Fluke 80i-110s Instruction Manual

®

S

0

5

80i-110s

AC/DC Current Probe

Instruction Sheet

Introducing The Current Probe

• The Fluke 80i-110s is a clamp-on AC/DC Current Probe that

reproduces current waveforms found in modern commercial and

industrial power distribution systems. The probe's performance

is optimized for accurate reproduction of currents at line

frequency and up to the 50th harmonic waveform. The 80i-110s

is also compatible with any instrument capable of millivolt

measurements. The Current Probe (shown in Figure 1) provides

the following benefits:

• Accurate AC, DC and AC+DC current measurements for

Electrical, Electronic and Automotive applications.

• Shielded for high noise immunity around electronic motor drives

and ignition systems.

• Wide measurement range from 50 milliamps to 100 amps,

useful to 10 milliamps.

• Jaw shaped for easy access to cramped spaces.

• Safety-designed 600 volt insuIated BNC - compatible with Fluke

ScopeMeter® test tools, Power Harmonic analyzers, and

oscilloscopes.

• Selectable output of 10 millivolts per 1 amp for the 100 A range,

and 100 millivolts per 1 amp for the 10 A range.

Figure 1. 80i-110s AC/DC Current Probe

Unpacking

The following items should be included in your Current Probe box:

• AC/DC Current Probe, 80i-110s

• Instruction Sheet (this sheet)

• 9 volt Battery, type IEC 6LR61

Check the contents of the shipping box for completeness. If

something in the box has been damaged or missing, contact your

distributor or the nearest FLUKE sales or service office immediately.

4822 872 30777

October 2005

© 2005 Fluke Corporation.

All rights reserved.

Printed in the Netherlands.

All product names are trademarks

of their respective companies.

Tactile Indicator

Warning

To avoid electrical shock, unclamp the current probe

from any conductor, and disconnect the scopemeter

test tool or any other measurement device before

installing or replacing the battery.

At first use, remember to install the battery. Referring to Figure 2,

use the following procedure to install the battery:

1. Be sure that you have unclamped the Current Probe from any

conductor and have disconnected the ScopeMeter test tool or

any other measurement device.

2. Be sure that the Current Probe is in the OFF position.

3. Locate the battery cover on the handle. (see Figure 2.) Loosen

the screw with a flat-blade screwdriver.

4. Slide the battery cover away from the Current Probe.

5. Install the battery (IEC 6LR61) as shown in Figure 2. Arrange

the battery leads so that they will not be pinched between the

handle bottom and the battery cover.

6. Reinstall the battery cover and secure the screw.

+

T77

Figure 2. Installing the Battery

Safety information

Installing The Battery

To ensure safe operation and service of the Current Probe,

follow these instructions:

• Read the operating instructions before use and follow all safety

• Use the Current Probe only as specified in the operating

• Adhere to local and national safety codes. Individual protective

• Do not hold the Current Probe anywhere beyond the tactile

• Before each use, inspect the Current Probe. Look for cracks or

• Check the magnetic mating surfaces of the Current Probe jaws;

• Never use the Current Probe on a circuit with voltages higher

• Use extreme caution when working around bare conductors or

• Use caution when working with voltages above 60 V dc, 30 V ac

• Use of this equipment in a manner not specified herein may

Read First: Safety Information

instructions.

instructions, otherwise the current probe's safety features may

not protect you.

equipment must be used to prevent shock and arc blast injury

where hazardous live conductors are exposed.

indicator, see Figure 1.

missing portions of the Current Probe housing or output cable

insulation. Also look for loose or weakened components. Pay

particular attention to the insulation surrounding the jaws.

these should be free of dust, dirt, rust and other foreign matter.

than 600 V CAT II or 300 V CAT III.

− CAT II equipment is designed to protect against transients

in circuits directly connected to the low-voltage installation,

such as household appliances, portable tools and similar

equipment.

− CAT III equipment is designed to protect against transients

in equipment in fixed equipment installations, such as

distribution panels, feeders and short branch circuits, and

lighting systems in large buildings.

bus bars. Contact with the conductor could result in electric

shock.

rms or 42 V ac peak. Such voltages pose a shock hazard.

impair the protection provided by the equipment.

Symbols

May be used on HAZARDOUS LIVE conductors.

