Page 1

Limited permission for the U.S. Government to reproduce Fluke

®

87 V/AN

Digital Multimeter

Service Manual

Item #2153596 is provided pursuant to FAR 52.227.14 Alt. II.

PN 2153596

July 2004

© 2004 Fluke Corporation, All rights reserved. Printed in USA

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is one year and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

To register your product online, visit register.fluke.com

Page 3

Table of Contents

Title Page

Introduction....................................................................................................... 1

Contacting Fluke............................................................................................... 1

Unpacking the Meter......................................................................................... 2

Inspection...................................................................................................... 2

Inspection Interval........................................................................................ 2

Preparations for Use.......................................................................................... 2

Precautions and Safety Information.................................................................. 2

Electrical Symbols ............................................................................................ 4

Specifications.................................................................................................... 5

General Specifications.................................................................................. 5

Detailed Specifications................................................................................. 5

Theory of Operation.......................................................................................... 9

Functional Block Diagram............................................................................ 9

Power Supply and Voltage Reference .......................................................... 10

Function Selection and Overload Protection ................................................ 11

Analog Signal Conditioning......................................................................... 13

VAC.......................................................................................................... 13

VDC.......................................................................................................... 14

mVDC ...................................................................................................... 14

Temperature.............................................................................................. 14

Ohms Below the 6 MΩ Range.................................................................. 14

Ohms in the 6 MΩ & 50 MΩ Range and Siemens in the 60 nS Range.... 15

Continuity in all Ohms and the Siemens Ranges...................................... 15

Capacitance............................................................................................... 15

Diode Test ................................................................................................ 15

mA, µA and AAC..................................................................................... 15

mA, µA and ADC..................................................................................... 16

Active Filter.................................................................................................. 16

800 Hz Low Pass Filter................................................................................. 16

RMS to DC Converter.................................................................................. 16

Analog to Digital Converter ......................................................................... 17

Secondary Analog Circuits........................................................................... 17

Keypad.......................................................................................................... 17

Microprocessor & Support Circuits.............................................................. 18

LCD .............................................................................................................. 18

i

Page 4

87 V/AN

Service Manual

Backlight....................................................................................................... 18

Beeper........................................................................................................... 18

Troubleshooting................................................................................................ 19

Restoration Actions....................................................................................... 19

Basic Maintenance............................................................................................ 19

Cleaning the Meter........................................................................................ 19

Opening the Meter Case ............................................................................... 20

Accessing the PCA and Replacing the LCD................................................. 21

Reassembling the Meter Case....................................................................... 22

Replacing the Battery.................................................................................... 22

Testing Fuses and Current Circuitry............................................................. 22

Replacing the Fuses...................................................................................... 23

Required Equipment.......................................................................................... 24

Performance Tests............................................................................................. 24

Basic Operability Tests................................................................................. 25

Testing the Fuses .......................................................................................... 25

Testing the Display....................................................................................... 25

Testing the Pushbuttons................................................................................ 27

Testing Meter Accuracy................................................................................ 27

Calibration Adjustment..................................................................................... 29

Calibration Adjustment Counter................................................................... 29

Calibration Adjustment Password................................................................. 29

Changing the Password............................................................................ 29

Restoring the Default Password ............................................................... 30

Meter Buttons Used in the Calibration Steps................................................ 31

Calibration Adjustment Procedure................................................................ 31

Service and Parts............................................................................................... 33

Schematic Diagrams.......................................................................................... 38

ii

Page 5

List of Tables

Table Title Page

1. Electrical Symbols................................................................................................. 4

2. AC Voltage Function Specifications..................................................................... 6

3. DC Voltage, Resistance, and Conductance Function Specifications..................... 6

4. Temperature Specifications................................................................................... 6

5. Current Function Specifications............................................................................ 7

6. Capacitance and Diode Function Specifications................................................... 7

7. Frequency Counter Specifications......................................................................... 7

8. Frequency Counter Sensitivity and Trigger Levels............................................... 8

9. Electrical Characteristics of the Terminals............................................................ 8

10. MIN MAX Recording Specifications.................................................................... 8

11. Input Path Components......................................................................................... 11

12. Overload Protection Components.......................................................................... 12

13. Required Tools and Equipment............................................................................. 24

14. Display Features.................................................................................................... 25

15. Accuracy Tests ...................................................................................................... 27

16. Calibration Adjustment Steps................................................................................ 32

17. 87 V/AN Final Assembly...................................................................................... 33

18. A1 Main PCA........................................................................................................ 35

iii

Page 6

87 V/AN

Service Manual

iv

Page 7

List of Figures

Figure Title Page

1. 87 V/AN Block Diagram....................................................................................... 10

2. Opening the Meter, Battery and Fuse Replacement.............................................. 20

3. Removing LCD Mask to Access LCD.................................................................. 21

4. Testing the Current Input Fuses............................................................................. 23

5. Display Features.................................................................................................... 25

6. Restoring the Default Password ........................................................................... 30

7. 87 V/AN Final Assembly...................................................................................... 34

8. A1 LED PCA......................................................................................................... 39

v

Page 8

87 V/AN

Service Manual

vi

Page 9

Introduction

To avoid shock or injury:

• Read “Precautions and Safety Information” before

performing the verification tests or calibration adjustment

procedures documented in this manual.

• Do not perform the verification tests or calibration

adjustment procedures described in this manual unless you

are qualified to do so.

• The information provided in this manual is for the use of

qualified personnel only.

• The 87 V/AN Digital Multimeter contains parts that can be

damaged by static discharge.

• Follow the standard practices for handling static sensitive

devices.

The 87 V/AN Service Manual provides the following information:

XW Warning

WCaution

• Safety information

• Specifications

• Theory of operation

• Basic maintenance (cleaning, replacing the battery and fuses)

• Performance test procedures

• Calibration adjustment procedures

• Replaceable parts and schematics

For complete operating instructions, refer to the 87 V/AN Users Manual.

Contacting Fluke

To contact Fluke or locate the nearest Service Center, call one of the following telephone

numbers:

USA: 1-888-44-FLUKE (1-888-443-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or, visit Fluke's Web site at www.fluke.com

.

To register your product, visit register.fluke.com

1

Page 10

87 V/AN

Service Manual

Unpacking the Meter

Inspection

Inspection Interval

Open the Multimeter box. Inside you will find the 87 V/AN Digital Multimeter

(hereafter referred to as “the Meter”) the test leads, the Product Manuals CD, the printed

87 V/AN User Manual, and the printed 87 V/AN Service Manual (this manual). Remove

the Meter from its plastic wrapping.

Inspect all contents for any visible shipping damage. Look for scratches or any other

damage. If the unit is damaged, contact Fluke immediately using the contact information

stated previously.

Inspect the Meter and test leads before each use.

XWWarning

To avoid possible electric shock or personal injury, inspect the

test leads for damaged insulation or exposed metal. Check the

test leads for continuity. Replace damaged test leads before

using the Meter.

Preparations for Use

Before using or servicing the Meter, read all associated safety information. Make sure

you have complete understanding of all safety issues.

Precautions and Safety Information

In this manual, a Warning identifies conditions and actions that pose hazard(s) to the

user; a Caution identifies conditions and actions that may damage the Meter or the test

instruments.

XWWarning

To avoid possible electric shock or personal injury, follow

these guidelines:

• Use this Meter only as specified in this manual or the

protection provided by the Meter might be impaired.

• Do not use the Meter if it is damaged. Before using the

Meter, inspect the case. Look for cracks or missing plastic.

Pay particular attention to the insulation surrounding the

connectors.

• Make sure the battery door is closed and latched before

operating the Meter.

• Replace the battery as soon as the battery indicator (M)

appears.

2

• Remove test leads from the Meter before opening the

battery door.

• Inspect the test leads for damaged insulation or exposed

metal. Check the test leads for continuity. Replace damaged

test leads before using the Meter.

Page 11

Digital Multimeter

Precautions and Safety Information

• Do not apply more than the rated voltage, as marked on the

Meter, between the terminals or between any terminal and

earth ground.

• Never operate the Meter with the cover removed or the case

open.

• Use caution when working with voltages above 30 V ac rms,

42 V ac peak, or 60 V dc. These voltages pose a shock

hazard.

• Use only the replacement fuses specified in this manual.

• Use the proper terminals, function, and range for

measurements.

• Avoid working alone.

• When measuring current, turn off circuit power before

connecting the Meter in the circuit. Remember to place the

Meter in series with the circuit.

• When making electrical connections, connect the common

test lead before connecting the live test lead; when

disconnecting, disconnect the live test lead before

disconnecting the common test lead.

• Do not use the Meter if it operates abnormally. Protection

may be impaired. When in doubt, have the Meter serviced.

• Do not operate the Meter around explosive gas, vapor, or

dust.

• Use only a single 9 V battery, properly installed in the Meter

case, to power the Meter.

• When servicing the Meter, use only specified replacement

parts.

• When using probes, keep fingers behind the finger guards

on the probes.

• Do not use the Low Pass Filter option to verify the presence

of hazardous voltages. Voltages greater than what is

indicated may be present. Make a voltage measurement

without the filter to detect the possible presence of

hazardous voltage, then select the filter function.

XCaution

To avoid possible damage to the Meter or to the equipment

under test, follow these guidelines:

• Disconnect circuit power and discharge all high-voltage

capacitors before testing resistance, continuity, diodes, or

capacitance.

