Page 1

They are better

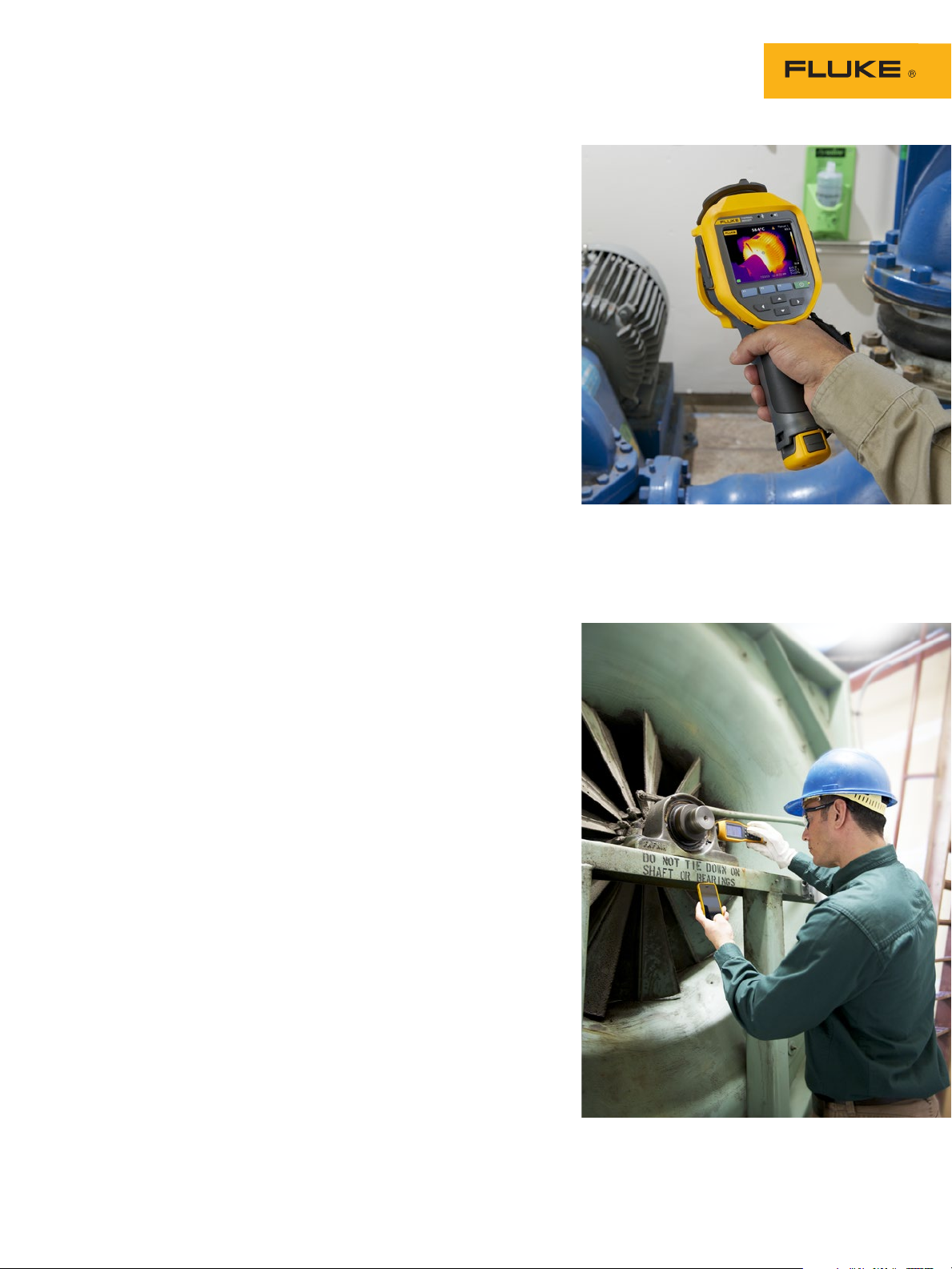

together—Ti400

Infrared Camera

and Fluke 805

Vibration Meter

If a tree falls in the forest . . . it makes a noise,

whether anybody’s there to hear it or not.

Just like that fabled tree, machines in trouble provide

telltale evidence to warn of impending problems—if

you just know how to look and listen. Two of the most

useful indicators are temperature and vibration. Most

mechanical components emit a certain amount of

heat and vibration in the normal course of operation.

But excessive heat, cold or vibration can tip you off to

underlying problems, so you can fix them before they

lead to breakdown and bring production to a halt.

New test tools such as the Fluke Ti400 Infrared

Camera and Fluke 805 Vibration Meter are available to

help measure heat and vibration and the 805 can help

interpret the data. They tell you what the underlying

problem may be and guide you in making repairs.