Product is protected by double insulation.

Risk of Danger. Important information. See

Instruction Sheet.

Risk of Electric Shock.

Conforms to relevant European standards.

Earth ground.

Battery.

Electrical Specifications

All Electrical Specifications are valid at a temperature of 23 °C

± 3°

C (73 °F ± 5 °F).

Current Ranges: 0 to 10A dc or ac peak

0 to 100A dc or ac peak

Output Signals: 10A range: 100 mV/A

100A range: 10 mV/A

Working voltage (Probe jaws to Ground) &

Floating Voltage (Output cable and connector to

Ground):

600V ac rms on Measurement Category II (CAT II) & 300V

Basic Accuracy (DC to 1kHz):

Input

Current (DC

or AC peak)

0 to 10A

0 to 40A

40 to 80A

80 to 100A

Extended Accuracy:

For other frequencies, refer to the appropriate input current range

and add the error listed below to the "Basic Accuracy" error.

Frequency

1 to 5 kHz

5 to 20 kHz

>20 kHz

Input Load Impedance (of host instrument):

>1 MΩ in parallel with up to 100 pF

Useful Bandwidth (-3 dB): 0 to 100 kHz

Rise or Fall Time: <4 µsec

Output noise level: 10 mV/A typ. 480 µV pk-pk

100 mV/A typ. 3 mV pk-pk

Max. non destructive current: 0 to 2 kHz 140A peak

2 to 10 kHz 110A peak

10 to 20 kHz 70 A peak

20 to 50 kHz 30A peak

50 to 100 kHz 20A peak

Temperature coefficient:

2000 ppm/°C max. for temperature from 0 to 50 °C (32 to 132 °F)

ac rms on Measurement Category III (CAT III) circuits per

EN/IEC 61010-1.

Error (after zero check)

100 mV/A 10 mV/A

<3% of reading +50 mA

-

-

-

100 mV/A 10 mV/A

3%

12%

not specified

<4% of reading +50 mA

<12% of reading +50 mA

<15% of reading

Additional Error

3%

12%

not specified

General Specifications

Dimensions: 67 x 231 x 36 mm (2.6 x 9.1 x 1.4 inches)

Weight: 330g (11.6 oz.), battery included

Output Cable: 1.6 meters (63 inches)

Maximum Conductor Size: 11.8 mm (.46 inch)

Maximum Jaw Opening: 12.5 mm (.49 inch)

Temperature: operating: 0 to 50°C (32 to 122°F)

nonoperating: -30 to 70°C (-22 to 158°F)

Relative Humidity (Operating): 0 to 85% (0 to 35°C; 32 to 95°F )

0 to 45% (35 to 50°C; 95 to 122°F)

Altitude: operating: 0 to 2000 meters (0 to 6560 feet)

nonoperating: 0 to 12000 meters (0 to 40000 feet)

Demagnetize Probe: Open and close probe jaws several times

Safety Specifications

Complies with American Industry standards UL61010B-1 &

UL61010B-2-032, Canadian standards CAN/CSA C22.2 No. 610101 (2004) & No. 61010-2-032 (2004) and European standards

EN/IEC 61010-1 2nd Edition & EN/IEC 61010- 02-032.

Measurement Category Rating: 300V CAT III & 600 V CAT II,

pollution degree 2.

This product is in conformity with Electromagnetic Compatibility

Directive 89/336/EEC, and low Voltage Directive 73/23/EEC.

This conformity is indicated by the symbol

européenne”.

, i.e. “Conformité

Battery Information

Battery: 9 volt, IEC 6LR61

Consumption: 8.6 mA typical

12 mA maximum

Service life: 55 hours typical, when Alkaline IEC 6LR61 is used

40 hours minimum, when Alkaline IEC 6LR61 is used

Battery indicator (ON):

Green LED dims when battery voltage is below 6.5V

Warning

To avoid false readings which could cause injury,

replace battery as soon as the Battery Indicator green

LED dims.

Overload indicator (OL):

Red LED indicates that waveform or impulse is out of range

Instrument Compatibility

The 80i-110s is compatible with any Fluke ScopeMeter test tool,

Power Harmonics Analyzer, Oscilloscope, Multimeter, or other

voltage measurement device that has the following features:

• BNC input connector. A BNC-to-banana adapter (order

PM9081/001 from Fluke) can also be used with standard inputs

on a digital multimeter (DMM).