• Before measuring current, check the Meter's fuses.

See " Testing Fuses (F1 and F2) ”.

3

Page 12

87 V/AN

Service Manual

Electrical Symbols

Electrical symbols used on the Meter and in this manual are explained in Table 1.

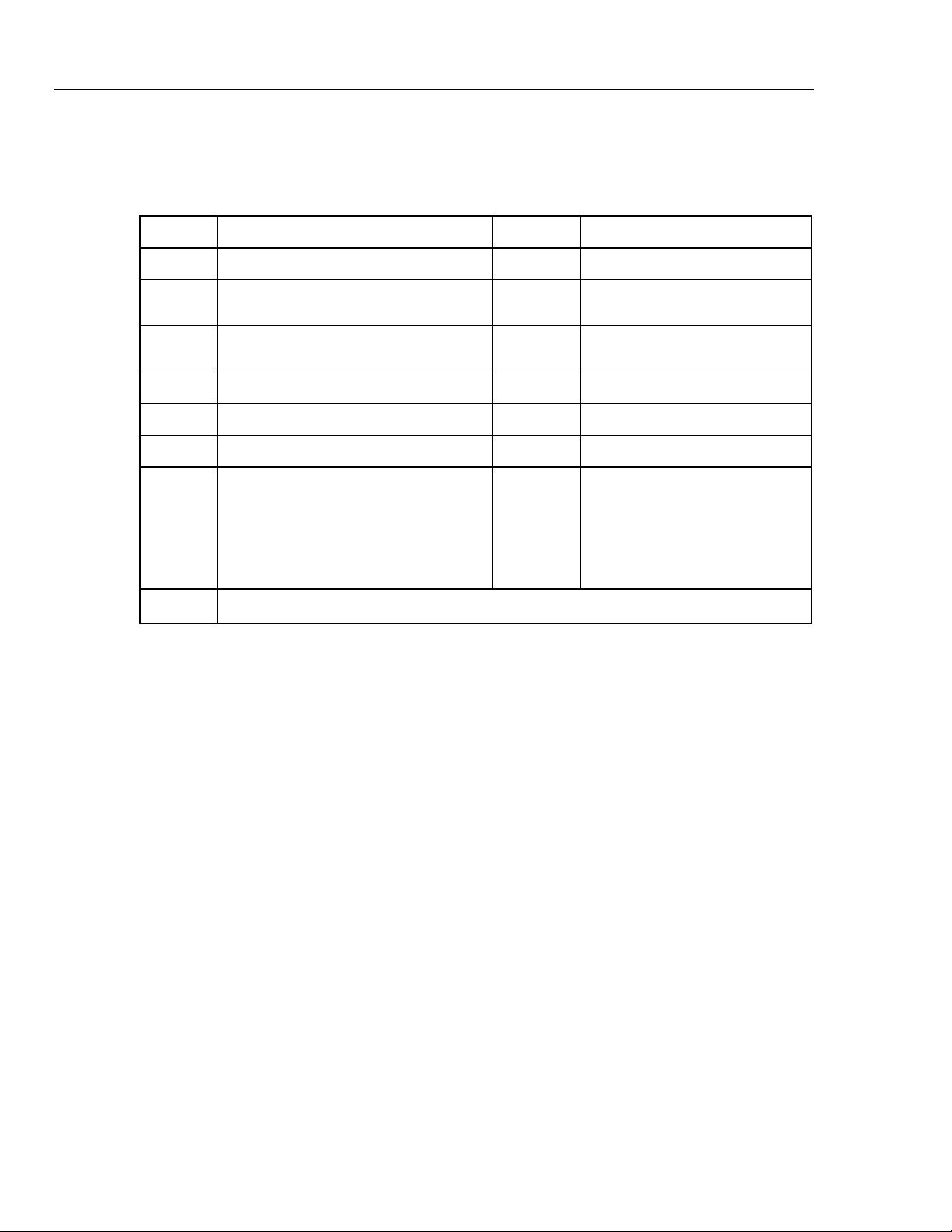

Table 1. Electrical Symbols

B

F

X

W

M

R

t

CAT III

s

AC (Alternating Current)

DC (Direct Current)

Hazardous voltage.

Risk of Danger. Important information.

See Manual.

Battery

Continuity test or continuity beeper tone.

Underwriters Laboratories

IEC overvoltage category III

CAT III equipment is designed to protect

against transients in equipment in fixedequipment installations, such as

distribution panels, feeders and short

branch circuits, and lighting systems in

large buildings.

Inspected and licensed by TÜV Product Services.

I

P

$

E

G

CAT IV

J

T

Earth ground

Fuse

Conforms to European Union

directives

Conforms to relevant Canadian

Standards Association directives

Double insulated

Capacitance

Diode

IEC overvoltage category IV

CAT IV equipment is designed to

protect against transients from the

primary supply level, such as an

electricity meter or an overhead or

underground utility service.

4

Page 13

Digital Multimeter

Specifications

Specifications

General Specifications

Maximum Voltage between any Terminal and Earth Ground: 1000 V rms

W Fuse Protection for mA or µA inputs: 44/100 A, 1000 V FAST Fuse

W Fuse Protection for A input: 11 A, 1000 V FAST Fuse

Display: Digital: 6000 counts updates 4/sec. The Meter also has 19,999 counts in high-resolution mode.

Analog Bargraph: 33 segments, updates 40/sec. Frequency: 19,999 counts, updates 3/sec at > 10 Hz.

Temperature: Operating: -20 °C to +55 °C; Storage: -40 °C to +60 °C

Altitude: Operating: 2000 m; Storage: 10,000 m

Temperature Coefficient: 0.05 x (specified accuracy)/ °C (< 18 °C or > 28 °C)

Electromagnetic Compatibility: All ranges unless otherwise noted: In an RF field of 3 V/m total

accuracy = specified accuracy + 20 counts

Except: Temperature not specified.

Relative Humidity: 0 % to 90 % (0 °C to 35 °C); 0 % to 70% (35 °C to 55 °C)

Battery Type: 9 V zinc, NEDA 1604 or 6F22 or 006P

Battery Life: 400 hrs typical with alkaline (with backlight off)

Vibration: Per MIL-PRF-28800 for a Class 2 instrument

Shock: 1 Meter drop per IEC 61010-1:2001

Size (HxWxL): 1.25 in x 3.41 in x 7.35 in (3.1 cm x 8.6 cm x 18.6 cm)

Size with Holster and Flex-Stand: 2.06 in x 3.86 in x 7.93 in (5.2 cm x 9.8 cm x 20.1 cm)

Weight: 12.5 oz (355 g)

Weight with Holster and Flex-Stand: 22.0 oz (624 g)

Safety: Complies with ANSI/ISA S82.01-2004, CSA 22.2 No. 1010.1:2004 to 1000 V Overvoltage

Category III, IEC 664 to 600 V Overvoltage Category IV. UL listed to UL61010-1. Licensed by TÜV to

EN61010-1.

Detailed Specifications

For all detailed specifications:

Accuracy is given as ±([% of reading] + [number of least significant digits]) at 18 °C to

28 °C, with relative humidity up to 90 %, for a period of one year after calibration

adjustment. In the 4 ½-digit mode, multiply the number of least significant digits

(counts) by 10. AC conversions are ac-coupled and valid from 3 % to 100 % of range.

The Meter is true rms responding. AC crest factor can be up to 3 at full scale, 6 at half

scale. For non-sinusoidal wave forms add -(2 % Rdg + 2 % full scale) typical, for a crest

factor up to 3.

Tables 2 through 10 list the Meter’s detailed specifications.

5

Page 14

87 V/AN

is a true rms responding meter. When the input leads are shorted together in the ac functions, the Meter

