Page 1

This manual pertains to instruments with serial number 6820XXX

or higher.

8060A

True-rms Multimeter

®

Instruction Manual

PN 609146

May 1997 Rev.3, 11/00

© 1997,1998,1999, 2000 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY & LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship

under normal use and service. The warranty period is one year and begins on the date

of shipment. Parts, product repairs and services are warranted for 90 days. This

warranty extends only to the original buyer or end-user customer of a Fluke authorized

reseller, and does not apply to fuses, disposable batteries or to any product which, in

Fluke’s opinion, has been misused, altered, neglected or damaged by accident or

abnormal conditions of operation or handling. Fluke warrants that software will operate

substantially in accordance with its functional specifications for 90 days and that it has

been properly recorded on non-defective media. Fluke does not warrant that software

will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to

end-user customers only but have no authority to extend a greater or different warranty

on behalf of Fluke. Warranty support is available if product is purchased through a

Fluke authorized sales outlet or Buyer has paid the applicable international price. Fluke

reserves the right to invoice Buyer for importation costs of repair/replacement parts

when product purchased in one country is submitted for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price,

free of charge repair, or replacement of a defective product which is returned to a Fluke

authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center or

send the product, with a description of the difficulty, postage and insurance prepaid

(FOB Destination), to the nearest Fluke authorized service center. Fluke assumes no

risk for damage in transit. Following warranty repair, the product will be returned to

Buyer, transportation prepaid (FOB Destination). If Fluke determines that the failure

was caused by misuse, alteration, accident or abnormal condition of operation or

handling, Fluke will provide an estimate of repair costs and obtain authorization before

commencing the work. Following repair, the product will be returned to the Buyer

transportation prepaid and the Buyer will be billed for the repair and return

transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, WHETHER ARISING FROM BREACH OF WARRANTY

OR BASED ON CONTRACT, TORT, RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied

warranty, or exclusion or limitation of incidental or consequential damages, the

limitations and exclusions of this warranty may not apply to every buyer. If any

provision of this Warranty is held invalid or unenforceable by a court of competent

jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

5/94

Page 3

Safety Information

This meter has been designed and tested in accordance with IEC

Publication 348. To ensure that the meter is used safely, follow all safety

and operating instructions in this manual. If the meter is not used as

described in this manual, the safety features of the meter might be

impaired.

•

Do not use the meter if the meter or test leads look damaged, or if you

suspect that the meter is not operating properly.

•

Turn off power to the circuit under test before cutting, unsoldering, or

breaking the circuit. Small amounts of current can be dangerous.

•

Do not apply more than 500V rms between a terminal and earth ground.

•

Use caution when working above 60V dc or 30V ac rms. Such voltages

pose a shock hazard.

•

When using the probes, keep your fingers behind the finger guards on

the probes.

•

Disconnect the live test lead before disconnecting the common test lead.

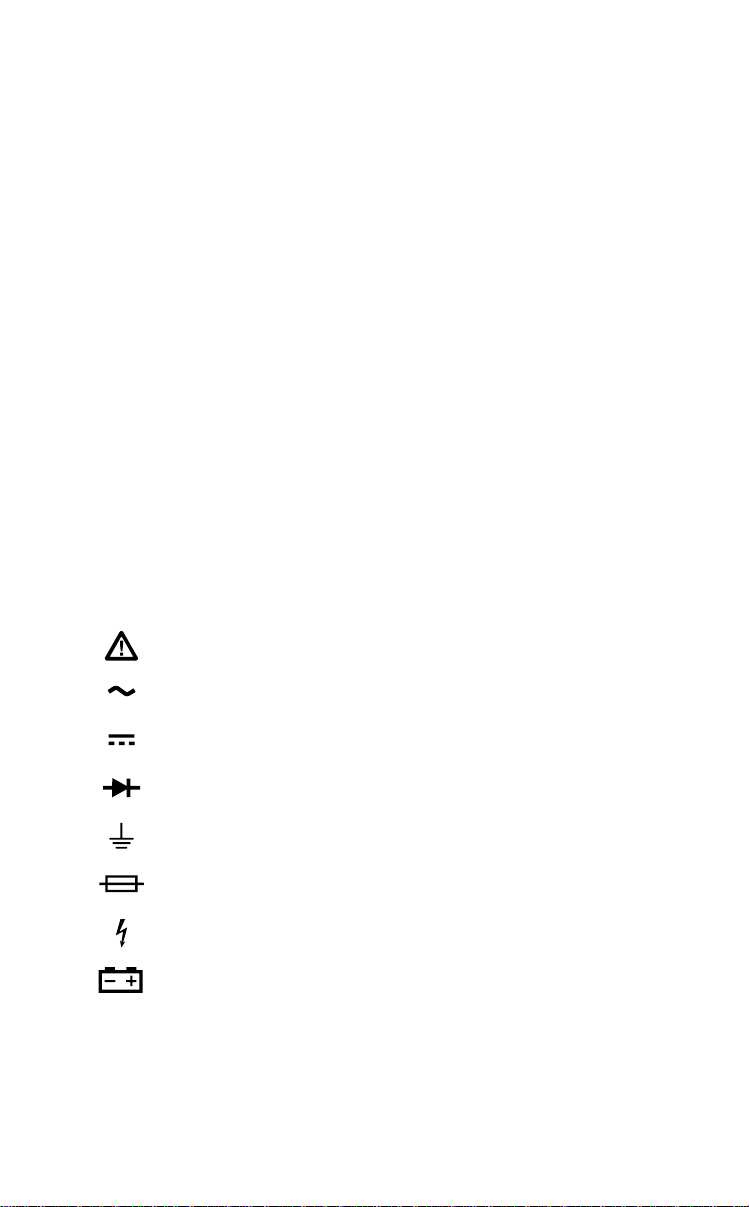

Symbols

The following international symbols are used in this manual:

Important Safety Information in Manual

AC

DC

Diode Test

Ground

Fuse

Indicates Terminals At Which Dangerous Voltages May Exist

Battery

Page 4

Page 5

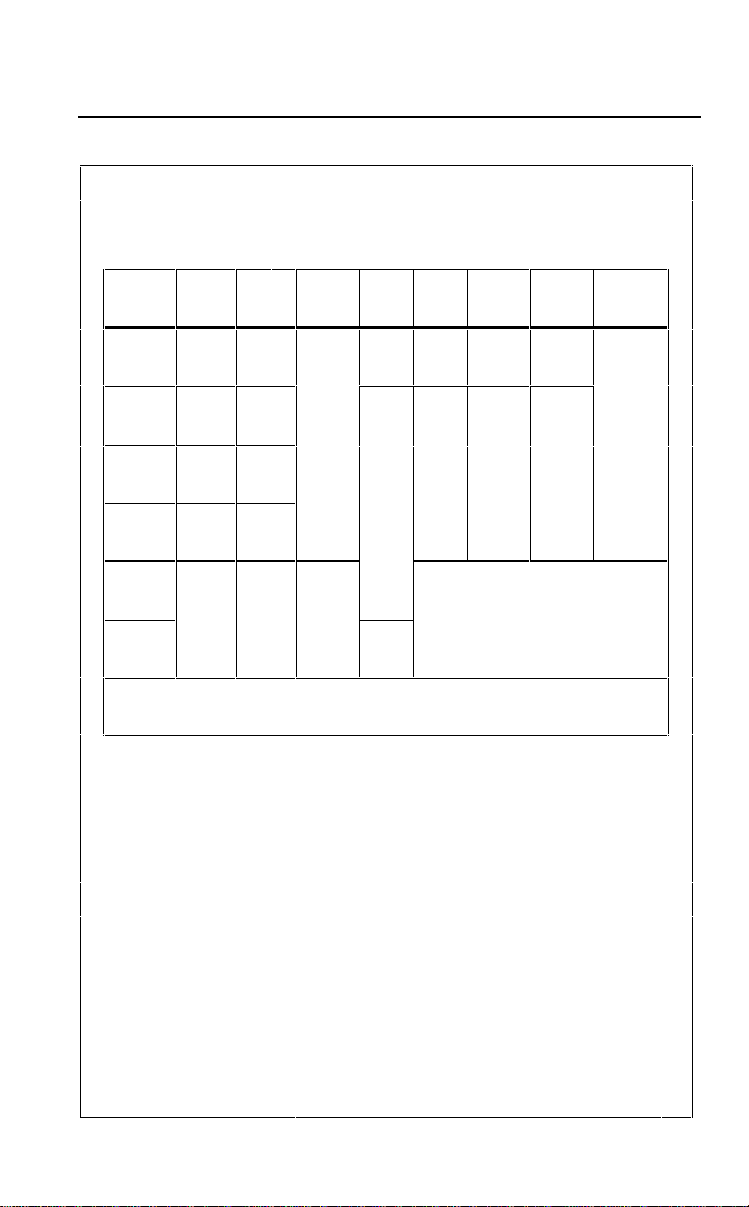

Table of Contents

Chapter Title Page

1 Introduction and Specifications............................................. 1-1

1-1. Introduction.............................................................................. 1-3

1-2. Items Furnished with Equipment............................................. 1-4

1-3. Specifications........................................................................... 1-4

2 Operating Instructions............................................................ 2-1

2-1. Introduction.............................................................................. 2-3

2-2. Unpacking Your Instrument .................................................... 2-3

2-3. Battery Installation or Replacement......................................... 2-3

2-4. Fuse Replacement.................................................................... 2-5

2-5. Physical Features ..................................................................... 2-6

2-6. Front Panel........................................................................... 2-6

2-7. Display................................................................................. 2-8

2-8. Signal Input Limits .................................................................. 2-9

2-9. Operation ................................................................................. 2-10

2-10. Power-On Self-Test ............................................................. 2-10

2-11. AC/DC Voltage (V)............................................................. 2-11

2-12. True rms Measurement.................................................... 2-12

2-13. AC-Coupled AC Measurements...................................... 2-12

2-14. Waveform Comparison and Conversion.......................... 2-13

2-15. High Impedance DC Voltage........................................... 2-14

2-16. AC/DC Current (A).............................................................. 2-16

2-17. Resistance (Ω)...................................................................... 2-18

2-18. Autoranging Megohms .................................................... 2-20

2-19. Autoranging Kilohms....................................................... 2-21

2-20. Conductance (S)................................................................... 2-22

2-21. Diode Test (

2-22. Relative (REL)..................................................................... 2-27

2-23. Frequency (Hz).................................................................... 2-29

2-24. Decibel (dB)......................................................................... 2-32

2-25. dBV...................................................................................... 2-33

2-26. Continuity (

2-27. Initial Check-Out Procedure .................................................... 2-36

) ................................................................... 2-25

)........................................................... 2-34

i

Page 6

8060A

Instruction Manual

3 Applications............................................................................. 3-1

3-1. Introduction .............................................................................. 3-3

3-2. Determining Amplifier Bandwidth........................................... 3-3

3-3. Using the 8060A as a Q-Meter................................................. 3-4

3-4. Measuring Amplifier Stage Gain with Relative dB.................. 3-5

3-5. General Audio Uses.................................................................. 3-6

