Page 1

Victoreen® 875

High Range Containment Monitor

February 2005

Manual No. 877-1-1 Rev. 9

©2004, 2005 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies

Operators Manual

Page 2

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

120 Andrews Road

Hicksville, New York 11801

516.870.0100

www.flukebiomedical.com/rms

Page 3

Table of Contents

Section 1: Introduction................................................................................................ 1-1

1.1 General Description ..................................................................................... 1-1

1.2 Specifications............................................................................................... 1-1

1.3 Equipment Overview.................................................................................... 1-3

1.4 Receiving Inspection.................................................................................... 1-8

1.5 Storage ........................................................................................................ 1-9

1.6 Procedures, Warnings, and Cautions .......................................................... 1-9

Section 2: Installation.................................................................................................. 2-1

2.1 Installation.................................................................................................... 2-1

2.2 Cable and Wiring Installation ....................................................................... 2-3

Section 3: Operation.................................................................................................... 3-1

3.1 Operation ..................................................................................................... 3-1

Section 4: Operation.................................................................................................... 4-1

4.1 Functional Description ................................................................................. 4-1

4.2 Readout Module 876A-1.............................................................................. 4-1

Section 5: Maintenance, Calibration, and Troubleshooting..................................... 5-1

5.1 Maintenance ................................................................................................ 5-1

5.2 Calibration.................................................................................................... 5-1

5.3 Troubleshooting ........................................................................................... 5-3

5.4 Power Supply Measurements ...................................................................... 5-4

5.5 Signal Input Circuit....................................................................................... 5-4

5.6 Metering Circuit............................................................................................ 5-5

5.7 The Alarm Circuits ....................................................................................... 5-5

5.8 High Alarm Circuit........................................................................................ 5-6

5.9 Muting Stages of the Alarm Circuits............................................................. 5-6

5.10 ESC Board................................................................................................... 5-7

5.11 Overall Fail Circuitry Associated with the ECS Test .................................... 5-9

5.12 Starting with Pins M and P on the Power Supply Schematic ....................... 5-9

5.13 Starting with Terminal H on Relay Driver Board .......................................... 5-9

5.14 Provision of Inputs to Terminals M and P on the Power Supply Board........ 5-9

5.15 Outputs of U206 Pulse Generator on the ECS Board................................ 5-10

5.16 Operation of the Latch Circuit .................................................................... 5-10

i

Page 4

Appendix A: Calibration and Test Procedures..............................................................A-1

A.1 Calibration Procedures ................................................................................A-1

A.2 Test Procedures .......................................................................................... A-1

Appendix B: Cable and Pull Box Procedures................................................................B-1

B.1 Cable and Pull Box Procedures ................................................................... B-1

Appendix C: Applicable Drawings and Bill of Materials...............................................C-1

C.1 Applicable Drawings ....................................................................................C-1

C.2 Bill of Materials ............................................................................................C-3

ii

Page 5

Introduction

General Description

1

Section 1

Introduction

1.1 General Description

Containment Monitor 875

The 875 Containment Monitor has been qualified

for use in Nuclear Safety related applications.

Qualification Test Reports, 950.301, 950.308A, and

950.310A define the parameters that have been

verified by test and are available for purchase.

Containment Monitor 875 functions as an accident monitor for reactor containments, refer to Figure 1-1. It

consists of the 877-1 Ion Chamber Detector that is located within the reactor containment, and the 876A-1

Readout Module that is contained in a rack in the control room. The readout module contains a power

supply that provides the necessary power both for itself and the detector. The readout module is

connected to the detector by two cables, a coaxial high voltage cable and a coaxial signal cable.

Specifications for the detector and readout module are contained below.

NOTE

1.2 Specifications

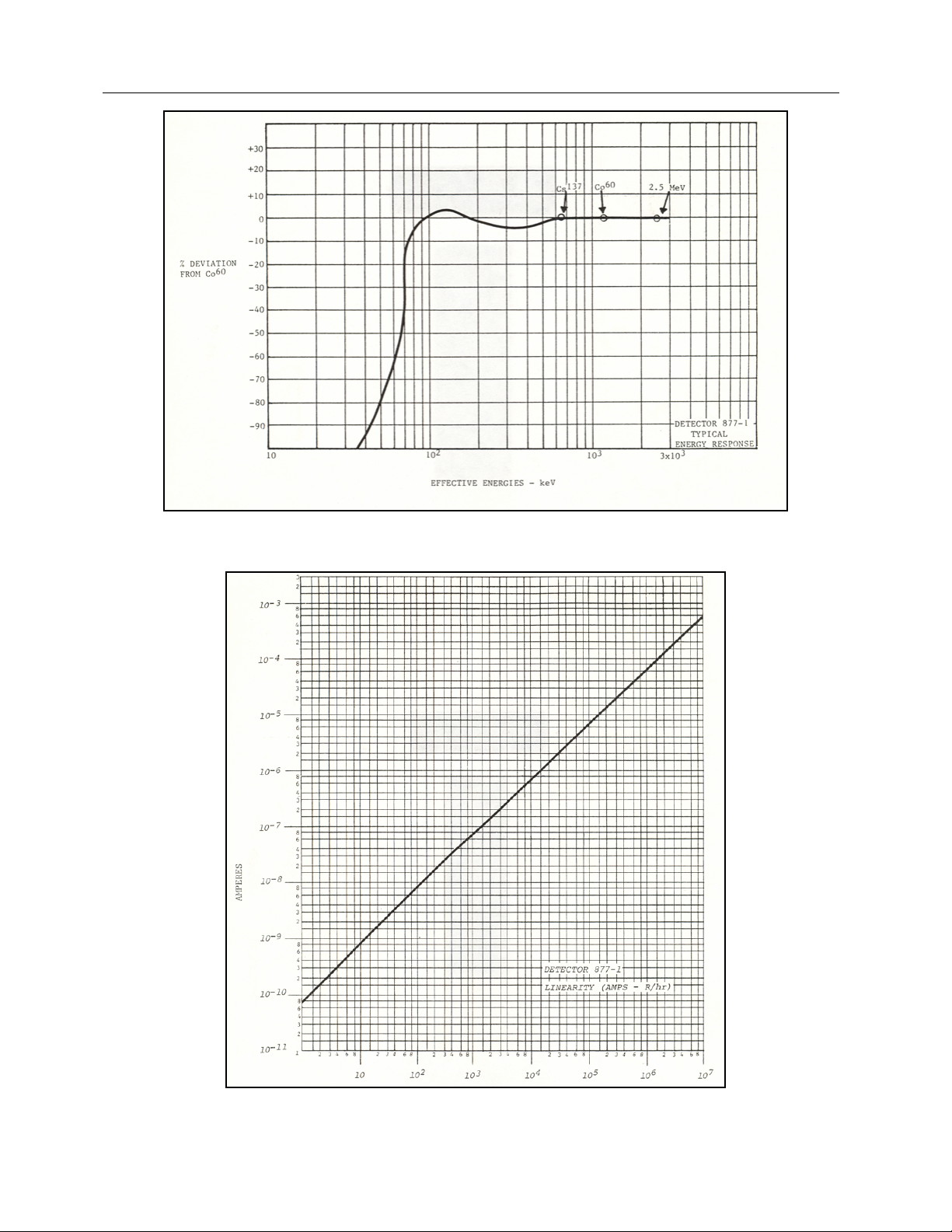

Detector 877-1

Radiation Detected Photons above 60 keV

Range 1 R/h to 1E7 R/h

Energy Response ± 20% from 80 keV to 2 MeV

Chamber Construction Stacked parallel plate, 316 stainless steel housing, 3

terminal, guarded ion chamber

Saturation >80% up to full scale on instrument

Collection Voltage 450 to 550 VDC

Current Output 7E-11 to 7E-4 Amp/R/Hr (nominal)

Chamber Capacitance 435 picofarads (nominal)

Voltage Withstand and Leakage 5E10-5 amperes @ 500 VDC between either ground and

connector pins

Capacitance Approximately 430 pf

1-1

Page 6

Victoreen 875

Operators Manual

Hermetic Integrity 1E10-5 cm

3

of helium per second @ one standard

atmosphere

Chamber Fill Gas Nitrogen/helium (2%) at atmospheric pressure

Dimensions (W x H x D) with Mounting Bracket 9.25 x 12.5 x 10.06 in

(234.95 x 317.5 x 255.52 mm)

Weight Approximately 18 lb (8.17 kg)

Temperature, Storage 40° to 160°F (4° to 71°C)

Temperature, Operating 40° to 160°F (4° to 71°C)

375°F (180°C) peak, accident, 3 hours

Relative Humidity 100% (waterproof)

60

Total Integrated Dose 2E8 Rads + 10% margin,

Chemical Spray 0.45 Gallons/minute/ft

Co

2

(0.28 molar H3BO3, 3000 ppm

Boron, and NaOH; ph of 11, 24 hrs

LOCA Test Duration 28 days

(Consult Fluke Biomedical, Radiation Management Services, for a complete description of Qualification

Test Results)

Readout Module 876A-1

Range 1 to 10

Input Current Minimum: 6.5 to 7.5 x 10

Maximum: 6.5 to 7.5 x 10

Recorder Output 0 to +1 VDC, logarithmic (0 - 10 mV and 0 – 5 V

optional)

Computer Output 0 to +5 VDC, logarithmic (0

optional)

(Other Outputs Available Upon Request)

System Accuracy (during "all" conditions) Accumulative @ Meter +36% of input radiation

Analog Outputs +28% of input radiation

Power Requirements: a) AC Voltage: 108 to 132 VAC, RMS @ 60 ± 3 Hz

b) Battery Power: 22 to 32 VDC @ 600 mA DC

maximum

Temperature Coefficient

0.40%/°C, + 0.25 R/h/°C

Dimensions (W x H x D) 8.46 x 5.25 x 15.21 in

(214.88 x 133.35 x 386.33 mm)

7

R/h

-11

A

-4

A

- 100 mV and 0 - 50 mV

Weight 20 lbs (9.07 kg)

Environmental Parameters Temperature (Storage): 40° to 140°F (4° to 60°C)

Temperature (Operating): 40° to 120°F (4° to 49°C)

1-2

Page 7

Introduction

Specifications

Relative Humidity (Storage): 0 to 95% (noncondensation)

Relative Humidity (Operating): 0 to 90% (noncondensation)

Irradiation: 3.5 to 1 x 10

40 years life.