Service Manual

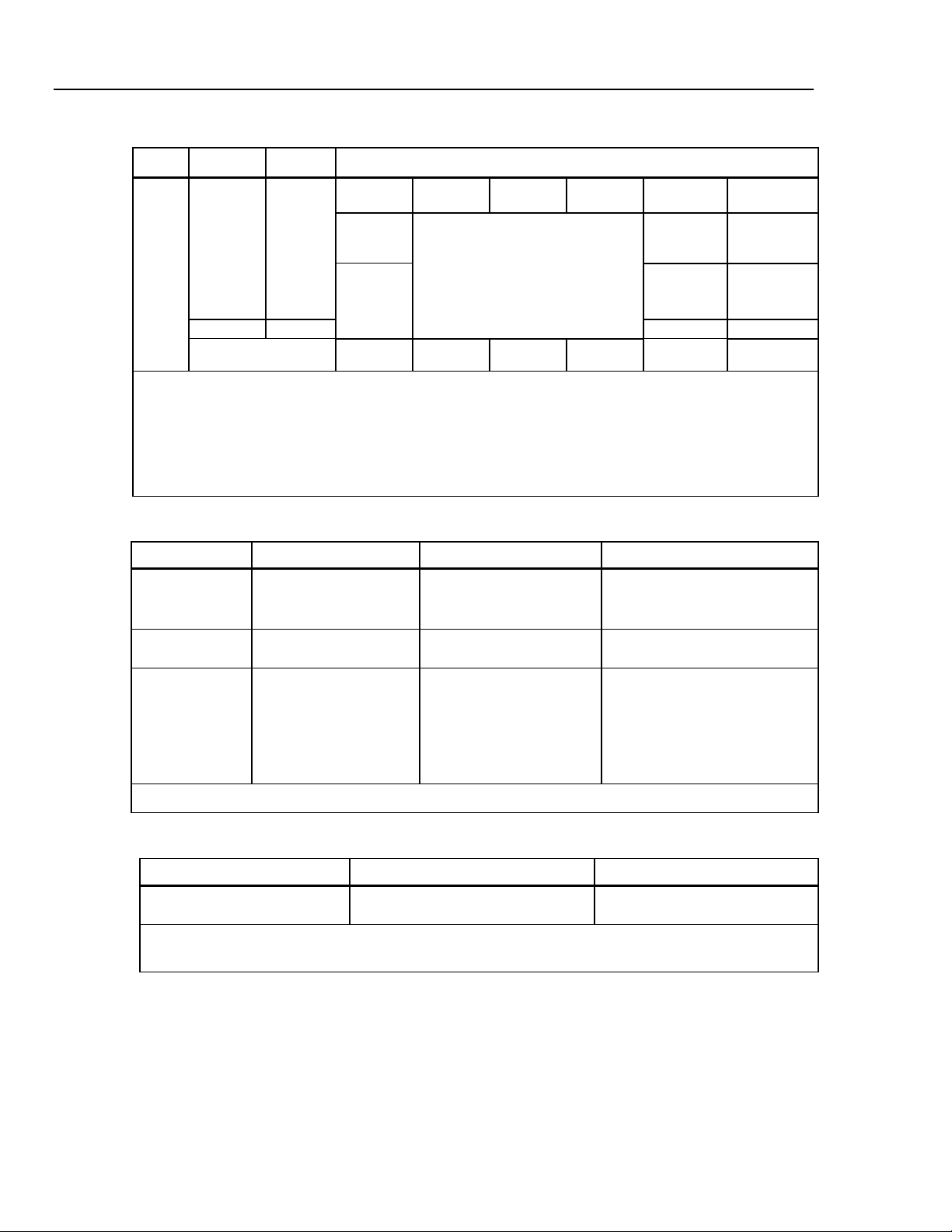

Table 2. AC Voltage Function Specifications

Function Range Resolution

600.0 mV

2,4

K

6.000 V

60.00 V

600.0 V

1000 V 1 V

Low pass filter ± (0.7 % + 2)

1. Below 10 % of range, add 12 counts.

2. The Meter

may display a residual reading between 1 and 30 counts. A 30 count residual reading will cause only a 2-digit

change for readings over 3 % of range. Using REL to offset this reading may produce a much larger constant error

in later measurements.

3. Frequency range: 1 kHz to 2.5 kHz.

4. A residual reading of up to 13 digits with leads shorted, will not affect stated accuracy above 3 % of range.

5. Specification increases from -1% at 200 Hz to -6% at 440 Hz when filter is in use.

0.1 mV

0.001 V

0.01 V

0.1 V

45 - 65 Hz 30 - 200 Hz

± (0.7 % + 4)

± (0.7 % + 2)

± (1.0 % + 4)

200 - 440 Hz

± (1.0 % + 4)

+1 % + 4

-6 % - 45

Accuracy

440 Hz - 1

kHz

unspecified

1 - 5 kHz 5 - 20 kHz

± (2.0 % + 4)

± (2.0 % + 4)

unspecified unspecified

unspecified unspecified

± (2.0 % + 20)

3

unspecified

Table 3. DC Voltage, Resistance, and Conductance Function Specifications

Function Range Resolution Accuracy

6.000 V

L

F

mV

e

nS

1. When using the REL ∆ function to compensate for offsets.

2. Add 0.5 % of reading when measuring above 30 MΩ in the 50 MΩ range.

60.00 V

600.0 V

1000 V

600.0 mV 0.1 mV ± (0.1 % + 1)

600.0 Ω

6.000 kΩ

60.00 kΩ

600.0 kΩ

6.000 MΩ

50.00 MΩ

60.00 nS

0.001 V

0.01 V

0.1 V

1 V

0.1 Ω

0.001 kΩ

0.01 kΩ

0.1 kΩ

0.001 MΩ

0.01 MΩ

0.01 nS

± (0.05 % + 1)

± (0.05 % + 1)

± (0.05 % + 1)

± (0.05 % + 1)

± (0.2 % + 2)1

± (0.2 % + 1)

± (0.2 % + 1)

± (0.6 % + 1)

± (0.6 % + 1)

± (1.0 % + 3)

± (1.0 % + 10)

2

1

1

Table 4. Temperature Specifications

Temperature Resolution Accuracy

-200 °C to +1090 °C

-328 °F to +1994 °F

1. Does not include error of the thermocouple probe.

2. Accuracy specification assumes ambient temperature stable to

rated accuracy applies after 1 hour.

0.1 °C

0.1 °F

± 1 °C. For ambient temperature changes of ± 5 °C,

6

1 % + 10

1 % + 18

1,2

Page 15

Digital Multimeter

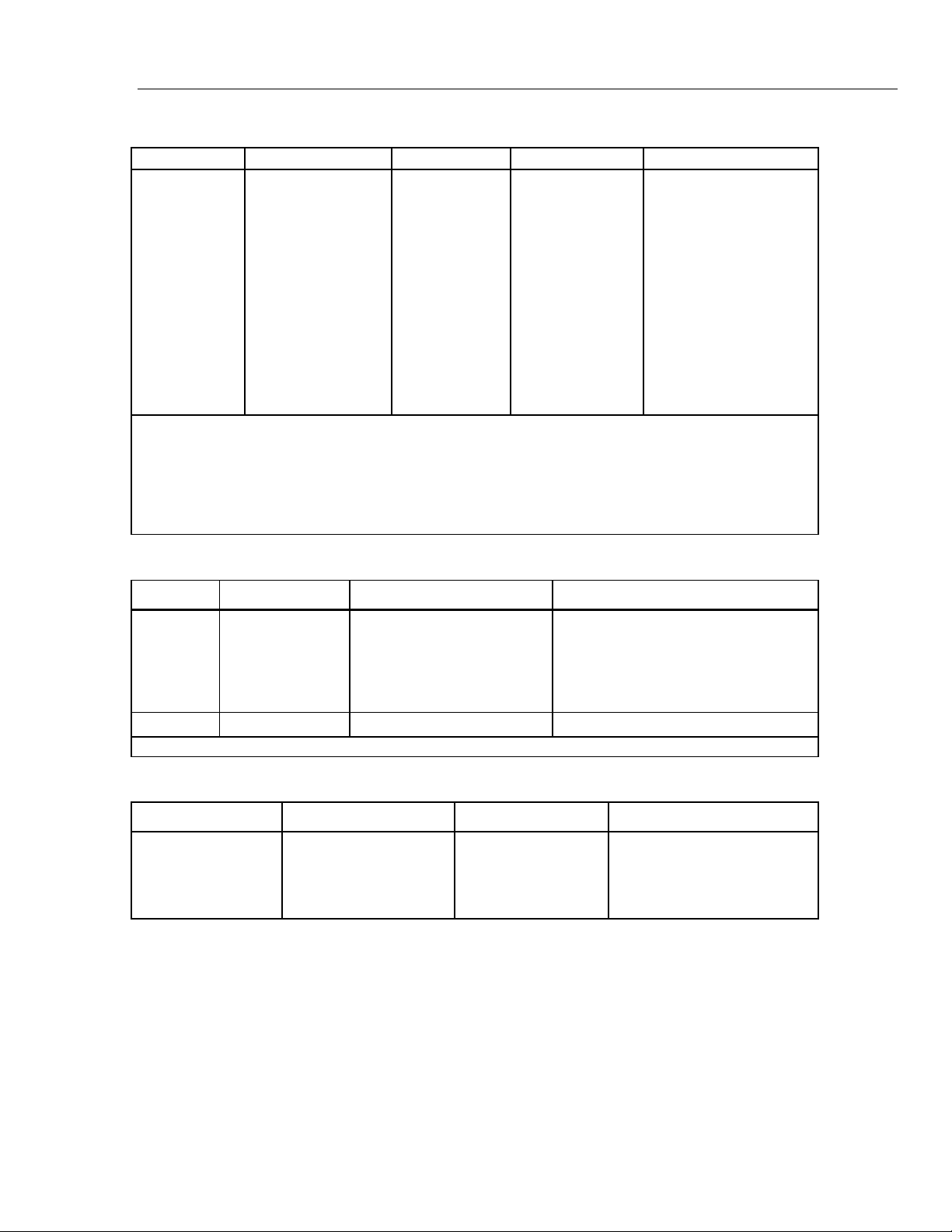

Table 5. Current Function Specifications

Function Range Resolution Accuracy

mA

\

(45 Hz to 2 kHz)

mA

[

µA B

(45 Hz to 2 kHz)

µAF

1. AC conversions are ac coupled, true rms responding, and valid from 3 % to 100 % of range, except 400 mA range

(5 % to 100 % of range) and 10 A range (15 % to 100 % or range).

2. The Meter is a true rms responding meter. When the input leads are shorted together in the ac functions, the

Meter may display a residual reading between 1 and 30 counts. A 30 count residual reading will cause only a 2

digit change for readings over 3 % of range. Using REL to offset this reading may produce a much larger constant

error in later measurements

3. W 10 A continuous up to 35 °C; < 20 minutes on, 5 minutes off at 35 °C to 55 °C. 20 A for 30 seconds maximum;

> 10 A unspecified.

4. 400 mA continuous; 600 mA for 18 hrs maximum.