3-6. Using the 8060A to Measure Extremely Low Currents ........... 3-7

3-7. Making dBm or dBW Measurements with Other Reference

Impedances............................................................................... 3-7

3-8. Changing AC dB Reference Impedances with a DC Source.... 3-9

4 Theory of Operation ................................................................ 4-1

4-1. Introduction .............................................................................. 4-3

4-2. Functional Description ............................................................. 4-3

4-3. Microcomputer..................................................................... 4-4

4-4. Measurement Acquisition Chip (MAC) ............................... 4-5

4-5. A/D Conversion Cycle ......................................................... 4-6

4-6. Voltage Measurement........................................................... 4-8

4-7. Current Measurement........................................................... 4-10

4-8. Resistance Measurement ...................................................... 4-10

4-9. Conductance Measurement................................................... 4-11

4-10. Continuity Measurement ...................................................... 4-12

4-11. Frequency Measurement ...................................................... 4-13

5 Maintenance............................................................................. 5-1

5-1. Introduction .............................................................................. 5-3

5-2. Service Information.................................................................. 5-3

5-3. General Information ................................................................. 5-4

5-4. Handling Precautions for Using Static Sensitive Devices.... 5-5

5-5. Disassembly and Reassembly............................................... 5-5

5-6. Calibration and Backup Fuse Access ............................... 5-6

5-7. Main PCB Access............................................................. 5-8

5-8. LCD and Microcomputer PCB Disassembly and

5-9. Backup Fuse Replacement.................................................... 5-12

5-10. Cleaning................................................................................ 5-12

5-11. Performance Tests .................................................................... 5-13

5-12. Initial Procedure ................................................................... 5-13

5-13. Microcomputer and Display Test......................................... 5-13

5-14. Voltage Test.......................................................................... 5-13

5-15. Resistance Test..................................................................... 5-15

5-16. Continuity Test..................................................................... 5-16

5-17. Conductance Test ................................................................. 5-16

5-18. Current Test.......................................................................... 5-17

5-19. Diode Test ............................................................................ 5-18

5-20. Frequency Test ..................................................................... 5-18

5-21. Calibration Adjustment............................................................. 5-19

5-22. Troubleshooting........................................................................ 5-21

Assembly.......................................................................... 5-9

ii

Page 7

Contents

5-23. Self-Tests............................................................................. 5-21

5-24. Ratio Self-Test................................................................. 5-21

5-25. Switch Decoding Self-Test.............................................. 5-22

5-26. Troubleshooting Guide ........................................................ 5-23

6 List of Replaceable Parts........................................................ 6-1

6-1. Introduction.............................................................................. 6-3

6-2. How to Obtain Parts................................................................. 6-3

6-3. Manual Status Information ...................................................... 6-4

6-4. Newer Instruments................................................................... 6-4

6-5. Service Centers........................................................................ 6-4

7 Schematic Diagrams ............................................................... 7-1

(continued)

iii

Page 8

8060A

Instruction Manual

iv

Page 9

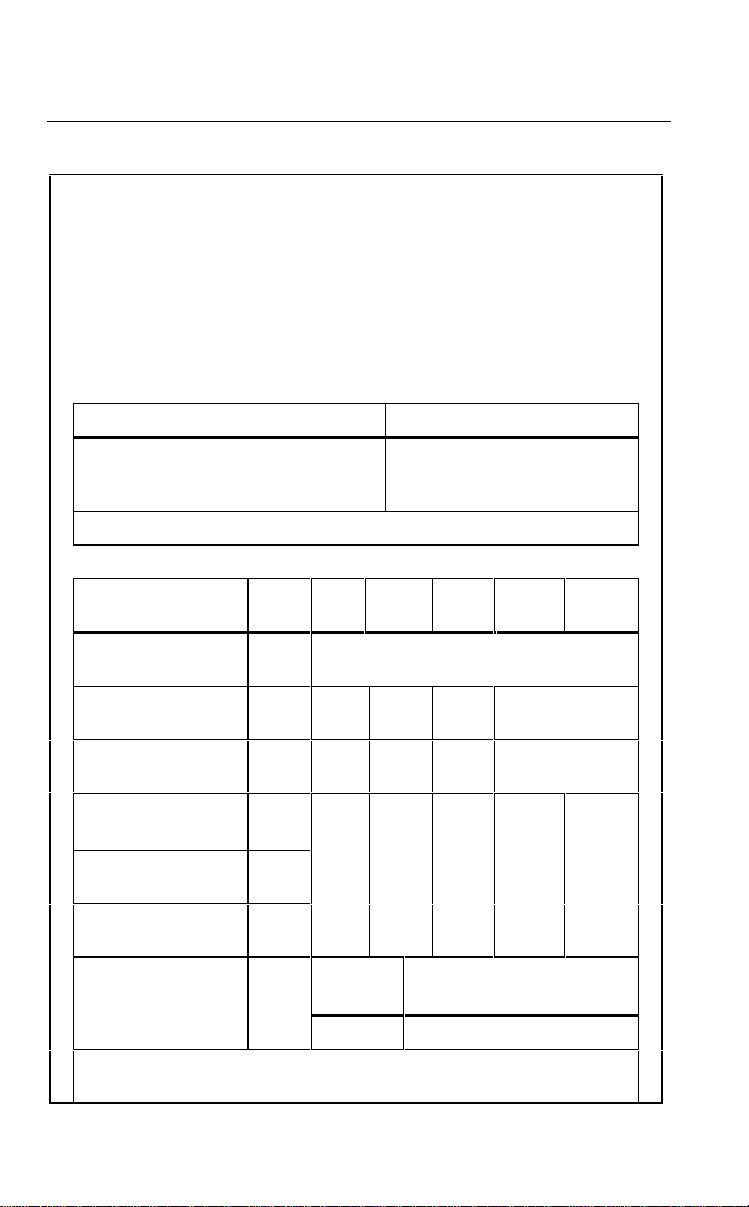

List of Tables

Table Title Page

1-1. 8060A Specifications............................................................... 1-5

2-1. Controls, Indicators and Connectors........................................ 2-7

2-2. Input Overload Limits.............................................................. 2-10

2-3. Resistance Function Autoranges and Resolution..................... 2-20

2-4. Frequency Function Autoranges and Resolution..................... 2-30

2-5. Sensitivity for the Frequency Function.................................... 2-31

2-6. Maximum Input Voltages for the Frequency Function............ 2-31

3-1. Equivalent Voltage Levels for Modifying the Reference

Impedance................................................................................ 3-8

4-1. Voltage Input Divider.............................................................. 4-10

5-1. Required Test Equipment ........................................................ 5-4

5-2. Voltage Test............................................................................. 5-14

5-3. Resistance Test ........................................................................ 5-16

5-4. Current Test ............................................................................. 5-18

5-5. Frequency Test......................................................................... 5-18

5-6. Switch Decoding Self-Test...................................................... 5-23

5-7. Troubleshooting Guide............................................................ 5-24

5-8. Troubleshooting the Resistance Function: Voltage Sources

for Ranges................................................................................ 5-29

5-9. U3 (MAC) Pin Descriptions .................................................... 5-29

6-1. 8060A Final Assembly ............................................................ 6-5

6-2. A1 Main PCB Assembly.......................................................... 6-9

6-3. A3 Rms PCB Assembly........................................................... 6-13

v

Page 10

8060A

Instruction Manual

vi

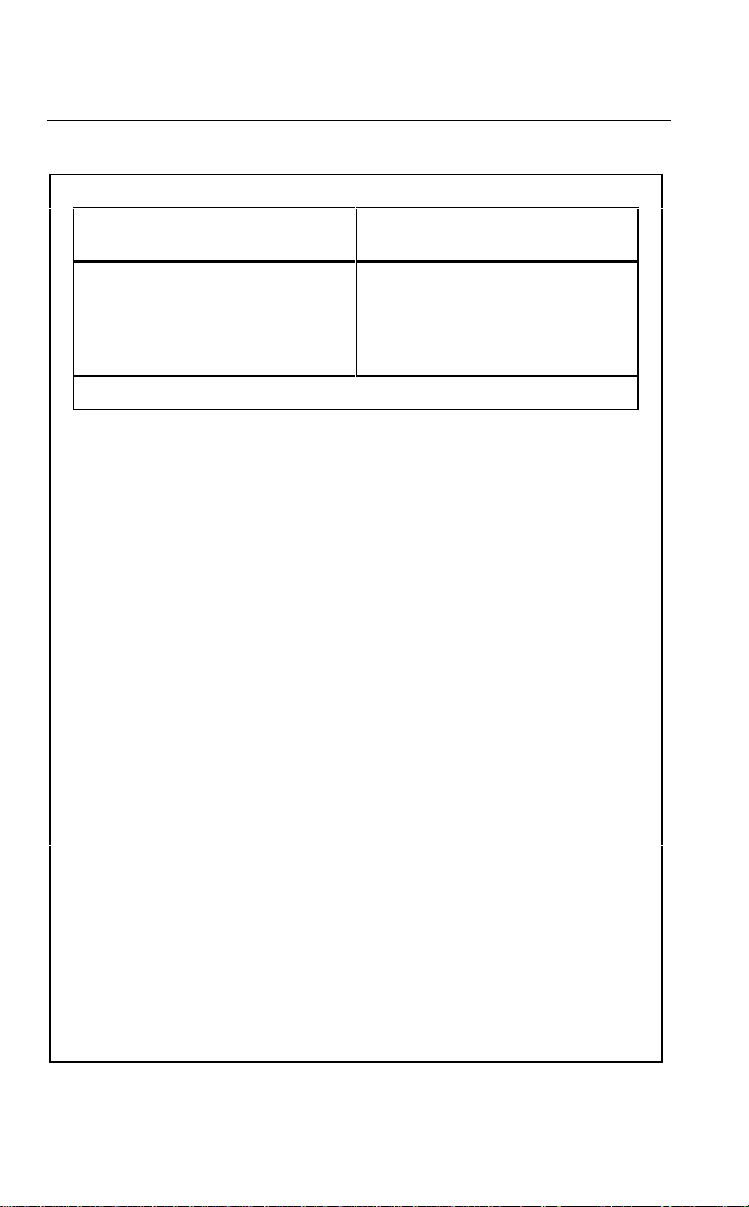

Page 11

List of Figures

Figure Title Page

2-1. Removal of Battery Compartment Cover................................ 2-4

2-2. Battery Removal and Fuses ..................................................... 2-4

2-3. Controls, Indicators and Connectors........................................ 2-6

2-4. 8060A Display......................................................................... 2-8

2-5. Overrange Indicator................................................................. 2-9

2-6. Voltage Operation.................................................................... 2-11

2-7. AC and DC Wafeform Components........................................ 2-13

2-8. Multiplication Factors for Converting Waveforms.................. 2-14

2-10. Current Operation .................................................................... 2-17

2-11. Calculating Burden Voltage Error ........................................... 2-18

2-12. Resistance Operation ............................................................... 2-19

2-13. Selection of Autoranging Kilohms .......................................... 2-22