Mounting 876-1-55, Rack Chassis

Available Options (consult factory) 876A-100: Readout, for use with digital systems

Outputs: 0

- 100 mV

3

Rads @ 60°C integrated over

1

0

0

0

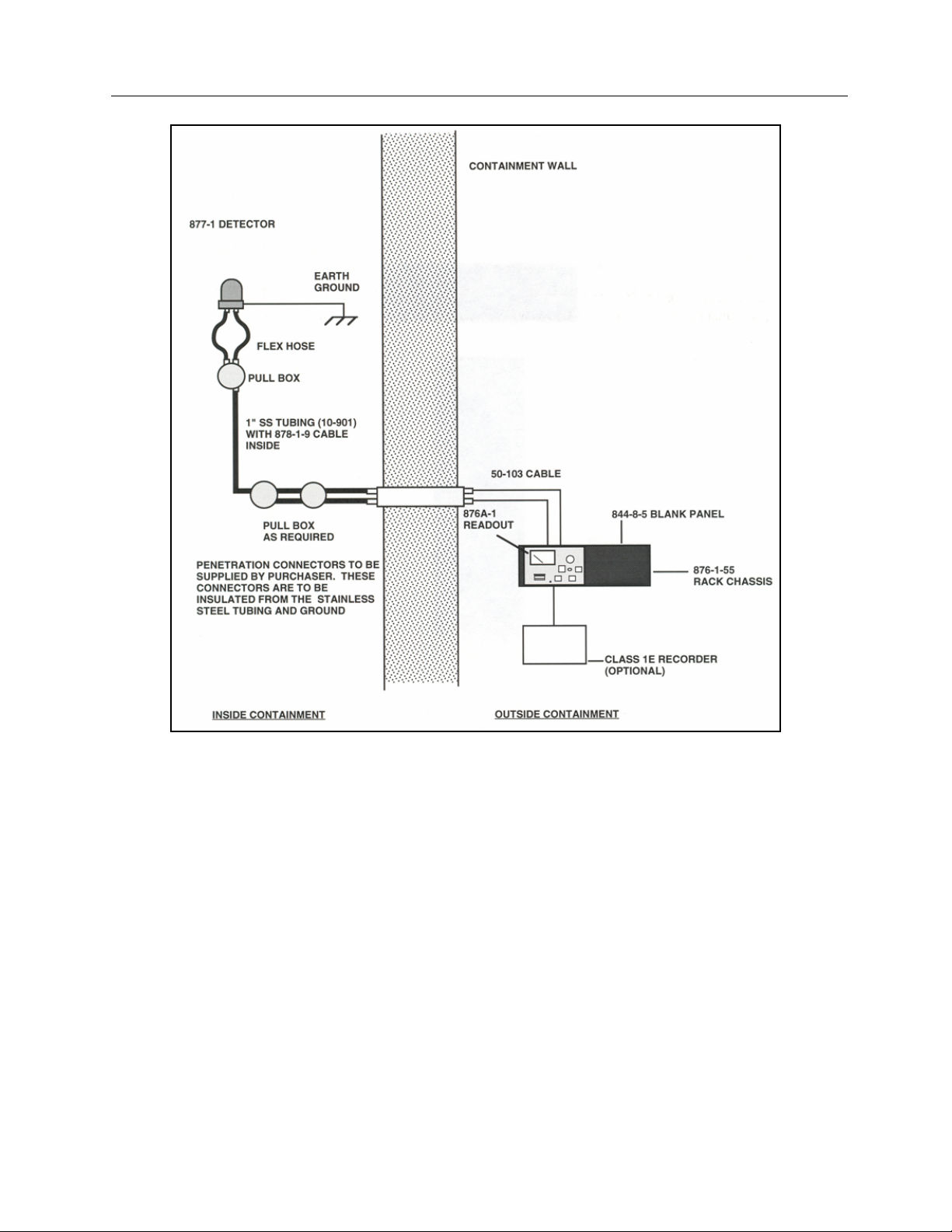

Figure 1-2 illustrates the typical energy response for the detector, Figure 1-3 illustrates typical linearity for

the detector and Figure 1-4 illustrates radiation input versus meter reading.

- 50 mV

- 10 mV

- 5 V

1.3 Equipment Overview

High-Range Containment Monitor Detector (877-1)

The high-range containment monitor detector is an ion chamber detector that has the appearance of a

six-inch diameter domed cylinder about seven inches long. Inside the cylinder are two flange-mounted

electrodes consisting of 31 flat, disk-shaped plates, each about four inches in diameter, stacked, and

mounted on disk rods. The assembly has the appearance of a large air capacitor. The mounting posts are

attached to the mounting flange through insulating spacers, so the flange and housing will be neutral with

respect to the charges applied to the electrodes.

The whole assembly is covered by the six-inch diameter housing which contacts only the neutral

mounting flange. The mounting flange is pierced by three holes. One hole supports the exhaust tube used

for exhausting and back filling the chamber. The other two support two 2-pin connectors, one for each

electrode. One pin in each pair is connected to the neutral mounting flange. When the coaxial signal

cable is connected to this connector, the cable shield is connected to the neutral pin.

The entire chamber is filled with a mixture of helium and nitrogen at atmospheric pressure and sealed.

For further information refer to Section 4, Functional Description.

Readout Module (876A-1)

The 876A-1 Readout Module is designed to give an indication, on an analog meter, of radiation levels

within the containment area. The readout is composed of an analog meter, indicator lights and operating

switches. The meter has a range of 1 to 10

readout is mounted in the 876-1-55 Rack Chassis located in the control room.

For further information refer to Section 4, Functional Description.

7

R/h and is controlled by an eight position rotary switch. The

Rack Chassis (876-1-55)

The 876-1-55 Rack Chassis permits mounting of two readout modules or one readout module and one

optical isolator in a 19-inch wide RETMA equipment rack. The panel height is 5.21 inches.

For further information refer to applicable drawing located in Appendix C.

1-3

Page 8

Victoreen 875

Operators Manual

Pull Box Assembly (878-12-5)

The 878-12-5 Pull Box Assembly is designed to allow for thermal expansion of the detector cables and to

provide a service loop. Various optional pull-box configurations are available per Table 1-1. For more

information refer to Section 2, Appendix B, and Appendix C.

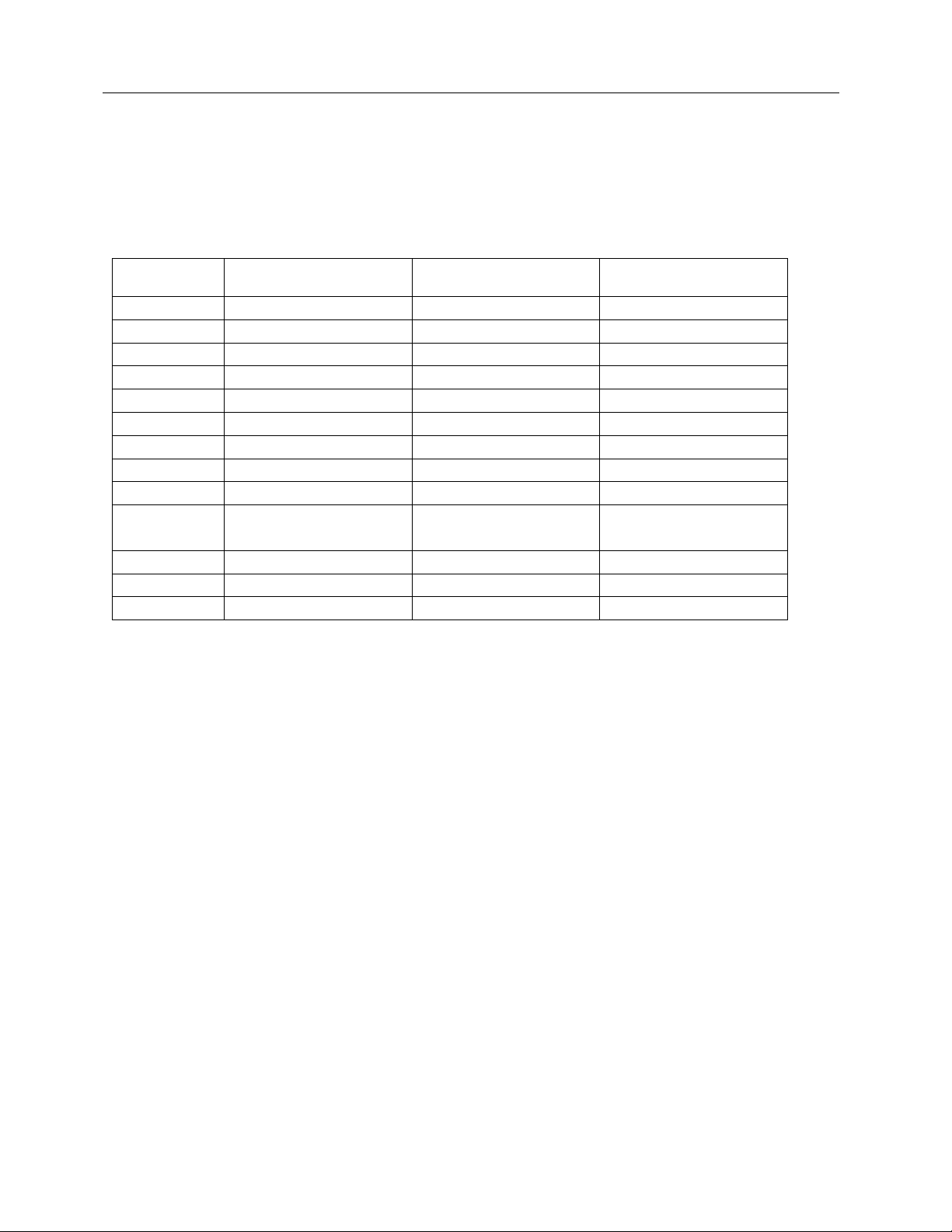

Table 1-1. Pull-box Variations

Model Inlet, Size and Location

878-12 1" 270° 2, ¾", 90° 180°

878-12-M 1 1" MNPT 270° 2, ¾", 90° 180°

878-12-M2 1" MNPT 270° 2, 1", 90° 180°

878-12-M3 1" 270° 1, 1", 90° 180°

878-12-M4 1" 270° 1, 1", 90° 90°

878-12-M5 ¾" 270° 2, ¾", 90 180°

878-12-M6 2, ¾" 0°/360° 2, ¾", 90 90°

878-12-M7 1" MNPT 270° 2, ¾", 90 90°

878-12-M8 2, ¾", 0° 1,1", MNPT, 90° 90°

878-12-M9 1,1" MNPT 90° 1, ¾" MNPT, 120° 150°

1, ½" MNPT, 210° 210°

878-12-M10 1,1" MNPT 2, ¾ 90° 0°

878-12-M11 2, ¾", 90° 1,1" MNPT 90° 0°

878-12-M12 2, ¾", 270° 1" MNPT, 0° 90°

Outlet, Size and

Location

Inlet/Outlet Orientation

Flexible Tubing (878-12-30TAB)

1.0 inch diameter flexible stainless steel tubing is available in various lengths to interconnect the 877-1

Detector to the first pull-box.