60.00 mA

400.0 mA

6.000 A

3

10.00 A

60.00 mA

400.0 mA

6.000 A

3

10.00 A

600.0 µA

6000 µA

600.0 µA

6000 µA

4

4

0.01 mA

0.1 mA

0.001 A

0.01 A

0.01 mA

0.1 mA

0.001 A

0.01 A

0.1 µA

1 µA

0.1 µA

1 µA

± (1.0 % + 2)

± (1.0 % + 2)

± (1.0 % + 2)

± (1.0 % + 2)

± (0.2 % + 4)

± (0.2 % + 2)

± (0.2 % + 4)

± (0.2 % + 2)

± (1.0 % + 2)

± (1.0 % + 2)

± (0.2 % + 4)

± (0.2 % + 2)

1, 2

Burden Voltage (typical)

1.8 mV/mA

1.8 mV/mA

0.03 V/A

0.03 V/A

1.8 mV/mA

1.8 mV/mA

0.03 V/A

0.03 V/A

100 µV/µA

100 µV/µA

100 µV/µA

100 µV/µA

Specifications

Table 6. Capacitance and Diode Function Specifications

Function Range Resolution Accuracy

E 10.00 nF

100.0 nF

1.000 µF

10.00 µF

100.0 µF

9999 µF

0.01 nF

0. 1 nF

0.001 µF

0.01 µF

0.1 µF

1 µF

± (1 % + 2)1

± (1 % + 2)

± (1 % + 2)

± (1 % + 2)

± (1 % + 2)

± (1 % + 2)

1

G 3.000 V 0.001 V ± (2 % + 1)

1. With a film capacitor or better, using Relative mode to zero residual.

Table 7. Frequency Counter Specifications

Function Range Resolution Accuracy

Frequency

(0.5 Hz to 200 kHz,

pulse width > 2 µs)

199.99

1999.9

19.999 kHz

199.99 kHz

> 200 kHz

0.01 Hz

0.1 Hz

0.001 kHz

0.01 kHz

0.1 kHz

± (0.005 % + 1)

± (0.005 % + 1)

± (0.005 % + 1)

± (0.005 % + 1)

unspecified

7

Page 16

87 V/AN

Service Manual

Table 8. Frequency Counter Sensitivity and Trigger Levels

Minimum Sensitivity (RMS Sine wave)

Input Range1

5 Hz - 20 kHz 0.5 Hz - 200 kHz

600 mV dc

600 mV ac

6 V

60 V

600 V

1000 V

Duty Cycle Range Accuracy

0.0 to 99.9 % Within ± (0.2% per kHz + 0.1 %) for rise times < 1 µs.

1. Maximum input for specified accuracy = 10X Range or 1000 V.

70 mV (to 400 Hz)

150 mV

0.3 V

3 V

30 V

100 V

70 mV (to 400 Hz)

150 mV

0.7 V

7 V (≤ 140 kHz)

70 V (≤ 14.0 kHz)

200 V (≤ 1.4 kHz)

Table 9. Electrical Characteristics of the Terminals

Common Mode

Rejection Ratio

(1 kΩ unbalance)

Function

Overload

Protection

Input Impedance

1

(nominal)

L 1000 V rms 10 MΩ < 100 pF > 120 dB at dc,

50 Hz or 60 Hz

F

mV

1000 V rms 10 MΩ < 100 pF > 120 dB at dc,

50 Hz or 60 Hz

Approximate Trigger

Level

(DC Voltage Function)

40 mV

1.7 V

4 V

40 V

100 V

Normal Mode Rejection

> 60 dB at 50 Hz or 60 Hz

> 60 dB at 50 Hz or 60 Hz

K 1000 V rms 10 MΩ < 100 pF (ac-

coupled)

> 60 dB, dc to 60 Hz

Full Scale Voltage Typical Short Circuit Current

Open Circuit

Test Voltage

To 6.0 MΩ

e 1000 V rms < 7.5 V dc < 4.1

V dc

50 MΩ or

60 nS

< 4.5

V dc

600 Ω

1 mA 100 µA 10 µA 1µA 1 µA 0.5 µA

6 k 60 k 600 k 6 M 50 M

G 1000 V rms < 3.9 V dc 3.000 V dc 0.6 mA typical

6

1. 10

1. For repetitive peaks: 1 ms for single events.

V Hz max

Table 10. MIN MAX Recording Specifications

Nominal Response Accuracy

100 ms to 80 %

(dc functions)

120 ms to 80 %

(ac functions)

250 µs (peak)

1

Specified accuracy ± 12 counts for changes > 200 ms in duration

Specified accuracy ± 40 counts for changes > 350 ms and inputs > 25 % of range

Specified accuracy ± 100 counts for changes > 250 µs in duration

(add ± 100 counts for readings over 6000 counts)

(add ± 100 counts for readings in Low Pass mode)

8

Page 17

Digital Multimeter

Theory of Operation

Theory of Operation

This section provides the theory of operation for the 87 V/AN Digital Multimeter to a

depth that is required for troubleshooting to the component level. The functional block

diagram provides an overview for the description. The schematic diagrams included in

the manual are referred to during the following detailed circuit descriptions.

Functional Block Diagram

Figure 1 shows the top-level function block diagram for the Meter. Each of the blocks in

this diagram is discussed in detail in the following paragraphs.

The parameter to be measured is connected with test leads to the appropriate two input

terminals shown at the left of the block diagram. After the Meter is set to the desired

function, the signal is routed to the signal conditioning circuit. Either automatically or

manually, a range is selected that puts the signal to be measured within the dynamic

range of the analog-to-digital converter (ADC) or other signal conditioning circuits like

the RMS-to-DC converter discussed in “RMS to DC Converter”. A scaled AC signal

voltage is routed directly, or via an 800-Hz low-pass filter, to the RMS-to-DC converter

circuit. A DC input signal or DC output of the RMS-to-DC converter (for AC functions)

is routed to a low-pass, 6-Hz, 2-pole active filter to prepare it for ADC measurement.

The conditioned analog input signal voltage is converted to a digital value by the ADC

and sent to the microprocessor. The microprocessor converts this digital value for

display on the LCD based on the function, range and keypad entered options. The output

of the signal-conditioning block is also routed to the secondary analog circuits block to

be further conditioned for input to the fast ADC contained within the microprocessor

block. Other analog circuits that control the behavior of the Meter are located in the

secondary analog circuits block and are discussed later.

9

Page 18

87 V/AN

Service Manual

V/Ohms

mA/µA

AMPS

Common

Low

Pass

Filter

Power

Supply

Function

Selection

&

Overload

Protection

Active

Filter

Analog

Signal

Conditioning

Reference

RMS

Converter

Analog

to

Digital

Converter

Secondary

Analog

Circuits

Microprocessor

&

Support

Circuits

Back-

light

LCD

Keypad

Beeper

10

Figure 1. 87 V/AN Block Diagram

Power Supply and Voltage Reference

A 9-V alkaline battery supplies power to the Meter and is connected via a cable assembly

to J3 on the A1 printed circuit assembly (PCA). Diode CR3 protects the Meter from

damage due to accidental polarity reversal at J3.

Q13 is used as a remote power switch that connects the battery to the power supply

regulators when the Meter is turned on. When S1 is in the OFF position, Q14 is off to

allow the battery voltage to turn off Q13 via R73. When the Meter is turned on, S1

makes a momentary contact to the battery voltage via R80, turning on Q14, which turns

on Q13, which connects the battery voltage to R74, which holds Q14 until S1 is returned

to the OFF position.

When Q13 is on, battery voltage is applied to regulators U6 and U10, bypass capacitors

C12 and C14 and the low battery detect divider resistors R15 & R16. Note that since the

power supply levels are referenced to the COMMON input terminal of the Meter, the

negative end of the battery is the -2.5 V power supply.

U6 is a 3.3-V regulator that generates the +0.8-V (-2.5 V + 3.3 V) power supply. U10 is

a 5.0-V regulator that generates the +2.5-V (-2.5 V + 5.0 V) power supply. U10 is

ama101f.eps

Page 19

Digital Multimeter

Theory of Operation

enabled and disabled via control line V5* from microprocessor U2. C15 bypasses the

output of U10.

When U10 is enabled, 5 V is supplied to the voltage reference U8 input. U8 is a 2.5-V

reference with a buffered output and accurately holds the COMMON input 2.5 V above

the -2.5 V power supply or at 0 V. The triangular ground symbol represents this

reference level throughout the Meter schematic. C16, C57, C50 and R109 bypass the

output of U8 keeping the voltage between COMMON and the -2.5 V power supply noise

free and stable. C50 and R109 form a low Q bypass that is directed at electromagnetic

interference (EMI).

Function Selection and Overload Protection

Sections of rotary switch S1 connect the V/Ohms and mA/µA input jacks to the signal

conditioning circuit as required for the respective Meter functions. The Meter schematic

symbols for each of the sections of S1 have the functions that correspond to the closed

positions listed next to them. Table 11 indicates the components that complete normal

operation signal path/paths from input jacks to the required signal conditioning

circuit/circuits for each Meter function.