2-14. Conductance Operation............................................................ 2-23

2-15. Conductance/Resistance Conversion....................................... 2-24

2-16. Diode Test................................................................................ 2-25

2-17. Relative (REL) Operation........................................................ 2-26

2-18. Frequency (Hz) Operation ....................................................... 2-29

2-19. Decibel (dB) Operation............................................................ 2-33

2-20. Continuity (

3-1. Measuring Amplifier Bandwidth............................................. 3-4

3-2. Measuring Q with the 8060A................................................... 3-6

3-3. Measuring Stage Gain with Relative dB.................................. 3-6

4-1. 8060A Block Diagram............................................................. 4-4

4-2. Analog Portion of the A/D Converter...................................... 4-7

4-3. A/D Measurement Cycle.......................................................... 4-7

4-4. Voltage Measurement.............................................................. 4-9

4-5. Current Measurement............................................................... 4-11

4-6. Resistance/Conductance/Continuity Measurement.................. 4-12

4-7. Frequency Measurement.......................................................... 4-13

5-1. Calibration and Backup Fuse (F2) Access) ............................. 5-7

5-2. Assembling/Disassembling the Microcomputer PCB and

LCD ......................................................................................... 5-10

5-3. Disassembling the LCD........................................................... 5-11

5-4. General Equipment Connection............................................... 5-15

5-5. Equipment Connection for Current Test.................................. 5-17

6-1. 8060A Final Assembly ............................................................ 6-7

) Operation ................................................... 2-35

vii

Page 12

8060A

Instruction Manual

6-2. A1 Main PCB Assembly .......................................................... 6-12

6-3. A3 Rms PCB Assembly ........................................................... 6-14

7-1. A1 Main PCB Component Locations....................................... 7-3

7-2. Test Point Locations................................................................. 7-4

7-3. A/D Measurement Cycle.......................................................... 7-5

7-4. Switch Detail............................................................................ 7-6

7-5. A1 Main PCB Schematic Diagram........................................... 7-7

7-6. A3 rms PCB Schematic Diagram............................................. 7-8

viii

Page 13

Chapter 1

Introduction and Specifications

Contents Page

1-1. Introduction ...................................................................... 1-3

1-2. Items Furnished with Equipment...................................... 1-4

1-3. Specifications ................................................................... 1-4

1-1

Page 14

8060A

Instruction Manual

1-2

Page 15

Introduction and Specifications

Introduction

1

1-1. Introduction

Your Fluke Model 8060A is a handheld, microcomputer-based 4½ digit

multimeter that is ideally suited for use in the field, laboratory, shop, or

home. The 8060A has all the features that have become accepted standards

for quality handheld multimeters, as well as some new features that have not

been offered before in a handheld multimeter. New features include the

following:

•

True rms measurements for ac signals up to 100 kHz.

•

Frequency measurements up to 200 kHz.

•

Voltage measurements in dBm referenced to 600Ω or in dB relative to

an operator-selected reference voltage.

•

Resistance measurements up to 300 MΩ.

•

Ability to store any input signal as an offset or relative reference value.

Other features include:

• Functions:

All standard DMM measurement functions, such as ac and dc volts and

ac and dc current, as well as resistance, conductance, continuity, and

diode test.

• Ranges:

Leading zero suppression.

Automatic polarity.

Overrange indication.

Protection from overloads and transients up to 1500V peak.

Dual-slope integration a/d conversion to ensure noise-free

measurements.

Autoranging MΩ resistance range (to 300 MΩ), as well as four fixed

resistance ranges from 200Ω to 200 kΩ.

• Operator Convenience:

4½ digit Liquid Crystal Display.

Software-controlled self-test routines for quick verification of internal

circuitry and operation.

1-3

Page 16

8060A

Instruction Manual

•

Power:

170 hours of continuous operation can be expected from a 9V alkaline

battery (NEDA 1604).

Low battery voltage is automatically detected and displayed. The low

battery indication, BT, appears on the display when about 20% of the

battery life remains.

A full line of accessories is available to enhance the capabilities of the

8060A.

1-2. Items Furnished with Equipment

Items shipped with your True rms Multimeter are as follows:

•

Battery

• DMM Accessory List

• Instruction Manual

• Operator Guide Card

• Registration Form

• Statement of Calibration

• Test Leads

1-3. Specifications

The specifications for the 8060A are listed in Table 1-1.

1-4

Page 17

Introduction and Specifications

Specifications

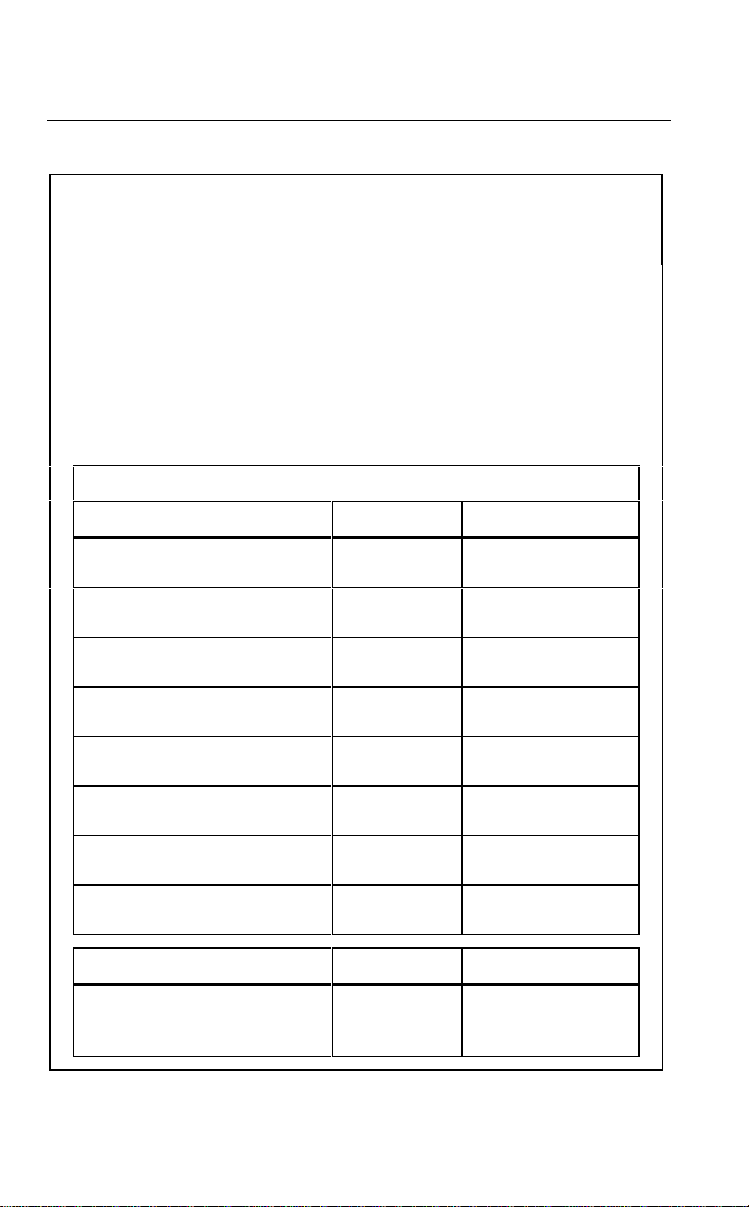

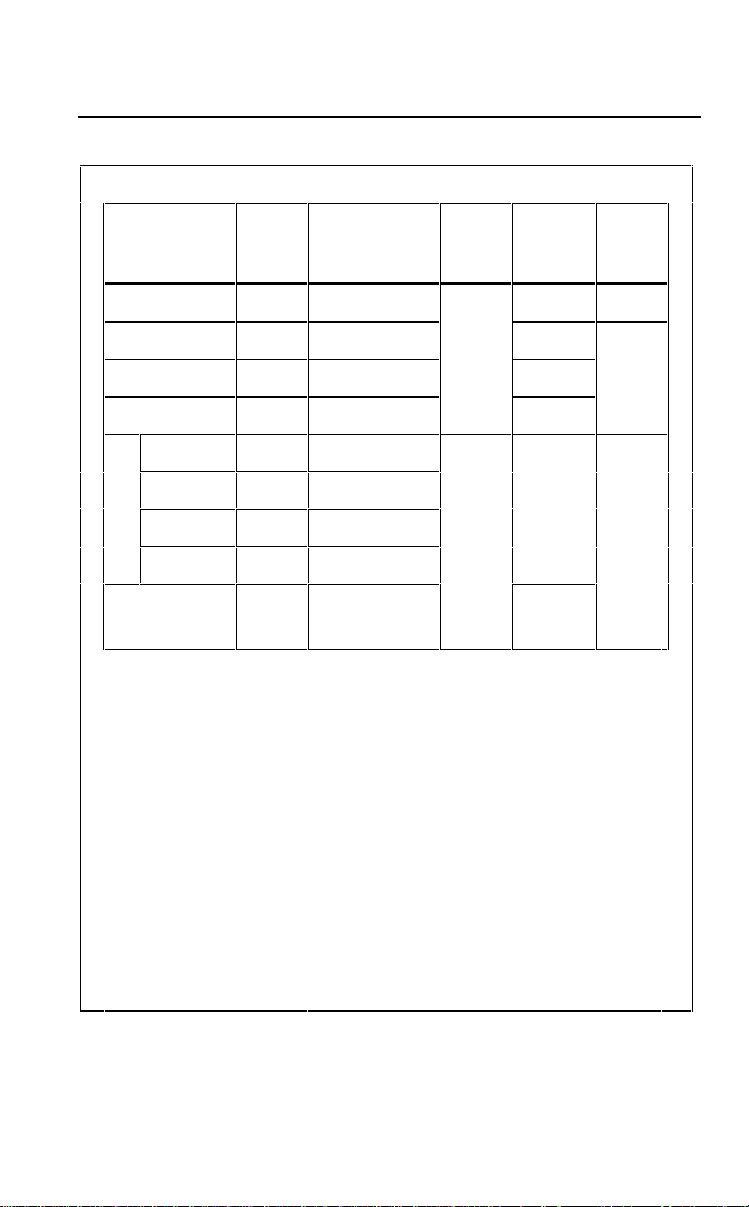

Table 1-1. 8060A Specifications

Electrical

The following specifications are based on a one-year calibration cycle, an

operating temperature of 18 to 28°C (64 to 82°F) and a relative humidity

not exceeding 80%.

DC Voltage

1

Range Resolution

200 mV

2V

20V

200V

1000V

Response Time............................. 1 second maximum, to rated

Input Impedance ........................... 10 MΩ nominal

Normal Mode Noise Rejection ...... >60 dB at 50 Hz or 60 Hz

Common Mode Noise Rejection ... >120 dB at dc, >90 dB at 50 Hz

Overload Protection ...................... 1000V dc or peak ac

DC Voltage, High Impedance Mode

All specifications are the same as for the dc voltage mode except

the following (only 200 mV and 2V ranges are available):

Range Resolutions

.01 mV

.1 mV

1 mV

10 mV

100 mV

±(% of reading + no. of digits)

accuracy within selected range.

and 60 Hz (1 kΩ imbalance)

continuous, except 20 seconds

maximum on 200 mV and 2V

ranges above 300V dc or rms.