Cables/Connectors/Panel

In-Containment Cable: (878-1-9-TAB)

Ex-Containment Cable: (50-103-TAB)

Replacement Detector Connector Kit: (878-7-5)

Blank Panel: (844-8-5)

Optional Equipment

The following optional equipment is available:

137

878-10 Field Calibrator - 250 mCi

1-4

Cs

Page 9

Introduction

Equipment Overview

Figure 1-1. High-Range Containment Monitor 875

1

1-5

Page 10

Victoreen 875

Operators Manual

Figure 1-2. Typical Energy Response Curve – Detector 877-1

1-6

Page 11

Introduction

Equipment Overview

Figure 1-3. Typical Linearity Detector 877-1

Figure 1-4. Radiation Input vs. Meter Reading (Calculated Curve)

1

1-7

Page 12

Victoreen 875

Operators Manual

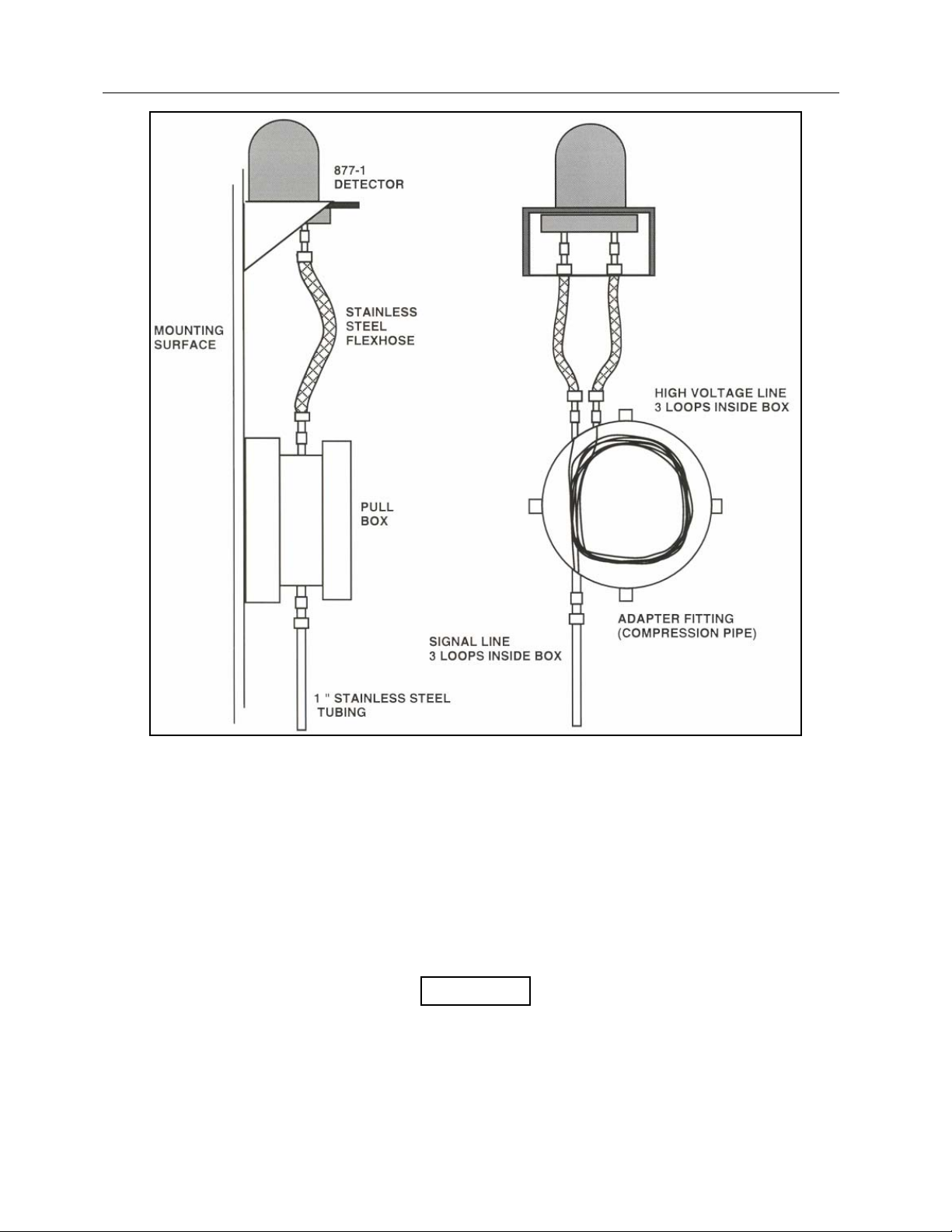

Figure 1-5. High-Range Detector, Recommended Installation

1.4 Receiving Inspection

Upon receipt of the unit:

1. Inspect the carton(s) and contents for damage. If damage is evident, file a claim with the carrier and

notify Fluke Biomedical, Radiation Management Services at 440.248.9300.

2. Remove the contents from the packing material.

3. Verify that all items listed on the packing list have been received and are in good condition.

If any of the listed items are missing or damaged,

notify Fluke Biomedical.

1-8

NOTE

Page 13

Introduction

Storage

1

1.5 Storage

Storage of Victoreen instruments must comply with level B storage requirements as outlined in ANSI

N45.2.2 (1972) Section 6.1.2(.2). The storage area shall comply with ANSI N45.2.2 (1972) Section 6.2

Storage Area, paragraphs 6.2.1 through 6.2.5. Housekeeping shall conform to ANSI N45.2.3 (1972).

Level B components shall be stored within a fire resistant, tear resistant, weather tight enclosure in a wellventilated building.

Storage of Victoreen instruments must comply with the following:

1. Inspection and examination of items in storage must be in accordance with ANSI N45.2.2 (1972)

Section 6.4.1.

2. Requirements for proper storage must be documented and written procedures or instructions must

be established.

3. In the event of fire, post-fire evaluation must be in accordance with ANSI N45.2.2 (1972), Section

6.4.3.

4. Removal of items from storage must be in accordance with ANSI N45.2.2 (1972), Sections 6.5 and

6.6.

1.6 Procedures, Warnings, and Cautions

The equipment described in this manual is intended to be used for the detection and measurement of

ionizing radiation. It should be used only by persons who have been trained in the proper interpretation of

its readings and the appropriate safety procedures to be followed in the presence of radiation.

Although the equipment described in this manual is designed and manufactured in compliance with all

applicable safety standards, certain hazards are inherent in the use of electronic and radiometric

equipment.

WARNINGS and CAUTIONS are presented throughout this document to alert the user to potentially

hazardous situations. A WARNING is a precautionary message preceding an operation that has the

potential to cause personal injury or death. A CAUTION is a precautionary message preceding an

operation that has the potential to cause permanent damage to the equipment and/or loss of data.

Failure to comply with WARNINGS and CAUTIONS is at the user's own risk and is sufficient cause to

terminate the warranty agreement between Fluke Biomedical and the customer.

Adequate warnings are included in this manual and on the product itself to cover hazards that may be

encountered in normal use and servicing of this equipment. No other procedures are warranted by Fluke

Biomedical. It shall be the owner’s or user's responsibility to see to it that the procedures described here

are meticulously followed, and especially that WARNINGS and CAUTIONS are heeded. Failure on the

part of the owner or user in any way to follow the prescribed procedures shall absolve Fluke Biomedical

and its agents from any resulting liability.

Indicated battery and other operational tests must be performed prior to each use to assure that the

instrument is functioning properly. If applicable, failure to conduct periodic performance tests in

accordance with ANSI N323-1978 (R1983) Radiation Protection Instrumentation Test and Calibration,

paragraphs 4.6 and 5.4, and to keep records thereof in accordance with paragraph 4.5 of the same

standard, could result in erroneous readings or potential danger. ANSI N323-1978 becomes, by this

reference, a part of this operating procedure.

1-9

Page 14

Victoreen 875

Operators Manual

(Blank page)

Page 15

Installation

Installation

Section 2

Installation

2.1 Installation

Installation of the monitoring system consists of selecting suitable mounting sites for each component of

the system, mounting each of the components, and connecting the components into the system

configuration.

Installation of this system is as follows:

2

Refer to the applicable drawings in Appendix C for

further installation Instructions.

Rack Chassis

The 876-1-55 Rack Chassis is a standard 19-inch chassis with a flame barrier. When seismic qualification

is required for the readout, seismic support brackets (P/N 876-1-114) are needed to support the rear of

the rack chassis. The brackets are designed to mount on the 19-inch qualified equipment rack.

Recommended mounting is shown on drawings GEL876-1-55, and 876-1-114.