Table 11. Input Path Components

Function Components

K

VAC

V

VDC

L

m

mV dc

L -

m

mV dc – HiZ

d

Temperature

T

Ohms (Below 6 MΩ)

T

Ohms (6 MΩ, 50 MΩ, nS)

X

Continuity (below 6 MΩ)

X

Continuity (6 MΩ, 50 MΩ)

HiZ

RT1, R1, R2, C1, Z1(9.997 M), C43, R94

RT1, R1, S1(1,3), Z1(9.997 M)

RT1, R1, S1(1,3), Z1(9.997 M), S1(29,5), R85

RT1, R1, S1(29,5), R85

RT1, R1, S1(1,2), R3, S1(29,5), R85, S1(1,3)

Z1(9.997M)

RT1, R1, S1(1,2), R3, Z2, S1(4,5), R85

RT1, R1, S1(1,2), R3, S1(1,3), Z1(9.99 7M)

RT1, R1, S1(1,2), R3, Z2, S1(4,5) R85

RT1, R1, S1(1,2), R3, S1(1,3), Z1(9.997 M)

E

Capacitance

G

Diode Test

RT1, R1, S1(1,2), R3, Z2, S1(4,5) R85

RT1, R1, S1(1,2), R3, Z2, S1(4,5), R85

11

Page 20

87 V/AN

Service Manual

The Meter uses diode clamps, a positive temperature coefficient thermistor, metal oxide

varistors (MOVs) and fuses for protection when inadvertent overload conditions are

applied across the input terminals. Table 12 shows the components that limit and direct

overload currents to prevent damage to the Meter.

Table 12. Overload Protection Components

Function Components Protected Protection Components

U1 pin 3 Z1(9.997 M), U1-3 clamps K

VAC

VDC

S1(1,2)(1,3)(29,5)(4,5), Z1(9.997 M) RT1, R1, RV1, RV2, Z2, RV3

U1 pin 3 Z1(9.997 M), U1-3 clamps V

S1(1,2)(29,5)(4,5), Z1(9.997 M) RT1, R1, RV1, RV2, Z2, RV3

L, d

m

mV dc, Temperature

T, E,X

Ohms, Capacitance,

Continuity

G

Diode Test

U1 pin 36 RT1, R1, CR10, VR1, CR8, CR9, R3, U1-36

clamps

U1 pin 3 RT1, R1, CR10, VR1, CR8, CR9, Z1(9.997 M),

U1-3 clamps

U1 pin 1 RT1, R1, CR10, VR1, CR8, CR9, R85, U1-1

clamps

S1(4,5) Z2, RV3, RV2, RT1, R1, CR10, VR1, CR8,

CR9

U1 pin 36 RT1, R1, CR10, VR1, CR8, CR9, R3, U1-36

clamps

U1 pin 3 RT1, R1, CR10, VR1, CR8, CR9, Z1(9.997 M),

U1-3 clamps

U1 pin 1 Z2, R85, U1-1 clamps

S1(29,5) RT1, R1, CR10, VR1, CR8, CR9

U1 pin 36 RT1, R1, CR10, VR1, CR8, CR9, R3, U1-36

clamps

U1 pin 3 RT1, R1, CR10, VR1, CR8, CR9, R2, C1,

Z1(9.997 M), U1-3 clamps

U1 pin 1 Z2, R85, U1-1 clamps

S1(1,3)(29,5) RT1, R1, CR10, VR1, CR8, CR9

S1(7,8)(7,6) F1, CR1, CR2 Voltage applied to

mA/µA input jack in

any of the above

functions or OFF

input jack in any

function including OFF

U2 pin 3 after F1 opens R7, CR5

R5 F1, CR1, CR2, R6 mA/A

U2 pin 3 after F1 opens R7, CR5

R4 F1, CR1, CR2 µA

U2 pin 3 after F1 opens R7, CR5

R6 F2 (assuming enough current is available) Voltage applied to A

U2 pin 2 after F2 opens R10, CR6

12

Page 21

Digital Multimeter

Theory of Operation

Internal diodes on each pin of U1 clamp the voltage to a diode drop above or below the

power supply levels. Further, U1 power supplies are internally clamped together to

prevent overvoltage damage to circuits within U1. U1 pins 1 & 36 have the positive

clamp tied to the voltage at CPH (U1 pin 32), which is approximately 5 V above the

2.5-V power supply when the charge pump and current source in U1 are enabled. When

an overload voltage is present on the V/Ohms input jack with respect to the COMMON

input jack, clamp diodes in U1 conduct enough to drop the offending voltage on resistors

that handle the resulting overload current. Additional clamps, CR8, CR9, CR10 and

VR1, are used to keep currents from large overload voltages out of U1 pin 36 by safely

clamping the voltage at TP6 to approximately +8.9 V and -2.1 V with respect to

COMMON. Positive temperature coefficient thermistor, RT1, will aid the safe handling

of the overload by increasing in resistance and thereby reducing the overload current

being handled by these additional clamps. R1 is a high voltage resistor that drops the

overload voltage until RT1 can catch up.

During voltage overload conditions exceeding approximately ±2 kV at the V/Ohms input

jack, the open contacts of S1 need to have the voltage across them kept below the arcover level. RV1, RV2 & RV3 MOVs will conduct and limit the voltage at TP5 and TP11

to a magnitude of less than 2 kV unless TP5 is connected to TP6 by S1(1,2). The voltage

at TP6 will be held by clamps CR8, CR9, CR10 and VR1 as described above with RT1

and the high voltage resistor R1 safely dropping the overload voltage.

During voltage or current overload conditions at the mA/µA input jack with the mA/A or

µA Meter function selected, current shunts R4, R5 & R6 and the closed contacts of S1

are protected by F1 opening. CR1 & CR2 limit the voltage at the mA/µA input to

approximately ±2.1 V regardless of the Meter function selected, thereby protecting the

open or closed contacts of S1 (and the current shunts, if connected) while allowing time

for F1 to open.

During voltage or current overload conditions at the A input jack current shunt R6 is

protected by F2 opening.

C43 and R94, which are in parallel with Z1 (9.997 MΩ), are used in conjunction with

components in the signal conditioning circuit for frequency compensation. C3 reduces

input noise in the signal path. R100, R101 & R103 provide a current limited connection

to voltages that will minimize the leakage current of CR8, CR9 and CR10, which

combines with the input signal creating a temperature-dependent error in the reading.

Inductors L1, L2, L4 & L5 attenuate electromagnetic interference (EMI) and capacitive

coupled noise that is picked up by the input circuit and test leads that is passed to the

signal conditioning circuit.

The operation of R7, R10, R11, R48, C26, C31, CR5 and CR6 is described in

“Secondary Analog Circuits”.

Analog Signal Conditioning

U1 provides the switching that is necessary for range selection, the operational

amplifiers that are used for buffering and filtering, various current source values and

various voltage comparator functions, which are required to transform the input signal to

a representation that can be measured and quantified.

VAC

The V/Ohms input is connected, as described in Table 11, to DIV_A (U1 pin 3) and

routed by U1 internal switches to the inverting input of an internal operational amplifier.

The overall gain to ACAMP_O (U1 pin 22) is set by the total resistance to the inverting

input from the V/Ohms input, the selected range resistor in Z1, R105, R12 and R8. U1

works in conjunction with C43 & R94 to compensate the frequency response of this path.

The signal at ACAMP_O is, therefore, a scaled representation of the AC input signal

13

Page 22

87 V/AN

Service Manual

VDC

mVDC

within the band pass specification of the Meter. The signal at ACAMP_O is routed to the

Low-Pass Filter and/or the RMS Converter using multiplexer U12. The output of LowPass Filter or the RMS Converter is routed back into CONV_IN (U1 pin13), filtered,

buffered and passed to FE_O (U1 pin 19) ready for measurement. If the Hz function is

selected, the scaled voltage at ACAMP_O is also routed within U1 to comparators that

will produce a digital signal at COMP_O (U1 pin 24) ready for frequency measurement.

The V/Ohms input is connected, as described in Table 11, to DIV_A (U1 pin 3) and

routed by U1 internal switches to one of the other resistors in the Z1 network to be

divided. The divided voltage is filtered, buffered and passed to FE_O (U1 pin19) ready

for measurement. If the operator selects the Hz function, the signal is routed within U1 to

comparators that will produce a digital signal at COMP_O (U1 pin 24) ready for

frequency or duty cycle measurement.

The V/Ohms input is connected, as described in Table 11, to SENSE_HI (U1 pin 1) and

routed by U1 internal switches to be filtered, buffered and passed to FE_O (U1 pin19)

ready for measurement. The resistor Z1 (9.997 MΩ), is used to provide a 10 MΩ

impedance across the Meter V/Ohms to COMMON input jacks by connecting DIV_A

(U1 pin 3) to R3 (U1 pin 9), which in turn is connected to COMMON by Z1 (440.4 Ω)

and R8. This connection is opened by U1 when the HiZ input power up option is

selected. If the operator selects the Hz function, the signal is routed within U1 to

comparators that will produce a digital signal at COMP_O (U1 pin 24) ready for

frequency or duty cycle measurement.

Temperature

The V/Ohms input is connected the same as in mVDC to FE_O (U1 pin 19) with the

exception that U1 provides a gain of 10 to the signal. Another measurement of the

temperature of the input terminals where the thermocouple wire transitions to copper is

required to calculate the actual temperature sensed by a thermocouple. Since U1 is

controlled by the microprocessor, this measurement is done by routing two different

values of current from the U1 current source via RJT_I (U1 pin 35) to Q3 and the

resulting VBE is routed, buffered and passed to the FE_O (U1 pin 19) ready for

measurement. The reference junction temperature is calculated from these

measurements. Inductor L2 and capacitor C2 keep noise out of the measurement

circuitry. Since thermocouples are easily broken and give incorrect readings, a periodic

test of the thermocouple is required. A current from the U1 current source is routed to

ISRC (U1 pin36) and on to the thermocouple that is connected from V/Ohms to

COMMON. The resulting voltage drop across the thermocouple is connected to the U1

internal comparators and converted to a digital signal at COMP_O (U1 pin 24) ready for

evaluation by the microprocessor.