±(% of reading + no. of digits)

Accuracy

0.04% + 2

0.05% + 2

Accuracy

200 mV

2V

Input Impedance ........................... >1,000 MΩ, typically 10,000 MΩ

Overload Protection ...................... 300V dc or rms continuous, 20

.01 mV

.1 mV

0.05% + 2

seconds maximum 300V to

1000V dc or peak ac.

1-5

Page 18

8060A

Instruction Manual

Table 1-1. 8060A Specifications (cont)

DC Voltage, dB Mode

Measurements are made in dBm referenced to 600Ω or relative dB. All

specifications are the same as for dc voltage except the following:

Dynamic Range............................. With full .01 dB resolution, 99.79

dB. Total specified dynamic

range is 136.22 dB (160 µV to

1000V).

Resolution and Accuracy .............. Depends on linear dc count

(count refers to the display in dc

volts independent of the decimal

points - see table below).

Accuracy

dBm Ref. 600

-74 to -56

(160 µV to 1.27 mV)

-55.6 to -37.6

(1.28 mV to 10.23 mV)

-37.58 to -31.77

(10.24 mV to 19.99 mV)

-31.76 to -11.76

(20 mV to 199.99 mV)

-11.76 to 8.24

(.2V to 1.9999V)

8.24 to 28.24

(2.000V to 19.999V)

28.24 to 48.24

(20.00V to 199.99V)

48.24 to 62.22

(200.0V to 1000V)

Linear Counts Resolution Accuracy

19.999 to 1024

1023 to 128

127 to 16

Ω

Range Tolerance

200 mV

200 mV

200 mV

200 mV

2V

20V

200V

1000V

.01 dB

.1 dB

1 dB

±1 dB

±.2 dB

±.04 dB

±.04 dB

±.04 dB

±.04 dB

±.04 dB

±.04 dB

±.04 dB

±.2 dB

±1 dB

1-6

Page 19

Introduction and Specifications

V

Specifications

Table 1-1. 8060A Specifications (cont)

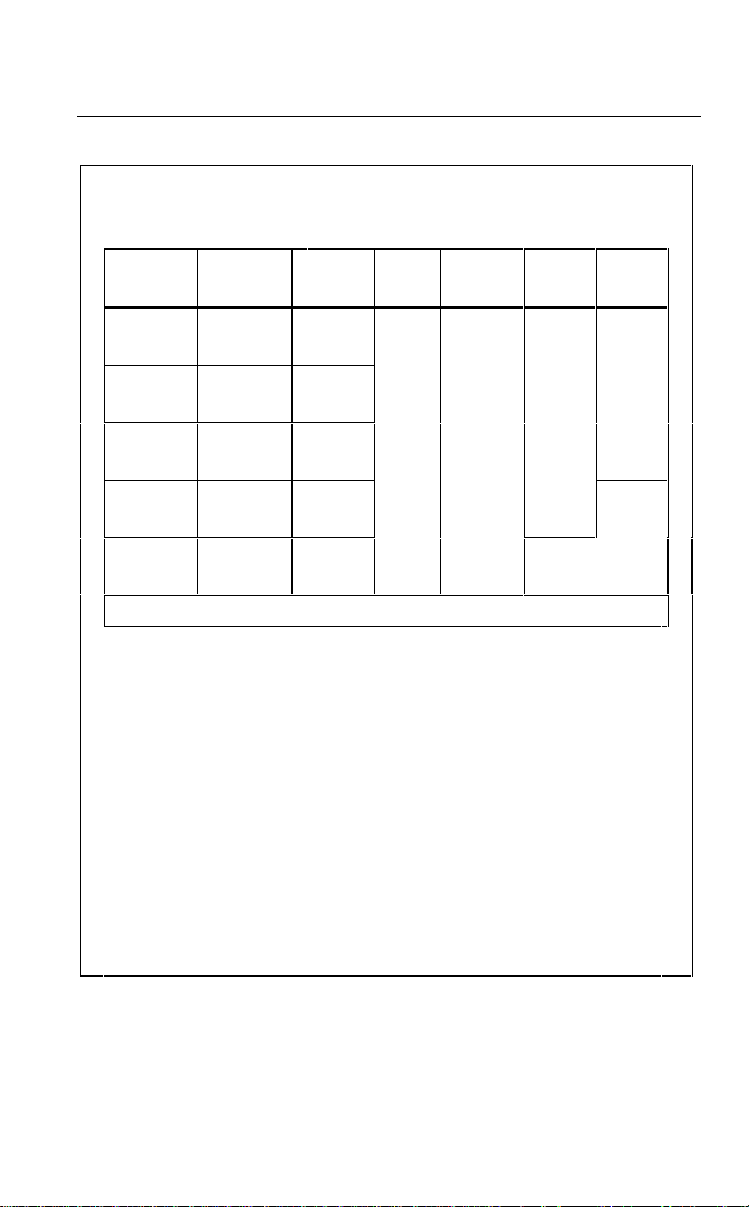

AC Voltage (True rms, AC-Coupled)

Ranges.................. 200 mV, 2V, 20V, 200V, 750V

Accuracy *............. ±(% of reading + no. of digits). See table below:

1

Input

Voltage

20.0 -

199.99 m

.2000 -

1.9999V

2.000 -

19.999V

20.00 -

199.99V

75.0 -

4.99.9V

500.0 -

750.0V

* Not specified for input signals <10% of range.

** For input voltage between 10% and 15% of range, add an additional 140 counts.

Reso-

Range

lution

.01 mV 200 mV

.1 mV 2V

1 mV 20V

10 mV 200V

100 mV 750V

20 Hz -

45 Hz -

1 kHz -

10 kHz -

45 Hz

1 kHz

10 kHz

30 kHz

0.2%

0.2%

0.5%

+ 12

+ 20

+ 401%+ 100

1% + 10

0.5%

0.5%

1% +40 2% +100

+12

+20

Not Not Specified

Specified

1%

+12

30 kHz -

50 kHz

50 kHz 100 kHz

3% +200**

Input Impedance......... 10 MΩ shunted by <100 pF

Common Mode Noise

Rejection..................... >60 dB at 50 Hz and 60 Hz (1 kΩ

imbalance)

Crest Factor Range .... 1:1 to 3:1

Response Time........... Five seconds maximum to rated accuracy

within selected range, 12 seconds to rated

accuracy from an overload.

Overload Protection.... 750V rms or 1000V peak continuous

except 20 seconds maximum on the 200

mV range above 300V rms or 300V dc.

Input not to exceed a volt-hertz product of

7

(for example, 200V at 50 kHz).

10

1-7

Page 20

8060A

0

Instruction Manual

Table 1-1. 8060A Specifications (cont)

AC Voltage, dB Mode (True rms, AC-Coupled)

Measurements are made in dBm referenced to 600Ω or relative dB. All

specifications are the same as for ac voltage except the following:

Dynamic Range... With full .01 dB resolution, 97.30 dBm. Total specified

Resolution ........... Depends on number of linear ac counts (count refers

dynamic range is 109.72 dBm (2.45 mV to 750.0V ac

rms).

to the actual number on the display independent of

the decimal point. See table below).

Linear Counts* Resolution

19.999 to 1024

1023 to 128

127 to 16

*Not specified below 245 counts.

Accuracy................. See table below:

dBm Ref. 600Ω Range 20 Hz -

-50.0 to -31.76

(2.45 mV to 20.00 mV)

-31.76 to -29.83

(20.00 mV to 25.00 mV)

-29.83 to -11.76

(25.00 mV to 199.99 mV)

-11.76 to 8.24

(.2000V to 1.9999V)

8.24 to 28.24

(2.000V to 19.999V)

28.24 to 48.24

(20.00V to 199.99V)

48.24 to 59.72 750V

(200.0V to 750.0V)

*Specification applies above 8000 linear counts.

**Not specified for input signals <10% of range.

45 Hz**

10 kHz**

200 mV Not Specified

200 mV 0.20 dB 0.50 dB 1.00 dB 2.70 dB

200 mV 0.10 dB 0.15 dB 0.30 dB 0.50 dB

2V

.10 dB*0.10 dB* 0.15 dB* 0.30 dB* 0.50 dB*

20V

200V 0.15 dB 0.30 dB 0.30 dB 0.65 dB 1.83 dB

20 Hz -

1 kHz**

0.5 dB Not Specified

45 Hz -

.01 dB

.1 dB

1 dB

10 kHz 30 kHz**

30 kHz 50 kHz**

1 kHz - 100 kHz**

50 kHz -

100 kHz**

1-8

Page 21

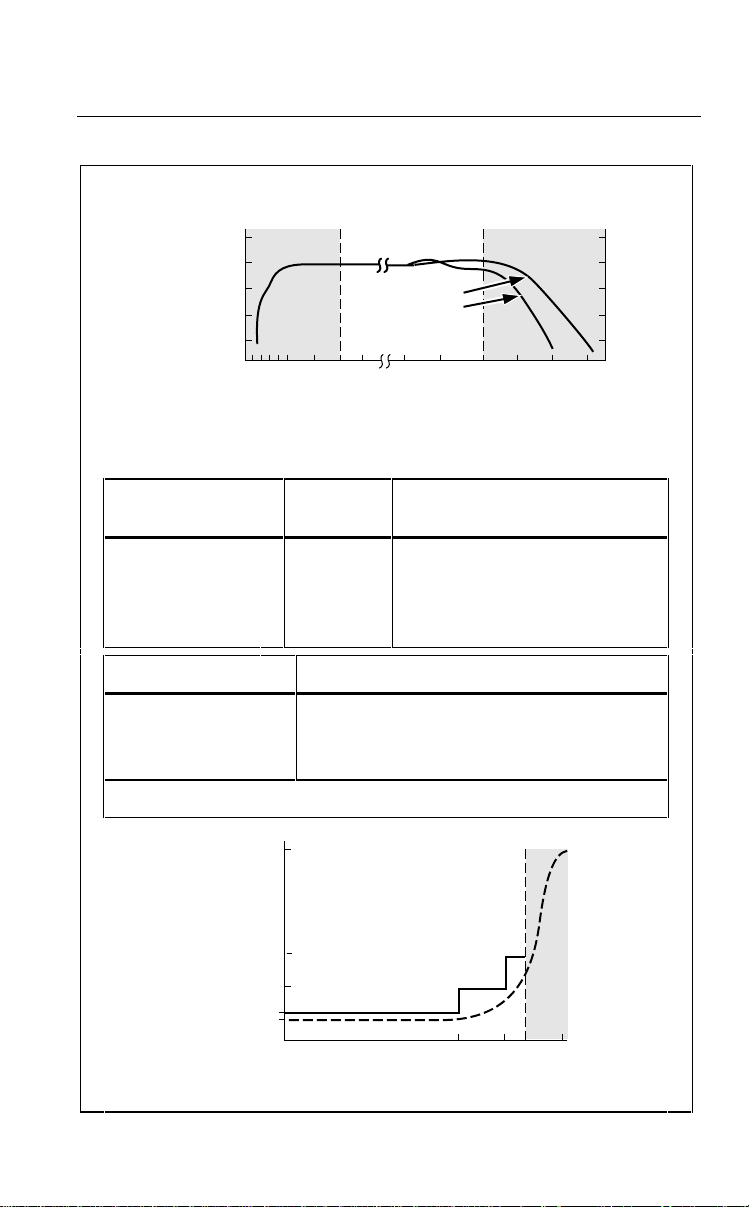

Table 1-1. 8060A Specifications (cont)

AC Voltage, dB Mode (cont.)