• Input accuracy of 2% or better to take full advantage of the

accuracy of the probe.

• Input impedance of greater than or equal to 1 MΩin parallel with

a maximum of 100 pF.

• A passband of more than four times the frequency of the

waveform to be measured.

Using The Current Probe

To use the Current Probe, follow these instructions:

1. Connect the 80i-110s Current Probe to the desired input on the

measuring instrument. When the ScopeMeter test tool or an

oscilloscope is used, it must have DC coupled input. When you

are using a digital multimeter, use the BNC-to- banana adapter

(PM9081/001) to connect the probe to the input.

2. On the Current Probe, select the least sensitive range (10

mV/A). Ensure that the green ON-indicator lights. See Figure 4

for selector switch and green On indicator locations.

3. On the Current Probe, rotate the ZERO thumbwheel to adjust

the probe reading to zero. See Figure 4 for the ZERO rotary

knob location.

4. Select the appropriate probe sensitivity on your ScopeMeter

test tool or oscilloscope.

5. Clamp the Current Probe around the conductor; be sure that

the arrow marked on the jaw of the Current Probe points

toward the correct orientation. (see Figure 3.)

ST770

6

S

G

Figure 3. Orientation of the Current Probe

6. Observe the current value or waveform on your display or the

current value readout on the multimeter.

7. On the ScopeMeter test tool, adjust the vertical range knob

and time division knob for the best display.

8. If the red OL-indicator lights, the Current Probe is in overload

mode.

9. At completion, be sure to set the range selection switch to OFF

again. A measuring setup using the Current Probe and a

ScopeMeter test tool is shown in Figure 4.

A

X

X

.

X

T7704

Figure 4. Measuring Setup

Measurement considerations

Observe the following guidelines for positioning the Current Probe

Jaws:

• Center the conductor inside the probe jaws.

• Make sure the probe is perpendicular to the conductor.

• Make sure that the arrow marked

on the jaw of the

Current Probe points toward the correct direction.

Observe the following guidelines when making measurements:

• If possible, avoid measurements close to other current-

carrying conductors.

• On the Current Probe, the 100 mV/A range offers the best

accuracy.

Maintenance

Before each use, assure continued safety by inspecting the probe.

Look for cracks or missing portions of the probe housing and output

cable insulating cover and for loose or weakened components. Pay

particular attention to the insulation surrounding the probe jaws. If a

probe fails this inspection, tape it shut to prevent unintended

operation. To check probe performance, complete the "Performance

Verification" procedure.

Warning

These servicing instructions are for use by qualified

personnel only. To avoid electric shock, do not

perform any servicing procedures unless you are

qualified to do so. Read the information titled "Safety

Information" at the beginning of this instruction sheet

before proceeding.

Repairs or servicing not covered in this Users Manual should be

performed only at a Fluke Service Center. A probe under warranty

will be promptly repaired or replaced (at Fluke's discretion) and

returned at no charge.

Cleaning and storage

Periodically wipe the case with a damp cloth and detergent; do not

use abrasives or solvents. Open the jaws and wipe the magnetic

pole pieces with a lightly oiled cloth. Do not allow rust or corrosion

to form on the magnetic core ends. If the probe is not used for

periods of longer than 60 days, the battery should be removed and

stored separately.