Readout Module

Readout Module 876A-1 is designed to fit into one-half of an 876-1-55 Rack Chassis. Insert the readout

module in the rack chassis (see drawing GEL876A-1), then insert and tighten the two holding screws in

the rear flanges of the rack chassis. The pawl fastener on the front panel of the readout must be

tightened.

Optical Isolator (No longer manufactured, consult factory)

Detector

The detector case MUST BE PHYSICALLY

GROUNDED TO EARTH GROUND. The readout

instrument circuit common SHOULD NOT be

grounded to earth ground.

The 877-1 Detector is designed to mount on the containment wall. A mounting bracket attached to the

detector has four holes that are used for mounting. Studs must be placed in the containment wall before

mounting the detector. Dimensions for the studs are the same as the dimensions of the holes in the

mounting bracket (refer to drawing GEL877-1). Recommended studs are 5/16 inch Grade 5. No lock

washers are to be used and recommended torque for the nuts is 18 ft. lbs. Orient the detector so that the

cable connectors are on the underside. Attach the detector to the mounting bracket with the four clamps

provided, securing the bolts with a torque of 132 in. lbs. (Figure 1-5 and GEL877-1).

NOTE

NOTE

Pull Box

A cable pull box is required to allow for thermal expansion of the detector cables and to provide a service

loop. The pull box (drawing 878-12-5) is a typical type that mounts to the containment wall. It should be

mounted directly below the detector as shown in Figure 1-1. Depending on actual detector location, more

than one pull box may be necessary.

2-1

Page 16

Victoreen 875

Operators Manual

NOTE

Under potential L.O.C.A. conditions of pressure and

temperature, the cable may expand as much as 11

inches per 100 feet.

The distance from the pull box to the detector will be determined by the amount of flex hose used to seal

the detector cables. Additional information is found in the paragraph below Cable Sealing and in CABLE877 and 878-12-3 procedures in Appendix B.

Once the cables have been pulled and tested, the pull box cover must be bolted shut. To bolt the pull box

shut, follow the steps outlined in procedure 878-12-3 in Appendix B. Pull box material type and grade is

304 stainless steel.

Cable Sealing

In-containment cable is 878-1-9. This is special cable designed to withstand the potential high radiation

that may exist following a L.O.C.A. or similar event. In order to withstand the high pressure and moisture

generated during such an event, the entire cable length must be sealed so that moisture will not come in

contact with the cable. Cable specifications are listed below.

Specifications for Cable 878-1-9

Conductor #24 AWG, 19/36 Tinned Copper

Insulation Tefzel (BIWF)

Shield #36 AWG, Tinned copper brand, 90% Coverage

Jacket Tefzel (BIWF)

Outside Diameter 0.250 to 0.295 in

(6.35 to 7.49 mm)

Impedance 75 ohms nominal

Capacitance 22 pf/ft nominal

Dielectric Strength 7000 V minimum

Operating Voltage 2300 V maximum

The following guidelines are based on the sealing method used during the qualification test. Stainless

steel Flex Hose 878-12-30, ¾ inch diameter x 18.5 inches long (with welded Swagelok connectors)

should be installed between the detector and pull box. Stainless steel tubing (¾ inch diameter) should be

installed from the pull box to the penetration for each cable. If a common stainless steel tubing run is

used, a one (1) inch diameter tube is recommended.

NOTE

Seismic support and the sealing technique at

penetration vary with plant requirements.

Techniques and materials used are the customer's

responsibility.

Attach the stainless steel tubing to the pull box with compression fittings (¾ inch) and, after finger

tightening, tighten at least 1-¼ turns. The flex hose connection at the pull box is installed in the same

manner. The detector end of the flex hose is swaged to the cable connector backshell. This should not be

2-2

Page 17

Installation

Installation

done until cable is pulled and tested. (Refer to the procedure Cable-877, in Appendix B, for more

information.)

NOTE

2

Minimum bend radius of the 878-1-9 cable is four

inches. When bending conduit or flex hose, take

this into consideration. Typical bend radius for P/N

878-12-30 is ¾ inch; stainless steel flex house is 12

inches.

2.2 Cable and Wiring Installation

Detector Cable Inside Containment

Detector cables used inside containment are to be installed and terminated according to procedure

Cable-877, in Appendix B. Do not allow any moisture or contaminants to deposit on the connectors used

for installing cables due to the potential for electrical leakage. Because the detector transmits extremely

small current signals, no terminal block connections are acceptable in the penetration. Signal conductor

must be shielded but not grounded (qualified butt splices are acceptable). Refer to drawing GEL875-1 for

electrical connections and to 878-1-9 for cable data.

CAUTION

The detector and readout must not be connected

during the following test.

Detector Test After Installation

Testing of detector cables after installation is required. A leakage test from the center conductor to the

shield should yield better than 1000 megohms at 1000 VDC.

Typical resistance of the center conductor is 0.022 ohm per foot at 20°C (68°F).

Detector Cable Outside Containment

Detector cables used outside containment should be a qualified coaxial type RG 59/U. Ideally, the cable

should connect directly from the penetration to the appropriate connectors on Readout Module 876A-1.

Terminal block connections and unshielded center conductors are not acceptable for installation. Fluke

Biomedical recommends that cable 50-103 be used. Typical wiring is shown on drawing GEL 875-1. After

installation, testing is required as described in the previous paragraph. Specifications for cable used

outside containment are listed below. Refer to drawing 50-103 for additional data.

Specifications for Cable 50-103

Type RG 59/U, alternate

Conductor 19/36 Tinned copper

Insulation Cross-linked polyethylene

Flame Tape Mica tape

Shield #36 AWG, 92% coverage

Insulation Wrap 0.001 inch (0.03 mm) mylar

Jacket Type Bostrad 7 (CSPE)

2-3

Page 18

Victoreen 875

Operators Manual

Thickness 0.015 inch (0.38 mm) nominal

Outer Diameter 0.217 inch (5.51 mm) nominal

Impedance 75 ohms nominal

Capacitance 22 pf/ft nominal

Ancillary Wiring

Ancillary wiring for computer, recorder, power and alarm contacts are installed according to drawing GEL

875-1 and Table 2-1 which indicates connector pin designations.

Table 2-1. Installation

Function J3

Ground D

Ground F

Computer E

Recorder C

Alert Alarm I N NO NC

P C C

R NC NO

Alert Alarm II D NO NC

E C C

F NC NO

High Alarm I S NO NC

T C C

U NC NO

High Alarm II G NO NC

H C C

J NC NO

Fail Alarm I K NO NC

L C C

M NC NO

Fail Alarm II A NO NC

B C C

C NC NO

Line A

Neutral B

Chassis Ground C

* Relays are Fail Safe, i.e. energized for normal operation. Relays de-energize during an alarm condition.

All Alarms on P2 Normal Operation * Shelf State

Computer & Recorder

Power Connections (P1)

NO = Normally open

C = Common

NC = Normally closed

2-4

Page 19

Operation

Operation

Section 3

Operation

3.1 Operation

Once installation is completed, operation is fully automatic. The 876A-1 Readout Module continuously

indicates the level of radioactivity measured at the detector site. When the radiation level exceeds an

alarm set point, an alarm is actuated.

The following steps explain how to operate the 875 monitor:

1. Turn the function switch to the TEST position, and press and release the Electronic Check Source

(ECS) push button. About four seconds later, the SAFE-RESET light should come on. Then press

and hold the CHANNEL TEST push button. The ALERT, HIGH, and CHANNEL TEST lamps should

light immediately.

When channel test is pressed, the high and alert

alarm relays are deactivated. (Their coils are deenergized). The wiring of the channel test circuit is

such that the channel test lamp will not light unless

the alarm relay contacts are in the deactivated or

tripped state. This is for the purpose of assuring

that an actual contact state change has occurred,

identifying that the channel is in the test mode.

Reconciling these alarm conditions is the user's

responsibility, since the remote alarms are not

included in the standard containment monitor

system.

2. Release the CHANNEL TEST push button. The SAFE-RESET lamp should stay on. Either or both

of the HIGH (red) and ALERT (yellow) lamps may stay on or go out depending on the alarm reset

mode chosen by the installation of jumpers on the alarm circuit board. The monitor is supplied with

the manual reset mode selected.

3. To reset any alarm light, press the SAFE-RESET push button. If conditions are normal, the light will

go out.

4. Switch the function switch to the ALL position.

5. Again press the ECS push button. The panel meter indicator should go to a reading of about 10

R/h and the green SAFE-RESET light stays on in the operating condition. If the panel meter shows

little or no deflection at the pressing of the ECS push button, the green light should go out four

seconds after the ECS push button is pressed. In this case, follow troubleshooting procedures.

6. To set the alert and high alarm adjustments, remove two screws in the rear of the chassis, loosen

the knurled knob on the front of the chassis, and slide the module forward part way out of the rack

to reveal the adjustment potentiometers R513 and R509 on the relay driver printed circuit board. To

adjust the HIGH alarm, depress the red HIGH push button and adjust R513 (drawing 876A-1-75A)

until the meter indicates the desired alarm level. To adjust the ALERT alarm, depress the yellow

ALERT push button and adjust R509 (drawing 876A-1-75A) until the meter indicates the desired

NOTE

3

3

3-1

Page 20

Victoreen 875

Operators Manual

alarm level. Return the module to its proper position in the rack. Tighten the rear holding screws.

Tighten the knurled holding knob on the front. Return the module to service.

During normal operation, the radiation field is usually less than 1 R/h (the lower limit of detection of the

high range detector) and the analog meter display will be at the low end of the meter scale.