Introduction and Specifications

Specifications

1

+1

dB

(relative

to 200 Hz

reading)

0

-1

-2

-3

1Hz5Hz10Hz20Hz100Hz10

Not Specified

Typical Response in 200 mV Range

100 mV

kHz

25 mV

50

kHz

100

kHz

200

kHz

Frequency

Frequency Range

(Fully Autoranging)

200 Hz

2000 Hz

20 Hz

200 Hz

Resolution

.01 Hz

.1 Hz

1 Hz

10 Hz

(% of reading + no. of digits)

±

Accuracy

.05% + 1

Input Signal Sensitivity (based on sine wave V rms)

12 Hz to 20 kHz

20 kHz to 100 kHz

100 kHz to 200 kHz

20 mV or 10% of voltage range*

50 mV or 25% of voltage range*

150 mV or 75% of voltage range*

*Whichever value is greater.

300

400

kHz

kHz

Frequency

+1

0

-1

Not Specified

-2

-3

5V

150 mV

Voltage

50 mV

(sine wave rms)

20 mV

16 mV

Spec. Limit

Typical

Frequency (kHz)

Frequency Input Sensitivity (200 mV range)

Not Specified

70020010020

"

1-9

Page 22

8060A

Instruction Manual

Frequency (cont.)

AC Voltage Range

Table 1-1. 8060A Specifications (cont)

Maximum Useable AC

Voltage*

200 MV

2V

20V

200V

750V

±5V peak

±50V peak

±500V peak

±1000V peak

±1000V peak

*Signal not to exceed a volt-hertz product of 1 x 107.

Input Characteristics ..... Ac-coupled, 10 MΩ shunted by <100 pF

Overload Protection ...... 759V rms or 1000V peak continuous

except 20 seconds maximum on the 200

mV range above 300V rms or 300V dc.

Input not to exceed a volt-hertz product of

7

10

(for example, 200V at 50 kHz).

Extended Frequency

Selection................... Enabled by holding down Hz button at

power on.

Range....................... 12 Hz to 700 kHz, typically.

Resolution ................ 100 Hz above 200 kHz.

Accuracy................... ±(0.5% of reading + 2 digits)

Sensitivity

(sine wave V rms)..... Typically 100 mV at 200 kHz increasing to

4.5V at 700 kHz in the 200 mV range. Will

measure a TTL signal (50% duty cycle) to

420 kHz, typically.

Resistance

Ranges.......................... 200Ω, 2 kΩ, 20 kΩ, 200 kΩ, autoranging

MΩ. The MΩ range extends from .0001

mΩ to 300 MΩ in three autoranged

ranges. Upscale range changes are made

at 2 MΩ and 20 MΩ. Downscale range

changes are made at 19 MΩ and 1.9 MΩ.

Accuracy ....................... ±(% of reading + no. of digits). See table

below.

1-10

Page 23

Table 1-1. 8060A Specifications (cont)

Resistance (cont.)

Introduction and Specifications

Specifications

1

Range

200Ω 0.01Ω (0.07%+2+.02Ω) <1.1 mA <4.8V

2 kΩ 0.1Ω (0.07%+2)

20 kΩ 1Ω (0.07%+2) <15 µA <1.5V

200 kΩ 10Ω (0.07%+2) <1.5 µA

0-1.9999 MΩ 100Ω (0.15%+2)

2-19.99 M

MΩ

20-99.9 MΩ 100 kΩ (1%+3) <2.5V <2.5V

100-300 MΩ 1 M Ω (2%+3)

Autoranging

k

Ω

Resolution

Ω 10 kΩ (0.2%+3) 2.5 µA

0.1Ω

to 1 kΩ

Accuracy

(0.2%+5) <1.0 mA

Full-

scale

Voltage

<250 mV

Max

Current

<150 µA

Response Time.............. Two seconds maximum to rated accuracy

for all ranges except MΩ. For MΩ, 8

seconds maximum.

Overload Protection....... 300V dc or rms ac for all ranges

Conductance

Open

Circuit

Voltage

Range............................ 2000 nS (equivalent to a resistance

range from 500 kΩ to 10,000 MΩ)

Resolution...................... 0.1 nS

Accuracy........................ ±(0.5% of reading + 20 digits)

Open Circuit Voltage...... <1.5V

Overload Protection....... 300V dc or rms ac

1-11

Page 24

8060A

Instruction Manual

Table 1-1. 8060A Specifications (cont)

Continuity

Ranges.......................... All resistance ranges

Threshold ...................... Nominally 10% of range (for example,

Display Indication.......... Horizontal bar across the top of the

Response Time............. 50 µs maximum (10 µs typical)

Overload Protection ...... 300V dc or rms ac

Diode Test

Range............................ 2V

Test Current.................. 1 mA (typical)

Accuracy ....................... ±(0.05% of reading + 2 digits)

Response Time............. 2 seconds maximum

Overload Protection ...... 300V dc or rms ac

DC Current

Range Resolution

20Ω in the 200Ω range) for 200Ω, 2 kΩ,

20 kΩ, 200 kΩ ranges. Nominally 20 kΩ

in MΩ range.

display and/or 2.667 kHz tone. Indication

is present for a minimum of 200 ms.

(Specification applies for voltage

measurement)

Accuracy

±(% of reading + no. of

digits)

Burden

Voltage

200 µA

2 mA

20 mA

200 mA

2000 mA

Overload Protection ......... 2A/250V fuse (operator replaceable) in

.01 µA

.1 µA

1 µA

10 µA

100 µA

0.2% + 2

0.3% + 2

series with 3A/600V fuse (service

personnel replaceable).

1-12

.3V typical

.3V typical

.3V typical

.3V typical

.9V typical

Page 25

Introduction and Specifications

Table 1-1. 8060A Specifications (cont)

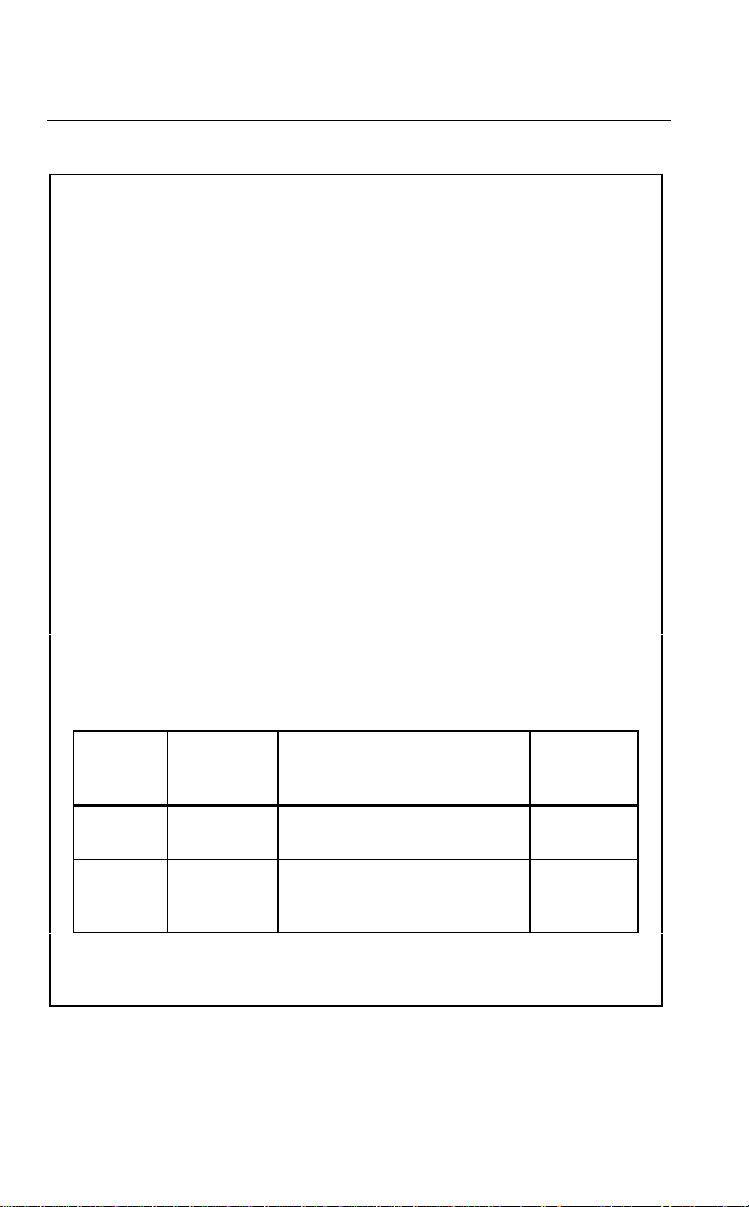

AC Current (True rms Responding, AC-Coupled

Accuracy *.......................

Input

Current

Resolution Range

±(% of reading + no. of digits). See table

below:

20 Hz -

45 Hz

45 Hz -

3 kHz

Specifications

3 kHz 10 kHz

10 kHz -

30 kHz

1

20.00 to

199.99 µA

.2000 to

1.9999 mA

2.000 to

19.999 mA

20.00 to

199.99 mA

200 to

1999.9 mA

*Not specified for input < 10% of scale

0.01 µA 200 µA

0.1 µA 2 mA 2% + 40

1 µA 20 mA

10 µA 200 mA

100 µA 2000 mA

1% + 10 0.75% + 10 2% + 20

Not Specified

Burden Voltage ............. 0.3V rms typical except 2000 mA range,

0.9V rms typical

Overload Protection ...... 2A/250V fuse (operator replaceable) in

series with 3A/600V fuse (service

personnel replaceable).

Relative

Selection ....................... When the REL button is pushed, the

input applied at that time is stored as a

zero reference point. Subsequent

readings indicate deviations (±) from the

reference point.

Accuracy ....................... Error does not exceed the sum of the

errors of the reference reading and the

subsequent reading.

1-13

Page 26

8060A

Instruction Manual

Table 1-1. 8060A Specifications (cont)

General

Maximum Common

Mode Voltage............... 500V dc or ac rms

Display Update Rate ... 2.5 readings/second for all functions

except frequency and dB. For frequency,

1 reading/second. For dB, 1.4

readings/second.

Electromagnetic

Compatibility ..................

Display ............................ 4½ digit duplex LCD (19,999 counts),

Display Annunciators.... BT (low battery indicator), Hz or kHz

In an RF field of 1 V/m on all ranges

and functions: Total Accuracy =

Specified Accuracy + 2.3% of range.