Application Note

Trouble heats up

An abnormally hot or cold spot

or an unusual thermal pattern

on process equipment often indicates an emerging problem. This

makes thermal cameras, which

capture two-dimensional images

of the apparent surface temperatures of objects, useful tools for

regular predictive maintenance

of mechanical, electrical and

other equipment. With thermal

imaging you can discover and

diagnose various issues including high-resistance electrical

connections that impede airflow,

bearing issues on motors and

tank levels, and many other

mechanical problems.

In a major Florida brewery,

scanning with a Fluke infrared

camera revealed that the gearbox of a bottle labeling machine

was running hotter than normal

– nearly boiling hot. A physical

inspection showed the box was

filled with water, not lubricant.

A damaged seal had allowed the

water in. A breakdown could

have shut down the bottling

line.

One way to prioritize infrared

scanning is to begin with the

critical assets whose failure

would threaten people, property or product. Then determine

what conditions add stress and

monitor those assets more frequently. For example, the sludge

and particulates found in many

processes put extra stress on

motors affecting bearings, windings and insulation. This stress

can show up as heat detectable by a thermal imager. Such

motors should be scanned for

fre q uently.

What to look for

Use your thermal imager to look

for hot and cold spots, as well

as other anomalies. Be especially aware of similar kinds

of equipment operating under

similar conditions, but at different apparent temperatures.

Such deviations might signal

a problem. A good approach is

From the Fluke Digital Library @ www.fluke.com/library

Page 2

to create inspection routes that

include all critical assets using

Fluke Connect™ EquipmentLog™

history.

Using the EquipmentLog™

history feature you can create

a folder for each critical equipment asset with a description

of the asset and the location

in the Fluke Cloud™ storage.

Each time you inspect a piece

of equipment you or any other

team member who has been

given access, saves a thermal

image or measurement data to

that equipment folder, allowing

you and your team to track and

monitor the equipment condition

over time and getting instant

access to historical data – all

from one location. Now maintenance technicians can easily

do a side-by-side comparison

from previous inspections to

help determine whether a hot

spot or cool spot is unusual and

if any planned maintenance is

required. This keeps your equipment running longer, saving you

time and money and reduces the

risk of unplanned downtime.

When vibration shows

a problem

Vibration can be normal in

machine operation—or it can be

a sign of trouble. Most industrial devices are engineered to

operate smoothly and AVOID

vibration, not produce it. In electric motors, rotary pumps and

compressors, fans, and blowers,

low vibration is the ideal. In

these machines, vibration can

indicate problems or deterioration in the equipment.

But how can the plant

maintenance professional tell

acceptable, normal vibration

from the kind of vibration that

requires immediate attention,

to service or replace troubled

equipment?

Use vibration to screen

machine health

Unchecked machine wear

can quickly damage equipment, cause safety problems,

and degrade plant working

conditions. In the worst cases,

machine faults can knock equipment out of service and halt

plant production that cuts into

the bottom line.

When machines are screened,

vibration can be used in a

preventive maintenance program as an indicator of machine

condition, and you can target

remedial action before disaster

strikes. This gives maintenance

staff time to schedule repairs

and acquire needed parts.

Increased maintenance intervals

mean machine life is extended

and maintenance can be scheduled by need. Peace of mind

builds confidence in maintenance schedules, budgeting and

productivity estimates.

The hand-held Fluke 805

Vibration meter with Fluke

Connect ShareLive™ not only

measures machine vibration,

bearing impacting, and bearing temperature, but compares

the readings to 37 specific

machine categories—all while

letting you stay in direct contact with your team. This gives

the maintenance technician

critical information about the

machine health and warning

of bearing failures in a wide

variety of mechanical equipment, including motors, pumps,

fans, blowers, compressors and

more. You can reduce equipment downtime and costs with

the EquipmentLog™ history

function of the Fluke Connect™

app. With EquipmentLog™ you

can create unique folders for

individual machines, storing

historical inspection data that

can be accessed later by your

team. This allows side-by-side

comparisons of previous measurements so any accelerated

trends of degradation can be

identified to help determine how

quickly a repair is needed or if

it can be delayed to a more convenient time. Trending vibration

2 Fluke Corporation They are better together–Ti400 Infrared Camera and Fluke 805 Vibration Meter

Page 3

readings over time will help you

to know which machines need

to be scheduled for repair before

a simple bearing failure leads to

the loss of the shaft, loss of the

machine, or loss of production.

Instead of complicated vibration analyzers that require an

experienced vibration expert to

analyze complex waveform data,

the vibration meter is a tool that

a maintenance technician with

no formal vibration analysis

training can use to screen the

many machines in the plant.

The Fluke 805 quickly screens

vibration in order to let the

user know which machines are

healthy and which ones need

repairs and with the Fluke Connect ShareLive video call feature

you can get questions answered

or work authorized in an instant

without even leaving the field.

3 Fluke Corporation They are better together–Ti400 Infrared Camera and Fluke 805 Vibration Meter

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2014 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 4/2014 6002682A_EN

Modification of this document is not permitted

without written permission from Fluke Corporation.

®

Loading...

Loading...