Figure 3-1. Readout Module 876A-1, Front and Rear View (reference only, not to scale)

3-2

Page 21

Function Description

Functional Description

4

Section 4

Function Description

4.1 Functional Description

High-Range Containment Monitor Detector 877-1

The high-range containment monitor detector is an ion chamber detector that has the appearance of a

six-inch diameter domed cylinder about seven inches long, mounted on an L shaped bracket. Inside the

cylinder are two flange-mounted electrodes consisting of 31 flat, disk-shaped plates, each about four

inches in diameter, stacked, and mounted on disk rods. The 31 disks form two groups, interleaved with

each other, 16 collection disks and 15 signal disks. Because of the interleaving, they appear as only one

stack, but the collection disks are mounted on three collection disk-posts and the signal disks on three

signal disk-posts. Spacers on the posts keep the disks separated so they do not come in contact, and

clearance holes in the disks allow posts of the opposite polarity to pass through without contact. The

assembly has the appearance of a large air capacitor. The mounting posts are attached to the mounting

flange through insulating spacers, so the flange and housing will be neutral with respect to the charges

applied to the electrodes. The collecting diskposts are elongated beyond the last collecting disk to support

a cup-shaped liner having the same potential as the collecting disks, thus becoming part of the collector.

The whole assembly is covered by the six-inch diameter housing which contacts only the neutral

mounting flange. The mounting flange is pierced by three holes. One hole supports the exhaust tube used

for exhausting and back filling the chamber. The other two support two 2-pin connectors, one for each

electrode. One pin in each pair is connected to the neutral mounting flange. When the coaxial signal

cable is connected to this connector, the cable shield is connected to the neutral pin.

The entire chamber is filled with a mixture of helium (2%) and nitrogen at atmospheric pressure and

sealed.

The seal on this chamber must not be broken. To

do so would alter the calibration and specified

energy response of the system.

CAUTION

4.2 Readout Module 876A-1

Drawings 876A-1-3H and 876-1-3A serve as

interconnecting diagrams for tracing signals

between printed circuit boards. In addition, drawing

876-1-3A contains the main power supply

NOTE

4-1

Page 22

Victoreen 875

Operators Manual

PreamplifierIMeter Printed Circuit Board (P/N 876A-1-86, Schematic 876A-1-3E)

The detector current, measuring from 7 x 10

the reading range, enters the readout on rear panel connector J1. From the rear panel, the ion chamber

current enters the preamplifier circuit through terminal J302. It passes to U301, a seven-decade

logarithmic amplifier, where it produces an output voltage of 5 V for minimum currents and -2.6 V for

maximum currents. This voltage can be monitored at TP501, on the relay driver PC Board.

Q301A and Q301B have their bases connected to their collectors, so that they operate as diodes. Q301

limits over-range inputs to U301. Q302A is a lower-level clamp on the input to logarithmic amplifier U301,

keeping the current from falling below 1 % of the lower limit of sensitivity. This limiting of the low level

current speeds the response of the logarithmic amplifier. The output of U301appears on terminal 13 of

J301. This terminal is connected to terminal 13 of J103 on the motherboard by a ribbon cable. From this

point, connection is made to terminal 14, J106 of the relay driver printed circuit board. This terminal is

effectively the point of input to the meter circuit and high and alert alarm circuits.

Amplifier and meter circuits can be tested by turning the function switch to TEST and depressing the

CHANNEL TEST push button on the front panel. This applies 15 volts to a circuit of which Q302B is a

series element; the purpose is to generate an input current for U301 (at pin 2) such that panel meter

M401 will be driven full scale.

Panel meter M401 may be switched into anyone of six positions of different sensitivity. The meter current

is determined by the voltage applied to pin 10 of U401 from pin 3 of J401. U401 is driven in turn by U501

of the relay driver printed circuit board. Connection is made from terminal 12 of the relay driver printed

circuit board to terminal 3, J401 of the preamplifier metering printed circuit board through pins 11 and 14,

J101 of the switchboard (drawing 876-1-3J) so that the signal path may be interrupted when it is desired

to use the meter for alarm setpoint checks.

-11

to 7 x 10-4 amperes respectively, at the bottom and top of

One of the six sensitivity positions, the ALL position, displays all seven decades on the red meter scale.

Each of the other positions expands the scale to achieve a three-decade display on the black scale. In

addition there is a TEST position and an OFF position. The TEST position is also a seven-decade meter.

Power Supplies

Mother Board Power Supplies (P/N 876-1-78, Schematic 876-1-3A)

T101 acts as a step down transformer producing an output voltage of 24 VDC. This is rectified in the fullwave rectifier consisting of four diodes, CR101 through CR104. The 0.1 microfarad capacitors on the AC

input suppress spikes and limit noise. The output of this 24-volt supply provides the power to both the

positive and negative power supplies on the power supply printed circuit board.

Printed Circuit Board Power Supplies (P/N 876-1-89, Schematic 876-1-3C) (P/N 876-1-89A,

Schematic 876-1-93A)

Positive Power Supply

Twenty-four (24) V power from the motherboard enters the power supply board on terminal 1. Integrated

circuit U2 is a voltage regulator; +15 V comes out of pin 2 of U2. A second supply of +14 volts is provided

through pass element Q1. This output serves relays, lights, and other high current circuit elements. It is

current-limited through R29. The 14 V supply is monitored at TP3.

Negative Power Supply

Transistors Q7 and Q8 make up a free-running multivibrator with a 9 kHz repetition rate, which is powered

by the unregulated 24 volts from the motherboard power supply. Q6 acts as a current limiter for this

multivibrator. U1, pins 8, 9, and 10, and Q5 accept its output and act as a driver stage for the rectifier

which follows. This rectifier consists of CR4 and CR5, and produces a negative voltage, which should be

about -21 VAC, and can be measured at TP5. Voltage regulator U1 (located on the 876-1-89A add-on PC

board) takes this voltage as an input, and delivers a -10 V regulated voltage, which is obtained from

terminal K of the board, and can be monitored at TP4.

4-2

Page 23

Function Description

Readout Module876A-1

4

High Voltage Power Supply Normal Operation (non-ECS Test)

The multivibrator circuit of Q7 and Q8 also supplies the input to the high voltage generator. Two of the

transistors of U1 act as buffers between the multivibrator and the high voltage circuit. Q4 and Q3 serve an

output driving stage for the primary of high voltage transformer T1. The input to T1 is a square wave,

approximately 12.5 V peak to peak. T1 has a step-up ratio of approximately 20: 1. C22, CR15, CR14, and

C20 form a voltage doubler that gives a DC output of approximately 525 volts. The resistor capacitor

circuit R42, R43, and R44, and C17, C18, and C19 serve for further filtering, and ultimately a 506 volt

output is delivered at J1.

R37, R40 and R41 form a voltage divider across the 515 V input to the resistor capacitor filter. The

voltage at the junction of R37 and R40 is the input to OP AMP U2 pins 6 through series resistor R39. Pins

5 and 6 of U2 are the inputs to a difference amplifier, which acts to produce additional regulation of the

high voltage.

U2 (pins 1, 2, 3) is used as a logic circuit in the SAFE/FAIL circuit of the monitor, refer to FAIL/SAFE

Comparison Circuit on Power Supply Board for additional information. In addition to the 6.2 V

reference signal, a voltage will be present at terminal P that comes from terminal 8 of the ECS board

during the ECS test, and a muting signal will also be present at terminal M. This circuit is a part of a

complex checking circuit during the ECS test, and is described in more detail in the "FAIL/SAFE"

paragraph.

Operation of High Voltage Supply During ECS Test

A low voltage ramp (approximately 0 to 6.2 V) from the ECS board enters the power supply board on

terminal 12, and proceeds through a series of auxiliary circuits to give a ramp of the same waveshape on

the center-tap of the primary of high voltage transformer T1, which point is also the source of power to the

driving circuit Q3 and Q4. As a result of this variation of the voltage at the center-tap, the amplitude of the

current in the primary varies accordingly, and ultimately the voltage output at J1 varies from 0 to 506

volts, linearly with time. This high voltage ramp generates the current in the detector circuit during the

ECS test period.

FAIL/SAFE Comparison Circuit on Power Supply Board

The comparison circuit on the power supply board, consisting of U2, pins 1, 2, and 3 has two functions:

The first function, a monitoring of the high voltage, is in operation at all times except during the ECS test.

If this voltage falls below 80% of its rated value, (roughly, from 500 to 400 volts), the FAIL/SAFE circuit

will go out, and the FAIL relay will de-energize. During this period, a steady 6.2 volts, which is input on

terminal 13, serves as a comparison voltage. The voltage on pin 2 is proportional to the high voltage

through a high ratio voltage divider.

The second function, a monitoring of the result of the ECS test, is in operation during this test. During this

period, the high voltage falls well below 400 volts (actually, practically to zero) so the monitoring of the

high voltage as in the above paragraph is inapplicable. Instead, the following are the input and output

conditions.

On pin 2 there is impressed a positive 15-volt signal that lasts for the duration of the ECS test (6.0

seconds). The voltage on terminal M is 15 volts during the ECS test and zero at all other times. The wave

shape that creates this condition on terminal M is called the muting signal wave shape. It will override

whatever voltage would otherwise be present through the high ratio voltage divider from J1.

On pin 3 of the comparison circuit there is impressed a DC voltage that is either 6.2 volts (safe condition)

or 15 volts (fail condition). This voltage arrives on terminal P of the power supply board from a latch circuit

on the ECS board, which circuit will be described in connection with that board. A safe condition causes

the output on terminal N (from pin 1 of U2) to be -10 volts; a fail condition causes it to be +15 volts.

Terminal N is connected to the SAFE/FAIL circuit on the relay driver board, which controls the action of

the fail relay and the SAFE-RESET green lamp on the panel. A fail condition causes the green lamp to go

out and de-energizes the fail relay, although the muting signal delays these actions until the end of the six

(6) second ECS test period. For the safe condition the green light is on, and the fail relay is energized.

4-3

Page 24

Victoreen 875

Operators Manual

PreamplifierIMeter Board Power Supply (P/N 876-1-86, Schematic 876-1-3E)

A +6.2 V power supply contained on the preamplifier meter board has as its input the +15 V from the

power supply board. Integrated circuit U401, pins 12, 13, and 14 is a voltage regulator with diode U402

providing a stable reference voltage. The output is adjustable by R413.