Ohms Below the 6 MΩ Range

The U1 current source is enabled and routed to ISRC (U1 pin 36) and on to the V/Ohms

input jack, which is also connected to SENSE_HI (U1 pin 1) via the components

indicated in Table 11. SENSE_HI is routed by U1 internal switches, filtered, buffered

and passed to FE_O (U1 pin19) ready for measurement. Resistor R51 sets the reference

for the 1 mA and 100 µA U1 current-source currents. Resistor R52 sets the reference for

the 10 µA, 1 µA and 0.5 µA U1 current source currents. Capacitors C4 and C5 are used

by the U1 current source charge pump to set the available compliance voltage at ISRC to

7.5 V with respect to COMMON. The 0.5-µA current source is not used for resistor

measurements in these ranges. If the operator selects the Hz function, the signal is

14

Page 23

Digital Multimeter

Theory of Operation

routed within U1 to comparators that will produce a digital signal at COMP_O (U1 pin

24) ready for frequency or duty cycle measurement.

Ohms in the 6 MΩ & 50 MΩ Range and Siemens in the 60 nS Range

The U1 current source is enabled and routed to ISRC (U1 pin 36) and on to the V/Ohms

input jack, which is also connected to DIV_A (U1 pin 3) via the components indicated in

Table 11. DIV_A is routed by U1 internal switches to R0 (U1 pin 5) and on to Z1 (1.106

MΩ) to divide the sensed voltage by 10. The divided voltage is filtered, buffered with a

gain of two, and passed to FE_O (U1 pin19) ready for measurement. Only the 1 µA and

0.5 µA current sources are used in these ranges. If the operator selects the Hz function,

the signal is routed within U1 to comparators that will produce a digital signal at

COMP_O (U1 pin 24) ready for frequency or duty cycle measurement.

Continuity in all Ohms and the Siemens Ranges

The same measurement paths discussed above apply with the exception that the filtering

is turned off to speed up the circuit response and the signal at FE_O (U1 pin 19) is

routed to U1 comparators, which convert it to a digital signal at CONT_O (U1 pin 24)

ready for evaluation by the microprocessor.

Capacitance

The U1 current source is enabled and internally routed to COMMON. ISRC (U1 pin 36)

is routed to the V/Ohms input, which is also connected to SENSE_HI (U1 pin 1) via the

components indicated in Table 11. The voltage signal at SENSE_HI is internally routed

in U1 to the comparators converted to a digital signal at COMP_O (U1 pin 24) ready for

evaluation by the microprocessor, buffered and passed on to FE_O (U1 pin 19) ready for

measurement. The capacitor is discharged to below a value set on the comparator via

ISRC (U1 pin 36), which is connected to COMMON or the negative voltage rail

depending on how much voltage is on the capacitor being measured. Once the capacitor

is discharged sufficiently, current is applied to it in accurately measured packets until the

U1 comparator signals that the capacitor under test has been sufficiently charged. By

measuring the voltage at discharge and after charge the value of the capacitor is

calculated by the microprocessor.

Diode Test

The U1 1-mA current source is enabled and routed to ISRC (U1 pin 36) and on to the

V/Ohms input, which is also connected to SENSE_HI (U1 pin 1) via the components

indicated in Table 11. SENSE_HI is routed by U1 internal switches to R1 (U1 pin 7) and

on to Z1 (110.01 kΩ) & R8 which form 10-to-1 divider with Z2. The divided voltage

signal is filtered, buffered with a gain of two and passed to FE_O (U1 pin19) ready for

measurement.

mA, µA and AAC

The mA/µA input and the A input are connected to R4 (U1 pin 10) as described in Table

11. The voltage at R4 is proportional to the product of the current being measured and

the shunt resistance that is in use. The voltage at R4 is routed by U1 internal switches to

the inverting input of an internal operational amplifier. The overall gain to ACAMP_O

(U1 pin 22) is set by the total resistance from the shunt in use to the inverting input,

either resistor Z1(1.106 MΩ) or Z1(110.01 kΩ), R105, R12 & R8. The signal at

ACAMP_O is, therefore, a scaled representation of the AC current input signal. The

signal at ACAMP_O is routed to either the Low-Pass Filter or the RMS Converter or

both using multiplexer U12. The output of the Low-Pass Filter or the RMS Converter is

routed back into CONV_IN (U1 pin13), filtered, buffered with a gain of two and passed

to FE_O (U1 pin 19) ready for measurement. If the operator selects the Hz function, the

15

Page 24

87 V/AN

Service Manual

mA, µA and ADC

Active Filter

scaled voltage at ACAMP_O is also routed within U1 to comparators that will produce a

digital signal at COMP_O (U1 pin 24) ready for frequency measurement.

The mA/µA input and the A input are connected to R4 (U1 pin 10) as described in Table

11. The voltage at R4 is proportional to the product of the current being measured and

the shunt resistance that is in use. The voltage at R4 is routed by U1 internal switches,

filtered, buffered with a gain of 1 or 10 depending upon the range selected and passed to

FE_O (U1 pin 19) ready for measurement. If the Hz function is selected, the signal at

FE_O is also routed within U1 to comparators that will produce a digital signal at

COMP_O (U1 pin 24) ready for frequency or duty-cycle measurement.

The U1 buffer amplifier connected to FE_O (U1 pin 19) is zeroed digitally by the

microprocessor. The voltage at ZERO_IN (U1 pin 14) is routed by U1, buffered with the

selected gain and passed on to FE_O ready for measurement.

C9, C10, R17 & R18 are used in conjunction with an operational amplifier internal to U1

to form a low-pass active filter. This configuration produces the equivalent of two

cascaded filters, each at approximately 6 Hz. R18 is bypassed by switches in U1 when

the input impedance of the range voltage divider is above 1 MΩ.

800 Hz Low Pass Filter

R86, R87, R88, C36, C37, C38 & U4 form an 800-Hz low-pass filter (three pole

Butterworth) that can be selected in the VAC function. This filter is used to stop high

frequency noise such as that encountered in motor drive controllers from passing on to

the measurement circuits. The A switch of multiplexer U12 is used to select between

either the input or output of this filter as an input to the RMS Converter. The B switch of

multiplexer U12 can select the output of this filter for input to CONV_IN (U1 pin 13)

and bypass the RMS Converter when the Frequency function or pm option is

selected.

RMS to DC Converter

C6, U7 & C7 form the RMS-to-DC conversion circuit. C33 & C35 are RF-bypass

capacitors. C32 & C34 are power-supply bypass capacitors for U7. R29, R30, R32, R33,

Q6 & Q7 form the power-control circuit for U7.

The selected AC signal at the A output of U12 is passed to U7 pin 1 via DC-blocking

capacitor C6. U7, with the aid of the averaging capacitor C7 on pin 5, produces a DC

output at pin 6 that is proportional to the RMS of the input.

U7 is powered on and off as needed for the selected Meter function by the

microprocessor controlling the AC* signal. When AC* is driven to a logic high (+0.8 V),

Q6 is turned on, turning on Q7, which connects the positive end of the battery (6 V

minimum) to the pin 3 of U7, thereby powering it down. When AC* is driven to a logic

low (-2.5 V), transistor Q6 is turned off, turning off Q7, which allows U7 pin 3 to be

pulled to +0.8 V through R33, thereby allowing Q7 to power on.

16

Page 25

Digital Multimeter

Theory of Operation

Analog to Digital Converter

U3 is a 20-bit Σ∆ analog-to-digital converter (ADC). C21 & C22 are power-supply

bypass capacitors. The DC signal at FE_O (U1 pin 19) provides the signal input for U3.

The reference for conversion is supplied by U8 as described in 1.3 to the REF and VIN*

(compliment of VIN) inputs. Since REF* (compliment of REF) is tied to -2.5 V and both

pairs of inputs to U3 are handled differentially, the dynamic range of the VIN is ±1.25 V

around COMMOM. The microprocessor U2 uses three digital lines to communicate with

U3. U3 signals the microprocessor U2 that a conversion is completed by pulling the SDO

signal line to logic low (-2.5 V), which is coupled through current limiting resistor R31

to DOUT. When U2 is ready for the reading, it pulls ADCS* of U3 to a logic low and

clocks the data serially out of SDO with the signal ADSCK applied to SCK. Connecting

F0 of U3 to -2.5 V sets the internal clock so that the normal mode rejection ratio

(NMRR) of the digital filter will provide adequate rejection of both 50 Hz and 60 Hz.

Secondary Analog Circuits

Several secondary analog circuits are used to provide signals to a 12-bit, 200 kilo

samples per second (ksps) (8000 sps is the highest rate used) analog to digital converter

(ADC) with eight multiplexed-inputs in U2.