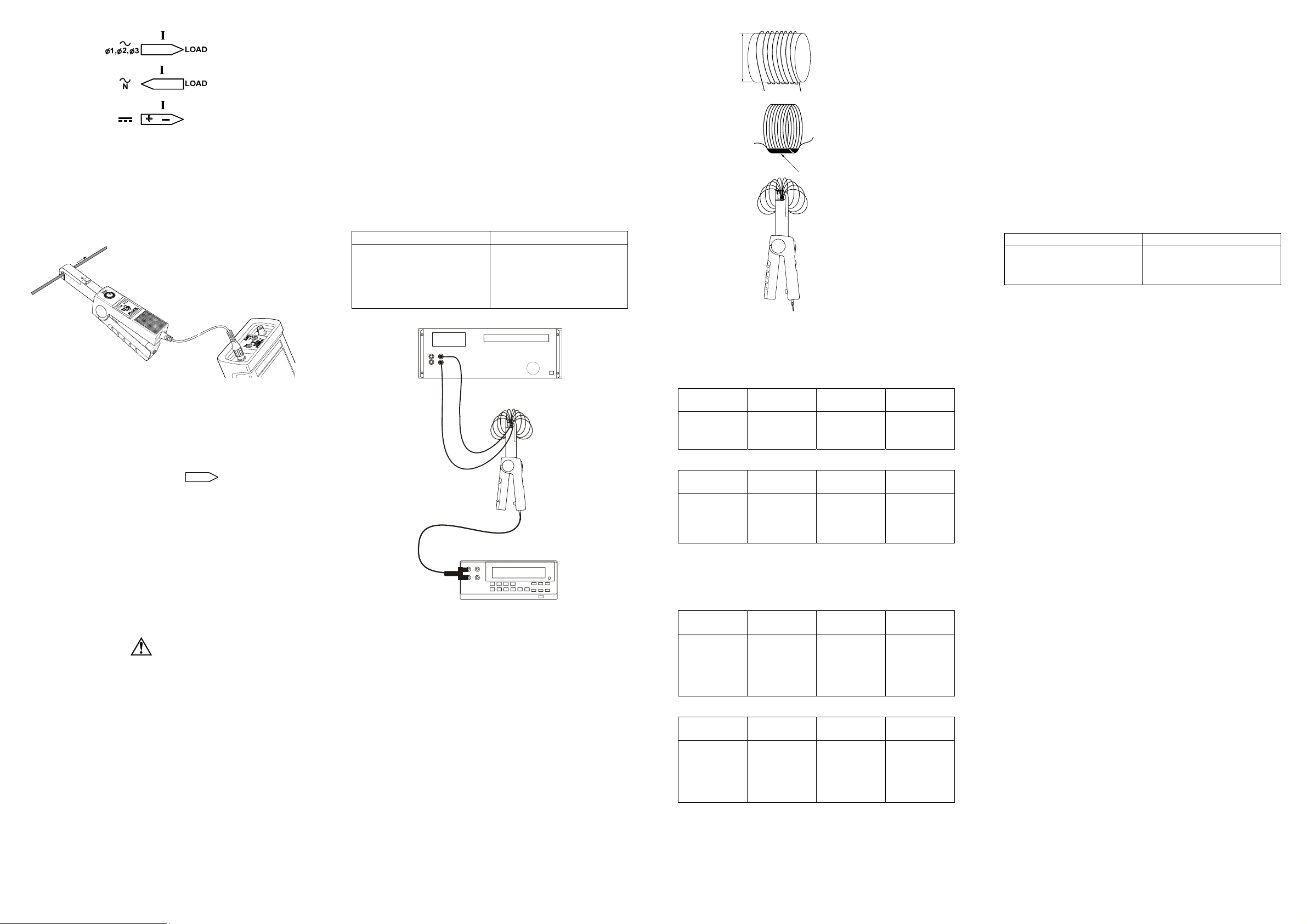

Performance verification

Verify probe accuracy with the test setup shown in Figure 5.

Required test equipment is defined in Table 1. Toroid coil

construction is illustrated in Figure 6.

Do the following to verify the probe accuracy:

1. Set up Connection.

2. Make the checks called for in Table 2 (100 mV/A).

3. Make the checks called for in Table 3 (10 mV/A).

REQUIRED RECOMMENDED MODEL

AC/DC Calibrator

Digital Multimeter (DMM)

Small insulated screwdriver

Banana-to-BNC Adapter

10-Turn Toroid Coil

Table 1. Required Test Equipment

Fluke Model 5520A

Fluke Model 45

Spectrol

Fluke Model PM9081/001

(see Figure 6.)

5520A

10.5CM

(4 INCH)

10 TURNS WOUND ON

CYLINDRICAL FORM USING

10-GAUGE MAGNET WIRE.

REMOVE FORM AND TAPE

COIL TOGETHER MAKING

SURE 10 WIRES ARE TAPED.

TAPE

FAN OUT COIL TO APPROX. 270°

WITH SPACING 5 CM (2 INCH) USIN

TAPE TO MAINTAIN COIL SHAPE.