Relay Driver Printed Circuit Board (P/N 876A-1-75A, Schematic 876A-1-3B)

The signal input to the relay driver printed circuit board which is taken from pin 13 of the preamplifier

meter may be monitored at this point through test point TP501. The signal enters pin 13 of OP AMP

U501, and the output is taken from pin 14. The gain of this amplifier stage can be adjusted by

potentiometer R503. The output of the OP AMP can be monitored at TP502; it provides inputs to:

• High Alarm circuit

• Alert Alarm circuit

• Meter buffer amplifier circuit

• Recorder/Computer drivers

High Alarm Circuit

The signal output to the high alarm circuit enter OP AMP U502 on pin 5. This is a difference amplifier,

whose other input (pin 6) is determined by the setting of potentiometer R513. The main purpose of this

stage is to control the high alarm threshold.

The output of the comparison OP AMP is connected, through diode CR504, to pin 6 of U503, which acts

mainly as a power stage for the HIGH ALARM (red) panel light. The output of this stage (pin 7) also

serves as the input to the high alarm relay driver stage U503, whose main function is to drive relay K502.

The input to the high alarm relay driver stage of U503 is on pin 9, and the output is taken from pin 8.

Relay K502 is energized in the non-alarm state, and a signal above threshold serves to de-energize it.

There is a red HIGH ALARM jumper connected to the collector (pin 8) of the relay driver U503. The

following options are available with the presence or absence of the jumper when the radiation level

exceeds the threshold and triggers the alarm:

Manual Reset - The alarm will continue to be activated even after the radiation level recedes below

threshold until the SAFE/RESET indicator push button on the panel is depressed. This option occurs

with the jumper in place.

Automatic Reset - The alarm will continue to be activated only as long as the radiation exceeds the

threshold level. This option occurs with the jumper removed.

The red warning light acts similarly to the alarms. It lights when the alarm relay is de-energized.

Each relay contains four Form C contacts, but only two of the four are accessible through the rear

connector.

The connection to the red panel warning light is from terminal 3 of the printed circuit board, which is

connected to the collector (pin 7) of U503 through resistor R521.

Alert Alarm Circuit

The signal input to the alert alarm circuit enters OP AMP U502 on pin 3. This is a difference amplifier,

whose other input (pin 2) is determined by the setting of potentiometer R509. The main purpose of this

stage is to control the alert alarm threshold. The output of the comparison OP AMP is connected, through

diode CR501, to pin 13 of U503, which acts mainly as a power stage for the Alert (yellow) panel light. The

output of this stage (pin 14) also serves as the input to the alert alarm relay driver stage U503, whose

main function is to drive relay K501. The input to the alert alarm relay driver stage of U503 is on pin 2,

and the output to the relay is taken from pin 1. Relay K501 is energized in the non-alarm state, and a

signal above threshold serves to de-energize it.

4-4

Page 25

Function Description

Readout Module876A-1

There is a yellow ALERT ALARM jumper connected to the collector (pin 1) of the alert alarm relay driver

stage of U503. The following options are available with the presence or absence of the jumper when the

radiation level exceeds the threshold and triggers the alarm:

Manual Reset - The alarm will continue to be activated even after the radiation level recedes below

threshold until the SAE/RESET indicator push button on the panel is depressed. This action occurs with

the jumper in place.

Automatic Reset - The alarm will continue to be activated only as long as the radiation exceeds the

threshold level. This action occurs with the jumper removed.

The yellow warning light acts similarly to the alarms. It lights when the alarm relay is de-energized.

Each relay contains four Form C contacts, but only two of them are accessible from the rear connector.

The connection to the yellow panel warning light is from terminal 2 of the printed circuit board, which is

connected to the collector (pin 14) of U503 through R526.

4

Fail/Safe Circuit

Input to the fail/safe circuit comes from pin 1 of U2 on the power supply board, entering the relay driver

board on pin H of the relay driver printed circuit board. The input is a DC voltage that is either high (15 V)

or low (0 V); if it is low, relay K3 is energized (non-alarm condition). If the signal is high, the green

SAFE/RESET lamp will go off and the relay is de-energized, indicating a fault somewhere in the system.

The circuit consists basically of two inverters in tandem so the voltage on the collector of Q502 is

approximately the same as the input voltage, the diode CR508 preventing current flow through the

solenoid if the collector is slightly higher than the 14 V at the other end of the solenoid coil.

Recorders and Computer Buffers

Provisions have been made for delivering DC output voltages to a recorder and computer for further

processing. The buffers are located on the relay driver board. If a commercial device is to be connected, a

signal isolator must be installed between the device and the 876A-1 Readout Module output. Inputs to

both computer and recorder buffers arrive at pin R of the relay driver printed circuit board, coming from

terminal 3 on the ECS printed circuit board. The computer buffer consists of and OP AMP using pins 1, 2

and 3 of U501, the output being taken off the relay driver board at pins 4 (+) and 2 (-) of P502. Resistors

R532 and R533 act as voltage dividers for the output. Their values for standard usage and available

options are shown in Table 4-1.

The recorder buffer consists of an OP AMP using pins 5, 6 and 7 of U501, the output being taken off the

relay driver board at pins 1 (+) and 3 (-) of P502. Resistors R530 and R531 act as voltage dividers for the

output. Their value for standard usage and available options are shown in Table 4-1. Both buffers are

disabled during the ECS test by a switching circuit on the ECS board, so that the ECS current is not

recorded. This circuit consists of Q201 and Q202 on the ECS board and is activated by a muting voltage

during the ECS test.

Table 4-1. Resistance Options for Voltage Dividers

Resistor Std. Option 1 Option 2 Option 3

Recorder

Voltage

R530 1 kilohm 119.8 kilohms 200 ohms 200 ohms

R531 200 ohms 200 ohms 1 kilohm 1 kilohm

Computer

Voltage

R532 200 ohms 11.8 kilohms 23.8 kilohms 200 ohms

R533 1 kilohm 200 ohms 200 ohms 1 kilohm

0 – 1 V 0 – 10 mV 0 – 5 V 0 – 5V

0 – 5 V 1 – 100 mV 0 – 50 mV 0 – 5 V

Pen Clamp

4-5

Page 26

Victoreen 875

Operators Manual

The pen clamp circuit is a clamping circuit consisting of U501, pins 8, 9 and 10 and diode CR502. It

prevents pin 9 from going negative. The purpose of this is to prevent the recorder pen from being jammed

against the baseline.

Electronic Check Source (ECS) Printed Circuit Board (P/N 876A-1-92, Schematic 876A-1-

30)

Due to the range of the detector (1 to 10E7 R/h), a remotely activated radioactive check source is

impractical, since the source activity would be high and the shielding necessary for this source would

effect detector energy response. For this reason, an electronic check source is provided. During check

source operation, the detector remains connected to the system as a passive capacitive element. Since

the current-voltage relation in a capacitor is such that the current is proportional to the rate of change of

the applied voltage, an applied voltage, in the form of a linear ramp, will produce a steady current. It is this

current which is read during the ECS test.

The ECS board (drawing 876A-1-3D) has two main functions: 1. To generate the low voltage ramp which,

in the high voltage supply, develops the high voltage ramp responsible for the test current in the detector

during the ECS test. 2. To monitor the current flowing during the ECS test, and recognize whether the test

signifies a passing of failing condition in the circuits of the unit. One of the circuits involved in this

monitoring process is actually on the power supply printed circuit board.

The voltage ramp which develops the detector current during the ECS test rises from 0 to 506 volts over

three seconds, so that the rate of change of voltage is approximately 170 V/second. The capacitance of

the detector is approximately 435 picofarads and therefore, the steady current during the rise of the

voltage ramp is approximately 7 x 10

The ramp occurs when ECS is initiated for a period of about six (6) seconds, during which time the

system is not acting as a radiation monitor.

-8

amperes, which puts the panel meter at about one-third full scale.

The ECS test may be initiated at the will of the operator. For this purpose there is a manually operated

ECS push button. If the ECS test is not initiated by the operator, it will take place automatically every 17.1

minutes. After each manually initiated test, the automatic circuits are reset so that a test will be initiated

17.1 minutes later.

In addition to causing visual alarms and relay de-energizing if circuit failures are found, the ECS test

affects the panel meter as in the three cases described below. It is the processing of the voltage read by

the panel meter during the ECS test that is responsible for the action of the circuits directly involved in

driving the visual (green light) and relay (fail) alarm circuits. Recorder and computer outputs are muted

during the ECS and will indicate zero while the test is in progress, approximately six (6) seconds.

Panel Meter Action During ECS Test

The meter action to be expected during the test period with the containment monitor operating properly

can best be explained by considering three initial conditions: 1) Panel meter is resting at extreme lower

end of scale; 2) Panel meter on scale but below 10

1. Meter at extreme lower end of scale

In this case, the meter needle should remain motionless for about 1 second, rise to 10

remain there for about three seconds, and then fall to its initial position.

3

2. Meter on scale, but below 10

R/h

In this case, the meter needle should fall to zero at the beginning of the test period. It will then rise

to approximately one-third full scale, and remain in this position for about four seconds. After this, it

will resume its original reading, with perhaps some slight negative overshoot.

3

3. Meter above 10

R/h at start of test

This case is quite similar to the above except that the meter may not fall to zero at the start of the

test, and at the upswing, it will take a position higher than 10

ambient radiation. It will ultimately resume the same position as before the test as in item 2 above.

3

R/h; 3) Meter above 103 R/h at start of test.

3

R/h, the excess depending on the

3

R/h and

4-6

Page 27

Function Description

Readout Module876A-1

NOTE

4

During the ECS test, all alarms are muted; that is,

their operation is disabled until the completion of

the test. During this six-second period there is no

warning of a high radiation condition. If this

situation is not tolerable, two containment monitors

must be installed.

Action of Green Safe/Reset Light and Alarm During ECS Test

The behavior of the green SAFE/RESET panel light during the test is as follows:

A pass condition is indicated by the green light remaining lighted throughout the test.

A fail condition is indicated if the green light goes out at the end of the test.

Circuit Actions at Manual and Automatic Initiation of ECS Test

Whether the ECS test is initiated automatically or at the will of the operator, a trigger signal is delivered to

pin 4 (manual) or pin 5 (automatic) of U206, whose output initiates the low voltage ramp generation.

Automatic operation may be disabled by the removal of jumper 200A. The system will then respond only

to the pressing of the ECS button.