Performance above 1 V/m is not

specified.

leading zero suppression, autopolarity.

(frequency unit), dB (dB function

enabled), REL (relative function

enabled).

function enabled), and — (bar indicates

continuity detected).

and (continuity

A/D Converter................. Dual-slope converter

Power .............................. Single standard 9V battery (NEDA

1604)

Battery Life ..................... Typically 170 hours with an alkaline

battery. BT appears on display when

approximately 20% of battery life

remains.

Size.................................. 180 mm L x 86 mm W x 45 mm H (7.1”

L x 3.4” W x 1.8” H)

Weight ............................. .41 kg (14.5 oz.)

Shock and Vibration ...... MIL-T-28800B

1-14

Page 27

Introduction and Specifications

Table 1-1. 8060A Specifications (cont)

General (cont)

Environmental

Operating Temperature ..... 0 to 50°C

Storage Temperature......... -35 to + 60°C

Specifications

1

Accuracy Temperature

Coefficient...........................

Relative Humidity............... 0 to 80% R.H. from 0 to + 35°C, 0 to

Safety

Safety Standards................ Designed to Protection Class II

Certifications

0.1 x the applicable accuracy

specification per °C (plus the initial

23°C specification) for 0 to 18°C and

28 to 50°C.

70% from + 35°C to + 50°C, except 0

to 70% R.H. for MΩ range above 20

MΩ.

requirements of IEC 348, UL1244

ANSI C39.5 andCSA Bulletin 556B.

1-15

Page 28

8060A

Instruction Manual

1-16

Page 29

Chapter 2

Operating Instructions

Contents Page

2-1. Introduction ..................................................................... 2-3

2-2. Unpacking Your Instrument............................................ 2-3

2-3. Battery Installation or Replacement................................ 2-3

2-4. Fuse Replacement............................................................ 2-5

2-5. Physical Features............................................................. 2-6

2-6. Front Panel................................................................... 2-6

2-7. Display......................................................................... 2-8

2-8. Signal Input Limits.......................................................... 2-9

2-9. Operation......................................................................... 2-10

2-10. Power-On Self-Test ..................................................... 2-10

2-11. AC/DC Voltage (V)..................................................... 2-11

2-12. True rms Measurement............................................. 2-12

2-13. AC-Coupled AC Measurements............................... 2-12

2-14. Waveform Comparison and Conversion.................. 2-13

2-15. High Impedance DC Voltage................................... 2-14

2-16. AC/DC Current (A) ..................................................... 2-16

2-17. Resistance (Ω).............................................................. 2-18

2-18. Autoranging Megohms............................................. 2-19

2-19. Autoranging Kilohms............................................... 2-20

2-20. Conductance (S)........................................................... 2-21

2-21. Diode Test (

2-22. Relative (REL)............................................................. 2-25

2-23. Frequency (Hz) ............................................................ 2-27

2-24. Decibel (dB)................................................................. 2-30

2-25. dBV.............................................................................. 2-31

2-26. Continuity (

2-27. Initial Check-Out Procedure............................................ 2-34

)........................................................... 2-23

) .................................................... 2-32

2-1

Page 30

8060A

Instruction Manual

2-2

Page 31

Operating Instructions

Introduction

2

2-1. Introduction

This chapter describes how to make measurements with your 8060A. Even

though you may have used a multimeter before, we suggest that you take the

time to read this material carefully so that you can take full advantage of the

wide variety of measurement functions offered by the 8060A.

2-2. Unpacking Your Instrument

Your instrument was shipped with two test leads (one red and one black), a

9V battery, and this manual. Check the shipment carefully and immediately

contact the place of purchase if anything is missing or damaged in shipment.

If reshipment is necessary, please use the original shipping container. If the

original container is not available, be sure that adequate protection is

provided to prevent damage during shipment. It is recommended that the

instrument be surrounded by at least three inches of shock-absorbing

material in the shipping container.

2-3. Battery Installation or Replacement

The 8060A is designed to operate on a single, common, inexpensive 9V

battery (NEDA 1604). When you receive the instrument, the battery will not

be installed. You can expect a typical operating life of up to 170 hours with

an alkaline batter, or 80 hours with a carbon-zinc battery. When the battery

has exhausted about 80% of its useful life the BT indicator will appear at the

far left of the display. Your instrument will continue to operate properly for

at least 24 hours with an alkaline battery after BT first appears on the

display. The 8060A also may be operated from a standard ac power line

outlet when used with the optional A81 Battery Eliminator (refer to Chapter

7 for a description). Use the following procedure to install or replace the

battery:

Warning

To avoid electrical shock, turn off the instrument and

remove the test leads and any input signals before

replacing the battery.

2-3

Page 32

8060A

Instruction Manual

1. Set the 8060A power switch to OFF.

2. Remove test leads from external connections and from the 8060A input

terminals.

3. Turn the instrument over and remove screw from battery cover as shown

in Figure 2-1.

4. Use your thumbs to push off the battery cover as shown in Figure 2-1.

5. Slide the battery out of the compartment as shown in Figure 2-2.

6. Carefully pull the battery clip free from the battery terminals (if

replacing the battery) and attach the new battery.

7. Slide the battery and its leads into the compartment and slide the cover

into place.

WARNING

TO AVOID SHOCK REMOVE

INPUTS BEFORE OPENING

CLOSE COVER BEFORE USE

WARNING

TO AVOID SHOCK REMOVE

INPUTS BEFORE OPENING

CLOSE COVER BEFORE USE

Use thumbs to push

battery cover down

and then out from

instrument case.

2-4

Backside of

8060A

dx03f.eps

Figure 2-1. Removal of Battery Compartment Cover

Fuse in Circuit

Spare Fuse

dx04f.eps

Figure 2-2. Battery Removal and Fuses

Page 33

Operating Instructions

Fuse Replacement

You can measure the voltage of your battery by using the following

procedure:

1. Select the dc voltage function and the 20V range (refer ahead to Figure

2-6 if necessary).

2. Locate the opening for the battery eliminator jack on the right side of the

instrument to the right of the display. Touch the red (VΩS) probe tip to

the side contact (not the center pin). Be sure you do not short the battery

by shorting the side contact to the center pin. Battery voltage should be

between 5.2V to 10V for proper operation. If the voltage is less, the

battery should be replaced.

2

2-4. Fuse Replacement

There are two fuses located at the right side of the battery compartment

(refer to Figure 2-2 or examine your instrument). The fuse at the far right is

F1. Fuse F1, 2A/250V, protects the current input from an input overload.

The other fuse is a spare fuse for F1. When you purchase your instrument,

F1 should be installed and the spare fuse should be in one of the two slots

next to it. The larger slot is for the American-style fuse, and the smaller slot

is for the European-style fuse (either style fuse fits in the installation

compartment).

If you need to replace F1, use the tip of a test lead to push the fuse forward

from the end and then up to release. Replace F1 with the appropriate

2A/250V fuse; American-style: fast-acting, type AGX2, 1/4 x 1”, Fluke PN

376582; European-style: 5 x 20 mm, Fluke PN 460972. Do not use makeshift

fuses or short-circuit the fuseholder.

There is another fuse, F2, 3A/600V, which also protects the current input.

The instrument cover must be removed to replace F2. This procedure is

described in Chapter 5 and should only be done by a person qualified to

service the instrument.

The following steps provide a quick and easy way to check the condition of

both fuses F1 and F2:

1. Select the resistance function and the 2 kΩ range.

2. Touch the red test lead tip to the A input jack so that the VΩS input and

the A input are shorted together.

3. If the display reads .1000 ± .0100 kΩ, both fuses are good.

4. If the display reads OL, one or both fuses need replacement.

2-5

Page 34

8060A

Instruction Manual

2-5. Physical Features

Before you begin using your 8060A, we suggest you take a few minutes to

familiarize yourself with the instrument. All of the externally accessible

features are shown in Figure 2-3 and described in Table 2-1. The front panel

and the display are also described in the following paragraphs.

12

11

10

9

8

7

Figure 2-3. Controls, Indicators and Connectors

2-6. Front Panel

Hz

2000mA

200mA

20mA

2mA

dB

1000 DC

200µA

750 AC

DC

1

REL

MΩ

2000nS

200k

200

20k

20

2k

2

200Ω

200mV

Hz

AC

A

A

V

2A MAX

COMMON

!

Ω

500V MAX

S

V Ω S

!

1000V DC

750V AC

MAX

2

3

4

5

6

dx05f.eps

The front panel of the 8060A is designed to make function and range

selection easy. The symbols and colors on the panel indicate which switches

to push or buttons to press to select the function you want. Details are

provided later with the description of each function.

2-6

Page 35

Operating Instructions

Physical Features

Table 2-1. Controls, Indicators and Connectors

2

Item

No.

1

*

2 Function Buttons:

3 Battery

4V Ω S Input

5 COMMON Input

6 A Input Connector Protected test lead connector used as the

7 Function

8 AC/DC Function

9 Range Switches Interlocked switches that are used to select

* For safe operation, fully insert the A81.

Name Function

Battery Eliminator

Connector

Hz, dB,

REL

Compartment and

Cover

Connector

Connector

Switches: A,V,

Ω,S

Switch

External input power connector for use with

the A81 Battery Eliminator accessory.

Push buttons that toggle on or toggle off the

‘secondary functions: frequency, dB, visible

,

or audible continuity, or relative. These

functions are selected in conjunction with the

primary measurement functions (see items 7

and 8).

Cover for the 9V battery and the current fuse

F1.

Protected test lead connector used as the

high input for all voltage, conductance,

resistance, continuity, frequency

measurements and diode test. All test lead

connectors accept standard or safetydesigned banana plugs.

Protected test lead connector used as the

low or commom input for all measurements.

high input for current measurements.

Interlocked switches that are used in

conduction with the input connectors to select

the measurement functions. Pushing one

switch releases the other, or both may be

pushed together.

Push-on/push-off switch is used to select ac

or dc for current or voltage measurements.

(Does not affect selection of diode test,

resistance, or conductance functions).

ranges. Pushing a switch selects the

corresponding range and released other

switch depressions. Also used to select

conductance and the diode test.

2-7

Page 36

8060A

Instruction Manual

Table 2-1. Controls, Indicators and Connectors (cont)

Item

No.

Name Function

10 Tilt Bail A fold-out stand. The bail may also be

removed (press on one of the legs at the

hinge of the bail) and reinserted from the top

as a hook for hanging the instrument.

11 Power Switch Slide switch for turning instrument on or off.

12 Display 4½ digit LCD display (19999 maximum) with

decimal point, minus sign, over-range, Hz,

dB, continuity and relative indicators.

2-7. Display

The 8060A provides measurement results on the 4½ digit LCD display (refer

to Figure 2-4 or your instrument). The decimal point is placed automatically.

Symbols in the upper portion of the display indicate when one of the

secondary functions is enabled. The unit for the autoranging frequency

measurement is displayed automatically as Hz or kHz. The units for all the

other measurements are indicated by the range switch that is pushed in.