R7, R48 C31 & CR5 form a circuit that determines whether a plug is inserted into the

mA/µA input jack. The signal MAJACK is held at -2.5 V via R48 if the split-jack J1 is

not shorted by a plug. When a plug shorts split-jack J1, current will flow through R7 and

the MAJACK signal is pulled to near COMMON via R28 or R4 and/or R5. MAJACK is

measured by U2 to determine if the function selected by the rotary switch S1 is in

conflict with the Meter inputs. C31 suppresses high frequency noise. Diode CR5

provides protection in case F1 is open. R10, R11, C26 & CR6 provide the same function

for the

A input with the COMMON connection via R6.

Keypad

R97 & R98 allow the Meter model and possible revision number to be read by the

microprocessor U2 as an analog signal over the single signal path MODEL.

R34, R35, R36, R37, C56 & U4 form a buffer and analog level shifter for allowing the

ADIN signal to be sampled by the faster U2 ADC. This ADC is used for auto-ranging,

for bar graph readings and p m. R34 and R35 set the DC gain at the output of

U4 to 2. Since the dynamic range of ADIN is ±1.25, the signal at the U4 output is ±2.5

V. Since R36 and R37 form a voltage divider referenced to -2.5V, the signal at

FASTADIN has a dynamic range of -2.5V to 0 V with respect to COMMON. C56

provides a band-limited response to the higher frequencies contained in signals that are

being evaluated for p m. C39 bypasses U4 power supplies.

S1, R22, R53, R54, R55, R58, R59, R60, R61, R84 & C20 allow the position of the

rotary switch S1 to be read by the microprocessor U2 as an analog signal over the signal

path SWPOS. U2 reads the position of S1 by pulling the SWPWR signal to logic high

(+0.8V) and reading the signal at SWPOS. The voltage divider formed by R61, R60,

R59, R58, R55, R54, R53 & R84 creates a signature voltage for each switch position of

S1. R22 will pull this voltage down slightly when the divider taps are connected, but will

pull the SWPOS voltage to -2.5 V when S1 is between switch positions. C20 suppresses

noise.

R15 & R16 form a voltage divider to allow the battery voltage to be monitored via

signal LOWBATT. C28 suppresses noise.

R40, R43, R68, S3, S4, S5, S6, S7, S8, S9, S10 & S11 form the buttons that allow access

to Meter functions that are not selected by rotary switch S1. The microprocessor U2 is

connected to 9 switches with three strobe lines PB4, PB5 & PB6 to three switches each.

The other end of each switch is pulled to +0.8 V by R40, R43 or R68 and connected to

17

Page 26

87 V/AN

Service Manual

Microprocessor & Support Circuits

sense lines PB1, PB2 & PB3 with one switch from each strobe group per sense line. U2

pulls each strobe line to -2.5 V in sequence and monitors the sense lines. U2 can

determine which switch is closed, debounce and handle multiple switch closures.

U2 is the microprocessor and Y1 is the crystal used for the clock generator that is

internal to U2. The 32.768-kHz oscillator is multiplied to above 1 MHz inside U2 when

the Meter is not in sleep mode. This low oscillator frequency helps reduce the standby

power required by U2 while the Meter is in sleep mode. C17, C18, C19, C25, C27 &

C29 are power supply bypass capacitors.

R21 & C8 form the power on reset circuit that holds the RST* signal to U2 at logic low

until C8 is charged to logic high on the way to 3.3 V (-2.5 V to +0.8 V).

U14 is an AND gate that allows the signal ODCMP from COMP_O (U1 pin 24) to gate

the SMCLK signal from U2 back to the DCMP input of U2 to facilitate the measurement

of duty cycle. When U2 sets SMCLK to logic high (+0.8 V), the ODCMP signal is

counted by U2 and frequency is measured. When U2 drives SMCLK with an

approximately 1-MHz clock, this signal appears at DCMP only when ODCMP is logic

high (+0.8 V). The frequency of the signal ODCMP is measured directly while the

multiple positive periods are measured referenced to the SMCLK. U2 uses the frequency

of ODCMP and the accumulated time that the signal was high to compute both the

positive and negative duty cycle.

LCD

U11 is a liquid crystal display (LCD) with four back planes that are multiplexed by U2

with the COM0-3 signals. Only 34 of the possible 40 segment drivers of U2 are

connected to U11 and not all combinations of segments and back planes are used.

R20, R25, R26, R27, R41 & RT2 form a temperature-compensated voltage divider used

to generate the four voltage levels used by the display multiplexer internal to U2. As the

temperature of the Meter is increased, U11 requires less total voltage to maintain the

desired contrast ratio. RT1 is a negative temperature coefficient device, so as the

temperature increases the total current through R27 increases and the voltage across R20,

R25 & R26 decreases, thereby maintaining the display contrast ratio. The opposite

occurs as the temperature lowers.

Backlight

DS3, R14, R46, R50, R96, R99, Q4, Q8 & Q17 form the backlight and backlight control

circuit. The microprocessor holds the backlight off or can turn it on with two levels of

intensity available. When the BKLT and HIBEAM signals from U2 are at logic low

(-2.5 V), Q4, Q8 & Q17 are off, allowing no current to flow through DS3. When U2

drives BKLT to logic high (+0.8 V), Q4 & Q8 are turned on. The current through DS3 is

set by R50, R96 and Q8, and regulated by Q4, which adjusts the base current of Q8 to

keep the voltage drop across R50 & R96 equal to the voltage drop across R46. When U2

drives HIBEAM to logic high (+0.8 V), Q17 is turned on and partially bypasses R96,

thereby requiring more current through R50 to keep the voltage across R50, R96 and

Q17 equal to the drop across R46 resulting in a brighter backlight.

18

Beeper

LS1, R19, R44, R47, R108, C11, Q5 & U5 form the beeper and beeper control circuit.

When the BPR signal from U2 is at logic low (-2.5 V), Q5 is off, which disconnects the

negative power supply connection of U5 disabling the beeper oscillator and drive circuit.

When the BPR signal from U2 is at logic high (+0.8 V), Q5 is on, which allows U5 to

power up. Pin 2 of piezoelectric beeper LS1 is driven by the parallel combination of two

U5 inverters and pin 1 of LS1 is driven by two more U5 inverters to supply enough

Page 27

Digital Multimeter

current to the beeper and ensure adequate loudness. R108 allows for limiting beeper

current if necessary due to future component changes. R44 in parallel with R47 & C11

set the frequency of the beeper oscillator (note that the junction of R44, R47 & C11

operates at voltages beyond the power supply values). The remaining two U5 inverters

are used in series to form the non-inverting buffer portion of the oscillator.

Troubleshooting

Troubleshooting

Refer to the “Theory of Operation” and “Schematics” sections to assist in troubleshooting the

Meter.

Restoration Actions

Refer to “Performance Tests”.

Basic Maintenance

XWWarning

To avoid possible electric shock or personal injury:

• Remove the test leads and any input signals before opening

the case or replacing the battery or fuses.

• Repairs or servicing covered in this manual should be

performed only by qualified personnel.

Cleaning the Meter

To avoid possible electric shock, personal injury, or damage to

the meter, never allow water inside the case.

To avoid damaging the Meter, never apply abrasives, solvents,

aromatic hydrocarbons, chlorinated solvents, or methanolbased fluids to the Meter.

Periodically wipe the Meter case with Fluke “MeterCleaner” or a damp cloth and mild

detergent.

Dirt or moisture in the A or mA µA input terminals can affect readings and can falsely

activate the Input Alert feature without the test leads being inserted. Such contamination

may be dislodged by turning the Meter over and, with all test leads removed, gently

tapping on the case.

Thoroughly clean the terminals as follows:

1. Turn the Meter off and remove all test leads.

2. Soak a clean swab with isopropyl alcohol and work the swab around in each input

terminal to remove contaminates.

XWWarning

WCaution

19

Page 28

87 V/AN

Service Manual

Opening the Meter Case

WCaution

To avoid unintended circuit shorting, always place the

uncovered Meter assembly on a protective surface. When the

case of the Meter is open, circuit connections are exposed.

To open the Meter case, refer to Figure 2 and do the following:

1. Disconnect test leads from any live source, turn the rotary knob to OFF, and remove

the test leads from the front terminals.

2. Remove the battery door by using a flat-blade screwdriver to turn the battery door

screws 1/4-turn counterclockwise.

3. The case bottom is secured to the case top by three screws and two internal snaps (at

the LCD end). Using a Phillips-head screwdriver, remove the three screws.

WCaution

To avoid damaging the Meter, the gasket that is sealed to the

bottom case, and is between the two case halves, must remain

with the case bottom. The case top lifts away from the gasket

easily. Do not damage the gasket or attempt to separate the

case bottom from the gasket.

4. Hold the Meter display side up.

5. Pushing up from the inside of the battery compartment, disengage the case top from

the gasket.

6. Gently unsnap the case top at the display end, see Figure 2.

F1

F2

20

Figure 2. Opening the Meter, Battery and Fuse Replacement

ama12.eps

Page 29

Digital Multimeter

Basic Maintenance

Accessing the PCA and Replacing the LCD

Once the case has been opened, the A1 Main PCA can easily be removed. The shields

disconnect from the PCA as follows:

1. Remove the five Phillips-head screw securing the top and bottom shields to the PCA.

2. Remove the top shield assembly that also houses the LCD and lightpipe for the LCD

backlight.

3. To access the LCD, unsnap the LCD mask using a small flat-blade screwdriver. The

LCD may now be removed. Refer to Figure 3.