The circuit containing U201 (pins 5, 6, 7) and U208 (pins 11 and 12) constitutes a clock with a 0.976

millisecond repetition rate. It is followed by counters U204 and U205. The action of U204 is entirely

restricted to automatic control of the ECS test, as is the output from pin 1 of U205 (note that it may be

open-circuited by the removal of jumper 200A). However, the outputs from pins 3, 5, and 6 have functions

that enter into both manual and automatic action. In addition, they involve both the ramp-generation and

monitoring functions of the ECS board, and also enter into the operation of two important auxiliary

functions: 1) generation of a muting pulse, so that the alarms will not be set off during the ECS test and;

2) re-initiation prevention--that is the prevention of malfunction on manual operation in case the operator

inadvertently presses the ECS button more than once. The monitoring function is involved because the

instant of generation of the latch-enable pulse occurs a precise time after the pressing of the ECS button

initiates the test (toward the end of the test, when conditions have stabilized). The path from U205 pin 6

to the latch-enable generator may be seen to involve the following points: 1) pin 10, U203; 2) pin 5, U207

(input); 3) pin 6, U207 (output) and finally pin 11, U207, whose output drives the latch-enable generator

Q205. The latch and latch enable functions will be explained with the monitoring circuits after the

explanation of the ramp generation.

Low Voltage Ramp Generator

The elements that enter the generation of the low voltage ramp are U203, U208, U201, Q204, and

associated capacitors, resistors, and diodes. U203 is an auxiliary element.

At the arrival of the trigger, Q204 serves the purpose of reducing the voltage previously at terminal 5

quickly to zero, at which instant the ramp-generator proper takes over. Basically, C210 is the charging

capacitor, and the other components serve either as charging resistors or linear elements. Potentiometer

R227, ramp voltage per second adjustment (RAMP V/SEC ADJUST), serves to determine the rate of

charge of capacitor C210, and consequently, the rate of rise of the voltage applied to the detector plates.

The ramp that is generated by the ramp generator appears at terminal 5, where its maximum is only 6.2

volts. From terminal 5, it is connected to the high voltage generator on the power supply printed circuit

board, where it controls the generation of the high voltage, as explained in the functional description of

the power supply printed circuit board.

Monitoring Circuits of The ECS Board

The input to the monitoring circuits of the ECS board is on terminal 1, the output on terminal 8. The input

on terminal 1 is effectively proportional to the current produced in the detector by the application of the

4-7

Page 28

Victoreen 875

Operators Manual

high voltage ramp. The overall circuit that monitors the ECS test also includes U2, described with the

power supplies; and the SAFE/FAIL circuit on the relay driver printed circuit board.

Ultimately, by the action of R218, the charge integration adjustment potentiometer (CHARGE INTEG.

ADJ.), charging capacitor C209, and other auxiliary elements, a DC voltage is produced on terminal 10 of

U201, and an output voltage on pin 8 which results in an input to pin 10 of U208 which will be

approximately zero if the system is operative, and approximately + 15 V it a malfunction is present, or on

channel power-up before the first automatic or manually initiated ECS test.

This signal is the input to the latch-and-flop circuit composed of the NOR circuits U202 (pins 1 to 13). The

latch is quiescent until triggered near the end of the ECS test period by the latch-enable input on pin 1 of

U202. This trigger voltage will cause the output (pin 10 of U202) to flop from a pass indication to a fail

indication if a malfunction exists in the detector cable, or signal input circuit.

If the system is operative, a voltage that is low (6.2 V) will appear at terminal 8; if the system has a

malfunction, a voltage that is high (+15 V) will appear at this terminal (+15 V will appear momentarily

immediately after power on). This voltage determines the action of a comparison circuit U4A, and the

output of U4A determines the action of the SAFE/FAIL circuit.

A block diagram of the entire monitoring circuit of the ECS test is shown in Figure 4-1.

Figure 4-1. Block Diagram of ECS Test

4-8

Page 29

Function Description

Readout Module876A-1

4

Safe/Reset Sub-circuits

The three sub-circuits described below are all involved in the operation of the green SAFE/RESET lamp

and its associated alarm:

1. A latch for the SAFE/RESET lamp built around four NOR circuits of integrated circuit U202, with

several auxiliary elements.

2. A threshold detector U201 (pins 8, 9, and 10) ascertains by comparison with a standard voltage

whether the current produced by the ECS ramp is sufficiently high.

3. A one-shot multivibrator, U207, pins 9 to 15, which provides an enable signal to allow the latch

circuit to flop from a pass to a fail condition if the signal from the threshold detector is a fail signal.

This enable signal is necessary because the detector current during the ECS test is higher than the

average normal radiation current. The monitoring circuits must therefore be examined just at the

proper time, which is immediately after the cessation of the ECS current.

It will be noted that a trigger signal from the counter U205 is applied to the base of Q207, whose collector

is connected to Q203. . The purpose of this sub-circuit is to short-circuit capacitor C209, so that the

integration of the ECS may proceed from a stable and repeatable starting point. If the system is a

functioning properly, a 2.57 volt level will be present at terminal 1 at the top of the ramp, corresponding to

the 103 R/h meter indication. If voltage at pin 1 is below 2.48 V at this point, ECS circuitry will indicate

channel failure. See Figure 5-1 and drawing 876A-1-3D. This voltage, applied to the integrator circuit

consisting of R218, R224, C209 and the OP AMP circuit U201, pins 12, 13 and 14, produces a linearly

failing voltage of about 2 V/second at pin 14 of U201. This voltage begins just above 0 V. When it reaches

-6.2 volts, a quick switching action takes place in U201, the important result being a sharp change in the

output voltage (pin 8) from +15 to 0 volts. A low (approximately 0 V) input at pin 10 of U208 results

ultimately in a safe report (green light stays on and the alarm relay is energized); whereas a high

(approximately 15 V) input results in a fail report (green light goes out and alarm relay is de-energized).

For any change in the output of the latch circuit (pin 10 of U202) an enable pulse is required. This signal

is output by one-shot multivibrator U207, pin 9, which receives its input from one of the outputs of the

muting multivibrator U207 (pins 1 to 8).

Muting Circuits of ECS Board

During ECS test, it is possible that the normal current generated by the ECS voltage ramp will exceed the

trip-level chosen for the high and/or alert alarm circuits. To avoid an unwanted alarm, the alarm circuits

are muted during the ECS test--that is the alarm circuits are made inactive, so that their lamps and alarm

relays will not respond during the test. Effectively, this is done by generating voltage pulses in the ECS

circuits which last for the duration of the test, and applying them at appropriate points in the alarm circuits

on the relay driver board, so that the alarm circuitry will be momentarily disabled. Computer and recorder

buffers are also muted during the ECS test.

The circuits of the ECS board that generate the muting pulses are, to some degree, involved with the

ramp-generating and monitoring circuits of the ECS board, since all must be in time synchronization.

Generally speaking, however, the most important elements of the muting circuits are contained in

integrated circuit U207 (pins 1 to 8) and integrated circuit U206 (pins 9 to 15). The muting pulse is a

voltage which starts from zero, rises abruptly to +15 V, lasts about six seconds, and falls abruptly to zero.

Initiation takes place on pin 5 of U207, and the output is taken from pin 13 of U208. The signal for muting

the alarms appears on terminal 9 of the ECS board, but a second path leading to pin 12 of U203 serves

the auxiliary purpose of preventing re-initiation of the manually generated trigger produced by pressing

the ECS button on the panel.

4-9

Page 30

Victoreen 875

Operators Manual

(Blank page)

Page 31

Maintenance, Calibration, and Troubleshooting

Maintenance

5

Section 5

Maintenance, Calibration, and Troubleshooting

5.1 Maintenance

The monitor is designed to operate for long periods in the containment without attention. The following

replacement schedule should keep the monitor in trouble-free operation.

Every five years - Replace the 4200 microfarad electrolytic capacitor, P/N 92-3005-A (C1 01), and the RFI

line filter, P/N 92-9015A (FL101), located on the 876-1-78 mother board of the 876A-1-108 or 876A-100

Readout Module.

Whenever detector cables are removed - Replace the nickel seals, P/N 877-1-60-1, on the detector

connectors as described in the CABLE-877 procedure in Appendix A.

5.2 Calibration

The monitoring systems require calibration before placing them into service. In addition, they should be

recalibrated at regular intervals during routine service. The length of time between calibration intervals

should be determined by operations personnel. For further calibration information, refer to the applicable

calibration procedure provided in Appendix A.

The high-range containment area monitor underwent a complete electronic and isotopic calibration prior

to leaving the Fluke Biomedical plant. The same electronic calibration procedure is supplied in this

manual. Prior to primary isotopic calibration, the detector's hermetically must be verified. Primary isotopic

calibration requires a highly radioactive source (greater than 400 curies) with National Bureau of

Standards (NBS) traceability. As this is beyond the capability of most facilities to perform, the following

method of verifying detector calibration is used:

Detectors shall either be returned to Fluke Biomedical at a five (5) year interval from the date of delivery

or the owner must establish a procedure to determine that the average A/R/h output current does not

deviate from original factory calibration by more than ± 10%.

To encompass Nureg-0737 guidelines, on-site in-situ calibration checks can be performed with the 87810 High-Range Field Calibrator that is capable of producing a 10 R/h indication on the channel under

test.

Electronic alignment of the 876A Readout may be performed using Functional Test Procedure, TP876A1-108 included in Appendix A, and the standard test equipment as listed in Table 5-1. Personnel must be

fully knowledgeable in the operation of the readout prior to attempting to perform the test.

Disconnect Detector 877-1 from Readout Module

876A-1 by removing cables from J1 and J2 before

starting electronic calibration.