Leading zeros are not displayed.

dB Function in Use

Frequency Unit

(Hz or kHz)

Continuity

Indicator

Visible Continuity

Enabled

Audible

Continuity

Enabled

2-8

Low Battery

Indicator

Relative

Function

in Use

dx06f.eps

Figure 2-4. 8060A Display

Page 37

Operating Instructions

Signal Input Limits

If you are taking a measurement and the OL symbol appears on the display

(Figure 2-5), an overrange condition is indicated, meaning that the input is

higher than the range selected. You should select a higher range for the

measurement. The OL symbol does not necessarily mean that the instrument

is being exposed to a damaging input condition. For example, when

measuring resistance, an open input will cause OL to appear.

2

Figure 2-5. Overrange Indicator

2-8. Signal Input Limits

Caution

Exceeding the maximum input overload limits can

damage your instrument.

Before you begin to use your 8060A, it is important to note the maximum

inputs that may be applied to the instrument. Table 2-2 presents the

maximum inputs that are allowed for each function, range, and input

terminal.

Warning

To avoid electrical shock and/or instrument damage, do

not connect the common input terminal to any source

more than 1000 volts dc or rms ac above earth ground.

dx07f.eps

2-9

Page 38

8060A

Instruction Manual

Function Input Terminals Maximum Input Limit

Table 2-2. Input Overload Limits

AC Voltage, AC dB,

Frequency

DC Voltage, DC dB VΩS and COMMON 1000V dc or peak ac

AC or DC Current A and COMMON 2A maximum, fuse

Resistance,

Conductance, Diode

Test, and Continuity

VΩS and COMMON 750V rms or 1000V peak

continuous except 20

seconds maximum on the

200 mV range above 300V

dc or ac rms.

continuous except 20

seconds maximum on the

200 mV and 2V ranges

above 300V dc or ac rms.

protected to 600V dc or ac

rms.

VΩS and COMMON 300V dc or ac rms

2-9. Operation

The following paragraphs describe the power-on self-test, and how to

operate your 8060A in each of the seven primary functions or the four

secondary functions.

2-10. Power-On Self-Test

To turn on your instrument, locate the green switch on the left side of the

instrument and slide it forward. Whenever you turn on the instrument, the

8060A automatically performs a self-test to make sure the display and the

microcomputer are functioning properly. If everything is functioning

properly, all the LCD segments in the display will turn on (Figure 2-4). After

about one or two seconds, the display will go blank briefly before responding

to switch selections.

2-10

Page 39

Operating Instructions

Operation

2

If the LCD segments do not all turn on during the self-test, or if the

instrument does not clear the display after the test and then respond to switch

selections, something is probably wrong with the instrument. Try the test

again, and if it fails, have a qualified person refer to Chapter 5. If there is no

display when you turn on the instrument, check the battery and battery

connections. You will find that if you turn off your instrument and then

immediately turn it back on, a random assortment of LCD segments may be

displayed. This is normal. After about a second the instrument should turn on

all the LCD segments as usual during the self-test.

2-11. AC/DC Voltage (V)

Selection of the ac or dc voltage (V) functions is described in Figure 2-6.

The 8060A offers five ac and five dc voltage ranges: 200 mV, 2V, 20V,

200V, and 750Vac/1000V dc. All ranges present a 10 MΩ input impedance,

which is shunted by <100 pF in ac voltage measurements.

Voltage (V)

REL

dB

1. Select a range.

2. Set AC/DC switch out

for DC, in for AC.

3. Press switch in to select

voltage function.

4. Ensure all other switches are out.

Hz

2000mA

200mA

MΩ

2000nS

1000 DC

750 AC

200k

200

20k

20

20mA

2k

2

2mA

200Ω

200mV

200µA

DC

Hz

AC

V

A

COMMON

A

!

2A MAX

Ω

500V MAX

S

V Ω S

1000V DC

750V AC

!

MAX

Low (-)

High (+)

5. Connect the test leads as shown above.

6. Heed the input overload limits (Table 2-2) and connect the leads

to the circuit being measured.

7. Read the measured value on the display.

Figure 2-6. Voltage Operation

dx08f.eps

2-11

Page 40

8060A

Instruction Manual

2-12. True rms Measurement

One of the most useful features of the 8060A is the direct measurement of

the True rms or effective ac voltages and ac currents. Mathematically, rms is

defined as the square root of the sum of the squares of the ac and dc

components. In physical terms, rms is equivalent to the dc value that

dissipates the same amount of heat in a resistor as the original waveform.

The reason that rms is so valuable is that it greatly simplifies the analysis of

complex ac signals. Since rms is the dc equivalent to the original waveform,

it can be used in the relationships derived from Ohm’s law (E = I x R), and it

provides a reliable basis for comparing dissimilar waveforms.

Most meters in use today have average-responding ac converters rather than

true rms ac converters like the 8060A. Usually the gain in averageresponding meters is adjusted so that the reading gives the rms value,

provided the input signal is a harmonic-free sinusoid. However, if the signal

is not sinusoidal, the average-responding meter does not give correct rms

readings.

The 8060A ac converter actually calculates the rms value through analog

computation. This means that 8060A readings are accurate rms values not

only for harmonic-free sinusoids, but also for mixed frequencies, modulated

signals, square waves, sawtooths, 10%-duty-cycle rectangular pulses, etc.

2-13. AC-Coupled AC Measurements

Input signals are ac-coupled in the ac functions. One of the major advantages

of ac-coupling is that ripple measurements can be made on power supplies,

phone lines, etc. Ripple measurements cannot be made with dc-coupling.

Remember, however, that when the 8060A measures signals with the ac

voltage function, the reading on the display does not include the dc

component (if it exists). For example, consider the waveform in Figure 2-7.

The ac voltage function will measure the ac rms component. The dc voltage

function will measure the dc component. To obtain the total rms value for

such a waveform, first measure the ac and dc values separately, then

calculate the total rms value using the formula given in Figure 2-7.

2-12

Page 41

0V

RMS Total =

(ac rms component)

Operating Instructions

Operation

AC Component

DC Component

2

+ (dc component)

2

2

Figure 2-7. AC and DC Waveform Components

dx09f.eps

2-14. Waveform Comparison and Conversion

Figure 2-8 shows the relationship between common waveforms and the

display readings for the 8060A and average-responding meters. Figure 2-8

also illustrates the relationship between ac and dc measurements for accoupled meters. For example, consider the first waveform, a 1.414V (0-pk)

sinewave. Both the 8060A and the rms-calibrated average-responding meter

display the correct rms reading of 1.000V (the dc component equals 0).

However, consider the 1.414V (0-pk) rectified square wave. Both types of

meters correctly measure the dc component (0.707V). But only the 8060A

correctly measures the ac component (0.707V). The average-responding

meter measures 0.785V, which amounts to a 5.6% error in the total rms

measurement calculated from the ac and dc components.

2-13

Page 42

8060A

Instruction Manual

AC Coupled Peak Voltages Display Readings DC and AC

Input AC Component Only DC Total rms

Waveform PK - PK 0 - PK

Sine

PK

0

Rectified Sine

(Full Wave)

PK

0

Rectified Sine

(Half Wave)

PK

0

Square

PK

0

Rectified

Square

PK-PK

PK

0

Rectangular

Pulse

PK

X

0

Y

D = X/Y

K = D-D

Triangle

Sawtooth

PK

0

PK-PK

PK-PK

PK-PK

PK-PK

PK-PK

2

PK-PK

2.828 1.414 1.000 1.000 0.000 1.000

1.414 1.414 0.421 0.435 0.900 1.000

2.000 2.000 0.764 0.771 0.636 1.000

2.000 1.000 1.110 1.000 0.000 1.000

1.414 1.414 0.785 0.707 0.707 1.000

2.000 2.000 2.22K 2K 2D 2

3.464 1.732 0.960 1.000 0.000 1.000

rms CAL* 8062A

Component

only

TRUE RMS =

22

ac + dc

D

rms CAL is the displayed value for average responding meters that are calibrated to display rms for sine waves.

Figure 2-8. Multiplication Factors for Converting Waveforms

Since average-responding meters have been in use for so long, you may have

accumulated test or reference data based on them. The conversion factors in

Figure 2-8 should help you convert between the two measurement methods.

2-15. High Impedance DC Voltage

Occasionally you may want to make dc voltage measurements in high

impedance circuitry where even the 10 MΩ input impedance for the normal

dc voltage function could load the circuit and cause significant errors. For

example, a 10 MΩ input impedance causes a 0.1% error when measuring the

voltage across the 10 kΩ leg of a 90 kΩ over 10 kΩ voltage divider. The

8060A offers a >1,000 MΩ (typically >10,000 MΩ) input impedance dc

voltage function which greatly reduces this error.

2-14

Page 43

Operating Instructions

Operation

2

Figure 2-9 describes how to select the high input impedance dc voltage

function (the ac voltage function does not operate in this mode). Notice that

all of the function switches must be out to select this function. Either the 2V

or the 200 mV range may be selected. Refer to Chapter 3 for more

applications of this function, including a technique for using the 8060A as an

electrometer to measure extremely low currents.

Note

When taking measurements in the high impedance dc voltage

function, do not select any ranges except the 2V or 200 mV ranges.

Measurement in other ranges will result in erroneous readings.

Note

When the high impedance dc voltage function is selected and no

input is applied, noise from the environment (such as rf or power

line noise) may cause the 8060A to display OL (overrange).

High Impedance

DC Voltage (V)

Hz

1. Select the 2V or

2000mA

the 200 mV range.

2. Ensure all function

switches are out.

3. Connect the test leads as shown.

4. Heed the input overload limits

(Table 2-2) and connect the leads to

the circuit being measured.

5. Read the measured value on the display.

Figure 2-9. High Impedance DC Voltage

200mA

REL

dB

MΩ

2000nS

1000 DC

750 AC

200k

200

20k

20

20mA

2k

2

2mA

200Ω

200mV

200µA

DC

Hz

AC

V

A

COMMON

A

!

2A MAX

Ω

500V MAX

S

V Ω S

!

1000V DC

750V AC

Low (-)

High (+)

MAX

dx10f.eps

2-15

Page 44

8060A

Instruction Manual

2-16. AC/DC Current (A)

Selection of the ac or dc current (A) function is described is Figure 2-10. The

8060A offers five ac (true rms ac-coupled) and five dc current ranges: 200

µ

A, 2 mA, 20 mA, 200 mA, 2000 mA. Each range is protected by a

2A/250V fuse in series with a 3A/600V fuse.

When a meter is placed in series with a circuit to measure current, you may

have to consider an error caused by the voltage drop across the meter (in this

case, across the protective fuses and current shunts). This voltage drop is

called the burden voltage. The maximum full-scale burden voltages for the

8060A are 0.3V for the four lowest ranges and 0.9V for the highest range.

These voltage drops can affect the accuracy of a current measurement if the

current source is unregulated and the resistance of the shunt and fuses

represents a significant part (1/1000 or more) of the source resistance. If

burden voltage does present a problem, you can calculated the error by using

the formula in Figure 2-11. You can minimize this error by selecting the

highest current range that provides the necessary resolution.