Note

Two elastomeric connectors make electrical contact between the LCD and

the PCA. These connectors usually stick to the LCD when it is removed. If

the connectors are to be reused, do not handle them, as the electrical

contact points might become contaminated. Use tweezers to remove these

connectors.

4. To reinstall the connectors, replace the LCD and LCD mask and lay the top shield

face down. Install the elastomeric connector strips into the slots on the top shield.

5. Place the PCA onto the top shield so that the screw holes align.

6. Place the bottom shield onto the PCA and secure the assembly with five Phillipshead screws. Ensure that the shields are tightly attached. Properly fitted shields are

required for the Meter to perform to specifications.

LCD Mask

LCD

Figure 3. Removing LCD Mask to Access LCD

21

ama08f.eps

Page 30

87 V/AN

Service Manual

Reassembling the Meter Case

To reassemble the Meter case:

1. Verify that the rotary knob and circuit board switch are in the

the gasket remains secured to the bottom case.

2. Place the PCA into the bottom case.

3. Place the case top on the case bottom.

4. To avoid damaging the battery wire, ensure the wire exits the middle of the battery

compartment.

5. Properly seat the case gasket and snap the case halves together above the LCD end.

See Figure 2.

6. Reinstall the three case screws and the battery door.

7. Secure the battery door by turning the screw 1/4-turn clockwise.

8. Go to “Performance Tests” later in this document, and perform the procedures

described.

Replacing the Battery

Replace the battery with a 9-V battery (NEDA A1604, 6F22, or 006P).

To avoid false readings, which could lead to possible electric

shock or personal injury, replace the battery as soon as the

battery indicator (b) appears. If the display shows “bAtt” the

Meter will not function until the battery is replaced.

OFF position, and that

XWWarning

Replace the battery as follows, refer to Figure 2:

1. Turn the rotary knob to OFF and remove the test leads from the terminals.

2. Remove the battery door by using a standard-blade screwdriver to turn the battery

door screws one-quarter turn counterclockwise.

3. Remove the old battery and replace it with a new one.

4. Align the battery leads so that they not pinched between the battery door and the

case bottom.

5. Secure the door by turning the screws one-quarter turn clockwise.

Testing Fuses and Current Circuitry

If a test lead is plugged into the mA/µA or A terminal and the rotary knob is turned to a

non-current function, the Meter chirps and flashes “LEAd” if the fuse associated with

that current terminal is good. If the Meter does not chirp or flash “LEAd”, the fuse is bad

and must be replaced. Refer to Table 17 for the appropriate replacement fuse.

Before measuring current, test the quality of the appropriate fuse and the current shunt

using the following procedure. See Figure 4.

1. Turn the rotary knob to N.

2. To test F2, insert a test lead into the I input terminal and touch the probe to

the A input terminal.

The input receptacles contain split contacts. Be sure to touch the probe to

the half of the receptacle nearest the LCD.

Note

22

Page 31

Digital Multimeter

Basic Maintenance

3. The display should indicate between 00.0 Ω and 00.5 Ω. If the display reads OL,

replace the fuse and test again. If the display reads another value, further servicing is

required.

4. To test F1, move the probe from the A input terminal to the mA/UA input terminal.

5. The display should read between 0.995 kΩ and 1.005 kΩ. If the display reads OL,

replace the fuse and test again. If the display reads another value, further servicing is

required.

XWWarning

To avoid electrical shock or personal injury:

• Remove the test leads and any input signals before

replacing the battery or fuses.

• Install ONLY specified replacement fuses with the

amperage, voltage, and speed ratings shown in Table 17.

TRUE RMS MULTIMETER

87

MIN MAX

Peak MIN MAX

4½ DIGITS

1 Second

mV

V

LOLO

V

OFF

AmACOM

A

10A MAX

FUSED

V

F

˚C/˚

AutoHOLD

RANGE

Hz %

REL

mA

A

A

V

400mA

FUSED

Good F2 fuse: 00.0 Ω to

00.5 Ω

Replace fuse: OL

Touch top half

of input contacts

Replacing the Fuses

To replace the fuse(s), perform the following procedure.

1. To open the Meter, refer to “Opening the Meter Case”. See Figure 2.

2. Grasp the fuse in the center with needle nose pliers. Pull straight up on the fuse

to remove it from the fuse clips.

3. Install ONLY specified replacement fuses with the amperage, voltage, and speed

ratings shown in Table 17.

4. To close the Meter, refer to “Reassembling the Meter Case”.

Good F1 fuse: 0.995 kΩ to

1.005 kΩ

Replace fuse: OL

Figure 4. Testing the Current Input Fuses

87

MIN MAX

Peak MIN MAX

4½ DIGITS

1 Second

mV

V

LOLO

V

OFF

AmACOM

A

10A MAX

FUSED

TRUE RMS MULTIMETER

V

400mA

FUSED

F

˚C/˚

AutoHOLD

RANGE

Hz %

REL

mA

A

A

V

aom5f.eps

23

Page 32

87 V/AN

Service Manual

Required Equipment

Required equipment for the performance tests is listed in Table 13. If the recommended

models are not available, equipment with equivalent specifications may be used.

XW Warning

• To avoid shock or injury, do not perform the verification

tests or calibration adjustment procedures described in this

manual unless you are qualified to do so.

• Repairs or servicing should be performed only by qualified

personnel.

Table 13. Required Equipment

Equipment Required Characteristics Recommended Model

Calibrator AC Voltage Range: 0 - 1000 V ac

Accuracy: ± 0.12 %

Frequency Range: 60 - 20000 Hz

Accuracy: ± 3 %

DC Voltage Range: 0 - 1000 V dc

Accuracy: ± 0.012 %

Current Range: 350 µA - 2 A

Accuracy: AC (60 Hz to 1 kHz): ± 0.25 %

DC: ± 0.05 %

Frequency Source: 19.999 kHz - 199.99 kHz

Accuracy: ± 0.0025 %

Amplitude: 150 mV to 6V rms

Accuracy: ± 5 %

Range: 1 Ω - 100 MΩ

Accuracy: 0.065 %

TC Adapter Accessory K-type Fluke 80 AK

K-type Thermocouple K-type, mini-plug on both ends

Fluke 5500A Multi-Product

Calibrator or equivalent

Performance Tests

The following performance tests verify the complete operability of the Meter and check

the accuracy of each Meter function against the Meter’s specifications. Performance tests

should be performed annually to ensure that the Meter is within accuracy specifications.

Accuracy specifications are valid for a period of one year after calibration adjustment,

when measured at an operating temperature of 18 °C to 28 °C and at a maximum of 90 %

relative humidity.

To perform the following tests, it is not necessary to open the case. No adjustments are

necessary. Make the required connections, apply the designated inputs, and determine if

the reading on the Meter display falls within the acceptable range indicated.

Note

If the Meter fails any of these tests, it needs calibration adjustment or repair.

24

Page 33

Digital Multimeter

pears in low pass filter mode. Also appears

s

Performance Tests

Basic Operability Tests

Refer to the following sections to test the basic operability of the Meter.

Testing the Fuses

Refer to “Testing Fuses (F1 and F2)”.

Testing the Display

Turn the Meter on while holding down D to view all segments of the display.

Compare the display with the appropriate examples in Figure 5 and Table 14.

18

10

17

9

7

6

5

4

3

2

Number Feature Indication

Y

Polarity indicator for the analog bar graph.

8

1

Figure 5. Display Features

Table 14. Display Features

11

12

13

14

Hi Res

15

16

A

TrigY

B X

C W

D g

Positive or negative slope indicator for Hz/duty cycle triggering.

The continuity beeper is on.

Relative (REL) mode is active.

Smoothing is active.

aom1_af.eps

E

F

G

H

I

J

K

-

Z

RS

S

p

m MAX

MIN AVG

K

25

Indicates negative readings. In relative mode, this sign indicates that the

present input is less than the stored reference.

Indicates the presence of a high voltage input. Appears if the input voltage is

30 V or greater (ac or dc). Also ap

in cal, Hz, and duty cycle modes.

AutoHOLD is active.

Display Hold is active.

Indicates the Meter is in Peak Min Max mode and the response time is 250 µ

Indicators for minimum-maximum recording mode.

Low pass filter mode.

Page 34

87 V/AN

terminal and the selected

Service Manual

Table 14. Display Features (cont.)

Number Feature Indication

The battery is low. XWWarning: To avoid false readings, which could lead

L

b

to possible electric shock or personal injury, replace the battery as soon as

the battery indicator appears.

M

N

O

P

Q

R

A, µA, mA

V, mV

µF, nF

nS

%

e, Me, ke

Hz, kHz

AC DC

°C, °F

610000 mV

HiRes

Auto

Manual

Amperes (amps), Microamp, Milliamp

Volts, Millivolts

Microfarad, Nanofarad

Nanosiemens

Percent. Used for duty cycle measurements.

Ohm, Megohm, Kilohm

Hertz, Kilohertz

Alternating current, direct current

Degrees Celsius, Degrees Fahrenheit

Displays selected range

The Meter is in high resolution

(Hi Res) mode. HiRes=19,999

The Meter is in autorange mode and automatically selects the range with the

best resolution.

The Meter is in manual range mode.

The number of segments is relative to the full-scale value of the selected

range. In normal operation 0 (zero) is on the left. The polarity indicator at the

left of the graph indicates the polarity of the input. The graph does not

operate with the capacitance, frequency counter functions, temperature, or

peak min max. For more information, see “Bar Graph”. The bar graph also