 1000 V 300 V

F V

RPM

F mV V ΩG 0.01 mV 400.0 mV 300 V

R Ω

G V Ω G 0.0001V 3.000 V 300 V

mA

A~

mA

A F

* 10A continuous, 20A overload for 30 seconds maximum.

7

** 10

V-Hz maximum.

Volts AC

Range Resolution

Red Lead

RPM 0.0001 V 1000 V 300 V

V Ω G

A

mA

A

mA

Min Display

Reading

0.01Ω

(Lo-Ohms)

0.1 mA

0.001 mA

0.1 mA

0.001

45 Hz to 1 kHz 1 kHz to 5 kHz

Max Display

Reading

400.0 MΩ 300 V

20.00 A**

400.0 mA

20.00 A**

400.0 mA

Accuracy *

Maximum Input **

10 A/300 V*

400 mA/300 V

10A/300 V*

400 mA/300 V

400.0 mV 0.1 mV ±(1.5%+10) ±(1.9%+10)

4.000 V 0.001 V ±(1.5%+5) ±(1.9%+5)

40.00 V 0.01 V ±(1.5%+5) ±(1.9%+5)

300.0 V 0.1 V ±(1.5%+5) ±(1.9%+5)

300 V 1 V ±(2.5%+5) ±(2.5%+5)

*Below a reading of 200 counts, add 10 digits.