Current (A)

1. Select a range.

2. Set AC/DC switch out

for DC, in for AC.

3. Push both switches at the same

time to select current function.

4. Ensure all other switches are out.

5. Connect the test leads as shown.

6. Heed the input overload limits (Table 2-2)

and connect the test leads to the circuit being

measured.

7. Read the measured value on the display.

Figure 2-10. Current Operation

2-16

Hz

2000mA

200mA

REL

dB

MΩ

1000 DC

750 AC

200k

200

20k

20

20mA

2k

2

2mA

200mV

200µA

DC

Hz

AC

V

A

A

2A MAX

2000nS

200Ω

COMMON

!

Ω

500V MAX

High (+)

S

V Ω S

!

1000V DC

750V AC

MAX

Low (-)

dx11f.eps

Page 45

Error:

Example:

Operating Instructions

Operation

IM

ES

EB

Ammeter Shunt

Es = Source Voltage

RI = Load resistance + Source resistance

Im = Measured current (display reading in amps)

Eb = Burden voltage (calculated)

Eb = meas. current [(200/current range in mA) + .35]

Error in % = 100 x Eb/(Es - Eb)

Error in A = (Eb x Im)/(Es - Eb)

RI

2

ES = 15V

RI = 100 kΩ

Im = 148.51 µA (.14851 mA)

Eb = 148.51 x 10 -6 x [(200/.2) + .35]

= 148.51 x 10-6 x 1000.35 = 148.56 mV

Max, error in % = 100 x [148.56 mV/(15V - .14856V)] = 1.0003%

Add this to the range spec. accuracy

Max. error in % = 1.0003% ±(.2% + 2 digits)

Max. error in A = (148.56 mV x 148.51 µA)/(15000 mV - 148.56 mV)

= 1.486 µA

Add 1.486 µA to the reading for correct current

Figure 2-11. Calculating Burden Voltage Error

2-17

Page 46

8060A

Instruction Manual

2-17. Resistance (Ω)

Selection of the resistance function is described in Figure 2-12. There are

four fixed ranges (200Ω, 2 kΩ, 20 kΩ, 200 kΩ) plus the autoranging M

range consisting of three ranges: 2 MΩ, 20 MΩ, and 300 MΩ.

In all fixed resistance ranges (200Ω to 200 kΩ), the test voltage is less than

that required to turn on most semiconductor junctions. This feature,

sometimes referred to as “low power” ohms, aids in troubleshooting by

allowing you to measure resistors independent of the effects of in-circuit

transistors and diodes. For the fixed ranges the maximum full scale voltage

across the circuit being measured is less than 250 mV. The autoranging M

ranges have enough voltage to turn on semiconductor junctions (maximum

2.5V full scale), but the current is very low (2.2 µA maximum).

Resistance ( )

REL

dB

1. Select a range

2. Push switch in for

resistance function.

3. Ensure all other switches

are out (except the AC/DC

switch which can be in or out).

4. Connect the test leads as shown.

5. Ensure that the device being measured

contains no electrical energy.

Hz

2000mA

200mA

MΩ

2000nS

1000 DC

750 AC

200k

200

20k

20

20mA

2k

2

2mA

200Ω

200mV

200µA

DC

Hz

AC

V

A

COMMON

A

!

2A MAX

Ω

500V MAX

S

V Ω S

1000V DC

750V AC

!

MAX

Low (-)

Ω

High (+)

Ω

6. Heed the input overload limits (Table 2-2) and

connect the test leads to the device being measured.

7. Read the measured value on the display.

Figure 2-12. Resistance Operation

2-18

dx13f.eps

Page 47

Operating Instructions

Operation

2

Resistance measurements for all ranges are made using a two-wire

ratiometric technique. This means that test lead resistance may affect the

accuracy in the 200Ω range. You can correct this error by shorting the test

leads together, reading the test lead resistance, and then subtracting it from

resistance readings. The most convenient way to do this is with the relative

function as described later in this chapter. This technique is also useful for

removing the 0.02Ω error factor in the 200Ω range (refer to resistance

specifications in Chapter 1).

2-18. Autoranging Megohms

When the autoranging MΩ range is selected, the 8060A automatically selects

the range appropriate for the measurement. The measurement resolution

decreases in the two higher MΩ ranges as shown in Table 2-3. Readings

made at the crossover points between ranges are microcomputer-stabilized

by an offset in the upscale and downscale directions. Range changes are

made at 2.00 MΩ and 20.00 MΩ as readings go upscale, or at 19.0 MΩ and

1.90 MΩ as readings go downscale.

Table 2-3. Resistance Function Autoranges and Resolution

MΩ

Autorange

kΩ

Autorange

Range Resolution

2 MΩ 100Ω 4½

20 MΩ 10 kΩ 3½

300 MΩ

2 kΩ

20 kΩ

300 kΩ

20 to 99.9 kΩ

100 to 300 MΩ

20 to 99.9 kΩ

100 to 299 kΩ

100 kΩ

1 MΩ

0.1Ω

10Ω

100Ω

1 kΩ

No. of Digits

Possible in

Reading

3

3

4½

3½

3

3

2-19

Page 48

8060A

Instruction Manual

2-19. Autoranging Kilohms

Although it is not indicated on the front panel, there is an additional

autoranging range available: the autoranging kΩ range, which consists of 2

kΩ, 20 kΩ, and 300 kΩ. To select this range, you must simultaneously press

the MΩ and the 200Ω switches as shown in Figure 2-13. Like the

autoranging MΩ ranges, the autoranging kΩ ranges have enough voltage to

turn on semiconductor junctions. Note that the use of the relative function

with the autoranging kΩ ranges is restricted to the autoranging kΩ ranges.

Refer to the description of the relative function for more information. The

autoranging kΩ has the same decrease in resolution (see Table 2-3) and the

same display hysteresis as the autoranging MΩ.

REL

dB

1. Push both the MΩ and

200Ω switches at the

same time to select the

KW autorange.

2. Press switch in to select

resistance function and

measure resistance as

described in Figure 2-12.

Hz

2000mA

200mA

MΩ

2000nS

1000 DC

750 AC

200k

200

20k

20

20mA

2k

2

2mA

200Ω

200mV

200µA

DC

Hz

AC

V

A

COMMON

A

!

2A MAX

Ω

500V MAX

S

V Ω S

1000V DC

750V AC

!

MAX

Low (-)

High (+)

2-20

Figure 2-13. Selection of Autoranging Kilohms

dx14f.eps

Page 49

2-20. Conductance (S)

Operating Instructions

Operation

2

Selection of the conductance function is described in Figure 2-14. The range

is 2000 nS (nS = nanosiemens or 10

-9

siemens, 1 siemen = 1/Ω) which

corresponds to a resistance range from 500 kΩ to 10,000 MΩ.

Conductance is a good way to measure high resistances, such as leakages in

diodes, capacitors, pcbs, or insulators. For example, you can measure the

conductance of a pcb and then covert the measurement to resistance by

referring to Figure 2-15. If you are measuring the leakage of a capacitor, be

sure to discharge it first by shorting its leads together. The positive (+) lead

of polarized capacitors should be connected to the VΩS input.

Conductance (S)

REL

dB

1. Push both switches

simultaneously to set range.

2. Press switch in for

conductance function.

3. Ensure all other switches are out

(except the AC/DC switch which can

be in or out).

Hz

2000mA

200mA

MΩ

2000nS

1000 DC

750 AC

200k

200

20k

20

20mA

2k

2

2mA

200Ω

200mV

200µA

DC

Hz

AC

V

A

COMMON

A

!

2A MAX

Ω

500V MAX

S

V Ω S

1000V DC

750V AC

!

MAX

Low (-)

High (+)

4. Connect the test leads as shown above.

5. Ensure that the device being measured

contains no electrical energy.

6. Heed the input overload limits (Table 2-2) and connect

the test leads to the device being measured (connect the

test lead from the V S input to the + lead of polarized

capacitors for leakage measurements).

7. Read the measured value on the display.

Figure 2-14. Conductance Operation

dx15f.eps

2-21

Page 50

8060A

Instruction Manual

nS

MΩ

*nS-to-MΩ

2000 nS Range

(1000/nS = MΩ)

nS

MΩ

2000 .5

1000 1

500 2

200 5

100 10

50 20

20 50

10 100

Conversion Scales

*S = Siemens = 1/Ω = International Unit

of conductance formerly known as the MHO.

Example: 250 nS = 4 MΩ

Figure 2-15. Conductance/Resistance Conversion

10

100

200

5

500

2

1000

1

.5

2000

5000

.2

.1

10,000

dx16f.eps

You may encounter situations where conductance is more convenient to

measure than resistance. For example, the resistance of a photodiode is

inversely proportional to the available light, i.e. as light increases, resistance

decreases. This might be confusing if you want to examine the response of

the component over a range of values. However, since conductance is the

reciprocal of resistance, photodiode conductance is directly proportional to

available light. As light increases, conductance increases. It might be easier

to examine the photodiode response in terms of conductance, and then covert

the measurements to resistance values if desired.

2-22

Page 51

Diode Test ( )

1. Press both switches

simultaneously

2. Set switch to select

diode test

3. Ensure all other switches

are out (except the AC/DC

switch which can be in or out).

4. Connect the test leads as shown.

5. Heed the input overload limits

(Table 2-2) and connect the test

leads to diode being measured.

6. Read the measured value on the display.

Forward Bias:

BlackRed

Reverse Bias:

Black Red

Operating Instructions

Operation

REL

dB

Hz

2000mA

200mA

MΩ

2000nS

1000 DC

750 AC

200k

200

20k

20

20mA

2k

2

2mA

200Ω

200mV

200µA

DC

Hz

AC

V

A

COMMON

A

!

2A MAX

Typical reading +

forward-biased

silicon diode.

Overrange display

if parallel resistance

is >2 KΩ.

Ω

500V MAX

S

V Ω S

1000V DC

750V AC

!

MAX

Low (-)

High (+)

2

Figure 2-16. Diode Test

dx17f.eps

2-21. Diode Test ( )

Selection of the diode test is described in Figure 2-16. Notice how the test

leads are placed to forward-bias or reverse-bias the diode in the figure.

The diode test measures the forward voltage of a semiconductor junction (or

junctions) at a 1 mA test current. Readings are displayed in the 2V range,

with OL displayed for voltages greater than 2V. For a silicon diode, the

typical forward voltage at 1 mA is about 0.6V. A reverse-biased

semiconductor junction should display the overrange (OL) indicator

provided that any resistance parallel to the junction is greater than 2 kΩ.

2-23

Page 52

8060A

Instruction Manual

A quick way to check for shorted or open junctions is to reverse the test

leads. If the junction indicates the same in-scale reading both directions, it is

probably shorted. If the junction indicates an overrange both directions, it is

open.

Relative (REL)

dB

Hz

1000 DC

750 AC

2000mA

200mA

20mA

2mA

200µA

DC

1.

Select range and function

(any measurement function:

V, A, Ω, S, Hz, dB or ).

Heed input overload limits (Table 2-2),

2.

connect test leads and take desired

measurement (example shows a 1.5000V