ST7683E

Figure 6. Toroid Coil Construction

If Your Current Probe Does Not Work

If the 80i-110s does not perform properly, use the following steps to

help isolate the problem:

1. Test the battery: be sure that the green ON-indicator lights

when you select the 10 mV/A range or the 100 mV/A range.

2. Inspect the jaw mating surface for cleanliness. If any foreign

material is present, the jaws will not close properly and errors

will result.

3. Verify that the probe is zeroed properly. For zeroing be sure

that the ScopeMeter test tool or oscilloscope is DC-coupled.

4. Verify that the function selection on the ScopeMeter test tool or

oscilloscope is correct, i.e., the display vertical resolution is not

too low or too high.

Replacement Parts

To order replacement parts in the USA, call 1-800-526-4731. To

order outside the USA, contact the nearest Service Center. Use the

following part numbers:

Description Part Number

9 Volt Battery (IEC 6LR61)

Battery Cover

Instruction Sheet

Order Fluke Part PM9081/001 BNC-to-Banana Adapter to use the

Current Probe with a digital multimeter.

4822 138 10116

5322 447 92322

4822 872 30777

LIMITED WARRANTY & LIMITATION OF LIABILITY

Table 2. Performance Test Points

Current range 0 to 10A (100 mV/A)

DC Measurement:

5520A

SETTINGS

0.1A

0.5A

0.9A

DC AMPS

MEASURED

1A

5A

9A

LOW LIMIT

OUTPUT

92 mV

480 mV

868 mV

HIGH LIMIT

OUTPUT

108 mV

520 mV

932 mV

AC Measurement:

DMM

5520A

SETTINGS

0.1A, 60 Hz

0.3A, 400 Hz

0.5A, 2 kHz

0.6A, 4 kHz

RMS AMPS

MEASURED

1A

3A

5A

6A

LOW LIMIT

OUTPUT

92 mV

286 mV

465 mV

559 mV

HIGH LIMIT

OUTPUT

108 mV

314 mV

535 mV

641 mV

Table 3. Performance Test Points

Current Range 0 to 100A (10 mV/A)

CAL5520A_45

Figure 5. Performance Test and Calibration Setup

DC Measurement:

5520A

SETTINGS

1A

3A

5A

7A

9A

DC AMPS

MEASURED

10A

30A

50A

70A

90A

LOW LIMIT

OUTPUT

95.5 mV

287.5 mV

439.5 mV

615.5 mV

765.0 mV

HIGH LIMIT

OUTPUT

104.5 mV

312.5 mV

560.5 mV

784.5 mV

1035.0 mV

AC Measurement:

5520A

SETTINGS

1A, 5 kHz

2A, 1 kHz

3A, 400 Hz

5A, 400 Hz

7A, 60 Hz

RMS AMPS

MEASURED

10A

20A

30A

50A

70A

LOW LIMIT

OUTPUT

92.5 mV

185.5 mV

287.5 mV

439.5 mV

595.0 mV

HIGH LIMIT

OUTPUT

107.5 mV

214.5 mV

312.5 mV

560.5 mV

805.0 mV

This Fluke product will be free from defects in material and

workmanship for one year from the date of purchase. This warranty

does not cover fuses, disposable batteries or damage from

accident, neglect, misuse or abnormal conditions of operation or

handling. Resellers are not authorized to extend any other warranty

on Fluke’s behalf. To obtain service during the warranty period,

send your defective product to the nearest Fluke Authorized Service

Center with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER

WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE IS NOT

LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM ANY

CAUSE OR THEORY.

Since some states or countries do not allow the exclusion or

limitation of an implied warranty or of incidental or consequential

damages, this limitation of liability may not apply to you.

Fluke Corporation Fluke Industrial B.V.

P.O. Box 9090 P.O. Box 90

Everett WA 7600 AB Almelo

98206-9090, USA The Netherlands

SERVICE CENTERS

To locate an authorized service center,

visit us on the World Wide Web:

http://www.fluke.com

or call Fluke using any of the phone numbers listed below:

+1-888-993-5853 in U.S.A. and Canada

+31-40-267-5200 in Europe

+1-425-446-5500 from other countries

Loading...

Loading...