NOTE

5-1

Page 32

Victoreen 875

Operators Manual

Table 5-1. Recommended Test Equipment

Current Generator - Test Electrometer

Range 1 x 10

Accuracy, Current Generator

Accuracy Test Electrometer

-12

Amps to 1 x 10-3 Amps

-12

10

Amps ± 10%

-11

10

Amps ± 3%

10

10

-10

-7

-7

to 10

Amps ± 2%

to 10-3 Amps ± 0.2%

± 0.2% ± 1 digit with integration time long enough to accumulate 3

significant digits of volts indicated on display V/R ± 0.2% ± 1 digit

Adjustable AC Voltage Source

Maximum Voltage Low range 140 VAC, high-range 280 VAC

Frequency 60 Hz

4 ½ Digit Digital Multimeter

Fluke 8600A or equivalent

Ranges + 0 to 100 mV up to + 0 to 100 V (20% over-range)

Accuracy

100 mV range: ± (0.05% of input ± 0.02% of range)

all other ranges: ± (0.02% of input ± 0.01% of range)

Input Impedance > 10 megohms

DC Voltage

AC Voltage

DC Current

± 0.03%

± 1%

± 0.3%

Trim Pot Adjustment Tool

Carbon Composition Resistor

Resistance 10 kilohms, ½ W, 5%

Lead Connectors Small alligator clips

DC Power Supply

Output Voltage 0 to + 25 VDC

Output Current 0 to 600 mA

Load Regulation

0.01% ± 4 mV

Adjustable Current Limit Down to 10 mA

Multi-function Counter

Fluke 1900A or equivalent

Frequency 5 Hz to 80 MHz (0.1 to 100 Hz Resolution)

Period 5 Hz to 1 MHz, single and multiple period averages

(1 to 100 nsec resolution)

Total Counts 1 to 999,999 counts

Test Procedure TP876A-1-108

Factory test procedure, TP876A-1-108, contains this information necessary to perform electronic

alignment of the 876A-1-108 Readout Module. This procedure is included in Appendix A.

5-2

Page 33

Maintenance, Calibration, and Troubleshooting

Troubleshooting

5

5.3 Troubleshooting

The 875 High-Range Containment Monitor is safety-related equipment. The monitor has been assembled

by techniques and with parts selected for the reliability required in a nuclear application. Any repairs made

to the detector or readout (other than replacement of parts listed in Section 5) may void the safety-related

rating. The troubleshooting procedure that follows is a guide to isolating a fault in the system.

Replacement of parts is at the printed circuit board level only. Printed circuit boards must be returned to

Fluke Biomedical for service.

There are two self-contained system tests available in Containment Monitor 875, the Channel Test and

the ECS Test. In both cases, the procedure is to put a known input into the system, and to look for the

desired output.

There is an important difference between the Channel Test and the ECS Test: the former applies an input

to the readout module (that is, to the first electronic circuit in the Containment Monitor); however, it does

not test the detector or the cables connecting the detector to the readout module. In addition, the Channel

Test applies a DC voltage, whereas the ECS Test applies a ramp voltage to the detector plates,

monitoring the resultant current into the readout module.

The digital multimeter mentioned in Table 5-1 of the calibration section is also recommended for

troubleshooting.

If the ECS Test gives a favorable result, the following conditions exist:

1. The detector cannot have any appreciable malfunction.

2. The cables must have continuity.

3. The ECS board and power supply board must be operative.

4. It is highly improbable that any malfunction exists in the fail/safe circuitry.

5. The amplifier, meter and alarm circuitry must be operative.

Essentially, the Channel Test verifies only #5 of the above. However, in doing so, it incidentally verifies all

of the power supplies except the high voltage power supply.

For clarity, troubleshooting is divided into six divisions:

1. Power supplies

2. Input circuit

3. Meter circuit

4. Alarm circuits

5. ECS board

6. Overall fail circuitry

NOTE

Disconnect Detector 877-1 from Readout Module

876A-1 by removing cables from J1 and J2 before

starting troubleshooting of readout module. The

user will probably wish to disconnect the external

alarms as well. It is the responsibility of the user to

see that the alarms are not set off by disconnection.

5-3

Page 34

Victoreen 875

Operators Manual

5.4 Power Supply Measurements (P/N 876-1-89 Schematic 876-1-3C)

Turn the 876A-1 on by turning the function switch to the ALL position.

CAUTION

Allow all equipment, including the readout module,

to warm up for at least 60 minutes before

attempting any calibration.

Adjust the mechanical zero of the panel meter (use mirror scale to avoid parallax error) so that the needle

is centered on the first hash mark of the black expanded arc to within 0.50 needle width.

Verify the output voltage of the power supplies as follows (See drawings 876-1-78 and 876-1-89).

Mother Board (P/N 876-1-78, Schematic 876-1-3A)

1. Connect the negative lead of the DMM to TP102.

2. Probe TP101 with the positive lead of the DMM. The DMM should read +24 ± 3 VDC.

Power Supply Printed Circuit Board (P/N 876-1-89, Schematic 876-1-3C)

3. Probe TP5 (white) with the positive lead. The DMM should read -21 ± 2 VDC.

4. Probe TP4 with the positive lead. The DMM should read -10.00 ± 0.01 VDC. Adjust R4 as

necessary to correct this reading.

5. Probe TP2 with the positive lead. The DMM should read + 15.0 ± 0.2 VDC. Adjust R5 as required to

achieve correct readings.

6. Probe TP3 with the positive lead. The DMM should read +14.3 ± 0.4 VDC.

PreamplifierIMeter Board (P/N 876A-1-86, Schematic 876A-1-3E)

7. Probe TP401 on preamplifier meter board with the positive lead. The DMM should read +6.200 ±

0.001 VDC. Adjust R413 as necessary to correct this reading.

Rear Panel

8. Probe the back panel high voltage connector, J2. The DMM should read +506 ± 10 VDC.

5.5 Signal Input Circuit

(P/N 876A-1-35, Schematic 876A-1-92 & P/N 876A-1-75A, Schematic 876A-13B)

The signal input circuit is partly on the preamplifier board, and partly on the relay driver board. It consists

of logarithmic amplifier U301 and its associated circuitry (preamplifier meter board) and amplifier U501

(relay driver board). The output of U501 provides the input for the meter circuit on the preamplifier meter

board and the high and alert alarm circuits on the relay driver board. The alarm circuits are covered in the

"Alarm Circuits" paragraph. The signal input circuit can be tested at two test points, using the CHANNEL

TEST push button to provide a convenient input signal. Voltages at these points should be measured with

no signal input.

1. Disconnect the cable connecting the readout module to the detector. Turn the function switch to

TEST.

2. Measure the voltages at TP501 and TP502 under two conditions: 1) with no signal input; 2) with a

signal input obtained by pressing the CHANNEL TEST push button.

The voltages should be:

Channel Test Signal

No Signal

5-4

Page 35

Maintenance, Calibration, and Troubleshooting

Signal Input Circuit

TP501 +5 V -2.8 V

TP502 -1.5 V +6.3 V

5

These voltages are approximate and actual values may differ somewhat. Any marked departures from

these values is an indication of a malfunction.

5.6 Metering Circuit (P/N 876A-1-3E, Schematic 876A-1-92)

The signal circuit that drives the meter is U401 (Figure 5-2). This is a voltage follower whose output on pin

9 should equal its input on pin 10.

These signals vary from -1.5 V with no signal to +6.3 V with the CHANNEL TEST push button pressed.

All other faults in the metering circuit should be detectable by resistance measurements.

The preamplifier metering board contains a

regulated power supply whose voltage is critical. It

should measure 6.2 ± 0.001 V at TP401. It may be

adjusted by R413.

NOTE

5.7 The Alarm Circuits (P/N 876A-1-75, Schematic 876A-1-3B)

The alert and high alarm circuits differ only in very minor details, so for troubleshooting purposes, it will be

sufficient to discuss them together. As a matter of fact, they are similar for troubleshooting purposes. E.g.

the simplest way to eliminate certain problems is to replace printed circuit board 876A-1-75. Where the

discussion is given in terms of particular pin numbers for definiteness, the alert alarm circuit is to be

understood, but completely analogous procedures apply to the high alarm circuit. At some points, it is

deemed sufficient to describe the voltage state as simply high or low; at other points, particular voltages

have been given. The maximum high value is +15 V, and the minimum low value is -10 V.

In the alert alarm circuit, if a measurement can be made directly on a pin of an OP AMP, a high reading

will usually be close to +15 V, and a low reading close to -10 V. For example, the normal (low input

current) voltage on pin 1 of U502 is -9.9 V (low) and the voltage at the same point is + 13.7 V when high.

However, if the voltage is measured on the other side of the resistor R510, the high is only +1.45 V,

whereas the low is still the same -9.9 V.

If the Channel Test has shown the system to be operative, the following will be the voltage states at

critical points in the signal chain between test point TP502 and relay K501:

The following are measured voltages at critical points in the alert alarm circuit (muting stages are treated

separately). Reset the alarm after every test.

1) TP502 0 to 6 V depending on strength of radiation

Test Point *Normal Channel Test

2) Pin 1 U502 -9.8 V +13.7 V

3) Junction of R510 and CR501 -9.8 V +1.45 V

4) Pin 14 U503 +14.1 V +0.2 V

5) Pin 1 U503 +0.08 V +13.7 V

5-5

Page 36

Victoreen 875

Operators Manual

*Normal here signifies a small radiation signal so that the voltage at TP502 is close to zero volts.

NOTE

Both of the solenoids of the alert and high alarm

circuits must operate for the CHANNEL TEST lamp

to light.

The lighting of the CHANNEL TEST lamp does not

of itself show that the remote alarm contacts have

closed (See Relay Driver Schematic, drawing

876A-1-3B.) However, simple resistance

measurements and reference to the relay driver

schematic can assure that the output to the remote

alarms is correct.

5.8 High Alarm Circuit

Troubleshooting in the high alarm circuit is completely analogous to that in the alert alarm circuit. Voltages

may be slightly different because R513 may be set differently from R509. However, the high and low state

should be recognizable.

5.9 Muting Stages of the Alarm Circuits

The muting stages of the alarm circuits (U502 pins 8, 9, 10 and pins 12, 13, 14) can cause trouble in two

ways:

1. They can fail to mute the alarm circuits during the ECS Test, thus causing the alarms to sound

when this is undesired.

2. They can mute the alarms when the alarms should sound. This is the more undesirable of the two

possibilities.