1-5

88

Service Manual

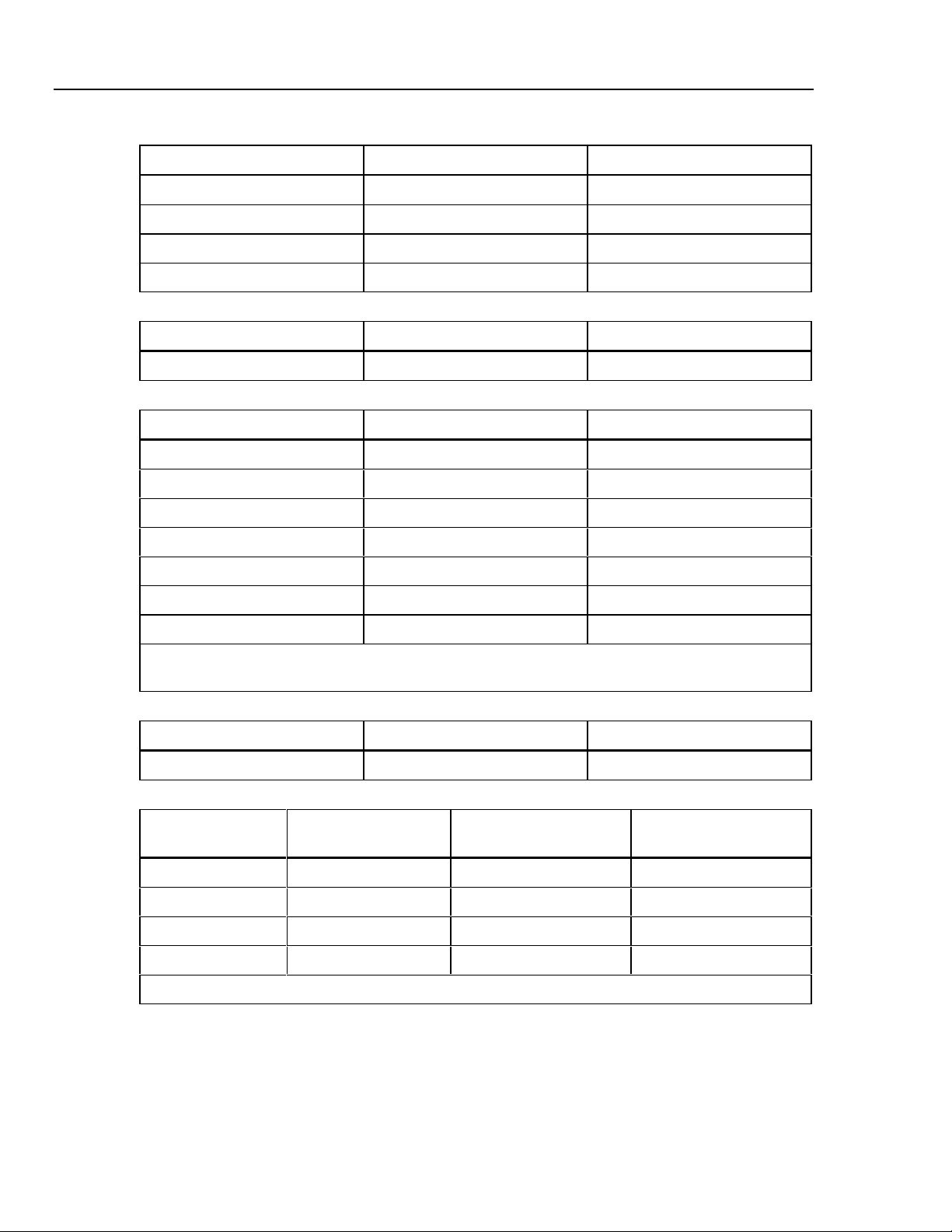

Volts DC

Range Resolution Accuracy

4.000 V 0.001 V ±(0.15%+2)

40.00 V 0.01 V ±(0.15%+2)

300.0 V 0.1 V ±(0.15%+2)

300 V 1 V ±(0.3%+2)

Millivolts DC

Range Resolution Accuracy

400.0 mV 0.1 mV ±(0.15%+2)

Resistance

Range Resolution Accuracy

400.0 Ω 0.1Ω* ±(0.2%+2)

4.000 kΩ 0.001 kΩ±(0.2%+2)

40.00 kΩ 0.01 kΩ±(0.2%+2)

400.0 kΩ 0.1 kΩ±(0.2%+2)

4.000 MΩ 0.001 MΩ±(0.2%+2)

40.00 MΩ 0.01 MΩ±(1%+3)

400.0 MΩ** 0.1 MΩ±(1%+20)

* In Lo-Ohms/High Resolution Mode, increases to 0.01Ω.

**This range will not be entered by Autorange. It must be selected manually.

Diode Test

Range Resolution Accuracy

3.000 V 0.001 V ±(2%+2)

mA/A DC

Range Resolution Accuracy Burden Voltage

40.00 mA 0.01 mA ±(0.8%+2) 2.3 mV/mA

400.0 mA 0.1 mA ±(0.8%+2) 2.3 mV/mA

4000 mA 1 mA ±(0.8%+2) 0.03 V/A

10.00 A* 0.01A ±(1.3%+2) 0.03 V/A

(typical)

1-6

* 10A continuous, 20A overload for 30 seconds maximum.

Introduction and Specifications

mA/A AC (45 Hz to 2 kHz)

Range Resolution Accuracy ** Burden Voltage

40.00 mA 0.01 mA ±(3%+10) 2.3 mV/mA

400.0 mA 0.1 mA ±(3%+5) 2.3 mV/mA

4000 mA 1 mA ±(1.5%+5) 0.03 V/A

10.0 A* 0.01 A ±(1.5%+5) 0.03 VA

* 10 A continuous, 20 A overload for 30 seconds maximum.

** Below reading of 200 counts, add 10 digits.

Frequency, RPM, Duty Cycle, and Pulse Width

(typical)

Specifications

1

Function Range Resolution Accuracy

Frequency** 199.99 0.01 Hz ±(0.01%+1) 1999.9 0.1

(0.5 Hz to 1999.9 0.1 Hz ±(0.01%+1) 5.00 0.01

200 kHz, 19.999 kHz 0.001 kHz ±(0.01%+1) 0.500 0.001

Pulse Width 199.99 kHz 0.01 kHz ±(0.01%+1) 0.0500 0.0001

>2 µs) >200 kHz 0.1 kHz Unspecified

RPM 1 30-9,000 1 RPM ± 2 RPM

RPM 2 60-12,000 1 RPM ± 2 RPM

% Duty Cycle*** 0.0-99.9%

(0.5 Hz to 200 kHz, Pulse Width > 2 µs)

Pulse Width *** 0.002-1999.9 ms

(4 Hz to 200 kHz, Pulse Width > 2 µs)

* Pulse Width range is determined by the frequency of the signal.

** Frequency measurements can be made on voltage or current inputs. The current inputs are always

dc-coupled.

*** For rise times < 1 µs. Duty Cycle accuracy: within ±(0.2% per kHz + 0.1%). Pulse Width accuracy:

±(00.002 ms + 3 digits).

Counter Sensitivity and Trigger Level

Pulse Width

Range (ms)*

Resolution

(ms)

Input Range* Minimum Sensitivity @ 0.5 Hz-200

kHz (RMS Sinewave)

400.0 mV dc 70 mV (to 400 Hz) 40 mV

400.0 mV ac 150 mV -

4.000 V 0.7 V 1.7 V

40.00 V 7 V 4 V

300.0 V 70 V (≤140 kHz) 40 V

Maximum input for specified accuracy = 10 × Range or 300 V.

Approximate Trigger Level (DC

Voltage Function)

1-7

88

Service Manual

Common and Normal Mode Rejection Ratio

Function Overload

Protection*

Input

Impedance

Common Mode Rejection

Ratio (1 kΩ unbalance)

Normal Mode

Rejection Ratio

(nominal)

F V 300 V rms 10 MΩ, <100 pF >120 dB at dc, 50 Hz, or 60 Hz >60 dB at 50 Hz or

60 Hz

F mV 300 V rms 10 MΩ, <100 pF >120 dB at dc, 50 Hz, or 60 Hz >60dB at 50 Hz or

60 Hz

B V 300 V rms 10 MΩ, <100 pF

>60 dB, dc to 60 Hz

(ac-coupled)

Open Circuit

Test

Voltage

Full Scale Voltage Short Circuit

To 4.0 mΩ 40 MΩ or

Current

nS

Ω 300 V rms <1.3 V dc <450 mV dc <1.3V dc <500 µA

Diode Test 300V rms <3.9 V dc 3.000 V dc 1.0 mA typical

7

* 10

V-Hz max.

MIN MAX Recording

Nominal Response Accuracy

100 ms to 80% Specified accuracy ± 12 digits for changes > 200 ms in duration

1 sec Same as specified accuracy for changes > 2 seconds in duration

1-8

Introduction and Specifications

Specifications

General

Maximum Voltage between any

Terminal and Earth Ground 300 V

Fuse Protection

mA 1 A 600 V FAST FUSE

A 15 A 600 V FAST FUSE

Display (LCD)

Digital Counts: 4,000

19,999 in High Resolution, 4½ -digit Mode only.

Update Rate: 1/sec in High Resolution, 4½ - digit mode only.

3/sec in RPM, Frequency, % Duty Cycle, and

Pulse Width

4/sec in all other functions and ranges.

Analog 2 x 32

Segments

Updates Rate: 40/sec

Frequency and RPM Counts: 19,999

Update Rate: 3/sec @ > 10 Hz

Backlight Backlight turns on for 68 seconds, then turns off automatically if not

turned off by user.

Meter Operating Temperature -20°C to 55°C (-4°F to 131°F)

Meter Storage Temperature -40°C to 60°C (-40°F to 140 °F)

Temperature Coefficient 0.05 x (Specified Accuracy)/ °C (<18°C or >28°C or 64°F or 82°F)

Relative Humidity 0% to 90% (0°C to 35°C; 32°F to 95°F)

0% to 70% (35°C to 55°C; 95°F to 131°F)

Altitude 2000 meters maximum

1

Inductive

Pickup

Input Magnetic Field from Spark Plug

Output Pulse to Trigger

Maximum RPM 12,000 (RPM 2)

Battery Type 9 V, NEDA 1604 or 6F22 or 006P

Battery Life 500 hrs typical with alkaline

Shock,

Vibration

Size (HxWxL)

Meter only 1.25 in x 3.41 in x 7.35 in (3.1 cm 8.6 cm x 18.6)

With Holster & Flex-

Stand

Weight

Meter only 12.5 oz (355 g)

With Holster & Flex-

Stand

Safety

Meter Complies with EN61010-1:1993, ANSI/ISA S82.01-1994,

Pickup Specified for spark-plug wire use only.

PER MIL-T-28800 for a Class 2 instrument.

2.06 in x 3.86 in x 7.93 in (5.2 cm x 9.8 cm x 20.1 cm)

22.0 oz (624 g)

CAN/CSA 22.2 No. 1010.1:1992 Overvoltage Category II. UL

License, TUV License, CSA License.

1-9

88

Service Manual

1-10

Chapter 2

Theory of Operation

Title Page

2-1. Introduction.......................................................................................... 2-3

2-2. Functional Block Description............................................................... 2-3

2-3. Detailed Circuit Description ................................................................ 2-5

2-4. Input Overload Protection................................................................ 2-5

2-5. Rotary Switch................................................................................... 2-5

2-6. Input Signal Conditioning Circuits.................................................. 2-5

2-7. Volts............................................................................................. 2-6

2-8. Ohms............................................................................................ 2-6

2-9. Analog Section of Integrated Meter IC (U4) ................................... 2-6

2-10. Microcomputer Control ................................................................... 2-8

2-11. Peripherals to U4.............................................................................. 2-9

2-12. AC Buffer .................................................................................... 2-10

2-13. AC Converter............................................................................... 2-10

2-14. Active Filter................................................................................. 2-10

2-15. A/D Converter ............................................................................. 2-10

2-16. Beeper.......................................................................................... 2-10

2-17. Reference Voltage ....................................................................... 2-10

2-18. Power Supply............................................................................... 2-10

2-19. Display............................................................................................. 2-11

2-20. Rotary Knob Switch and Potentiometer .......................................... 2-11

2-1

Loading...

Loading...